Ciclop desktop laser 3d scanner software

CowTech Ciclop 3D Scanner

CowTech Ciclop 3D Laser Scanner

Over $180,000 raised on Kickstarter! 1700+ scanners sold and counting.

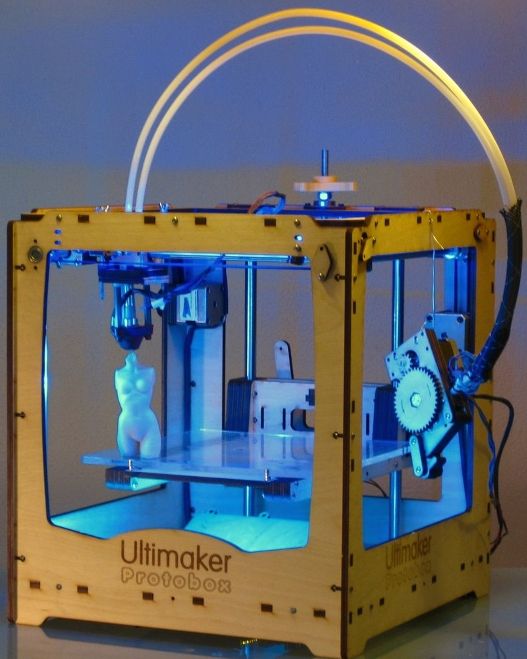

The 3D printing revolution has come, and it’s time for 3D scanning to follow. The CowTech Ciclop is a RepRap 3D scanner with a large scan volume, simple, yet elegant design, and a disruptive price point that blows any other laser scanner out of the water. The user prints the plastic parts on their own printer in any color and resolution they choose, and can assemble the scanner in less than 30 minutes. Then, simply take any object you want to replicate, set it on the 200mm laser cut acrylic turntable, and start scanning. We wanted to make sure our product was usable for anyone who owns a 3D printer, so we meticulously designed our parts for a print bed volume of only 115mm x 110mm x 65mm (4.5 x 4.3 x 2.6in) so they can be produced on even the smallest of printers.

Print your own parts and save money!

How It Works

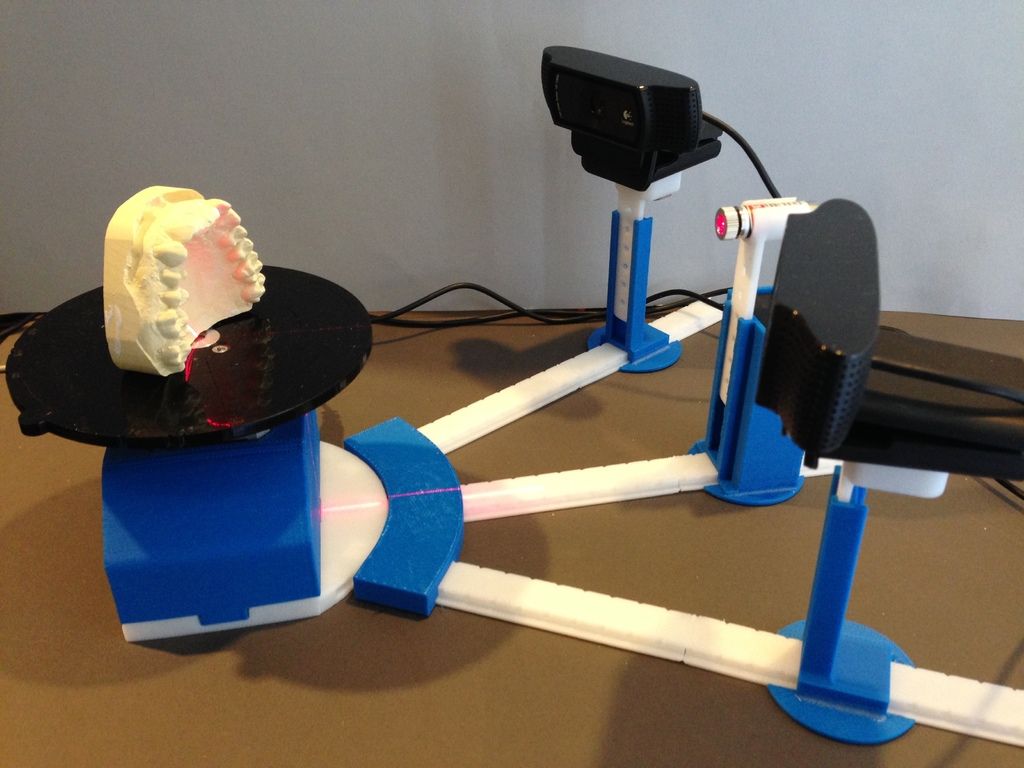

Laser scanners are a very common type of 3D scanner that use a pair of line lasers that flash in succession in combination with a camera and a rotating turntable. As the lines flash on the object, they trace the outline of the object in red light. The camera then picks up the location of the laser lines in 3D space, converting those lines into hundreds of thousands of points, and as the turntable rotates, every side of the object is scanned into a cloud of points, which can then be stitched together to form a mesh that replicates the surface of the object with up to 0. 5mm precision.

5mm precision.

3D printed model lion, 0.2mm resolution, PLA, Prusa i3

The term 3D scanner is a bit of a misnomer. Technically, most 3D scanners are actually point cloud generators. The scanner itself is a tool to make a .PLY file, or a point cloud, made up of hundreds of thousands of points that represent the geometry of the object. The typical user will want to convert this point cloud to an .STL file, which can easily be printed on a 3D printer.

Scanned and post processed model loaded into Cura for slicing alongside the model mesh in CloudCompare

User submitted 3D prints

Once you have a digital 3D file of the part, the possibilities are endless. The CowTech Ciclop uses Horus, software developed by BQ for their version of the scanner. Unfortunately, Horus doesn't support direct .STL exports at this time, but this feature may be developed in later versions of the program. Fortunately, there are many options for post processing programs that can stitch the point clouds together into a printable file. These include Meshlab, Cloudcompare, Netfabb, Blender, and more. We recommend Meshlab and Cloudcompare, and provide detailed documentation with the scanner on how to use these programs.

These include Meshlab, Cloudcompare, Netfabb, Blender, and more. We recommend Meshlab and Cloudcompare, and provide detailed documentation with the scanner on how to use these programs.

The CT Ciclop scanner is a fully open source Rep Rap project, and part files and details on how to build your own can be found in the downloads section of our website.

All laser scanners can struggle with objects that are very black, very shiny, or furry, as the laser doesn't register properly with the camera. The CowTech Ciclop, is designed for experienced users who can familiarize themselves with different software programs in order to use the scanner and get high quality outputs from it.

We like to think of a 3D scanner like a video camera. A nice camera gives you the tools to take great pictures and videos, but without post production work in a video editing or photo editing program, you will likely be disappointed in the end result.

Shop Now

CT Ciclop

Ready to Scan Kit

Now Just $179

Ships Free!

Shop Now

CT Ciclop

Standard Kit

Now Just $139

Ships Free!

Shop All CowTech Ciclop Scanners and Accessories

Ciclop - RepRap

Ciclop 3D Scanner Documentation

Main page | Ciclop 3D Scanner Buyer's Guide | Ciclop 3D Scanner Build Manual | Ciclop 3D Scanner User Manual | Ciclop 3D Scanner improvements

Ciclop

Release status: working

| Description | 3D Laser Scanner |

| License | CC-BY-SA |

| Author | User:bq |

| Contributors | CowTech |

| Based-on | None |

| Categories | 3D Scanner |

| CAD Models | |

| External Link | GitHub |

Ciclop 3D Scanner

Ciclop is an open source 3D laser scanner with a rotative platform. It has been developed from scratch by BQ, and now it has been released to the community, under Creative Commons Attribution-ShareAlike 4.0 International License.

It has been developed from scratch by BQ, and now it has been released to the community, under Creative Commons Attribution-ShareAlike 4.0 International License.

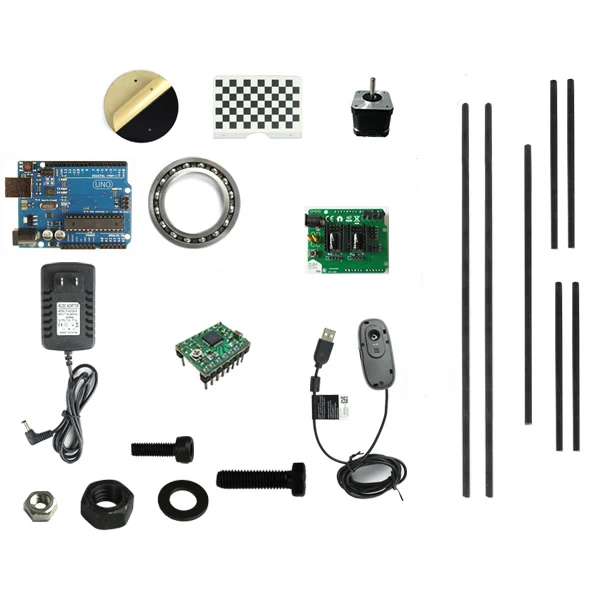

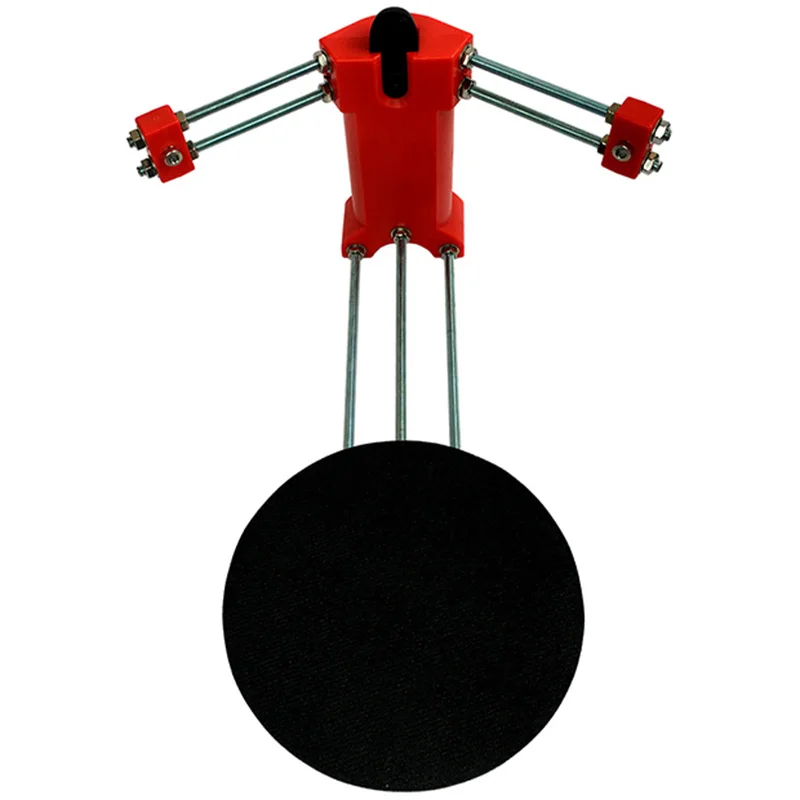

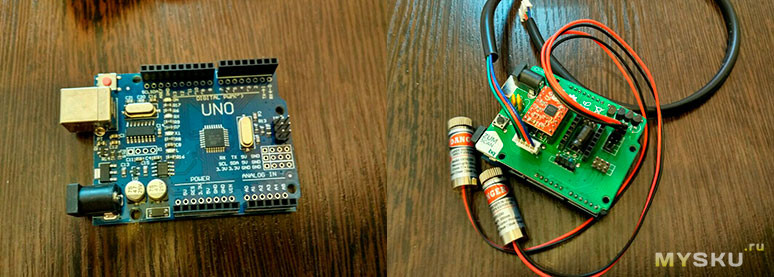

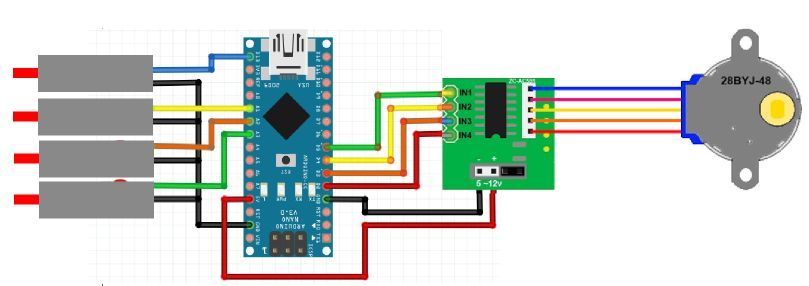

This 3D Scanner is composed by a structure of 3D printed parts, threaded rod, a Logitech C270 web cam, two line lasers and a turntable platform with a stepper motor.

Related to this device, Horus, a complete desktop application for 3D scanning, has been developed also from scratch.

In early 2015, CowTech Engineering released their version of the Ciclop, raising over $183,000 USD on Kickstarter. They made some changes to the physical design, but still use Horus as the scanning software. The CowTech version uses adjustable laser holders and connects the scanner using laser cut acrylic instead of threaded rod. They also redesigned the printed parts and reduced the 3D printer build volume needed to make the parts at home.

Specifications

| CowTech Ciclop | BQ Ciclop (via Lulzbot) | |

|---|---|---|

| Scan Time | 2-8 min | 2-8 min |

| Resolution | 0. 5mm 5mm | 0.5mm |

| Cost (USD) w/o Printed Parts | $119 | na |

| Cost (USD) w Printed Parts | $159 | $400 |

| Scan Area (mm) | 200 x 200 x 205 (h) | 200 x 200 x 205 (h) |

| Adjustable Laser Position | Yes | No |

| Frame Material | Laser Cut Acrylic | Steel Threaded Rod |

Both the Ciclop and Horus are works in progress, and the developers at BQ and CowTech would appreciate it if users shared any modifications with the open source community to continue development of these projects.

Contact on the Google Group or send an email to [email protected]

Resources

Most the important resources for assembling, calibrating and using the scanner, CAD models and .stl files, as well as Google and FB communities from BQ and CowTech are compiled in one place at the CowTech Resources tab. For more detailed resources, particularly pertaining to the development of Horus, please explore the GitHub and DIWO links below.

For more detailed resources, particularly pertaining to the development of Horus, please explore the GitHub and DIWO links below.

GitHub

- Sources

- Wiki

- Background / Scientific documentation

DIWO

- Presentation

- 3D Design

- Electronics

- Firmware

- Software

Where to buy?

- he3d

- CowTech Ciclop 3D Scanner

- HE3D Ciclop DIY 3D Scanner Kit Free Worldwide Shipping 130 USD |3D Printers Bay

DIY Cyclops assembly and laser scanning software

Greetings to all. Today is a small review of the Ciclop desktop scanner.

Once again, the store offered to take something for review. Since I have long been interested in the question of using this thing for the needs of decorative 3d printing, I chose a scanner.

So, the scanner itself was developed by the Spanish company BQ, which has now ceased its support (supposedly due to Chinese fakes, but it is doubtful. Now the American CowTech also sells this scanner. The source codes for 3d printing of parts of the scanner are freely available at Thingiverse (there are also links to software and electronics).0003

Links to complete documentation kits:

www.cowtechengineering.com/downloads

www.bq.com/ru/support/ciclop/support-sheet

In the kit we have such a “loose”:

The assembly is simple, however there are several points:

1. It is not worth rushing to tighten all the nuts - you still have to adjust the geometric dimensions - the convergence of lasers in the center of the site, the distance to the turntable.

2. In my stand, the camera “dangled” a little, by a fraction of a millimeter - but that was enough to skew the picture. Eliminated by laying foam material.

4. The turntable was transparent and uncoated (as in the original) - I painted it with plastidip.

5. Check the calibration checkerboard patterns. I don’t know how they printed the one from my kit - but the proportions of the squares were violated. I took it from the Internet and reprinted it myself.

6. The focus of the camera is not adjusted to the distance to the platform. He removed the cover and twisted the focus in place.

88. The economy is managed by the "native" Horus software from BQ.

After assembly, the scanner went through calibration procedures in the native Horus software.

Since by this point I already knew that the quality of scanning is very much dependent on the quality of lighting (stability, diffuseness, color temperature), I took care of having a small lightbox in advance in order to at least provide more or less comparable conditions for samples.

Having selected the "candidates" for the samples, I got ready.

Requirements for the object are stated as follows:

1. The object must be larger than 5x5 cm but smaller than 20x20 cm

The object must be larger than 5x5 cm but smaller than 20x20 cm

2. The object must be opaque and still

3. The object must weigh no more than 3 kg

Difficult to scan:

1. Shiny, luminous objects

2. Too dark objects

3. Objects with a blurred surface (eg soft toys)

The result of the scan is a cloud of points in PLY format (which must then be converted to a surface). Here is a guide for post-processing the cloud and preparing the STL file.

After reading the scan optimization guide, I decided to try with a simple cylindrical object.

After several attempts, I was convinced that I had a common problem - mismatches in the point clouds from the right and left lasers, and the issue with proportions.

Nothing worthwhile about this except for trying to calibrate the webcam settings (they are not calibrated when the calibration wizard is running) could not be found (a dude named Jesus from BQ support has not answered questions for a long time). To do this, you need to take several shots with different positions of the calibration table. Done. The situation has improved, but not completely.

To do this, you need to take several shots with different positions of the calibration table. Done. The situation has improved, but not completely.

I had to manually edit the calibration file (calibration.json in the Horus-a folder) and by trial and error, scanning a cylindrical object, to achieve the coincidence of the clouds.

And everything seems to be ok:

But no - on complex objects, cloud fragments still sometimes do not coincide, moreover, many "blind" zones are formed:

impossible, at least with regular lasers.

You can, of course, continue experimenting with scanning with individual lasers and trying to combine all this economy in third-party software, and then try to bring it into a viable form for STL.

All this is reminiscent of a joke about boats in bottles.

-How do you make boats in bottles?

-I put sand, silicate glue, sticks into the bottle and shake it.

It turns out all sorts of shit, and sometimes boats.

In general, I realized that I am not an adept of such creativity, and I have a suspicion that it is easier to model objects from scratch that are easier for a scanner.

And complex ones - the scanner cannot cope with complex ones in normal mode, two lasers are not enough for it - blind spots remain. To fix this problem, you need to scan in other positions and then again suffer with the combination of clouds. No thanks.

As a result - the thing will fit only for learning the basics of laser scanning, for something more - absolutely useless. No, of course, you can get something with outlines similar to the original model, but on this (and this, taking into account all the tambourines with cloud processing), that's it. No wonder the Spaniards abandoned this case.

The store made sure - in the description it is honestly stated that the result depends on the position of the planets and the mood of Aunt Sonya from the third floor. Open source and all that, let's dance together. No thanks.

Open source and all that, let's dance together. No thanks.

Conclusion - don't take it, but if you're into extreme hunting, assemble it yourself from the same material that your friend from the joke makes boats from.

Product for writing a review provided by the store. The review is published in accordance with clause 18 of the Site Rules.

3D Scanners - Pre-Purchase Instructions

In industrial and commercial applications—for examining building structures and taking accurate spatial measurements, digitally capturing a crime scene, and cataloging works of art or fossils—3D scanning has been used for many years. Meanwhile, 3D printing was gaining more and more popularity, especially among craftsmen and enthusiasts, and people wanted to read real objects and convert them into printable 3D models.

The market has, of course, responded, and today there are more low and very low price 3D scanners on offer than ever before. Prices for 3D scanners range from a few hundred to several thousand dollars, which should suit just about any budget. The decision on which 3D scanner to purchase depends entirely on what exactly it will be used for and how detailed you are going to scan objects.

Prices for 3D scanners range from a few hundred to several thousand dollars, which should suit just about any budget. The decision on which 3D scanner to purchase depends entirely on what exactly it will be used for and how detailed you are going to scan objects.

Software Solutions

Depending on what you want to scan, you may not need to purchase a 3D scanner. It's possible that you already have the one tool you need to create 3D models, and this tool is in your pocket. There are several programs that take ordinary pictures, even taken on a smartphone, and then extrapolate the available data, creating a completely three-dimensional image.

This process is called 3D photogrammetry and it starts by taking multiple pictures of the same object from different angles. The more images involved, the sharper and more detailed the final 3D model will be. This process may work on just three images, but for very detailed objects, dozens of them may be needed. Not only is this a less expensive option, it's also the best option for scanning 3D objects in public places or in the field where you don't want to carry additional 3D scanning equipment.

Autodesk 123D Catch

Price: Free (or $9.99/month for 123D Premium)

Technology: 3D Photogrammetry

Because 123D Catch2 is a great part of the cloud ecosystem, 123D Catch2 is a great fit for the Autoskde2 cloud ecosystem work on a smartphone or tablet. This makes it ideal for digitally capturing objects in public spaces that cannot be scanned in a studio—museum pieces, large structures, and natural formations.

Resolution: N/A

Pros: No 3D scanner needed, objects of any size can be captured, most program options are free, easy to use

Cons: Limited functionality, quality depends on lighting and number of source images ; may take several minutes to digitally capture an object, does not work well on humans or animals

Agisoft PhotoScan

Technology: 3D Photogrammetry

Agisoft PhotoScan is a stand-alone software suite specifically designed to generate high-quality 3D models from 2D photographs. It was originally aimed at museums and libraries to work for the benefit of archiving collections of artifacts and works of art, so it is able to produce exceptionally detailed 3D models.

It was originally aimed at museums and libraries to work for the benefit of archiving collections of artifacts and works of art, so it is able to produce exceptionally detailed 3D models.

Resolution: N/A

Pros: Can create high-resolution 3D models, one-time license is free, the program is easy to use, has many settings

Cons: Software needs to be installed on the computer, high resolution camera is required

DIY options

If you can't afford to spend a few hundred dollars on a 3D scanner, there are also less expensive DIY options .

Xbox Kinect with ReconstructMe

Price: Kinect (various), ReconstructME (free)

Technology: RGB camera, depth sensor

It's practically do-it-yourself, as it ends up assembling an inexpensive 3D scanner. Kudos to Microsoft for releasing a peripheral with a really powerful depth sensor and an RGB camera and leaving it open for use in third party applications! In this case, the combination of Xbox Kinect and free software like ReconstructMe is all you need to 3D scan people and objects.

Resolution: When like

Pros: Cheap, flexible, free software

Cons: Windows only, limited resolution, variable quality

BQ Ciclop

Technology: Laser triangulation

Ciclop is an open source desktop 3D laser scanner. The scanner uses printed components, so it can be made quickly and cheaply. This scanner can be purchased assembled or as a set of parts, and a parts list and free STL files are available online. Since the 3D scanner laser is a very delicate technique, self-assembly can be tricky and the results may vary depending on your skills.

Resolution: 0.5mm

Pros: Open source, build kit available, easy to modify and upgrade parts may not be as strong as traditionally made

Inexpensive 3D Handheld Scanners

A 3D handheld scanner, compared to a rotating 3D scanner, allows you to capture an object in a much wider range. These types of devices are commonly used to scan people and large objects, and even low-cost models produce amazingly detailed results. Typically, it takes three to five minutes to scan an object the size of a person, and the more information you capture, the higher quality the final 3D scan will be. Such low-cost options may not be ideal for commercial applications, but for small businesses and individuals, this is the ability to quickly capture 3D data, including colors, patterns, and even texture.

These types of devices are commonly used to scan people and large objects, and even low-cost models produce amazingly detailed results. Typically, it takes three to five minutes to scan an object the size of a person, and the more information you capture, the higher quality the final 3D scan will be. Such low-cost options may not be ideal for commercial applications, but for small businesses and individuals, this is the ability to quickly capture 3D data, including colors, patterns, and even texture.

XYZprinting 3D Scanner

Technology: Structured Illumination

XYZprinting's 3D scanner is one of the first devices to hit the market that uses the new Intel RealSense image capture algorithm. It is also the cheapest handheld spatial scanner on the market and is suitable for a wide range of applications.

Resolution: 1.5 mm

Pros: Low price, Intel RealSense technology, small size, portable

Cons: Windows only compatible, low resolution

Cubify Sense

Technology: Structured Lighting

Although the Cubify ecosystem is technically gone, 3D Systems continues to offer their 3D scanners. This handheld 3D scanner is easy to use, quickly converts scans into 3D printable files, and is backed by 3D Systems.

This handheld 3D scanner is easy to use, quickly converts scans into 3D printable files, and is backed by 3D Systems.

Approval: 0.9 mm

Pros: Small price, technical support, proven technology

disadvantages: Part of the non -working ecosystem Cubife, average scanning, only under Windows

ISENNER

Technology: Structured coverage. This 3D scanner from 3D Systems is connected to an iPad and has a powerful processor to produce pretty good quality 3D scans. A great option if you want maximum portability, because all you need is an iPad. Resolution: 0.9 mm

Pros: Affordable price, portable, battery powered, works with iPad

Cons: Part of broken Cubify ecosystem, average scan quality, requires iPad

3 Sensor Structure6

Technology: Structured Lighting

Structure Sensor was one of the first low-cost 3D scanners on the market, a successful Kickstarter project. The same technology is used in 3D Systems' iSense 3D scanner, so the two devices are almost identical. The Structure Sensor is completely portable and only requires an iPad.

The same technology is used in 3D Systems' iSense 3D scanner, so the two devices are almost identical. The Structure Sensor is completely portable and only requires an iPad.

Resolution: 0.9mm

Pros: Cheap price, portable, battery powered, works with iPad

Cons: Average scan quality, requires iPad

Desktop 3D scanners

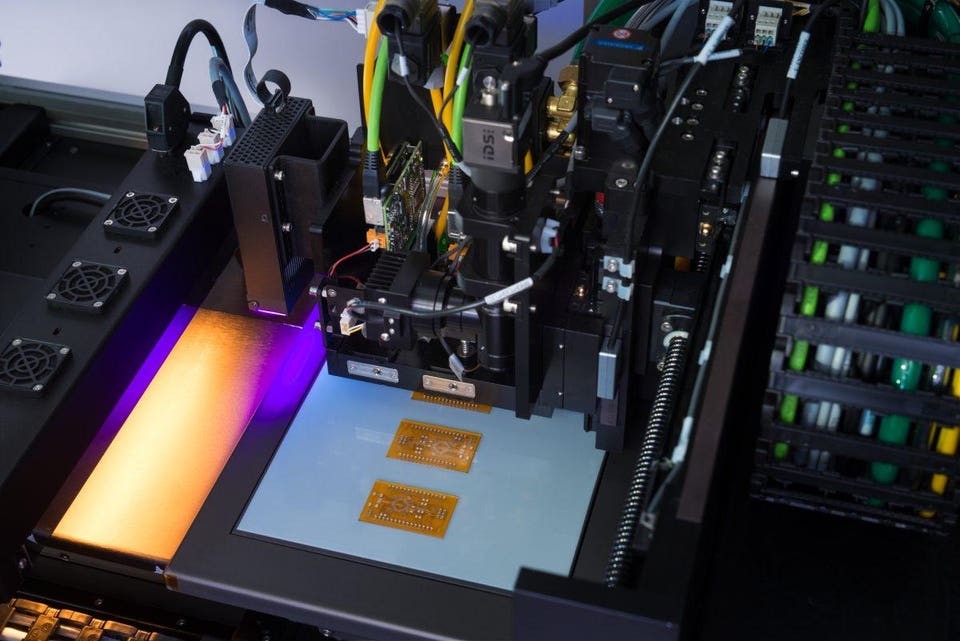

3D scanners use laser triangulation to capture high-quality details of small objects. These 3D scanners usually don't read colors and patterns, but they are accurate enough for all sorts of textures and details. There are, however, several models that fully read color and pattern data using either structured lighting technology or software implementations of the inverse transformation of laser reflection into color.Zmorph 2.0

Technology: Laser triangulation

The Zmorph 2.0 3D scanner is one of the most popular desktop 3D scanners on the market, and it also has excellent software. The device can not only capture fine details and texture, it also reads colors. It takes about five minutes to completely scan an object.

The device can not only capture fine details and texture, it also reads colors. It takes about five minutes to completely scan an object.

Resolution: 0.43 mm

Pros: Good value for the price, color capture, portability, multi-format export

Cons: Average scan quality, limited scan size, colors may be altered or inaccurate

MakerBot Digitizer

Technology: Laser triangulation

MakerBot Digitizer is an entry-level desktop 3D scanner capable of capturing fine details and textures, but does not distinguish colors. The scanner integrates seamlessly into the MakerBot ecosystem and users have access to technical support and a MakerCare service plan.

Resolution: 0.5mm

Pros: Part of the MakerBot ecosystem, lightweight

Cons: Doesn't understand colors, doesn't capture reflective or transparent objects, expensive for this scan quality, only exports to STL

EinScan- S

Technology: Structured Illumination

The EinScan-3 desktop 3D scanner is one of the best machines of its kind on the market. It distinguishes very small details, patterns and produces realistic colors. Unlike most desktop models, it uses structured lighting technology, which gives higher quality scan results.

It distinguishes very small details, patterns and produces realistic colors. Unlike most desktop models, it uses structured lighting technology, which gives higher quality scan results.

Resolution: 0.17 mm

Pros: High quality scans, color capture, export to different formats

Cons: Only works with very small objects, not compatible with Apple OS

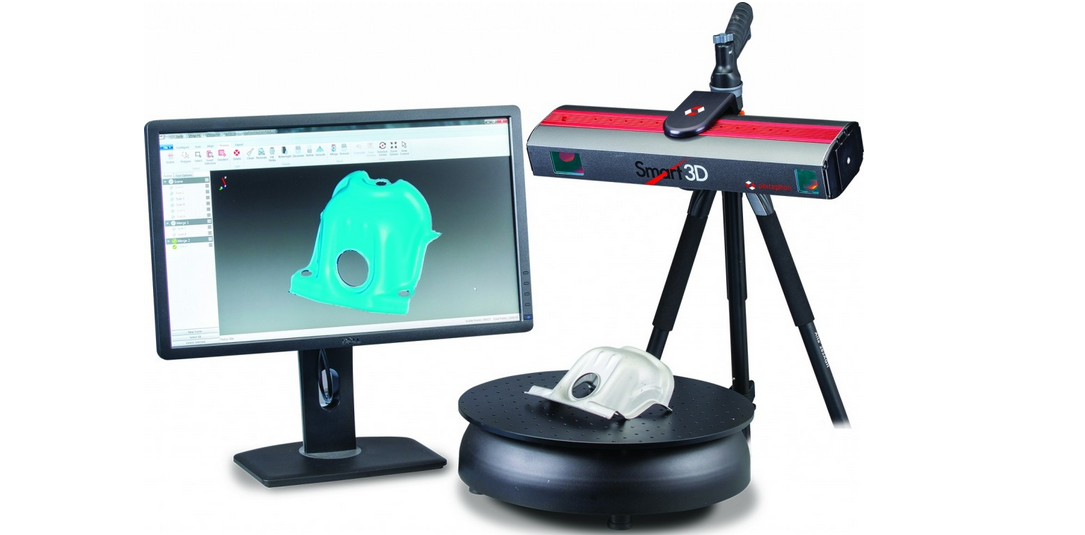

RangeVision Smart

Technology: Structured Illumination

The RangeVision Smart 3D Scanner is the most portable desktop 3D scanner, and can be set up outdoors to scan large objects like cars, with very fine scanning.