3D surveying scanner

3D Laser Scanning for Surveyors

3D laser scanning customer stories to inspire your business

3D laser scanning allows you to quickly capture, visualise and pre-register data in the field, which can then be processed in the office to deliver conventional 2D models and 3D digital twins, helping you to offer better and higher value services to your clients and win new business. Surveyors are measurement experts, and geared with 3D laser scanning, can document any structure or environment safer, faster and more efficiently.

Growing your business with 3D laser scanning

Nelson Boquin, founder of Nelson Surveys, based in Australia, explains how adding 3D laser scanning to its company services has resulted in more business.

Nelson Boquin, founder of Nelson Surveys, based in Australia, explains how adding 3D laser scanning to its company services has resulted in more business.

READ MORE

Five reasons to get into laser scanning and how to get started

Learn the easiest way surveyors can get started with laser scanning and hear from surveyor Don Smith the benefits of 3D laser scanning.

Learn the easiest way surveyors can get started with laser scanning and hear from surveyor Don Smith the benefits of 3D laser scanning.

READ MORE

Experience point cloud data from real projects

Explore the point cloud data in TruView from different projects and get inspired on how you can share a photorealistic digital reality environment with your clients from anywhere, anytime.

Explore the point cloud data in TruView from different projects and get inspired on how you can share a photorealistic digital reality environment with your clients from anywhere, anytime.

DISCOVER MORE

Deliver new services with 3D laser scanning

Civil infrastructure

See how surveyors can deliver the highest quality 3D data for civil infrastructure with scanning. From creating as-built representations of new civil infrastructure to measuring existing infrastructure before planning to rebuild or renovate, 3D laser scanning is the ideal reality capture technology for creating digital twins.

See how surveyors can deliver the highest quality 3D data for civil infrastructure with scanning. From creating as-built representations of new civil infrastructure to measuring existing infrastructure before planning to rebuild or renovate, 3D laser scanning is the ideal reality capture technology for creating digital twins.

From creating as-built representations of new civil infrastructure to measuring existing infrastructure before planning to rebuild or renovate, 3D laser scanning is the ideal reality capture technology for creating digital twins.

READ MORE

Building construction

Discover how surveyors can play a pivotal role by using 3D laser scanning technologies to improve the plan, design, construction, management and renovation processes for buildings.

Discover how surveyors can play a pivotal role by using 3D laser scanning technologies to improve the plan, design, construction, management and renovation processes for buildings.

READ MORE

Urban planning

Explore how surveyors can provide 3D models – the base for all operations in a smart city. 3D models provide the right insights so urban planners can understand risks and make informed decisions.

3D models provide the right insights so urban planners can understand risks and make informed decisions.

Explore how surveyors can provide 3D models – the base for all operations in a smart city. 3D models provide the right insights so urban planners can understand risks and make informed decisions.

READ MORE

Power and plant

Explore how 3D models enables surveyors to capture as-built data form a safe distance and create valuable models for planning, fabrication, and clash detection for power and plant documentation.

Explore how 3D models enables surveyors to capture as-built data form a safe distance and create valuable models for planning, fabrication, and clash detection for power and plant documentation.

READ MORE

Heritage and preservation

Learn how surveyors geared with 3D laser scanning can measure with high resolution any historical monument, building or heritage site to document, study, and understand any threats.

Learn how surveyors geared with 3D laser scanning can measure with high resolution any historical monument, building or heritage site to document, study, and understand any threats.

READ MORE

Your surveying partner

Only Leica Geosystems has 200 years of experience helping surveyors. Find out how we can support you with premium quality measuring and positioning solutions and services.

Find out how we can support you with premium quality measuring and positioning solutions and services.

Only Leica Geosystems has 200 years of experience helping surveyors. Find out how we can support you with premium quality measuring and positioning solutions and services.

Read More

Grow your business

Discover how embracing digitalisation with technologies and processes can support your business to create new opportunities, stay competitive and improve productivity.

Discover how embracing digitalisation with technologies and processes can support your business to create new opportunities, stay competitive and improve productivity.

Get Inspired

Surveying solutions

Regardless of how complex your task is, a solution is available within our diverse measuring, positioning, visualising and collaborating portfolio to help you succeed and be more efficient.

Regardless of how complex your task is, a solution is available within our diverse measuring, positioning, visualising and collaborating portfolio to help you succeed and be more efficient.

DISCOVER OUR SOLUTIONS

Improve your skills

Learn the skills to be more efficient and react to business opportunities. Unlock your potential to offer better, faster and more specialised services to your clients.

Unlock your potential to offer better, faster and more specialised services to your clients.

Learn the skills to be more efficient and react to business opportunities. Unlock your potential to offer better, faster and more specialised services to your clients.

Start Now

A Perfect Tool for Surveyors

Print 🖨 PDF 📄 eBook 📱

Running a surveying business is highly rewarding, but it comes with multiple technology considerations. As a surveyor, you need to choose the right tools for the job, and knowing which tools are most suitable for your projects can be a big hurdle when it comes to growing your business.

In this blog, Hexagon’s Andrea Biasion explains the different benefits of the 3D laser scanners in Leica Geosystems product portfolio – which includes tools designed for simplicity, speed, accuracy, precision and effectiveness in all environmental conditions.

Firstly, what is reality capture?Reality capture is the process of digitising the physical world. Professionals can use different measurement technologies to collect accurate 3D data for use in various software applications and workflows. The physical world can be digitised and represented in a 3D environment using 3D sensors, becoming the basis for decisions in different fields of work. Then, decisions based on the digital models can inform concrete actions in the physical world.

Professionals can use different measurement technologies to collect accurate 3D data for use in various software applications and workflows. The physical world can be digitised and represented in a 3D environment using 3D sensors, becoming the basis for decisions in different fields of work. Then, decisions based on the digital models can inform concrete actions in the physical world.

What are the applications of reality capture?

From traditional building construction and crime scene investigation to city mapping and volumetrics, reality capture applications are almost endless. The end-to-end workflow for reality capture is divided into four steps; capturing data, processing data, managing data and creating the end deliverables. The first – capturing data in the field – is what surveyors are most used to doing. The workflow’s other three phases are sequential and mainly performed in the office. The processing of the data is where the data is imported, registered and modelled. The management of the data is where the data is made available to create the final deliverables. At the end of the workflow, the data is put to work for all professionals that consume the data.

The management of the data is where the data is made available to create the final deliverables. At the end of the workflow, the data is put to work for all professionals that consume the data.

There are three flagship devices for the job; The Leica BLK360 Imaging Laser Scanner, the Leica RTC360 3D Laser Scanner and the Leica ScanStation P-Series.

To compare, the BLK360 is the smallest and lightest imaging laser scanner of its kind. It’s simple to use and captures full-colour panoramic images overlaid on a high-accuracy point cloud. The RTC360 allows users to automatically pre-register point cloud data in the field to conduct quality control checks quickly. Its streamlined process for reality capture makes it suitable for non-surveying users and allows individuals to make better-informed decisions on-site, even on complex projects. Finally, the ScanStation P-Series is a range of versatile, survey-grade 3D laser scanning solutions. These scanners deliver speed, accuracy and range for demanding scanning projects, making them perfect for creating as-built representations and capturing the 3D geometry of civil infrastructure.

These scanners deliver speed, accuracy and range for demanding scanning projects, making them perfect for creating as-built representations and capturing the 3D geometry of civil infrastructure.

What’s the difference between these 3D laser scanners?

The environment is a significant factor in deciding which laser scanner to invest in, especially if the user will be operating under extreme temperatures. The three laser scanners have a varied temperature range – the ScanStation P-Series can operate from -20°C to +50°C, whereas the BLK360 can operate between +5°C and +40°C and the RTC360 can operate between -5°C and +40°C.

Then there are differences in speed and resolution. The RTC360 has the highest scan speed at two million points per second, followed by the ScanStation P-Series at 1 million points per second and the BLK360 at 360,000 points per second. The ScanStation P-Series offers the highest resolution. The maximum range measurable also differs between them – the BLK360 is 20-60 metres, the RTC360 is 40-130 metres, and the ScanStation P-Series is 70-1,000 metres.

For software, all three laser scanners connect with the Leica Cyclone FIELD 360 mobile device app for data acquisition in the field. This means that each laser scanner is able to capture, register and examine scan and image data automatically. The user interface combines easy handling of complex calculations with graphical user guidance, which offers a remarkably straightforward user experience, even suitable for novice users.

How do I know which 3D laser scanner is right for my project?

Each scanner has its own unique offering, so choosing the right laser scanner comes down to the day-to-day projects your team works on. The BLK360 is perfect for relatively small-scale documentation applications where images are as important as accurate 3D data. It’s suitable for outdoor and indoor applications and works well in congested areas due to its maximum portability and simplicity. Users who have no experience using laser scanning technology can easily adopt this scanner due to its easy interface and one-button operation. What’s more, because it’s very light at only 1kg, it’s perfect for projects requiring a device that’s easy to handle.

What’s more, because it’s very light at only 1kg, it’s perfect for projects requiring a device that’s easy to handle.

Meanwhile, the RTC360 is a scalable solution for larger projects: think mapping something the size of an industrial plant. The laser scanner is perfect for projects where productivity and data quality are key factors, such as construction planning or public safety. It embodies a Visual Inertial System using five cameras and other sensors, allowing the scanner to track its position while moving from setup to setup. This streamlines all of the registration and processing operations, making the full end-to-end workflow faster and more optimised. Whether you operate in light or dark environments, the RTC360 can collect a full-dome HDR of pictures in less than one minute and has the highest scanning speed at up to two million points per second. It’s the perfect companion for challenging environments.

Finally, the ScanStation P-Series offers the right solution if your team requires highly reliable and accurate results to feed into a range of workflows. They are high-end laser scanners adopting surveying functionalities like target measurement, troubleshooting and inspections. These scanners are ideal if your team is operating in the harshest conditions with extreme temperature ranges; our customers use them in, for example, bridges, highways, mines, airports and dams. Due to their superior measurement range, they will be the instruments of choice when covering larger areas where data quality over a long-range is a key factor. In summary, the ScanStation P-Series are weatherproof, robust and perfect for teams that require best-in-class data quality.

They are high-end laser scanners adopting surveying functionalities like target measurement, troubleshooting and inspections. These scanners are ideal if your team is operating in the harshest conditions with extreme temperature ranges; our customers use them in, for example, bridges, highways, mines, airports and dams. Due to their superior measurement range, they will be the instruments of choice when covering larger areas where data quality over a long-range is a key factor. In summary, the ScanStation P-Series are weatherproof, robust and perfect for teams that require best-in-class data quality.

To learn more, watch Andrea Biasion’s presentation from Intergeo 2021, 3D Laser Scanners: A Perfect Tool for Surveyors.

Andrea Biasion

Product Manager, Laser Scanning

Reality Capture Division

3D ground laser scanning

Point cloud examples

Despite the fact that the first terrestrial 3D scanners appeared in the last century, there is no reason to state that 3D laser scanning technology is widely used in geodesy. The main reasons, probably, are the still high cost of such systems and the lack of information on how to use them effectively in various applications. Nevertheless, interest in this technology and its demand in the market of geodetic equipment are growing exponentially every year.

The main reasons, probably, are the still high cost of such systems and the lack of information on how to use them effectively in various applications. Nevertheless, interest in this technology and its demand in the market of geodetic equipment are growing exponentially every year.

What is a 3D laser scanner?

According to the type of information received, the device is in many ways similar to a total station. Similar to the latter, the 3D scanner uses a laser range finder to calculate the distance to an object and measure vertical and horizontal angles to obtain XYZ coordinates. The difference from a total station is that daily shooting with a ground-based 3D laser scanner is tens of millions of measurements. Obtaining a similar amount of information from a total station will take more than one hundred years ...

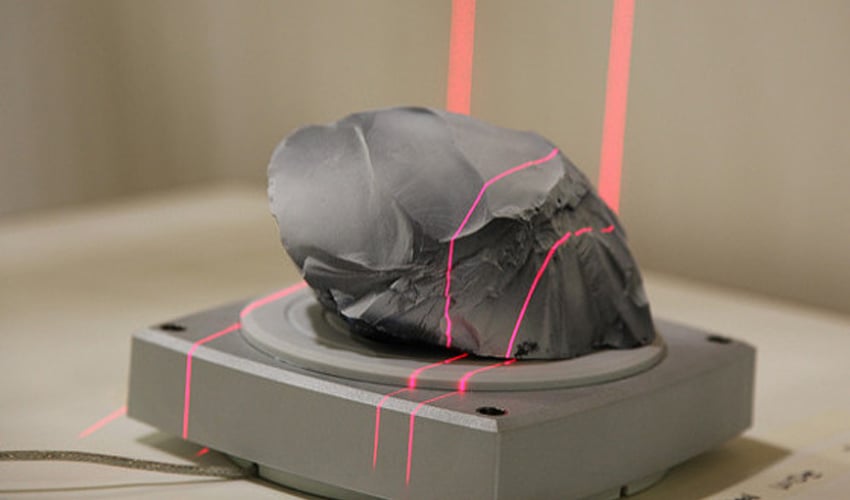

The initial result of the 3D laser scanner is a point cloud. In the process of shooting, three coordinates (XYZ) and a numerical indicator of the intensity of the reflected signal are recorded for each of them. It is determined by the properties of the surface on which the laser beam falls. The point cloud is colored depending on the degree of intensity and after scanning looks like a three-dimensional digital photo. Most modern models of laser scanners have a built-in video or photo camera, so that the point cloud can also be painted in real colors.

It is determined by the properties of the surface on which the laser beam falls. The point cloud is colored depending on the degree of intensity and after scanning looks like a three-dimensional digital photo. Most modern models of laser scanners have a built-in video or photo camera, so that the point cloud can also be painted in real colors.

In general, the operation of the device is as follows. The laser scanner is mounted opposite the object to be filmed on a tripod. The user sets the required point cloud density (resolution) and survey area, then starts the scanning process. To obtain complete data about an object, as a rule, it is necessary to perform these operations from several stations (positions).

Then the initial data received from the scanner is processed and the measurement results are prepared in the form in which they are required by the customer. This stage is no less important than field work, and is often more time-consuming and complex. Profiles and sections, flat drawings, three-dimensional models, calculations of areas and volumes of surfaces - all this, as well as other necessary information, can be obtained as the final result of working with a scanner.

Where can laser scanning be used?

Main applications of 3D scanning:

- industrial enterprises

- building and architecture

- road shooting

- mining

- monitoring of buildings and structures

- documentation of emergencies

This list is far from complete, since every year users of laser scanners perform more and more unique projects that expand the scope of technology.

Laser Scanning from Leica Geosystems - History of Laser Scanners

The history of Leica laser scanners began in the 90s of the last century. The first model 2400, then under the Cyra brand, was released in 1998. In 2001, Cyra entered Leica Geosystems into the HDS (High-Definition Surveying) division. Now, after 14 years, Leica Geosystems introduces a line of two scanning systems on the market.

As mentioned above, 3D laser scanning is used in completely different areas, and there is no universal scanner that would effectively solve all problems.

For shooting industrial facilities where a long range is not required, but the model must be very detailed (that is, an accurate high-speed device is needed), the laser scanner Leica ScanStation P30 will be optimal: range up to 120 m, speed up to 1,000,000 points per second.

Completely different requirements are imposed on the scanner when it comes to shooting opencast mines and storages of bulk materials in order to calculate volumes. Here, centimeter accuracy of the rangefinder is enough, and the shooting range and protection from weather conditions and dust come to the fore. The ideal tool for scanning in such conditions - Leica HDS8810 with a range of up to 2,000 m and IP65 dust and water resistance. In addition, this device is the only one on the market of scanning systems that operates in the temperature range from -40 to +50 degrees. That is, the HDS8810 is a laser scanner that works in all weather conditions.

The key model of Leica Geosystems' HDS division is the Leica ScanStation P40 . The famous and most popular ScanStation line in the world, whose history began in 2006, was replenished in April 2015 with the P40 scanner. The P40 inherited the accuracy and speed from the previous model, but has become more long-range, and the data quality has become even better. In terms of the range of tasks to be solved, this device is truly a leader in its segment. It is no coincidence that despite the "youth" of this model, it has already gained wide popularity in the world.

The famous and most popular ScanStation line in the world, whose history began in 2006, was replenished in April 2015 with the P40 scanner. The P40 inherited the accuracy and speed from the previous model, but has become more long-range, and the data quality has become even better. In terms of the range of tasks to be solved, this device is truly a leader in its segment. It is no coincidence that despite the "youth" of this model, it has already gained wide popularity in the world.

Software for processing laser scan data (point clouds)

It is impossible not to say a few words about the software for processing data received from the scanner. Potential customers pay undeservedly little attention to this component of the 3D laser scanning system, although data processing and obtaining the final result of the work are no less important stages of the project than field work. The range of Leica HDS software is truly the widest on the laser scanning market.

The main element of the spectrum is, of course, the Cyclone complex. This modular software system is rightfully considered the most popular in the world and has a large package of tools for processing data obtained using a scanner. Leica also has a number of more highly specialized programs. For those who are accustomed to working in traditional CAD, there is a series of software products Leica CloudWorx embedded in AutoCAD, MicroStation, AVEVA and SmartPlant, which allows users of these programs to work directly with point clouds. 3DReshaper builds high-quality triangulation models of object surfaces and allows you to monitor deformations by comparing object surveys taken at different times. The Leica HDS line of software even includes software for processing scan data in forensics.

This modular software system is rightfully considered the most popular in the world and has a large package of tools for processing data obtained using a scanner. Leica also has a number of more highly specialized programs. For those who are accustomed to working in traditional CAD, there is a series of software products Leica CloudWorx embedded in AutoCAD, MicroStation, AVEVA and SmartPlant, which allows users of these programs to work directly with point clouds. 3DReshaper builds high-quality triangulation models of object surfaces and allows you to monitor deformations by comparing object surveys taken at different times. The Leica HDS line of software even includes software for processing scan data in forensics.

Thus, laser scanning from Leica Geosystems is a whole complex of software and hardware solutions. For every, even a highly specialized task, Leica has a scanner + software combination that will help solve this problem as efficiently as possible.

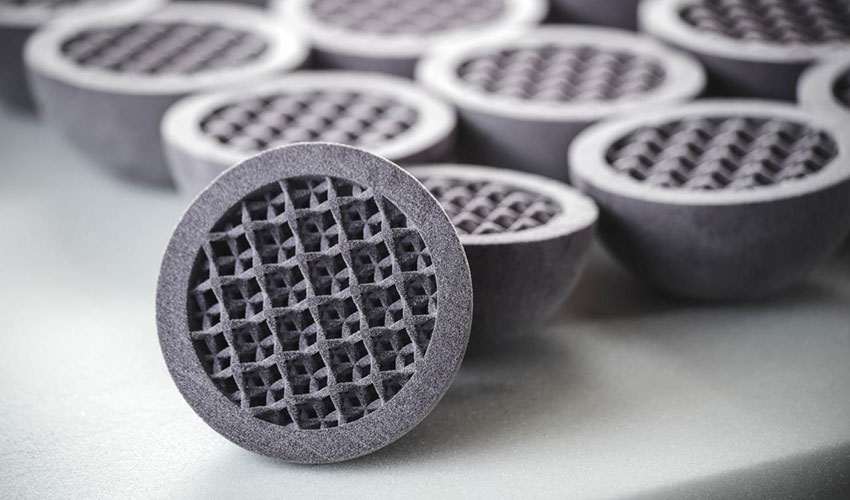

Geodetic Scanners

Ground-based laser scanner has firmly established its niche among geodetic instruments. Laser scanners are capable of more than one million measurements per second in completely reflectorless mode. As a result of scanning, we obtain spatial data on all objects that fell into the field of view of the device. This data is called a "point cloud". The laser scanner is used to measure objects of varying complexity: architectural structures, monuments, factories, hydroelectric power stations, nuclear power plants, ships, aircraft and much more.

Laser scanners are capable of more than one million measurements per second in completely reflectorless mode. As a result of scanning, we obtain spatial data on all objects that fell into the field of view of the device. This data is called a "point cloud". The laser scanner is used to measure objects of varying complexity: architectural structures, monuments, factories, hydroelectric power stations, nuclear power plants, ships, aircraft and much more.

The principle of operation of a terrestrial laser scanner is based on measuring the distance to an object using a non-reflective laser rangefinder and determining two angles of the direction of the laser beam, which ultimately makes it possible to calculate the coordinates of the reflection point. Distances are measured through a mirror continuously rotating around a horizontal axis; after each complete revolution of the mirror, the device is rotated around a vertical axis. Due to this, we get a set of profiles that form a complete picture of the surrounding space in coordinate form.

The field of view of the scanner is 320° vertically and 360° horizontally. Thus, only a small space under the scanner itself remains unmeasured, which can be neglected, provided that the surface under the scanner is straight and does not have visible cracks and other damage. To capture shadow areas that are not visible from the point where the scanner is installed, it must be reinstalled in a new position so that the shadow areas become visible. The scanner is rearranged and a new survey is made until there is not a single shadow zone left. The layout of the scanner installation points depends on the configuration of the room and the installed equipment. If it is necessary to scan the shadow zone under the scanner, the next standing point is chosen so that the shadow from the scanner is completely measured.

When scanning outdoors, stations are selected with the same calculation. As a rule, distances between standing points do not exceed 150m. This is due to the fact that the farther the subject is from the scanner, the worse the laser signal is reflected from it.