First robotics 3d printer

High School Teams Use 3D Printing for Custom Robotics Parts

Guest Blog from the Iron Maidens Team, Apple Valley High School, Apple Valley Minnesota

Iron Maidens from Apple Valley, Minnesota, the young and very talented winners of the competition, in a victory pose.Iron Maidens from Apple Valley, Minnesota, the young and very talented winners of the competition, in a victory pose.

FIRST Tech Challenge (FTC) robotics teams love 3D printed parts! From gears to treads, from wheels to phone mounts, from sprockets to strain relief, the FTC 2016 World Championship was full of colorful 3D printed parts. Simply walking down the aisles of the pits, we were hard-pressed to find a team that didn’t utilize this exciting technology in some way. Most teams use Stratasys 3D printers, we noted, including many MakerBots. Students were eager to speak with us about their 3D printed components, and we learned about many unique design elements made possible thanks to Stratasys 3D Printers.

On our World Championship robot, we used a large variety of 3D printed parts, including a sprocket, sensor mounts, strain relief, a wedge, a spool and a phone mount. We have found that Stratasys 3D printers are incredibly helpful in creating parts when nothing that fits our needs exists. Having access to a 3D printer allowed the team to visually see what they needed to fix and what they could leave “as-is.” We personally enjoy our Stratasys MakerBot Replicator 3D Printer because of its user-friendly interface; it gives us the power to create nearly anything.

Download your free 3D Printing Learning Module, developed by experienced instructors

When taking a quick glance over the lineup of robots present at the World Championship, anyone’s eye would immediately be caught by the robot designed and built by the Blockheads, FTC team 7117. Their rainbow-colored creation was almost entirely 3D printed, from the treads to the debris collector. By the team’s last count, their robot had more than 80 3D printed parts!

Although FTC team 5070 created the larger items above, FTC team 5890, E-lemon-ators, were able to create smaller parts that were more to their liking. Whether big or small, Stratasys was able to play a huge part in these amazing robots.

Whether big or small, Stratasys was able to play a huge part in these amazing robots.

As noted by the Philobots, FTC team 9048, 3D printing is very useful in creating custom parts. Teams often encounter problems that they can only solve with a “made to order” part. 3D printing is very useful when this sort of situation arises, and makes things a lot less stressful when changes need to be made. The Philobots followed this philosophy when creating their delivery and transport tube design, which would then take on a physical form thanks to a Stratasys 3D Printer.

Sign up for a free webinar on Project-based Learning, presented by an instructor who taught a successful 3D printing course

Like many other parts, the wheels -- and tape measures, specifically -- were worked on many times, until all flaws were corrected. FTC team 5064 explains just how great it was to be able to utilize the engineering and design process. Like many other parts, the wheels -- and tape measures, specifically -- were worked on many times, until all flaws were corrected. FTC team 5064 explains just how great it was to be able to utilize the engineering and design process.

FTC team 5064 explains just how great it was to be able to utilize the engineering and design process.

Another key benefit of 3D printing is that a team can redesign a part as many times as needed. This makes trial and error a lot easier for the team. FTC team Erebor, 7486, revised their tape measure device more than a dozen times. FTC team 5064, Aperture Science, proved this as well with many iterations of their wheels and tape measure device. Using the engineering design process, these teams were able to quickly work out flaws in their custom parts and test working prototypes one right after the other.

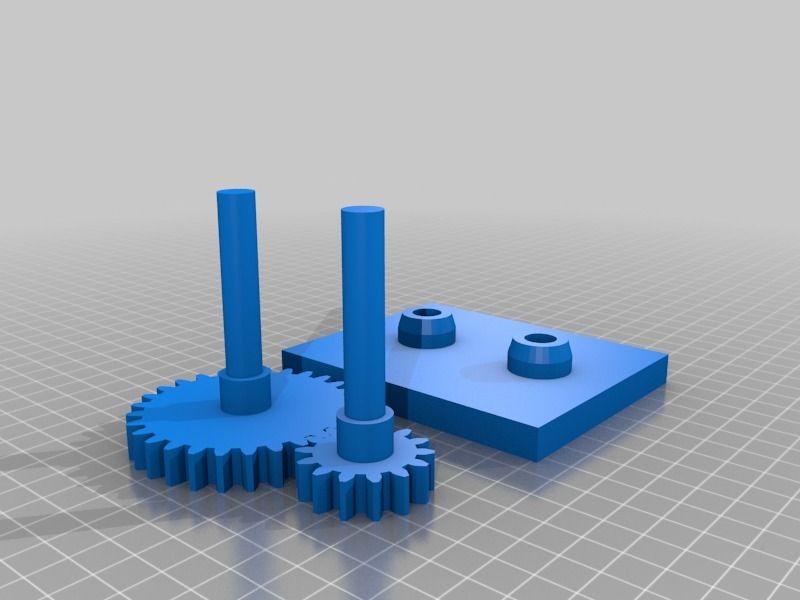

Some teams designed many 3D printed parts, such as NUTS (FTC team 5070) while others like FTC team 5890, the E-lemon-ators, designed less. NUTS used their MakerBot to create brackets, a device to push a button, gears and sprockets. The E-lemon-ators 3D printed small items, such as gears. Whether the part was large or small, both teams greatly appreciated their Stratasys 3D Printers.

There is no doubt about the impact that Stratasys 3D printers have had on FIRST Tech Challenge robotics teams. They allow for unique iterations and the ability to quickly test new solutions. We leave you with one final message: thank you, Stratasys!

-- Iron Maidens, FTC Team 9205

For more information on Stratasys 3D printers or their application in robotics education or competition contact a local reseller or visit www.stratasys.com/education.

FIRST Robotics Competition and 3D Printing in the Classroom: How They're Changing Education

3D printing and the FIRST Robotics Competition are changing the way students learn in school. 3D printing is making it possible for students to create objects they could never have before, while the FIRST Robotics Competition is teaching students teamwork and problem-solving skills. These two technologies are helping to prepare students for the future!

Background: The FIRST Robotics Competition (FRC) is an international high school robotics competition. Each year, teams of high school students, coaches, and mentors work during a six-week period to build a robot capable of competing a given challenge specific to the current year. The robot can only weigh up to 125 pounds.

Each year, teams of high school students, coaches, and mentors work during a six-week period to build a robot capable of competing a given challenge specific to the current year. The robot can only weigh up to 125 pounds.

Under strict rules, limited time and resources, teams of students are challenged to:

- Raise funds,

- Design a team “brand,”

- Hone teamwork skills, and

- Build and program industrial-size robots to play a difficult field game against like-minded competitors

High school students are able to partake in a similar experience to an actual engineer, learning how to fabricate a virtual, 3-d model. Volunteer mentors lend their time and talents to guide their team. The season ends with an exciting FIRST Championship tournament.

The FIRST Robotics Competition stages short games for multiple robots to take part in. The students remotely control the robots in competition rounds on the field.

Recently, we caught up with Dee Clark, a teacher, program coordinator, and engineer-mentor for the FRC Team 7407, the “Wired Boars. ” 7407 is the robotics team at Choate Rosemary Hall high school in Wallingford, Connecticut.

” 7407 is the robotics team at Choate Rosemary Hall high school in Wallingford, Connecticut.

The Wired Boars have been competing in the FIRST Robotics Competition for 4 seasons, and have participated in a total of 12 official events. Recently, the Wired Boars became the District Event Winners in the New England District competition. The team had an impressive season with a record of 42-10-0 (W-L-T) at their 3 official events (this includes a Qualification record of 29 – 5 – 0 (W-L-T) and a Playoff record of 13 – 5! The Wired Boars also took home several notable awards: Innovation in Control Award, Engineering Inspiration Award, and the FIRST Dean’s List Finalist Award!

Interview:

We asked Ms. Clark to shed some light on how the Wired Boars utilize 3D Printing technology in the classroom, and here is an excerpt from our interview:

1. How long have you been teaching and what is your background?

I have been mentoring students in FIRST Robotics for 10 years now, and have been professionally teaching for 2 years.

I was on an FRC Team in high school and my experience on the team inspired me to study STEM after high school. I attended Worcester Polytechnic Institute and received by bachelor’s degree in Environmental Engineering. From there I worked in the private sector for a consulting firm as a Water & Wastewater Engineer, as well as the public sector in Drinking Water Regulation. In 2020, I made the switch to teaching and taught the Vocational Engineering Shop class at Minuteman HS in Lexington, MA. I was then recruited to Choate as a Robotics and Mathematics teacher, and I am very happy here!

2. What do you like about the FIRST program?

There are so many incredible aspects to the FIRST program. One of the major ones I like is how hands-on and real-world the program is. It truly breaks down the classic classroom walls and invites students to learn in a project-based and hands-on manner. Students develop incredible passion and enthusiasm for the program, and this leads to them accomplishing some incredible feats along the way.

I love that any student can be a part of it and truly have their life changed for the better, whether they decide to pursue STEM after high school. There is no better way to learn real-world engineering skills than within FIRST!

3. Can you tell us about a particular part(s) that are 3D printed on FRC 7407 Robot?

3D printing is one of our main manufacturing techniques on FRC7407, and we were able to print many parts on the Airwolf EVO 22 machine. One part was a bracket for holding air tanks for our pneumatic system. We were running close to the weight limit and needed a lightweight solution, that could also have an irregular shape to fit within our robot’s frame perimeter. 3D printing this piece made the most sense and allowed us to save a lot of weight by using ABS filament instead of polycarbonate or aluminum sheet. The speed of the EVO 22 allowed us to iterate this design quickly as well, and take it from start to finish in a little over a day.

4. We have heard that your curriculum is a little different. Do you hit the ground running by teaching hands-on fabrication?

We have heard that your curriculum is a little different. Do you hit the ground running by teaching hands-on fabrication?

I take a very project-based learning approach with my curriculum. As educators learn more about neurodivergence in students and how to best meet the needs of all types of learners, it has become clear that classic STEM classes do not meet the needs of many students. There is a certain anxiety or fear that can develop as these concepts can be difficult to master, and the more negative experiences a student has in STEM, the worse the anxiety will become. By giving students long-term projects that teach core skills along the way, they are given the space to find methods that work for them, as well as room to be creative with their work. In the fall students in my CS450 course – Robotic Design & Fabrication – learned Computer Aided Design (CAD), CNC fabrication, 3D printing and a myriad of other mechanical concepts via a mechanism design project. They were challenged with making a sub-mechanism from an old FRC game over the course of the term, as well as produce a technical engineering report and design poster.

5. What CAD software are you using in the classroom?

We are using Onshape in the classroom.

6. We see that you won a “Rookie of the Year” in 2019 so you are relatively new to the scene. What words of advice can you other give other teachers that are considering starting an FRC team?

That Rookie Award was actually a part of the second FRC team I started after college! In 2016 I co-founded FRC 6328 out of Littleton, MA, and in 2017 FRC6328 won Rookie Allstar at New England District Championship. When I made the change to teaching, Minuteman did not have an FRC Team and was eager to bring FIRST into the school. Despite facing many challenges that the pandemic brought, we were still able to create an FRC robot from scratch and bring home the Rookie Game Changer Award! Starting teams is a massive undertaking, and I highly recommend reaching out to FIRST alumni to help get the team off the ground. FIRST alumni can be incredible mentors as they know what it was like being a student on an FRC Team.

The role a teacher plays in a team is critical, as they are the subject matter expert in how to get the kids to learn. It is key to build a strong relationship with STEM industry experts who may be mentoring the team and teachers, where you work together to figure out the best ways to teach the students.

We would like to give a special thank you to Ms. Clark for her time and contributions to this blog post. 3D printing is quickly becoming a staple in many classrooms, and we are so excited to see how it continues to change education for the better! If you are a teacher who 3D prints in your classroom, we would love to hear from you! Please email us at [email protected] with your story.

Inspiration:

See their robot in action: FRC 7407 Rapid React Auto-Aim Shooter Testing

Ready to start your own team? Start here!

Further Insight:

Airwolf 3D is conducting research on the topic of technology adoption and educators. The purpose of this study is to develop white papers and helpful guides for teachers. Participants in our study are guaranteed anonymity and compensation for completing our 15-minute survey. If you are an educator in the USA and would like to participate in our survey and receive a free bottle of Wolfbite, please drop us an email with the subject header “3D Printing Classroom Survey”.

The purpose of this study is to develop white papers and helpful guides for teachers. Participants in our study are guaranteed anonymity and compensation for completing our 15-minute survey. If you are an educator in the USA and would like to participate in our survey and receive a free bottle of Wolfbite, please drop us an email with the subject header “3D Printing Classroom Survey”.

Thank you for reading! We hope this was informative and helpful. If you have any questions or comments, please feel free to reach out to us at [email protected]. Be sure to stay tuned for more blog posts on 3D printing in the classroom, coming soon!

Did you know that Airwolf 3D offers an Education Discount? Be sure to request a quote here and check the box “Educational Agency”.

Want to learn to 3d print? Sign up for our online courses here.

3d printer in the computer science classroom, application experience / Sudo Null IT News Informatics teacher Pavel Tomshin participated in the marathon as a volunteer.

Pavel’s school (Lyceum No. 109) already has a 3D printer, and since the topic of using 3D printing technology in educational processes has long interested me in schools (in my opinion, quite interesting and promising), I asked him to tell me about the experience of using 3D printer at his school (lyceum). This is what the article will be about.

Technomarathon

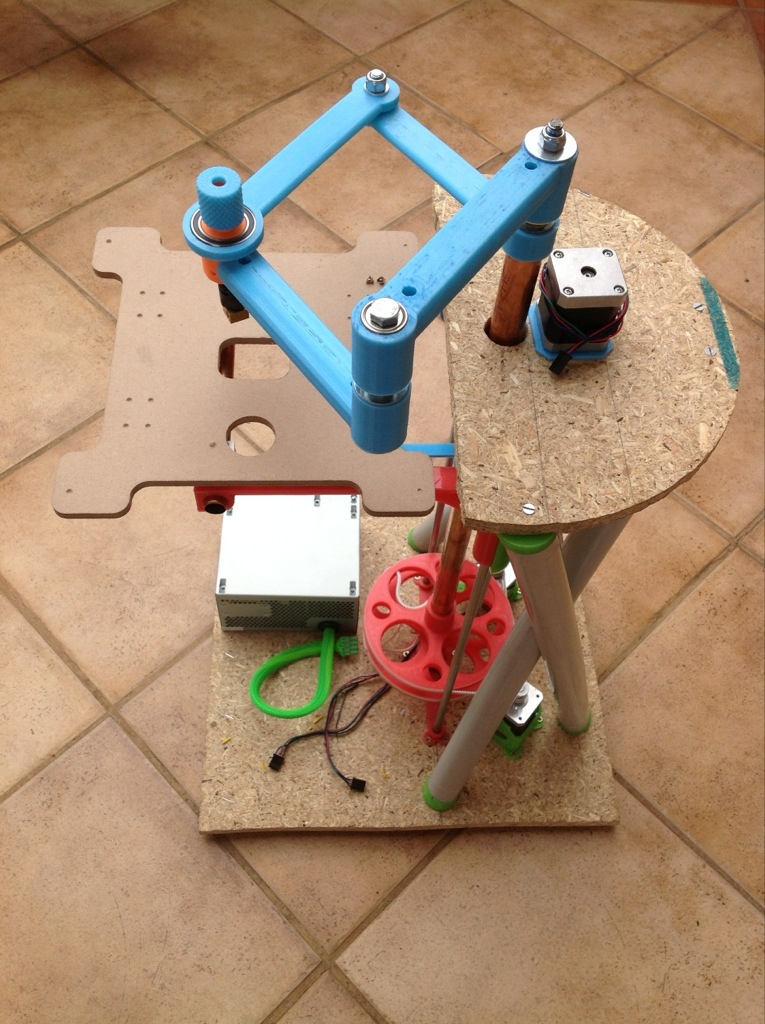

And here is a photo from the technomarathon — Pavel helped us a lot at the event, because already had experience with this printer model, helps to install the control module.

Beginning

Pavel:

The need for 3D printing at Lyceum No. 109, which had been brewing for some time, materialized in the form of a bq PRUSA i3 received for winning the robotic competition "Robot Racing" held by the Ural Federal University in early 2015 Since no harmful fumes are emitted when printing with PLA, the printer found its place on the teacher's desk.Now, a fourth thing has been added to the things that a person can look at forever: the process of printing a 3D printer.

Models

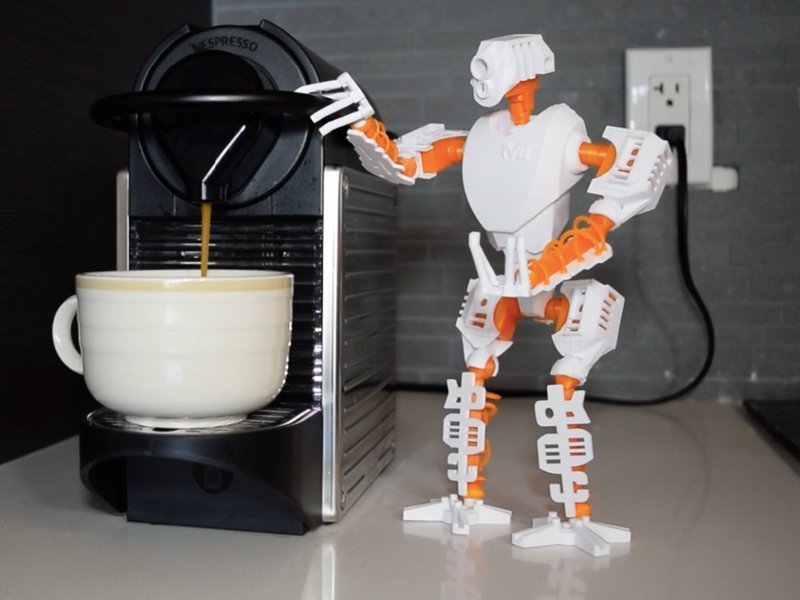

Of course, first of all, models from the Internet are printed, such interesting models were printed

in this program.

Here is what Pavel himself says:

As I got to know 3D printing technology, I came to understand what and how to do with students to popularize 3D technologies in the lyceum. A trial course of 3D modeling has been developed and is being implemented with fifth-graders, followed by printing of the results of the classes. We model in 3DMax (the Lyceum has a license for 14 places Autocad, 3DMax, moreover, these products have been free for educational institutions for a couple of years). The very first lesson involves the creation of a spectacular model - a "ball in a cube"

At the next lesson, the guys created a “medal with a text”.The guys googled the work with the Text spline and the Extrude modifier on their own. Construction was born

For lessons

Of course, 3D modeling can be useful in school subjects as well.

Mathematics teacher Yusupova Tatyana Viktorovna gave our 3D-circle an order for the production of three-dimensional figures - visual aids for geometry lessons in high school. It was not difficult for the five-graders to complete this task.

Pyramid for mathematicians:

Bodies of rotation (there is a lesson in mathematics in the computer class - "Bodies of rotation", with further printing:

Construction

Of course, a separate topic in 3D modeling is design.

The guys made a lamp. Designed, printed, finished with a file to insert 2 batteries and an LED on adhesive tape:

3D printing for Lego

Pavel runs a Lego robotics group at school, and one of the problems is organizing the storage of parts.

And for this he made - Lego modules for classes. Where fastenings are made using 3D printing, specifically for certain parts from the Lego set. At the beginning of the lesson, you can see where to get it from, at the end - is everything in place.

In the development of the theme: mobile box for outdoor classes.

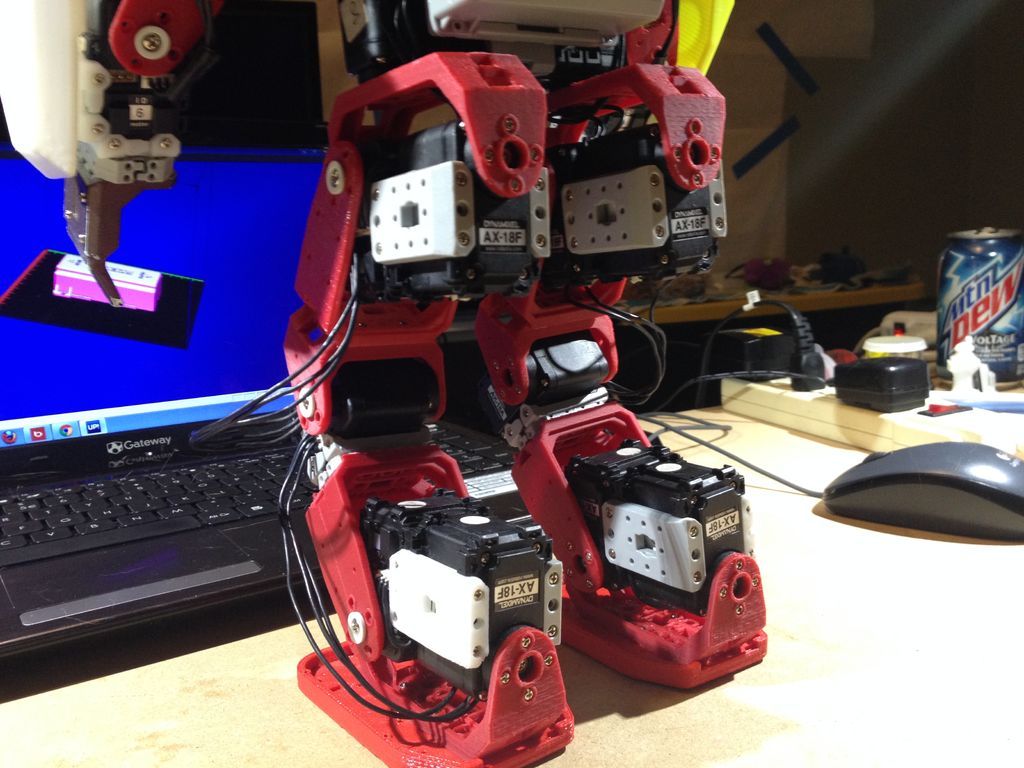

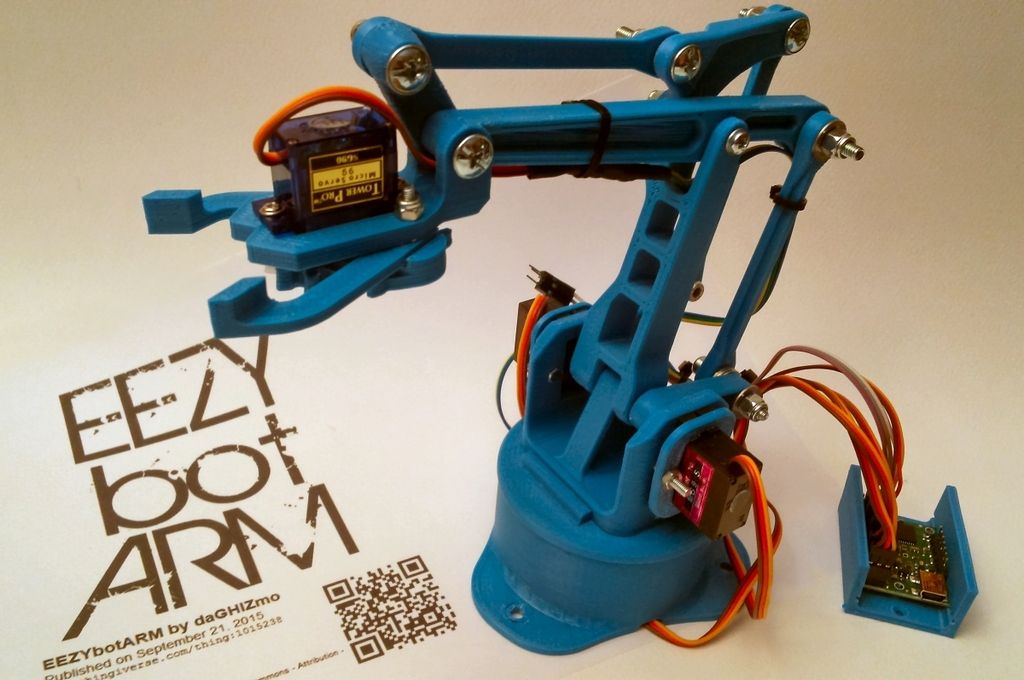

3D printing in robotics

An example of expanding the functionality of LEGO through 3D printing - a marker holder was made so that you can control the drawing: lower / raise the marker. For the lesson of informatics "Coding of graphic information".

Presentations

Excursion, within the framework of "MDO Constellation":

Immediately there is an application for 3D printing :)

Robotics

I asked Pavel a question about the prospects for the use of robotics in educational processes, his thoughts on this matter:

There is a problem of interdisciplinary connections in solving problems by students.Example: in mathematics, the student clearly knows what C=2Pi*R is, in computer science, he does not know the formula for the circumference of a circle. Robotics appeals to interdisciplinary connections, showing where and how to put into practice what was studied in the lessons of physics, mathematics, geometry, computer science. The trend "Engineering personnel in Russia" obviously requires the introduction of engineering subjects at school. We need a public resource on developments in this area. Association. Cities/regions - support for competitions, grants for teams to the winners of local stages for a trip to events of the next levels.

3D Print

3D Print - Description

-

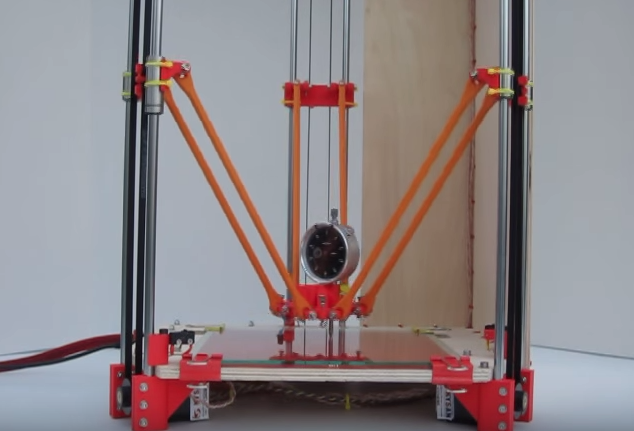

How to 3d print another 3d printer

How to 3d print another 3d printer? This question was asked by many of their owners and in this article we will answer what needs to be done!

Read

-

Review of 3d printers Makerbot

This article will be devoted to the study of the Makerbot 3D printer line.

Read

-

3d printing problems and solutions

In this article, we will analyze the most common 3d printing problems!

Read

-

Connecting a 3d printer to a computer

In this article we will answer the question of how to connect a 3d printer to a computer.

Read

-

Ramps 1.4 connection in 3d printer

Why do you need a Ramps 1.4 shield in a 3d printer and how to connect it to Arduino Mega, read on!

Read

-

Repetier Host. Slicer setup. Part 2

In this article, we will continue to study Repetier Host, namely, we will teach you what parameters you need to set in various fields of the slicer and what they are for!

Read

-

Robotics for Beginners

Is it necessary to prepare your children for the future in the world of robots, how to do it right and what robotics circles for beginners teach in our new article!

Read

-

Repetier Host setup and instructions.