Buy 3d print designs

Buy Professional 3D Printing Models

Our website uses cookies to collect statistical visitor data and track interaction with direct marketing communication / improve our website and improve your browsing experience. Please see our Cookie Notice for more information about cookies, data they collect, who may access them, and your rights. Learn more

Explore 3D Printing Model

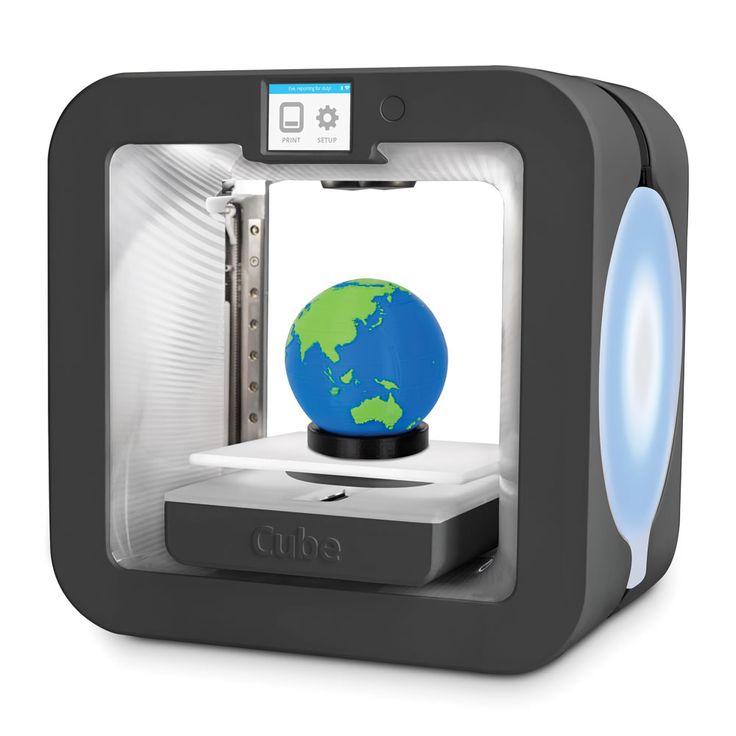

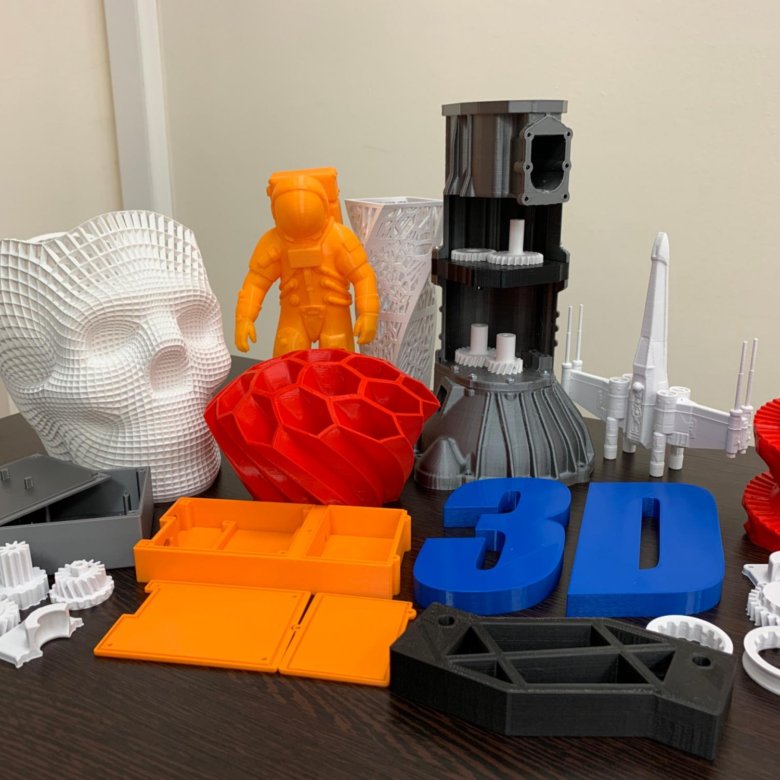

CategoriesProfessional 3D models ready to be printed at home with desktop FDM or industrial SLS 3D printers, available in many industry formats including OBJ, STL, WRL. If you are 3D printing hobbyist, maker, educator or business prototyping by 3D-printing, our home decorations, trendy gadget accessories, eye-catching fashion pieces, unique jewelry, mechanical parts, and variety of miniatures will surely give you an inspiration boost.

Art 3D Printing ModelsThis is where the artistic 3D prints go. Looking for fancy sculpture design recreating classical works and statues of historic personalities, or inspiring figurines, maybe even 3D-printable logos? That is the category.

Beautiful and stylish things that you can wear are found in this category. See if you can find any use for fancy space age footwear, novelty glasses and cosplay accessories found here.

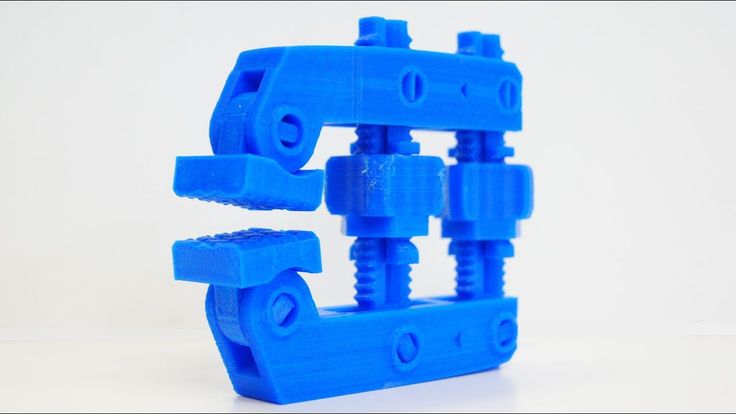

Gadgets 3D Printing ModelsAll iPhone, iPad (and other smart devices) cases can be found in gadget category. From simple 3D add-ons to complex parts and “hacks” for your items, this is the category for the creatives, and lovers of technology.

Games & Toys 3D Printing ModelsGames and toys is the category covering printable 3D alien or monster miniatures, tiny tanks, funky chess pieces, movie character helmets, hobby paraphernalia and accessories. This is the to-go category for all things geeky.

Hobby & DIY 3D Printing ModelsIf you are our next great inventor and want to build your DIY project or get some spare parts for your drone, this is the place to be. Additionally, it features a lot things for people who want to make their own figurines or plastic gun replicas.

Additionally, it features a lot things for people who want to make their own figurines or plastic gun replicas.

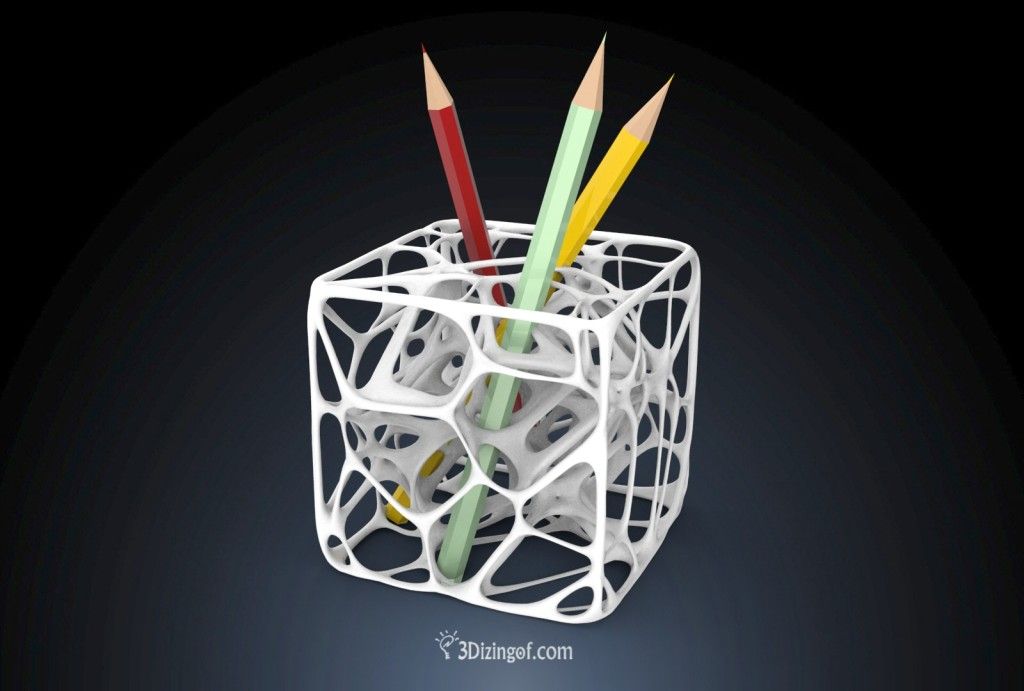

All sorts of knick-knacks can be found here. Lamps, artistic bowls, and all kinds of holders whether you cannot find a right spot for your phone, keep order of toothpicks, pile of pens or jewelry on your desk.

Jewelry 3D Printing ModelsJewelry is where you go to get bracelets and pendants or rings with diamonds. While 3D printers aren’t good enough to make diamonds - yet - you can still print out a metallic ring as a base for your IT geek proposal ring.

Miniatures 3D Printing Models3D printable characters, famous people, landmarks, animals, Male, female, monsters, aliens - it’s all here. Whether you’re printing utility vehicles to put on your table or creating miniatures for your tabletop games, it’s your category.

Browse all models

| 3D Printing Models for Sale

Popular Newly listed Most purchased Price: high to low Price: low to high

tiny

huge

Size of Files: 1324.

51 MB

51 MB Optimized Print Size:

10.2 cm x 55 cm x 15.5 cm

4.02" x 21.65" x 6.1"

(2)

Nautilus Submarine 3D Printing Model | Assembly + Active

type Fiction by Jason Burrows

$34.99

Size of Files: 572.66 MBOptimized Print Size:

5.9 cm x 49 cm x 17 cm

2.32" x 19.29" x 6.69"

(1)

USS Enterprise NCC-1701-E 3D Printing Model | Assembly

type Space Ships by Danny Lee

$34.99

Size of Files: 2160.71 MBOptimized Print Size:

15.2 cm x 15.2 cm x 23 cm

5.98" x 5.98" x 9.06"

(1)

Jinx 3D Printing Figurine | Assembly

type LOL by Danny Gallant

$24. 99

99

Optimized Print Size:

32.2 cm x 804.1 cm x 14.5 cm

12.68" x 316.57" x 5.71"

(3)

Eagle Transporter 3D Printing Model | Assembly + Active

type Fiction by Leo Martel

$34.99

Size of Files: 3157.86 MBOptimized Print Size:

45.2 cm x 41.3 cm x 40.9 cm

17.8" x 16.26" x 16.1"

(1)

Sephiroth 3D Printing Figurine | Assembly

type Anime by Takashi-01

$24.99

Size of Files: 1071.26 MBOptimized Print Size:

19.5 cm x 16.8 cm x 28.2 cm

7.68" x 6.61" x 11.1"

(3)

Cain 3D Printing Model | Assembly + Active

type Villains by Black Wolf

$29. 99

99

Optimized Print Size:

25.7 cm x 27 cm x 17.2 cm

10.12" x 10.63" x 6.77"

(1)

Red Hood vs Joker 3D Printing Figurines in Diorama | Assembly

type DC Comics by Carlos

$24.99

Size of Files: 182.35 MBOptimized Print Size:

22 cm x 19.1 cm x 27.6 cm

8.66" x 7.52" x 10.87"

(4)

Axman-2N 3D Printing Model | Assembly + Active

type Mech Warrior by Maverik

$26.99

Size of Files: 1520.19 MBOptimized Print Size:

17 cm x 17 cm x 37 cm

6.69" x 6.69" x 14.57"

(2)

Shoretrooper 3D Printing Figurine | Assembly

type Space War Online by KcStudio

$24. 99

99

Optimized Print Size:

26.9 cm x 62.8 cm x 21.1 cm

10.59" x 24.72" x 8.31"

(1)

Shuttle Battlestar Galactica 3D Printing Model | Assembly

type Space Ships by Chris Nichols

$26.99

Size of Files: 3425.32 MBOptimized Print Size:

16.5 cm x 10.8 cm x 20.5 cm

6.5" x 4.25" x 8.07"

(3)

Yuffie Kisaragi Standing Posture 3D Printing Figurine | Assembly

type Heroes by Arkey

$24.99

Size of Files: 368.67 MBOptimized Print Size:

18.9 cm x 14 cm x 24.5 cm

7.44" x 5.51" x 9.65"

(2)

Leatherface Bust 3D Printing Figurine | Assembly

type Villains by DP

$12. 99

99

Optimized Print Size:

12.6 cm x 19 cm x 25.5 cm

4.96" x 7.48" x 10.04"

(4)

Galadriel 3D Printing Figurine | Assembly

type LOTR by Valar

$24.99

Size of Files: 1907.4 MBOptimized Print Size:

20.7 cm x 24.9 cm x 28 cm

8.15" x 9.8" x 11.02"

(3)

Crypt Keeper Bust 3D Printing Figurine | Assembly

type Villains by Docik

$19.99

Size of Files: 3118.95 MBOptimized Print Size:

17.9 cm x 47.6 cm x 21.7 cm

7.05" x 18.74" x 8.54"

(3)

Ecto-1 3D Printing Model | Assembly + Active

type Fiction by Mark B

$39. 99

99

Optimized Print Size:

31.6 cm x 35.3 cm x 22.6 cm

12.44" x 13.9" x 8.9"

(4)

Starbug 3D Printing Model | Assembly + Active

type Space Ships by Ariax

$29.99

Size of Files: 1043.89 MBOptimized Print Size:

23.7 cm x 19.7 cm x 26.4 cm

9.33" x 7.76" x 10.39"

(1)

Baby Yoda Thanksgiving 3D Printing Figurine | Assembly

type Space War Online

$24.99

Size of Files: 1407.96 MBOptimized Print Size:

28.7 cm x 38.8 cm x 48.8 cm

11.3" x 15.28" x 19.21"

(4)

Super Battle Droid 3D Printing Model | Assembly + Active

type Space War Online by Rafael3D

$24. 99

99

Optimized Print Size:

23.2 cm x 23.2 cm x 41 cm

9.13" x 9.13" x 16.14"

(4)

Chucky 3D Printing Figurine | Assembly

type Villains by Accio3D

$29.99

Size of Files: 964.17 MBOptimized Print Size:

0.1 cm x 0.1 cm x 0.1 cm

0.04" x 0.04" x 0.04"

(1)

Anycubic Mono 4K 3D Printer + Kevin + Monica

type 3D Printers by Anycubic

$219.00 $338.98

1 2 3 4 5 6 7 8 9 10 Next »

combining architecture, biology and 3D printing — Design on vc.

ru

ru We have designed a 59-meter private house that highlights the features of cellular 3D printing, borrowing the principles of organization in nature.

303 views

SAlab | GYROID house

3D printing – the obvious incredible?

What technologies allow modern buildings to merge as much as possible with the natural environment, giving birth not so much to object architecture as to architectural landscapes? The answer is on the surface: it's 3D printing.

How does this technology differ from traditional building methods and what innovations make it a breakthrough in the construction industry?

First of all, 3D printing solves the most pressing problems in this area: the lack of economical building materials and the reduction of construction time with an increase in its quality. Due to what? Due to the features of additive technologies, which are based on the method of layer-by-layer printing of buildings or building structures using large-scale robots based on a digital model. In other words, the additive (from the English additive - added) production involves the addition of layers of composite materials according to the algorithm specified by the project, which makes it possible to implement the most complex architectural ideas, no longer limited by the imperfection of the usual building technologies.

In other words, the additive (from the English additive - added) production involves the addition of layers of composite materials according to the algorithm specified by the project, which makes it possible to implement the most complex architectural ideas, no longer limited by the imperfection of the usual building technologies.

Both the design and construction process is undergoing a digital transformation. This means a different logic for the transition of a project idea to implementation - file to factory . The digital model, the result of algorithmic design, is already being implemented on the basis of complex calculations, which significantly reduces the time it takes to correct it during the construction process. Both design and construction are getting polished, paperless and customized (from the English to customize - to customize) in connection with the introduction of design amendments and "settings" for a specific consumer directly into the project itself. All design materials arrive at the construction site already in digital form, practically “on a flash drive”, and are read by robots during the construction implementation of the facility, which makes it possible to obtain the final result of additive technologies better, faster and cheaper. In other words, a customized architecture that differs from its typical freeform geometry doesn't beat it on a budget.

Cellular Fabrication Technology

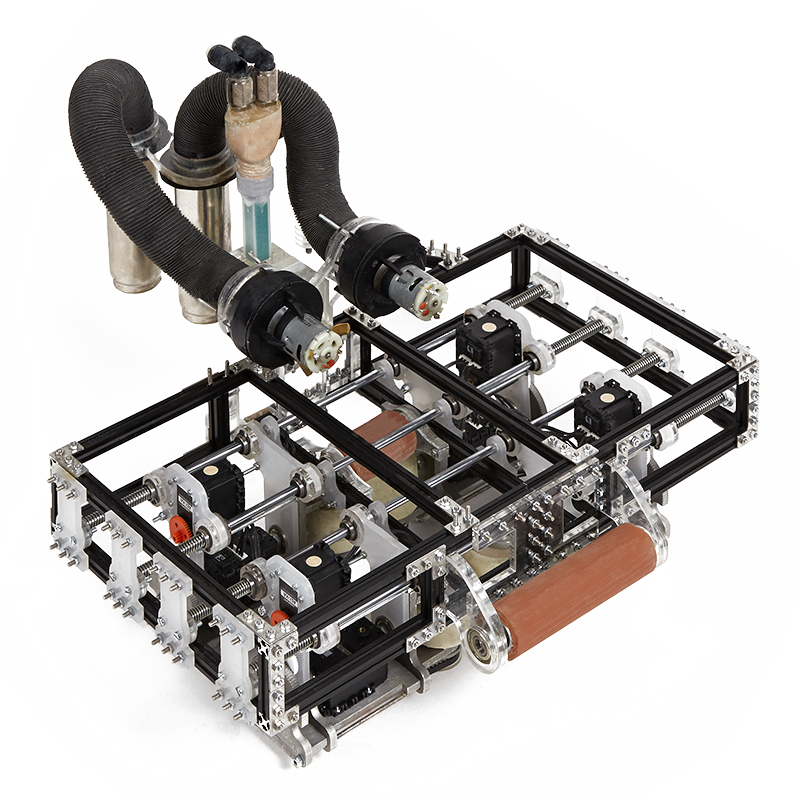

Branch Technology is committed to revolutionizing the architectural environment. Her team of real inventors - architects, designers, engineers, builders, mathematicians - builds large structures from carbon fiber reinforced ABS plastic based on 3D printing. This lightweight material is able to withstand a weight almost a thousand times greater than its own. A feature of the Cellular Fabrication technology that the company uses is the cellular printing method, which greatly facilitates the weight of hollow structures compared to layer-by-layer wall building. Cellular structures represent the supporting frame of the building, interior and exterior finishes can be anything, which allows you to create lightweight and durable hybrid structures. When they are created, the consumption of finishing materials is significantly reduced, which can be as inexpensive as insulating foam and concrete, or can represent a local market for building materials characteristic of the area, such as clay or sand. In this way, a whole host of problems is solved: the lack of materials, the complex logistics of their delivery, the toxicity of their composition, the high cost of their manufacture, etc.

Cellular structures represent the supporting frame of the building, interior and exterior finishes can be anything, which allows you to create lightweight and durable hybrid structures. When they are created, the consumption of finishing materials is significantly reduced, which can be as inexpensive as insulating foam and concrete, or can represent a local market for building materials characteristic of the area, such as clay or sand. In this way, a whole host of problems is solved: the lack of materials, the complex logistics of their delivery, the toxicity of their composition, the high cost of their manufacture, etc.

Cellular Fabrication

Indicative in this respect is the experience of the last Venice Architecture Biennale. The Golden Lion, the main prize of the biennale, went to the creators of the UAE pavilion, built from an alternative building material, which embodies the idea of “future vernacular”. The bricks for the pavilion were made from saline residues from industrial water desalination in the United Arab Emirates. Thus, a material native to the area, moreover, obtained from waste, was evaluated as an environmentally more acceptable replacement for Portland cement, which accounts for 36% of CO2 emissions associated with construction activities. The presentation of the Golden Lion is a sign of preferences of the world architectural community. It should take into account global trends: with such rapid urbanization, it is necessary to build a lot, quickly and inexpensively. But the main thing is diversity, avoiding the mistakes of the past, when the same goals led the world to the monotony of standard buildings.

It was this kind of problem statement that drew our attention to Branch Technology's 2016 Freeform Home Design Challenge for a one-story, single-family home that could be built using the company's patented Cellular Fabrication 3D printing technology. It was decided to test the potential of this method and highlight it with the help of our project.

Gyroid house: a form search

The Gyroid house project we created is a reflection of the SA lab philosophy. Architecture for us is a phenomenon at the intersection of the real and digital worlds, which usually exist in parallel. Not being implemented, our project remained in the digital space of ideas, but, designed to be implemented in line with the latest technologies, it unequivocally looked into the realities of the physical world and could well get along with them. Let's see how?

Architecture for us is a phenomenon at the intersection of the real and digital worlds, which usually exist in parallel. Not being implemented, our project remained in the digital space of ideas, but, designed to be implemented in line with the latest technologies, it unequivocally looked into the realities of the physical world and could well get along with them. Let's see how?

C-Fab - an artificial way to organize cells | GYROID - principle of cell organization in nature

The project involved the construction of a minimal model of human existence - a living cell. Under the terms of the competition, this is a house with an area of up to 60 sq. m. in a given area - rather narrow in its configuration. The design intent had to be realized in 3D printing, which meant more freedom of spatial design, far from being limited by Euclidean geometry. For us, this was the starting point. The search for a complex and expressive form was not originally an end in itself, but it gave us the opportunity to “highlight” the clear advantages of Branch Technology's cellular printing method.

On the allotted area, a conditional contour of a parallelepiped was outlined, within which it was necessary to form a living space that would meet a significant set of requirements formulated algorithmically. One of our ideas was to focus on minimizing the surfaces enclosing the living space. To achieve the goal, the computer was given a variational problem - to find the surface of the smallest area spanned by a given contour so that a hollow space is formed under it that meets the desired parameters. Ideally, this is the surface of a soap film (the result of uniform stress equilibrium). In mathematics, such surfaces are called minimal.

SAlab | GYROID house

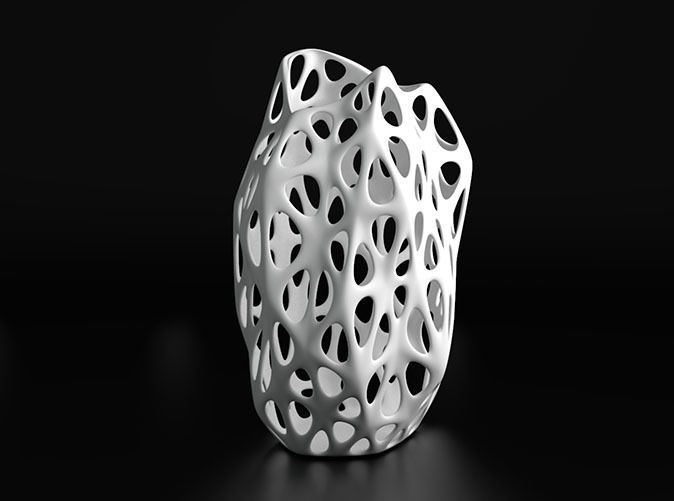

Of particular interest are minimal surfaces that repeat in three dimensions and form cellular structures. The Gyroid surface falls into this category. In nature, this is a way of connecting cells into more complex forms, for example, into the wings of butterflies. And despite the fragility of the butterflies themselves, Gyroid is a very strong mesh structure capable of forming not only their fluttering wings, but also a self-supporting architectural shell of the future building.

Gyroid house: the choice of form

By combining Gyroid surfaces and turning them at different angles, we get an infinite number of variations of architectural shells that form spaces of almost natural origin flowing into each other. Our approach to the choice of form coincided with the declared philosophy of Branch Technology, which seeks to take the logic of natural algorithms as a basis and shift them into construction.

SAlab | GYROID house | Form 9 search pattern0003

How does shape selection work in computational design? In the process of selection from an endless stream of geometric variations of the model that meets the objectively given parameters and the subjective preferences of the architect. In essence, the architectural form is born by chance - as a result of a symbiosis of the artist's creative intuition and the iron logic of a computer.

By “tuning” Gyroid surfaces with Rhino and Grasshopper algorithmic design tools, we changed not only the appearance and shape of objects, but their inner atmosphere and even the behavior of their interiors. The Gyroid fragment we have chosen, which by all criteria is suitable for the organization 59sq.m. living space, will help us to prove it.

The Gyroid fragment we have chosen, which by all criteria is suitable for the organization 59sq.m. living space, will help us to prove it.

Life in a 3D model - challenge or reality?

The original form of the house is a fragment of the Gyroid surface, subsequently optimized using the Galapagos and Ladybug plugins. Based on the received basis, a supporting structure was created. As enclosing structures, a glazing system on a metal frame was proposed. For the exterior of the building, fiberglass panels were supposed, and for the interior, plaster.

SAlab | GYROID house | Light Analysis

The main intrigue in the interior space was the light openings, the location of which was optimized by a computer program in the light design key we set. As a result, we got the effect of "gaps" in the clouds in the interior. The light streams of the Gyroid house enhanced the effect of a free transition from physical to virtual reality, due to the influence of game design images on the residential interior.

SAlab | GYROID house

In physical reality, the usual functional areas are located on an area of 59 squares: a living room, a dining room, a bedroom and a sanitary unit. If necessary, the zones can be interchanged, the interior can be "customized" to the specific requirements of the consumer, which allows free planning and natural fluidity of the living space. Complementing the living cell with identical modules (fragments of the infinite surface of the gyroid), it is possible to increase the area of the house from 59up to 175 square meters.

SAlab | GYROID house | Scheme of building elements and plan at the level of 0.000

SAlab | GYROID house | Module combination diagram

Turning to technology in the process of competitive design, we were convinced by our own experience that architecture - regardless of scale - is able to meet the most unpredictable challenges of the time. Being focused on the environmental efficiency of construction, it is able to build a respectful dialogue with nature, learn from it, fit into its context. The architecture we are working on is fundamentally adaptive. The future, meanwhile, requires flexible, mobile approaches, and in response we create them in the present.

The architecture we are working on is fundamentally adaptive. The future, meanwhile, requires flexible, mobile approaches, and in response we create them in the present.

We write about architecture and technology > https://t.me/SAlab_daily

See the full project >

Generative design - a revolution in 3D printing?

Reading time: ~8 min.

Knowledge base ⇢ Technical side

1

2

3

4

5

6

7,0003

8

+

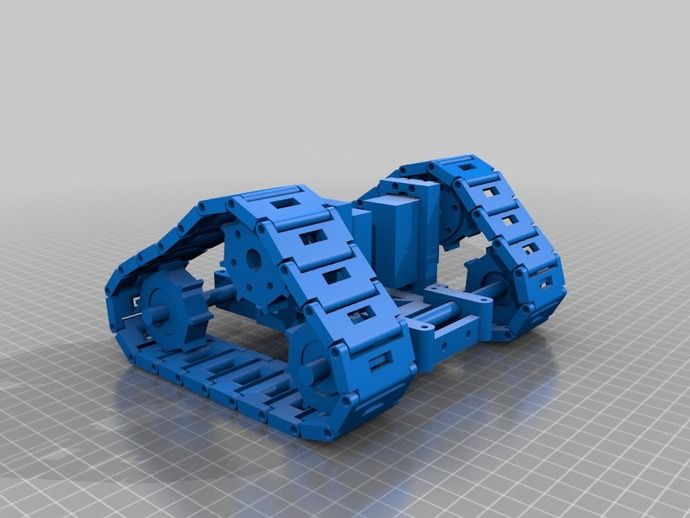

What do you see in this photo? How much weight do you think this design can support? Doesn't inspire confidence, does it?

Generative design is often compared to biological design. Look, it really looks like some absolutely amazing skeleton or interweaving of tree branches.

Real competition with nature!

Wait! What is the difference between topological optimization and generative design?

Topological optimization is a product design method aimed at improving the strength characteristics while significantly reducing the weight of the product. We get one single solution - the best option based on the existing model. Math doesn't lie!

We get one single solution - the best option based on the existing model. Math doesn't lie!

Generative design takes a different approach. The program sets the limiting conditions, the description of the model, and there is a "generation" process, where we get not one single solution, but several. Artificial intelligence chooses what it considers optimal. By studying a huge set of parameters, computers try to identify those that a person is likely to miss due to their inattention during development. It only remains for a person to choose which of the computer developments is the most suitable.

The main impetus for the development of generative design was metal 3D printing. But metal is very expensive. However, science does not stand still, and especially durable composite materials have already been developed that can become a worthy alternative.

Such solutions are more often used in areas where it is important to save every gram: spacecraft, aircraft industry, innovative mechanical engineering. Another related problem is saving expensive materials (complex alloys, rare metals). Generative design approach allows some companies to spend 30-50% less material.

Another related problem is saving expensive materials (complex alloys, rare metals). Generative design approach allows some companies to spend 30-50% less material.

Soft

All this is great, but how to bring it all to life? Is special education needed? What courses do you need to take?

Software for generative design is not yet available on the Russian market. But you can choose from what our Western colleagues offer us.

Do you think robots will take over the world? Already today and very close to you, amazing and completely new items are being created, the designs of which are much easier and more efficient. And the point here is not the genius of the human mind, but the genius of artificial intelligence.

So. Generative design.

Until recently, we knew very, very little about generative design, but those who seek will always find. .. And so we invited Denis Vavilov, Ph.D. knows about generative design in our new webinar. Thanks Denis! ;)

.. And so we invited Denis Vavilov, Ph.D. knows about generative design in our new webinar. Thanks Denis! ;)

1

But wait! Your brain is just fooling you! And we are confident in our words, because artificial intelligence created them all and conducted tests for each of the designs.

This amazing methodology dates back to the 1960s. At that time, there were no technologies that would reduce the metal consumption of the designed products. But science does not stand still, and with the advent of computational modeling, computer technology and finite element methods, a completely new mathematical tool has appeared that allows you to analyze the stress-strain state of the parts themselves. Knowing this state, we can reduce or completely eliminate the material that is less effective. As a result, such an approach as “topological optimization” appeared. This is the mathematical apparatus on which generative design relies.

Solid Edge

Optimization is carried out in several steps, without the need for fine adjustments: load the "blank", specify the holes and places of application of the load, set the required percentage of weight reduction and safety factor. The resulting part can be directly sent to print or finalized with standard Solid Edge tools.

2

NX

Universal complete system for engineering. The part to be optimized is placed in the workspace, others are added to it, which will not be affected by the process, but participate in the interaction. Fasteners and applied loads are specified within the assembly.

3

Autodesk Fusion 360

CAD/CAE/CAM design, engineering and preproduction platform for CNC machines. In the maximum subscription, called Ultimate, the Advanced Simulation module is available. He is responsible for deformation modeling, working with anisotropic materials and topology optimization - Shape optimization.

In the maximum subscription, called Ultimate, the Advanced Simulation module is available. He is responsible for deformation modeling, working with anisotropic materials and topology optimization - Shape optimization.

A huge advantage (and disadvantage at the same time) is that all work takes place in the cloud, so defense companies will have to find other software.

When signing up for a trial version, 300 credits will drop into your account (1 credit = $1). In order to run a generative design calculation in the cloud, you will need 25 credits (read $25), where you will be provided with up to 10 different materials. Farther. To unload the finished part, you need 100 credits.

With 300 credits on your account, you can already upload a maximum of 2 models.

We tried. Liked. The cost of the full version will cost you $450 per year and a separate payment for cloud credits.

The program is simple enough that a beginner in generative design can easily handle it.

4

ANSYS Mechanical

Allows you to simulate the deformation of structures under load, calculate the effects of vibrations and the occurrence of resonances. To carry out automated topological optimization, it is necessary to import a blank model of a part, specify attachment points and load applications, and set boundary conditions, such as a minimum thickness. It is possible to model both traditional and anisotropic materials - composites, 3D printed parts.

5

Altair OptiStruct

Computer technology for topological optimization of designs and development of complex cellular/lattice structures for 3D printing. Included in the Altair HyperWorks software package. OptiStruct allows you to analyze the stress-strain state of lattice structures, analysis for tension-compression, shear, bending, torsion, and evaluate fatigue characteristics. With this program, the engineer can determine the best distribution of material and the most effective zones for building lattice/cell structures. The system itself determines where dense material is needed in the structure, where it is cellular, and where reinforcement can be dispensed with.

With this program, the engineer can determine the best distribution of material and the most effective zones for building lattice/cell structures. The system itself determines where dense material is needed in the structure, where it is cellular, and where reinforcement can be dispensed with.

6

Autodesk Within

A software package designed to assist in the design of objects with a weight-optimized design, creation of lattice structures, strength calculations. Specially for 3D printing.

What to use

A computer is not a person, it does not require inspiration, it just does it and it is better than us. The software itself can be adjusted by setting certain parameters for the structure being created. For example, an engineer may be tasked with building an easy, reliable, and inexpensive option. In turn, the computer will create tens of thousands of options, from which it will choose the only one that meets all the criteria.

In turn, the computer will create tens of thousands of options, from which it will choose the only one that meets all the criteria.

When Airbus engineers needed to reduce the fuel consumption of their aircraft, they decided to reduce the weight of the aircraft by lightening the internal partitions. The generative algorithm proposed a variant of the partition design, which looked like a set of random axes. However, this design met all the requirements: it reduced the weight of individual aircraft modules by up to 45%, while maintaining the strength of the entire system.

Even NASA is involved in this, lightening up their spacecraft for missions to Jupiter and Saturn. Using generative design, Autodesk was able to reduce the weight of the lander's legs by 35%.

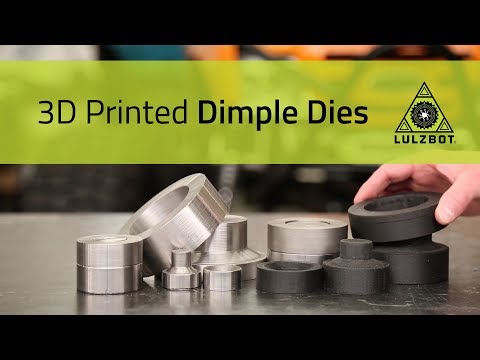

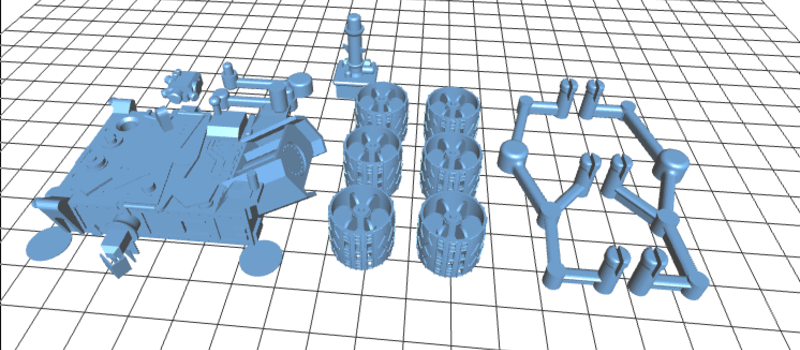

And by tradition... our version of the synthesis of generative design and additive technologies. We decided to test whether the printed racks can withstand speeds of more than 100 km/h.

We printed a (guess what?) car wing strut.

These struts are printed in carbon filled ABS and we'll mount them on the car, attach the wing and accelerate until it falls off! In the best traditions of Imprints)

The real racks are different from what you see in the screenshots, since these calculations were made for aluminum.

Once again, the printed rack is made of Formax material - this is ABS filled with carbon fiber. What is its feature? We asked Dmitry Miller, CEO of REC3D (surprise?)):

This material has two important advantages:

- carbon fiber adds strength to the product

- which reduces its strength. The presence of carbon fiber in the composition reduces the effect of heat shrinkage to almost 0, so the model is stronger than from pure polymers.

This allows you to introduce new tools and technologies into production.

So, we have sorted out the plastic.