How do 3d printed guns work

How 3-D Printed Guns Work

- Eight states announced on Monday that they were suing the Trump administration over giving the public access to blueprints for 3-D printed guns.

- The guns do not have serial numbers, people printing them would not have to undergo background checks, and the weapons would virtually be untraceable.

Concern over the rise of 3-D-printed guns has hit a climax as eight states announced on Monday that they were suing the Trump administration for allowing the public to download blueprints for such products.

The move would allow the public access to working guns that can fire real bullets, potentially including AR-15 semi-automatic assault rifles.

Because the guns can be printed at home, they do not have serial numbers, people printing them would not have to undergo background checks, and the weapons would virtually be untraceable.

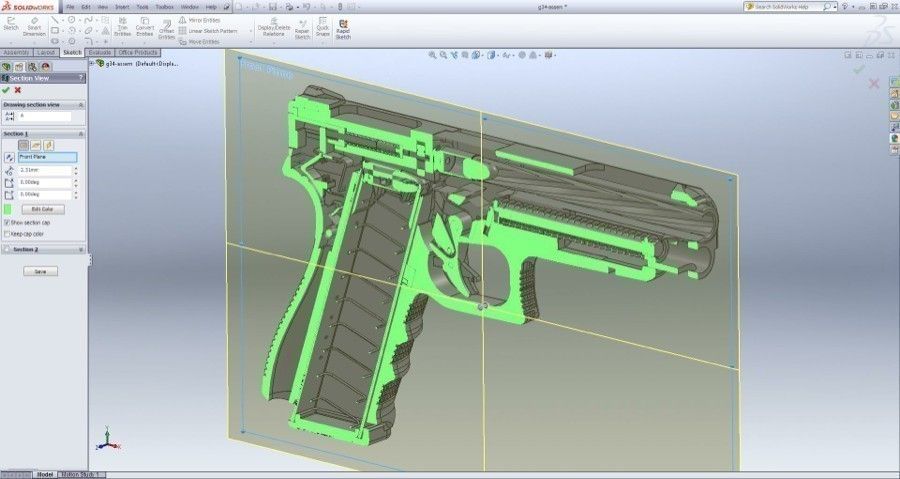

As of Wednesday, Texas-based Defense Distributed will be able to post blueprints for a variety of guns, including its most common, "The Liberator," as well as an AR-15 semi-automatic assault rifle, a Beretta M9 and other firearms.

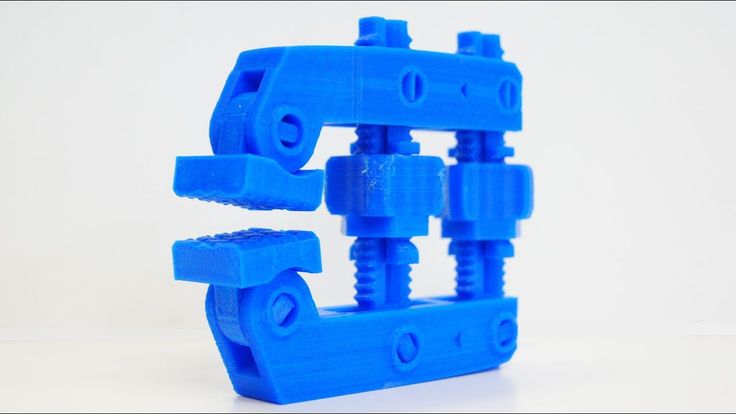

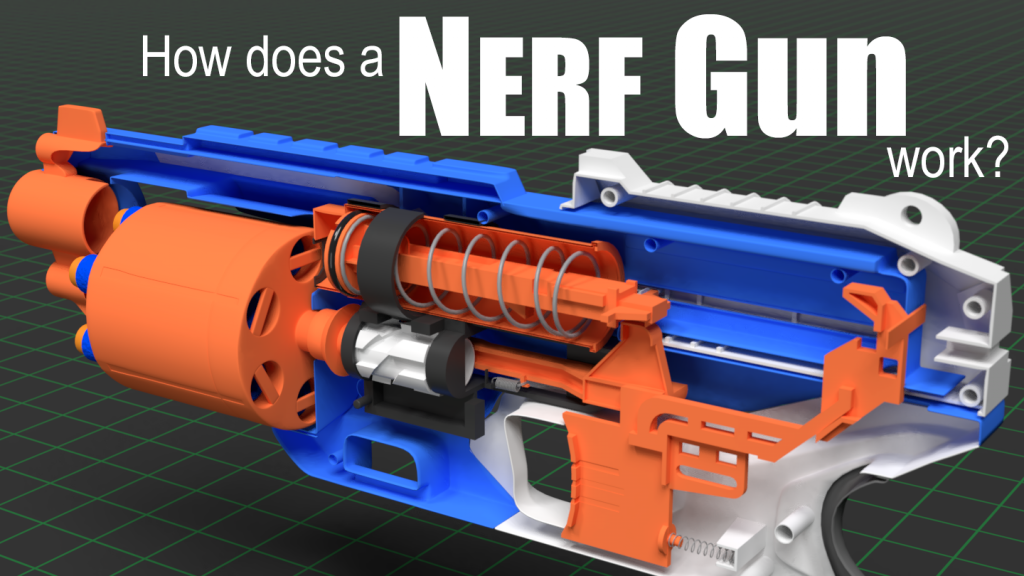

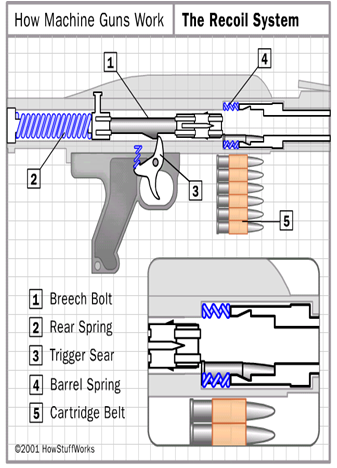

The weapons are printed in pieces through a 3-D printer, and the user then assembles the gun him or herself.

The only metal on the gun is the firing pin and the bullet itself. Some plastic guns can evade metal detectors, with only the small firing pin and a piece of steel put in to comply with the Undetectable Firearms Act, CBC News reported.

Each gun is reusable and fires a different number of rounds, depending on the type of firearm made with the 3-D printer.

3-D-printed guns can be lethal and fire hundreds of rounds, but they aren't durable3-D-printed guns aren't as durable as traditional guns, and many shooting ranges ban them from being used.

Defense Distributed's "The Liberator" has been known to break after one discharge, but founder Cody Wilson has been working to strengthen the gun design.

Cody Wilson, the founder of Defense Distributed, shows off a magazine he 3-D-printed for an assault rifle in 2013. Wilson's company is the subject of Monday's lawsuit. Defense Distributed via YouTube

Wilson's company is the subject of Monday's lawsuit. Defense Distributed via YouTube "There are a few types of guns that can be made on 3-D printers now, although none of them are reliable or have any type of substantial commercial quality that you might expect in a real gun," Wilson told Newsy.

He added: "It doesn't take a ton of knowledge or expertise. It might take a lot of patience."

The Bureau of Alcohol, Tobacco, Firearms and Explosives made a report on The Liberator and other 3-D-printed guns public in 2013, CNN reported.

At the time, ATF Firearms Technology chief Earl Griffith called The Liberator a "lethal weapon."

Officials said a gun made of the plastic ABS-M30, which is often used in toys, fired a .380-caliber round without failing eight times in a row.

The bullet traveled eight to 11 inches into a piece of gelatin made to simulate human soft tissue. A commercially available .380 pistol fired a similar round that traveled 18 inches into the gelatin.

A commercially available .380 pistol fired a similar round that traveled 18 inches into the gelatin.

Another plastic-made gun, however, called the VisiJet, exploded into shards when it was fired, according to the report, analyzed by CNN.

And German tests of 3-D-printed guns show weapons made out of plastic PLA materials could bend or deform after firing.

When a "mostly" 3-D-printed semi-automatic gun was created in 2016, its creator, a middle-aged man from West Virginia who went by the pseudonym Derwood, said he had to use some metal to complete it.

The gun's barrel began to melt after about 18 shots if it wasn't allowed to cool before firing, according to Wired. In total, he said he fired more than 800 rounds.

Blueprints for 3-D-printed firearms could be available soon — without a background check, proof of age, or licenseA government settlement with Defense Distributed last month allowed the Texas-based company to make plans for 3-D printed guns available online, years after it was ordered to cease operation on such blueprints.

Defense Distributed founder Wilson first published downloadable designs for a 3-D printed firearm in 2013, and they were downloaded approximately 100,000 times, according to the Associated Press, before being shut down.

He sued over the shut-down in 2015, and the State Department settled in June.

As early as Wednesday, Wilson's company could be allowed to republish blueprints, allowing Americans to again download untraceable plans for 3-D guns.

A lawsuit filed by several states asking the Trump administration to stop the blueprints from being available says that anyone can become a member of Defense Distributed without a background check, according to US News and Report.

Defense Distributed doesn't to ask for a proof of age or a valid permit or gun license, making it easy to surpass what a customer might go through when buying a gun at a store.

Access to 3-D printers is still a hurdle3-D-printed guns are printed in several plastic parts that the user has to assemble on his or her own. Wilson said it takes about 24 hours to create a pistol.

Wilson said it takes about 24 hours to create a pistol.

Although DIY kits for making at-home guns have long been available online, blueprints would allow easier access to anyone with a 3-D printer.

Gun experts claim, however, that criminals are still unlikely to use the blueprints because 3-D printers are still fairly expensive and the guns deteriorate more quickly than traditional firearms, TIME reported.

Printers needed to make the guns cost anywhere between $5,000 and $600,000.

Although 3-D printing is available in most public libraries, many have banned the machines from being used for unsafe or dangerous reasons, according to WJHG.

Users on Defense Distributed, who only need to pay a fee and include an email, username and password to register, can also share their own designs for guns, magazines and accessories, CNN reported.

What purpose do 3D printed guns really serve?

Stay up to date with everything that is happening in the wonderful world of AM via our LinkedIn community.

Whether you like firearms or not, you might agree that they can serve the purpose of maintaining order when used in the proper way by the proper people. In order to be effective, and in the right hands, firearms need to first and foremost be reliable. If an “operator” has to press the trigger, he or she needs to be sure that the gun will fire. In that sense, any homemade gun, whether it involves 3D printing or not, cannot offer this guarantee, making it de facto useless for any legitimate purpose. Here opinions differ greatly. But even in the case of guns that are 3D printed for fun, or for the pure thrill of going against gun control regulations, where such regulations exist, how functional are 3D printed guns that are entirely or partially made of plastics?

A recent episode made the headlines begging exactly that question. According to a story that appeared on Click2Houston, social media users sounded off after a person allegedly received more than $3,000 for turning in “ghost guns”, including several fully 3D printed ones, at a gun buyback program hosted by Houston and Harris County officials. The 3D printed guns were all considered to be non-functional and received the minimum $50 rate which multiplied by more than 60 units, amounted to over $3,000. Now the question arises once again: can 3D printed guns even be considered to be functional at all?

The 3D printed guns were all considered to be non-functional and received the minimum $50 rate which multiplied by more than 60 units, amounted to over $3,000. Now the question arises once again: can 3D printed guns even be considered to be functional at all?

This writer has previously argued that the debate around 3D printed guns serves little purpose other than creating fear and paranoia around a new technology that has many other uses. We think that is still the case but, in light of more evidence that has emerged, it may not be entirely useless, especially in terms of understanding what parts of guns can actually be 3D printed and why. It is in fact possible to 3D print some parts of guns using low-cost home 3D printers and affordable materials. While certainly able to fire several (even hundreds of) shots, these homemade devices appear to be far from reliable. they also still require a high amount of skills and regulated metal parts to actually work. A fully 3D printed plastic gun is very unlikely to ever function proficiently. While there are many degrees to which 3D printing can be implemented in a gun, the fact remains that any homemade firearm cannot be compared to an industrially manufactured one.

While there are many degrees to which 3D printing can be implemented in a gun, the fact remains that any homemade firearm cannot be compared to an industrially manufactured one.

Some questions should be asked

The “no questions asked” One Safe Houston program provided gift cards valued between $50 and $200, depending on the condition and type of firearm, to those who turned in the weapons. All guns were to be unloaded prior to arriving on-site, officials said.

According to the original Houston Chronicle story, authorities collected a box of ghost guns during the buyback event held Saturday at Wheeler Avenue Baptist Church. A social media user, @ModeratorGeorge, posted the amount received was more than $3,000. An image published on social media, showed several of these to be 3D printed guns made entirely out of plastic. The irony of it all is that, according to the post, they were all bought back as non-functional.

The post reads, “Hey so we talked with the gentleman who sold these back they bought them back as non-functional for 50$ each [SIC] with 63 sold back. So 3150$ [SIC] for an investment of 6-12$ [SIC] per Harlot and Cabfare.” And, we may add, a few more dozen dollars in filament and machine time. Some commenters began to make jokes, saying the city was seemingly outsmarted by accepting the homemade firearms, which were made for less than what they were returned for, but city officials said getting all unwanted weapons off the streets was the goal.

So, how real were those guns?

Since our coverage of 3D printing at Beretta, one of the leaders in the global firearms market, 3dpbm received reports and comments pointing to user communities of 3D printed gun enthusiasts 3D printing different test models of semiautomatic and even automatic guns, based on designs that are freely available online.

The very first 3D printed gun model, the Liberator by Cody Wilson’s Defense Distributed, dates back almost a decade and it is still popular today even if it can hardly be described as reliable or even functional. Many of the 3D printed guns collected by Houston officials were models of the Liberator but today’s gun 3D printing communities use more powerful firearms. “Hobbyists have been printing functional firearms for years now,” said one reader comment, “and not just wimpy, one-time use, political stunts either. These are nearly fully 3D printed guns, rifles, pistols, and submachine guns. They can be built to be robust and reliable.” However, the reader goes on to admit that “they are not very easy to print and often require fine-tuning of the slicer and high-strength PLA or in rare cases Nylon/CF.”

Many of the 3D printed guns collected by Houston officials were models of the Liberator but today’s gun 3D printing communities use more powerful firearms. “Hobbyists have been printing functional firearms for years now,” said one reader comment, “and not just wimpy, one-time use, political stunts either. These are nearly fully 3D printed guns, rifles, pistols, and submachine guns. They can be built to be robust and reliable.” However, the reader goes on to admit that “they are not very easy to print and often require fine-tuning of the slicer and high-strength PLA or in rare cases Nylon/CF.”

Some examples of the free gun 3D models can be found on collaborative communities on Reddit and videos of guns being fired are available on YouTube channels. From the videos, it appears fairly clear that these are relatively rudimentary guns and that, as the author of the comment clarified, “the long-term reliability is almost yet to be completely understood as many designs have only been available for a relatively short period of time. ”

”

According to another comment, “one of the most common filaments used to print guns is PLA+ from ESUN. this is a stronger PLA with a slightly different composition. It prints at a higher temperature and has the ability to be annealed […] Usually, the guns fail after a certain round count or how many bullets have been fired from the gun. This is often inconsistent and relies on factors such as print quality, build quality, type of ammo fired, design, and environment.

“Most good designs printed to spec can last anywhere from 1000-5000 rounds without major issues. Nylon/CF are still pretty new to the gun community so we don’t have enough data to really get an idea of longevity for those. We do know it is much stronger, just not sure how that applies to age/round count.”

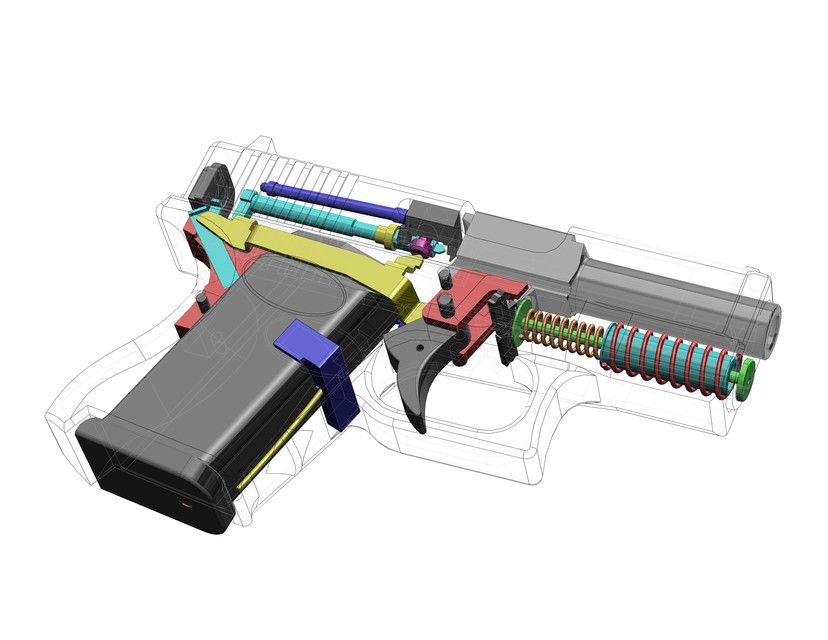

One of the key issues, however, is that a fully 3D printed, functional and reliable plastic gun is implausible, if not outright impossible. Metal is a requirement for the barrel and other parts that ensure the gun does not explode in the user’s hand when fired. The barrel of a gun needs to have detailed and specific features that ensure the bullet exits in a straight line. Firing a few (or even several) random shots is not impossible (with a 3D printed gun as with any other rudimentary homemade firearm), but repeatedly and reliably firing shots in a time of need seems to be a very different matter.

The barrel of a gun needs to have detailed and specific features that ensure the bullet exits in a straight line. Firing a few (or even several) random shots is not impossible (with a 3D printed gun as with any other rudimentary homemade firearm), but repeatedly and reliably firing shots in a time of need seems to be a very different matter.

FGC

Most 3D printed guns community members agree that “the use of metal parts in 3D printed designs is essentially required. All designs use metal parts to some extent. In some models, this may be as little as just a few screws, a tube, and a U.S. 10-cent coin whereas other designs require full kits designed for a given firearm. Usually designs that are built to be accessible to those who live in areas where guns are illegal, and purpose-built parts or parts kits are not legally source-able (or economically not feasible), are made from easy-to-get, legal, simple parts that would be impossible to ban (for example, you can’t ban a pipe that plumbers use every day just because it can also be used in guns). These designs, such as for example the FGC-9 model are actually aimed at lessening the effectiveness of gun control.

These designs, such as for example the FGC-9 model are actually aimed at lessening the effectiveness of gun control.

The FGC-9 was designed and built in the EU specifically because guns are hard to get there. It has (reportedly) been used to fight back against the oppressive government in Myanmar (Burma). However, its effectiveness has not been independently verified. In fact, at least one YouTube video shows the gun melting during use.

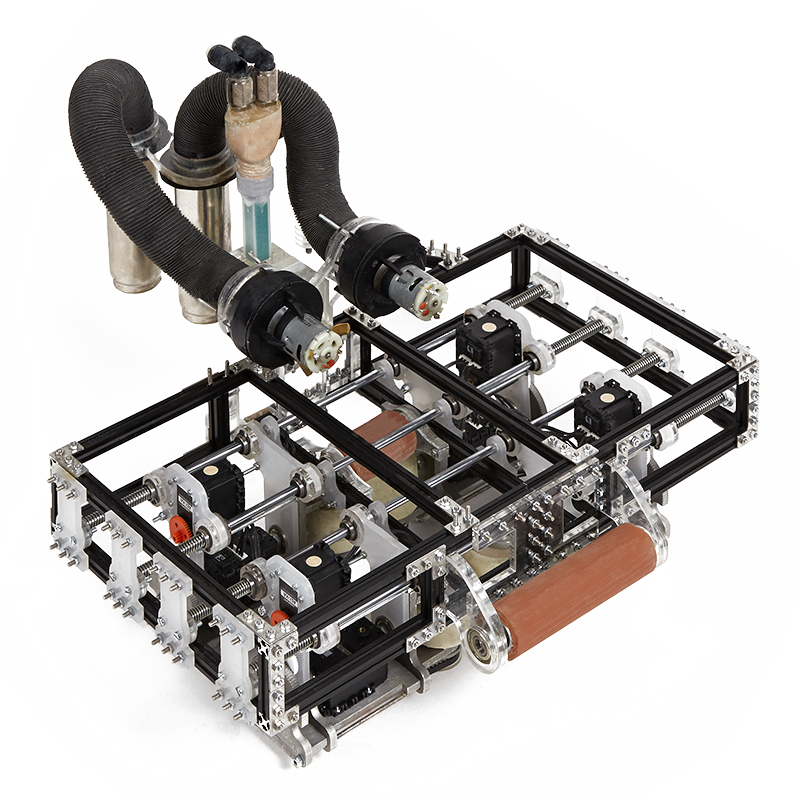

The upper and lower receivers of the FGC-9 are fully 3D printed, as are the pistol grip and stock. The structure of the magazine, based on the Glock magazine, can also be printed. For the MkI, an AR-15 or modified airsoft trigger system is needed for the fire control. In the MkII release, the developers released a package to 3D print the AR-15 trigger. The barrel can be rifled polygonally through electrochemical machining. The tooling cost for a completed FGC-9, including the price of the printer, is estimated to be about $500 (with electrochemical machining equipment. It can take an expert user between 1.5 to 2 weeks to build.

It can take an expert user between 1.5 to 2 weeks to build.

Fun in the gun

Now, if we shift our attention to those who build these guns out of entertainment as opposed to necessity, we see a lot more designs with purpose-built gun parts and parts kits. These would be the more popular AR-15 builds and Glock builds. The only required 3D printed parts in these builds are the receivers (which is the only part the U.S, government regulates). Some examples include the scorpion Evo, Mac-10/11, tac daddy. Despite the ability to print other required parts for the guns to function, in these cases it is easier, cheaper, safer, and more common to use off-the-shelf parts.

There are also hybrid designs that use generic metal parts and more 3D printed parts. These parts can be sourced easily using hardware supply stores online and online gun parts stores for the purpose-built gun parts. Many parts have to be shaped by hand and instructions are generally provided alongside the 3D printed files.

According to a user comment, “about 25% of the community designs, prints and contributes purely for going against gun control. Another 25% of the community is purely there for the sport and fun of it and taking it like a hobby and stretching the limits of 3D printing. Then I’d say the remaining 50% is somewhere in the middle where they have varying feelings about each side.”

But the bottom line, this user agrees, is that “[3D printing] guns still take time, knowledge, and trial and error just like gunsmithing with metal guns. You cannot just download a gun and print it in a few hours and go use it right away. It often takes days of printing (100% infill for strength), hours of assembly, and hours of tuning. It is not practical for the majority of criminals to use 3D printed weaponry hence it’s rare to see it used for committing crimes today.”

Chasing ghosts

Back to the Houston buyback, it should be noted that the issue is relative to all ghost guns, not just 3D printed ones. Ghost guns are privately-made firearms without serial numbers. Generally, firearms manufactured by licensed companies are required to have serial numbers that allow officials to trace the gun back to the manufacturer, the firearms dealer and the original purchaser. Purchases of kits or individual parts do not require a background check, meaning they can essentially be bought by anyone, including children. Some ghost guns can be fabricated using kits and parts purchased online in as little as 30 minutes.

Ghost guns are privately-made firearms without serial numbers. Generally, firearms manufactured by licensed companies are required to have serial numbers that allow officials to trace the gun back to the manufacturer, the firearms dealer and the original purchaser. Purchases of kits or individual parts do not require a background check, meaning they can essentially be bought by anyone, including children. Some ghost guns can be fabricated using kits and parts purchased online in as little as 30 minutes.

The mayor did acknowledge receipt of the weapons, noting that, in the future, more guidelines may be put in place. “One of our primary goals in this gun buyback program and any future event is to establish a safe and secure environment for citizens to turn in unwanted guns. As a part of my One Safe Houston initiative, this is a major component that allows the community to proactively assist us in getting unwanted guns off the street that could find their way into the hands of those committing violent crimes.

“The community response was robust and we also learned that in future gun buybacks, we will need to establish some guidelines regarding Privately Manufactured Firearms (more commonly referred to as Ghost Guns or PMFs). These firearms can come in many styles and configurations and thus, in the future, we will communicate well in advance if PMFs will be accepted during the buyback program. This program was not designed to establish a place for PMFs to be profitable but rather to get unwanted firearms off the streets of Houston that could become crime guns.”

3D printed weapons: myth or reality?

Photo: Scott Olson / Getty Images

Is it possible to create a pistol, submarine or grenade launcher using 3D printing and without legal consequences? logos on a 3D printer is gradually entering the industrial circulation. Many are wondering what the potential of this technology is. In September 2020, an underground workshop was found in Spain with two 3D printers, an exact copy of an assault rifle, and parts of other weapons. The trial in this case was classified as “secret” for several months, and the incident became known in early April 2021. Do 3D printers really allow you to create weapons that can be used in practice, or are they just plastic models?

The trial in this case was classified as “secret” for several months, and the incident became known in early April 2021. Do 3D printers really allow you to create weapons that can be used in practice, or are they just plastic models?

A real weapon or a plastic toy

Alexander Golovin, a 3D printing engineer, said that the materials used in printers are not engineering materials. They are unlikely to hold the structure in the case of the production of weapons or other heavy items. The maximum that 3D printers are capable of so far is printing key rings, gifts and logos. Of course, you can also print a gun, but functionally it will not differ in any way from a children's plastic toy and it will not work to shoot from it.

The thing is that the material for a 3D printer is fragile and brittle. To create weapons, you need metal parts that could support the main warhead: the receiver, the barrel itself and the bolt. But you should not do this: for a fake design, you can get a real term.

Is it profitable to print weapons

Printed weapons are unlikely to pay off, and their production will take a long time. 3D printing of weapons on a metal printer will cost about ₽100 thousand. Meanwhile, a rifle in a store can be bought for ₽15 thousand. Of course, you will need to spend money on training and a safe, but it will still come out cheaper.

Even on the black market, the cost of such weapons is much less than the cost of entering the metal printing industry. What's more, it's illegal, so the chance of a 3D weapon maker getting caught increases exponentially.

News about the successful 3D printing of weapons: fact and fiction?

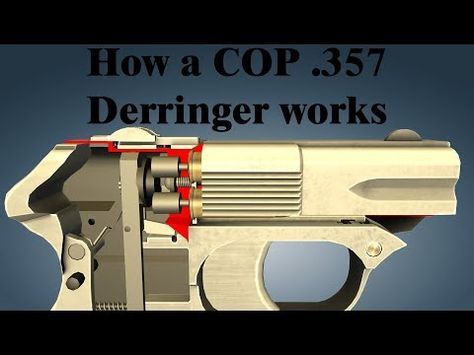

Back in 2013, Solid Concepts printed the Colt 1911 metal pistol. However, this news raises many questions. The classic "colt" has a rifled barrel - it is impossible to print one. Plus, the model requires grinding and processing.

The news that the US Army has built a 3D grenade launcher is a little embellished. It is quite possible to print a model of a grenade launcher, because this weapon is a pipe - it does not matter what it is made of. But it is unlikely that a 3D printer will be able to print explosives or projectiles. Even if this succeeds, when used, the plastic case will scatter in different directions.

It is quite possible to print a model of a grenade launcher, because this weapon is a pipe - it does not matter what it is made of. But it is unlikely that a 3D printer will be able to print explosives or projectiles. Even if this succeeds, when used, the plastic case will scatter in different directions.

Another 3D printing experiment belongs to the US Navy. They printed a submarine. Alexander explained that, most likely, only some part of the submarine was created - it is impossible to restore it completely without aluminum. The printed boat has a number of limitations related to the strength of the material and the loads it can take. Moreover, it is not known how well such a submarine will be able to dive into the water.

The editors of RBC Trends reminds that the development, production and storage of weapons and their main parts are subject to licensing in accordance with the Russian legislation on licensing certain types of activities. Illegal manufacture, alteration or repair of firearms and illegal manufacture of ammunition are criminal acts .

Weapons and 3D printing: nothing is impossible

In recent years, 3D printing has reached a qualitatively new level in its development. The equipment, which was initially positioned as purely industrial, smoothly migrated to the desktop for ordinary users. Today, a desktop 3D printer can handle complex mechanical prototyping with ease. In addition to flower pots and jewelry, modern additive printers make it possible to produce designer shoes, engineering tools, and even quadcopters at home.

Use our services

It was only a matter of time before 3D printed weapons. It has now become available to everyone. You can talk a lot about how dangerous it is that anyone, armed with an inexpensive FDM printer and a spool of plastic filament, can print military firearms in a matter of hours. We will leave this topic to be eaten up by journalists, while we ourselves will focus on the achievements of additive technologies.

Liberator

It is believed to be the first 3D printed firearm. Compact pistol, for which you will need cartridges of 9x17 millimeters (US marking). Most of the structure is created using additive technology. In this case, the instructions can be found in the public domain. It was posted by the author of the product, Cody Wilson.

Compact pistol, for which you will need cartridges of 9x17 millimeters (US marking). Most of the structure is created using additive technology. In this case, the instructions can be found in the public domain. It was posted by the author of the product, Cody Wilson.

The original pistol could only fire one shot. After that, the weapon became unusable. During the tests, it was found that Liberator, alas, gives a lot of misfires (almost half the time).

The updated version of the Lulz Liberator is free from the above disadvantages. It is characterized by an increased margin of safety (up to 8 shots).

Сolt M1911

3 years ago Solid Сoncepts presented to the world community one more model of quite effective 3D printed weapon. The main difference between the Solt M1911 and the Liberator was that it looked more like a conventional firearm. From the name it is clear that the developers used the original Colt M19 model as the basis11.

From the name it is clear that the developers used the original Colt M19 model as the basis11.

A 3D printed version of the pistol was made from Inconel 625. It is a chromium/nickel/molybdenum metal alloy. Thanks to this, about 2000 shots can be fired from the weapon with a minimum number of misfires. The model is characterized by a high level of operational safety.

Feinstein for the AR-15 and AK-47

Defense Distributed, the company that made the Liberator didn't stop there. She set about creating functional horns for the Kalashnov and R-15 automatic weapons. Feinstein showed itself perfectly in fire tests.

New rifle horns feature a smooth texture and light weight. True, due to the relatively high cost, it is not yet possible to launch mass production of these products.

The design of such elements is the first step towards the development of mass production of 3D weapons, including automatic ones.

Michael Gaslick and his experiments

This American designer managed to quite successfully print several parts for the AR-15 self-loading rifle on a regular Stretasus:

- frame;

- stock;

- lower receiver.

The use of such elements made it possible to turn the submachine gun into an ordinary pistol. If the legislature did not restrict the activities of makers in this direction, Michael would have been able to make a full-fledged rifle.

Shutu-MP1

An interesting example of a 3D printed weapon was posted on YouTube. A certain "derwoodvw" made a video in which tests were carried out on this firearm. It looks like a mini pistol / machine gun, although, apparently, the weapon does not have an automatic fire mode.

Almost all parts of the product were printed using additive technology. Only 5% are original items:

- springs;

- bolts;

- barrel.

Of course, they could also be created on a 3D printer. But then the safety of the operation of weapons would be a big question. Deformation of the pistol/machine gun occurs after the 18th shot.

But then the safety of the operation of weapons would be a big question. Deformation of the pistol/machine gun occurs after the 18th shot.

Despite the functionality of the Shutu-MP1, its author does not want to publish instructions for its manufacture on the net.

Parts from Stankoprom

The printing of weapons, as it turned out, is a priority area for Russia as well. Domestic holding "Stankoprom", for example, launched the printing of parts for machine guns / pistols. The company wants to establish close cooperation with the TsNIItochmash and Kalashnikov concerns.

For this, specialists are already working on the production of elements from metal powder. Also considered are options for the production of products from polymer consumables. It is planned that the details will be used as testing of certain design solutions.