3D printing mexico

3D Printing Service Mexico | Instant Quotes Online

Our 3D printing capabilities

We have over 90 3D printing shops in our network and are well known for manufacturing high-quality parts at competitive prices, from rapid prototyping with Fused Deposition Modeling (FDM) to functional end parts made with Selective Laser Sintering (SLS) or Multi Jet Fusion (MJF).

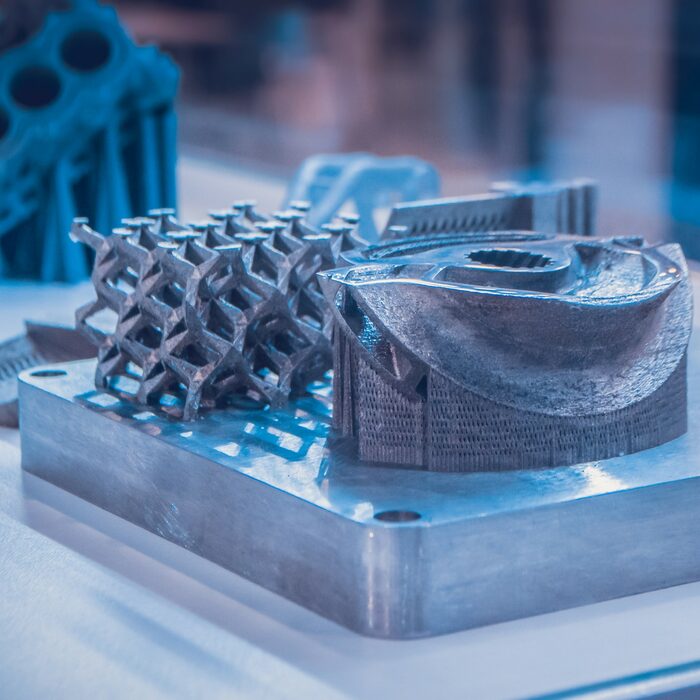

Gallery of 3D printed parts manufactured by Hubs

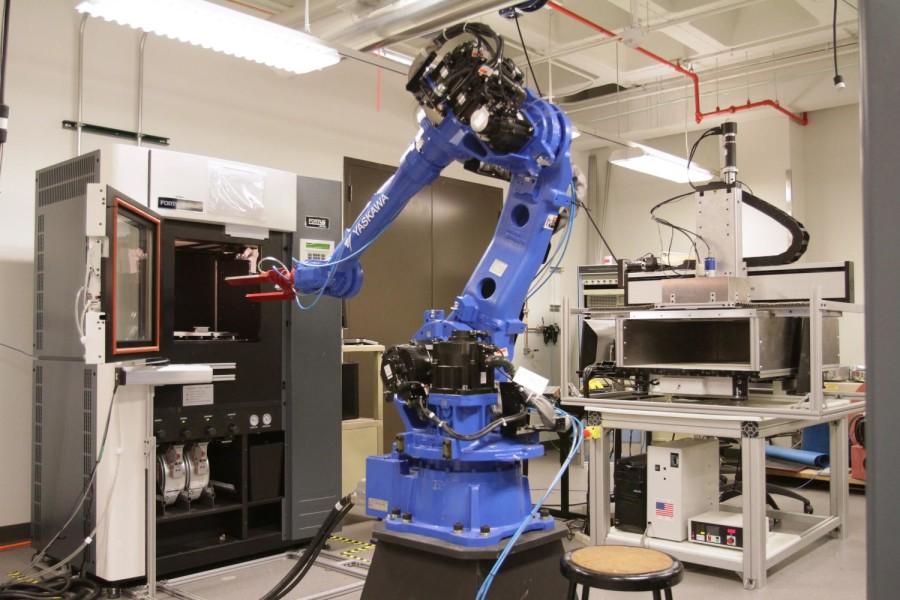

With over 65,000 customers from every industry, including aerospace, defense, robotics, medical, machinery, automotive and electronics, we have extensive experience meeting a diverse range of 3D printing requirements, from prototyping to production: Visual aids, concept models, injection-molding prototypes, form-fit & function prototypes, tooling and casting patterns, jigs, grips and fixtures, and durable end parts.

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

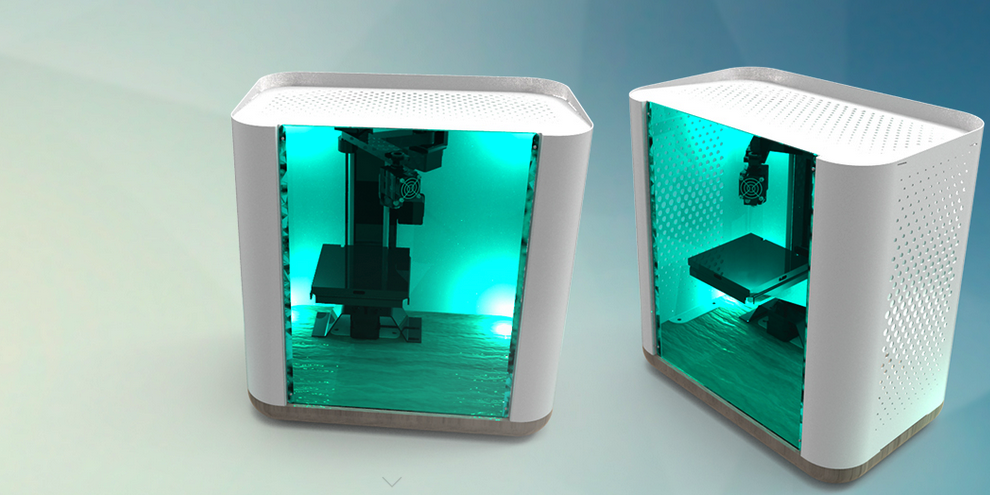

Instant, online 3D printing quotes

-

Upload a CAD to start (STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT, STL, OBJ or X_T)

-

Price updates in real-time as you change materials, lead time, etc.

.

. -

No hidden costs. Our instant quotes are not just indications, but the actual price, and include shipping and customs up front.

Learn about how our quoting algorithm works

Our ordering process

Receive instant quote

Upload your CAD to our online quoting platform

Confirm specs

Configure your part specifications and select a lead time that suits your schedule

Production

We select the best manufacturer for your order, and production begins immediately

Quality control

We take full responsibility for making sure your parts are manufactured according to our standards

Delivery

Our 3D printing service has been rated 4.9/5

Over 225 customers are satisfied with our 3D printing service.

“Excelente servicio! atencion, y calidad. gracias!”

“Eficiente y de calidad. Muy contenta con el producto!”

“Great service and product. Great communication!”

“Informative, reliable and excellent customer service. ”

“Provided a great product, and did communicate well! Thanks very much!”

“Excellent service , fast delivery, perfect quality ”

“Great quality, quick service, all around awesome.”

“Nice print quality and it was done very fast! Highly recommended!!!”

“The parts came in excellent condition and in the expected time. ”

“A great buying experience from start to finish! Looking forward to future purchases 👍”

“Definitely worth having anything printed here. Great quality and service. ”

“Print is fantastic - exactly what I was looking for!”

“thank you for your attention to detail, surface finish and wall thickness are generously wonderful. Much appreciated!”

“Good communication and print quality. Also fast! ”

Also fast! ”

“Great turn around time and patience to provide the best quality print possible. Do recommend using them and will in the future.”

“Great service with quick turnaround time, will use again.”

“Great communication and speed on the job! Highly recommend!”

“Great parts! Fast service! Sent me photos of the printed parts a day or two after I ordered.”

“The print was a good quality and the turnaround time was quite fast”

“Smooth printed parts, great communication. ”

“Super easy to work with! Responded very quickly, fixed a file within minutes that I had not submitted correctly, and communicated every step of the way. Would highly recommend! ”

“Excellent job! Will definitely use again. A+”

“Fast turn around, good communication, and lovely print quality :)”

“Amazing turn around time and very friendly and helpful. Would use again anytime.”

“The order was completed much faster than I anticipated and came out great. Awesome customer service, almost instant responses to everything. ”

Show more reviews

Show less reviews

Teams build better parts

Create your Hubs team and start collaborating

Read more

The Hubs Standard - consistent quality, every time

Hubs takes the stress out of manufacturing by guaranteeing the quality and consistency of every part. Each order is dimensionally and visually inspected to make sure it meets the Hubs Standard.

3D printing materials

We can generate instant 3D printing quotes for 25+ plastics. For metal 3D-printed parts, you can request a quote from our parent company, Protolabs.

Available materials

SLS

PA 12 Glass filled PA 12

Desktop FDM

Prototyping PETG Prototyping ASA Prototyping TPU Prototyping ABS Prototyping PLA

Desktop SLA

Formlabs Standard Resin Formlabs Clear Resin Formlabs Tough Resin 2000 Formlabs Rigid Resin 4000 Formlabs Grey Pro Resin Formlabs Flexible Resin 80A Formlabs High Temp Resin Formlabs Durable Resin

MJF

HP PA 12 Glass filled HP PA 12

Industrial FDM

Markforged Onyx ABSplus Stratasys ULTEM 9085 Stratasys Stratasys ASA ABS M30 Stratasys ULTEM 1010 Stratasys

Industrial SLA

Accura 25 (PP-like) Accura ClearVue Accura Xtreme White 200 (ABS-like)

3D printing locations near Mexico

Mission, TX Pharr, TX McAllen, TX

Edinburg, TX Harlingen, TX Brownsville, TX

Laredo, TX Eagle Pass, TX Corpus Christi, TX

San Antonio, TX

The 3D Printing Handbook

No one understands 3D printing like us - our founders literally wrote the book. Click here to download the sample chapters.

Click here to download the sample chapters.

Buy the book from Amazon

FAQ's

How much does your 3D printing service cost?

The cost of your 3D printed parts depends on factors such as part volume, part complexity, choice of material, which 3D printing technology is used, and if any post processing is required. For more details on these cost factors, see our article on the cost of 3d printing. To check the cost of your 3D printed part, simply upload a CAD (.STL) file and select your material and 3D printing technology to receive a quote within seconds.

How do you guarantee the quality of my prints?

Your parts are made by experienced 3D printing shops within our network. All facilities are regularly audited to ensure they consistently meet the Hubs quality standard. We include a standardized inspection report with every order and offer a First Article Inspection service on orders of 100+ units.

We have partners in our network with the following certifications, available on request: ISO9001, ISO13485 and AS9100.

Follow this link to read more about our quality assurance measures.

How do I select the right 3D printing process for my prints?

You can select the right 3D printing process by examining which materials suit your need and what your use case is.

By material: if you already know which material you would like to use, selecting a 3D printing process is relatively easy, as many materials are technology specific.

By use case: once you know whether you need a functional or visual part, choosing a process is easy.

For more help, read our guide to selecting the right 3D printing process. Find out more about Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF) and Stereolithography (SLA).

How can I reduce the cost of my 3D prints?

In order to reduce the cost of your 3D prints you need to understand the impact certain factors have on cost. The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

Once these have been decided, an easy way to further cut costs is to reduce the amount of material used. This can be done by decreasing the size of your model, hollowing it out, and eliminating the need for support structures.

To learn more, read our full guide on how to reduce the cost of 3D printing.

Where can I learn more about 3D printing?

Our knowledge base is full of in-depth design guidelines, explanations on process and surface finishes, and information on how to create and use CAD files. Our 3D printing content has been written by an expert team of engineers and technicians over the years.

See our complete engineering guide to 3D printing for a full breakdown of the different 3D printing technologies and materials. If you want even more 3D printing, then check out our acclaimed 3D printing handbook here.

We have an extensive range of online resources developed to help engineers improve their capabilities.

Introductory guides

Design guides

Material guides

Applications

CAD & file preparation

Post processing & finishing

Our other manufacturing capabilities

CNC machining

CNC machining

Milling (3-, 4- & full 5-axis), turning and post-processing

-

50+ metals and plastics & 10 surface finishes

-

Tolerances down to ±.0008” (0.020 mm)

-

Lead times from 5 business days

See our CNC machining services

Put your 3D printed parts into production today

Get an instant 3D printing quote

a Promising Combination for the Mexican Economy « Fabbaloo

Shipping containers and container ships are seen at the ports of Long Beach and Los Angeles on September 20, 2021. (Mario Tama/Getty Images) [Source: CNN]

(Mario Tama/Getty Images) [Source: CNN]Charles R. Goulding and Andressa Bonafe examine the latest developments in additive manufacturing in Mexico. (Spanish version to follow.)

While much of the ongoing supply chain crisis can be traced back to the Covid-19 outbreak, recent events, particularly the rising prices of several goods, lead to the conclusion that issues are likely to persist. The latest World Economic Outlook by the International Monetary Fund (IMF) lists continued supply chain disruption as one of the main reasons for a predicted economic slowdown in 2022.

Coming to terms with a new normal in which cost-effective and reliable shipping is no longer a given, a growing number of manufacturers are striving to bring production closer to their customers. Known as “nearshoring”, this strategic response to supply chain instability can reduce risks, increase profits, and enhance competitiveness.

For companies targeting the U.S. market, northern Mexico is a prime destination, as proximity to the border reduces reliance on overcrowded, often unpredictable ports. Juarez, Tijuana, Reynosa, Matamoros, and Piedras Negras are examples of “magnet cities” for foreign plants. During the 1990s, the region became home to numerous maquiladoras, especially after the Nafta agreement took effect. However, competition from China resulted in economic stagnation.

Juarez, Tijuana, Reynosa, Matamoros, and Piedras Negras are examples of “magnet cities” for foreign plants. During the 1990s, the region became home to numerous maquiladoras, especially after the Nafta agreement took effect. However, competition from China resulted in economic stagnation.

The new wave of investments began in response to Trump’s tariffs on Chinese products and was accelerated by the pandemic. Despite the negative impact of Covid-19 on the Mexican economy, projections of recovery are optimistic as the country benefits from the relocation of international manufacturing plants. The IMF estimates that total GDP will amount to $1.37trn in 2022, above pre-pandemic levels.

[Source: Deloitte Insights]The 2021 Kearney Reshoring Index underlines that Mexico is a viable option for companies willing to diversify supply chains and enhance resilience. The report calls particular attention to the automotive, aerospace, and electrical components industries, in which the country has established infrastructure and a trained labor force.

Interest in nearshoring seems to be growing across all industries, as exemplified by toymaker Mattel, Inc.’s recent $50 million expansion of its plant in Monterrey, Mexico. Covering 2.25 million square feet, the location employs nearly 3,500 workers and is now the company’s largest plant (even larger than the ones in China, Vietnam, and Malaysia). The move is part of a broader diversification effort, in which Mattel has invested in media assets that now include movie making and Non-Fungible Tokens (NFTs).

Mattel’s Montoi plant in Escobedo, Mexico [Source: Reuters]3D Printing in Mexico

Adding to Mexico’s strategic position to meet supply chain needs, the country’s growing additive manufacturing capabilities contribute to enhanced competitiveness. Examples of 3D printing in Mexico attest to the potential for innovative applications, as discussed in the following sections.

Infrastructure and construction: Mexico is implementing an ambitious infrastructure program aimed at revitalizing the country’s economy and increasing its generation capacity. In 2020 alone, 68 projects were announced, including the construction of six natural gas-powered combined cycle power plants, one natural gas pipeline, one compression station, and a liquefied natural gas export terminal. The four-year program is expected to require a US$43 billion investment, potentially generating an annual growth of more than 4 percent, and creating hundreds of thousands of jobs. The potential for 3D printing applications is enormous, ranging from concrete, fasteners, and tools to telecom antennas and water/sewer projects. In fact, Mexico has been home to exciting 3D printing developments in construction, particularly the world’s first 3D printed community located in Tabasco.

In 2020 alone, 68 projects were announced, including the construction of six natural gas-powered combined cycle power plants, one natural gas pipeline, one compression station, and a liquefied natural gas export terminal. The four-year program is expected to require a US$43 billion investment, potentially generating an annual growth of more than 4 percent, and creating hundreds of thousands of jobs. The potential for 3D printing applications is enormous, ranging from concrete, fasteners, and tools to telecom antennas and water/sewer projects. In fact, Mexico has been home to exciting 3D printing developments in construction, particularly the world’s first 3D printed community located in Tabasco.

Oil and gas: 3D printing technologies can be greatly beneficial to the oil and gas industry. Among the most relevant opportunities are the potential to decrease time to market in tightly scheduled projects and to provide replacement parts for legacy equipment often situated in remote areas. In this context, avoiding costly downtime that usually accompanies the replacement of critical parts would represent major savings and greater competitiveness. Among the largest companies in Latin America, Petroleos Mexicanos (Pemex) is a producer, refiner, and distributor of crude oil, natural gas, and petroleum products. Similar to other state-owned oil and gas companies, such as Brazil’s Petrobras, Pemex shows great potential to take advantage of additive manufacturing, particularly metal applications.

In this context, avoiding costly downtime that usually accompanies the replacement of critical parts would represent major savings and greater competitiveness. Among the largest companies in Latin America, Petroleos Mexicanos (Pemex) is a producer, refiner, and distributor of crude oil, natural gas, and petroleum products. Similar to other state-owned oil and gas companies, such as Brazil’s Petrobras, Pemex shows great potential to take advantage of additive manufacturing, particularly metal applications.

Automotive parts: The automotive industry in Mexico has traditionally benefited from nearshoring practices, attracting carmakers from around the globe along with numerous suppliers. Considering pre-pandemic data, Mexico Business News points out that vehicle production increased by 66 percent between 2010 and 2019, reaching 3.75 million units in 2019, while exports increased 188.4 percent in value to reach US$11.8 billion as of December 2019.

Despite the challenges that ensued from the Covid-19 pandemic, Mexico’s automotive sector is poised to remain strong and develop an enhanced focus on technological innovation. The pandemic has underlined the value of 3D printing as a means to produce automotive parts with far less overhead and trickle-down cost savings through the supply chain.A telling example comes from American multinational automotive supplier BorgWarner, which expanded its manufacturing facility in Ramos-Arizpe, Mexico in 2015 to meet increasing demand for emissions technologies in North America. BorgWarner has been at the forefront of 3D printing innovation with ever growing applications to increase cost-efficiency and automation.

The pandemic has underlined the value of 3D printing as a means to produce automotive parts with far less overhead and trickle-down cost savings through the supply chain.A telling example comes from American multinational automotive supplier BorgWarner, which expanded its manufacturing facility in Ramos-Arizpe, Mexico in 2015 to meet increasing demand for emissions technologies in North America. BorgWarner has been at the forefront of 3D printing innovation with ever growing applications to increase cost-efficiency and automation.

Fashion: 3D printing has made its way into the fashion industry, helping push the boundaries of design and functionality. From record-breaking footwear to smart fabrics, additive manufacturing plays an increasingly central role in a variety of innovative efforts. Supply chain and geopolitical disruptions have fueled a renewed interest in nearshoring for fashion brands. Mexico is home to an important footwear cluster that includes international companies such as Nike, Crocs, and Louis Vuitton. More widespread 3D printing adoption could further enhance competitiveness and consolidate the country’s position as a global hub for apparel manufacturing.

More widespread 3D printing adoption could further enhance competitiveness and consolidate the country’s position as a global hub for apparel manufacturing.

While facing the challenges of supply chain disruptions, U.S.-based companies should consider the potential benefits of bringing production closer to home. These companies can also take advantage of R&D tax credits to support their innovative efforts, as described below.

The Research and Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing, and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Mexico is particularly well-equipped to respond to the many challenges of the new global supply chain. As a growing number of companies make the strategic decision to bring production closer to their end customers, Mexico’s great potential for 3D printing application promise additional gains in efficiency.

Mexico has the world's first 3D printed residential area

Not far from a city in southern Mexico, a ten meter printer has recently printed walls for the world's first 3D printed residential area.

At the beginning of December, the printed houses received a roof, windows and interior decoration. New Story, a charity behind the project, believes 3D printing can bring affordable housing to people in the poorest parts of the world. “We believe we were able to prove the reality of this idea by taking this device to rural Mexico where there is seismic activity and being able to print the first houses with it,” says Brett Hagler, CEO and co-founder of New Story.

New Story, a charity behind the project, believes 3D printing can bring affordable housing to people in the poorest parts of the world. “We believe we were able to prove the reality of this idea by taking this device to rural Mexico where there is seismic activity and being able to print the first houses with it,” says Brett Hagler, CEO and co-founder of New Story.

Founded five years ago, his company provides housing for people living in extreme poverty. The organization has already built more than 2,700 houses in the traditional way in Bolivia, Mexico, El Salvador and Haiti.

Photo: New Story

After the 2010 earthquake in Haiti, it was difficult to rebuild houses after the destruction, but New Story improved the construction process so that housing could be built faster. The organization realized that with the help of new technology, it was possible to work faster and at less cost. Two years ago, she partnered with Icon to develop a 3D printer capable of printing even under the most difficult conditions.![]()

The printer is called Vulcan II. This is not the first device that can print an entire house. However, a new residential area in Mexico of 50 printed houses will be the first place where this technology has been used on such a scale. Other companies have experimented with building printed houses, but all trials have been conducted in controlled environments or locations with a low risk of natural disasters.

Initially, the New Story team planned to print houses in another part of Mexico, but ran into difficulties - for a long time the organization could not obtain a building permit from the government. Therefore, it was decided to print houses further south, in Tabasco, a state bordering Guatemala. The new location had a higher risk of earthquakes, so the design of the houses had to be finalized.

Photo: New Story

After successful testing, the printer was trucked to the state, but it got stuck in customs for three months. “The device is brand new, obviously it doesn’t exist [in the database],” Hagler explains. When the 3D printer arrived at its destination, the rainy season began. At some point, the entrance to the construction site was flooded, and no one could get there for a week.

When the 3D printer arrived at its destination, the rainy season began. At some point, the entrance to the construction site was flooded, and no one could get there for a week.

However, the most important test—whether the printer can print on site at home—succeeded. The printer lays out the concrete mixture in layers, and the floors and walls are obtained. The program monitors the weather conditions and adjusts the mixture accordingly. “The weather can be dry in the morning and wet in the evening, so you have to change the viscosity of the mixture to keep the print quality the same all day,” explains New Story co-founder Alexandria Lafzi.

The printing process is autonomous, the team can only make minor adjustments to the scheme. In this case, you can print several houses at the same time. The first two houses printed at the same time, the total printing time was 24 hours, but it lasted several days because the team only wanted to work during the day. In the future, the authors of the project hope to be able to run the printer for longer periods to speed up the construction process.

The resulting houses have two bedrooms, a living room, a kitchen, and a bathroom, much better than the simple huts the locals live in. Families who will live in printed houses earn an average of $76.50 a month. “For many families, this will be the first home with a toilet outside the yard and a full sewer,” says Lafzi. And, unlike huts, such houses are able to withstand an earthquake. The charity is partnering with the local government to provide land and infrastructure to build roads and provide electricity to 50 families who need housing the most. When New Story finishes printing all the houses, new tenants will immediately move into them.

Photo: New Story

Some families have already inspected the resulting houses and noted that they do not leak during heavy rain. “When it rains, the roof of our house starts to leak, and the worst thing is when it happens at night,” says Candelaria Hernandez, who lives in a one-room hut with seven members of her family.:quality(80)/images.vogel.de/vogelonline/bdb/1470100/1470104/original.jpg) “We have to wake up and arrange the pans so that things don’t get wet.”

“We have to wake up and arrange the pans so that things don’t get wet.”

“The construction industry needs a paradigm shift,” says Alex Le Roux, co-founder and CTO of Icon. “We don’t have to choose between affordability and reliability.” The company plans to print more new houses and develop its technology. Many representatives of local governments in Latin America have already shown interest in the project and even visited the current construction site. “Once people see our project with their own eyes, it no longer seems like a crazy idea to them,” says Hagler.

Source.

What the first 3D printed village looks like

Trends

TV channel

Newspaper

Pro

Investments

RBC+

New economy

Trends

Real estate

Sport

Style

National projects

City

Crypto

Debating club

Research

Credit ratings

Franchises

Conferences

Special projects St. Petersburg

Petersburg

Conferences St. Petersburg

Special projects

Checking counterparties

RBC Library

Podcasts

ESG index

Politics

Economy

Business

Technology and media

Finance

RBC CompanyRBC Life

RBC Trends

Photo: New Story

Do you dream of cheap and beautiful housing? It can be created in just a day using a 3D printer. So, in Mexico, by the end of 2020, they plan to print an entire village. Two houses are ready and residents have moved in

3D printing of real estate is gaining popularity: it is cheap, fast and requires relatively little energy. Technology allows you to create housing in just 24 hours - who among us will refuse a village house, which can be entered in just a day after the start of construction?

Technology allows you to create housing in just 24 hours - who among us will refuse a village house, which can be entered in just a day after the start of construction?

Photo: New Story

But for now, technological know-how is serving the needs of the poorest, most vulnerable. For example, it may be the construction of temporary shelters for victims of military conflicts.

New Story, a non-profit organization with the support of local governments, 3D printed two houses in the Mexican village of Tobasco. This housing is intended for the poor and those who have lost their homes due to an earthquake or flood - in the area where the village is located, they occur quite often. By the end of 2020, New Story plans to build 50 one-story 3D houses with an area of about 47 square meters. m each.

The houses were printed with a Vulcan II printer. It works as follows: cement is squeezed out of the nozzle of the apparatus and applied layer by layer around the perimeter of the designed house.