3D printing items for sale

3d Printing - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

(1,000+ relevant results)

Related to 3d printing

- 3d printed

- 3d printing service

- 3d printing files

- custom 3d printing

- 3d printer

- 3d wall art

3d Printing - Etsy Canada

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

(1,000+ relevant results)

Related to 3d printing

- 3d printed

buyers, be careful in the world of non-free 3D models / Sudo Null IT News But what about paid models? Putting a model somewhere and placing a "buy" button next to it is no longer a problem, but after spending some time buying and printing various non-free 3D models, I began to see some obvious shortcomings of this system.

The specific problems and solutions depend on how these models are marketed, but one thing is clear: Poorly designed 3D models are bad for both consumers and the future pay-per-download market.

Various ways to sell models

There are many ways to sell models online. Online stores are great for digital models because they are not physical goods, and serving a thousand customers is no different than serving ten. Technically, the user pays for a license to use the model, and its conditions vary significantly depending on the creators and intermediaries.

Direct sales with payment per model

Direct selling is similar to downloading 3D models, only before you receive the link, you will see the price of the link. Sites like Cults3D and MyMiniFactory allow creators to set their own prices for non-free models. It is quite difficult to estimate the number of their sales, but the number of downloads for popular models is measured in hundreds or thousands.

Standing apart is the successful Hero Forge project, which allows users to create their own miniatures for board games using a web interface. Users can pay to download the STL file for the model they have created, or buy a printed version. Hero Forge is proprietary, but very successful, judging by their recent Kickstarter campaign.

Indirect sales with payment for access to models

Indirect sales mean that customers pay for access rather than buying models one by one. Successful creators make models in niche areas, and people pay to access their creator's library of work.

The usual way to manage monthly subscribers and provide access to files for 3D modelers is through Patreon. One common niche is board games, and some of the most successful creators have thousands of followers.

Another way of indirect sales is crowdfunding. Money is collected to create a certain set of models, and sponsors get access to the resulting files. Again, there are a lot of miniatures of heroes and territories for desktops.

Again, there are a lot of miniatures of heroes and territories for desktops.

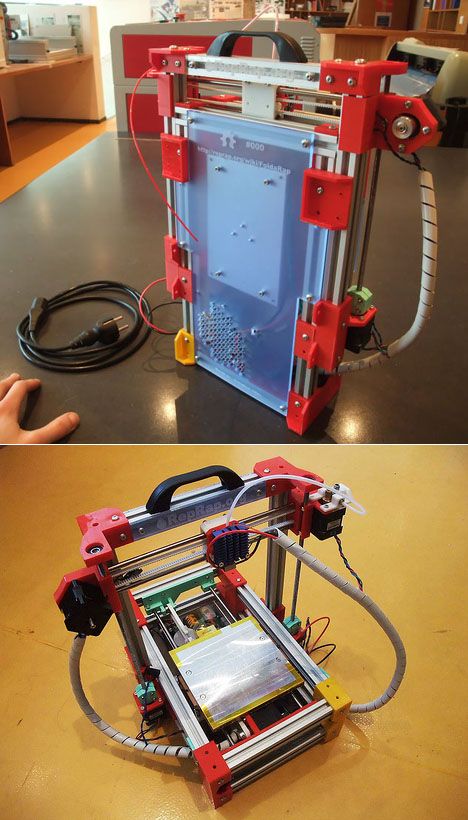

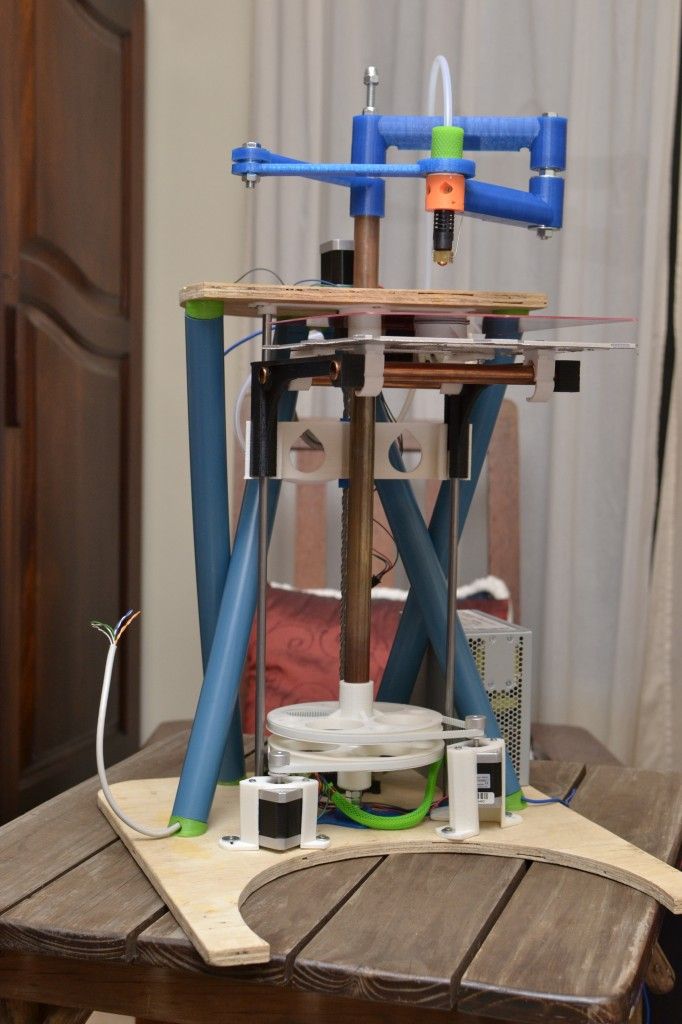

Self-printing kits

With this approach, 3D models are sold as part of a larger product. The buyer purchases the kit and prints plastic components for it himself, while the kit may contain electronic components and other parts. The result is a set that can include fewer items, is easier to produce, cheaper to ship, and usually costs less than if the seller had to do everything themselves.

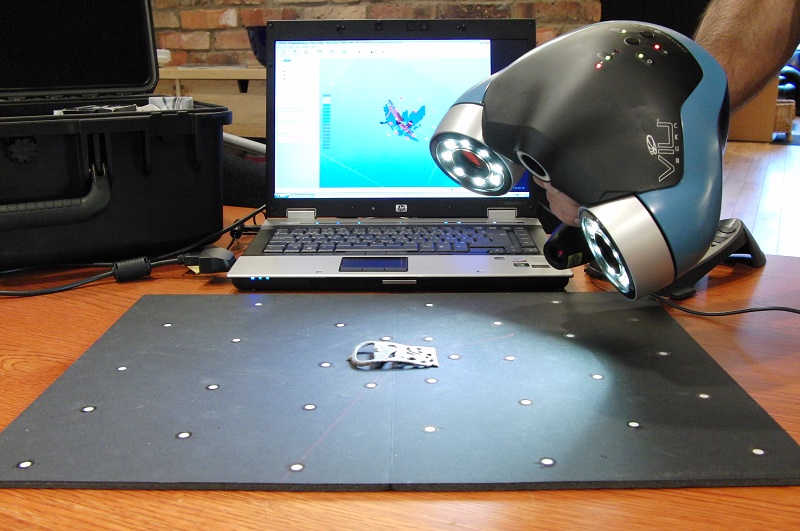

Bulwark Blaster (NERF compliant) and OpenScan (open source 3D scanner) are examples of this business model. In both cases, the designs are based on 3D printed components and specific parts lists. The purchaser usually acquires a license to use one copy of the product.

And what's the problem?

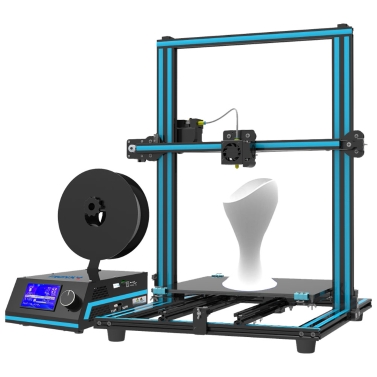

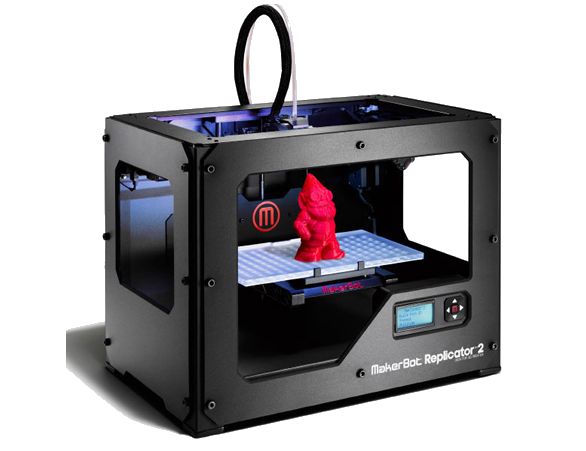

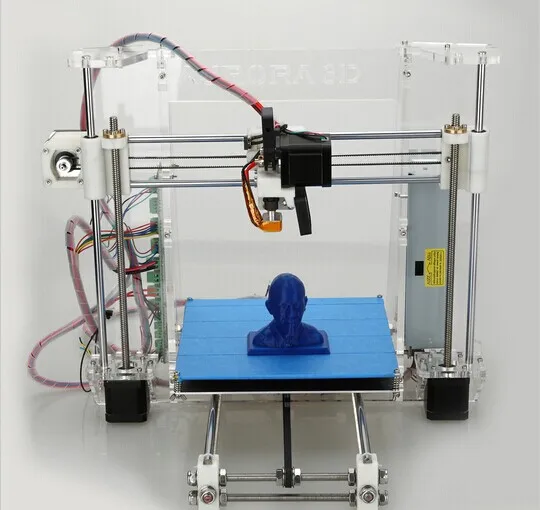

In an ideal world, 3D printers reliably print parts of any shape without problems with overhangs, bridges, distortions or supports. You can buy a 3D model and get exactly what you expected. Unfortunately, we have not yet reached this point.

You can buy a 3D model and get exactly what you expected. Unfortunately, we have not yet reached this point.

Quality 3D models need to be developed specifically for 3D printing, especially when it comes to money - because under the current system, all the risks fall on the buyers.

No test drives, no fitting rooms, no refunds

The world of non-free 3D models is like a clothing store without fitting rooms, or a car dealership without a test drive. “No money back” is a common phrase in sales and services, but when combined with the inability to try the product before buying, the result can be disappointing if the quality of the model turns out to be poor.

Low technology models

3D printers, like any tool, are good in some situations, not bad in others, and terrible in others. This means that models intended for 3D printing need to be designed taking into account the strengths and weaknesses of 3D printers. About the model developed in this way, we can say that it is made with high manufacturability.

About the model developed in this way, we can say that it is made with high manufacturability.

If the model was not designed with 3D printing in mind, it could create problems for the person trying to print it. The problem is that it is not always possible to identify models with which problems will arise, only by their image. Here are two examples.

For this model, supports and post-processing will be required regardless of the print orientation. The problem here is subtle: it was designed in such a way that it is almost impossible to print without props, regardless of the print orientation. She has other problems, but more on that later.

Let's add props - and we will face the need for post-processing and poor surface in the places where they were attached. If you place them on the visible side, the detail will be ugly. If it is invisible (where the loop is), they will hardly fit there.

These problems are solved in post-processing, but the point is not that - but that it would be better to avoid these problems while developing the part.

Cut in half, colors added to contrast inner and outer layers. The model is not complete. The problem arises where there are gaps between the outer and inner layers.

Second example. This model was advertised as being compatible with SLA (Laser Stereolithography). FDM and SLA printers have very different benefits, so it was interesting to see a model specifically designed for SLA.

But disappointment awaited me. The model was not solid. There are gaps between the outer layer of the model (the clothes of the figure) and the inner layer (the body), since these layers were modeled separately - and they left it that way.

Uncured material accumulates in these gaps, and the surrounding parts of the model are very thin, which directly attracts imperfections in printing. Such a scheme of the model ensures that, most likely, its outer layers, those that are visible from the outside, will suffer during printing. And these problems were not visible until the model was paid for.

Issues like this and more show poor manufacturability that you can't see in screenshots and renders, and as I noted earlier, pay-per-download is now territory of no refunds and dangers for buyers.

Why poor quality models are a big problem

The problem with bad models is this: by the time it turns out that the model has a problem (or it cannot be made properly, or it is too wasteful to print), it turns out that the buyer has already invested much more in it than just the purchase price. A bad model only repels a person who wants to hit the "Buy" button.

Passing all the risk on the buyer, so that all his money and efforts go to waste - this should be the last thing on any platform seeking to grow.

Ways to improve the situation

It's tempting to try to solve this money-back problem with a file access control system, but then it becomes suspiciously DRM-like, and that's not likely to be a good way forward.

On the other hand, it is possible to increase confidence in the quality of models and purchases without changing too much in current platforms. Here's what you can do.

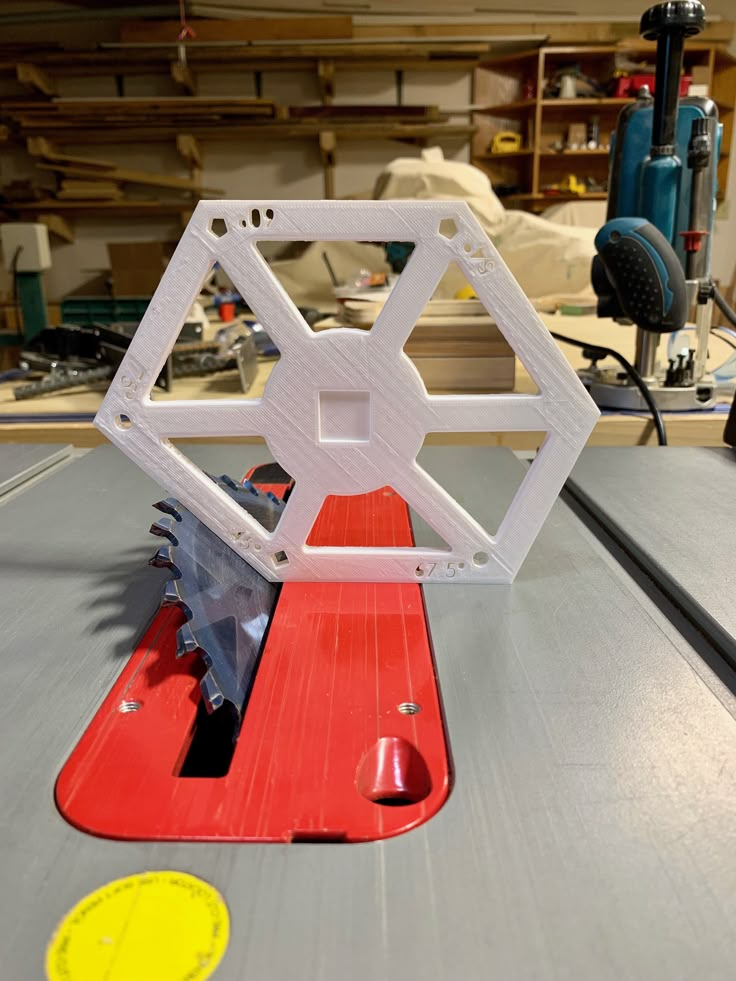

Demonstrate the quality of models with photographs and documentation

Documentation and a photo of the printed results, rather than just rendering models on a computer, is an effective way to provide the buyer with additional information about the model. The documentation does not have to be extensive, but it should list design elements, assemblies, or areas that require special control. An example is a printable vise model by Christoph Leimer. This is a free model, but its excellent documentation inspires confidence in its quality.

Models that require additional components must clearly list them in the description, along with specifications and sources. The latch model I used as an example of poor manufacturability requires some sort of arcane spring, with no dimensions or where to find it. This is another problem that comes to light too late.

This is another problem that comes to light too late.

If the developer has not clearly and clearly demonstrated that he successfully printed his own development, do not buy it.

Provide test drive parts

Designers of kits and other prefabricated structures can give free access to some components, as if to say, "if you can print and assemble these models, then you will succeed, because the principles for developing my product were the same." If customers cannot return purchases, then this approach will at least give them a semblance of a test drive.

Run automatic quality check on models

Professional print studios like 3D Hubs analyze uploaded items as part of the approval process and warn of features such as thin walls, small parts that can get lost, and potential issues with prop removal. Model hosting and selling services could improve customer confidence by doing similar checks on the models they sell, and displaying the results of that analysis along with the model and price.

What was your experience with paid models?

Have you bought models online, or do you sell your own? What was your experience and what would you change about this system?

Raise3D: using 3D printing to create furniture and interior items

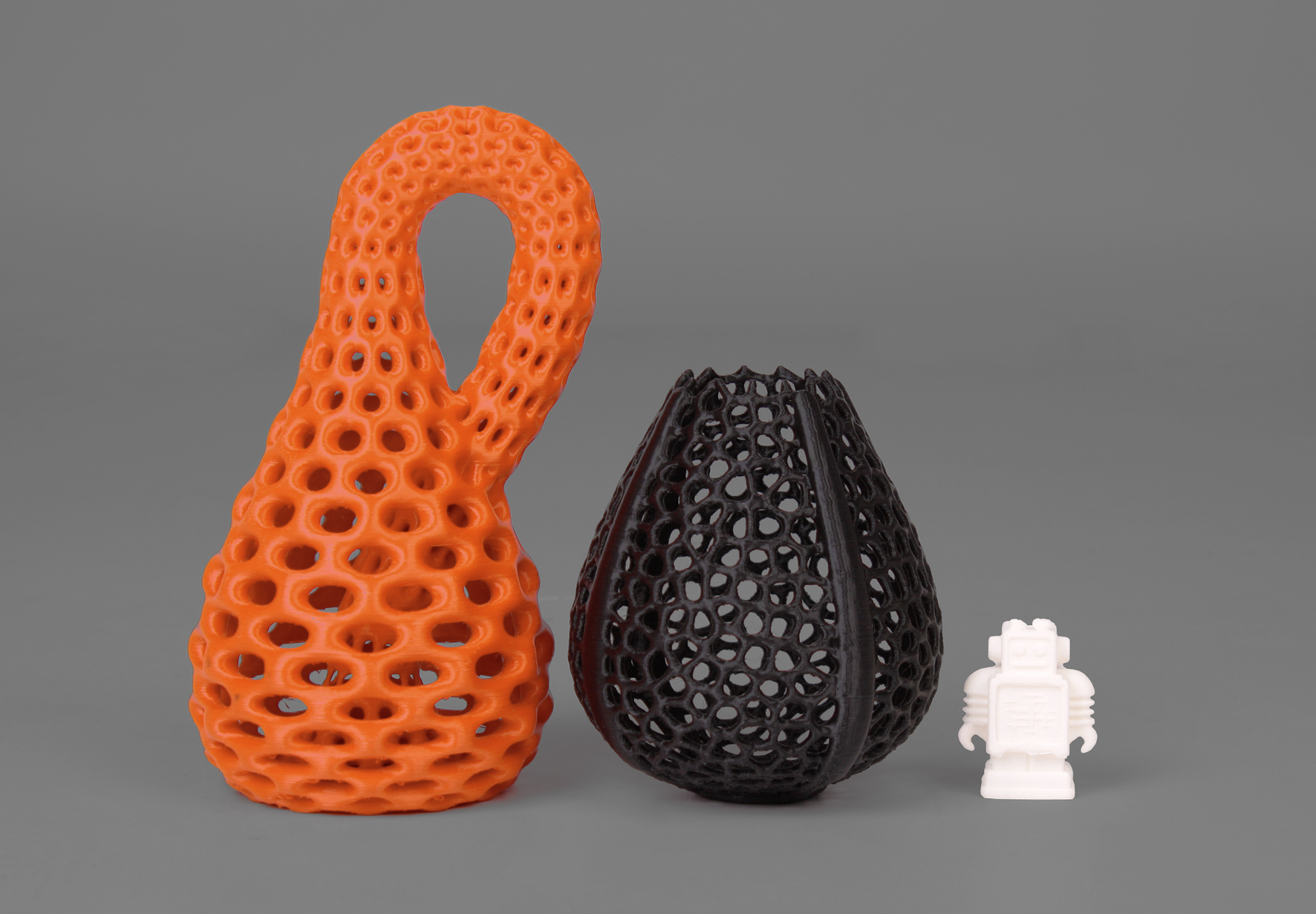

With the advent of 3D printers, many advanced designers tried to use 3D technologies to create furniture and interior elements, but the first attempts were more experimental.

It has only recently become a real business idea with the advent of affordable professional printers that designers and small businesses can afford.

Janne Kitanen, a digital sculptor, has pioneered the use of 3D hardware for design creation, creating complex geometric objects with incredible designs, from exclusive platform shoes to chairs and even ping-pong tables. Despite the space cost (by the standards of a simple layman), Janne's products are sold out like hot cakes.

The cost of this sofa is $ 100,000

The main advantages of using 3D printing in this area:

- new possibilities in design solutions;

- implementation of complex exclusive projects;

- cost is lower compared to traditional production methods.

Let's tell you about 3 designers who use Raise3D 3D printers to create interior and furniture items.

Wanhao Chai - designer and owner of Yujia Metal Science

Yujia Metal Science creates exclusive metal furniture, and Raise3D N2 is used to optimize production processes. Wanhao Chai says, “The 3D printer can improve efficiency and save labor costs. Products become clear visually already at the prototyping stage, you can see all the details and quickly make adjustments.»

Sofa printed on Raise3D N2

Yujia Metal Science creates metal household items: partitions, doors, windows, furniture, wine cabinets, metal decorations and other interior elements. Positioning itself as a designer furniture boutique and exclusive manufacturing, Yujia operates in a narrowly segmented direction - the manufacture of furniture and interior items according to individual order.

Positioning itself as a designer furniture boutique and exclusive manufacturing, Yujia operates in a narrowly segmented direction - the manufacture of furniture and interior items according to individual order.

Yujia Metal Science turned to 3D printing to solve the main problem - to increase speed of production and frequency of new products./p>

Before using Yujia 3D printers, very expensive wooden prototypes were ordered to validate and validate models. This process was repeated before the steel version was made. repeatedly. Many factories do not welcome this format of cooperation with small-scale production, considering it not rational to spend time on the production of single prototypes. Therefore, Yujia often found themselves in a difficult situation and were rejected by companies due to small volumes of orders.

Using Raise3D 3D printers, the company was able to:

- Reduce production time by using 3D printers, and by sharing prototype printing across multiple printers.

- Reduce costs by reducing labor required and using cheaper materials for prototypes.

- Move the production of prototypes and products completely to your own production. Thanks to this, they got rid of the extra costs and uncertainty that were inevitable when working with outsourcing companies.

- Create the largest and most complex versions of your designs with the large printable area and high precision of Raise3D.

Production process:

Prototyping requires only product drawings, a slicer, printing plastic and Raise3D N2 printers. At the beginning, the required file is converted to STL, then the print preview is used to minimize the number of supports and optimize all layers, layout of elements, and the appearance of the model.

The purpose of printing the first model is to see the appearance of the structure. Using the printed prototype, the designer can physically interact with it, see all the nuances and shortcomings, decide on changes and quickly correct the model.

Metal parts and legs will be used in the final chair design

As a result of the use of 3D printers achieved:

- 91.67% reduction in total production time

- 75% reduction in working hours

- 99.17% reduction in prototype costs

Marco Rubini, Italian architect and designer

Prints furniture prototypes on the Raise3D N2 Dual Plus.

Marco founded his own design studio in 1992. His main areas of activity are design development and consulting in the field of architecture. It has always been important for Marco to offer his customers customized solutions, which N2 Plus is currently helping him with.

He uses Raise3D to print prototypes and original pieces of furniture in 1:1 scale.

What Marco values most about the 3D printer is its endurance and durability, seeing Raise3D as a workhorse.

Hanger 100% printed on Raise3D

Corey Zwerlin (Still Alive Lights LLC) - 3D printed lighting fixtures

Corey designs designer lampshades (including solar-powered lamps).

On the Raise3D N2 Plus, he prints shades in the shape of animals, flowers and more. To achieve maximum transparency and the best light transmission, Corey adjusts the print settings to the smallest thickness of the model. For his creations, he uses ordinary PLA plastic.

Currently, 3D printing allows you to create complex objects of unusual shape, the production of which by other methods is the most expensive and difficult to implement. Additive technologies increase productivity and reduce material and labor costs, which is why many companies are already using 3D printing and 3D scanning to produce furniture and interior items.