3D printed wallet design

💳 Best 3D print models of Wallets・Cults

💳 Best 3D print models of Wallets

Download 3D models for 3D printer of wallets and card holders

Thanks to your 3D printer you will be able to create your own decorative objects but also everyday objects. The famous wallet that is always in your pocket is an excellent example of what 3D printing is now capable of!

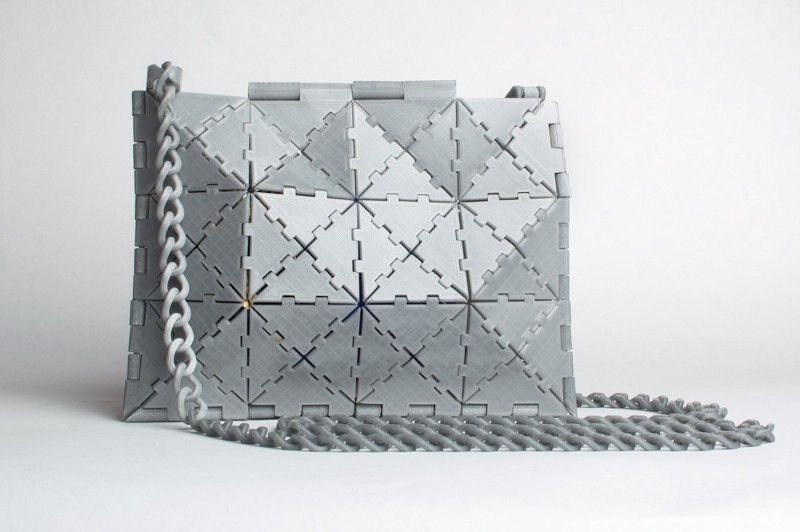

Smaller Chainmail Wallet!

Free

CARDHOLDER-WALLET (only back plate with logo Cyberpunk)

Free

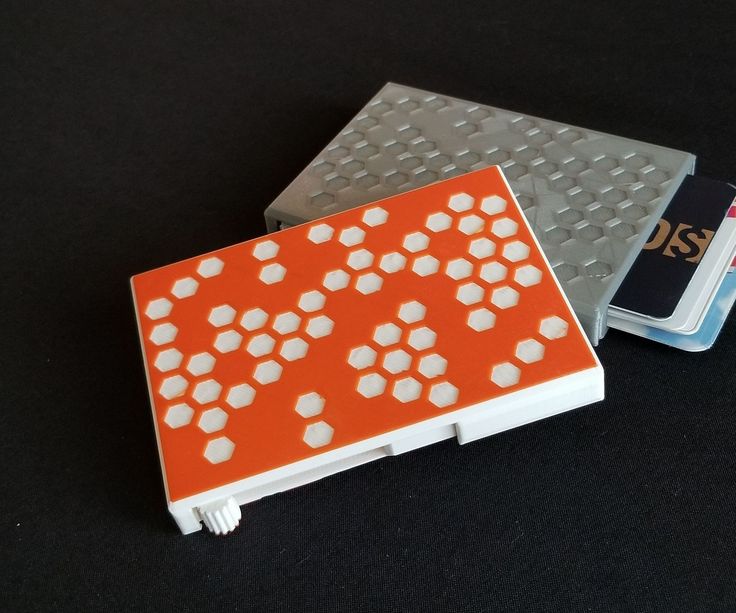

Cardholder-wallet (universal package)

€1.38

FlexWallet (multiple designs)

Free

Tiny Wallet

Free

CARDHOLDER-WALLET (ONLY BACK PLATE WITH LOGO CS:GO)

Free

Simple TPU Wallet

Free

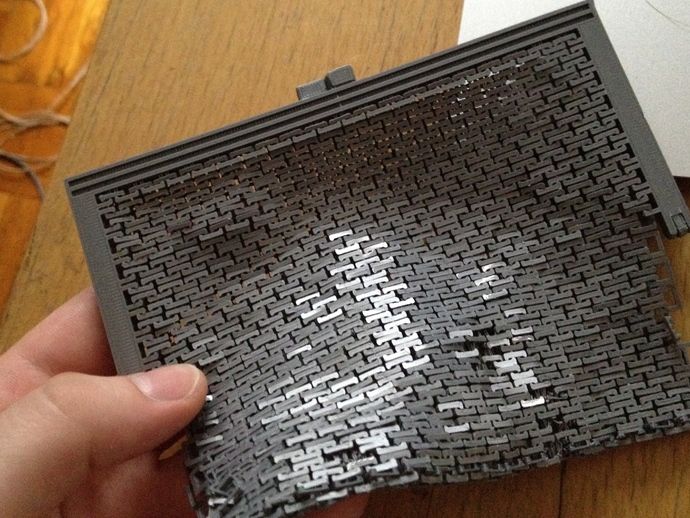

ChainMail Wallet - Single Print!

Free

Tesla Cyberwallet

Free

Slim - Smart Wallet

€2. 39

Slim Wallet V2.0

Free

Slim and Simple Wallet / Card holder

Free

Minimalistic Wallet // 3DWB

Free

Money Clip

Free

Double Money Clip

Free

minimalist wallet

Free

simple wallet

Free

Credit card and identity card wallet

Free

Credit Card / Loyalty Card / Business Card / Wallet

Free

Minimalist Wallet

Free

Phone Card

Free

CARDHOLDER-WALLET (only back plate with logo FORTNITE)

Free

Classic Money Clip

Free

MAGNETIC Chainmail Wallet! -Single print!

Free

$$$-box - Print in Place

€1. 42

42

An Open Wallet

Free

Slim TPU Wallet

Free

Slim Wallet V4.0

Free

MAGNETIC Chainmail Wallet with exposed Magnets

Free

Shield Wallet

Free

Smart Wallet - Diferent Lock

Free

Credit cards case/holder wallet

Free

Urban Minimalist Wallet

Free

Cassettes Wallet

Free

Minimal TPU Wallet

Free

3 Card Wallet with Money Clip

Free

Mobile Phone Stand

Free

Slim Wallet with cash holder

Free

Wallet. Credit Card Case

Free

Wallet for cards and money clip

Free

3DWB // Minimalistic Wallet

Free

black bulls wallet

Free

3D Fabric Wallet

€0. 50

50

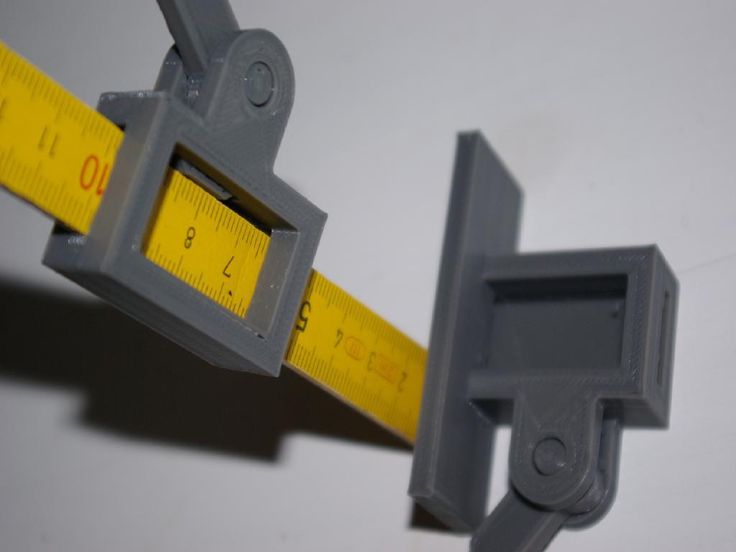

EDC WALLET MODULAR- (INTERCHANGABLE MODULE CLIPS)

Free

wallet card holder

Free

Minimalist wallet

Free

Wallet

€0.50

Credit card wallet for ten (10) cards

Free

Cardholder-wallet (universal package)

Cardholder-wallet (universal package)

Cardholder-wallet (universal package)

Cardholder-wallet (universal package)

Discover our selection of the best 3D wallet and card holder files for 3D printer. All these STL, OBJ, 3MF, CAD files are perfectly 3D printable, so just download them, start your 3D printer and choose your colors and filament materials. This collection was made by selecting the best creations from the 3D print file download site Cults.

You will find in this collection various styles of wallets and card holders, there is the classic one that folds in half to fit in your bag or your back pocket of jeans, but there is also the very simple card holder or the wallet with a mechanism that allows cards to go up. In short, there is something for everyone and for every need. Once you have selected the format and size of your wallet, simply choose the most beautiful color among all your filaments for 3D printers and get started!

3D printing a wallet also means making the most of your printer, as you will be able to use flexible filaments to obtain a wallet that can adapt to the quantity of cards you will need to put in it. If you don't have flexible filament, this is not a problem, the 3D designers who offer their STL models on Cults have the solution with 3D files that will be flexible once printed.

15+ Cool 3D Printed Wallets You Can Download & Print Today

Since wallets are traditionally soft and flexible, 3D printed wallets are a little difficult to imagine. But actually, there are tons of cool wallet designs you can 3D print today.

But actually, there are tons of cool wallet designs you can 3D print today.

Rigid wallets and flat card holders are the most common 3D printed wallets, but that doesn’t mean they’re all the same. With some smart models and designs out there, we’re going to look at some of the coolest 3D printed wallets to check out if you happen to need a new one.

Simple Wallets

Simple and minimalist wallets are popular these days. They’re light, easy to carry around, and harder for pickpockets to nab.

They are effectively small rigid wallets with segments to hold credit cards, business cards, and even keys.

So, here’s a few easy-to-print wallets without all the bells and whistles that anyone can 3D print.

EDC Wallet

This EDC wallet is a cool design that holds all your important cards (and a few bills if you like) in one place.

You will need to use a rubber band or something as elastic to hold it together, however, as the design doesn’t allow for free movement of the parts.

Slim Wallet

Spare keys are good to have around, but simply storing them in your house defeats the purpose. While doormats and fake rocks are often go-tos, they’re obvious spots for would-be thieves to check.

This slim wallet is a take on a traditional minimalist wallet that has enough space for a single key. Avoid being locked out by carrying your spare key in this 3D printed wallet so you’ll know it’s safe and out of the scope of uninvited guests.

The designer has admitted to not being a 3D printing expert, so you may need to tweak the design and infill, but it looks solid to me!

In addition, if you like to take your files with you, I recommend this minimalist wallet that’s similar to the slim one above, but with a built-in slot for a single USB drive.

Flipping Wallet

Flat card holders are handy enough, but they normally can’t hold much without being too big to be practical.

3D printed flipping wallets are great for those of you who have a few too many cards for a standard wallet. This flipping wallet design is one of many, but it’s the one I’ve found to be the most reliable while still being simple to make.

This flipping wallet design is one of many, but it’s the one I’ve found to be the most reliable while still being simple to make.

The Smart Wallet

Speaking of cool flip wallet designs, this smart wallet is a sleek model that holds up to nine cards.

There are two different designs, one that simply holds your bills and one that actually hides them when the wallet is closed. This is good news if you’re worried about thieves but still like to carry cash.

Non-Money 3D Printed Wallets

3D printed wallets aren’t just for holding credit cards and cash. Sometimes they’re just useful tools to store and keep track of other important objects. I for one dislike having things loose in my pockets or bags, so I have any number of organizers for any pocket-size things I happen to need to carry around.

SD Card Wallet

If you’re a shutterbug, then you probably know the pain of keeping those tiny SD cards safe and organized.

Fortunately, this simple SD card wallet is a great way to keep them all together and away from pocket lint. Could be a lifesaver on your next vacation or tour!

Could be a lifesaver on your next vacation or tour!

If you carry around more than 4 SD cards, then you can simply tweak the design or choose from one of the similar models here.

Technicians’ Wallet

The heavy duty technicians’ wallet is a 3D printed carrier for just about anything. As an all-in-one, it’s practically a pocket-size travel box, making it one of the coolest 3D printed wallet designs out there!

A simple print that’s been tweaked over time, the heavy duty wallet can hold an SD card, SD card reader, floss pick, nano Wi-Fi adapter, USB stick, and up to nine business and credit cards just to name a few!

It’s easy to see why this is the perfect wallet for anyone who finds themselves digging through bags and drawers for the smallest of conveniences.

Wallets don’t have to be simple billfolds or plastic with slots. Sometimes putting a new or even practical touch on a wallet makes it a lot better.

Here are some 3D printed wallets with cool touches that make them even more useful.

IOT Wallet

Millions of people around the world have invested in cryptocurrencies, and each of them needs to keep constant track of what they’re worth.

If you’re an investor yourself and don’t mind some extra work, then you’ll definitely want to check out this cool 3D printed wallet case. It comes with instructions on how to add a small screen that, if kept connected to Wi-Fi, keeps live track of your crypto’s value.

It makes sense when you think about it. What better way to keep track of your money than with the wallet in which you carry it?

Similarly, there’s this digital wallet that’s partially 3D printed and, with the right software, helps you keep track of your passwords for various social media sites. Just be extra sure not to lose that one!

Squishy Wallet

There are two things we carry around a lot, wallets and phones. Both of these are noticeable rectangles in our pockets and can ruin a good outfit or even be uncomfortable to carry around. Not to mention they’re very easy for would-be pickpockets to see and target.

Not to mention they’re very easy for would-be pickpockets to see and target.

If you’re a fan of skinny jeans then you’ll know exactly what I’m talking about.

With flexible filament, you can 3D print this squishy wallet. It’s just like carrying your bills loose in your pocket while still keeping them organized.

It’s a simple idea that’s great for quick shopping trips or nights out so you don’t need to fumble with an awkward rectangle when you need to pay and will barely even notice carrying around.

If you still need it to be slimmer, then you’ll be happy to know that the designer made an even thinner version.

Coin Holder

As someone whose day-to-day wallet doesn’t have a coin pouch, I can tell you it gets very annoying when I’ve got change burning a hole in my pocket.

If you’re sick of sounding like a cowboy when you walk around too, then you’ll like this wallet addition for holding small change.

It’s still a work in progress, but since you’ll need to change the measurements to fit your own wallet anyway, that shouldn’t be an issue.

For a cooler option (albeit a little less useful) there’s also this neat quarter holder for those sneaky trips to the vending machine.

Cassette Tape Wallet

No more practical than a normal 3D printed wallet but a cool design nonetheless is this cassette tape wallet. It looks cool and is pretty well-detailed to boot.

If you’re old enough to remember using these (I don’t know about you but I always found rewinding them with a pencil pretty satisfying), then you’ll love keeping your bank cards and bills organized in this 3D printed blast from the not-too-distant past.

The X Wallet

The most minimalist wallet I could find is the X wallet. The bill clip is optional, but I think it really makes it look cool and means you won’t need to squish your cash in with your cards.

With the clip, the X wallet can hold up to seven credit cards and a small wad of bills. It takes very little material to make, and looks way cooler than you’d expect from a design this simple. All in all, it’s one of my favorites and is wide open for changes and customization.

All in all, it’s one of my favorites and is wide open for changes and customization.

FAQs

Can you make a wallet with a 3D printer?

Yes, 3D printed wallets and card holders are very easy to make and come in a variety of styles, from minimalist and practical, to zany and fun. Using a sturdy filament like PLA is a good way to ensure you get top-quality results.

Other articles you may be interested in:

- 34+ coolest things to 3D print at home

- 3D pen art projects you can make at home

- 50+ Pokemon 3D prints you can download and make today

3D Printing in the Fashion Industry: A New Dimension

We are witnessing what many call the third industrial revolution: 3D printing, or additive manufacturing, has the potential to move us away from the era of mass production and into a new reality of customized custom manufacturing. A good example is fashion. In the recent past, "fashion houses" were more like multidisciplinary research institutes. To create a collection of clothes, in addition to an expert sense of style, you need knowledge in anatomy, advanced sewing machines, appropriate fabrics and accessories, accessories, shoes, people (cutters, seamstresses, models and many others). Through trial and error, an art object is created, rarely successful, but always laborious. 3D printing is a toolless manufacturing method that allows physical objects to be produced from a 3D model, usually in layers. The term is also used generically as a synonym for rapid prototyping. The scope of the technology is endless: from tools and toys to robots and mechanical parts. There is no limit to what a 3D printer can create.

To create a collection of clothes, in addition to an expert sense of style, you need knowledge in anatomy, advanced sewing machines, appropriate fabrics and accessories, accessories, shoes, people (cutters, seamstresses, models and many others). Through trial and error, an art object is created, rarely successful, but always laborious. 3D printing is a toolless manufacturing method that allows physical objects to be produced from a 3D model, usually in layers. The term is also used generically as a synonym for rapid prototyping. The scope of the technology is endless: from tools and toys to robots and mechanical parts. There is no limit to what a 3D printer can create.

Alexander Kornveits, expert in the field of additive technologies, founder and CEO of Tsvetnoy Mir

Fashionable futuristic design requires innovative production technologies, here 3D printing comes to the rescue. A wide variety of fashion accessories including bracelets, rings, brooches, necklaces and pendants can now be easily 3D printed. Let's take a closer look at how this technology can be used in the fashion world...

Let's take a closer look at how this technology can be used in the fashion world...

Custom Design

One of the unique aspects of 3D printing is the ability for designers to create custom shapes and sizes that would be impossible to produce with traditional methods.

Photopolymer 3D printing allows designers to produce products in small batches. Fashion designers can now create bold, one-of-a-kind pieces. In addition to time, technology can significantly reduce costs.

Accessories

The range of fashion accessories depends more on the imagination of the creator than on the possibilities of your wallet. All this can be easily printed using a conventional photopolymer 3D printer. Need a flower ring? No problem! 3D printing can do this and more. What else can be produced in this way?

Brooches

Brooches are intricate pieces of jewelry that highlight your personality. Business women especially like to use them to decorate and complement their business suits. For example, Madeleine Albright, the first female US Secretary of State, over the years of her career has created a new diplomatic language, full of metaphors and secret meanings. Through jewelry, she expressed her mood, intentions or the situation at the negotiations, and political scientists and journalists vied with each other to interpret the images on the left lapel of her jacket. 3D printing can be used to produce a custom brooch that can complement the look, and perhaps say something to the “initiates”.

For example, Madeleine Albright, the first female US Secretary of State, over the years of her career has created a new diplomatic language, full of metaphors and secret meanings. Through jewelry, she expressed her mood, intentions or the situation at the negotiations, and political scientists and journalists vied with each other to interpret the images on the left lapel of her jacket. 3D printing can be used to produce a custom brooch that can complement the look, and perhaps say something to the “initiates”.

Rings

3D printing can be used to make a prototype ring before making it into the final version of precious metals and stones. This will allow the designer to easily and quickly make adjustments, ensuring the ring fits perfectly and matches the client's expectations and end result. Important factors are saving time, money and, of course, a significant reduction in the likelihood of errors in the final product.

If earlier only professional 3D printers costing from $50,000 were suitable for the jewelry industry, now with the introduction of inexpensive mono LCD displays with 4K resolution, such printing is available to any jewelers and designers. The purchase budget fell below $500.

The purchase budget fell below $500.

Bracelets

Similarly, intricately designed bracelets can be created using photopolymer or wax 3D printers. It can be an exclusive version, one of a kind, which, if necessary, can be mass-produced. Technology allows you to think more broadly and not be afraid to experiment with expensive precious metals and stones. After all, modern consumables allow you to create prototypes with a high level of reliability.

Clothing and footwear

Shoes, dresses and other fashion items can also be 3D printed. This allows you to create ready-made items for wear, as well as improve the design of the model before launching into mass production. Shoes with geometrically complex 3D designs often find their way into the fashion mainstream.

And for more mundane purposes, there are sneaker soles. For example, Adidas makes them from a mixture of polymer resin with polyurethane added and prints in a lattice structure that promotes proper load distribution.

Adidas claims the Futurecraft 4D shoes are incredibly comfortable, with unparalleled ergonomics and wear resistance.

Simultaneously with shoes, there are numerous experiments on the use of 3D printing to create designer outfits and especially dresses.

One of the first 3D printed dresses was presented by American model and singer Dita Von Teese in March 2013 in New York. Couturiers Michael Schmidt and Francis Bitonti teamed up with 3D printing service Shapeways to print it using additive manufacturing technology. It consisted of 17 nylon parts, which were painted black and encrusted with 13,000 Swarovski stones.

In 2019, a whole series of such models was presented at the famous MetGala charity ball in New York. In the photo - American celebrities in outfits with 3D printed elements. Everyone was especially struck by the dress in the form of a rose petal (in the center), in which the British model Jordan Dunn appeared at the ceremony.

It, like the entire collection, was created by fashion designer Zac Posen in collaboration with GE engineers and 3D printers and made a splash on the red carpet of the event.

It is too early to talk about the widespread introduction of 3D printing in the fashion industry, but it is already clear that this process will continue. Creating custom-made jewelry is not a trend of the future, but of the present, a prerequisite for meeting the needs of the customer.

Source

3D printing in the fashion industry, 3D printer, Alexander Kornveits, Tsvetnoy Mir company, making a prototype of jewelry, 3d printed shoes, using 3D printing to create designer outfits and especially dresses

Best SLS 3D Printing Services | Accuracy, Affordability

What is SLS 3D printing?

Selective Laser Sintering (SLS) 3D printing is a prototyping process that combines microscopic particles.

Technically, it uses a polymer powder in a solid structure based on a 3D model.

For decades, SLS 3D printing has been favored by experts and manufacturers for its amazing results.

How does SLS 3D printing work?

SLS 3D printing works with an energy source that selectively melts powdered plastic material, fusing it into a 3D printed part.

In addition, it contains the following three steps:

printing

The printer preheats the powder to a temperature just below the melting point of the raw material, which allows the laser to raise the temperature of the metal powder areas.

In particular, the laser scans the bridge of a 3D model by heating the powder just below or just above the melting point of the material.

The resulting unmelted powder acts as a support structure during printing, eliminating the need for additional support structures.

Cooling

First, the build chamber is cooled slightly inside the print body.

Afterwards outside the printer to ensure perfect mechanical properties and prevent wrapping of parts.

Post-processing

However, finished components must be removed from the chamber, sorted and vacuumed to remove excess powder.

What's more, the powder used in the process is recyclable and the printed components can be further processed.

What are the benefits of SLS 3D printing?

The benefits of SLS 3D printing are many because SLS has long been the order model for rapid prototyping, especially for serial production of unique parts.

Below are the main benefits of SLS 3D printing:

High resolution images

This allows you to create high quality images that can be used for a variety of purposes.

Fast reaction time

This is a fast process and does not take several hours.

Outstanding mechanical properties

The resulting product has excellent mechanical properties without any disadvantages.

Superior Strength and Stiffness

SLS 3D printing produces durable prints that can be used with confidence as they are both strong and rigid in their structure.

Wide choice of materials

You can choose from a variety of materials, and they are not limited to any one material.

What are the disadvantages of SLS 3D printing?

The disadvantages of SLS 3D printing technology are listed below:

Limited materials

Since SLS 3D printing can produce products from plastic and metal, the choice of raw materials is not exhaustive.

This is because metals and plastics cannot be fully controlled with 3D printing.

In addition, many of these printed materials cannot be recycled and very few are food safe.

Postprocessing

Postprocessing procedures are complex and time consuming.

High volume

SLS 3D printing is a fixed cost, unlike more traditional methods such as injection molding where high volume production can be more profitable.

Although the initial investment in SLS 3D printing may be less than other production methods, once the investment is increased to produce large volumes for mass production, the unit cost does not decrease. Same as injection molding.

Structure of parts

In SLS 3D printing, parts are usually created layer by layer, also known as additive manufacturing.

This means that although the layers are tightly held together, they are susceptible to splitting when subjected to loads with a specific orientation or stresses.

This is a problem that often occurs with objects created using Fusion Deposition Modeling (FDM).

In addition, Multijet and Polyjet parts are usually more fragile.

Therefore, it may be better to use SLS 3D Printing Injection Molding when making homogeneous parts as they are stronger and less likely to fail under structural loading.

Limited assembly size

The camera built into SLS 3D printers is usually relatively small, which limits the size of parts that can be printed.

Therefore, any larger items must be printed separately and then assembled after production.

As a result, this increases the cost and time required to print because the SLS 3D printer has to print several parts before you can go ahead and manually join the parts.

Design inaccuracies

Another potential problem with SLS 3D printing is directly related to the type of machine or process used.

In addition, some SLS 3D printers have lower tolerances, which means that the final parts may differ from the original design.

This can be corrected in post-processing, but it should be noted that this will further increase the time and cost of production.

Reduction in production jobs

Another disadvantage of SLS 3D technology is the potential reduction in human labor, since most of the production is automated and done by printers.

However, many Third World countries depend on low-skilled jobs to support their economies.

This technology could endanger these manufacturing jobs, eliminating the need for overseas manufacturing.

Copyright notices

As SLS 3D printing becomes more popular and affordable, people are more likely to create counterfeit products.

Are SLS 3D printed parts resistant to high temperatures?

Yes, SLS printed parts are high temperature resistant, extremely durable, acid resistant and fairly heat resistant.

What's more, it can withstand operating temperatures up to 70 degrees Celsius.

While equally easy to print, SLS 3D printed parts are technically more resistant to high temperatures, making them a great choice for everyone.

Are SLS 3D printed parts durable?

Yes, SLS 3D printed products are strong, tough, strong and durable thanks to SLS technology. Among all materials, nylon is highly resistant to UV radiation, heat, moisture, chemicals, temperature and water.

In addition, it is also resistant to abrasion, especially when using special threads such as polycarbonate, which is used for bulletproof glass and riot shields.

In addition, increased strength can be achieved by adjusting the infill density, wall thickness and print orientation.

In addition, some SLS 3D printers have lower tolerances, which means that the final parts may differ from the original design.

This can be corrected in post-processing, but it should be noted that this will further increase the time and cost of production.

Can SLS 3D printed parts be surface finished?

Yes, SLS 3D printed parts must be surface finished.

Therefore, 3D printed objects created with SLS 3D printing are highly accurate and durable and are often used as functional components.

In addition, processing SLS parts after they have been printed is common practice and there are many processes and finishes available.

Coatings are also regularly applied to SLS parts to improve their performance; however, excess powder must be removed.

What are SLS 3D printing applications?

SLS 3D printing applications are widespread in various fields.

However, it is rapidly being used in modest production for the manufacture of final components for aerospace, military and electronics.

The following are some examples of SLS 3D printing applications:

Wind tunnel test models

It provides wind tunnel test models with great care.

Automotive Design

It has amazing automotive design with prototyping technology.

Elastomeric and urethane parts

This includes elastomer and urethane parts such as gaskets, seals and hoses.

Aerospace Parts and Flame Retardant Parts

It is specially built with aerospace, chrome and fire retardant parts for your good use.

Small-scale and mass customization solutions

Get customized mass production and small-scale production with SLS 3D printing.

Medical Devices

The company is driven by the vision of providing affordable, affordable and highly functional medical training equipment worldwide.

Functional proof-of-concept and design evaluation models

It comes with functional proofs, offers concept and incredible design models for evaluation.

What is the difference between industrial and commercial SLS 3D printing?

The difference between industrial and commercial SLS 3D printing is that the former is designed for aerospace applications and uses SLS technology to process metal objects.

On the other hand, the commercial SLS 3D printer uses resin-based technology to achieve positive results.

SLS vs SLA 3D printing which is perfect for my projects?

Among SLS and SLA-3D printing, the one with more precise and useful features is ideal for your projects.

While SLA is ideal for small parts, SLS has an advantage over SLA in that the adjacent powder supports the parts during production.

What's more, it allows complex shapes and channels that would be unattainable in SLA without powder support, while SLS allows for a wide range of materials.

In addition, SLS machines are more risky due to the higher power of the lasers and as such are completely insulated from the print.

However, the laser is much weaker in SLA machines. Tinted glass or plastic allows the user to view prints while preventing dangerous UV radiation from escaping.

FDM vs SLS 3D printing which is perfect for my projects?

Among FDM and SLS 3D printing, SLS 3D printing is the perfect option for you.

Some 3D printers use Fused Deposition Modeling (FDM) because it uses multiple filaments to be layered to form the structure.

In contrast, laser processes such as selective laser sintering (SLS) use only one filament material to create strong structures.

Compared to SLS, FDM cannot print complex designs or highly detailed products.

Subsequently, a better finish can be achieved by using chemical and mechanical polishing methods.

DLP vs SLS 3D printing, which is perfect for my projects?

Among DLP and SLS 3D printing, both can be ideal for your projects according to their respective conditions.

Indeed, you may want to consider using SLS professional 3D printers for more complex projects.

Compared with DLP, SLS is also useful for rapid prototyping, functional prototype, rapid production and small batch production.

PLA vs SLS 3D printing which is perfect for my projects?

Among PLA and SLS 3D printing, PLA 3D printing parts are perfect for your projects.

This is because PLA is short for polylactic acid (or polylactide). This ubiquitous thermoplastic is affordable, easy to print and biodegradable.

PLA is the material used in 3D printing and SLS is the printing method.

PLA is mainly used for Rapid Prototyping, Display Modeling and Education.

On the other hand, selective laser sintering (SLS) is a technology for rapid prototyping and production of functional components.

Numerous nylon based materials are available resulting in very strong end components.

Polyjet vs SLS 3D printing which is perfect for my projects?

Among Polyjet and SLS 3D printing, SLS 3D printing is perfect for you because of good detail quality.

SLS produces stunning, detailed models but is limited by breakaway support material and general process clutter. Therefore SLS is better.

With a soluble support material, faster print speeds and unrivaled multi-material capabilities, PolyJet technology takes resin SLS 3D printing to the next level.

What's more, PolyJet 3D printers transfer resin to the print bed using an inkjet printhead. This eliminates the need for the dirty, smelly and potentially hazardous resin used in SLA machines.

MJF vs SLS 3D printing which is perfect for my projects?

Among MJF and SLS 3D printing, MJF is superior due to its flexibility and some other qualities.

Industrial 3D printing uses powder bed fusion processes such as Multi Jet Fusion (MJF) and Selective Laser Sintering (SLS).

Both methods involve the layering of polymer powder particles and their thermal fusion (or sintering). Both MJF and SLS consist of granulated thermoplastic polymers.

Compared with SLS parts, which are weaker in the printing direction, MJF parts printed with this material have higher strength, flexibility, and uniform mechanical properties.

Does DEK offer customized SLS 3D printing services?

Yes, DEK offers customized SLS 3D printing services.

DEK has created unique solutions to your challenges through constant experimentation and a combination of new methodologies.

In addition, we use a wide range of materials that we have mastered to provide accurate SLS 3D printing services.