3D printing research

3D Printing Research at EPA

Studies have found that the 3D printing process releases gases and particulates which could pose health risks to users. These emissions include volatile organic compounds, referred to as VOCs, some of which are hazardous to human health when inhaled. In addition to VOC emissions 3D printers can release particles of ultrafine size (1–100 nm), and researchers have found that they are small enough to be deposited deeper into the respiratory system. These particles can be more difficult to clear from the body than larger solid particulates.

What material do these emissions come from?

Common 3D printer ‘ink’, called filament, is a thermoplastic that is partially melted during the printing process to form the desired 3D object, one layer at a time. There are different types of filaments to choose from, with the most popular material choices being poly-lactic acid (PLA) and acrylonitrile butadiene styrene (ABS). PLA filament is derived from renewable sources like corn and is advertised for its abilities to biodegrade and reduce greenhouse gases during use. ABS is derived from processing petroleum and is often used in industry because of its chemical resistance.

EPA researchers have conducted studies to examine the emissions of these filament types, finding that the different filaments release different amounts of respirable particles during the printing process. Learn more:

Particle emissions from fused deposition modeling 3D printers: Evaluation and meta-analysis.

Recent 3D Printer Emissions Research at EPA.

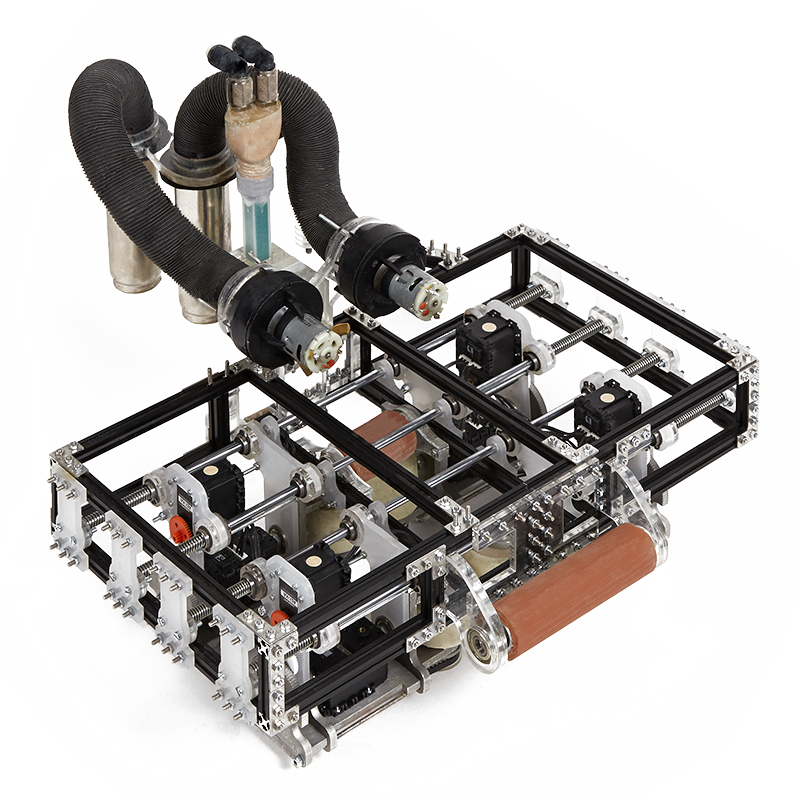

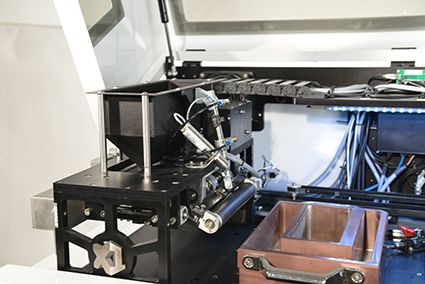

Filament Extruders

Instead of using pre-made filament, users can use filament ‘extruders’, which create feedstock for 3D printers from raw plastic pellets. EPA researchers studied these extruders to build their understanding of any additional emissions that would result from extruder use. Through their research, they found that ultrafine particle emission rates from extruders were comparable to those found in other 3D printer studies, concluding that filament extruders may present additional exposure to these particles for users. There is also an expanding market for a range of specialty filaments with additives such as metal particles, metal–containing flame retardants and others. These additives may pose additional health risks.

There is also an expanding market for a range of specialty filaments with additives such as metal particles, metal–containing flame retardants and others. These additives may pose additional health risks.

Learn more:

Particle and volatile organic compound emissions from a 3D printer filament extruder.

Human exposure to metals in consumer-focused fused filament fabrication (FFF)/ 3D printing processes

Children’s exposure to 3D printing emissions

The availability of published studies evaluating the effects of 3D printer emissions on respiratory health is limited, and all have focused solely on adults. However, 3D printing has become a popular educational tool, meaning children and teenagers could be regularly exposed to 3D printer emissions. This is of concern because children may be a vulnerable population, meaning that the effects of these emissions could disproportionately harm them. Children may be exposed to high concentrations of 3D printer ultrafine particles due to uncontrolled use of the printers within confined spaces, such as classrooms and libraries.

EPA researchers used an open access model called multiple path particle dosimetry model (MPPD v3.04) to predict the amount of particles that may be deposited from 3D printer emissions in different regions of the respiratory tract. Specifically, these models focused on children of various age groups from three months to eighteen years old. From this modeling, the researchers found that the greatest predicted mass deposition was highest in the range of nine to eighteen-year-olds, and that the greatest mass deposition was predicted to occur in the lungs. Learn more:

3D printer particle emissions: Translation to internal dose in adults and children.

The National Institute for Occupational Safety and Health recommends that 3D printer users protect themselves by using materials with lower emissions, using enclosures for 3D printers and ventilation to capture chemical emissions, and reducing time spent near the printer while it is running. Additional resources about 3D Printing safety:

3D Printing with Filaments: Health and Safety Questions to Ask

Characterizing 3D Printing Emissions and Controls in an Office Environment

Contact Us to ask a question, provide feedback, or report a problem.

Last updated on June 1, 2022

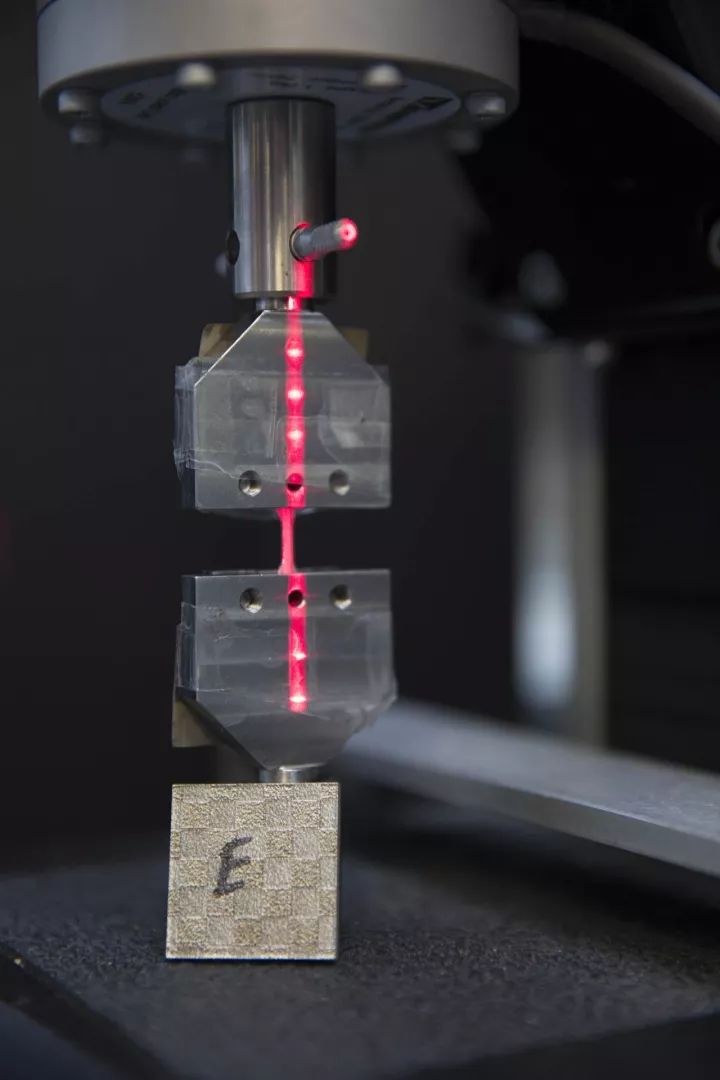

Researchers Uncover How to 3D-Print One of the Strongest Stainless Steels

A microscopic image of 3D-printed 17-4 stainless steel. The colors in the left-side version of the image represent the differing orientations of crystals within the alloy.

Credit: Q. Guo/University of Wisconsin-Madison

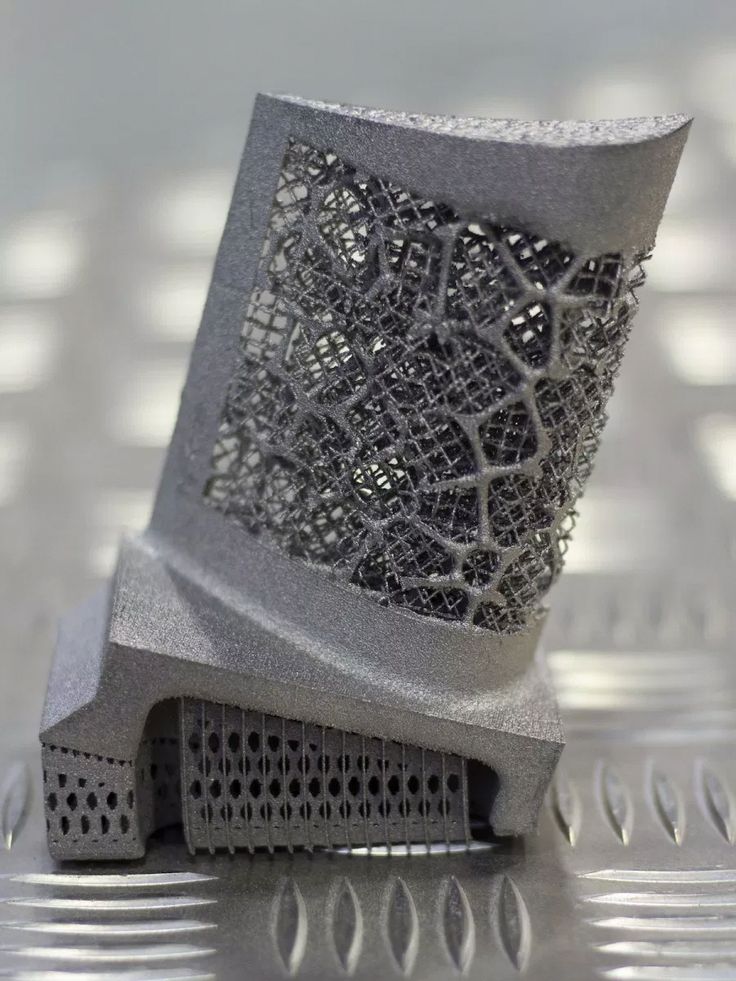

For airliners, cargo ships, nuclear power plants and other critical technologies, strength and durability are essential. This is why many contain a remarkably strong and corrosion-resistant alloy called 17-4 precipitation hardening (PH) stainless steel. Now, for the first time ever, 17-4 PH steel can be consistently 3D-printed while retaining its favorable characteristics.

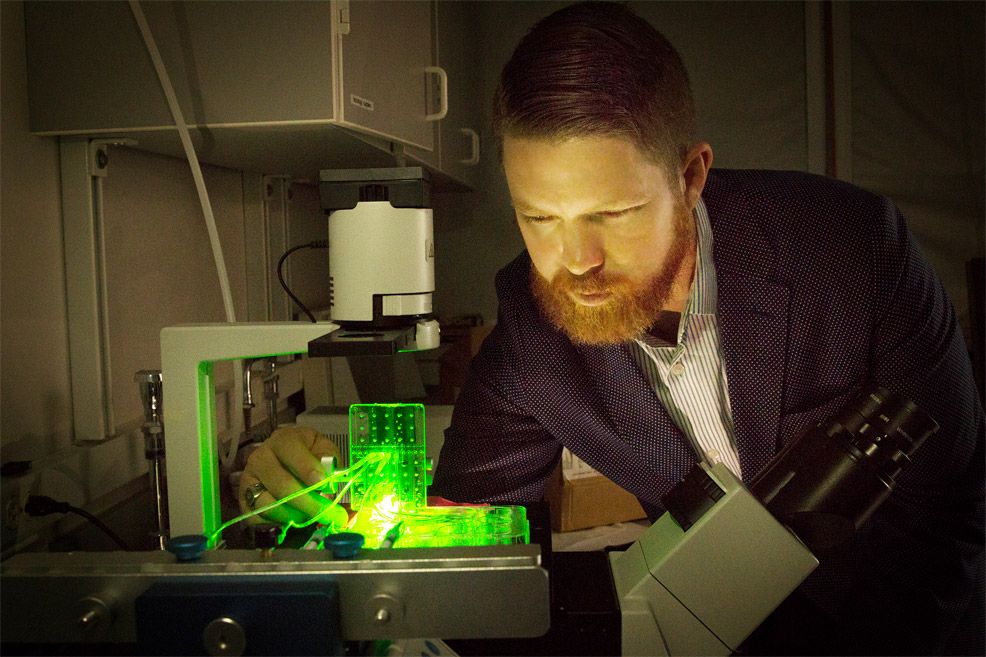

A team of researchers from the National Institute of Standards and Technology (NIST), the University of Wisconsin-Madison and Argonne National Laboratory has identified particular 17-4 steel compositions that, when printed, match the properties of the conventionally manufactured version. The researchers’ strategy, described in the journal Additive Manufacturing, is based on high-speed data about the printing process they obtained using high-energy X-rays from a particle accelerator.

The researchers’ strategy, described in the journal Additive Manufacturing, is based on high-speed data about the printing process they obtained using high-energy X-rays from a particle accelerator.

The new findings could help producers of 17-4 PH parts use 3D printing to cut costs and increase their manufacturing flexibility. The approach used to examine the material in this study may also set the table for a better understanding of how to print other types of materials and predict their properties and performance.

Despite its advantages over conventional manufacturing, 3D-printing of some materials can produce results that are too inconsistent for certain applications. Printing metal is particularly complex, in part because of how quickly temperatures shift during the process.

“When you think about additive manufacturing of metals, we are essentially welding millions of tiny, powdered particles into one piece with a high-powered source such as a laser, melting them into a liquid and cooling them into a solid,” said NIST physicist Fan Zhang, a study co-author. “But the cooling rate is high, sometimes higher than one million degrees Celsius per second, and this extreme nonequilibrium condition creates a set of extraordinary measurement challenges.”

“But the cooling rate is high, sometimes higher than one million degrees Celsius per second, and this extreme nonequilibrium condition creates a set of extraordinary measurement challenges.”

3D Printing with a Laser and Metal Powder

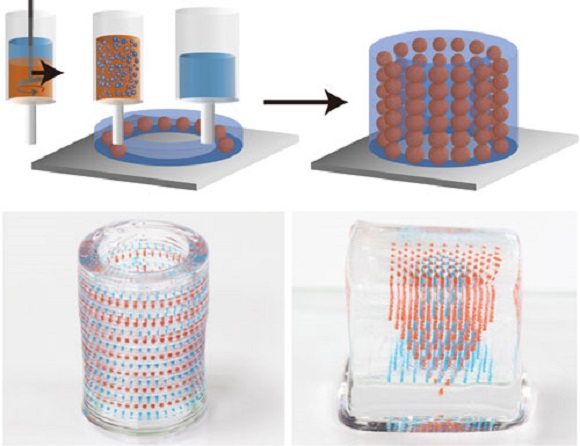

A 3D printer of the laser powder-bed fusion type, in action. Laser powder-bed fusion adds successive layers of metal powder and then uses a laser to melt each layer into place on the part being created.Because the material heats and cools so hastily, the arrangement, or crystal structure, of the atoms within the material shifts rapidly and is difficult to pin down, Zhang said. Without understanding what is happening to the crystal structure of steel as it is printed, researchers have struggled for years to 3D-print 17-4 PH, in which the crystal structure must be just right — a type called martensite — for the material to exhibit its highly sought-after properties.

The authors of the new study aimed to shed light on what happens during the fast temperature changes and find a way to drive the internal structure toward martensite.

Just as a high-speed camera is needed to see a hummingbird’s flapping wings, the researchers needed special equipment to observe rapid shifts in structure that occur in milliseconds. They found the right tool for the job in synchrotron X-ray diffraction, or XRD.

“In XRD, X-rays interact with a material and will form a signal that is like a fingerprint corresponding to the material’s specific crystal structure,” said Lianyi Chen, a professor of mechanical engineering at UW-Madison and study co-author.

At the Advanced Photon Source (APS), a powerful light source at the Department of Energy's Argonne National Laboratory, the authors smashed high-energy X-rays into steel samples during printing.

The authors mapped out how the crystal structure changed over the course of a print, revealing how certain factors they had control over — such as the composition of the powdered metal — influenced the process throughout.

While iron is the primary component of 17-4 PH steel, the composition of the alloy can contain differing amounts of up to a dozen different chemical elements. The authors, now equipped with a clear picture of the structural dynamics during printing as a guide, were able to fine-tune the makeup of the steel to find a set of compositions including just iron, nickel, copper, niobium and chromium that did the trick.

The authors, now equipped with a clear picture of the structural dynamics during printing as a guide, were able to fine-tune the makeup of the steel to find a set of compositions including just iron, nickel, copper, niobium and chromium that did the trick.

“Composition control is truly the key to 3D-printing alloys. By controlling the composition, we are able to control how it solidifies. We also showed that, over a wide range of cooling rates, say between 1,000 and 10 million degrees Celsius per second, our compositions consistently result in fully martensitic 17-4 PH steel,” Zhang said.

As a bonus, some compositions resulted in the formation of strength-inducing nanoparticles that, with the traditional method, require the steel to be cooled and then reheated. In other words, 3D printing could allow manufacturers to skip a step that requires special equipment, additional time and production cost.

Mechanical testing showed that the 3D-printed steel, with its martensite structure and strength-inducing nanoparticles, matched the strength of steel produced through conventional means.

The new study could make a splash beyond 17-4 PH steel as well. Not only could the XRD-based approach be used to optimize other alloys for 3D printing, but the information it reveals could be useful for building and testing computer models meant to predict the quality of printed parts.

“Our 17-4 is reliable and reproducible, which lowers the barrier for commercial use. If they follow this composition, manufacturers should be able to print out 17-4 structures that are just as good as conventionally manufactured parts,” Chen said.

Paper: Q. Guo, M. Qu, C.A. Chuang, L. Xiong, A. Nabaaa, Z.A. Young, Y. Ren, P. Kenesei, F. Zhang, and L. Chen. Phase transformation dynamics guided alloy development for additive manufacturing. Additive Manufacturing. Published online Aug. 2, 2022. DOI: 10.1016/j.addma.2022.103068

Manufacturing, Additive manufacturing, Sustainable manufacturing, Materials and Metals

3D Printing Market Research: 6 Important Trends

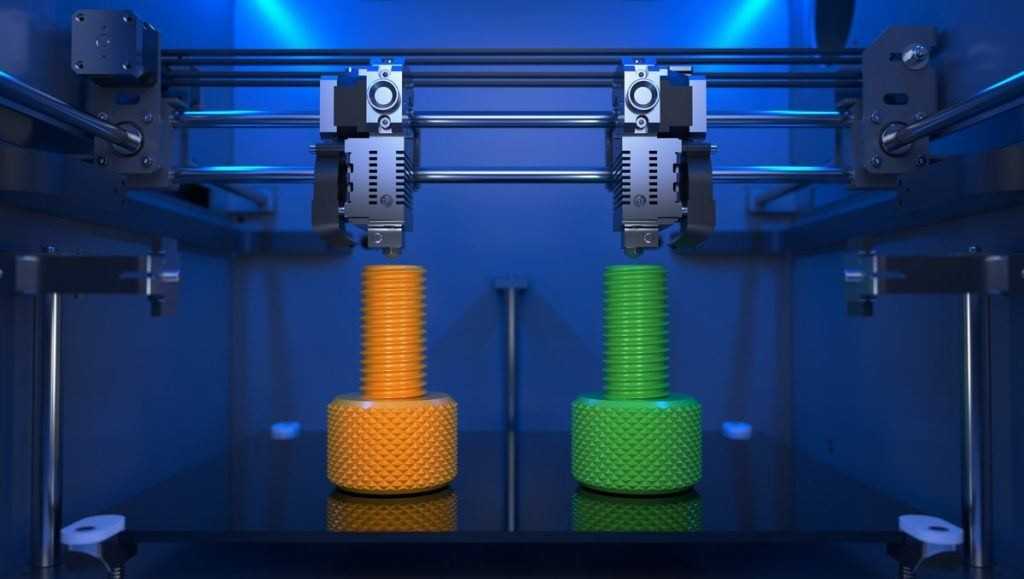

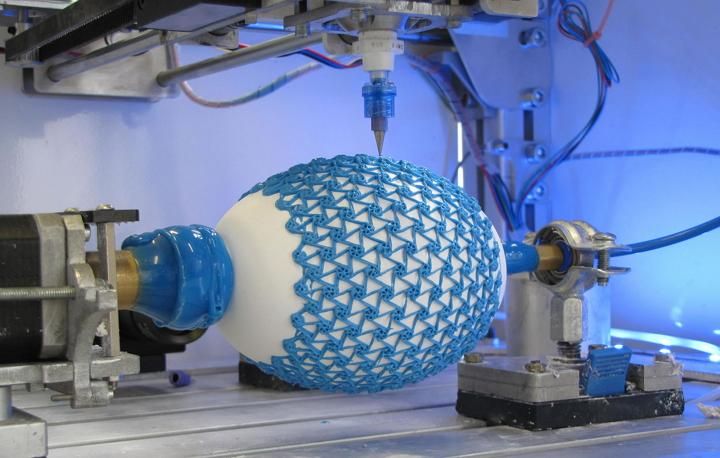

Time is the most valuable commodity today. High competition and the emergence of new business models require accelerated development cycles to quickly and flexibly implement innovative ideas. With new, more efficient equipment, high productivity, and a wide choice of materials, 3D printing technology saves time and money in the development and production of parts.

High competition and the emergence of new business models require accelerated development cycles to quickly and flexibly implement innovative ideas. With new, more efficient equipment, high productivity, and a wide choice of materials, 3D printing technology saves time and money in the development and production of parts.

3D printing was originally designed to completely change the principles of production. The technology has a number of strategic advantages, such as design flexibility, reduced time to market, mass customization, distributed manufacturing, and many others. Despite some difficulties, 3D printing continues to show undeniable advantages.

Over the past few years, Jabil, a global manufacturing services company, has sponsored three 3D printing trend studies to help guide additive manufacturing and assess current realities. The 2021 survey surveyed more than 300 people responsible for making 3D printing decisions in manufacturing companies. The report allows you to get acquainted with the experience and opinion of professionals working "at the forefront". Respondents work in a wide range of industries, including electronics, plastics and packaging, industrial engineering, automotive, healthcare, and many others, giving us a comprehensive understanding of the 3D printing market and how additive technologies are being used.

Respondents work in a wide range of industries, including electronics, plastics and packaging, industrial engineering, automotive, healthcare, and many others, giving us a comprehensive understanding of the 3D printing market and how additive technologies are being used.

1. The scope of 3D printing is rapidly expanding

Thirty years is a very short time when it comes to traditional production methods. Additive technologies are revolutionizing a wide variety of industries.

The results of the last two surveys contrast sharply with the information that was obtained during the first survey in 2017. Even in the past two years, the adoption of 3D printing has increased significantly. The rise in popularity and expansion of the scope of additive manufacturing is clearly seen in the present study.

In 2017, the most popular answer to the question “what is 3D printing used for in your company?” was the answer "for rapid prototyping". Seven out of ten respondents confirmed the use of 3D printing for this purpose. The remaining answer options lag far behind the first: only three out of ten respondents chose the second option (tooling production). Since then, the scope of 3D printing has expanded significantly.

The remaining answer options lag far behind the first: only three out of ten respondents chose the second option (tooling production). Since then, the scope of 3D printing has expanded significantly.

R&D has become the most popular area for 3D printing, ahead of prototyping. At the same time, there is a sharp increase in application scenarios in other areas. Since 2017, the proportion of companies using additive manufacturing to manufacture parts and tooling has doubled, and the use of these methods for mass production of parts has tripled.

Nearly 100% of study participants reported that they use 3D printing to produce functional or final parts. Undoubtedly, the scale of their production varies. Nearly 80% of respondents report using additive manufacturing to make at least 25-50% of functional parts.

Improvements in 3D printers allow companies to experiment with additive technologies in areas where they were previously unavailable. As the price of 3D printers declines and their productivity rises, the technology will become more accessible and will change the manufacturing industry as a whole.

2. The growth of additive manufacturing: forecasts are more optimistic than ever

The prospects for the development of 3D printing are extremely positive. Market participants are confident in a significant increase in the popularity of technology in the future. 97% of respondents believe that the adoption of 3D printing in their companies will grow in the next five years.

Most of the study participants believe that the use of 3D printers in their organizations will at least double over this period of time. Nearly half of respondents expect usage to double, and 4 out of 10 expect much more significant increases (5x or more). In addition to the growing popularity of additive technologies, a significant role in expanding their use, as already mentioned, will be played by their availability.

Companies in general plan to increase their additive capacity, but the highest expectations are in mass production of parts and goods. Slightly more than 80% of respondents expect that the use of additive technologies for mass production of products in their organizations will grow at least twice over the next five years.

H. 3D printing brings many benefits to companies

During the first study, many of the benefits were perceived as "intangible" concepts. However, over the past few years, use cases have increased, concepts have become reality, and two years later, respondents are even more inspired by the benefits of additive technologies. We have identified three main benefits of additive manufacturing according to reviews.

Perhaps the rise in popularity of 3D printing is not a coincidence, but is due to increased demand for additive manufacturing during the COVID-19 crisis. As the pandemic spread, companies with 3D printers began to produce personal protective equipment such as respirators and masks that suddenly became scarce. When developing new diagnostic equipment and analysis kits, the use of 3D printing has accelerated the process of prototyping and design.

Respondents chose faster manufacturing of parts as the main benefit of additive manufacturing. Jabil saw this first hand: indeed, the desire to eliminate the labor-intensive iterative process was the driving force behind the introduction of additive manufacturing into the Auburn Hills facility. Not only did it speed up workflows, but it also helped reduce costs by being able to immediately recreate the exact geometry (no need to cut off excess material). In fact, savings amounted to 30-40% on tooling and 80% on lead times.

Jabil saw this first hand: indeed, the desire to eliminate the labor-intensive iterative process was the driving force behind the introduction of additive manufacturing into the Auburn Hills facility. Not only did it speed up workflows, but it also helped reduce costs by being able to immediately recreate the exact geometry (no need to cut off excess material). In fact, savings amounted to 30-40% on tooling and 80% on lead times.

“With the power of 3D printing, every aspect of manufacturing has been greatly improved,” said John Wahl VI, Tooling Engineer at Jabil's Auburn Hills facility. “The first aspect is time, the second is a more creative approach, the third is costs, the fourth is materials.”

According to the distribution by job level, senior managers are more optimistic about the benefits of 3D printing than department heads. Since it is the leaders who shape the vision (and plan the budget) for the future of the company, everything points to the further spread of 3D printing.

4. 3D printing materials become more affordable

Compared to 2019, companies are using many more types of 3D printing materials. Despite the fact that plastics/polymers are still leading the way, other materials are not losing ground and are catching up. This confirms our conclusion that the scope of 3D printing is expanding.

When it comes to primary material, the difference between plastic and metal in 3D printing is not as big as you might think. More than a third of respondents answered that they use plastic and metal equally, and those who choose only plastics are only 10% more.

Certainly some problems must be overcome in order to use some materials. More than half of the respondents (twice as many as in 2019) said that it takes too long to develop the necessary materials. Slightly more survey participants said that some materials are too expensive for large-scale use, and are not available or certified.

However, as these problems are overcome, interest in different materials increases. When you look at what materials companies actually use and what they would like to use, plastic still comes out on top. At the same time, the desire to use almost all materials exceeds the current use. It is noteworthy that the interest in printing with glass exceeds the actual use by 20%, ceramics - by 14%, metal - by 10%. It will be interesting to see the changes in the use of materials in the next two years.

When you look at what materials companies actually use and what they would like to use, plastic still comes out on top. At the same time, the desire to use almost all materials exceeds the current use. It is noteworthy that the interest in printing with glass exceeds the actual use by 20%, ceramics - by 14%, metal - by 10%. It will be interesting to see the changes in the use of materials in the next two years.

5. Additive manufacturing is still a source of problems

Despite the optimistic view of the development of additive manufacturing, companies still have to solve a number of problems associated with 3D printing. In 2019, half of respondents cited material costs as a problem, but this year only about two-fifths did so. All problems are located approximately on the same level: most of them fluctuate around 40%.

However, many of the current problems are related to costs, since 95% of respondents reported financial barriers to adopting additive manufacturing. Obtaining appropriate qualifications and certifications is the main challenge, followed by capital expenditures associated with equipment and the need for in-house specialists.

Obtaining appropriate qualifications and certifications is the main challenge, followed by capital expenditures associated with equipment and the need for in-house specialists.

In 2021, pre- and post-processing costs have become a major concern. Companies are using more and more pre- and post-processing methods. In 2019, just over half of respondents reported using mechanical finishing, now it is almost three-quarters, with no polishing being the most common option. Given that the use of all processing methods has increased significantly, it is possible that companies are experiencing growth difficulties. If these problems continue to be given priority attention, they can be overcome.

6. Training of specialists is a priority

Now about three-quarters of the respondents are engaged in additive manufacturing on their own. Given that half of the time they chose “lack of in-house talent” as their problem, it can be assumed that companies are prioritizing educating their employees about additive manufacturing or attracting professionals with experience and knowledge in the field of 3D printing.

This does not mean that organizations are opposed to outsourcing additive manufacturing: in fact, almost 100% of respondents said they were considering this option. When looking at potential suppliers, companies take into account a variety of criteria. Design capability is key, and scalability, pricing, and experience continue the list.

We are seeing significant growth in 3D printing in some areas. In others, this growth is still small. Four years ago, companies used 3D printers primarily for fast, low-cost prototyping: Few businesses relied on additive manufacturing for full-scale production. However, in just four years, as the problems with materials for additive manufacturing were solved and the scope of its use increased, the situation has changed. We have seen how 3D printing has literally taken over many manufacturing industries, which is reflected in the growth of market performance. Slowly but surely, the adoption of additive manufacturing continues. Digital manufacturing is the future.

Source

Tags:

business model, 3d printing, Jabil, 3d printing trends, automotive, prototyping, R&D, additive manufacturing, 3D printer, additive technologies, plastic, polymer, 3D printing materials

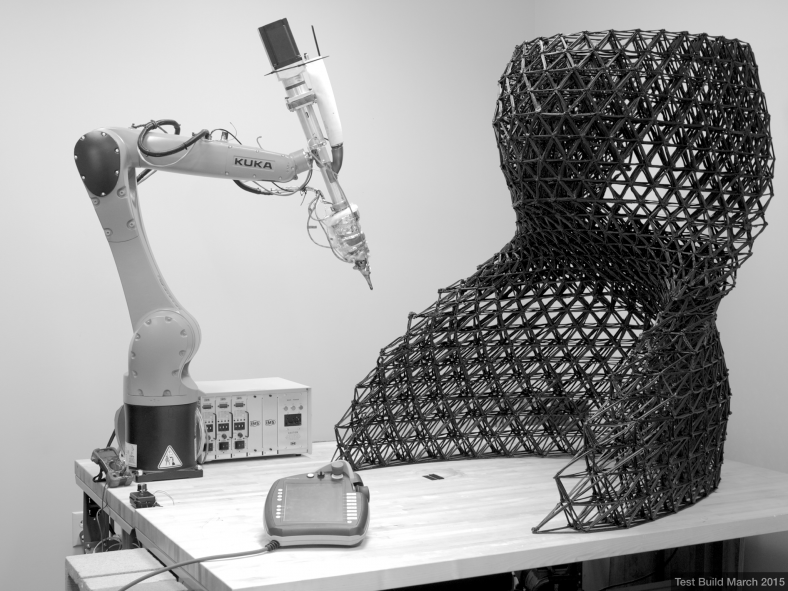

Job Research and applications of the 3D printer

The article reflects the history of creation, practical use and efficiency of 3D printing technology; talks about its distribution and application in everyday life.

Keywords: 3D printer, 3D model, 3D printing technology .

Over time, innovative technologies enter our lives in a dense stream, finding new and new applications for themselves. Much that today is commonplace for an ordinary person, for a person of the last century was something fantastic and unattainable. In today's time, there is a beneficial development of all kinds of technologies that somehow make our life easier and more rational. Every year there is a place for a new discovery and a new movement in science. If we also take into account the development of electronics in general, then progress is evident, and most importantly, as can be seen from visual statistics, it is in no hurry to stop. You can simply combine what was said in one expression: “We still have something to strive for!”.

Every year there is a place for a new discovery and a new movement in science. If we also take into account the development of electronics in general, then progress is evident, and most importantly, as can be seen from visual statistics, it is in no hurry to stop. You can simply combine what was said in one expression: “We still have something to strive for!”.

One of the major steps in the development of automated manufacturing technology was the development of the 3D printer. In 2012, this device has already received worldwide publicity, having reached Russia. Already in the first half of the year, tests and announcements of future development were made. At first glance, the device appears to the user as something unimaginable, a device that can create three-dimensional models by pressing a key of any complexity. This made the printer a technology of the future, many noted that all subsequent discoveries will be connected in one way or another with a 3D printer [13].

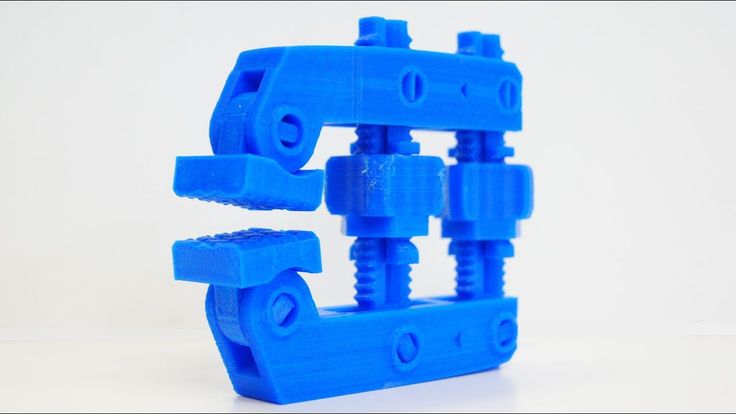

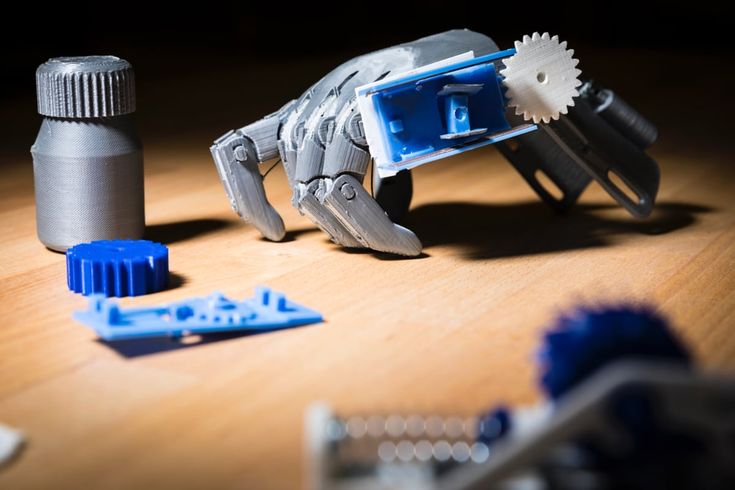

This is a newfangled technological process that is gaining more and more fans. The technology of such printing has become almost a trend, mainly due to the abundance of stylish and unusual accessories that the Internet is oversaturated with. Today, almost everything is printed on 3D printers: phone cases and jewelry, funny toys, but beyond that, digital printing has created a buzz in the scientific world. A 3D printer is an amazing invention of mankind, because it can be used to create three-dimensional objects based on 3D computer models. The first models were bulky and expensive, and were used only by industrial, construction and scientific organizations. To date, compact 3D printers have already appeared for a wide audience of users. Such devices have become more affordable and it is possible to use them at home. In relation to 3D printers, quite enthusiastic epithets are expressed that this is the technology of the future or a new reality, and this will not be an exaggeration, because the capabilities of such printers have already reached tangible heights. There is already a case when the world media made a report that a resident of Holland was implanted with a jaw made using a 3D printer.

3D printing technologies allow developers to almost completely recreate the appearance, tactile qualities and functionality of the intended object. New technologies give engineers the opportunity to make a reduced layout, and designers have the opportunity to see the operation of the mechanism “from the inside”, creating a structure from a transparent material. 3D printers are already successfully competing with traditional production technologies [3]. If we take the full production cycle, then 3D printers have an advantage here, they are much cheaper and faster, and also easy to operate. To print on a 3D printer, it is enough to be a confident user of a personal computer. Thus, research is being actively carried out and it can be assumed that in the very near future - in ten years - the use of 3D printers will make it possible to create complex three-dimensional projection models of buildings with a transmission accuracy of 100 microns, which are especially relevant for scientific institutions, because now you can not only do prototype, but also to touch it in ongoing research. Analyzing the scientific literature on this issue, we did not find its systematic coverage, although many authors considered some aspects of the creation, development and use of 3D printers.

Analyzing the scientific literature on this issue, we did not find its systematic coverage, although many authors considered some aspects of the creation, development and use of 3D printers.

Our work is designed to prove the legitimacy of the existence of technology that will allow us to perform useful tasks in science, art, education, the jewelry industry and many other industries.

Thus, the problem of research is to comprehend the creation and practical use of 3D printers.

The methodological basis of the study was the works of the following scientists: Slusar V.I., Ivanov V.P., Lee J., Ware B., Snook G., Hern D., Baker M.P., Angel E.

The very first 3D prototyping machine was an American SLA machine designed and patented by Charles Hull in 1986. Of course, this was not yet the first 3D printer in the modern sense, but it was she who determined how a 3D printer works: objects are built up in layers. The first model of this machine, which was widely used, was the SLA-250 developed in 1988. In 1990, a new method for obtaining volumetric "printing impressions" was used - the fusing method. It was developed by Scott Crump, founder of Stratasys, and his wife, who continued the development of 3D printing. After that, the concepts of “3D laser printer” and “3D inkjet printer” began to be actively used [4]. The modern historical stage in the development of 3D printing started at 1993 with the founding of Solidscape. It produced inkjet printers that preceded 3D printers. In 1995, an inkjet printer was modified by two MIT students. He created images not on paper, but in a special container, and they were voluminous. At the same time, the concept of "3D printing" and the first 3D printer appeared. This method was patented and is now used by a company founded by the same students. Technology began to develop around the world. A lot of companies appeared that brought new features and improvements. A breakthrough in young technology was the emergence of the PolyJet printing method, which uses photopolymer liquid plastic for a three-dimensional model.

In 1990, a new method for obtaining volumetric "printing impressions" was used - the fusing method. It was developed by Scott Crump, founder of Stratasys, and his wife, who continued the development of 3D printing. After that, the concepts of “3D laser printer” and “3D inkjet printer” began to be actively used [4]. The modern historical stage in the development of 3D printing started at 1993 with the founding of Solidscape. It produced inkjet printers that preceded 3D printers. In 1995, an inkjet printer was modified by two MIT students. He created images not on paper, but in a special container, and they were voluminous. At the same time, the concept of "3D printing" and the first 3D printer appeared. This method was patented and is now used by a company founded by the same students. Technology began to develop around the world. A lot of companies appeared that brought new features and improvements. A breakthrough in young technology was the emergence of the PolyJet printing method, which uses photopolymer liquid plastic for a three-dimensional model. A variant of this 3D printing was cheaper and more accurate. This allowed us to make not only layouts and prototypes, but also ready-to-use objects.

A variant of this 3D printing was cheaper and more accurate. This allowed us to make not only layouts and prototypes, but also ready-to-use objects.

For many today, it is simply unthinkable to abandon the new technological innovations that have become a necessity for mankind [11]. The way a 3D printer works was recently out of reach for most users, today the technology is available to everyone. Thanks to this device, fantasy becomes reality.

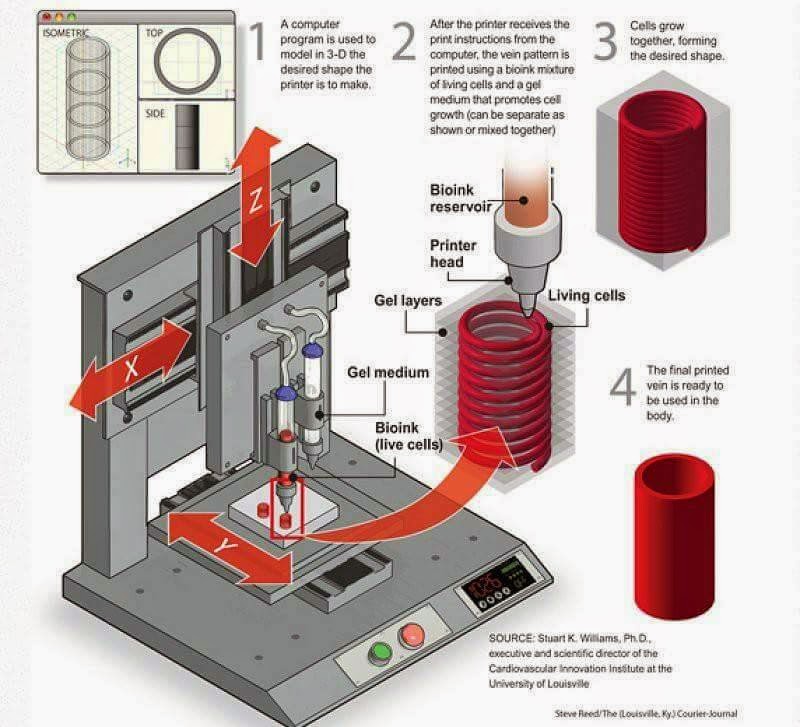

The main task of this process is to transform the idea of the model into a physical object. To do this, this very idea is initially implemented on a computer using software.

After creating a 3D model, you can start printing. The finished file is placed in the software, where, if necessary, you can change the scale of the created object, orient it and specify the number of required copies. The prepared model is loaded into a special generation program, which divides the object into thin horizontal layers and forms a chain of commands understandable to the printer.

When all the necessary parameters are set, the object is printed by pressing one button: the 3D printer prints each level according to the “layer by layer” principle, squeezing a thin stream of molten material onto the working platform [5]. As a result, a physical model is created in the build chamber, which, at the end of the process, is dried and then can be extracted.

They can be examined more closely and even picked up. Thanks to this, there is a unique opportunity to imagine how the part will look like in actual size. It takes up to several hours to print a 3D model, depending on the complexity of the product. Printing technology has advanced so much lately that there are printers that can print anything from chocolate to metal to sand!

What is a 3D printer capable of? Is it really necessary for a person? In what areas are 3D printers used today and what are the most exotic ways of using them?

3D printers have recently gained quite wide popularity, and their scope is expanding every day. We will talk about those areas in which three-dimensional printers are beginning to be actively used.

We will talk about those areas in which three-dimensional printers are beginning to be actively used.

Three-dimensional printers can be used to create architectural models of buildings, individual urban areas, and towns. The use of such models allows you to get a full-color layout.

The use of 3D printing in education makes it possible to quickly and easily obtain useful visual aids for schoolchildren and students distributed in educational institutions. If such institutions are equipped with 3D printers, this will make the educational process even more efficient, and students will be able to better absorb the material. 3D printing will enable students to manipulate real physical models.

Here are the two main benefits that education has from the advent of new technology:

- now the teacher himself creates three-dimensional visual aids, without which it is difficult to understand the material;

- 3D printers make it possible to put learning into practice: students can independently create prototypes and the necessary parts, embodying their design and design ideas.

Our city has a Center for Youth Innovative Creativity, where children are taught robotics, 3D printing, 3D modeling, programming, and much more. I attended classes at this center where I created and printed my 3D model.

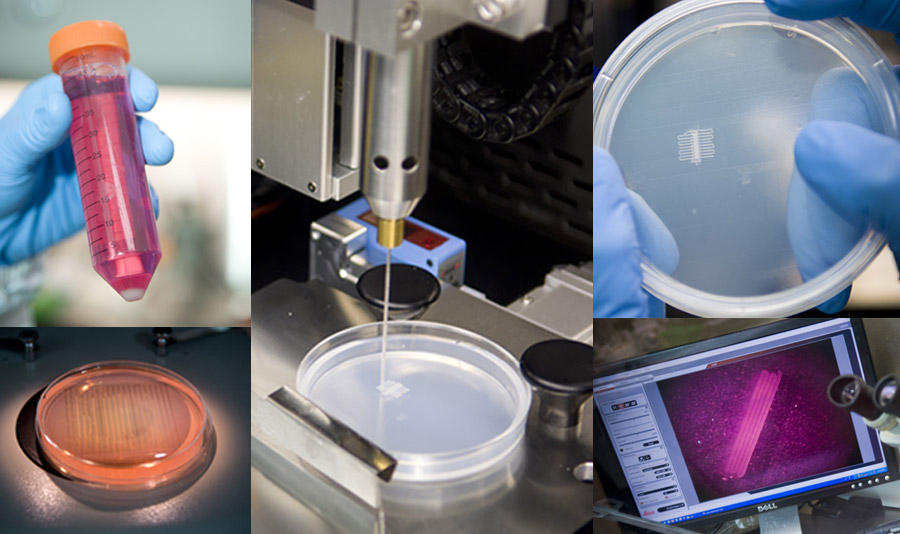

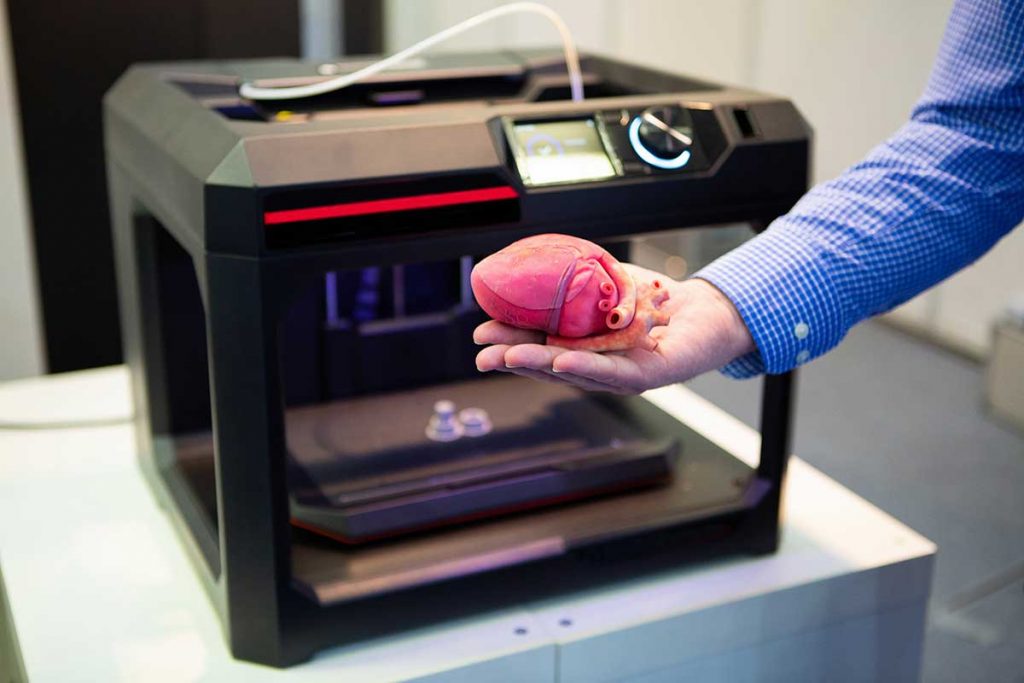

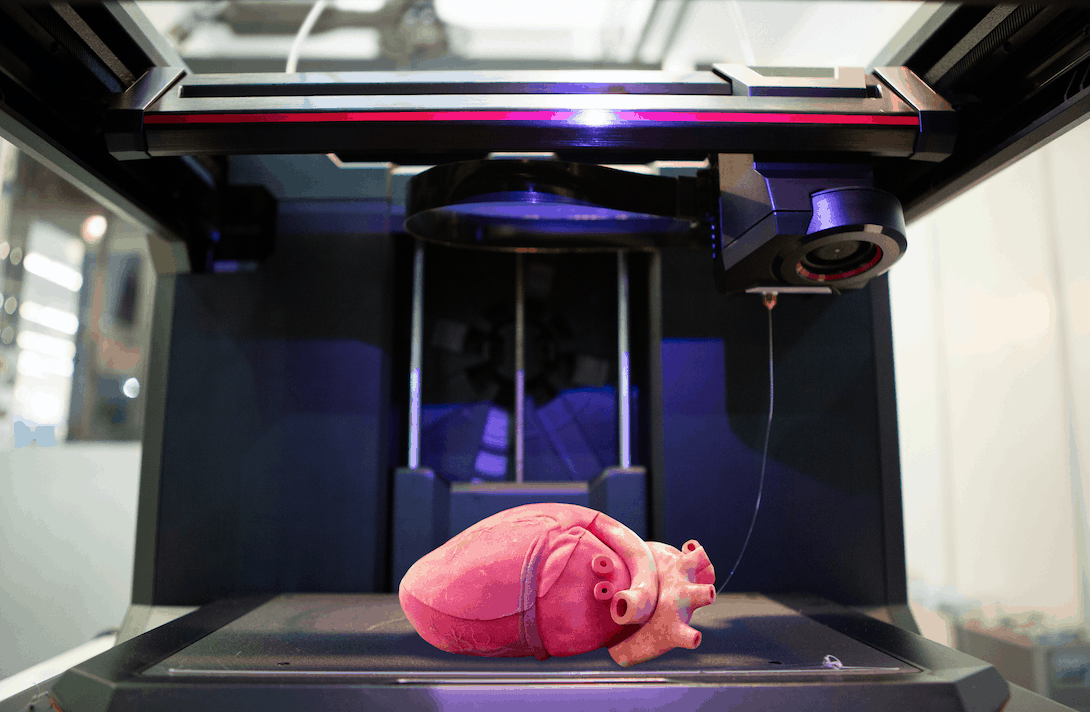

Modern technologies of three-dimensional printing can be successfully applied in today's medicine. In dentistry, for example, 3D printing makes it possible to obtain prostheses and crowns in a much shorter time period than with the use of traditional production technology. In addition, it is also worth noting that 3D printers are capable of reproducing an exact copy of individual parts of the human body or the entire skeleton for training doctors or for practicing techniques before a difficult operation.

The ability to manufacture living organs in the future will provide great opportunities for the medical industry. In the near future, 3D printers will be able to create any organ. This will allow patients to get rid of the need to stand in line for a long time, waiting for a transplant.

3D printing can also be applied in the clothing industry. Designers, using three-dimensional printers, get the opportunity to quickly develop exclusive models. There are fashion designers who have already managed to master this direction and produce collections created on a printer.

Similar technologies are used not only in the creation of fashion design, but also in the manufacture of shoes and jewelry.

The principle of operation of a food 3D printer is very similar to the principle of operation of a conventional inkjet printer. Only instead of cartridges with liquid dyes, the food printer uses cartridges with food ingredients. There are many recipes stored in the printer's memory. To print a dish, you must select one of the recipes and press the button. After that, the printer, in accordance with the algorithm embedded in it, will begin to lay out the ingredients in layers on the work surface or on a plate. The product thus obtained is cooled or baked.

Samara State Aerospace University is developing a 3D printer for printing chocolate products. Representatives of SSAU decided to work on 3D food printers in connection with the need to provide astronauts with a balanced diet during expeditions.

The main advantages of a 3D printer are as follows:

1) the prototype of the object is created in a short time without the use of additional equipment;

2) the possibility of modeling many samples is provided for conducting parameter studies and choosing the best option;

3) the accuracy of reproduction and detailing of the object by its 3D prototype does not depend on the human factor and can be considered error-free.

We also conducted a market research on 3D printing services in the city. In Samara, there are 8 points for the provision of these services. Approximately 82% of customers apply for the production of accessories, small parts, souvenirs for personal needs.

We printed on a 3-D printer for the New Year a souvenir - a symbol of 2016.

In the process of research work, after analyzing the scientific literature, tracing the history of the creation of 3D printers, identifying the achievements and prospects for the development of this technology in various industries, visiting a practical workshop where he created and printed his model, he came to the conclusion that every day this printing technology finds itself in new areas. An interesting service in the field of entertainment is this service: anyone can make a scan of their body and get their own miniature copy. In the field of medicine, the manufacture of shoes, insoles, and headphones is gradually coming into use, ideally repeating the shape of certain parts of the body or detailed parts for the functioning of the body, for example, a section of the human cranial cortex. The size of parts is gradually increasing, and the choice of materials for printing is also expanding. In creating models using a 3D printer, there is no restriction on the design and complexity of the form, which allows you to fully use your imagination and make an individual and original product. Products are very light, and at the same time their production time is minimal. This technology is only gaining momentum in its development and distribution. This can be seen from our study in the city of Samara. Most of the orders belong to the group of personal interest in the new technology and nothing more. But it is also impossible not to notice that the process of using 3D printing technology in large and useful projects for society is already underway. 3D printer is the future! Soon, 3D printers can easily be called a magic wand that will radically change the world around us.

Products are very light, and at the same time their production time is minimal. This technology is only gaining momentum in its development and distribution. This can be seen from our study in the city of Samara. Most of the orders belong to the group of personal interest in the new technology and nothing more. But it is also impossible not to notice that the process of using 3D printing technology in large and useful projects for society is already underway. 3D printer is the future! Soon, 3D printers can easily be called a magic wand that will radically change the world around us.

Literature:

- Ivanov, V.P. Three-dimensional computer graphics / Ed. G. M. Polishchuk. - M.: Radio and communication, 1995. - 224 p.

- Lee, J., Ware, B. Three-dimensional graphics and animation. - 2nd ed. – M.: Williams, 2002. – 640 p.

- Slyusar, V. I. Fabber technologies: a designer and a manufacturer himself. - Constructor. - 2002. - No. 1. - C.

5 - 7.

5 - 7. - Slyusar, V. I. Fabber technologies. New 3D modeling tool. – Electronics: science, technology, business. - 2003. - No. 5. - C. 54-60.

- Slyusar, V.I. Factory in every house. Around the world. - No. 1 (2008). - January, 2008. C. 96-102.

- Snook, G. Realtime 3D Landscapes in C++ and DirectX 9. - 2nd ed. — M.: Kudits-press, 2007. — 368 p.

- Herne, D., Baker, M.P., Computer Graphics and the OpenGL Standard. - 3rd ed. – M.: Williams, 2005. – 1168 p.

- Angel, E. Interactive computer graphics. An introductory course based on OpenGL. - 2nd ed. – M.: Williams, 2001. – 592 p.

- Evans Briand, Practical 3D Printers: The Science and Art of 3D Printing. Press, 2012.

- Canesa I., Fonda S., Zenaro M. Accessible 3D printing for science, education and sustainable development. The Abdus Salam International Center for Theoretical Physics, 2013.

- Mikhailova, A.D. Doshina // Young scientist.