3D printing montreal

3D Printing Service Montreal | Instant Quotes Online

Our 3D printing capabilities

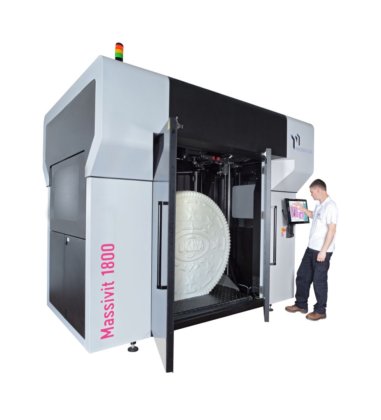

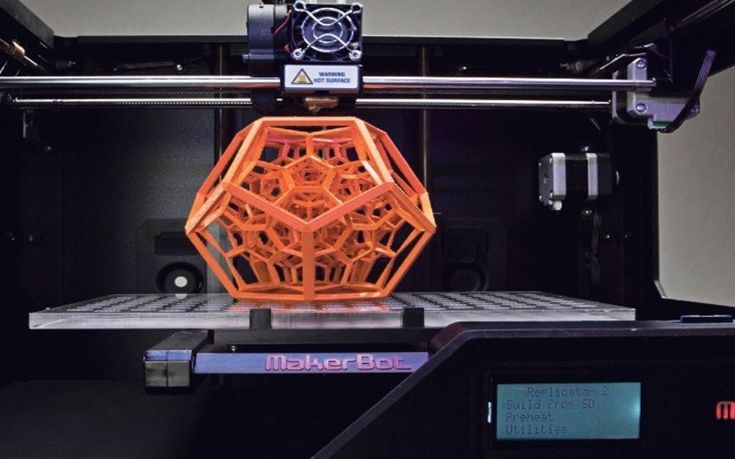

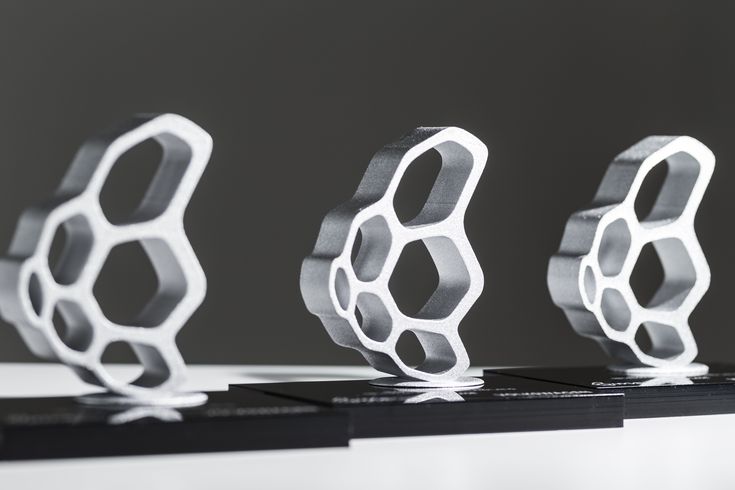

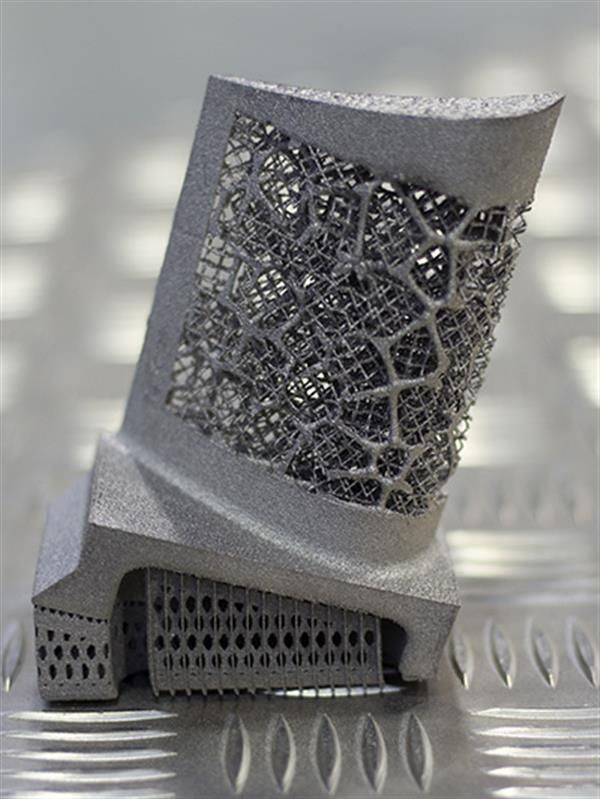

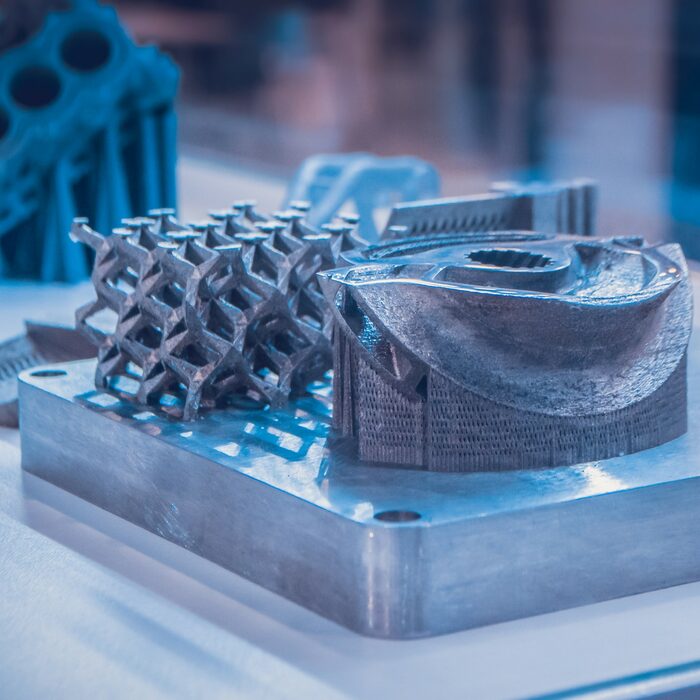

We have over 90 3D printing shops in our network and are well known for manufacturing high-quality parts at competitive prices, from rapid prototyping with Fused Deposition Modeling (FDM) to functional end parts made with Selective Laser Sintering (SLS) or Multi Jet Fusion (MJF).

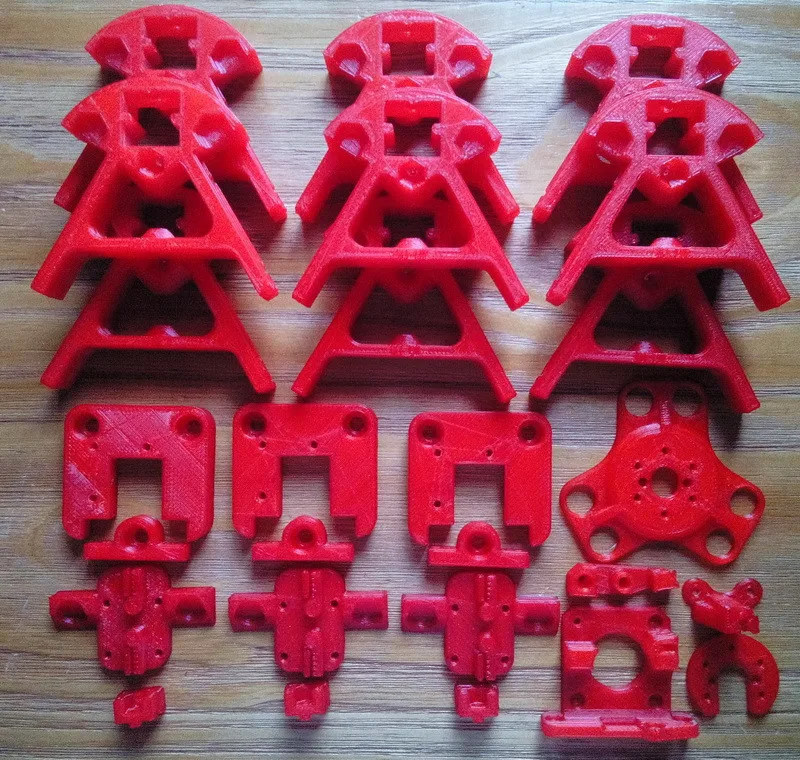

Gallery of 3D printed parts manufactured by Hubs

With over 65,000 customers from every industry, including aerospace, defense, robotics, medical, machinery, automotive and electronics, we have extensive experience meeting a diverse range of 3D printing requirements, from prototyping to production: Visual aids, concept models, injection-molding prototypes, form-fit & function prototypes, tooling and casting patterns, jigs, grips and fixtures, and durable end parts.

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

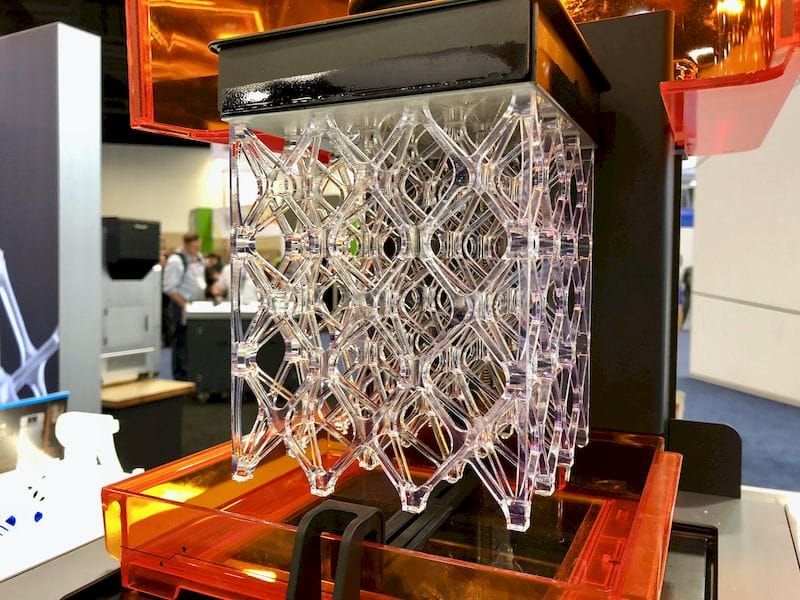

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

Instant, online 3D printing quotes

-

Upload a CAD to start (STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT, STL, OBJ or X_T)

-

Price updates in real-time as you change materials, lead time, etc.

.

-

No hidden costs. Our instant quotes are not just indications, but the actual price, and include shipping and customs up front.

Learn about how our quoting algorithm works

Our ordering process

Receive instant quote

Upload your CAD to our online quoting platform

Confirm specs

Configure your part specifications and select a lead time that suits your schedule

Production

We select the best manufacturer for your order, and production begins immediately

Quality control

We take full responsibility for making sure your parts are manufactured according to our standards

Delivery

Our 3D printing service has been rated 4.9/5

Over 282 customers are satisfied with our 3D printing service.

“Thank you, the part is accurate & the service is really fast.”

“Parts were completed quickly and appear to be good quality.”

“Fantastic service and great quality prints. Thank you. ”

“Awesome. Will get all my repeat business.”

“Very good 3D print job, and a great service.”

“Overall, the service was great & fast. I definitely consider ordering more parts to your company in the very near future!”

“The quality of the printing is really good,far better than any other service I used.Thank you :)”

“Very good print for the price and pretty fast turn around.”

“Quick response with a very good printing quality.”

“Printed overnight and was able to pick up early morning. Great turnaround and quality.”

“Quick turnaround. Easy communication. Would use again! ”

“EXCEPTIONAL PRINT. Fast, clear, easy communication. Kind & Wonderful & Great. Stellar! Thank you very very very much!”

“Excellent communication. Highly recommend. ”

Highly recommend. ”

“Love that guy ! Insane service , fast and the quality is perfect. Thanks”

“Super imprimeur, je le recommande les yeux fermés.”

“Excellent service and knowledgable friendly printer. Definately will come back to print more ”

“Nice quality, speed and service. I recommend him”

“Outstanding service. He was able to print a huge batch of parts overnight and they were flawless! 10/10 ”

“Fast initial contact and very fast printing and shipping Great quality of print ”

“Awesome! Will order again in the future and recommend him to friends that need prints.”

“Good quality print and really helpful, A+”

“The product is perfect and the service is awsome”

“Excellent quality of the print and the finishing. Communication was easy. ”

“Easy pickup box for orders, very good quality.”

“Insanely fast communication and print time. The order was placed, completed and picked up within 12 hours! Unheard of service. ”

”

Show more reviews

Show less reviews

Teams build better parts

Create your Hubs team and start collaborating

Read more

The Hubs Standard - consistent quality, every time

Hubs takes the stress out of manufacturing by guaranteeing the quality and consistency of every part. Each order is dimensionally and visually inspected to make sure it meets the Hubs Standard.

3D printing materials

We can generate instant 3D printing quotes for 25+ plastics. For metal 3D-printed parts, you can request a quote from our parent company, Protolabs.

Available materials

SLS

PA 12 Glass filled PA 12

Desktop FDM

Prototyping PETG Prototyping ASA Prototyping TPU Prototyping ABS Prototyping PLA

Desktop SLA

Formlabs Standard Resin Formlabs Clear Resin Formlabs Tough Resin 2000 Formlabs Rigid Resin 4000 Formlabs Grey Pro Resin Formlabs Flexible Resin 80A Formlabs High Temp Resin Formlabs Durable Resin

MJF

HP PA 12 Glass filled HP PA 12

Industrial FDM

Markforged Onyx ABSplus Stratasys ULTEM 9085 Stratasys Stratasys ASA ABS M30 Stratasys ULTEM 1010 Stratasys

Industrial SLA

Accura 25 (PP-like) Accura ClearVue Accura Xtreme White 200 (ABS-like)

3D printing locations near Montreal

Saint-Jérôme Montreal Trois-Rivières

Drummondville Burlington, VT Ottawa

Sherbrooke Glens Falls, NY Watertown, NY

Quebec City

The 3D Printing Handbook

No one understands 3D printing like us - our founders literally wrote the book. Click here to download the sample chapters.

Click here to download the sample chapters.

Buy the book from Amazon

FAQ's

How much does your 3D printing service cost?

The cost of your 3D printed parts depends on factors such as part volume, part complexity, choice of material, which 3D printing technology is used, and if any post processing is required. For more details on these cost factors, see our article on the cost of 3d printing. To check the cost of your 3D printed part, simply upload a CAD (.STL) file and select your material and 3D printing technology to receive a quote within seconds.

How do you guarantee the quality of my prints?

Your parts are made by experienced 3D printing shops within our network. All facilities are regularly audited to ensure they consistently meet the Hubs quality standard. We include a standardized inspection report with every order and offer a First Article Inspection service on orders of 100+ units.

We have partners in our network with the following certifications, available on request: ISO9001, ISO13485 and AS9100.

Follow this link to read more about our quality assurance measures.

How do I select the right 3D printing process for my prints?

You can select the right 3D printing process by examining which materials suit your need and what your use case is.

By material: if you already know which material you would like to use, selecting a 3D printing process is relatively easy, as many materials are technology specific.

By use case: once you know whether you need a functional or visual part, choosing a process is easy.

For more help, read our guide to selecting the right 3D printing process. Find out more about Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF) and Stereolithography (SLA).

How can I reduce the cost of my 3D prints?

In order to reduce the cost of your 3D prints you need to understand the impact certain factors have on cost. The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

Once these have been decided, an easy way to further cut costs is to reduce the amount of material used. This can be done by decreasing the size of your model, hollowing it out, and eliminating the need for support structures.

To learn more, read our full guide on how to reduce the cost of 3D printing.

Where can I learn more about 3D printing?

Our knowledge base is full of in-depth design guidelines, explanations on process and surface finishes, and information on how to create and use CAD files. Our 3D printing content has been written by an expert team of engineers and technicians over the years.

See our complete engineering guide to 3D printing for a full breakdown of the different 3D printing technologies and materials. If you want even more 3D printing, then check out our acclaimed 3D printing handbook here.

We have an extensive range of online resources developed to help engineers improve their capabilities.

Introductory guides

Design guides

Material guides

Applications

CAD & file preparation

Post processing & finishing

Our other manufacturing capabilities

CNC machining

CNC machining

Milling (3-, 4- & full 5-axis), turning and post-processing

-

50+ metals and plastics & 10 surface finishes

-

Tolerances down to ±.0008” (0.020 mm)

-

Lead times from 5 business days

See our CNC machining services

Put your 3D printed parts into production today

Get an instant 3D printing quote

3D Printing Service Montreal, Quebec, Canada – Fablab Inc.

3D Printing Service Montreal, Quebec, Canada – Fablab Inc.

3D Printing Service Montreal, Quebec, Canada – Fablab Inc. 3D Printing

Consult the printing costs immediately and obtain your parts in just a few days by using our intuitive online platform.

- arrow_right Wide selection of technology and material options

- arrow_right Chose the color and surface finish for your parts

- arrow_right The prices are calculated and displayed in real time

- arrow_right Allow others to print your models via an email link

- arrow_right Request and save a quote for larger quantities

- arrow_right Save your 3D models in your catalogue for later

- arrow_right Easily review your previous orders and invoices

3D Scanning

The scanning process allows you to convert your real life items into detailed 3D models. You can then reproduce the object, or reverse engineer it's design.

You can then reproduce the object, or reverse engineer it's design.

- arrow_right Generate a highly detailed 3D model

- arrow_right Works with any object size

- arrow_right Accuracy up to 50 microns

- arrow_right Captures the actual textures of your object

- arrow_right Convert real objects to digital objects, and vice versa

Design

Let us help you with our expert advice and 3D modeling services. We can assist with every step of your project, ranging from the initial design ideas to your final prototypes.

We can assist with every step of your project, ranging from the initial design ideas to your final prototypes.

- arrow_right Develop your ideas and designs

- arrow_right Prepare professional renderings

- arrow_right Parametric 3D modeling

- arrow_right 3D surface modeling

- arrow_right Finite element analysis

- arrow_right Development of specifications

- arrow_right Small series production

Our service in three steps:

Use our online quoting tool to upload your 3D files

We print and prepare your parts accordingly to your demand

We ship the printed parts directly to you

Materials

Castable Wax resin is now available at Fablab Inc!

We have incorporated a new engineering resin into our material options which is used in the lost wax casting process.

This resin is a material containing 20% wax, allowing reliable and clean burning, without residue or ash. It perfectly reproduces intricate details and results in smooth surfaces characteristic of stereolithographic printing. The printed parts are strong enough to be handled without UV curing after printing, to undergo fittings and to be used directly for casting.

Read more

New product

Use polyjet technology to bring new opportunities to your business

Our new polyjet machine is now ready to produce your parts!

Able to go up to a resolution of 13 microns, this technology makes it possible to combine precision and speed. It can also print large parts thanks to its 260 x 260 x 200 mm (10.24 × 10.24 × 7.9 in) area.

Several materials are available to order!

New: The RUSH 24 delay option is now available for this technology.

Read more

Materials

Sacrificial tooling for composite part fabrication

Although basic shapes and cross-sections are easily manufactured using traditional techniques, complex parts with hollow interiors still present a real challenge to manufacture in the composite parts industry.

Using thermoplastics that can be dissolved after printing, it's possible to better control the dimensions and even simplify components with complex geometries.

There are many advantages to using this material and you can learn more about them here.

Read more

New service

Receive your parts as quickly as you need using our RUSH options

Using our 3 RUSH production options, your parts can be ready in 24, 48, or 72 hours.

These accelerated lead times will help you validate your 3D designs and build of your prototypes faster.

Connect to our online quoting services to place your order now.

Read more

Guide

The advantages of 3D printing in the medical sector

The medical field is a sector where there are many constraints that are always evolving and changing with the new technologies being developped. The resources used in surgery or to treat patients must be very precise and personalized. This means that the parts required are limited and therefore very expensive. 3D printing is a solution that is increasingly being considered and which brings a lot to the future of health and allows care adapted for each patient.

New applications of this technology are used creative ways, find out how these could one day help you!

Read more

Stay in touch

Our online platform is constantly evolving, as are our printing technologies and material options. You can keep informed of our news, services, and latest offers by subscribing to our mailing list.

You can keep informed of our news, services, and latest offers by subscribing to our mailing list.

We send a maximum of one email per month.

Canadian researchers 3D printed metal crowns to protect endangered walrus tusks

Researchers from the Canadian École de Technologie Supérieure -Éverséal de Ts ) have 3D printed protective "crowns" for endangered walrus tusks at the nearby Quebec Aquarium.

Four marine mammals are protected in the aquarium, but their new concrete habitat is not very suitable for their teeth, as they help themselves with fangs and tusks when they emerge from the water. Using a 3D scanning and printing approach, the team was able to accurately fabricate metal caps that fit walrus tusks precisely and prevent them from suffering from dental abscesses.

“This practice [tooth-assisted walking] is not a problem in a natural environment of ice and soil,” explains Dr. Claire Grosset, Professor of Animal Medicine at the University of Montreal. “But things are different in a habitat made up of concrete, metal and other materials chosen to support these animals, which can weigh over a ton.”

Claire Grosset, Professor of Animal Medicine at the University of Montreal. “But things are different in a habitat made up of concrete, metal and other materials chosen to support these animals, which can weigh over a ton.”

Many Atlantic walruses, scientifically known as Odobenus rosmarus, used to live in Canada's northern Arctic region, but have been endangered for many years. Atlantic walrus, on which at 17-19hunted for centuries for tusks, meat and fat, it is now completely extinct in the once populous areas of Newfoundland and Nova Scotia.

Oil and gas production is also becoming a threat to Arctic mammals due to reduced available sea ice and stampede on healthy and stress-sensitive animals. The Aquarium of Quebec adopted them to ensure the reproduction of endangered species and draw attention to their plight.

The Latin name for this species, Odobenus rosmarus, roughly translates to "tooth-walking", which is an apt description of how they rise out of the water in their natural habitat. Unfortunately, now that they live in an aquarium, the concrete and metal surfaces around the walrus enclosure can damage their fangs, putting them at risk of dental abscesses.

Unfortunately, now that they live in an aquarium, the concrete and metal surfaces around the walrus enclosure can damage their fangs, putting them at risk of dental abscesses.

One of the 400 kg, four-year-old female walruses in the aquarium (who, unfortunately, was not named) was found to be at particular risk of splitting or breaking tusks. To prevent further damage to her pearly white fangs, veterinarians recommended protecting them with custom metal caps.

Caps can be considered like a human filling because it avoids the need to extract any "teeth", which is a much more invasive procedure. What's more, the anesthesia-free treatment is very helpful, as some sedatives can be lethal to this species of walrus.

While other tusk plugs have been developed in the past, they were created using conventional manufacturing processes, and the team started by evaluating what metal would make the best device. In the end, the researchers chose cobalt-chromium because it prevented repetitive friction while being resistant to oxidation in salt water.

Three different caps were 3D printed with a gap of 0.25 mm to 0.45 mm to the tusk. Various size options allowed the veterinarian to choose the optimal device that would not weaken the adhesive bond and would not interfere with its snug fit to the ivory.

Given the potential effects of anesthesia on the walrus, the team decided to train the walrus to remain still, completely avoiding the need for sedatives. Over several months, the walrus was trained three or four times a day to remain still for increasingly longer periods of time, and rewarded with treats for success.

Ultimately, the marine animal managed to stay still for five consecutive minutes, allowing the veterinarian to successfully install one of the 3D printed devices. According to the researchers, it was a combination of the unique crown-making process and the bond between the mammal and its handler that made the whole procedure possible.

In recent years, 3D printing has proven to be an effective means of wildlife conservation in a variety of ways.

Scientists from the University of Kent and conservation organization Paso Pacifico have developed 3D printed sea turtle eggs to prevent real turtles from being stolen and sold in Costa Rica. Additional devices, nicknamed "InvestEggators", were equipped with GPS trackers, allowing them to be used to detect illegal trade routes up to 137 km away.

Meanwhile, engineers at the Georgia Institute of Technology have developed an innovative method for monitoring the environment at the Atlanta Botanical Garden: a 3D printed sloth. The robotic mammal is currently loitering through the trees above the 40-acre forest, making sure the temperature, weather and carbon dioxide levels stay the same.

Elsewhere, a team of architects from the University of Hong Kong (HKU) 3D printed 128 hexagonal clay tiles and dropped them into the ocean in an attempt to save the local marine park. It is hoped that the fabricated structures, seeded with popular species from the bay, will become a new home for corals to land on.

Source: /

Contacts of the 3D Technology Center, how to find the 3D Technology Center, supplier of 3d printers, 3d scanners all over Russia

Call us!

Free call from Russia Tomsk

+7(3822) 25-59-25

Sot. Megaphone

+7(923) 401-31-00

or write:

Marketing Department of Russia and the CIS countries:

You can call us free of charge from your city by typing in tone set: 64008

Australia, Melbourne + 61 (39) 111-24-60 (84+7) 078 650

Australia, Sydney +61 (28) 880-04-33

Austria National +43 (720) 775-512

Argentina, Buenos Aires +9004 (8507) 11) 521-70-773

Belgium, Mobile +32 (466) 900-986

Bulgaria, Burgas +359 (56) 918-319

Brazil, Rio de Janeiro +55 (21) 404-200-67 UK , London +44 (203) 769-01-65

Guatemala, Guatemala +502 (2) 375-00-15

Germany, Berlin +49 (305) 201-42-42

Denmark, 9007 National +45 (7) 873-09-60

Israel, Jerusalem +972 (2) 569-50-85

Israel, Tel Aviv +972 (3) 374-12-78

Ireland, National +353 (76) 888-92-44

Iceland, Reykjavik +354 (5) 395-011

Spain, Barcelona (93 34+) 164-17-78

Spain, Madrid +34 (91) 082-27-97

Kazakhstan, Nur-Sultan (Astana) +77 (172) 472-839

Canada, Montreal +1 ) 819-05-77

Canada, Toronto +1 (647) 496-82-62

Canada, Toronto +1 (437) 800-55-03

Cyprus, Nicosia +357 (22) 030-216

Colombia, Bogota +57 (1) 580-03-35

Kyrgyzstan, Bishkek +996 (312) 962-693

9007+ Latvia, Riga 9007 88-15-29

Lithuania, Vilnius tel:+370 (5) 259-61-71

Mexico, Mexico City +52 (55) 852-62-722

New Zealand, Wellington ) 889-49-10

Panama, Panama +507 (836) 77-75

Poland, Warsaw +48 (22) 602-21-91

Russia, Belgorod +7 (4722) 777-170

Russia, Voronezh +7 (4732) 007-316

Russia, Ekaterinburg +7 (3432) 264-777

Russia, Kazan

Russia, Kaliningrad +7 (4012) 92-08-66

Russia, Krasnodar +7 (861) 217-6-777

Russia, Krasnoyarsk +7 (391-989-7019) Russia, Moscow - bronze +7 (495) 777-66-75

Russia, Nizhniy Novgorod4-10

Russia, Novosibirsk +7 (3832) 35-92-92

Russia, Omsk +7 (3812) 99-16-40

Russia, Perm +7 (3422) 33-83- 05

Russia, Rostov-on-Don +7 (863) 308-17-60

Russia, Ryazan +7 (4912) 29-40-35

Russia, Samara +7 (846) 970- 77-77

Russia, St.

Learn more