3D printing with ceramics

3D Printing Materials: Ceramic Resin

Skip to Main Content

3D print parts with a stone-like finish and fire them to create a fully ceramic piece with Ceramic Resin, an experimental material that pushes what’s possible with the Form 2. Fabricate ceramic parts for engineering research, or create distinctive art and design pieces.

Download the Usage Guide

Formlabs is excited to offer the first affordable ceramic 3D printing material for the world’s most popular desktop stereolithography (SLA) system. Be one of the first to work with a material at the forefront of SLA polymer development, previously only available in industrial and research environments at prohibitively high costs.

Ceramic Resin is a silica-filled photopolymer. After firing, the photopolymer network burns out to form a true ceramic part. Fired parts have unique properties that can be leveraged for applications where fired part accuracy is not critical.

View Technical Data (PDF)

Digital artists and designers can use Ceramic Resin to fabricate complex geometries that wouldn’t be possible by hand. Pieces printed in Ceramic Resin can be fired and glazed to produce functional objects.

Order Now

Ceramic Resin is a Form X product. This material is more complex to work with than other Formlabs products and requires extra steps and additional experimentation for successful printing. It may take a few iterations to create a final fired part that meets your specifications.

Make sure to read the Usage Guide in full before using this material.

WATCH THE PROCESS VIDEO

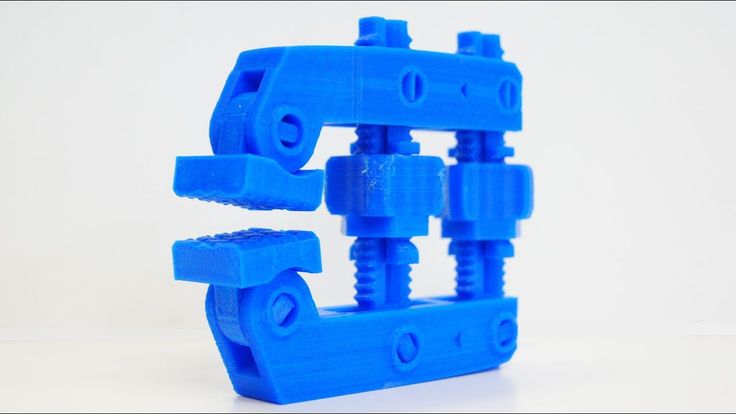

1. Design

Ceramic Resin requires designing within specific constraints for successful printing and firing. Start small, follow the usage guidelines, and experiment.

2. Prep

Sand your build platform to increase print adherence, shake the cartridge to mix the material, and clear the bite valve.

3. Print

Scale your parts in PreForm to accommodate for shrinkage during firing. Send your design to the Form 2 and press print.

4. Post-process

Wash your prints in isopropyl alcohol (IPA) and remove supports (no post-curing necessary). Ensure that parts are completely dry before firing.

5. Fire

Fire your part in an actively ventilated kiln that fires to at least cone 8 to burn out the photopolymer from the material and create a fully ceramic final part. Parts will shrink by around 15% in XY and 29% in Z during firing.

6. Glaze

If desired, apply a glaze of your choosing, following the manufacturer’s instructions.

Ready to start working with Ceramic Resin?

Order Ceramic Resin Now

Data Sheets

Download safety and technical data sheets for all Formlabs materials.

Handling & Safety

Handling & Safety

Resin should be handled with care. Proper handling will ensure safe printing and efficient use. Our resins have been designed to be similar or safer to handle as other household chemicals or adhesives. Formlabs materials do not contain volatile solvents so special ventilation is not required. Skin contact should be avoided.

Proper handling will ensure safe printing and efficient use. Our resins have been designed to be similar or safer to handle as other household chemicals or adhesives. Formlabs materials do not contain volatile solvents so special ventilation is not required. Skin contact should be avoided.

The Safety Data Sheets (SDS) are up to date for every resin product and follow the latest government guidelines. Always consult the SDS as the primary source of information to understand safety and handling of Formlabs materials. For more information about handling resin, learn more tips for resin maintenance in our Help Center.

Technical Data

Technical Data

Plastics are complex materials, and finding the right one for your specific application requires balancing multiple attributes. Our library of resins is ideal for product development, rapid prototyping, and a variety of specialized applications. Download our Technical Data Sheets to explore the mechanical properties of each material.

Material

– Select –BioMed AmberBioMed BlackBioMed ClearBioMed WhiteBlackCastableCastable WaxCastable Wax 40CeramicClearColor BaseColor PigmentsCustom TrayDental LT ClearDental LT Clear V2Dental SGDigital DenturesDraftDurableESDElasticElastic 50AFlexibleFlexible 80AFull Materials LibraryGreyGrey ProHigh TempIBTModelModel V3Nylon 11Nylon 11 CFNylon 12Nylon 12 GFPU Rigid 1000PU Rigid 650Permanent CrownReboundRigid 10KRigid 4000Soft TissueSurgical GuideTemporary CBToughTough 1500Tough 2000White

Language

– Select –BulgarianChineseCroatianCzechDanishDutchEnglishEstonianFinnishFrenchGermanGreekHungarianIrishItalianJapaneseKoreanLatvianLithuanianMalteseNorwegianPolishPortugueseRomanianRussianSlovakSlovenianSpanishSwedishTurkish

Technical Data Sheets

There is no technical data sheet available for the chosen material.

Safety Data Sheets

There is no safety data sheet available for the chosen material.

Intro to Ceramic 3D Printing

The modern 3D printing space is a far cry from the days of plastic prototypes. Today’s users have their choice of materials, from rigid and flexible polymers to high-performance composites. One such material that’s finding more uses across industries is ceramic. We touched lightly on ceramic 3D printing when we looked at metal DLP 3D printing but let’s take a deeper dive.

3D Printing Ceramics

So what is ceramic? It’s a fairly broad term that includes everything between earthenware and Alumina. The origins of ceramic can be traced to Greece where they would bake clay at high temperatures to make it rigid. Technically speaking, ceramic is a solid material comprising an inorganic compound of metal, non-metal, or ionic and covalent bonds. Carbon and silicon can be considered ceramics from that perspective, and that’s important to note because the names of many of the 3D printable ceramics sound more like metals as they are not derived from clay. Nowadays, ceramics are divided into two categories: classic ceramics that are made up of only natural raw materials (clay) and technical ceramics that include other materials like silicon, carbon, and nitrogen.

Nowadays, ceramics are divided into two categories: classic ceramics that are made up of only natural raw materials (clay) and technical ceramics that include other materials like silicon, carbon, and nitrogen.

Classic ceramics include stoneware, earthenware, and porcelain. Technical ceramics are also known as engineered ceramics and industrial ceramics, and their list would be much longer because more are regularly created as custom solutions for specific applications. Some popular technical ceramics are Aluminum Nitride, Zirconia, Silicon Nitride, Silicon Carbide, and Alumina. Technical ceramics have dramatically improved mechanical, thermal, chemical, and electrical properties as compared to classic ceramics. Most 3D printed ceramics fall into the technical category but the extrusion based printing process (discussed below) works primarily with classic ceramics.

Why print with ceramic?

- Aesthetic

- Tactility

- Chemical resistance

- Biocompatible

- High or low thermal conductivity, depending on formulation

- Electrical insulator

- Very hard

- High strength-to-weight ratio

Industries

That’s quite an appealing list of physical and mechanical properties. It makes sense that ceramic is used in many industries, and 3D printed versions are quickly replacing traditional ceramic parts. The first thing that comes to mind when thinking about ceramic is usually pottery and cookware, and yes, some artists are 3D printing ceramic vases, bowls, and sculptures. Ceramic has a pleasant look and feel and it can be fired to alter both of those traits. That’s just the tip of the iceberg, though. Here are some of the industries that rely upon ceramics:

- Aerospace – The dimensional stability and low density of ceramic makes it ideal for sending into space on rockets and satellites in the form of bearings, seals, and thermal shields; parts undergo extreme temperature changes in space depending on their relative position to the Sun so it’s important that materials don’t shrink and expand in those temperature shifts, and of course, the cost of sending anything into space is directly tied to mass (weight) so lightness is always a priority.

- Aviation – Those same properties are just as helpful, if not more so, in Earth’s atmosphere where there’s much more turbulence and (air) friction to deal with; ceramic is highly resistant to abrasion and heat so it can be found in various aircraft components, including armor, electrical insulation, and fuel nozzles. There’s good reason the NASA Space Shuttle was covered with ceramic plates (it was to prevent it from burning up upon reentry).

- Automotive – The hardness and toughness of ceramic are especially useful in the automotive manufacturing space because, let’s face it, we’re kind of rough on our cars. Temperature swings, vibration, humidity, various chemicals and oils; our vehicles have to deal with it all. From spark plugs and brakes to sensors and filters, there are countless parts in any given car that have ceramic in them.

- Medical – The fact that ceramic is light, durable, and biocompatible makes it a great material for the medical and surgical industries where it’s used for implants, surgical tools and guides, and diagnostic equipment.

- Energy – Power generation and distribution systems are both highly demanding and critical and ceramic contributes to the reliability of these systems. Its wear-resistance, electrical insulation, and rigid mechanical properties allow it to survive the harsh environments of power plants.

- Chemical and pharmaceutical – Synthesizing chemicals and drugs requires processes that involve rapid temperature changes, pressure, and corrosion. Custom ceramics can be engineered to outlast most metals in the specialty machines used in the industry.

- Electrical engineering – Lots of electrical components have to operate in hostile environments, like the sensors in engines and furnaces as well as the vacuum chambers of particle accelerators; these are all cases where ceramics shine.

This is only a partial list as other applications of ceramics include optics, metallurgy, and textiles. The point is: ceramics are all around us and they do a lot. That means the potential market for 3D printed ceramics is rather large.

That means the potential market for 3D printed ceramics is rather large.

Types of Ceramic 3D Printing

There are five major processes for 3D printing ceramic:

- Extrusion – A paste or slurry of clay is pushed through a nozzle and parts are built up layer-by-layer like on a desktop 3D printer; resolution is lowest on this technology but it also scales up to the largest build volumes.

- Binder jetting – A binding agent is selectively applied to a bed of ceramic powder one layer at a time; final parts must go through a debinding process.

- Powder sintering – A high-power laser sinters the cross-sections of each layer onto a bed of ceramic powder.

- NanoParticle Jetting – Liquid suspensions containing solid ceramic nanoparticles are deposited with inkjets layer-by-layer.

- Photopolymerization (DLP) – Resin that’s filled with ceramic particles is used in a DLP printer that cures each layer into a solid with UV light; final parts must go through a debinding process.

All of the processes require firing to completely harden and some of the systems require an additional sintering step before firing. They can then be glazed to make them food, freezer, oven, and dishwasher safe. While the extrusion-based technology produces pretty rough results, the level of detail that can be achieved with the other printing processes is incredibly high. 3D printing enables ceramic geometries that could not be fabricated through traditional injection molding techniques so it’s no wonder that companies are adopting AM technologies to optimize their ceramic parts. The turnaround time on printed ceramic parts is much shorter as well, which is generally compelling to production managers. The same network of post processors that handle the sintering of many metal 3D printed objects will also be able to handle ceramic sintering so expect to see much more ceramic 3D printing.

Featured image courtesy of City University of Hong Kong.

Ceramic 3D printing | Alumina Systems GmbH

Ceramic 3D printing has been on everyone's lips for several years and has several hypotheses and names such as Rapid Prototyping (RP), Solid Freeform Fabrication (SFF), Additive Manufacturing (AM) or whatever is currently popular name 3D printing. Hypotheses have been born again and again from the idea that with the help of a 3D printer, Al2O3 printed components can be produced by anyone in the shortest possible time, and that conventional production will be redundant in the future.

Hypotheses have been born again and again from the idea that with the help of a 3D printer, Al2O3 printed components can be produced by anyone in the shortest possible time, and that conventional production will be redundant in the future.

Each new hype disappeared when it became clear that this would not happen. Despite all this, technical ceramics with 3D printing technology, especially for materials of the metal and plastic class, have been used in industry for many years. The market is yielding to stable growth. Especially at trade shows such as the annual Formnext trade show in Frankfurt am Main, it is always clear how high the proportion of 3D printing equipment suppliers and service providers is. The field of ceramic 3D printing, especially technical ceramics, is lagging behind metal and plastic. This is mainly due to the high demands placed on technical ceramics and their non-trivial manufacturing process.

Alumina ceramics 3D printing

There are currently only two major suppliers of technical ceramics 3D printing equipment on the market: Lithoz, which developed LCM technology based on photocrosslinkable polymers, and 3DCERAM, which successfully applies the same physical basis for laser stereolithography in the production of technical ceramics. Alumina Systems has worked closely with Lithoz for over 5 years and has brought LCM technology to the industry in a matter of months.

Alumina Systems has worked closely with Lithoz for over 5 years and has brought LCM technology to the industry in a matter of months.

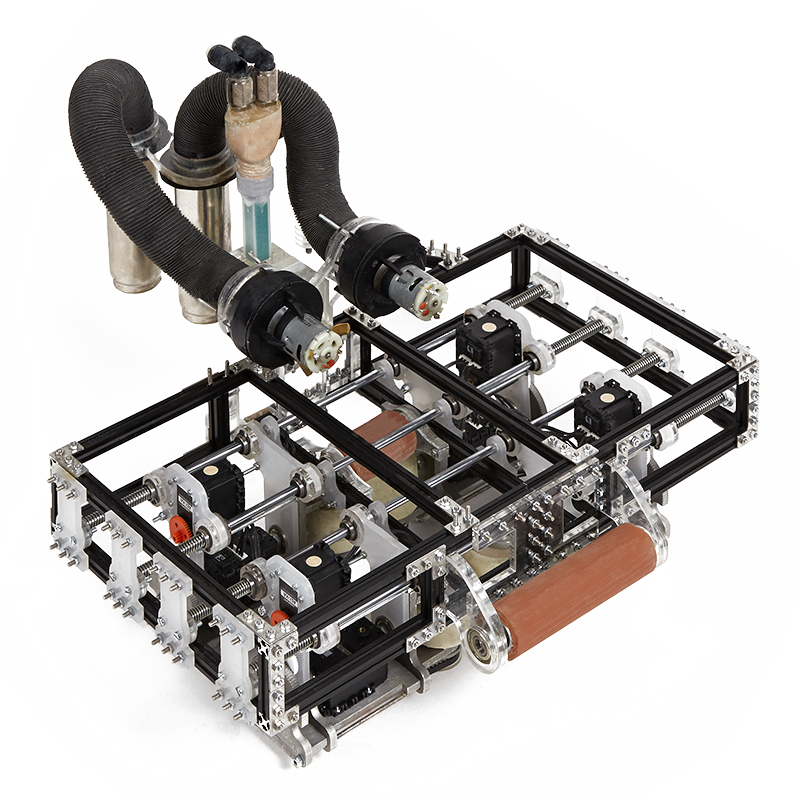

3D printed ceramic components

Alumina's in-house 3D printing has been enhanced by the acquisition of 3DCERAM's largest commercially available 3D printer. The printer has a construction area of 600mm x 600mm, which allows the production of 3D printing components in unprecedented dimensions. In addition, it is possible to manufacture special parts in small or series production. Alumina Systems claims to be the undisputed leader in technical ceramics 3D printing due to innovation and customer proximity. To do this, Alumina Systems acquired a dedicated IP address to develop their own 3D printing process for industrial use.

A new process that will be available as an alpha tool from Alumina in early 2020 is the laser-induced casting of plain bearings. This process processes many times cheaper ceramic materials than any other printer on the market. In addition, the assembly time is less and the geometry of the components in terms of wall thickness and dimensions is practically unlimited physically. Because this produces a "green" body with a low binder content, the long and delicate debinding process required by other processes is obsolete. It follows that the reliability of the process is greatly increased and the costs and time for heat treatment are significantly reduced.

In addition, the assembly time is less and the geometry of the components in terms of wall thickness and dimensions is practically unlimited physically. Because this produces a "green" body with a low binder content, the long and delicate debinding process required by other processes is obsolete. It follows that the reliability of the process is greatly increased and the costs and time for heat treatment are significantly reduced.

Ceramic Prototyping in Ceramic 3D Printing

In terms of innovation and component geometries, Alumina Systems is already a leading company in ceramic 3D printing and will continue to do so in the future.

Ceramic 3D printing - Al2O3 condenser

Ceramic 3D printing - Al2O3 heat exchanger

Ceramic 3D printing - Al2O3 mixing section

Ceramic 3D printing - Al2O3 separation column

Overview of 3DCeram ceramic 3D printers

Ceramic is a unique material. Due to its low weight, strength, chemical resistance, toughness and biocompatibility, the resource is in demand in various industries, providing the ability to quickly produce useful things on a 3D printer. Additive manufacturing of ceramic products allows you to create objects of individual configuration. The technique involves the prompt introduction of design changes and helps to achieve the desired characteristics of a part or a finished item.

Additive manufacturing of ceramic products allows you to create objects of individual configuration. The technique involves the prompt introduction of design changes and helps to achieve the desired characteristics of a part or a finished item.

Printing technologies used

Ceramic 3D printing is done in different ways: paste extrusion, powder sintering or photopolymerization.

But most often ceramic printers work on SLA technology. The method is based on the illumination of ceramic paste with a laser to form three-dimensional objects or prototypes. The construction is done in layers, and each layer is scanned and drawn with a beam according to the digital model. After building the next level, the working platform is lowered to a given layer thickness, a new portion of the paste is leveled, and the process of scanning the next section of the part is performed.

The technique helps to achieve uniform shrinkage during sintering, which guarantees maximum accuracy in the construction of the element.

The Ceramaker 3D printer series is a development of the company that implements the additive technology of layer-by-layer curing of a specialized paste - a composite of a photopolymer substance with ceramic powder. After completion of the model building cycle, the surface is freed from particles of non-polymerized composition and washed in a special solution. Then the object goes through the stage of burning out the photopolymer, which acts as a temporary binder. Next, the final sintering of the workpiece at a high temperature is performed.

Ceramic Printing Materials

3DCeram has developed original formulations that use its ceramic 3D printers. Raw materials are fed evenly, with a given accuracy, which ensures the high quality of the manufactured object and its compliance with strict industrial criteria.

Ceramic resources are neither metallic nor organic. Usually they are molded at room temperature, and acquire special properties during the sintering process. The choice of material for printing a product depends on the conditions in which the parts are to be used.

Usually they are molded at room temperature, and acquire special properties during the sintering process. The choice of material for printing a product depends on the conditions in which the parts are to be used.

3DCeram offers the following options:

Zirconia is a material with excellent mechanical properties that are stable at all temperatures. The composition is characterized by low thermal conductivity and chemical inertness. Products from this resource are hard and wear-resistant.

Alumina is the base material required by the industry. AL203 stands out for its mechanical strength and is a good dielectric.

Silicon nitride - compound resistant to heat and corrosion. The resource is actively used in the manufacture of pumps and valves.

Silicore is a compound used to make blade cores. Porous ceramics with good leaching properties are compatible with various alloys.

Tricalcium phosphate is a biocompatible raw material used for the production of implants;

Hydroxyapatite is a resource in demand in biomedicine for “growing” bone substitutes, since it is characterized by good osseointegration;

Aluminum nitride - electrical insulator with high thermal conductivity, in demand in the electronics industry;

Cordierite is a low thermal expansion ceramic suitable for vacuum applications.

Raw materials are supplied by means of a hopper that is filled before starting the printer. However, it is permissible to fill the device during the operation of the equipment.

Ceramic 3D printer software

The company supplies equipment with open source software that allows the buyer to develop and use their own formulations. The printers support Windows, Linux and OSX operating systems.

Review of 3DCeram

ceramic 3D printers The French engineering company offers interesting solutions for the manufacture of complex ceramic parts for various industries. What can be done with a 3D printer for sale? The possibility of printing finished items and individual elements of ceramics interested jewelers and watchmakers. End products and spare parts are durable, resistant to scratches and chips, hypoallergenic. 3D printing with clay is in demand for creating designer masterpieces, art objects and interior elements. Also, proprietary technology is actively involved in the aerospace and aviation industries, mechanical engineering, and biomedicine.

The Ceramaker printer series is designed to produce detailed and functional elements with consistently high quality.

Popular ceramic printers

Ceramaker 100 is a device for development and prototyping. The printer is easy to operate and uses materials economically. The equipment is equipped with modules of various sizes, which makes it possible to optimize the consumption of paste during printing. Open settings allow you to adapt to personal requirements.

Ceramaker 900 – industrial technology. The device creates models with high surface quality, is used to manufacture functional elements that have the same characteristics as parts created by traditional methods (pressing, casting). It is the only machine on the market capable of producing objects according to the established specifications and criteria of the end user. This multi-component printer is capable of producing both simple structural elements and full-fledged functional devices.