3D printing molds for silicone casting

Ultimate Guide to Silicone Molding for 3D Printing (Part 1)

Download the full Guide

as a PDF!

The simple post-processing techniques presented in this guide are an excellent way for professionals to create low-cost silicone molds, threaded inserts for enclosures, vacuum formed parts, and more.

Silicone molding is a powerful production method that, when combined with 3D printing, can allow you to make several copies of one product. You can also create a product in a material that is not supported by your 3D printer.

In this How To, we will show you some of the best practices associated with creating silicone molds around 3D printed parts.

Working time will vary depending on a number of factors. Creating a mold around our 3D printed part took us about 1.5 hours. Casting into our mold took about 15 minutes.

Supplies

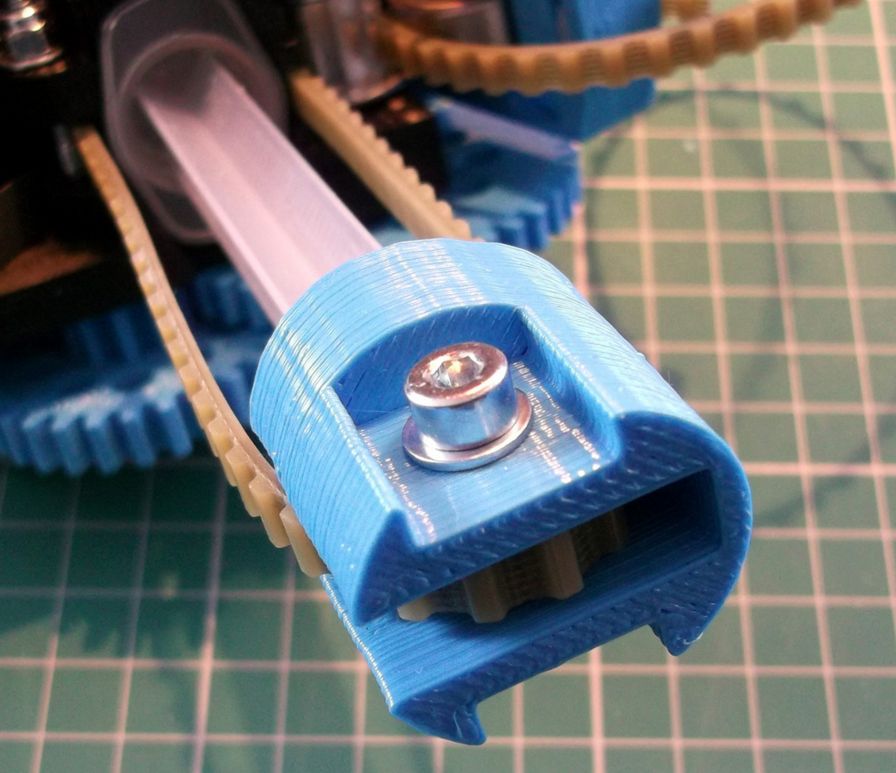

3D printed mold box, hardware, vents & keys (read on for more info).

Master (the print you are molding)

Silicone

Resin and dye

Mixing cups

Mixing sticks

Mold release spray

Hot glue or cyanoacrylate glue

Funnel

Ex acto knife

Rubber bands, tape, or straps

Gloves

Respiratory mask

Eye protection

Need some of these products? We've curated an Amazon wish list for you.

Step 1: Choose a file to cast a mold around

Obtain a file that you would like to either make several of, or create in a material not supported by your printer.

We chose the cap to a perfume bottle to understand what the process would look like for a product development team attempting to produce several concept models of a prototype.

The next step is to create your mold box. This is the structure that will hold the silicone in place around your part when pouring. Your master will need to be suspended in this structure.

You can create mold boxes from:

Foam core board

Legos

3D printing

We chose to design and print ours as this method has a few benefits. Designing and 3D printing mold boxes allows you to:

Print in pour holes and vents

Easily calculate the volume of our mold

Create boxes that perfectly fit the parts you plan to create a mold of

Re-use mold boxes to create multiple molds

While 3D printing your mold box isn’t necessary, it provides you with a reusable customizable mold box that the other methods cannot produce.

Step 3: Prepare and Print

Because the silicone molding process is not very demanding on the 3D printed mold box or master, you can select standard print settings.

The 2021 Guide to 3D Printing Materials

Learn about polymers, composites, and metals all available for 3D Printing!

Supplies Used:

3D printed mold box, 3D printed master, Cyanoacrylate glue, Mold release spray, Vents & Keys

A: Spray your mold box, master, vents, and keys with mold release.

B: Choose points across model to glue vents

C: With our 3D printed mold box we were able to glue our master directly onto the pour hole during preparation.

D: Spray again with mold release for good measure

You can suspend your master using popsicle sticks, skewers, or 3D printed rods glued to the surface of the master in an inconspicuous place. The holes left in their place after your mold has cured will aid in resin flow through the mold.

Step 5: Open Bottles of Silicone (Parts A and B) and Stir Thoroughly

Supplies Used: Silicone (Part A & B), Mixing Sticks

As silicone comes in two parts, it needs to be mixed both individually and once combined with its hardener.

Mix slowly using separate mixing sticks.

Supplies Used: Measuring cups

A: Determine the volume of silicone needed to fill your mold

B: Measure desired amount of silicone and hardener separately in two measuring cups.

We calculated our mold volume by filling our 3D printed mold box with water and pouring the water into a measuring cup to find exact volume.

For two part molds like the one shown, you only need to mix enough silicone to fill half of the volume of your mold.

Once you have measured each part, combine the two parts into one mixing cup and stir slowly with a mixing tool.

Be cautious not to stir in air bubbles. Be sure to scrape the sides of the cup to mix in all material.

Once your parts are thoroughly mixed the curing process will begin.

TIP

Read instructions on your silicone for “pot-life”. This is how long you have to work with the silicone before it cures.

Supplies Used: Mixed silicone, prepared mold box and master

Pour silicone into the first half of your mold box.

When pouring, pour slowly into one corner of the mold box and allow the silicone to run to other parts of the mold box as it fills.

Stop when the silicone reaches the top of the first half of your mold box.

Once you have poured your silicone place small keys into the silicone. These will create negative spaces and allow the mold halves to fit together once poured. We will remove them before pouring the second half of our mold.

Depending on what type of silicone you are using it can take anywhere from 75 minutes to overnight to cure.

Temperature and humidity will affect curing times, so we recommend this process be done in a room temperature environment.

Step 10: Attach and Prepare Mold Part Two

Supplies Used: Mold box part two, hardware (nuts & bolts)

Once our mold has set, we will prepare to pour the second half of our mold.

A: Remove the keys you inserted in step 9.

B: Attach and secure second half of mold box.

C: Spray with mold release

Next, repeat steps 5-9 and create the second half of your mold using the methods mentioned above.

Step 12: Let Cure

Supplies Used: Pliers or Ex-Acto knife

Once both halves of your mold have cured you are ready to remove them from the mold box and begin using them to recreate parts.

A. Remove the hardware

B: Remove the mold from the mold box and open.

C: Remove the master and vents.

Supplies Used: Cured mold, mold release spray, rubber bands

Next, you will need to reassemble your mold.

A: Ensure that all parts of your mold are correctly aligned, and plug any holes created by vents.

B: Secure mold pieces using rubber bands, straps, or tape.

Tip

Another great application for 3D printing would be to design and print a box to hold the mold together when pouring resin, or modify the mold box we used to serve the same purpose.

TIP:

If your vents leave holes in areas where resin can spill out during the pour, they will need to be plugged.

Supplies Used: Resin (Part A & B), measuring cups, measuring sticks, dye.

Just as with silicone you will need to measure each part of the mixture taking into account the volume needed to create a part.

If you have made several molds, you can mix a larger quantity of resin and pour several molds at once.

Add dye to the part of the resin mixture specified in the instructions.

Step 16: Mix Resin

Combine both parts of the resin mixture and mix thoroughly being sure not to stir in air bubbles.

TIP:

Resins typically have a shorter “pot-life” than silicone meaning they will cure faster.

Step 17: Pour Resin

Supplies: Funnel

Once mixed, pour immediately into the opening of your mold using a funnel.

Pour slowly as not to overfill and spill resin.

Any resin that remains in the mixing cup will harden, but can typically be removed afterwards.

Step 18: Let Cure

Once poured, allow the resin to cure for the appropriate amount of time.

Supplies Used: Pliers

Once your resin has cured, you can open the mold and remove your cast part.

Any resin that escaped through seams or voids and cured is called “flash”. Flash will need to be removed from the part through post processing.

Below, you can see that we were able to recreate our perfume bottle cap in several different colors and opacities using silicone molding.

Visit one of our other applications pages for tips on how to take your print even further.

We recommend that you visit our pages on:

Silicone Molding Part II

Vacuum Forming

Sanding

Last but not least, remember to share your work with us on Thingiverse and social media @MakerBot.

We can’t wait to see what you make!

Powered by MakerBot Learning.

Ultimate Guide to Silicone Molding for 3D Printing (Part 2)

Download the full Guide

as a PDF!

The simple post-processing techniques presented in this guide are an excellent way for professionals to create low-cost silicone molds, threaded inserts for enclosures, vacuum formed parts, and more.

Silicone molding is a powerful production method that when combined with 3D printing, can allow you to make several of one product, or create a product in a material that is not supported by your 3D printer.

In this How To, we will show you some of the best practices associated with 3D printing molds to pour into. To demonstrate this process, we will create a bicycle handlebar grip out of flexible silicone using a 3D printed mold.

Working time will vary depending on a number of factors. This process took us about 30 minutes excluding cure times, which will vary depending on the silicone products used.

Supplies

3D printed mold

Mold release spray

Measuring/mixing cups

Mixing sticks

X acto knife

Silicone

Gloves

Eye protection

Respiratory mask

Need some of these products? We've curated an Amazon wish list for you.

PRINT MOLD

As silicone molding is not very demanding on your prints, there are minimal print settings to take into account when printing a mold.

In this case we used standard settings. If surface finish of the cast part is of concern, consider sanding your printed mold.

PREPARE MOLD

Spray all mold surfaces with mold release & fasten mold pieces together with rubber bands

You will need to stir each part of the silicone individually before mixing.

Be sure not to stir too vigorously, otherwise you will stir in air bubbles which can be detrimental to your cast part.

Measure Part A

Measure Part B

Add dye to either Part A or B (this will be specified on your silicone/dye)

Stir in dye

Combine parts A and B and stir.

Stir slowly as not to mix in air bubbles.

Check instructions for the “pot-life” of your silicone. This will tell you how long you have to work with your silicone until it cures.

Here we used a three piece mold, so we only filled about ¾ of the mold to account for the third piece.

After pouring, the insert seen here was added to create a channel in the cast part for a bicycle handlebar.

The 2021 Guide to 3D Printing Materials

Learn about polymers, composites, and metals all available for 3D Printing!

You may need a flat tool like the one shown below to provide leverage when opening the mold.

Open slowly as not to damage your part.

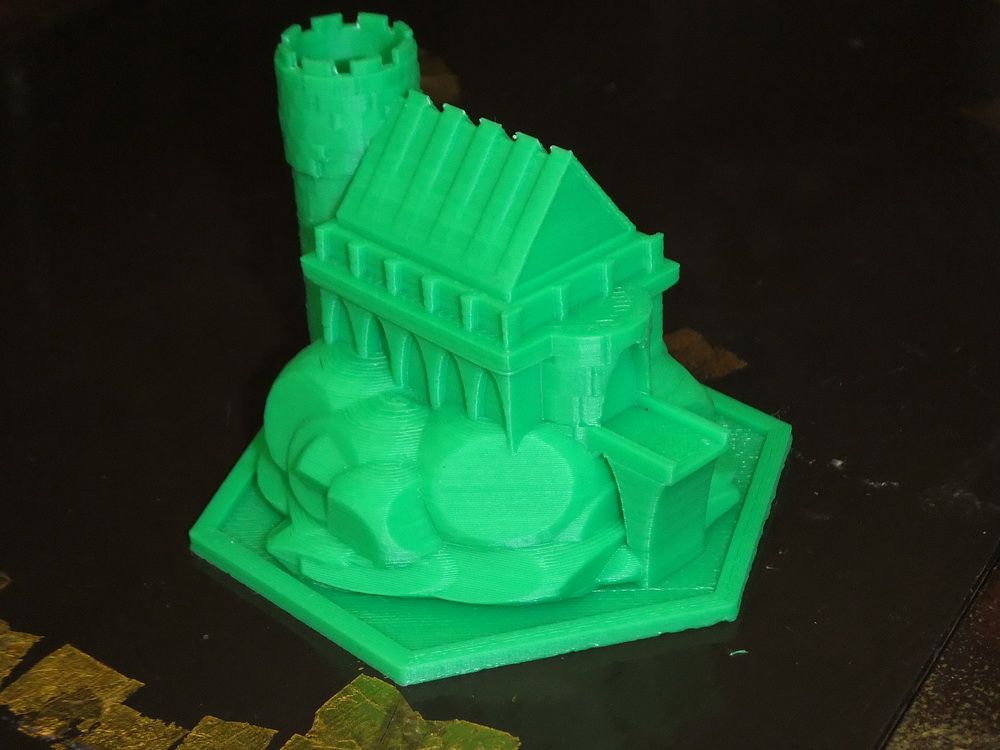

Here, you can see the part we were able to create using a 3D printed mold.

Visit one of our other applications pages for tips on how to take your print even further.

We recommend that you visit our pages on:

Silicone Molding Part I

Vacuum Forming

Sanding

Painting

Gluing

Last but not least, remember to share your work with us on Thingiverse and social media @MakerBot.

We can’t wait to see what you make!

Bike Handle Bar Grip Mold

Rconroy

6/14/2013

https://www.thingiverse.com/thing:103723

Published by MakerBot Learning

Powered by the MakerBot Learning Team

Making a silicone mold "Olympic Bear" for pouring chocolate using 3D printing.

All good mood friends! Today I want to share my experience in creating a 3D printed chocolate mold.

How it's done...

1) A master mold for silicone molding is designed in a 3D editor and printed on a 3D printer (the most interesting stage).

2) All details of the master form are processed with a file or a drill to make the forms smooth (the most hard labor stage).

3) Then the master form is filled with food silicone and it hardens (the most exciting stage).

4) Chocolate or baking dough is poured into the silicone mold (the most delicious stage).

So, let's start with the design of a master mold for silicone casting. First, we create in the 3D editor the figure that we should get at the output in the form of sweets. I have this figurine of the Olympic bear.

You can also make a chocolate bar as another example.

This figurine is embossed on the front side, smooth and flat on the back side. This is how chocolate should be.

This is how chocolate should be.

In the silicone mold, this object must be concave so that the poured chocolate or dough will be a copy of our model. On one form, we will have three concave olympic bears connected to each other at the top with a 2 mm silicone layer. Even in this form there should be edges of 10 millimeters, so that it is easier to take and carry it by them.

Therefore, we are designing a tray-like figure with a side height of 2 mm, which will accommodate all three Olympic bears. The distance from each bear figurine to the sides is about 10 mm.

Silicone filled up to the edge of these edges will be the same 2 mm layer that connects the figures and serves for comfortable holding of the mold.

Next, we design the upper part, which lies on the tray and has protrusions in the form of bears. From the highest point of the figure of the bear to the very top edge of this part, there should be a distance of about 2 mm - these are the bottoms of the silicone mold.

If we look at another example, with the master shape of a chocolate bar, then the tray is exactly the same, but the upper part is slightly different.

The master mold model is ready, it remains to be printed on a 3D printer.

But then the question arises! Do you print the figures of the bears and the tray at once as a whole or separately, and then glue them together? Of course, in a good way, it is better to print them immediately, then there will be no gaps between them. But then it will be very difficult to process the entire solid form with a file. And you will have to process it, since smooth forms do not come out from under the 3D printer. You can make chocolate with rough surfaces for yourself and not worry too much about it, but if you are making for a gift or for other people to order, you are usually very jealous of the smoothness of the forms. So post-processing is much more convenient if you separately print a tray, separately three figures of bears. Sand each of them, and then glue to the right places. This is also convenient because the entire structure of the tray and three figures will be printed for several hours, and if the light is suddenly turned off or some other unforeseen failure occurs, it will be painful and insulting for the wasted plastic. And if they are printed separately, then the failure will occur on one part. It is easier to reprint it than the entire structure.

Sand each of them, and then glue to the right places. This is also convenient because the entire structure of the tray and three figures will be printed for several hours, and if the light is suddenly turned off or some other unforeseen failure occurs, it will be painful and insulting for the wasted plastic. And if they are printed separately, then the failure will occur on one part. It is easier to reprint it than the entire structure.

The next step, as an inquisitive reader understood, is post-processing. It is good to use PLA plastic - it is quite easy to grind. HIPS is even better - rub it a couple of times with a file and all the roughness is already smoothed out. Can be processed with a file or drill. Bear figurines need to be smoothed as best as possible, and the tray and the upper part, in principle, can not be processed, because their smoothness-roughness will not affect the chocolate in any way. Those who absolutely need the whole shape to be smooth will have to work on the upper part as well. Then we wash off the plastic dust from the figures, which was formed during grinding. But this is not enough. All the same, small grains remain, and if silicone is poured now, then small specks of plastic will be imprinted into it. So I also soaked the brush in acetone and smeared all the surfaces that were being sanded. Acetone does not dissolve PLA or HIPS plastic, but it smoothes their surfaces and sticks together all the small particles. And if two surfaces of PLA plastic are lubricated with acetone, and then joined together, they can no longer be torn apart. So I used acetone to glue the bear figurines onto the tray. Then you need to wait for the time when the surfaces are completely dry and the acetone evaporates, rinse all the forms again and dry again.

Then we wash off the plastic dust from the figures, which was formed during grinding. But this is not enough. All the same, small grains remain, and if silicone is poured now, then small specks of plastic will be imprinted into it. So I also soaked the brush in acetone and smeared all the surfaces that were being sanded. Acetone does not dissolve PLA or HIPS plastic, but it smoothes their surfaces and sticks together all the small particles. And if two surfaces of PLA plastic are lubricated with acetone, and then joined together, they can no longer be torn apart. So I used acetone to glue the bear figurines onto the tray. Then you need to wait for the time when the surfaces are completely dry and the acetone evaporates, rinse all the forms again and dry again.

The third step in this process is pouring the silicone into the master mold.

Silicone I bought food certified Penelast-750. It is not cheap, but it has all the necessary documents. With it, you need to buy a lubricant-wax, in order for the frozen form to better stick off the plastic.![]() I have this Penta-126.

I have this Penta-126.

This silicone consists of two components that are mixed together in equal proportions. Then they need to be intensively mixed for 3 minutes. In a good way, then this mixture should be placed in a degasser chamber, a vacuum should be created so that all air bubbles come out and then poured into the master mold. These degassers are a bucket with a faucet and a glass lid. They can be found in online stores and bought. But those who do not have this camera, like me, for example, can resort to this method.

First mix a small amount of silicone - a tablespoon of each of the components and a thin layer, using a brush, cover the entire surface of the master mold. If bubbles appear somewhere, they will either burst immediately or be visible to remove them. Then wait 3-5 minutes for the thin layer to lightly set.

Mix some more silicone and fill it up to the level of the sides.

We wait another 3-5 minutes, put on the upper part of the master form and fix it with paper clips.

Mix the silicone and pour it into each of the three bear figurines to the end of the sides.

This whole mold should be cured for about a day, according to the instructions.

After 24 hours, we take out the mold and wash it. But the processes of the final formation of molecular bonds in silicone will continue for two more days. So, in a good way, you can use the form for its intended purpose only three days after pouring.

It's time for the most delicious step - pouring chocolate. You can buy ready-made chocolate and melt it in a water bath, but I prefer to make my own chocolate from cocoa butter, cocoa powder and powdered sugar. Powdered milk is used for white chocolate.

First pour 50% white chocolate, then 60% milk chocolate and finally 75% dark chocolate.

We got such delicious Olympic bears.

I also bring to your attention a more detailed video for the article:

All creative success and bon appetit!

Creation of casting molds on the Objet

3D printer Few people know, but on the Objet 3D printer you can create not only details, figurines, decor elements, gifts, toys and many other products, but also print real molds for plastic injection molding that does not need further refinement.

Here are the main casting technologies in which we use molds printed on the Objet printer.

Low Pressure Injection Molding

Low Pressure Injection Molding is a relatively new technology in small series and prototype production. As with silicone vacuum casting, castings are made from two-component polyurethane resins. A wide range of resins and hardeners makes it possible to obtain castings with physical and mechanical properties close to those of thermoplastics.

The distinguishing feature of this casting is the short curing time of the casting, so a vacuum oven for degassing is not used. When making molds directly on the Objet 3D printer, the time to obtain castings is drastically reduced (no need to make a silicone mold) and no additional equipment is required, except for a mixer for pouring a mold under pressure. At the same time, the quality of manufacturing molds on the Objet 3D printer is so high that the molds themselves usually do not require manual finishing.

When making molds directly on the Objet 3D printer, the time to obtain castings is drastically reduced (no need to make a silicone mold) and no additional equipment is required, except for a mixer for pouring a mold under pressure. At the same time, the quality of manufacturing molds on the Objet 3D printer is so high that the molds themselves usually do not require manual finishing.

Lost Wax Casting

In order to obtain metal castings in the manufacture of small series or prototypes, molds made using 3D Printing technology on OBJET equipment are successfully used. Casting wax is poured into these molds, then waxes are used to make ceramic molds in the investment casting process. This is a fairly economical technology for small series, since a mold grown on a 3D printer can be used many times to produce waxes.

At the same time, it is a well-tested, well-known technology, successfully used in many enterprises. Waxes obtained from molds grown on the Objet 3D printer are of high quality, however, there is no need to change anything in the metal casting technology itself, enterprises can use standard, already available casting equipment.

Earth casting

Earth casting is one of the oldest processes in the production of metal products, which has survived almost in its original form to this day, but at the same time this method has become faster and more economical for the customer. Despite the fact that earth casting is not as precise as pouring metal into investment molds, this process is in demand in many areas of our lives.

The Objet 3D printer allows you to print a detailed model of the future product, which will be used for molding in sand, and also, on this printer, you can create special liners if they are needed during the work process.

The most interesting thing is that after coating the model with a layer of paint, it is reliably protected from damage, which increases its service life by several times, while maintaining the detail of the casting throughout the entire period of use. This is the advantage of casting on a painted model, because even with the help of one correctly printed product, you can start a full-fledged medium-scale production process.