Dlp 3d printer price

Best resin 3D printers in 2022

What is the best resin 3D printer on the market?

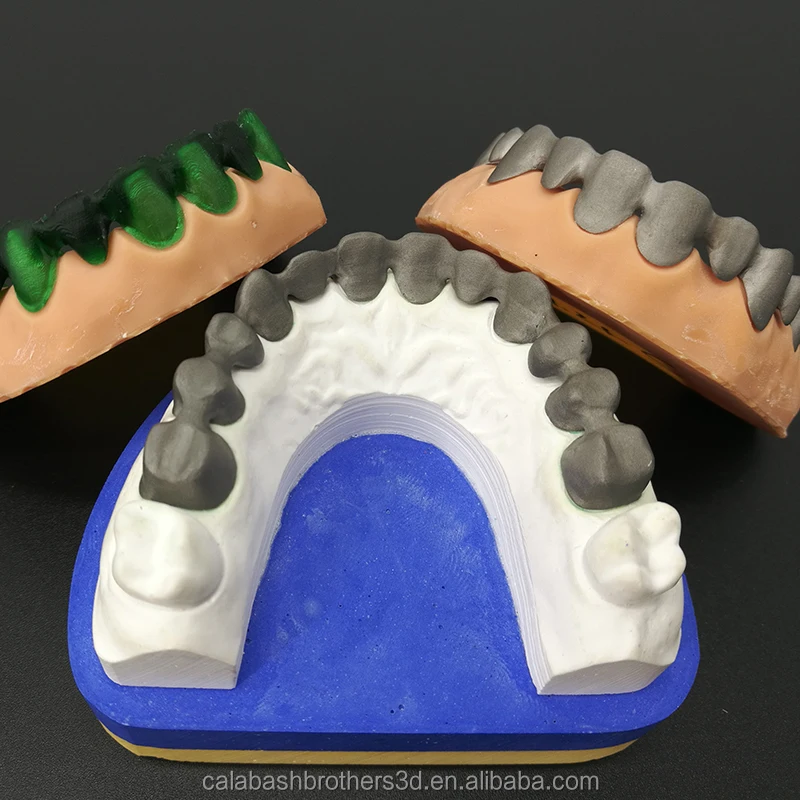

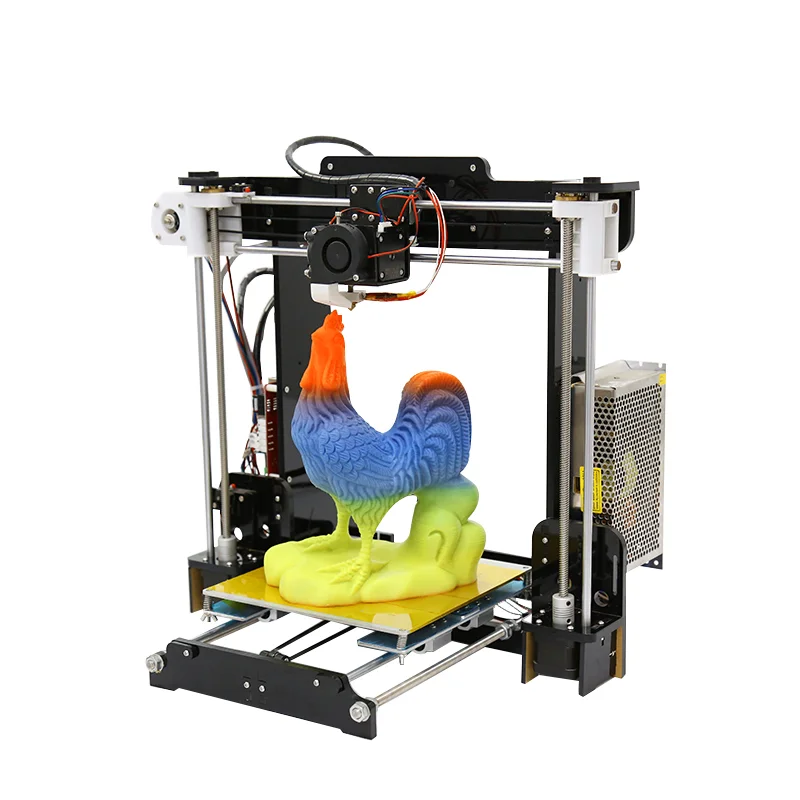

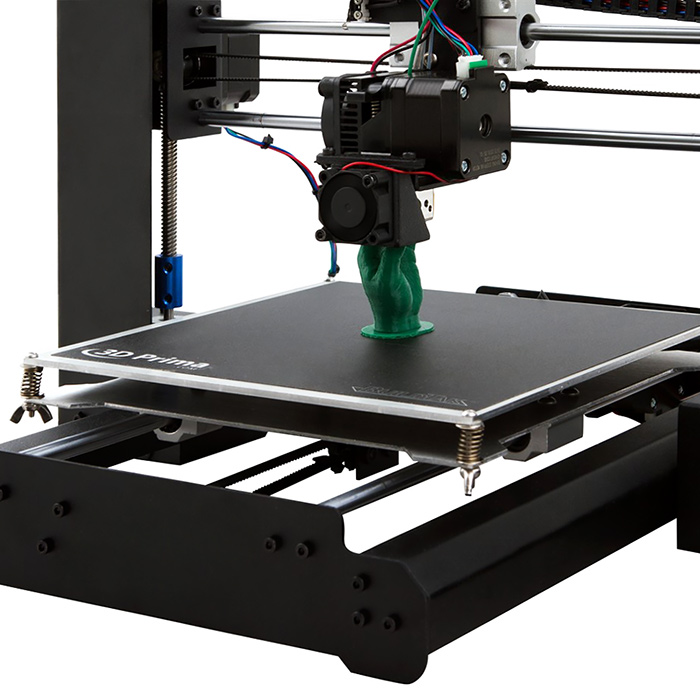

Resin 3D printers are able to offer a very high level of detail and smooth surfaces. They are most commonly seen in dental labs and clinics as well as in jewelry workshops but are also increasingly popular with hobbyists and makers.

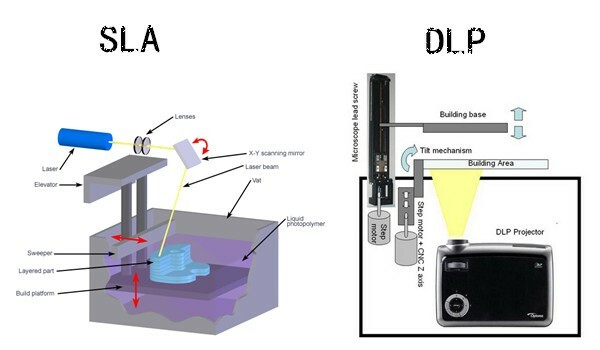

The way a resin 3D printer works depends on its technology: laser SLA (stereolithography), DLP (Digital Light Processing), or LCD-based (using an LCD screen to mask projected light).

All resin 3D printers involve the same workflows, however, requiring several post-processing steps such as resin removal and post-curing.

In this guide, we take a look at some of the best resin 3D printers available in each category (SLA, DLP, and LCD) and provide you with key concepts linked to resin 3D printing.

The best resin 3D printers (SLA/DLP/LCD)

| Brand | Product | Build size | Country | Price Approximate starting prices based on supplier-provided information and public data. | |

|---|---|---|---|---|---|

| Prusa Research | Original Prusa SL1 | 120 × 68 × 150 mm4.72 × 2.68 × 5.91 in | Czech Republic | $ 1,6991 727 €1,507 £253,246 ¥ | Buy |

| Peopoly | Phenom | 276 × 155 × 400 mm10.87 × 6.1 × 15.75 in | China | $ 1,9991 899 €1,773 £297,963 ¥ | Contact |

| Formlabs | Form 3 | 146 × 145 × 185 mm5.75 × 5.71 × 7.28 in | United States | $ 3,4993 557 €3,104 £521,547 ¥ | Quote |

| UNIZ | SLASH 2 | 190 × 120 × 200 mm7.48 × 4.72 × 7.87 in | – | $ 3,5003 558 €3,105 £521,696 ¥ | Quote |

| FlashForge | Hunter DLP | 120 × 67 × 150 mm4.72 × 2.64 × 5.91 in | China | $ 3,9994 065 €3,547 £596,075 ¥ | Quote |

| DWS | XFAB | 180 × 180 × 180 mm7. 09 × 7.09 × 7.09 in 09 × 7.09 × 7.09 in | – | $ 6,6006 000 €5,854 £983,770 ¥ | Quote |

| B9Creations | B9 Core 550 | 96 × 54 × 127 mm3.78 × 2.13 × 5 in | – | $ 9,95510 119 €8,830 £1,483,852 ¥ | Quote |

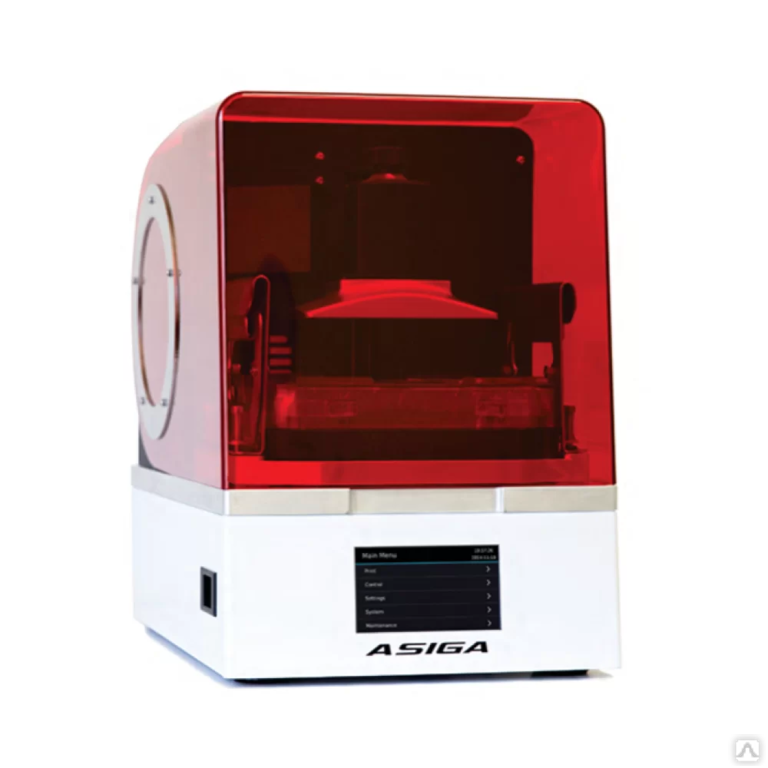

| Asiga | MAX | 119 × 67 × 75 mm4.69 × 2.64 × 2.95 in | – | $ 10,99011 171 €9,749 £1,638,125 ¥ | Quote |

| ETEC | Envision One | 180 × 101 × 175 mm7.09 × 3.98 × 6.89 in | Germany | upon request | Quote |

Expand to see more specs

The products in the table are ranked by price (low to high).

| Brand | Product | Technology | Build size | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|---|

| Prusa Research | Original Prusa SL1 | LCD | 120 × 68 × 150 mm4. 72 × 2.68 × 5.91 in 72 × 2.68 × 5.91 in | Czech Republic | $ 1,6991 727 €1,507 £253,246 ¥ | Buy on Prusa |

| Peopoly | Phenom | LCD | 276 × 155 × 400 mm10.87 × 6.1 × 15.75 in | China | $ 1,9991 899 €1,773 £297,963 ¥ | Contact manufacturer |

| Formlabs | Form 3 | SLA | 146 × 145 × 185 mm5.75 × 5.71 × 7.28 in | United States | $ 3,4993 557 €3,104 £521,547 ¥ | Get a quote |

| UNIZ | SLASH 2 | LCD | 190 × 120 × 200 mm7.48 × 4.72 × 7.87 in | – | $ 3,5003 558 €3,105 £521,696 ¥ | Get a quote |

| FlashForge | Hunter DLP | DLP | 120 × 67 × 150 mm4.72 × 2.64 × 5.91 in | China | $ 3,9994 065 €3,547 £596,075 ¥ | Get a quote |

| DWS | XFAB | SLA | 180 × 180 × 180 mm7.09 × 7.09 × 7.09 in | – | $ 6,6006 000 €5,854 £983,770 ¥ | Get a quote |

| B9Creations | B9 Core 550 | DLP | 96 × 54 × 127 mm3. 78 × 2.13 × 5 in 78 × 2.13 × 5 in | – | $ 9,95510 119 €8,830 £1,483,852 ¥ | Get a quote |

| Asiga | MAX | DLP | 119 × 67 × 75 mm4.69 × 2.64 × 2.95 in | – | $ 10,99011 171 €9,749 £1,638,125 ¥ | Get a quote |

| ETEC | Envision One | CDLP | 180 × 101 × 175 mm7.09 × 3.98 × 6.89 in | Germany | upon request | Get a quote |

Overview of the best resin 3D printers (SLA/DLP/LCD)

This overview is divided into three sections according to the resin 3D printers’ technology (SLA, DLP, or LCD).

The best SLA 3D printers (laser stereolithography)

Formlabs has been one of the main players on the professional resin 3D printer market for years. The Form 3, evolution of the award-winning Form 1 and Form 2, is their latest model, along with the Form 3L (large volume). This professional liquid resin printer boasts an array of practical features that make it a great choice for many businesses.

In the past, users have praised Formlabs’ hardware quality and precision, while criticizing the company’s decision to limit compatible materials to expensive Formlabs proprietary resins only. Today, the Form 3 features an “Open mode” that allows the use of generic materials.

Contact manufacturer Get a quote Add to comparison

The Phenom is an affordable and large-format LCD (MSLA) 3D printer that is suitable for hobbyists and professionals alike. An advantage of this resin 3D printer is large-format. The Peopoly Phenom 3D printer also exists in larger versions: Phenom L, Phenom Noir, Phenom XXL.

Contact manufacturer Get a quote Add to comparison

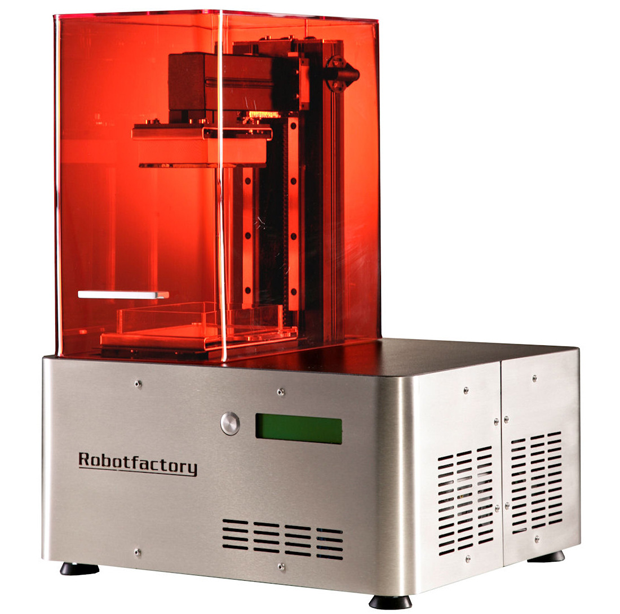

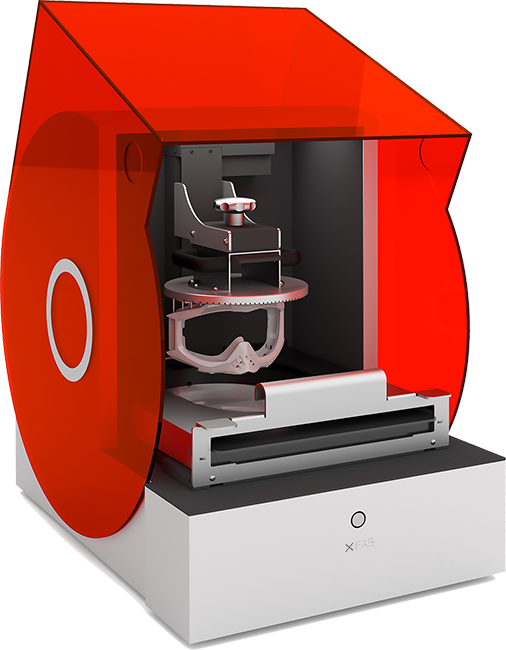

DWS Systems is specialized in manufacturing professional and industrial-grade resin 3D printers. The XFAB stereolithography 3D printer is their most affordable option, but is capable of delivering high-quality results. One of this SLA 3D printer’s most interesting characteristics is its cartridge resin system.

This makes material handling much easier and cleaner than with non-cartridge systems.

Contact manufacturer Get a quote Add to comparison

The best DLP 3D printers (Digital Light Processing)

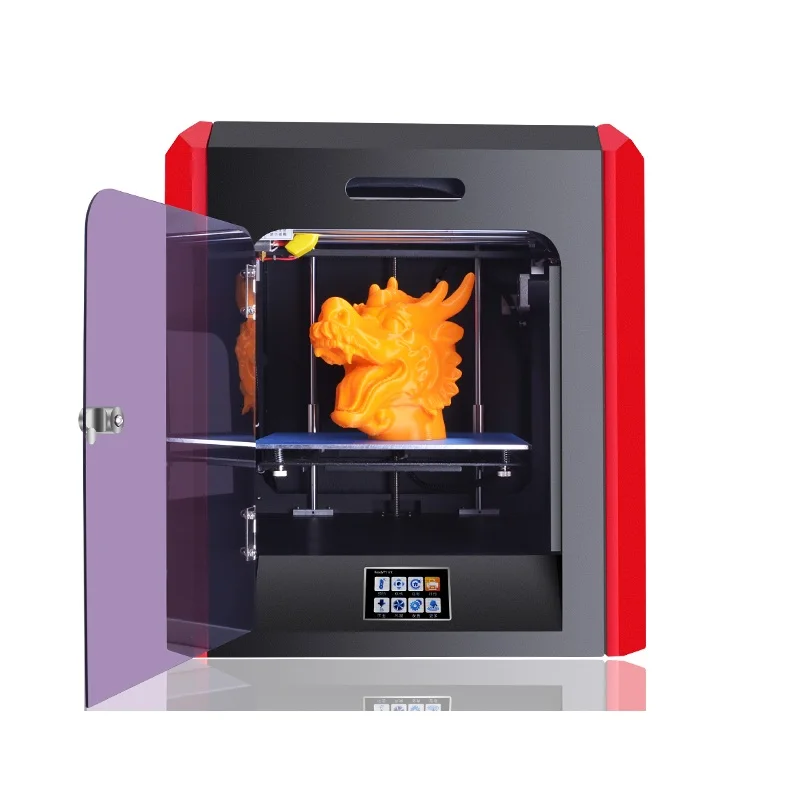

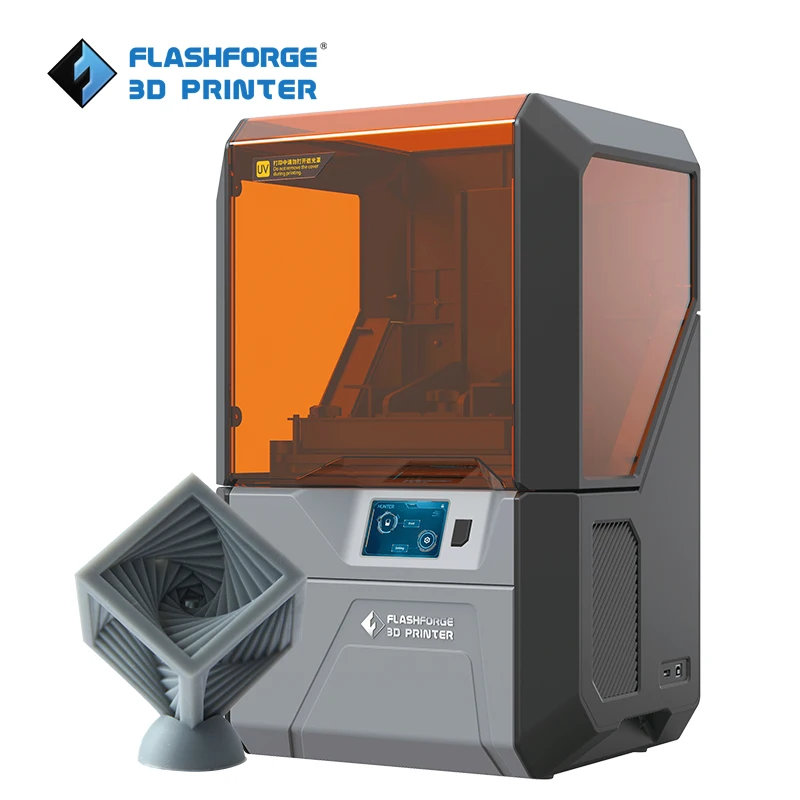

This professional resin 3D printer boasts a number of user-friendly features including a touchscreen, automatic calibration, and Wi-Fi connectivity. FlashForge develops its own resins, but users may also use third-party materials.

With its special jewelry support mode, the Hunter DLP mainly targets jewelers.

Contact manufacturer Get a quote Add to comparison

B9Creations’ Core series of 3D printers all provide fine levels of detail for professionals. According to the manufacturer, the B9 Core 550 resin 3D printer offers faster printing speeds (100+ mm/hour) than most DLP 3D printers in the same price range.

This digital light processing 3D printer is available with a smaller build volume (B9 Core 530).

Contact manufacturer Get a quote Add to comparison

The Envision One is a professional resin 3D printer produced by ETEC. ETEC, a German company known as EnvisionTEC before its acquisition by Desktop Metal in 2021, manufactures professional DLP 3D printers. The ETEC Envision One uses CDLP 3D printing technology. This 3D printer offers a build volume of 180 x 101 x 175 mm.

ETEC, a German company known as EnvisionTEC before its acquisition by Desktop Metal in 2021, manufactures professional DLP 3D printers. The ETEC Envision One uses CDLP 3D printing technology. This 3D printer offers a build volume of 180 x 101 x 175 mm.

Contact manufacturer Get a quote Add to comparison

The Asiga MAX is equipped with a resin level sensor, automatic calibration function and touch screen. Asiga also provides free lifetime technical support.

This 3D printer is particularly suitable for the medical and dental sectors, being compatible with silicone resins.

Contact manufacturer Get a quote Add to comparison

The best LCD 3D printers (liquid crystal display)

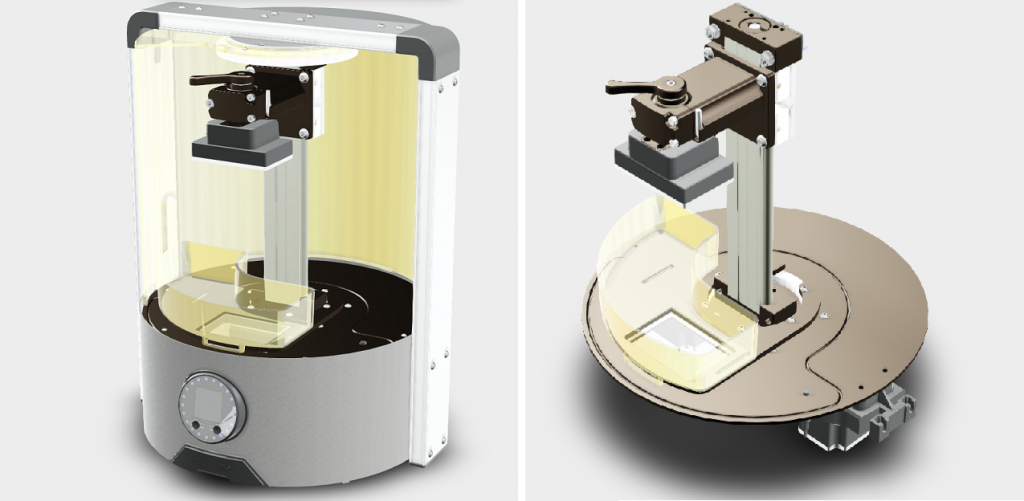

For many years, Prusa Research has been famous for manufacturing reliable 3D printers. The Original Prusa SL1 is Josef Prusa’s first resin 3D printer, but there is no doubt that it has been endowed with as much quality as the award-winning Prusa MK3 FDM 3D printers.

This LCD 3D printer– which is also available as a DIY kit– is packed with features such as a tilted print bed, auto calibration, vapor extraction, and more.

Buy on Prusa Get a quote Add to comparison

The SLASH 2 is a desktop resin 3D printer produced by UNIZ. UNIZ is a 3D printer manufacturer based in China. The UNIZ SLASH 2 uses resin 3D printing technology. This 3D printer offers a build volume of 190 x 120 x 200 mm.

Contact manufacturer Get a quote Add to comparison

Resin 3D printers under $1,000

As LCD screens are very affordable, they have been the key to bringing resin 3D printing to the masses. Indeed, more and more manufacturers are launching affordable desktop resin 3D printers with LCD 3D printing technology, and the price drop is radical.

These affordable resin 3D printers obviously can’t be expected to provide the same level of detail and accuracy as the professional 3D printers listed above. However, they are great as an introduction to resin 3D printing and they do produce good quality prints.

However, they are great as an introduction to resin 3D printing and they do produce good quality prints.

Read our full-length budget resin 3D printer article for a list of affordable machines (starting from $149).

Post-processing for resin 3D prints: necessary steps

Resin removal

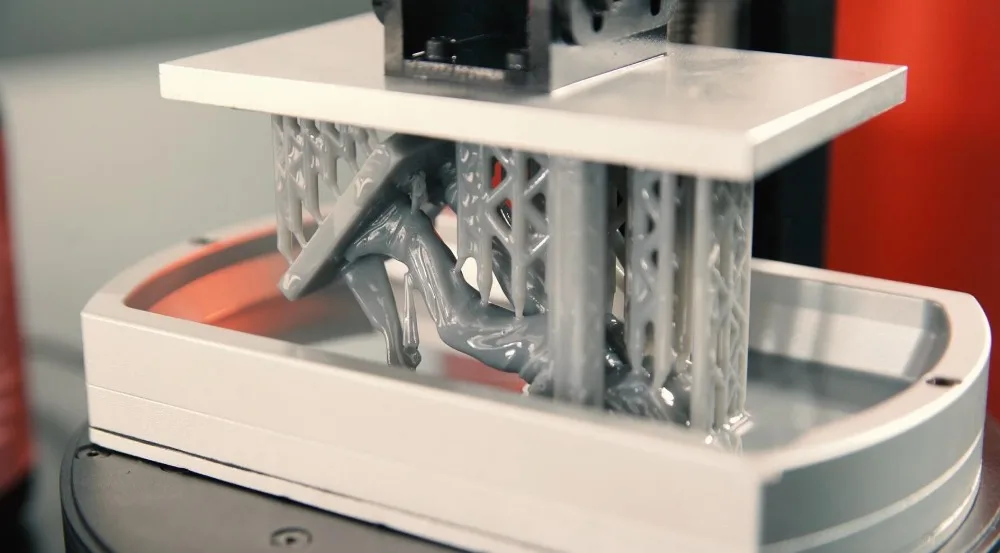

Since the objects are printed within a tank of resin, resin drips off of the objects as they are lifted up and out of the tank. There’s always a layer of uncured resin left on the object, and it must be removed with IPA (isopropyl alcohol).

This can be done manually by dipping the part in an IPA bath and gently scrubbing the part with a soft brush, but it is quite time-consuming.

For users that produce resin parts on a regular basis, there are machines called resin washers, or resin cleaners. Ackuretta, for example, markets Cleani, a dual-tank resin cleaner that can wash both the parts and the printer’s platform (yes, that needs to be washed, too. ).

).

Post-curing

When removing a resin 3D printed part from the build plate, it is still soft and slightly malleable. To reach its final physical state the part must go through a post-curing step. This means exposing the object to heat or light. Various SLA post-curing techniques exist:

UV curing chamber / UV cure box

Professional users will definitely want to use a dedicated UV curing chamber for their parts in order to get the most out of the material (strength, for example). Most resin 3D printer manufacturers have UV curing chambers available separately.

UV nail lamp

For small parts, nail UV lamps can do the trick. There are dozens of nail UV lamps available for less than $50.

DIY UV curing chamber

Crafty people also have the possibility to make their own UV curing station!

How do resin 3D printers work and what are the differences between LCD, DLP, and SLA 3D printing?

SLA 3D printers, LCD 3D printers, and DLP 3D printers all use liquid resin as a 3D printing material. The resin, a photopolymer, becomes solid when cured (activated) by a specific light source.

The resin, a photopolymer, becomes solid when cured (activated) by a specific light source.

That light source cures the liquid resin, which is stored in a tank or vat, to form the object layer after layer.

The resin solidification process (photopolymerization) is at the core of three main 3D printing technologies:

- Laser-based Stereolithography (SLA): a UV laser cures the resin in the tank to form the object point by point.

- Digital Light Processing (DLP): the resin is cured by a light projector one whole layer at a time. The light shines in a specific shape depending on the layer.

- Liquid Crystal Display (LCD) or Masked SLA (MSLA): An array of LED lights shine through an LCD screen. The LCD screen acts as a mask or stencil between the LED and the bottom of the resin tank, only letting light through in specific shapes.

All of these resin-based 3D printing technologies form part of the same family: stereolithography. That’s why some manufacturers include “SLA” in the name of their 3D printers, while they actually use DLP or LCD-based technology.

That’s why some manufacturers include “SLA” in the name of their 3D printers, while they actually use DLP or LCD-based technology.

Laser-based SLA 3D printing technology

An SLA 3D printer cures the liquid resin spot by spot with a laser, so it is potentially more precise than DLP 3D printing.

Contrary to DLP 3D printing, the build volume is completely independent of the resolution of the 3D print. A 3D print with a laser stereolithography 3D printer can be of any size and resolution.

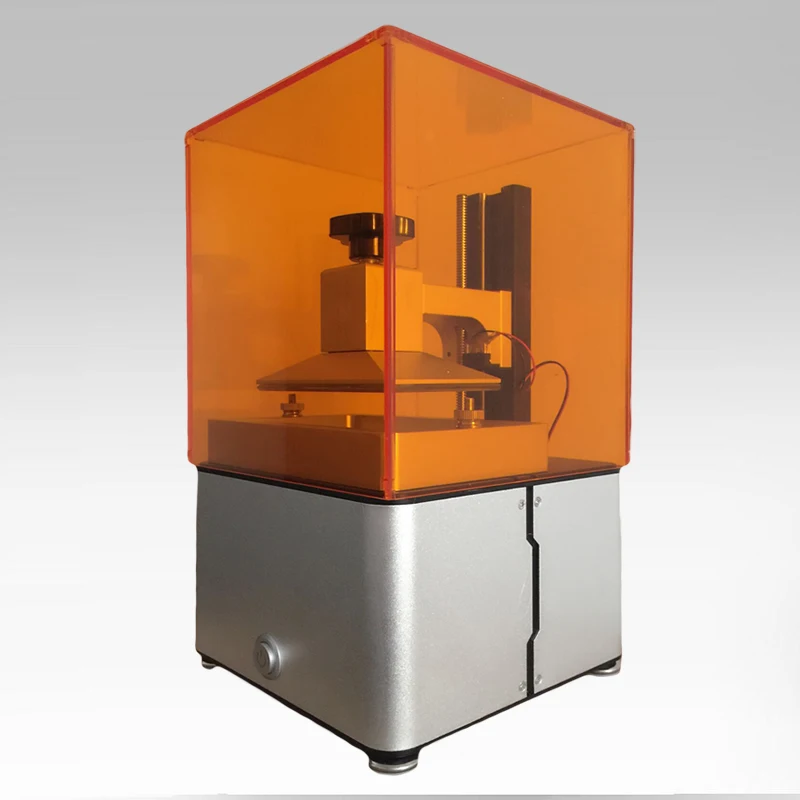

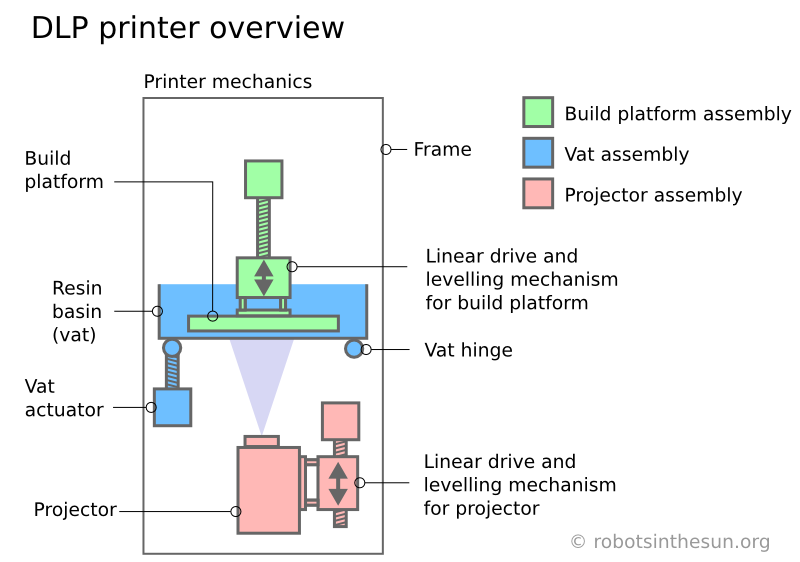

DLP 3D printing technology (digital light processing)

DLP 3D printers use a light projector. The layer’s shape is defined by reflecting or deflecting light with mirrors. With DLP, the 3D printer is able to cure a whole layer of resin at once. Therefore, a DLP 3D printer can potentially 3D print faster than an SLA 3D printer, as an entire layer is exposed all at once instead of one spot at a time with a laser.

However, a DLP 3D printer’s resolution depends on its projector and how many pixels/voxels are available (a full HD projector usually offers 1080p). A 3D printer with a large build volume has a fixed number of pixels, making it impossible to 3D print small details when building at full scale.

The projector used by the DLP 3D printer is less expensive and easier to change than the laser used by SLA 3D printers.

LCD-based resin 3D printing technology

Most LCD resin 3D printers use an LCD screen as a photomask– like a stencil– above another light source (LED, UV…). This is where LCD resin 3D printing is different than DLP 3D printing, which makes use of mirrors or other complex systems to direct the light into a certain shape. The technology is also called Masked Stereolithography (MSLA).

Since LCD screens are inexpensive, this technology has made resin 3D printing much more affordable than before and there are now dozens of low-cost, budget resin 3D printers available for a couple of hundred dollars.

In some cases, the light emitted by an LCD screen is used to directly cure the daylight-sensitive resin.

What is best between LCD, DLP, and SLA 3D printers?

The answer depends on the user’s needs in precision, speed, and budget. We can highlight that:

- Laser SLA 3D printers are best for 3D printing highly detailed and intricate 3D prints, big or small.

- LCD and DLP 3D printers are best for 3D printing batches of small parts, or quickly 3D printing large parts without too many details.

- LCD-based 3D printers are generally much more affordable than SLA and DLP 3D printers.

Main resin 3D printing applications

Samples by La Bête à Pois, SprintRay, and Photocentric (top to bottom). Source: AniwaaResin 3D printers mostly target professional users. Indeed, they are suited for specific applications requiring high levels of detail and top-quality finishes. These applications include:

These applications include:

Resin 3D printers for jewelry

Jewelers use high-precision 3D printers to create molds with the lost wax technique and create incredible jewels.

SLA, DLP, and LCD 3D printers in dentistry

Dentists and dental labs are starting to use resin 3D printing to build dental crowns, mouth guards, surgical guides, and much more.

Resin 3D printing in medical and healthcare fields

SLA and DLP 3D printing can be used to create medical appliances such as hearing aids.

Hobbies: resin 3D printer for miniatures

Some tinkerers, DIYers, and cosplayers love 3D printing miniatures and figurines.

Key benefits and limitations of resin 3D printing

Benefits of LCD, DLP, and SLA 3D printing technologies

These are some of the advantages of 3D printing with resin:

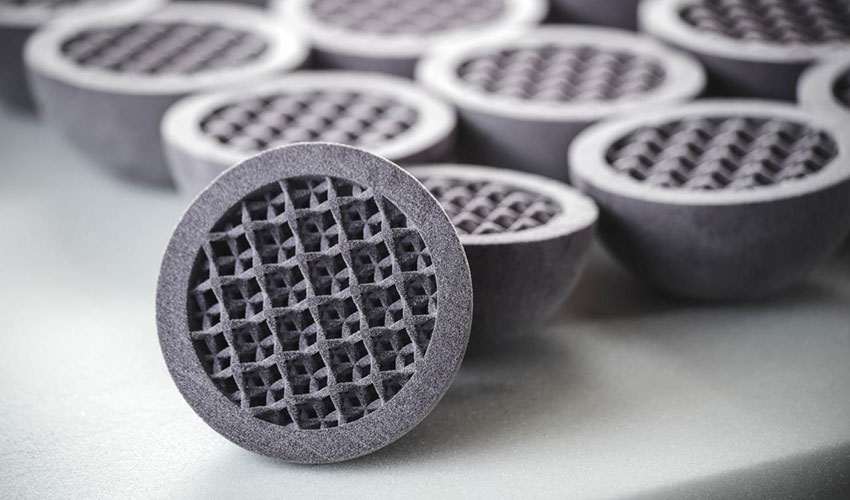

- Ability to build small and very detailed parts or objects with fine, complex geometries

- Diversity of 3D printable resin materials (ceramic, metal, biocompatible, flexible, rigid, etc.

)

) - Smooth finish of the parts produced (no easily visible layers like with FFF 3D printers)

Limits of resin 3D printing

As with any technology, resin 3D printing has its limits:

- Post-processing is mandatory (removing delicate support structures, post-curing, resin removal, etc.) and requires a UV curing chamber for good results

- Requires time-consuming cleaning time (for the vat and for the 3D printed part)

- Very smelly and toxic fumes

- Safety precautions required when handling the material

Resin 3D printer price

Laser SLA resin 3D printer price

SLA 3D printer prices depend on many factors. The price for a basic SLA 3D printer kit like the Peopoly Moai usually starts at about $1,200. Industrial resin 3D printers, on the other hand, can reach several hundred thousand dollars.

DLP resin 3D printer price

The price of a DLP 3D printer generally starts around $2,000 or $3,000. DLP 3D printers with higher precision and more features cost around $10K to $20K. More expensive digital light processing 3D printers also exist.

DLP 3D printers with higher precision and more features cost around $10K to $20K. More expensive digital light processing 3D printers also exist.

LCD resin 3D printer price

LCD-based resin 3D printers are the most affordable resin 3D printer type. There are many LCD resin 3D printers available for under $1,000, and even under $300. Higher-quality LCD 3D printers may cost a few thousand dollars.

UV curing chamber price

Most resin 3D printer brands sell UV curing chambers separately, with prices starting around $300 to $500.

FAQ

What does SLA stand for in 3D printing?

In 3D printing, SLA stands for stereolithography.

What does DLP stand for in 3D printing?

In 3D printing, DLP stands for Digital Light Processing.

What does LCD stand for in 3D printing?

LCD stands for Liquid Crystal Display, which is a type of screen used in electronic devices (smartphone, TV, etc. ). A growing number of resin 3D printers use an LCD screen’s light to cure light-sensitive resin and form objects in 3D.

). A growing number of resin 3D printers use an LCD screen’s light to cure light-sensitive resin and form objects in 3D.

What is SLA resin made of?

SLA resin is a photopolymer material, which is mainly composed of monomers, oligomers, and photoinitiators. Depending on the “recipe”, the stereolithography resin can be plastic, ceramic, or even metal-based.

How much does a resin 3D printer cost?

A resin 3D printer can cost anywhere from $500 to over $250,000. However, there are many resin 3D printers available for under $10,000.

What is a resin 3D printer?

A resin 3D printer (stereolithography) is a machine that solidifies liquid resin layer by layer to form an object in 3D.

Where are resin 3D printers for sale?

There are resin 3D printers for sale on major e-commerce sites like Amazon, AliExpress, GearBest, and Banggood. Online retailers specialized in 3D printing also exist, such as MatterHackers.

Online retailers specialized in 3D printing also exist, such as MatterHackers.

Best Resin 3D Printers in December 2022 (Every Price Range)

Resin 3D printers are more affordable than ever – you can now pick up a great quality resin printer with a 4K LCD screen for just a few hundred dollars. So if you’re a home maker who wants to make detailed miniatures for your next game, or have more professional ambitions, it’s never been easier.

MSLA (masked stereolithography) 3D printers have taken over the low-cost space, using LCD screens to cure resin models based on your sliced STL file.

With 2K, 4K, and even up to 8K LCD screen quality available under $1,000, and sub-35-micron resolution becoming increasingly common, with the right settings you can create incredible-looking miniature models, as well as key uses in jewelry molds and in the dental industry.

Here are our top picks for 4K, 6K, and 8K screens:

Budget Pick

Anycubic Photon M3High quality 4K resolution for low price

Larger build volume than Photon Mono 4K and Elegoo Mars 3

Available at Anycubic here at Amazon Here

mid-range Pick

Anycubic Mono X 6KHigher-quality 6K LCD screen

Much larger print area for printing many minis in one job

Available At Anycubic here at Amazon here

Premium Pick

Phrozen Sonic Mini 8KExtremely high-res 8K LCD screen with 22-micron accuracy

Reasonable price for the quality

Available At phrozen here at amazon here

We’ve split our recommendations into the best cheap resin 3D printers with recommendations for $200, $300, $500, and $700, as well as recommending a couple of clear winners for professional resin 3D printers if you’re looking to start a business or scale things up.

The Best Resin 3D Printers 2022 – Reviews

| Resin printer | Price | Best price at | Alternative |

|---|---|---|---|

| Elegoo Mars 2 Pro / 3 | $200-349 | Elegoo here | Amazon here |

| Anycubic Photon M3 | $300 | Anycubic here | |

| Anycubic Mono X 6K | $639 | Anycubic here | |

| Elegoo Saturn | $499 | Elegoo here | Amazon here |

| Phrozen Sonic Mini 8K | $799 | Phrozen Store here | |

| Prusa SL1S Speed | $1,999 | Prusa Store here | |

| Formlabs Form 3 | $3,499 | Dynamism store here |

Best Cheap Resin 3D Printers (Under $1,000)

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

Elegoo Mars 2 Pro / Mars 3

BUDGET PICK

Elegoo Mars 2 Pro

Print Volume: 129 x 80 x 160 mm

Screen size: 6. 08″ 2K Monochrome LCD

08″ 2K Monochrome LCD

XY Resolution: 50 microns

Speed: 30-50 mm/h

Cleaning/Curing: Elegoo Mercury Plus/X

Available at:

PREMIUM PICK

Elegoo Mars 3

Print Volume: 143 x 90 x 175 mm

Screen resolution: 6.6″ 4K LCD

XY Resolution: 35 microns

Speed: 1.5-3 seconds per layer

Cleaning/Curing: Elegoo Mercury Plus/X

Available at:

While there are newer Mars printers like the Mars 3 and brand-new Elegoo Mars 3 Pro, the Mars 2 Pro still offers great quality if you’re on a budget. It features the revamped z-axis linear guide system for smoother layers and better surface areas.An accurate dinosaur head we 3D printed on the Elegoo Mars 2 Pro.Clank video game 3D print on the Elegoo Mars 2 Pro.

It features the revamped z-axis linear guide system for smoother layers and better surface areas.An accurate dinosaur head we 3D printed on the Elegoo Mars 2 Pro.Clank video game 3D print on the Elegoo Mars 2 Pro.

But for those looking for more precise detailing on their miniatures or other prints, consider upgrading to the Mars 3 range.

Whereas the Mars 2 Pro has a 6.08-inch 2K LCD, the Mars 3 and Mars 3 Pro both have 6.6-inch 4K screens, improving XY resolution from 50 microns to 35 microns – a 30% accuracy improvement.

You also get a 37% larger build volume: 143 x 90 x 175mm on the Mars 3, vs the 129 x 80 x 160 mm. This is ideal for printing a number of models at once to save time, and for printing larger models that might not quite have fit into the Mars 2 Pro’s build area.

So if you’re on a tight budget, the Mars 2 Pro is still a fine choice – we’ve printed some great detailing in our dinosaur head’s teeth, and in video game miniatures. But, for sharper accuracy and larger build areas, upgrade to the Mars 3, or Mars 3 Pro.

Read our full review: we tested the Elegoo Mars 2 Pro

Compared: Elegoo Mars 2 Pro and 3 vs Elegoo Saturn

Anycubic Photon M3

- Price: Check latest price at Anycubic here

- Build Volume: 180 x 163 x 102 mm

- XY Resolution: 40 microns

- Minimum Layer Height: 10 microns

- Speed: 50mm/h

Pros

Larger build volume and 4K LCD screen than the Photon Mono 4K.

Low cost, high quality

Perfect if you’re looking to print larger minis faster, and several at once.

Cons

40-micron resolution vs 35 microns on the Mono 4K – though you’ll probably not notice the difference.

The latest entry-level Photon 3D printer, the Anycubic Photon M3 takes everything we loved about the series – fast print times, excellent resolution, and a user-friendly printing experience – and levels it up with a few choice enhancements.

Among the improvements, Anycubic has upgraded to a 180 x 163 x 102 mm build volume, which lends itself to larger prints along with the superb high detail models and miniatures the Mono 4K is known for, even intricate articulated figurines.

Another benefit of the build volume is the possibility of producing bigger batches of the same Warhammer or D&D mini-figures, ideal if you’re hoping to use your M3 to fuel a small business.

Though the Anycubic Photon M3 includes an excellent 7.6″ 4K monochrome screen, the resolution drops slightly to 40 microns – 5 microns higher than the Mono 4K. For us, this is a reasonable compromise for the extra printing space.

At this level of detail, you’d be hard-pressed to notice any tangible difference between the two resolutions, so the larger screen and print area is worth the drop to us – though you can opt for the Anycubic Photon Mono 4K if you prefer 35 micron resolution and a smaller build volume.

It’s cheap, user-friendly, and creates feature-rich, detailed 4K parts, models, figurines, and minis.

Anycubic Mono X 6K

- Price: Check latest price at Anycubic here

- Build Volume: 197 x 122 x 245 mm

- XY Resolution: 34 microns

- Minimum Layer Height: 10 microns

- Speed: 80 mm/h

Pros

Market leading print quality.

Reasonably priced for the specs it offers.

Cons

Average build volume.

The Anycubic Mono X 6K allows makers to craft exceptionally detailed 6K prints at 34 microns XY resolution without sacrificing build volume (or vice versa), which inches close to standard FDM printer sizes at 197 x 122 x 245mm. A max print speed of 80 mm/h also prints the most complex minis and models at a blistering pace.

If you’re not constrained by a tight budget and want some of the best quality offered by any consumer-grade printer, there’s no question the Anycubic Mono X 6K is a sensible buy. The same goes for those piecing together the kit needed to take a budding minis business to the next level.

But, for those restricted to a smaller budget, the original Mono X and the even lower-cost M3 are perfect for those that want to print high-quality minis without breaking the bank. The trade-offs are smaller build volume, slightly lower resolutions, and longer print times – nothing that should hamper the majority of hobbyist resin projects.

Elegoo Saturn

- Price: Check latest price at Elegoo here / Available on Amazon here

- Print Volume: 192 x 120 x 200 mm

- Screen resolution: 3840 x 2400 pixels

- Screen size: 8.9″ 4K Monochrome LCD

- XY Resolution: 50 microns

- Speed: 30-40mm/h

- Cleaning/Curing: Elegoo Mercury Plus/X Washing and Curing Station

Featuring an 8.9-inch 4K monochrome LCD screen for fast layer curing, the Elegoo Saturn comes much upgraded on standard models, printing 60% faster than the Elegoo Mars Pro, printing a layer every 2-3 seconds.

For your money, you get a number of other key upgrades, most notably the larger build area, turning the Elegoo Saturn into a solid resin 3D printer for larger resin models or terrain for miniatures, as well as for printing more minis in one batch and taking advantage of resin printers’ abilities to print entire layers at once.

The improved precision, owing to the Saturn’s double linear guideway Z-axis structure makes it steadier than ever, ensuring accuracy and uniformity across the print.

If this isn’t enough, you have two upgrade options:

- Elegoo Saturn S: a slight improvement across the board, with an 9.1” 4K LCD, and a slight build volume increase to 196 x 122 x 210 mm

- Elegoo Saturn 2: upgrades to a 10” 8K LCD, 28.5nm XY resolution, and a larger 219 x 123 x 250 mm build area.

| Elegoo Saturn | Elegoo Saturn S | Elegoo Saturn 2 | |

|---|---|---|---|

| LCD Quality | 8. 9″ 4K LCD 9″ 4K LCD | 9.1″ 4K LCD | 10″ 8K LCD |

| Build Volume | 192 x 120 x 200 mm | 196 x 122 x 210 mm | 219 x 123 x 250 mm |

| XY Resolution | 50 microns | 48 microns | 28.5 microns |

| Buy here | Buy here | Preorder here |

Read more: Elegoo Saturn vs Anycubic Mono X – compared

Phrozen Sonic Mini 8K

- Price: Check latest price at Phrozen here

- Build Volume: 165 x 72 x 180 mm

- XY Resolution: 22 microns

- Minimum Layer Height: 10 microns

- Speed: 80 mm/h

Phrozen’s flagship resin printer capitalizes on a sleek 7.1″ LCD screen and 22-micron resolution to deliver frankly outstanding print detail and surface quality that more budget-priced printers simply can’t provide.

As consumer printers go, the Phrozen Sonic Mini 8K has the potential to produce the most intricate, detail-rich models of any printers currently on the market.

The jump from a 2K, and even a 4K/6K, to an 8K screen is apparent when scrutinizing a print fresh off the Mini 8K bed. This is the main reason it out-classes Phrozen’s excellent budget Sonic Mini 4K, albeit with a hefty but warranted price increase.

For lots of makers, the jump in quality won’t be enough to justify spending more than double the price of a Photon or Mars, but the Phrozen Sonic Mini 8K fleshes out the proposition with superb all-around usability and a decent 165 x 72 x 180 mm build volume.

If that’s not quite enough for your larger print projects or you’re looking to batch print to stock an online mini store, there’s always the Phrozen Sonic Mighty 8K, and its 123 x 218 x 235 mm printable area.

Best Desktop Resin 3D Printers (Between $1,000 and $3,000)

Prusa SL1S Speed

- Price: $1,999 — Available at Prusa Store here

- Print Volume: 120 x 68 x 150 mm

- Screen resolution: 2560 x 1620 pixels

- Screen size: 5.

96” 2K Monochrome LCD

96” 2K Monochrome LCD - XY Resolution: 47 microns

- Print Speed: 50mm/h

- Cleaning/Curing: Original Prusa CW1S

Prusa printers are known for being the best open-source FDM kits around, but have since ventured into resin printing.

One thing we really want to drive home is how important it is not to get tunnel vision when looking at the specs of printers when choosing which to buy. As we explain in the buyer’s guide portion below, a well-made printer made from high-quality parts that can handle precise movements and stability will outperform a printer with a higher-spec LCD screen but worse build quality.

The 5.96” monochrome LCD is smaller than some lower-priced printers like the Elegoo Saturn 2, but it is capable of fantastic accuracy, even for tiny miniature models smaller than a penny. It’s made from high-quality parts to minimize vibrations, with a rigid aluminum body, and features a quick release mechanism to maintain z-axis calibration.

It’s also super fast, with 1.4-second layer exposures even on standard 405nm resins. If you’re a small business owner looking to produce minis at scale, or just want to print lots of models for yourself, the SL1S Speed suits you well.

You can buy the printer on its own, or as a bundle with the CW1S 4-in-1 wash and cure machine. It pre-heats your resin before use, washes resin prints, dries them off, and cures them, all in one add-on. The bundle is available here.

Professional Resin 3D Printers ($3,000+)

Formlabs Form 3 — best professional resin 3D printer

- Price: $3,499 — Available on Dynamism Store here

- Build Volume: 145 x 145 x 185 mm

- XY Resolution: 25 microns

- Print speed: 70mm/h

- Cleaning/Curing: Formlabs Form Wash & Cure

Formlabs make professional resin 3D printers, but at desktop resin printer prices. The US manufacturer sells the Form 3 SLA 3D printer for $3,499, with its quality making it key for super accurate prototypes, as well as being adopted in the dental and jewelry industries.

The Form 3 comes with a huge variety of new features as compared with the previous Form 2. It comes with new LFS technology advantages as well as a new Light Processing Unit (LPU) to improve resin part surface finishes, as well as better layer registrations. The Form 2 was already fantastic, and these added features elevate the Form 3 to a whole new dimension within desktop SLA printers.

Additionally, the Formlabs Form 3 has an automated resin system and uses smart cartridges that automatically fill the resin tank – key for business owners looking to maximize efficiency and revenue per hour.

In addition, it has a scanning system for the resin tray after each layer, and automatically adjusts based on the type of resin used. Furthermore, its got a fantastic touch screen and can be operated remotely via a WiFi connection, as well as operable as part of a factory with Formlabs’ industrial multi-printer ‘Form Cell’ solutions.

This UV 3D resin 3D printer has a print volume of 145 x 145 x 185 mm, and is extremely precise with 25-micron XY resolution. The Formlabs Form 3 is compatible with a large number of resins, from ceramic, to flexible resins, to castable resins, though Formlabs also sell their own high-quality resin materials.Formlabs resins are available here.

The Formlabs Form 3 is compatible with a large number of resins, from ceramic, to flexible resins, to castable resins, though Formlabs also sell their own high-quality resin materials.Formlabs resins are available here.

Curing and Cleaning Stations

With washing and curing an unavoidable part of resin 3D printing, we’ve rounded up a few choice washing and curing stations well worth weaving into your printing setup to take some of the sting and mess out of post-processing.

Anycubic Wash & Cure

- Available at Anycubic Store here / Amazon here

The Anycubic Wash & Cure is an all-in-one station compatible with the overwhelming majority of resin printers. Thanks to a nifty recent price cut from Anycubic, the Wash & Cure sets you back under $100.

The wash mode has adjustable wash cycles, including 2, 4, and 6 minutes. Cure mode employs a wide range 356 nm and 405 nm UV light set mounted on a 360° rotating platform to ensure a uniform cure of all and any print sized at 115 x 65 x 165 mm and under.

Anycubic has simplified the whole wash and cure process thanks to a set-and-forget design – choose either wash or cure on the touch button interface, and off it goes. The station blocks 99.95% of UV light and comes with an auto-pause function if the cover inadvertently comes off. The station has an adjustable bracket that can latch onto an Anycubic build platform if you’re working with a Photon Mono series printer.

Elegoo Mercury Plus

- Available at Amazon here

Another all-in-one station, but this time from Elegeoo, the Elegoo Mercury Plus is an easy-to-use option for hands-free post-processing.

The accepted max print size is 125 x 85 x 160 mm for washing and 140 x 165 mm for curing. You can either use the provided cleaning basket or mount an Elegoo build plate with models still attached, making it compatible with most if not all resin 3D printers, not just with Elegoo machines.

A 385 nm and 405 nm UV light set and 360-degree rotating curing turntable do all the curing work with the option to key in and monitor curing time up to 30 minutes on the TFT touchscreen. Safety’s covered with an anti-UV lid that blocks 99.95% of UV rays and a suspend operation function should the cover come off during curing.

Safety’s covered with an anti-UV lid that blocks 99.95% of UV rays and a suspend operation function should the cover come off during curing.

Expect to pay more than the Anycubic station, but at roughly $120, you’ll deck out your resin 3D printing setup with a quality mess-free station.

Buyer’s Guide – What to Consider When Buying a 3D Resin Printer

RGB vs Mono LCD Screens – Pick a Mono Resin 3D Printer

Most modern resin printers now ship with monochrome LCD screens instead of the RGB variants found in earlier models.

The shift is all to the benefit of makers as monochrome screens have many advantages over RGB:

- They print faster, often up to 3x quicker

- They are more durable, lasting up to 4-5x longer before replacing

LCD Screen Resolution: 2K, 4K, 6K, 8K – What Quality Do You Need?

Raw specs do translate to better quality overall. You will notice the difference in sharpness on corners, and on precise features of models such as facial features and hair on an 8K screen versus a 4K or 2K print. 4K vs 8K resin printed miniature. Source: Geek Gaming Scenics

4K vs 8K resin printed miniature. Source: Geek Gaming Scenics

However, while a higher resolution makes a clear difference to print results, even the highest resolution 3D printer will not perform as well as a lower-res 2K screen if it is built from low-quality parts.

Therefore, buy from a reputable brand known for making high-quality parts, such as well-built screws and z-axis parts for the build plate, and resin vat screws, to deliver top quality.

We recommend resin printers from Anycubic, Elegoo, and Phrozen for hobbyist printing, and Prusa and Formlabs for professional resin printing.

Build Volume

As a general rule, resin printers feature smaller build volumes than more common FDM machines, hence why makers and professionals use them to create small intricate parts with high precision.

If you do need extra printing space for duplicate part printing or larger figurines and models, consider larger format resin printers such as the Peopoly Phenom and Phrozen Sonic Mighty 4K.

Post-Processing Equipment

Resin 3D printing is a messy business, and post-processing is a core part of the printing process. Post-processing breaks down into two parts, washing and curing.

Washing involves removing any residual uncured resin from the print using isopropanol.

Curing uses further UV light source slexposure to complete the curing polymerization process to improve the part’s finish and overall rigidity.

Self-guided, hands-on post-processing is one way to go, but manufacturers now propose all-in-one washing and curing stations to take much of the messy hassle out of the process.

How Does a Resin 3D Printer Work?

Resin is sticky, liquid, and moves around in any container (or resin vat) that you pour it into. However, take that container outside, and the sun’s UV rays will almost immediately cure and solidify the resin.

Your resin printer’s LCD screen uses the same UV light as the sun but in a more stable indoor environment, flashing light at certain parts of the resin to selectively cure parts, based on your model’s features.

The LCD screen blocks off the LEDs from certain parts so that the resin isn’t cured in some places – only where your model file is sliced to be.

The screen sits under the resin vat, and projects light upwards into the build platform. An FEP screen (fluorinated ethylene propylene) protects the screen from damage – though these FEP films themselves need to be replaced more often than any other parts of the printer.

As each layer is cured, the resin printer’s z-axis platform, lifts up one layer, for the next resin layer to be cured. The cured model sticks to the build platform as it moves up out of the resin (if it sticks to the resin, the print fails), with the layer on the edge cured and moved up each time.

Resin 3D Printing Tips for Beginners:

Check the MSDS (material safety data sheet) for the resin you’re using – all reputable resin manufacturers will have these sheets. They outline any potential hazards, and how you can keep safe and prevent these issues.

Print in a relatively warm environment – room temperature is fine, but if resin gets too cold it become more viscous and difficult to print.

Wear gloves when handling resin – nitrile rubber disposable gloves work well.

Pick the best slicer for you – if you use a certain brand such as Prusa, you’ll likely use Prusa Slicer. For simple everyday use, CHITUBOX is fine, but other options for great resin results include Lychee Slicer. We have a full run-down of resin slicers here.

Take care over supports – within your slicer, take care over how you position your model, and the supports you use. Flat printed models don’t work as well as they do in FDM, as you can damage the resin print scraping it off – though there are workarounds with sacrificial rafts. Generally, lift the model off the bed and have supports between the bottom raft and the FEP sheet. If you’re technical, there is a very powerful tool called UVTools which automatically detects likely errors, resin traps and islands, and with one click fixes them all. It is available at Github here. It acts as a kind of previewer, showing you where potentials for print failure are, so you can avoid the costly failed prints, and optimize them automatically.

It is available at Github here. It acts as a kind of previewer, showing you where potentials for print failure are, so you can avoid the costly failed prints, and optimize them automatically.

How Much is a Resin 3D Printer?

Good cheap resin 3D printers start at around $200, with either a 2K or 4K screen that can still print precise features on miniature models. 6K and 8K screen resin printers cost from $600 to $1000+, and professional resin 3D printers from companies like Formlabs cost $3500 and up.

Uses of resin 3D printers

Budget resin 3D printers are typically used by hobbyists to make accurate figures and miniatures at details FDM printers just cannot reach. They’re commonly used for 28mm miniatures, D&D figures, and other similar projects for tabletop models.

See also: our buyer’s guide for the best 3D printers for miniatures.

However, these low cost options can sometimes be used for creating wax molds for jewelry casting. For better quality casting with precious metals however it is recommended to use a more professional resin 3D printer capable of better resolutions and precision.

For better quality casting with precious metals however it is recommended to use a more professional resin 3D printer capable of better resolutions and precision.

See also: our guide to the best jewelry 3D printers.

Resin printers are commonly used in the dental, audiology, jewelry, and medical industries. For example, within dentistry resin 3D printers can print orthodontic models and implants, and within audiology, almost 100% of custom hearing aids are now 3D printed.

See also: 3D printing in the dental industry.

See also: how 3D printed hearing aids took over the world.

Is Resin Printing Messy?

Though the resin printing process isn’t messy per se, the post-processing of a finished resin print invariably descends into a frustrating, sloppy, not to say potentially harmful mess of dripping resin and pungent isopropanol. It isn’t for the faint of heart or those wary of getting stuck in.

Fortunately, curing and cleaning stations help contain resin processing’s messiness, so you’re not caking your hands in muck by juddering your prints around in a vat of isopropanol.

FAQs

What are the best resin 3D printer brands?

For the home resin 3D printing $200-600 range, the best resin 3D printer brands are Anycubic, Elegoo and Phrozen, who make high-quality printers capable of accurate details. In the professional resin printer range, Prusa, Formlabs and Peopoly are well-reputed, as well as industrial brands like 3D Systems, Carbon 3D and EnvisionTEC.

Is it worth getting a resin 3D printer?

Resin 3D printers can print incredible-looking details for miniatures that FDM simply can’t compete with, so for anything precise and detailed, resin printers can’t be beaten. However, if you want a simpler printing experience without washing or curing prints, or want to print large-scale models, go for an FDM 3D printer instead.

Do You Need To Wash and Cure Resin Prints?

Yes. The resin printing process leaves uncured residual resin on the finished part. Rinsing off the excess resin ensures all the detail and finish of the print remain accurate once you move to the curing process. There’s also a safety concern; washing resin prints removes potentially toxic uncured liquid resin, so you can handle the part safely.

There’s also a safety concern; washing resin prints removes potentially toxic uncured liquid resin, so you can handle the part safely.

Curing is an equally important part of the process. When a printer completes a part, the resin is in a transitory state: hard enough to retain the desired shape and detail but lacking overall rigidity, making it prone to scratches, scarring, and blemishes. By curing the print with UV, or even sunlight if you’ve got time on your side, the resin reaches its optimal, finished state.

If you liked this ranking, you may also like:

- Top 10 SLS 3D printers

- The best metal 3D printers

- Best Dual Extruder 3D Printers

- 3DSourced’s Overall Top 20 Best 3D Printers

- Our guide to the 10 types of 3D printers

- Best large resin 3D printers

- Best resin curing stations

DLP 3D printing | Description and features of the technique

What is DLP 3D printing?

DLP 3D printing is an additive manufacturing technique that uses liquid photopolymer resins to build objects that are cured by light waves. “Yes, this is an SLA print!” - exclaim those who are already familiar with the methods of additive manufacturing. Indeed, the principle of operation of these two technologies is almost identical. However, the curing of the object in DLP printing occurs under the influence of a different light source.

“Yes, this is an SLA print!” - exclaim those who are already familiar with the methods of additive manufacturing. Indeed, the principle of operation of these two technologies is almost identical. However, the curing of the object in DLP printing occurs under the influence of a different light source.

In general, DLP 3D printing can be described as a direct analogue of SLA 3D printing, even surpassing it in some aspects. For example, the print speed in DLP 3D printers is an order of magnitude higher than in SLA devices. And the difference in fidelity varies depending on the specific equipment and consumable, and is generally small. Now let's move on to the technical aspects and talk about the principle of operation of DLP technology.

Technology Description

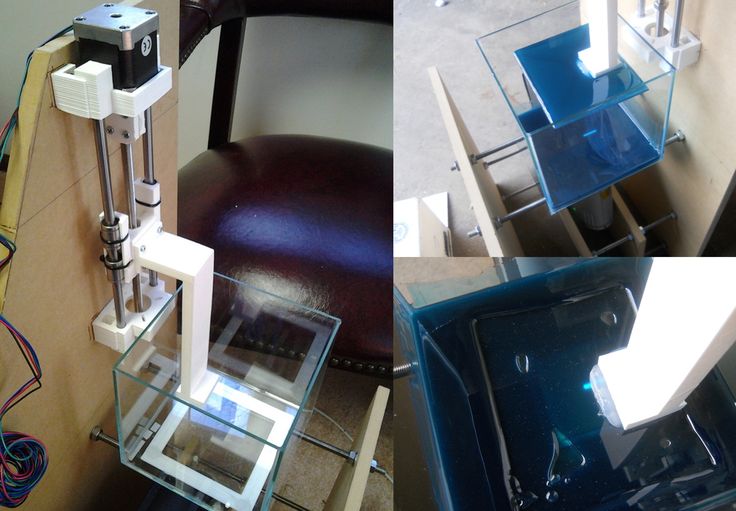

As with all 3D printing technologies, the first step in manufacturing a physical object is to create a 3D digital model of it. We will not delve into the details of this stage, you can read more about 3D modeling for 3D printing here. The finished 3D model is loaded into a slicer program designed to set print settings and “cut” the model into layers. This step also generates supporting structures under the overhanging elements of the object. The received settings are saved, the model is converted into a control code for a 3D printer. Now you can start printing.

The finished 3D model is loaded into a slicer program designed to set print settings and “cut” the model into layers. This step also generates supporting structures under the overhanging elements of the object. The received settings are saved, the model is converted into a control code for a 3D printer. Now you can start printing.

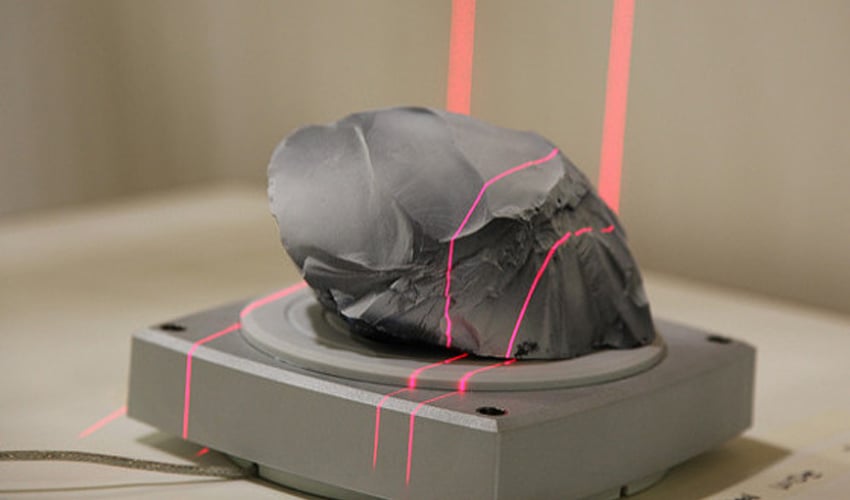

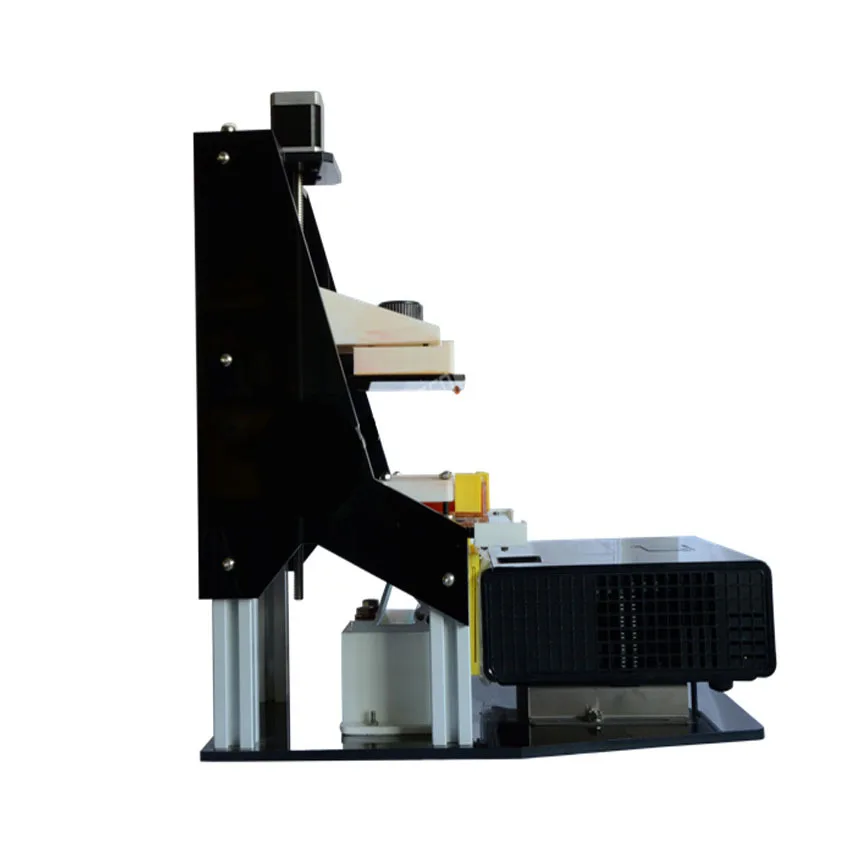

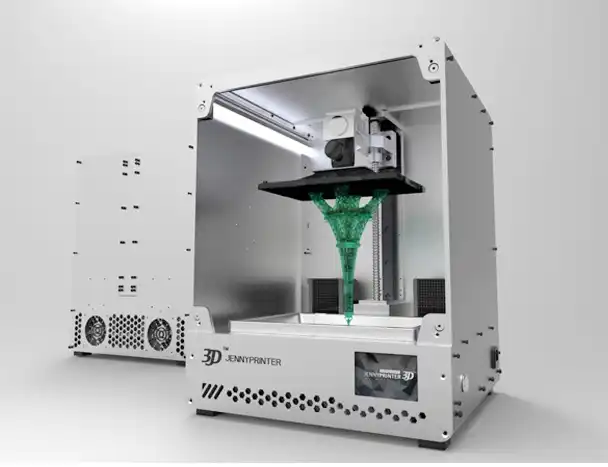

Above we mentioned the similarities between DLP and SLA 3D printing. It's time to talk about their difference and how DLP printers work. Instead of a laser machine (as in SLA), DLP 3D printing works with a special projector as a light source. This technique is not new: you can also find such DLP projectors in other, more common devices, for example, in TVs. Here they are also used for curing liquid consumables - photopolymer resins.

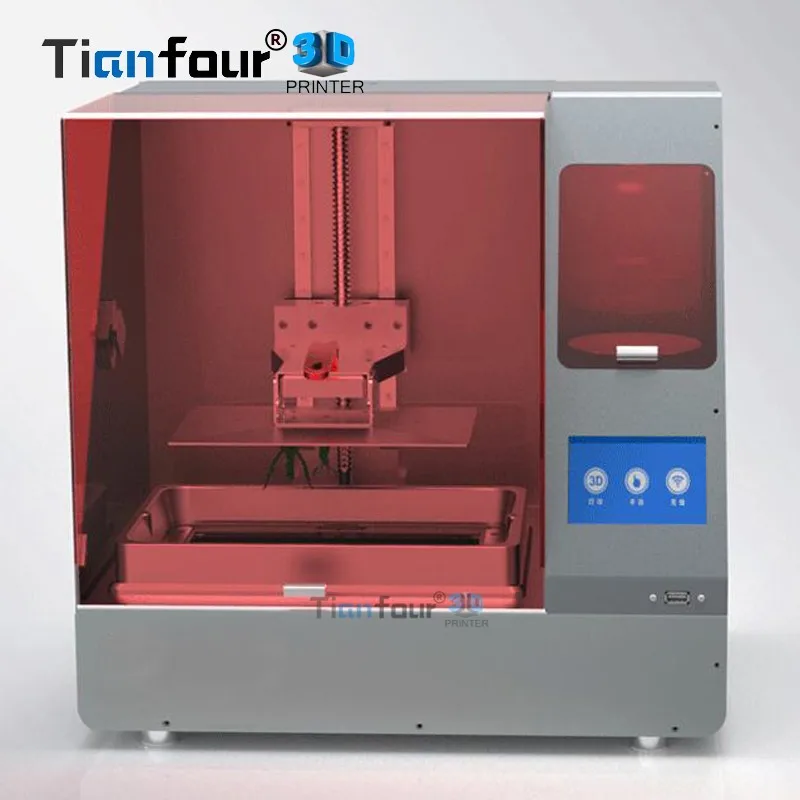

As in SLA printing, there are two options for DLP 3D printing devices: in one, the object is built from the bottom up (the working platform goes down), and vice versa (the working platform goes up). In our article, we will consider DLP 3D printing using both types of devices as an example.

In our article, we will consider DLP 3D printing using both types of devices as an example.

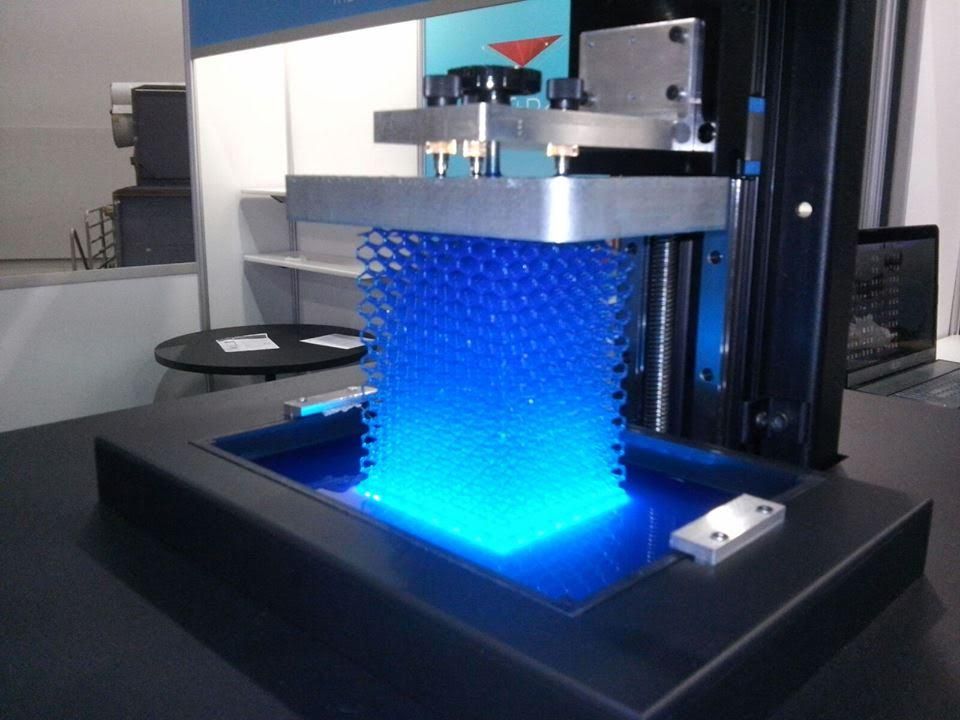

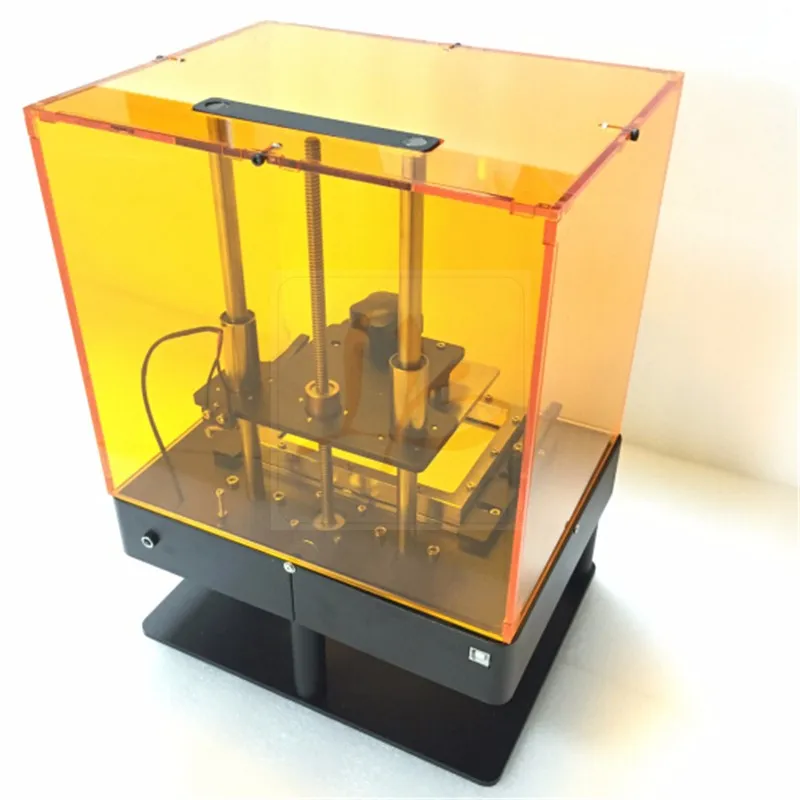

Reverse DLP 3D printing

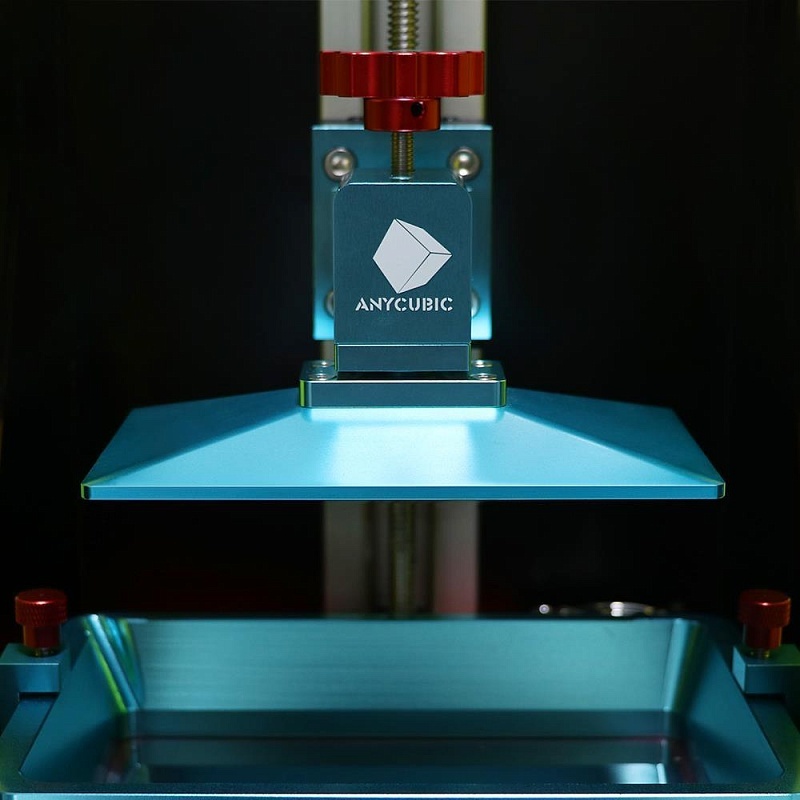

So, a special container of a 3D printer is filled with photopolymer resin to a certain level. The building platform is lowered into the container so that the gap between it and the bottom is equal to the height of one layer. Under the tank is a DLP projector. Light corresponding to the section of the first layer of the model is projected onto the platform. After its curing, the platform rises and the illumination of the second layer begins.

So, step by step, a physical object is created. Upon completion of printing, the platform rises above the level of the photopolymer, the product is removed and cleaned of the remnants of the consumable. After that, it is necessary to perform the final illumination in a UV lamp for complete curing of the material.

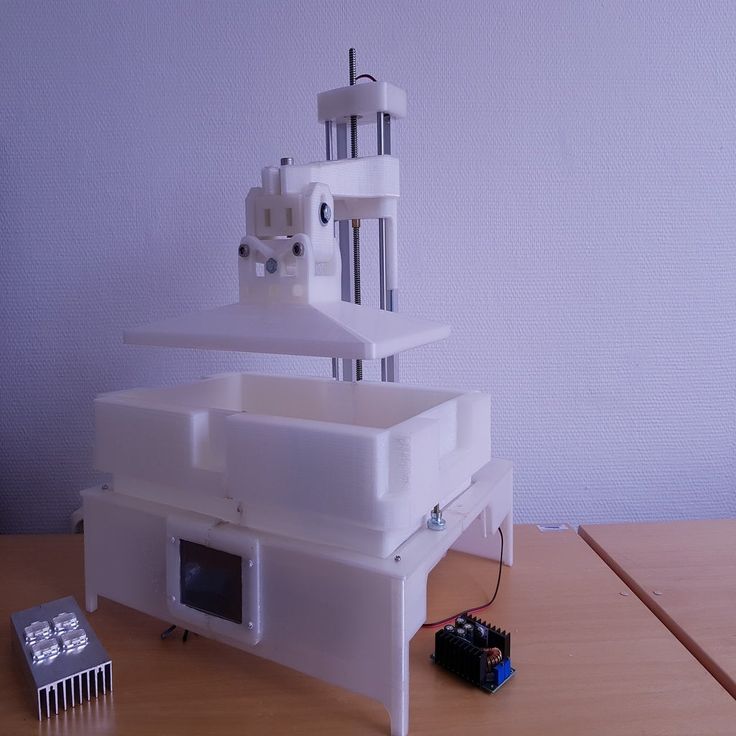

Direct DLP 3D printing

Unlike reverse printing, the DLP projector is located on top, above the resin tank. In this case, the working platform is located directly in it. To build the first layer, the platform rises so that the gap between it and the surface of the consumable corresponds to the height of the first layer.

In this case, the working platform is located directly in it. To build the first layer, the platform rises so that the gap between it and the surface of the consumable corresponds to the height of the first layer.

The cross section of the first layer is projected onto the platform, curing the photopolymer, after which the platform is lowered down to the height of one layer. These steps are repeated until the complete construction of the product. Further actions are identical to those described in the previous paragraph: the object is removed, cleaned of consumables and subjected to additional illumination.

Benefits

Why is DLP 3D printing so interesting? What features of it help this technique to gain more and more popularity every day? Let's watch:

- Faster print speed than SLA 3 D printers. In contrast to laser stereolithography, DLP 3D printing projects a whole layer onto the photopolymer at once, and does not gradually pass through its sections with a laser.

Due to this, the speed of creating products increases several times;

Due to this, the speed of creating products increases several times; - High print precision. In terms of the accuracy of the created objects, DLP 3D printing is in no way inferior to SLA 3D printing: the layer height in this technique can reach 15 microns! However, it all depends on the type of 3D printer and the specific material;

- Large selection of consumables. As for photopolymers, their range in the 3D printing market is so wide today that it is sometimes difficult to decide. Moreover, often DLP 3D printers can work with the same consumables as SLA printers;

- Affordable equipment price. DLP projectors are much cheaper than laser systems, which affects the cost of 3D printers for DLP printing for the better. Technology is developing rapidly and many today are opting for digital LED projection.

Among the shortcomings, it is worth highlighting only the rather high cost of consumables.

Applicable materials

DLP 3D printing works with liquid photopolymer resins (much the same as SLA 3D printing). Some consumables are even suitable for both methods. It depends on the wavelength of illumination and consumables. However, even specifically for digital LED projection, excellent professional lines of photopolymer resins have been developed.

So, today in the 3D printing market you can find flexible and rigid materials, transparent photopolymers and resins of a wide variety of colors. Consumables for specific applications are also available. For example, dental photopolymers with various properties, as well as burnable materials for the manufacture of jewelry master models.

Equipment

Even today, some DLP 3D printers can compete directly with SLA printing equipment. Our store presents a variety of devices, both professional and budget class, for DLP 3D printing. Some of them are listed below:

- WANHAO DUPLICATOR 7

- M-ONE

- WANHAO DUPLICATOR D7 PLUS

- B9CREATOR

- TITAN1

All 3D printers available for order. For additional questions, write to us by e-mail, or call the numbers listed in the "Our Contacts" section.

For additional questions, write to us by e-mail, or call the numbers listed in the "Our Contacts" section.

What is DLP 3D printing for?

We have figured out how the technology works. Now consider the scope of 3D printing DLP:

- Jewelery;

- Dentistry;

- Art and design;

- Souvenir products.

In general, DLP 3D printing is suitable for any area where high precision and detail of the created products is important. With equal success, this method is used in architectural prototyping, as well as for small-scale production of small-sized products.

Back to main page

Useful information

There is a wide variety of 3D printers on the market today. LCD, DLP and SLA 3D printers use photopolymer resins. But which ones are best for your needs?

Today we will focus specifically on the aforementioned photopolymer 3D printers. We'll take a look at the pros and cons of each type of printer and compare their resolution, accuracy, clarity, speed, and cost.

A BRIEF DESCRIPTION OF LCD 3D Printers

LCD 3D printers use a liquid crystal screen to project a specific light pattern, which is then used to cure a photopolymer resin in a bath. The LED lamp is used as the light source, while the LCD screen controls the light pattern. The light is emitted by an LED lamp. Then it passes through the liquid crystal screen and is absorbed by the resin. The image of each layer is generated on the LCD screen and at the same time it is completely solidified.

Phrozen LCD 3D printers use ParaLED technology, in which an array of LED chips projects light through an LCD screen, which is then evenly distributed over the print area.

A BRIEF DESCRIPTION OF DLP 3D Printers

DLP 3D printing, or digital light processing, uses a digital projector to flash ultraviolet light in the area to be printed and immediately cures the resin layer.

The optical pattern for DLP 3D printing is mainly generated by a digital micromirror device (DMD) inside the projector lens. The DMD itself is made up of many tiny mirrors that control the pattern of light being projected. Light is reflected from its surface, located at an angle to the liquid resin.

The DMD itself is made up of many tiny mirrors that control the pattern of light being projected. Light is reflected from its surface, located at an angle to the liquid resin.

A BRIEF DESCRIPTION OF SLA 3D Printers

SLA 3D printing, or stereolithography, uses lasers as a light source for 3D printing. The resin hardens as the laser beam prints each dot in a specific layer.

When a laser beam is reflected from a computer-controlled mirror, it is directed by the mirror to various coordinates that are in the resin and cures it in layers.

COMPARISON PERMISSIONS

Resolution is related to 3 dimensions: XY resolution and Z resolution.

The Z resolution is mainly determined by the specification of the 3D printer motor, motor driver, and lead screw. The Z resolution refers to the minimum layer height. For daily printing, we will use the average layer height, for example 30-100 µm, for printing instead of the minimum layer height.

For example, the Z resolution of the Sonic 4K Phrozen printer is 10 µm, but we usually print at a layer height of 30-100 µm. The lower the layer height, the longer it will take to print the model. This means that as the number increases, the printer will print faster. Please note that the layer thickness can be preset on each 3D printer.

Keep in mind that the resolution of the STL file itself will also affect the resolution of the final print.

For each type of 3D printer, the XY resolution is defined as follows:

LCD 3D printers: For LCD 3D printers, the XY resolution is determined by the pixel size.

LCD 3D printers can produce higher resolution 3D prints, depending on the pixel size of the printer's LCD display.

For an LCD screen, you can calculate the pixel size by dividing the length of the LCD by the number of pixels along its length. Take Phrozen's Sonic 4K as an example, its X-axis resolution (pixel size) is 134. 4 mm / 3840 pixels = 0.035 mm.

4 mm / 3840 pixels = 0.035 mm.

Phrozen's Sonic 4K allows you to print in 4K at 35µm resolution and 722 PPI (the highest PPI on the market). PPI stands for Pixels Per Inch. The higher the PPI of the printer, the more detailed the 3D model will be.

DLP 3D printers:

For DLP 3D printers, the XY resolution is also determined by the pixel size. Although the difference is that the pixel size of DLP 3D printers depends on the size of the small mirrors on the DMD.

Each layer is seen as square pixels and light is projected according to the size of the pixel.

DLP 3D printers use the same concept as LCD 3D printers; you can calculate the pixel size by dividing the length of the small mirrors by the number of pixels present on the DMD.

SLA 3D printers: For SLA 3D printers, the XY resolution will depend on the average spot size of the laser beam and the amount of steps that the laser beam is driven.

The size of the laser spot can be adjusted according to the size of your print. Some may also define its resolution in different ways, such as scan speed or beam size at minimum power.

Some may also define its resolution in different ways, such as scan speed or beam size at minimum power.

Due to differences in methods, SLA 3D printers should be treated as a separate case when compared to DLP and LCD 3D printers.

Comparison of measurement accuracy.

LCD 3D Printers: With a wide variety of LCD 3D printers on the market, companies are now rushing to create LCD 3D printers that are far more accurate than previously possible. This means that LCD 3D printers are approaching the accuracy of traditional SLA 3D printers with the proper calibration components.

Phrozen 3D printers use ParaLED technology to provide the most parallel angle of UV light emission. This is to ensure that each resin layer receives an equal amount of UV light during the printing process, improving the efficiency of light passing through the LCD screen while projecting each pixel size accurately and accurately.

DLP 3D printers:

DLP 3D printers tend to be less accurate than SLA and LCD 3D printers.

This is because DLP printers use the projector lens to project light from a small source to a wider source, which increases the chance of pixel distortion due to spherical aberration.

Some professional DLP 3D printers try to improve this slight distortion by building floor standing 3D printers to increase projection length to reduce the effect of spherical aberration.

SLA 3D printers:

Because SLA printing uses lasers, 3D models printed using this technique are generally accurate. SLA 3D printers print models with a flat and smooth surface as the laser travels in a continuous path, slowly drawing out each layer.

Although SLA 3D printers can print smooth models, the purchase price of such a device can be 3-5 times higher than LCD 3D printers. In addition, printing on an SLA 3D printer takes much longer, we will talk about this later. For those who want to print miniatures and other similar models at home, it would make more sense to purchase an LCD 3D printer.

Speed Comparison

LCD 3D printers:

LCD 3D printers are similar to DLP 3D printers in that the entire resin layer cures at once, which means it can also print much faster than SLA 3D printers and print out a collection of 3D models in one go.

Print speeds can vary from 20mm/hr for Phrozen's Shuffle XL Lite to 80mm/hr for our Sonic 4K, depending on whether the 3D printer uses a single crystal screen.

Monocrystalline screens last much longer and print much faster than regular color LCD screens.

This is because monochrome LCD screens are designed to provide higher light transmission and higher thermal resistance. Thus, 3D printers using Mono-LCD screens can cure resin with shorter layer exposure time and have a longer life than color LCD screens.

In comparison, color LCD screens take longer to cure the resin, as the LCD panel has a lower light transmission rate than Mono-LCD screens.

Being ahead of the curve, Phrozen pioneered Mono-LCD display technology in the world of 3D printing.

DLP 3D Printers: Because the entire resin layer is cured with UV light at the same time, this means you can print a large number of tiny models at the same time when using a DLP printer. This process will be much faster than with an SLA 3D printer and even some LCD 3D printers.

DLP printers can print between 20 and 140mm/hr, but they lose resolution and produce smaller print sizes than LCD 3D printers.

SLA 3D printers:

Since SLA 3D printers use lasers to trace the pattern of one layer before moving on to the next layer, it takes much longer to print each individual model using this type of printing technique.

The printing speed can vary from 14mm/hour to 36mm/hour.

Because SLA 3D printers use a different printing technique, it cannot be fully compared to the printing methods of DLP or LCD 3D printers. If you want to print models at high speed, it would be better to purchase LCD 3D printers as SLA 3D printers print very slowly.

Price

LCD 3D Printers: Compared to other 3D printing methods, LCD 3D printers are designed as an affordable alternative to their 3D printing counterparts. These 3D printers use a liquid crystal panel for printing, which can be easily replaced. Also, LCD printers can be small, so most LCD 3D printers are desktop-sized, making them easy to store.

LCD printers can cost anywhere from $500 to $3,000, such as the Sonic Mini Phrozen, which costs around $500, and our Sonic XL 4K, which costs $3,100.

Phrozen 3D printers produce models with high efficiency, providing high resolution printing to capture all the fine details of your 3D models. Phrozen offers a wide range of 3D printers for personal use, dental applications, jewelry and more.

DLP 3D printers:

DLP 3D printers are more expensive than LCD 3D printers because this printer requires the use of a digital micromirror device (DMD), which also tends to be expensive.

The price of DLP 3D printers typically ranges from $5,000 to $100,000.