3D printer resume

Resuming a failed 3D print — CNC Kitchen

Just a quick PSA before we start. If you’re currently reading this because this happened to you only minutes ago, make sure you go back to your printer and keep the bed heated so that your part doesn’t release from it.

I’m quite sure that almost anyone who owns a 3D printer already had a long print fail at some point just because no material somehow got extruded anymore. This is precisely what happened to me a bunch of weeks ago while filming my filament recycling video. I was easily able to continue mine with some simple G-Code trickery and thought this is actually an essential skill I’d like to teach you. Maybe even make a print fail on purpose and try to recover it with these methods before this happens with a precious 3-day print! Let me know in the comments if you ever recovered a failed print and how you were able to do it! My print failed because I had a small piece of metal in my recycled filament that at some point blocked the nozzle. In your case, you could also run out of power, encounter heat creep, have a knot in your filament, or even run out of filament without a material sensor.

The highest priority is that you keep your print attached to the print bed, and if you have a removable print sheet, then also don’t move it in any way because otherwise, we won’t be able to resume the print at the correct location.

If your model is already loose or you’re not able to recover your print like I’ll show you, there is still the possibility to measure the height you were able to print, enter your slicer of choice, cut off as much of the part as you’ve already printed, or just move it in the z-direction by that amount.

Sectioning an STL in PrusaSlicer

Print the parts you’re still missing and just glue everything together. Done!

Final 3D print, glued together from two halfs

If your part is still attached to the bed, there is a good chance that you can recover your 3D print with a bunch of simple steps.

Step 1: Clean the last layer

First, remove all the zits and leftover material on the layer that wasn’t correctly printed anymore. We need a clean and even surface to start with.

Small material leftovers, when the print failed

Step 2: Measure the failure height

Next comes the most important step, and that’s measuring the height of your part so we can determine where we need to resume printing. I tend to use three methods for that.

Step 2a: Use calipers or a ruler

If your part allows it and you have long enough calipers, simply measure the height with them. Make sure to measure perpendicular and all the way down to the bed, so not only onto the brim. If you don’t have suitable calipers, you can also try to use a ruler, which might be precise enough for your purpose. Make sure to measure more than one point on your part to avoid measuring errors. On my sample, I measured 90. 7 mm.

7 mm.

Step 2b: Determine height from geometrical features

Another very simple yet precise way is to use the geometrical features of your print. For that, you need to open the G-code you used for printing in a G-Code-Viewer. CURA and many other slicers allow you to do that, though I tend to use the G-code Viewer that comes with PrusaSlicer that also works well with G-code from many other slicers.

PrusaSlicer G-code viewer

When my boat previously failed, it was easy to spot because that was just when the bridging section on the model started.

On my latest print right here, it’s a little more complicated because there are no hard edges near where we failed, though there is a distinct pattern of retractions and moves only four layers before we stopped extruding. So the last layer that got printed was at 90.8 mm in height.

Features on print (left) and in the G-code viewer (right)

Step 2C: Using your 3D printer as a Coordinate-Measuring Machine (CMM)

The last method is great if you don’t have any equipment to precisely measure the height or no features on the print that you can use to determine where it exactly failed. We’ll use the 3D printer as a makeshift CMM or Coordinate-Measuring Machine. We’ll move the nozzle right to the point where it touches the last layer and read the height from the screen. For this, and in general, for resuming a print to work, we need to re-home the printer because we usually lose the absolute position once we stop printing. If your part is small and your printer usually homes at the edge of the bed, it’s easy, and you can use the normal homing routine. If it’s bigger, you need to make sure that there is enough clearance to not crash into the part. While you’re homing, if in doubt, always have your finger on the power switch to potentially kill it before it crashes into the print and rips it from the platform. If you don’t find a way to home z, don’t panic, there is still one last option I’ll show you at the end.

We’ll use the 3D printer as a makeshift CMM or Coordinate-Measuring Machine. We’ll move the nozzle right to the point where it touches the last layer and read the height from the screen. For this, and in general, for resuming a print to work, we need to re-home the printer because we usually lose the absolute position once we stop printing. If your part is small and your printer usually homes at the edge of the bed, it’s easy, and you can use the normal homing routine. If it’s bigger, you need to make sure that there is enough clearance to not crash into the part. While you’re homing, if in doubt, always have your finger on the power switch to potentially kill it before it crashes into the print and rips it from the platform. If you don’t find a way to home z, don’t panic, there is still one last option I’ll show you at the end.

After homing, we make sure that the nozzle is clean and then move the print head in small steps to the part until the tip just touches it. We can then read the height either from our printers’ screen, or if there’s no display, we can send M114 to the controller. For my model, it was again 90.7 mm.

For my model, it was again 90.7 mm.

Step 3: Determine the resuming height

All three methods were able to provide similar model heights down to 1/10 of a mm. Which one you use is up to you. Since I printed a layer height of 0.2 mm, the closest next layer to the 90.7mm measurements is layer 90.8, which is the same one we also got from looking at the G-Code-Viewer. This means that this was the last layer that was at least partially printed.

Now we need to determine at which layer we want to continue. Some might argue that we should reprint the last layer because it was probably not finished completely. In contrast to that, I tend to resume the print at the next layer because I want to avoid a double extrusion where the material gets all squished out, and the printhead might even get stuck. Since perimeters usually get printed before the infill, there is a good chance that we won’t even notice a gap on the outside, and a slight gap on the infill is usually not bad. I’ll therefore be resuming my printer at the height of 91 mm.

Over-extrusion at resuming location

Step 4: Modify the G-code

Now we need to slightly modify the G-code file we initially printed. Remove the SD card from your machine and open the G-code file in your text editor of choice. This might look intimidating at first, but G-code is really simple. Each line represents an instruction that gets processed one after the other. If you want to know what all the commands do, simply check out the Marlin G-code reference I linked below.

All the printing instructions up to somewhere in layer 90.8 mm were already processed, and we need to delete them. To do that, we need to find the section where the layer at 91 mm starts to get printed. Most slicers will add some comments when specific things happen, such as a layer change. Prusaslicer, for example, adds ;Z: and then the height. If you’re using CURA or you notice that your extrusions are set to absolute (M82), check the next paragraph for that approach. So we simply search for ;Z:91 and easily determine where the layer change starts. The following lines, in my case, are only the preparation steps for the layer change that are irrelevant to us, so we search the line where the printhead is lifted up to that layer, which is done with the instruction G1 Z layer height. We mark everything by clicking in front of the instruction, then holding the shift key and scrolling all the way up to the last instruction before the print starts, which is usually homing with the instruction G28. The only things that should be left in our G-code file are the initial setup and the instruction for setting extruder and bed temperature and homing. Then we directly move the printhead to the layer at 91 mm and continue printing. The only command I add manually is M106 S255 which turns the cooling fan on to 100%. If you’re not using a cooling fan or not the full power, adjust that value accordingly. Now simply save everything back to the SD card as a *.

So we simply search for ;Z:91 and easily determine where the layer change starts. The following lines, in my case, are only the preparation steps for the layer change that are irrelevant to us, so we search the line where the printhead is lifted up to that layer, which is done with the instruction G1 Z layer height. We mark everything by clicking in front of the instruction, then holding the shift key and scrolling all the way up to the last instruction before the print starts, which is usually homing with the instruction G28. The only things that should be left in our G-code file are the initial setup and the instruction for setting extruder and bed temperature and homing. Then we directly move the printhead to the layer at 91 mm and continue printing. The only command I add manually is M106 S255 which turns the cooling fan on to 100%. If you’re not using a cooling fan or not the full power, adjust that value accordingly. Now simply save everything back to the SD card as a *. gcode file.

gcode file.

Step 4 with absolute extrusions (e.g. CURA): Editing the G-code

How the amount of extruded material gets sent to the printer varies from slicer to slicer or can even be even set in the slicer itself. The code I showed you before was prepared in PrusaSlicer which mostly uses relative extrusions, which means that for each move we only send the amount of material feed, that’s needed, instead of the absolute filament feed. CURA profiles often use absolute extrusions which can easily be spotted if you take a look at some G1 commands. If the E parameter slightly increases every line that’s an indication for that. It’s even simpler to spot if you find M82 in the header of the G-code file which sets the extrusion mode to absolute (instead of M83, which sets relative extrusions).

This is an important difference and requires you to add one additional line of G-code to your edited file. Also finding the right section where a new layer starts can be a bit more complicated in CURA because the comments in the G-code file are a little different. Just divide your resume height by the layer height you printed and you should get a rough estimation on which layer you want to resume your print. Then search for ;LAYER:XXX in the file and confirm the right height by the G0/G1 command with the Z parameter a couple of lines earlier.

Just divide your resume height by the layer height you printed and you should get a rough estimation on which layer you want to resume your print. Then search for ;LAYER:XXX in the file and confirm the right height by the G0/G1 command with the Z parameter a couple of lines earlier.

Layer comment and layer height

Now again delete everything starting from before the Z-movement all the way up to the point where only the initial settings are done and the printer gets homed.

Now we need to add three additional lines manually:

M106 S255 sets the fan to full speed (adjust the values between 0 and 255 for different speeds)

G0 Z##.# go to the appropriate layer height (##.# will be the numeric value you measured)

G92 E##.# sets the extrusion amount to the right value. For this value use the next E parameter that you find in your G-code

Manual G-code lines you need to add

Save everything and you should be good to go.

Step 5: Resume the print

Make sure you fixed whatever caused your print to fail in the first place and start the print. If everything goes well, the printer will heat up, home, and continue printing just where it failed before. I’d still recommend having your finger on the power switch to stop the machine if anything looks strange to give you the possibility to find out what you did wrong and have the chance to give it another try! In my case, the point where I resumed printing is practically invisible, even though the machine did nothing for several hours. What a great success!

Storm Trooper helmet by Geoffro resumed after with barely any marks

As I said before, there are cases where you are not able to home the z-axis because your print blocks the movement. In such a case, not everything is lost. You still need to measure or find the height where it failed in some way. When now editing the G-code file, make sure you also delete the G28 command, so the printer doesn’t try to home because we will do that manually. Everything else stays the same. Next, you manually need to move the printhead to the height of the last layer by connecting your laptop and using Proterface, for example. If you’re running Octoprint or use the DUET web interface, that works excellent as well. Many machines will not let you move the printhead if it’s not homed, so we need to trick the controller. First home only X and Y by sending G28 XY to the printer. The default position for the axes is often 0, and many printers won’t let you go to negative coordinates. Send M211 S0 to disable the software end stops. If the z-axis still can’t be lowered, try sending G92 Z0. Move the nozzle until it touches the last layer. Now send G92 Z and the failure height you measured. This way, you manually set the right z-height without homing. Be quick with starting your edited G-code file that the motors don’t switch to idle and lose their position. After heating the bed and nozzle, the print should continue normally, and you again might have saved days of printing and a ton of material!

Everything else stays the same. Next, you manually need to move the printhead to the height of the last layer by connecting your laptop and using Proterface, for example. If you’re running Octoprint or use the DUET web interface, that works excellent as well. Many machines will not let you move the printhead if it’s not homed, so we need to trick the controller. First home only X and Y by sending G28 XY to the printer. The default position for the axes is often 0, and many printers won’t let you go to negative coordinates. Send M211 S0 to disable the software end stops. If the z-axis still can’t be lowered, try sending G92 Z0. Move the nozzle until it touches the last layer. Now send G92 Z and the failure height you measured. This way, you manually set the right z-height without homing. Be quick with starting your edited G-code file that the motors don’t switch to idle and lose their position. After heating the bed and nozzle, the print should continue normally, and you again might have saved days of printing and a ton of material!

Cyclops bust by Wekster resumed with a manually homed z-axis

Stefan Hermann

0 Likes3D Printing: Is It Worth Adding To Your Resume?

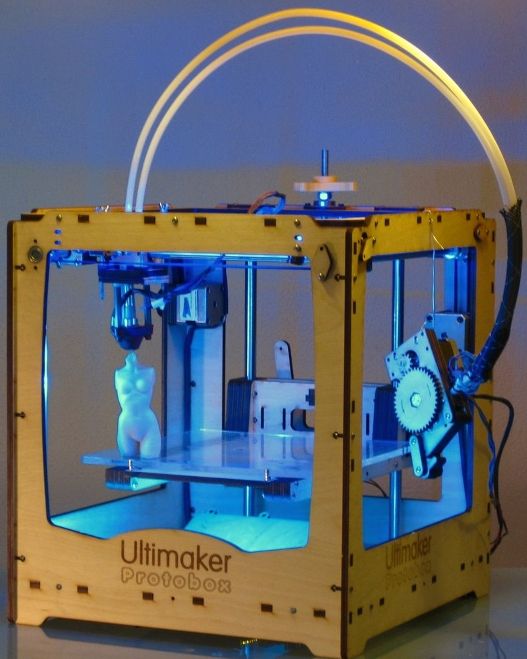

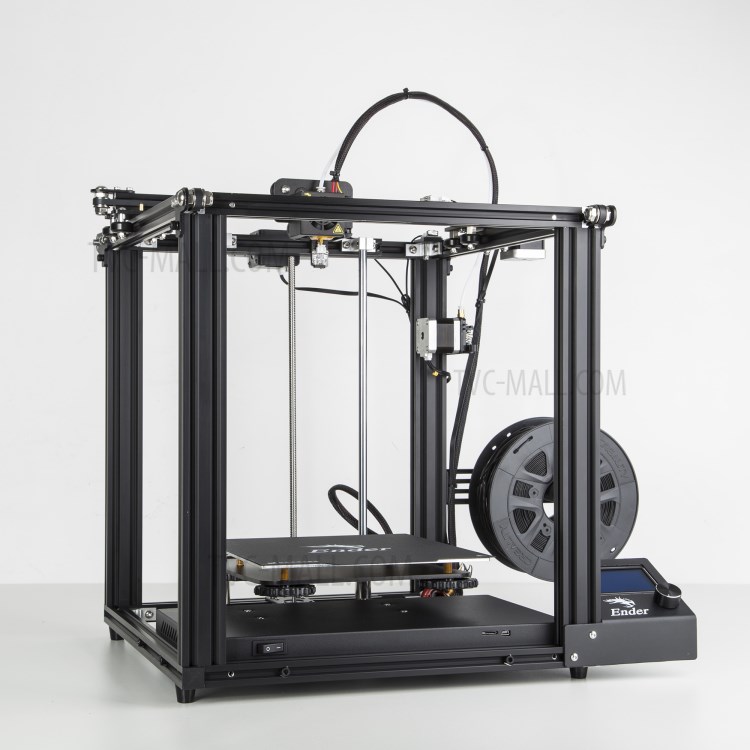

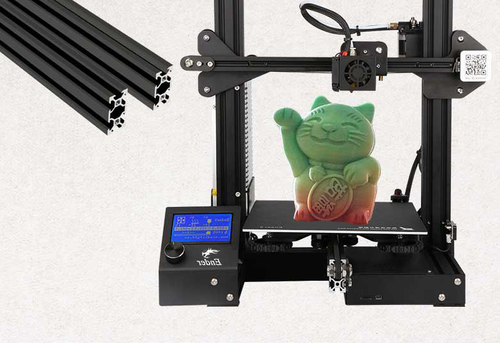

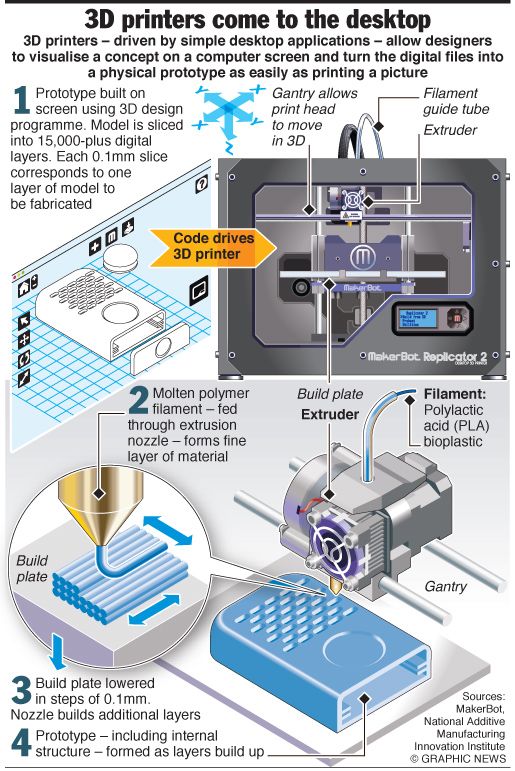

3D printing is an additive manufacturing technology that creates three-dimensional objects by successively building up layers of material. 3D printing is often touted as a technology that has the potential to revolutionize manufacturing, but it also has several applications in the realm of art and design. So, does 3D printing look good on a resume? The answer is, it depends. If you are applying for a job that requires design or engineering skills, then having experience with 3D printing can be a valuable asset. On the other hand, if you are applying for a job that has nothing to do with design or engineering, then your experience with 3D printing may not be relevant. In general, employers are always looking for candidates with relevant skills and experience, so if you have experience with 3D printing, be sure to highlight it on your resume. With the right skills and experience, you can make a strong case for why you are the best candidate for the job.

3D printing is often touted as a technology that has the potential to revolutionize manufacturing, but it also has several applications in the realm of art and design. So, does 3D printing look good on a resume? The answer is, it depends. If you are applying for a job that requires design or engineering skills, then having experience with 3D printing can be a valuable asset. On the other hand, if you are applying for a job that has nothing to do with design or engineering, then your experience with 3D printing may not be relevant. In general, employers are always looking for candidates with relevant skills and experience, so if you have experience with 3D printing, be sure to highlight it on your resume. With the right skills and experience, you can make a strong case for why you are the best candidate for the job.

3D printing skills are in high demand as a result of increased digitalization. If you have them, you can include them in your resume as long as you have permission. Just as important as making the perfect resume is giving a recruiter a good idea of what you can do. Because 3d printing is a rapidly expanding field, you have every right to highlight some of your skills on your resume. Enhancv.com analyzed over one million resumes and examples in the last two years. Here are some winning resume skills examples that can be used to enhance your resume. It is best to learn from people who have succeeded in their job search.

Because 3d printing is a rapidly expanding field, you have every right to highlight some of your skills on your resume. Enhancv.com analyzed over one million resumes and examples in the last two years. Here are some winning resume skills examples that can be used to enhance your resume. It is best to learn from people who have succeeded in their job search.

You can print your resume on a regular white piece of paper from your home using your printer. Because technology is such a part of life now, an employer does not expect you to submit a resume with a heavy stock, gold-colored cover letter.

Is 3d Printing A Marketable Skill?

Yes, 3d printing is a highly marketable skill in today’s job market. With the ever-growing popularity of 3d printing technology, there is a constant demand for individuals with the skills and knowledge to operate 3d printers. Individuals with 3d printing skills can find employment in a variety of industries, such as manufacturing, engineering, and design.

As 3D printing advances in a more modern industry, it has demonstrated its ability to accommodate a wide range of customization options. Professionals with extensive knowledge of 3D printing are in high demand. If you want to pursue a career that focuses on the field, you’ll need to hone some of these skills. As mass-produced 3D printed products become more common, there will be an increase in demand for 3D modelers. In the 3D printing workflow, post-processing is still performed manually. This includes sanding, powder removal, cutting off parts and pieces, polishing, inking, or UV treatment. You’ve probably heard of 3D printers capable of making entire meals, but they’ve never been invented.

To create materials for 3D printing, a combination of creativity and technical expertise is required. A product developer is in charge of coming up with new products that will appeal to an existing market. Despite the fact that 3D printing has grown in popularity in recent years, it is still a niche market. A patent attorney must be familiar with patent law, intellectual property ownership, licensing, and the scope of rights. A solid understanding of how 3D design and printing work is required in order to use IP protection mechanisms.

A patent attorney must be familiar with patent law, intellectual property ownership, licensing, and the scope of rights. A solid understanding of how 3D design and printing work is required in order to use IP protection mechanisms.

The market is expected to grow due to the rise in demand for customized products, the increased affordability of 3D printing technology, and the growing popularity of 3D printing among the general public.

The large-scale production of products using 3D printing is still some time away, but this technology has already begun to transform the way goods are manufactured.

prosthetic parts made of 3D printing have some intriguing applications. With this technology, people with disabilities will be able to live independently with affordable and adaptable prosthetic devices that will transform the way they do so.

3D printing has the potential to be used to create small, customized items, as well as large-scale industrial products. This is especially useful in an age when online shopping is becoming more prevalent, when customers want to order products that are specifically designed for them.

This is especially useful in an age when online shopping is becoming more prevalent, when customers want to order products that are specifically designed for them.

The technology of 3D printing is not limited to those with technical backgrounds; anyone interested in creating products for their own personal use can use it. For children, this is especially true when they create their own 3D-printed products.

3D printing, on the other hand, has the potential to transform how products are made, and it is an exciting technology that is not for the faint of heart. To learn more about this technology, check out the resources available on the internet.

How Do You 3d Print A Resume?

To 3D print a resume, you will need a 3D printer and a resume template. First, you will need to find a resume template that you like and that is compatible with your 3D printer. Next, you will need to print out the template on your 3D printer. Once the template is printed, you will need to fill it out with your personal information. Finally, you will need to 3D print your resume.

Finally, you will need to 3D print your resume.

Is 3d Printing A Career?

Credit: vengos.com

3D printing is a process of making three dimensional solid objects from a digital file. It is also known as additive manufacturing. The creation of a 3D printed object is achieved using additive processes, where successive layers of material are laid down in different shapes. 3D printing is the opposite of subtractive manufacturing, which is the traditional method of machining objects.

3D printing is a rapidly growing field with many different applications. It is being used in a variety of industries, including healthcare, aerospace, and automotive. 3D printing is a great career choice for those who are creative and have a background in engineering or design. There are many different job opportunities available in this field, from entry-level positions to management roles.

3D printing is an exciting field with a wide range of career options. The most important roles in 3D printing are those of a modeler and printer. Modelers are in charge of creating the 3D models that are used by 3D printers. A printer operator must ensure that the printers are in good working order and that the prints are of high quality. Quality control inspectors are in charge of ensuring that all product quality standards are met. A thorough understanding of both the theoretical and technical aspects of 3D printing is required to work as an engineer. This is a well-paying field that has plenty of opportunities for advancement. 3D printers can be used in a variety of fields, and there are numerous applications.

The most important roles in 3D printing are those of a modeler and printer. Modelers are in charge of creating the 3D models that are used by 3D printers. A printer operator must ensure that the printers are in good working order and that the prints are of high quality. Quality control inspectors are in charge of ensuring that all product quality standards are met. A thorough understanding of both the theoretical and technical aspects of 3D printing is required to work as an engineer. This is a well-paying field that has plenty of opportunities for advancement. 3D printers can be used in a variety of fields, and there are numerous applications.

A three-dimensional object can be created by printing multiple layers of material in a process known as additive manufacturing. A few years ago, the technology was popular, but it has recently gained popularity as a result of its ability to reduce the cost of producing items. As a result of these factors, 3D printing has gained popularity among industry players, and, as costs fall further, we can expect to see an increase in the adoption of 3D printing among the general public in the near future. There are numerous advantages to using this technology, but if you aren’t taking full advantage of them, you may be in a disadvantage. A 3D printer allows you to stay ahead of the game.

There are numerous advantages to using this technology, but if you aren’t taking full advantage of them, you may be in a disadvantage. A 3D printer allows you to stay ahead of the game.

Printing Skills Resume

In order to create a resume that highlights your printing skills, you should focus on any relevant experience you have in the printing industry. This could include any previous jobs you’ve had that involved printing, as well as any special training or education you have related to printing. If you have any relevant software skills, be sure to list those as well. Your resume should also highlight any special projects you’ve completed that involved printing, such as creating a large print run for a client. By focusing on your most relevant skills and experience, you can create a resume that will impress potential employers and help you land the printing job you want.

A resume should be sent electronically to a hiring manager or recruiter. It is possible that you will need a printed version, rather than a digital one, when you are in need of a print edition. A high-quality resume will help you stand out from the crowd and demonstrate your professionalism. The best kinds of paper for printing your resume, as well as how to make physical copies, are covered. Make your resume stand out by printing it at a professional printer. Papers with a thicker backing are more durable and less likely to crinkle. Make it simple to read your resume by using a paper color.

A high-quality resume will help you stand out from the crowd and demonstrate your professionalism. The best kinds of paper for printing your resume, as well as how to make physical copies, are covered. Make your resume stand out by printing it at a professional printer. Papers with a thicker backing are more durable and less likely to crinkle. Make it simple to read your resume by using a paper color.

The most professional font display should be done with white or off-white papers, such as ivory or cream. The watermark can only be seen if it is held up to a light. The watermark on resume paper is usually the logo or company name of the company that manufactured the paper. For some job seekers and employers, it may be preferable if their resume does not contain watermarks. When you print your resume on cotton paper, you give them a paper that will not crinkle easily and feel smooth. Cotton paper typically displays data in a clean and highly readable manner due to its weight and transparency. A thin piece of granite paper weighs at least 24 pounds, is light gray in color, and is thicker.

A thin piece of granite paper weighs at least 24 pounds, is light gray in color, and is thicker.

Creating a resume template will allow you to format it professionally and cleanly. Make certain that your company’s font is professional and easy to read, such as Times New Roman, Garamond, or Arial. For resumes, no more than one page should be required. If you are mailing out your resume, make sure to include a cover letter.

If you’re unsure whether to print a paper resume, go over the following questions with your interviewer. Do I need to send out my resume for job fair? How can I print out a resume? If you answered both of the questions correctly, printing out a paper resume is the best option. It not only makes your resume appear professional, but it also reduces the likelihood of your resume becoming lost or misplaced.

Resume Printing Services – Get The Best Possible Printing Results

If you need resume printing service, you can get the best results for your resume. Whether you want to print on standard paper or high-quality paper, we can assist you in obtaining the best possible results for your resume.

Whether you want to print on standard paper or high-quality paper, we can assist you in obtaining the best possible results for your resume.

3d Printing Skills

3D printing skills are in high demand as the technology continues to evolve. As a result, many companies are looking for employees with 3D printing skills. 3D printing can be used to create prototypes, models, and products. It is a rapidly growing field with many opportunities.

How do you 3D print a business card? I hope that by reading this article, you will be able to solve your doubt. It may be advantageous to begin with the knowledge and resources you already possess. One of the most difficult aspects is first contact. When you step onto a black ski slope with the courage to face it, it’s as if you’re stepping on a mountain with a black ski slope behind you. A 3D printer enables you to create an idea in minutes rather than hours. You must think outside of the box if you want to use a 3D printer.

You cannot customize objects if you do not have modeling skills. Even if you don’t need it, you can use some software like Tinkercad if you don’t have a technical background. Once you’ve mastered 3D modeling software, you can create wonderful and unique objects, even when they’re moving parts. You will be able to self-manage your time after some lessons because the required skills are not impossible. A good printer kit includes all of the necessary tools for mounting it, but after a while, you will still need to purchase specialized equipment for it to function properly. Before you begin, you should be familiar with the Arduino bundle, which is the software that allows you to use it for this type of operation. You will learn everything by taking the guide you are reading on the web by hand and through it.

Even if you don’t need it, you can use some software like Tinkercad if you don’t have a technical background. Once you’ve mastered 3D modeling software, you can create wonderful and unique objects, even when they’re moving parts. You will be able to self-manage your time after some lessons because the required skills are not impossible. A good printer kit includes all of the necessary tools for mounting it, but after a while, you will still need to purchase specialized equipment for it to function properly. Before you begin, you should be familiar with the Arduino bundle, which is the software that allows you to use it for this type of operation. You will learn everything by taking the guide you are reading on the web by hand and through it.

If we have the proper manual skills, we can create beautiful art. Even if you don’t have all of the skills mentioned before, if you have an insatiable curiosity, you will have everything you require. You may have to wait at first to resolve problems that appear to be impossible, at least the first time. It may appear impossible to mount a machine with a tight tolerance, such as a 3D printer.

It may appear impossible to mount a machine with a tight tolerance, such as a 3D printer.

G-code, as a general rule, is a well-known programming language; most 3D printers can read and write it. In some cases, such as the Formlabs Form 2 3D printer, which is based on proprietary technology, this is not the case.

What are the advantages of 3D printing? One of the most significant advantages of 3D printing is that it can create extremely complex objects that traditional manufacturing methods cannot match. Flexible materials such as plastic are used to create flexible objects with multiple parts that are linked together. Because of its ease of fabrication, 3D printing is an excellent method for developing prosthetic limbs and medical implants.

3D printing can also be accomplished in a shorter amount of time than traditional manufacturing methods. In comparison, using traditional methods can produce a one-of-a-kind object in less than an hour, but using 3D printing can take up to 24 hours. Because 3D printing uses layers of materials to create an object, it is more durable than traditional manufacturing methods.

Because 3D printing uses layers of materials to create an object, it is more durable than traditional manufacturing methods.

What are the advantages and disadvantages of 3D printing? The most significant disadvantage of 3D printing is its high cost. 3D printing is typically more expensive than traditional manufacturing methods, and it has not yet become as common as traditional manufacturing methods. Clothing and furniture are two examples of everyday objects that are not yet 3D printed.

Search for employees, workers, recruitment in Moscow, resume database Superjob

Updated at 12:35

56 years • experience 21 years and 9 months

Customs clearance manager, foreign economic activity, customer service manager

Moscow

60 000 ₽

English - basic and more 1

November 2009 - December 2016 (7 years and 2 months)

Customer Service SpecialistAgency Alfa LLC, customs representative, certificate 0516/00 dated 15.1. .

Formerly: Account Specialist, Customs Clearance Manager 2 more

Show Contacts

Add to Favorites

Find out how much your competitors are paying! Pay Meter - Your industry salary overview

New clients for your businessPlace your ad on 30 million users! Call: +7 495 580-61-76

Place an ad

Hire staff twice as fast Superjob's HR bot will save you time and money when hiring employees.

Learn more

Vaccinated. There is a certificate of

updated at 12:35

47 years • Experience 6 years and 10 months

Nurse Palatus Pediatrics

Lyubertsy

9000 ₽July 2022 - it now works (8 months)

Medical ward nurse of the department of pathology of newborns and premature babies of the perinatal center of the state budgetary institution "MMCC Kommunarka" DZM"

Previously: Nurse ward of the intensive care unit of the pediatric hospital

Show Contacts

Add to the chosen

updated at 12:34

26 years and 4 months

Chief accountant

Moscow, Medvedkovo, ready to move

at the agreement

June 2021 - is currently operating (1 year and 9 months)

Chief AccountantOOO "MIM"

Formerly: Head of Production and Trading Accounting Group, Chief Accountant more 6

Show contacts

Add to favorites

Vaccinated. Have a certificate

Have a certificate

Updated at 12:34

40 years • experience 11 years and 11 months

Master of the main production

Saratov, ready to move: Moscow, Samara and 48 other cities

70 000 ₽ 902 basic

December 2021 – active now (1 year and 3 months)

Foreman STSAO TRANSMASH

Formerly: Construction and installation foreman, Senior foreman more 1

Show contacts

Add to favorites

Updated at 12:34

41 years • Experience 15 years and 2 months

Plainer

Moscow, Domodedovskaya

70 000 ₽

November 2015 - operates now (7 years and 4 months)

ZOMPHOODO " "

Formerly: RTZ Acceptor, Sales Manager / Project Manager 2 more

Show contacts

Add to favorites

The applicant has 1 more resume, show

Vaccinated. There is a certificate

Updated at 12:34

56 years • Experience 15 years

Teacher of computer science

Kazan, ready for moving: Moscow

80 000 ₽

English - 5,0003

September 2010 - August 2021 (11 years)

Lecturer Sattam Bin Abdel Aziz University

Previously: Associate Professor

Show contacts

Add to favorites

Vaccinated. Have a certificate

Have a certificate

Updated at 12:34

36 years • experience 11 years

Gastroenterologist

Moscow, Dubrovka

100 000 ₽

June 2011-May 2022 (11 years old)

Gastroenterologist

Show Contacts

Add to the chosen

updated at 12:34

18 years old • 18 years old • experience 6 months

Intern-lawyer

Moscow, Ulitsa 1905 Goda and 2 more

15,000 ₽

English - technical and 1 more "

Formerly: Account Manager Assistant

Show contacts

Add to favorites

Vaccinated. There is a certificate of

updated at 12:34

27 years • Experience for 2 years and 7 months

Physician

Moscow, Voikovskaya and another 2,

,according to the agreement

English-spoken

November 2020-July 2022 (1 year and 9 months)

Therapist of the Therapeutic Covid Department Clinical Medical Center of the Moscow Medical and Dental University named after A. I. Evdokimov

I. Evdokimov

Formerly: General Therapist, General Therapist

Show contacts

Add to favorites

Updated at 12:34

62 years • experience 35 years and 5 months

Legal adviser, Lawyer Ugotovlperezkuz

: Moscow

By agreement

German - basic

April 2014 – August 2014 (5 months)

Legal Counsel LLC "PKP "Zavod VTO"

Previously: Lawyer, Lawyer more

0003Add to the elected

updated at 12:34

2 years and 1 month

System Administrator, Operator PC

Moscow, is ready to move

English and another 3

May 2019 – May 2021 (2 years and 1 month)

Woodworking machine operatorMebelgrad

Show contacts

Add to favorites

Updated at 12:34

43 years • experience 18 years and 3 months0003

Lawyer

Moscow, Academician Yangel Street, ready for moving

by agreement

English-Basic

February 2007-September 2021 (14 years and 8 months)

Lawyer-ad-Ovocatical company

Earlier: Lawyer, lawyer, Assistant Attorney, Trainee Attorney more 4

Show contacts

Add to favorites

Updated at 12:34

24 years • experience 5 years and 2 months

Packer

Moscow

, according to the agreement

Russian language - spoken

February 2017 - March 2022 (5 years and 2 months)

Domkom

Show Contacts

Add to the chosen

updated at 12:34

years of 10 years and 3 months

Software tester

Moscow, ready to move: Novosibirsk, Krasnodar and 1 more city

By agreement

English - fluent

November 2022 – active now (4 months)

Project ManagerOOO "Business Automation" (1C Franchise)

Formerly: Lead Inspector, Chief Specialist more 1

Show contacts

Add to favorites

Updated at

36 years • experience 6 years and 6 months

Wildberries manager remotely

Moscow

40,000 ₽

German - spoken

September 2016 - working now (6 years and 6 months)0003

Branch manager Rzhaksinskiy CDD

Show contacts

Add to favorites

Vaccinated. Have a certificate

Have a certificate

Updated at 12:34

43 years • experience 14 years and 5 months

Office driver

Moscow, Voikovskaya, Streshnevo

55 000 ₽

55 000 ₽

working December

Office driverOOO Sinera-KS

Formerly: Personal driver, Personal driver of the CEO 2 more

Show contacts

Add to favorites

The applicant has 1 more resumes, show

Vaccinated. There is a certificate of

updated at 12:34

45 years • Experience 27 years and 9 months

Service specialist AUTO/ Senior Mechanic

Moscow, Grandmother, ready to move

120 000 ₽

English - Technical

June 1995 - active now (27 years and 9 months)

Technician 9Ol000 Ownership

May 2022 - September 2022 (5 months)

Front Desk ManagerInternet Solutions

Formerly Warehouse Clerk

Show Contact

Add to Favorites

updated at 12:33

43 years • Experience 19 years and 7 months

Restaurant manager

Odintsovo

at an agreement

English - technical

February 2019 - operates now (4 years and 1 month)

Restaurant Manager La Mare

Formerly: Restaurant Manager, Senior Restaurant Manager 6 more

Show contacts

Add to favorites

Updated at 12:33

55 years • 28 years and 9 years of experienceMonths

Head of Occupational Health and Safety Department, Chief Specialist

Moscow, Govorovo

By agreement

Basic English

November 2013 – April 2021 (started 7 years and 6 months)

90 Emergencies and Civil Defense, Department of Occupational Health, Industrial, Fire and Environmental Safety Transneft Formerly: Head of the Department of Occupational Safety, Department of Occupational Safety and Production Control, Engineer for Occupational Health and Safety Cat. II, Head of the Department of Occupational Safety , Deputy Chief Engineer for Labor and Industrial Safety 1 more

II, Head of the Department of Occupational Safety , Deputy Chief Engineer for Labor and Industrial Safety 1 more

Show Contacts

Add to the Favorites

updated at 12:33

41 years (7 months)

Culinary sales consultantAuchan

Show contacts

Add to favorites

The applicant has 1 more resumes, show

Vaccinated. Have certificate

Updated at 12:33

39 years • Experience 19 years and 5 months

A nurse

Monino

60 000 ₽

September 2003 - January 2023 (19 years and 5 months)

Nurse

Show contacts

Add to favorites

The applicant has 2 more resumes, show

Vaccinated. Certified

Updated at 12:33

32 years • 9 years experience

RFID Project Manager

Moscow, Novogireevo

100 000 ₽

English-Basic

August 2022-it now works (7 months)

RFIDOOOOOOOOOOOOOODE

Earlier: laboratory assistant RFID, laboratory assistant RFID another 6

show Contacts

Add to the chosen

updated at 12:33

33 years • Experience 9 years and 11 months

Assistant Lawyer

Moscow, Rokossovsky Boulevard

80 000 ₽

English - Basic and another 1

January 2023 - February 2023 (2 months)

Senior Specialist "Voentelekom"

earlier: specialist 1 category, legal adviser 2,

Show Contacts

Add to the chosen

ON THE SECREMENT, Show

updated at 12:33

68 years • experience 35 years and 8 months

Boiler operator

Moscow, ready to move

35,000 ₽

April 1985 – November 9 and 8 months (3)0003

Boiler operator Mosenergo

Show contacts

Add to favorites

The applicant has 1 more resumes, show

Updated at 12:33

60 years • experience 11 years and 5 months Commercial refrigeration equipment repairman

3 cold), coolers, purifiers, household ice makers and refrigerators

Moscow

By agreement

October 2011 - working now (11 years and 5 months)

Cooler and purifier repairman

Show Contacts

Add to the chosen

updated at 12:33

23 years old • Experience 1 year and 11 months

The head of the transport department

Moscow, is ready to move

80 000 ₽

October 2021 - it works now (1 year and 5 months)

Car service inspectorAvtomir LLC

Previously: Mahaniye

Show contacts

Add to favorites

The applicant has 1 more resume, show

Vaccinated. Have a certificate

Have a certificate

Updated at 12:33

experience 38 years and 11 months

Sales manager, remotely

Moscow, ready to move: Samara, Nizhny Novgorod and 3 more cities

1000 ₽ 9002 spoken English and 1 more

January 1984 – November 2022 (38 years and 11 months)

Programmer, manager, accountantDIFFERENT COMPANIES

Show contacts

Add to favorites

The applicant has 3 more resumes, show

updated at 12:33

40 years • Experience 6 years and 1 month

Operator 1C

Moscow

70 000 ₽

January 2021 - June 2021 (6 months)

Analyst-consultant 1СZooshop-zoo

Formerly: PC operator / Operator 1С, Accountant-operator more 1

Show contacts

Add to favorites

The applicant has 1 more resume, show

Vaccinated. Have certificate

Updated at 12:33

42 years • Experience 20 years and 6 months

Trading

Moscow, Upper Likhobors

70 000 ₽

German - Basic

January 2016 - now works (7 years and 7 years and 7 years old (7 years 2 months)

Deputy General Director ANO PO "Training Center for Driving Education" "Professional"

Previously: Outdoor Advertising Manager, Sales Representative more 6

Show contacts

Add to favorites

The applicant has 1 more resume, show

123. ..167Next

..167Next

Resume "Operator-engineer (3D-printers)", Kiev, Remotely - Work.ua

Resume "Operator-engineer (3D-printers)", Kiev, Remotely - Work.ua- Candidates

- in Kyiv

- IT, computers, internet

Resume dated August 23, 2016Read more">PRO

Operator-engineer (3D printers)

- Employment:

- Part-time employment.

- Age:

- 39 years old

- City of residence:

- Kyiv

- Ready to work:

- Kyiv, Remotely

The applicant indicated phone and email mail.

Name, contacts and photo available only for registered employers. To access candidates' personal data, sign in as an employer or register.

You can get the contacts of this candidate on the page www.work.ua/resumes/3541671/

Work experience

3D printer engineer - IT specialist - microprocessor technology engineer

from 11. 2014 to 08.2016 (1 year 9 months)

2014 to 08.2016 (1 year 9 months)

3din, Kyiv (development and implementation)

Drawing 3D models according to drawings, sketches, pictures or according to the customer's words in 3D Max, blender, Sculpturis, zBrush, Corel, Illustrator, Cura, for subsequent printing on 3D printers or laser cutting.

Work with Prusa I3 3D printers, assembly, repair, adjustment, improvement, modernization, alteration.

There are ideas for developing new 3D printers, including a complete rendering of all its components.

Programming ATS (microprocessors) for example a series of ATmega8a, 256, etc. Writing code for them, debugging, flashing, pre-checking on the emulator. ISIS, CV AVR, extreme burner.

Development of devices based on microprocessors, from testing, debugging, assembly, soldering, for example: a laser gun, a target, a light board, temperature sensors, lighting, on and off relays, almost everything from the arduino sensor family, working with arduino + sensors, developing individual components for smart home systems, development of radio-controlled models.

I have experience in repairing DJI fantom 2 vision+ quadcopters, and one was smashed to smithereens.

Education

VMUROL "Ukraine"

Computer systems and services, Computer engineering, Kiev

Higher education, from 2001 to 2006 (5 years 4 months)

Professional and other skills

Professional and other skills capacitors, systems of the Windows xp-10 family, Ubuntu, 3D max, blender, UNITY, Kerio winrout, Kerio Mail server, Wialon, Visicar, Cura, ISIS AWR, Photoshop, Pinnacle 11-15, Sony sound forge, Office, C ++, writing bash scripts. etc.

Medium, currently using.

Medium, currently using.

Advanced, currently using it.

Medium, currently using.

Advanced, currently using.

Medium, currently using.

Advanced, 1 year ago.

Intermediate, 2 years ago.

Medium, currently using it.

Medium, currently using it.

Advanced, currently using it.

Language skills

English - intermediate

Additional information

I work with 3D printers, develop models for bottoms in 3D MAX, blender, work with Сura slicer, study Solid Work. There is a PRUSA I3 3d printer - which I have somewhat modified, and I am making plans for its further modernization. I understand the essence of 3D printers, I work layer-by-layer printing mainly with ABS plastic and PLA, I understand the components and principles of operation of printers, I can independently assemble 3D printers, repair, upgrade, design new elements, systems and printers themselves.

There is a PRUSA I3 3d printer - which I have somewhat modified, and I am making plans for its further modernization. I understand the essence of 3D printers, I work layer-by-layer printing mainly with ABS plastic and PLA, I understand the components and principles of operation of printers, I can independently assemble 3D printers, repair, upgrade, design new elements, systems and printers themselves.

I am engaged in the development of devices, soldering, drawings, board layout, writing code for ATS micro controllers, for example, the Atmega series in CVAVR, ISIS applications, firmware for micro controllers, code for working with arduino transmitters, I study arduino, I can develop components for a smart home, robots, radio-controlled toys, etc. . I plan to make a radio-controlled ornithopter.

I sometimes work with Unity, for example, I make 3D screen savers for the desktop, 3D presentations, WEBgl, demos. Well, and a lot of other things I am also friends with my hands and if you need something else - you ask maybe I already do this, or I know how to do it or I can learn it quickly :)

P. S. I like shooting from a classic bow, kayaking, doing 3D design, communicating with people, learning something new and interesting

S. I like shooting from a classic bow, kayaking, doing 3D design, communicating with people, learning something new and interesting

Offer a job

Similar candidates

- 3D modeler, 3D printer operator , 10000 UAH, Kyiv.

- 3D designer, 3D Artist, 3D modeler , Remotely.

- Design engineer, 3D modeler (Compass-3D, Solid Works) , 18000 UAH, Zaporozhye, Remotely.

- 3D sculpor, 2D, 3D motion designer, 3D modeller , 35000 UAH, Dnipro, remotely.

- 3D Modeler, 3D Artist, 3D Artist , 23500 UAH, Kyiv, Vinnitsa, 3 more cities.

Learn more