3D printer resin or filament

Resin or filament 3D printing: Which is best for you?

Joker bust designed by Wekster (Image credit: Windows Central)Resin or filament 3D printing: Which is best for you?

Best answer: You'll want a filament (FDM) printer for printing large models such as cosplay accessories. Resin (SLA/DLP) printers are best for miniatures with extra detail like tabletop game pieces.

What is filament (FDM) printing?

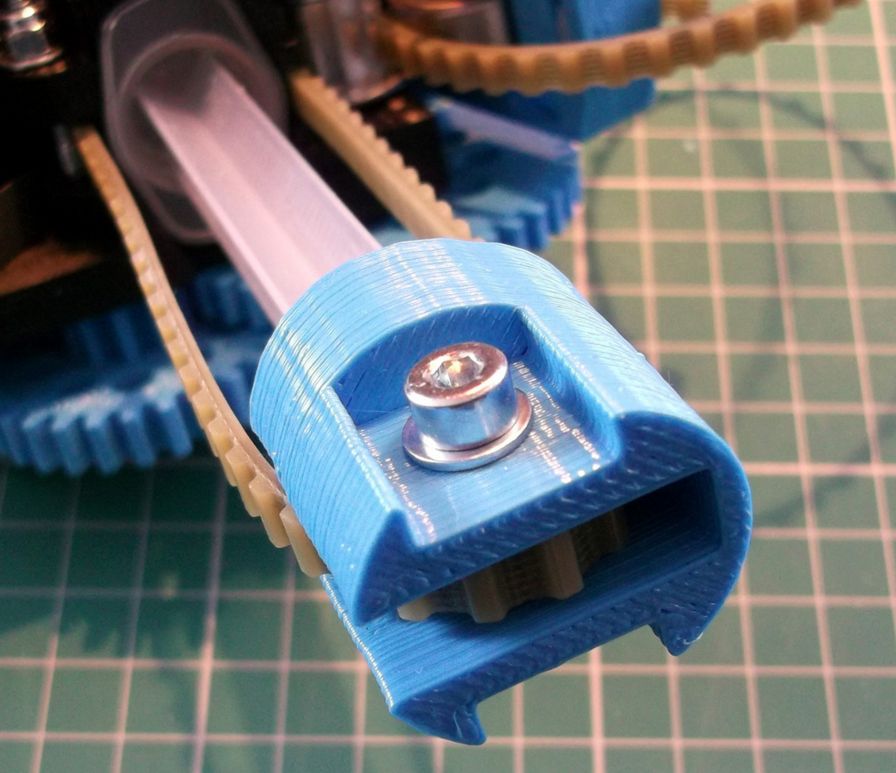

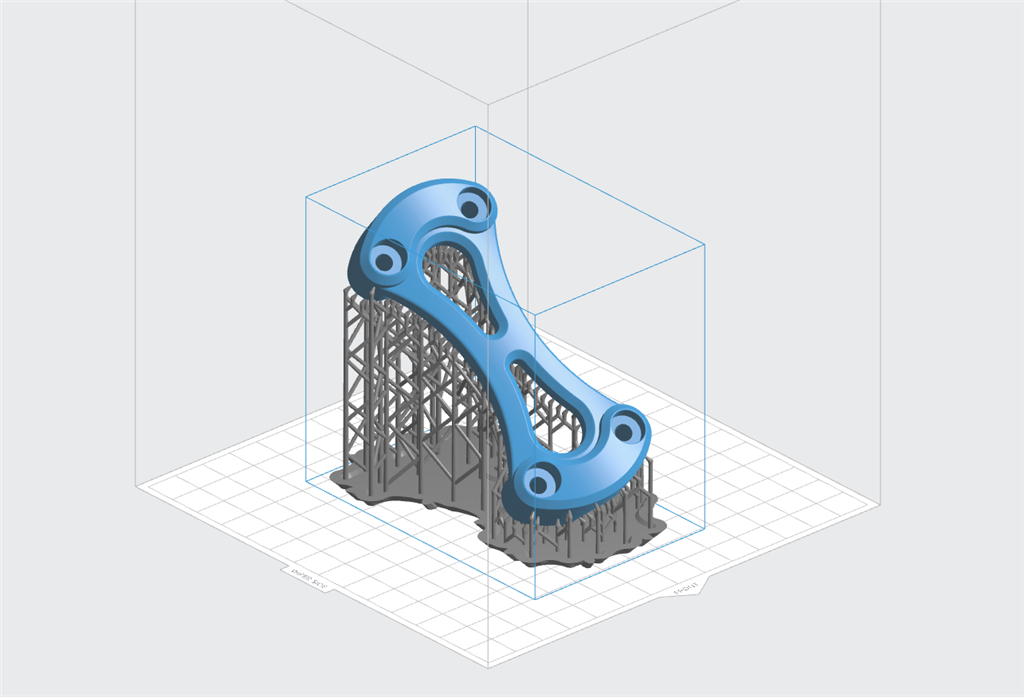

Fused deposition modeling (FDM) is the style of printing most people recognize. A string of plastic called a filament is melted through a hot end and deposited on the build plate, and the next layer is then placed on top of the previous layer.

FDM printing is used far and wide in modeling and producing larger parts like cosplay armor and helmets. The nature of the printing makes it very easy to set up and very easy to learn. Most maker spaces around the country use FDM printers as they are cheap and reliable, with plenty of options for 3D printing filament on a budget.

FDM printing is also very good at making practical prints. Many printers can print exotic materials like carbon fiber and nylons that are incredibly strong. These can be used to make strong models and moving parts.

When you want to make smaller models in finer detail, FDM printing can run aground. That isn't to say that a well-tuned FDM printer can't give you incredible detail; they can. If you look at the Joker model we used by Wekster, you can see that although the model isn't as smooth as the resin version, it still looks excellent.

What is resin (SLA/DLP) printing?

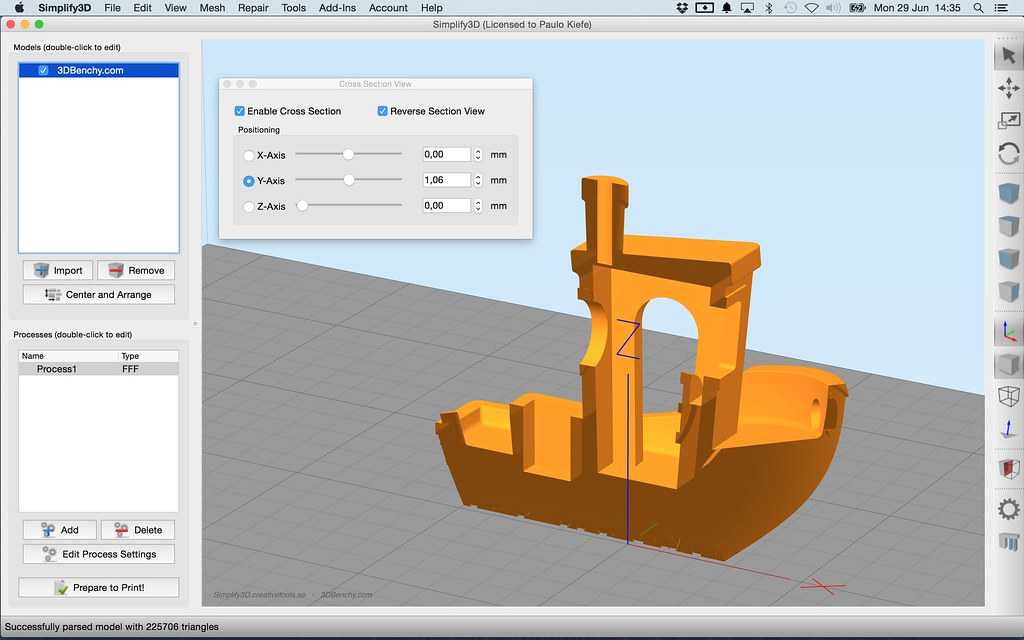

Stereolithography/digital light processing (SLA/DLP) printers are 3D printers that print using light to cure liquid resin into layers. The cheaper versions use an LCD to shine a UV image into the resin, which cures it into a solid layer. The print bed then rises slightly to let the next layer cure.

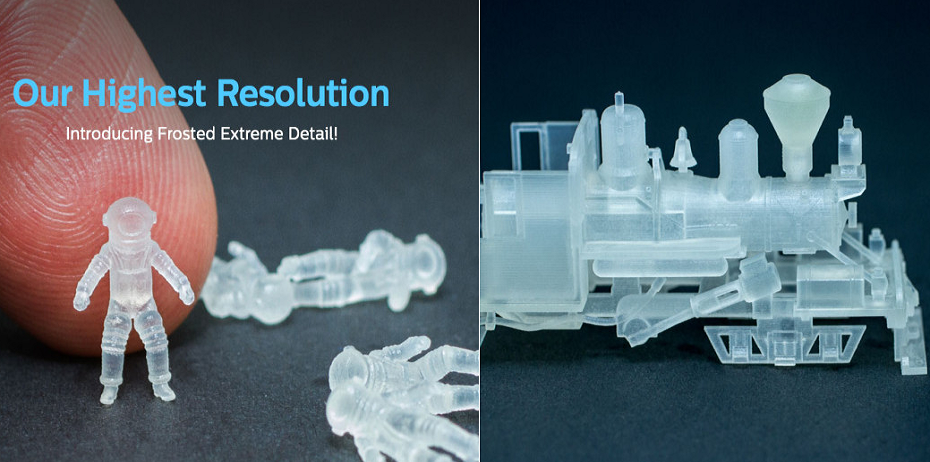

Resin allows you to print a model with fine details, far more than a standard FDM printer can produce, and the result tends to need far less post-processing work to give you a finished product.

The downside is that they tend to have smaller build plates than FDM printers, so you can't make large pieces on them. Resin also tends to be a little slower than filament as it needs to cure. You will also have to wash the model afterward to get the full effect.

There have been great strides to solve both these problems, though. You could buy the excellent Anycubic Wash and Cure V2 station and considerably speed up the curing process. There are also enormous options like the Peopoly Phenom resin 3D printer that will print your parts on a much larger scale, providing the best of both worlds.

Which should you buy?

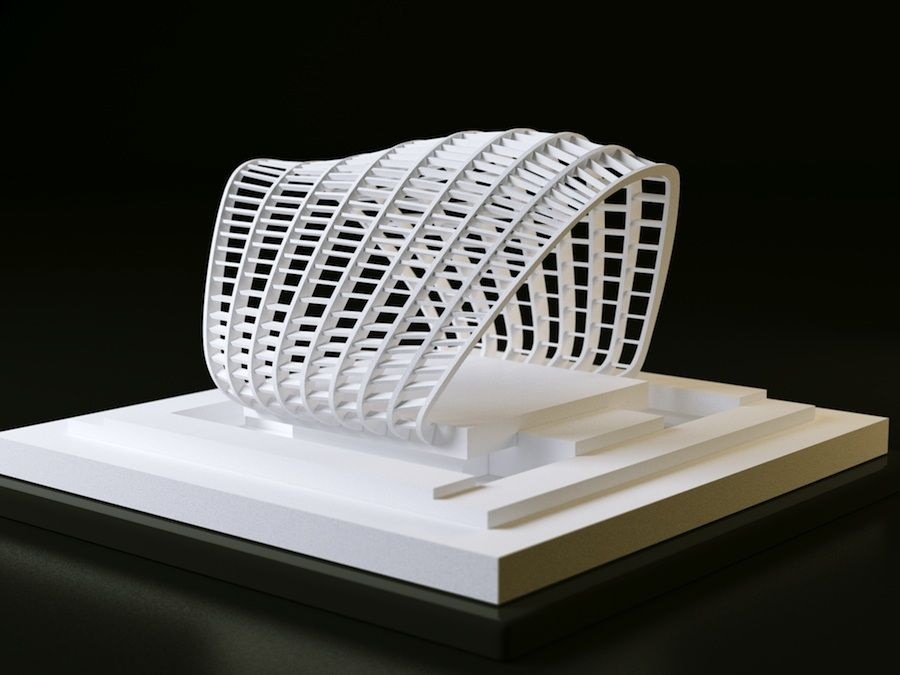

To build large-scale models, cosplay items like armor and helmets, or produce prototypes rapidly, an FDM 3D printer is likely the right choice. It gives you the greatest range of options, often at a reasonable price. The Creality Ender 3 V2 is an affordable way to start filament printing and features a resume function, so you won't lose progress on a print if there's a power cut.

Creality Ender 3 V2

For a first-time FDM 3D printer, you won't break the bank with the Creality Ender 3 V2. Its features and print quality make it one of the best 3D printers you can buy on a budget.

If you are hoping to print miniatures for board games, highly detailed models, or production-quality parts, then a resin (SLA/DLP) printer is best. The level of resolution that a resin printer can bring is extraordinary if you're willing to take a few extra steps to cure and clean your models. The Elegoo Mars has the right entry-level price for newcomers. The Mars is a revelation for anyone who has never used a resin printer before as it is so cheap and yet produces amazing prints every time.

Elegoo Mars Pro 2

The Elegoo Mars is impressive. For far less than you might think, you can have a resin printer that makes amazingly detailed models reliably.

Ben is the channel editor for all things tech-related at Windows Central. That includes PCs, the components inside, and any accessory you can connect to a Windows desktop or Xbox console. Not restricted to one platform, he also has a keen interest in Valve's Steam Deck handheld and the Linux-based operating system inside. Fueling this career with coffee since 2021, you can usually find him behind one screen or another.

That includes PCs, the components inside, and any accessory you can connect to a Windows desktop or Xbox console. Not restricted to one platform, he also has a keen interest in Valve's Steam Deck handheld and the Linux-based operating system inside. Fueling this career with coffee since 2021, you can usually find him behind one screen or another.

Peopoly Phenom resin 3D printer review: Phenomenal in every sense

For the last few months, I have been playing around with a printer that feels both very similar and very different. The Peopoly Phenom feels like a standard MSLA resin printer, like several I have recently reviewed, except it has one huge difference — it's enormous.

The size of the printer is not only impressive, but it's also made me rethink what it means to have a resin printer, and who it could benefit by having one of these fantastic machines in their lives.

Peopoly Phenom resin 3D printer

$2,000 at Matterhackers Bottom line: The Peopoly Phenom is perfect for starting your first mini-mass production business, or for making giant resin prints to wow your friends.

For

- Massive build area

- Simple control system

- Surprisingly good quality prints

Against

- It sounds like a million angry bees

- The build plate top collects resin

What you'll love about Phenom by Peopoly

Flash Helmet (Image credit: Windows Central)Flash Helmet (Image credit: Windows Central)Flash Helmet (Image credit: Windows Central)Source: Windows Central

I printed the Flash model you see above for an editor here, Russell Holly. His first helmet was produced on a small FDM printer by some friends, and the model from CAMACHOISBOSS had to be split in half to fit on the print bed. We've all been there, needing to cut a model up and make it fit the machine you have, and making it look whole again isn't easy. With the Phenom, I was able to print this full-size helmet in smooth Siraya Tech fast resin, in one single piece. Without the line down the center and some pretty excellent painting by me, the helmet looks as it should for a Flash cosplay.

The resin vat in the Phenom is massive, and can easily take one liter of resin

The Phenom handled this large print, taking 47 hours to print, and spat it out like it was nothing. It's easily the longest print I've done on a machine, and, astonishingly, it could do it in my garage with temperature changes from the low 40 degrees Fahrenheit to the high 70 degrees.

If you're a cosplayer, looking to create weapons and armor pieces with minimal sanding or gluing, then you should seriously consider investing in a Phenom.

Source: Windows Central (Image credit: Source: Windows Central)You may be worried, as I was, that a screen the size of the Phenoms couldn't possibly give you the level of detail required from an MSLA printer. However, the Phenom produces print quality as good as any printer I've used in the past year. With a screen resolution of 3840 x 2160 and the ability to use 8x antialiasing, the Phenom was capable of reproducing the details in every print I threw at it. From the very large, to the very small, the Phenom felt like it could handle the job, and still had more to give.

From the very large, to the very small, the Phenom felt like it could handle the job, and still had more to give.

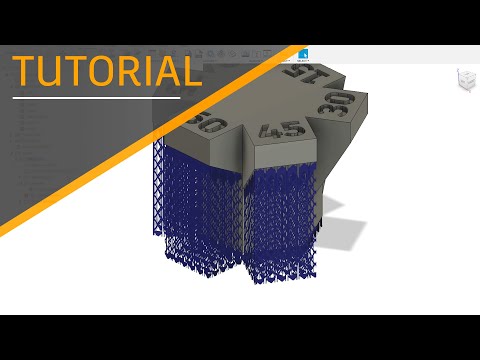

When you look at this Leonidas sculpture from Fotis Mint, you can see each hair in the plume of his helm, with the tiny cuts and scratches across his chest. The Phenom is even easy to print with, using Chitubox, the almost universal resin slicer, as its slicer and firmware. Hence, it's incredibly simple to load a model, hollow it, slice it, then print it. I love simplicity, especially when dealing with potentially hazardous materials.

What you'll dislike about Phenom by Peopoly

Source: Windows Central (Image credit: Source: Windows Central)I don't have a ton of problems with the Peopoly Phenom, beyond some minor gripes. For example, to keep the weight down on the gigantic build plate, they opted for a flat top and flat bottom. Unfortunately, it's perfectly flat, and a fair amount of resin accumulates over time. If the printer were smaller, this wouldn't be a huge deal. But if you forget about it and take your print out before your scrape it off, you're going to be pouring uncured, toxic resin all over your shoes.

But if you forget about it and take your print out before your scrape it off, you're going to be pouring uncured, toxic resin all over your shoes.

As soon as you turn the printer on, it sounds like a jetliner has just taken off and is flying directly through your skull

The other problem is the noise. This is not a machine you want anywhere that isn't a workshop. As soon as you turn the printer on, it sounds like a jetliner has just taken off, flying directly through your skull, and it never gets quieter. Peopoly has said it is looking at ways to reduce the sound, but if the massive fans weren't running, your LCD matrix would burn out, and the motherboard would fry on the first print. You get used to the noise — sort of.

The only other issue for some will be the cost of materials. The resin vat in the Phenom is massive, and can easily take one liter of resin. It's great if you want to print lots of pieces or one big creation, but not ideal if you're going to print a smaller model. Because of the surface area of the vat, you need to put at least 250ml of resin in to cover the bottom. In short, make sure you top up on resin.

Because of the surface area of the vat, you need to put at least 250ml of resin in to cover the bottom. In short, make sure you top up on resin.

Why the Phenom by Peopoly is a game-changer

Dragon Chess Phenom (Image credit: Windows Central)Dragon Chess Phenom (Image credit: Windows Central)Dragon Chess Phenom (Image credit: Windows Central)Source: Windows Central

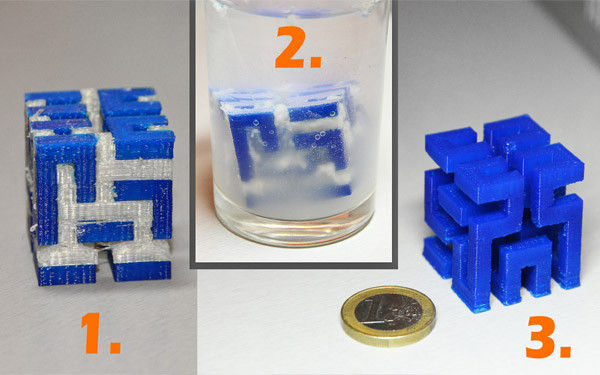

If you haven't seen Louise Driggers' work, you really should. She has made some fantastic pieces like Sir Pigglesby that she gives away for free on her My Mini Factory page, and recently made a set of models that shows how the Phenom can change the game for small businesses.

Louise made a set of 3d printable dragon chess pieces, purchasable so you can print them at home. She also sells the full chess set, including a board, that she has printed herself. The chess set is big though — 16 pieces for each side, 32 models in all — and to print them all takes a lot of time on a regular printer. Louise uses a standard size MSLA printer and can produce about two models at a time. With some quick math, it would take 120 hours of continuous printing for Louise to print an entire set of 32 chess pieces on her current machine.

Louise uses a standard size MSLA printer and can produce about two models at a time. With some quick math, it would take 120 hours of continuous printing for Louise to print an entire set of 32 chess pieces on her current machine.

On the Peopoly Phenom, it would take just 31 hours.

Because MSLA prints using the largest model as the time scale, you can print the entire chess set on just two build plates from the Phenom, with all tall pieces on one, and all the pawns on the other. That's 20 hours for the king plate and just 11 hours for the pawn plate.

Having a Phenom would mean Louise could produce four times more chess pieces per hour than she can currently. For a small business that makes models, that level of mass production cannot be understated. Having your own small-scale in your garage, one that can rapidly prototype new models as well as print them in bulk, could change the way we think about the manufacturing of art.

Should you buy Phenom by Peopoly 3D printer?

Source: Windows Central (Image credit: Source: Windows Central)Now, of course, $2,000 is a lot of money, but it isn't an unreasonable sum for a printer of this size and caliber. The Phenom prints extraordinarily well, and can print large models or lots of models with equal ease. But my issues with it are barely notable, and the positives far outweigh the downsides.

The Phenom prints extraordinarily well, and can print large models or lots of models with equal ease. But my issues with it are barely notable, and the positives far outweigh the downsides.

I would recommend the Phenom for anyone looking to take their MSLA resin printing to the next level. If you are a cosplayer and you want to make molds of your prints, this is an excellent printer to do so. And if you're going to mass-produce at a comfortable scale, one or two Phenoms would be ideal. And for me, I've enjoyed my time with the Phenom and will continue to use it to make awesome prints for my friends.

Detailed mass production

Peopoly Phenom

Massive build for the masses

If you have ever wanted to make your hobby into your job, this is the place to start. It's the perfect investment to help you grow.

James built his first PC when he was 13 and has never looked back. He can be found on Windows Central, usually in the corner where all the 3D printers are, or huddled around the Xbox playing the latest games.

How safe are 3D printing resins?

Filament Deposition Modeling (FDM) material extrusion is the most popular polymer 3D printing method, but resins are becoming more and more important to consumers. Resin technologies such as stereolithography (SLA) were previously only used in dental laboratories, engineering departments and manufacturing plants due to the high cost of the equipment. Now that machines have become more affordable, more and more ordinary users are using SLA technology, which calls into question their safety.

Unlike FDM devices, resin printers use photosensitive liquids to print, curing materials with ultraviolet light. Liquid polymers pose a greater potential health risk than raw materials in fiber form. The toxicity of the resource may put off some users, but printing with resin can be safe if the right algorithm is followed.

What are the Potential Risks of Resins

The word "toxicity" is troubling, but according to definitions developed by occupational health and safety professionals, any substance that, under certain conditions, can cause health problems or disease, is "toxic". According to this formulation, many substances around us are potentially dangerous, including perfumes and mattress filling. But are there any particular risks when using liquid resins for 3D printing?

According to this formulation, many substances around us are potentially dangerous, including perfumes and mattress filling. But are there any particular risks when using liquid resins for 3D printing?

The main concern with photopolymer resins is that they can cause skin irritation on contact. In some cases, contact of the substance with unprotected skin results in burns and blisters, which may require medical attention. If the materials come into contact with the eyes, they will cause irreparable damage.

Many resins are sensitizers, which means that prolonged exposure sometimes causes a mild allergic reaction. The chemicals that make up most resins are irritants that provoke the appearance of dermatitis - inflammation of the skin due to rejection of foreign elements. The skin quickly absorbs such chemicals, so prolonged contact with the composition or exposure to a large dose can lead to more serious consequences.

Another problem with resin 3D printing is air pollution. The material releases fumes, potentially reducing indoor air quality (IQA). Poor IQA scores can lead to headaches, fatigue, or more serious reactions such as breathing problems. These effects are due to volatile organic compounds (VOCs) and other small particles that cause an inflammatory response in the airways, leading to swelling or tenderness.

The material releases fumes, potentially reducing indoor air quality (IQA). Poor IQA scores can lead to headaches, fatigue, or more serious reactions such as breathing problems. These effects are due to volatile organic compounds (VOCs) and other small particles that cause an inflammatory response in the airways, leading to swelling or tenderness.

Long-term effects from working with liquid polymer are rare but significant:

• If the vapors are inhaled for a long time, chronic diseases of the respiratory system may appear.

• Some of the VOCs emitted by resins are suspected to be carcinogens, so they are likely to cause cancer after prolonged exposure.

• Constant physical contact can lead to severe allergies.

Standards and manufacturer's instructions

On the other hand, most resins on the market do not pose a significant hazard. Companies that produce such materials must comply with government standards and additional recommendations ISO 9001. Regulations ensure that chemicals produced by businesses are minimally harmful. However, some hazardous elements, such as asphalt fumes and synthetic mineral fibers used in fiberglass, are still widely used and over half a million workers are exposed to them.

Regulations ensure that chemicals produced by businesses are minimally harmful. However, some hazardous elements, such as asphalt fumes and synthetic mineral fibers used in fiberglass, are still widely used and over half a million workers are exposed to them.

Manufacturers usually provide Material Safety Data Sheets (MSDS) that list any potential health concerns. For example, corneal burns from overexposure to the eyes, or nausea and vomiting if swallowed. All these documents are provided in order to provide users with maximum safety when using consumables.

Some compounds may be more dangerous than others for certain people. If a person does not know if they are allergic to any materials, they should act as if they are and handle the product with care.

Safety Steps

Several government agencies have conducted research into the safety of epoxy 3D printing. They all showed that long-term emissions from printing are mostly negligible, although risks exist if proper precautions are not taken. Since studies have found traces of hazardous substances when working with resin formulations, safety regulations must be observed.

Since studies have found traces of hazardous substances when working with resin formulations, safety regulations must be observed.

3D printing resins are not as scary as they seem, but they still need to be handled with care. First of all, direct contact of the mass liquid with any part of the body must be avoided. Safety goggles and nitrile or latex gloves should always be worn to prevent toxins from getting into the eyes or onto the skin.

Also make sure that the workplace is well ventilated. Ventilation is critical for any 3D printer, but especially for resin printing equipment. It is best to work under an exhaust hood, but if this is not possible, it is advisable to print near an open window with a fan.

Read the safety data sheet from the manufacturer before opening the photopolymer container. If there are any special instructions regarding the use of the material, then they are reflected in the document.

Finally, residues or waste must not be dumped into the sewer, as this can be harmful to the environment. Either dispose of it in the manner recommended by the manufacturer, or dry with UV light until the mass hardens.

Either dispose of it in the manner recommended by the manufacturer, or dry with UV light until the mass hardens.

Resin printing is safe when proper precautions are taken

When the user knows what risks resin compositions present, he will be safe from trouble. Although 3D printing consumables are toxic, but if the safety procedures are strictly followed, then working with these materials becomes not dangerous. With the right precautions, there is no reason to avoid 3D printing with resin.

Properties of photopolymer resin for 3D printer. 3DMall

When buying a 3D printer DISCOUNT on plastics and polymers up to 10%

Properties of photopolymer resin for 3D printer

12/13/2020 powernic

Properties of photopolymer resin for 3D printer

Photopolymer resin is used for 3D printing using SLA, LCD, DLP technologies. The use of this material and printing technology is based on one property of the initially liquid photopolymer resin - to harden when the material is irradiated with a light wave of a certain length. That is, these substances are able to change their state of aggregation under the influence of ultraviolet radiation. At the same time, photopolymer resins differ in their physical and mechanical characteristics, which makes it possible to obtain products with different properties. Moreover, the variety of photopolymer resins allows them to be used not only in household, but also in professional and even industrial fields.

That is, these substances are able to change their state of aggregation under the influence of ultraviolet radiation. At the same time, photopolymer resins differ in their physical and mechanical characteristics, which makes it possible to obtain products with different properties. Moreover, the variety of photopolymer resins allows them to be used not only in household, but also in professional and even industrial fields.

Photopolymer resin characteristics

Photopolymer resins are truly versatile. The main properties of photopolymer resin for 3D printing, for which they are so appreciated:

- wide color palette;

- wide range of mechanical properties: elasticity, stiffness, hardness, etc.;

- tactile and optical properties: haze, transparency;

- chemical composition: composite, biocompatible, heat resistant, similar in properties to polypropylene, ABS;

- Application range: medicine, dentistry, footwear industry, orthopedics, jewelry, etc.

Photopolymer resins and 3D printing are even used in the aerospace industry.

Advantages of photopolymers over other materials for 3D printing:

- perfect smoothness of finished models;

- highest detail and precision;

- excellent physical and mechanical properties;

- wide choice of materials and colors;

- possibility of processing (colouring, gluing, grinding, etc.).

There are materials that can be used for casting and investment casting. This is applicable in the dental and jewelry industry, which allows you to model products with the highest accuracy and degree of complexity. All these are characteristic properties of a photopolymer resin for a specific purpose.

Models made of industrial photopolymer resins are characterized by high strength and functionality. In the field of medicine, materials are used that, thanks to their precision and detail, as well as biocompatibility, allow them to be used immediately after printing.