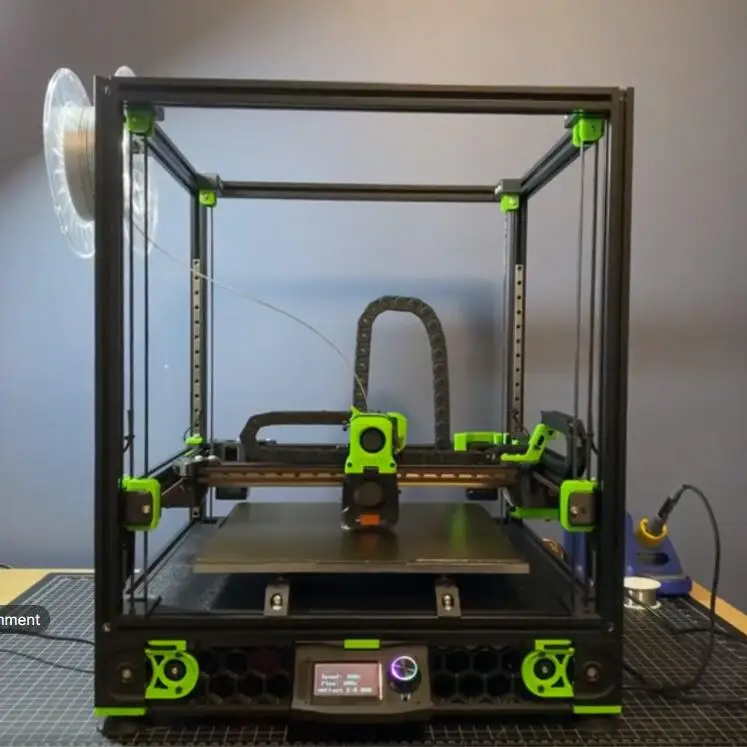

Diy 3d printer build plate

3D Printer Build Plate Comparison – Kywoo3d

3D Printer build plate can be said is one of the most important parts of any kind of FDM 3d printer, The build plate is probably among one of the most important parts of any kind of DIY 3D printer, as you can't extremely well print without it. They can be found in several variants, with different surface areas, thermal features, and prices.

On the one hand, the build plate can ensure a completely (or virtually perfectly) flat surface area for the bottom layer of your print. On the other hand, it usually offers an adhesive surface for the extruded plastic to develop a momentary bond with during a print, or a surface area onto which an adhesive can be applied.

Basically, the build plate is a flat surface that printed objects will stick to during a print. So with a better build plate, Your model will be more likely to be printed successfully.

Now, most people use the glass bed, PEI plate, and flexible plate a lot, may some beginners have no idea what are the differences between these three kinds of build plates, today we are just simply talking about these three build plates. Let’s move on.

Glass is extremely stiff and (if made properly) flat, meaning that it shouldn’t warp over time, and will always provide a solid surface to print on. It’s also dense and has a low thermal conductivity, which means it takes longer to heat up but also spreads the heat more evenly around the build area. Commonly used varieties are mirror tiles and purpose-made borosilicate glass sheets.

Glass is usually paired with an adhesive such as the everyday glue stick, painter’s tape, or some varieties of hairspray, all of which allow the bottom layers to stack nicely and not delaminate during a print. When used with a glue stick or hairspray, glass is known for the extremely smooth finish it gives to the bottom of prints.

Now, most 3d printer in the market remains the tempered glass bed as the advantages as follows:

It is extensively approved that no one build plate is best, it actually depends on what you want to print, glass as a bed for your 3D printer, nonetheless, offers several benefits that are worth taking into consideration.

Typically speaking, what makes glass a good choice is that it's a dependably level, tight, dense, as well as economical material. We can see that now most of the 3d printer in the market remains the tempered glass bed with the advantages as followings;

1.Flatness: printing build plate must be constantly flat while printing,

2. Smooth Finish: Designers desire the all-time low of their prints to be as smooth as feasible, and also glass assurances such a finish. It provides a mirror-like, glossy base that can't be achieved with the majority of other surfaces.

3. Easy Cleaning: Beds commonly gather oil, dirt, as well as undesirable plastic pieces that lead to an unequal and also unreliably adhesive print surface area. This makes cleaning a necessity, and few printer beds tidy as easily as a smooth sheet of glass, once more thanks to its smooth, level, and rigid surface area.

4. Uniform Home Heating: Even for products that do not require need it, heating up the print bed can substantially enhance how well a version prints. Lacking thermal conductivity, glass beds commonly take longer to heat up, yet they also spread out warmth much better than various other surface areas. This can considerably aid when experiencing very first layer issues, as you can be sure various locations will certainly be impacted similarly.

Lacking thermal conductivity, glass beds commonly take longer to heat up, yet they also spread out warmth much better than various other surface areas. This can considerably aid when experiencing very first layer issues, as you can be sure various locations will certainly be impacted similarly.

Polyetherimide, more typically understood in its shortened type PEI, is a "fairly maintenance complimentary" construct surface that can be used for all types of filament on a heated or unheated print bed. It does not need any type of additional adhesives such as glue or tape. In the 3D printing world.

PEI calls for "no-surface-prep" before usage, which makes it very hassle-free to work with. The standards for use additionally recommend that using a PEI sheet on your print bed will remove the requirement for a raft or border, as components are expected to adhere straight to the surface area uncreative.

PEI build plate has outstanding mechanical properties, radiation resistance, high as well as low-temperature resistance, high-temperature security, and also high wear resistance as well as good flame retardancy, chemical resistance, and also electrical insulation characteristics. Not to mention ... it can be found in several colors too!

Not to mention ... it can be found in several colors too!

- It is readily available, fairly low-cost to purchase, and also simple to use as well as eliminate.

- It can provide excellent adhesion for a printed item, removing the need for tapes and glues. Especially if you want to print with some flexible 3d filaments like PETG, ABS, TPU. It would be better you have one on your 3d printer.

- It offers a smooth surface finish (while it stays undamaged).It gives excellent thermal conductivity for a heated bed.

- It is relatively soft and also can be damaged by a badly changed print bed or extreme scratching.

- It can adhere extremely strongly to a published product, taking the chance of damages to both the bed as well as the item in addition to taking a lot of effort to eliminate the printed product.

Magnetic beds are the brand-new standard on lots of modern-day 3D printers due to the fact that they're straightforward to utilize, enable great adhesion, and also when finished, conveniently pop right off

Advantages:- Adaptable sufficient to release prints quickly

- Works exceptionally well with PLA filament

- Cheap to change if needed

Disadvantages:

- Prints can stick also well when utilizing ABS or PETG

- The upper limit of 80 ° C (losing its magnetism above that temperature level).

- Easily damaged

As I mentioned before, there’s no one can specifically saying which platform is the best, as we know that some 3d filaments like ABS, PETG requires higher nozzle and bed temperatures, we suggest print on PEI or tempered glass bed rather than the flexible magnetic plate,

If you print with PLA and TPU filament, these three build beds are optional, for easier removal of the model, flexible platform will be a good choice for you. If print on the glass bed, you might have to wait until the bed is cool enough to get the model. It really depends on what you need for printing.

Share:

Tags:

- Beginners' guide

In search of the ultimate build plate/surface.

.. - 3D Printers - Talk Manufacturing

.. - 3D Printers - Talk Manufacturingadrianq123

#1

Hi all,

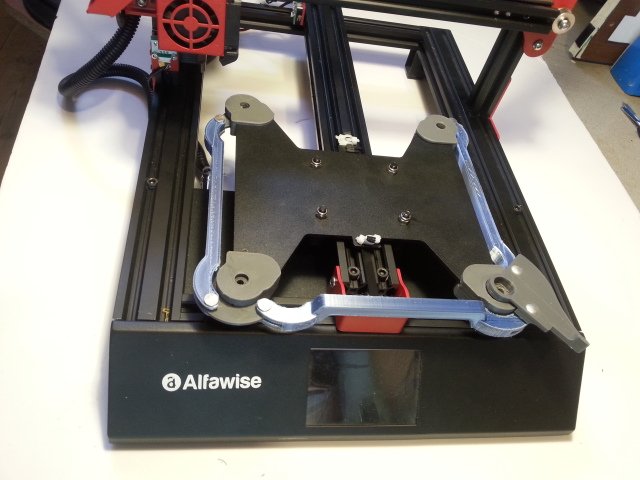

After about two months of my CTC printer printing really nicely, I started to get prints that were either not sticking, warping or both. I finally realized my stock aluminum built plate on my CTC printer is not flat. It has a dip in the middle that has made my printing …um…challenging. That has made me considered replacing my build bed.

To avoid confusion, I define Build plate as the main build bed, in my case the aluminum plate that the heating sheet attaches too. I define build surface as what sits on top of the bed (tape, buildtak, etc). Just so I am properly managing my expectations, are build plates considered ‘consumable items’? I sure hope not.

Ideally, I am looking for a LONG term solution with little to no fuss.

Here is my top list for build plates:

- Maghold Build Plate (http://www.3dprintermods.com/prestashop/index.php?id_product=5&controller=product) : Just a build plate, but looks pretty sturdy and less likely to warp.

- GeckoTec : This has a lot of people raving about how great it works. For $85 I get a magnetic build plate and the geckotec plate for pla/abs. My concern is longevity of the build surface.

- Glass : I really rather not deal with glass because of the glue/tape/hairspray,etc. I could be swayed if long term cost would be lower than the other options.

Here are my list of build surface options:

- BuildTak : I have tried it, not bad. It does eventually wear out and not exactly cheap. So will mostly likely discontinue use.

- GeckoTec : as above, sounds like a great option, but I am concerned about its longevity.

- Zebra/Fleks : same as GeckoTec

- Printbite : This sounds incredible, but I don’t really know where to get it. again, not sure of the price or longevity.

- PEI : I have a sheet (.003" 12x12), but have not been able to test it. I realize this is also a consumable, but any thoughts on how it will last in relation to the other options? Not super excited about having to use 3M thermal tape that isn’t cheap either.

At this point I am leaning toward MagHold and one of the build surface options. Any thoughts on what combination would give the results with long lasting use. I don’t mind spending the money for a long lasting solution.

I am looking forward to the responses.

SOC3D

#2

I find Glass with hairspray to work the best and cheapest for ABS/PLA and SuperGlue/Glass for PolyCarb and nylon. I replace my borosilicate glass when it shears off with prints and my non-borosilicate when it shatters. I also use Lexan/Makrolon and painters tape when needed.

Build surfaces seem to be like religions. Different people swear by different build surfaces and recommend them to everyone. If they are all correct and their build surface is the best then the world needs to implode. Find what you like and what you think will last or be cheaper and use it.

Keep in mind that the amount of print time you have, the materials you use and the print settings you use will have an affect on the life of the build surface so if someone is using more of a different material or even a different brand you may get drastically different results and life out of the same build surface.

If you are using thermal tape or adhesive look at the value (Watts per Meter Kelvin?) and compare it to something like Arctic Silver 5 thermal paste which might be better and cheaper. http://www.engineeringtoolbox.com/thermal-conductivity-d_429.html

D3DI

#3

Hi Adrianq123,

Great topic you have started here. I also have a few CTC printers and got excellent results straight out of the box. After a few dozen prints the red tape started peeling off and needed replacing, I tried using a cheap masking tape which works for a while but is now bubbling off from underneath and has gone ripply and miss-shapen, I think like most things you get what you pay for.

I also have a few CTC printers and got excellent results straight out of the box. After a few dozen prints the red tape started peeling off and needed replacing, I tried using a cheap masking tape which works for a while but is now bubbling off from underneath and has gone ripply and miss-shapen, I think like most things you get what you pay for.

The CTC printers I have are set to 110C build plate from the factory and I cannot see a control anywhere to turn this temperature down, I think I need a firmware upgrade. I can easily imagine why the plate will warp with constant heating and cooling cycles. One thing I am really not keen on either is how the plate moves when pulling off builds, the springs to level the bed work well but do not actually ‘fix’ the plate…sometimes the force required to remove prints seems like it might damage the machine. DO not get me wrong though I am delighted with my CTC printers, for the price, mostly built and calibrated out of the box - fantastic.

I have also used a lot of glass plates with my modified Rostock deltas, these work very well with ABS and PLA but I have found that to my surprise occasionally a chunk of glass will break off along with the print (glass impregnated additive manufacturing anyone?). With ABS I use a heated glass bed and a tiny bit of hairspray, the print sticks very well, the only way I can get it off is to allow the bed to cool down, when cool enough it pops off. I guess the thermal shock/constant cycling is not helpful. The glass plates do not cost very much money but obviously need to be handled carefully.

With ABS I use a heated glass bed and a tiny bit of hairspray, the print sticks very well, the only way I can get it off is to allow the bed to cool down, when cool enough it pops off. I guess the thermal shock/constant cycling is not helpful. The glass plates do not cost very much money but obviously need to be handled carefully.

RaoulDuke

#4

I habe not replaced the aluminum print bed yet, but I can recommend FR4 fibreglass plates as a print surface. Works well with PLA, ABS and PETG.

D3DI

#5

I like the sound of FR4 plates, what thickness are you using? 1. 6mm?

6mm?

Eduardo_Garcia

#6

I swear by glass build plate with hairspray. Every material I have used sticks and thru out all the build plate it’s flat as a pancake as long as you level.it right.

hubinio

#7

I use this plate for my ctc, its a spezial plate for the Replicator 2 with higher adhesion: http://www.3dprinterstore24.de/Dauerdruckplatten/Dauerdruckplatten-weiss-1mm/Dauerdruckplatte-weiss-1mm-230x150mm-fuer-z-B-Duplicator-SPEZIAL::132.html PLA and ABS stick perfect but for Nylon i need to use a glue stick. I am working with this plate for around a year and I think it will even last longer. The Name “Dauerdruckplatte” means “long lasting printing plate/surface”

The Name “Dauerdruckplatte” means “long lasting printing plate/surface”

RaoulDuke

#8

I usw 1mm FR4, but 1.6 would probably be better. For tiny prints I either add little feet to the print or glue stick mixed with alcohol.

Rick_deckard

#9

I took the glass plate out of an old printer/scanner ,cut it to the slightly bigger size i wanted with a glass cutter.

used 4 glue dots to stick it to the plate for position then 4 clips to stop it slipping squirt of hairspray and job done

easy cheap and works really well

Building a home 3D printer with your own hands: recommendations from personal experience

3D printing and assembly of 3D printers is my hobby and passion. Here I will not share detailed diagrams and drawings, there are more than enough of them on specialized resources. The main goal of this material is to tell you where to start, where to dig and how to avoid mistakes in the process of assembling a home 3D printer. Perhaps one of the readers will be inspired by applied engineering achievements.

Here I will not share detailed diagrams and drawings, there are more than enough of them on specialized resources. The main goal of this material is to tell you where to start, where to dig and how to avoid mistakes in the process of assembling a home 3D printer. Perhaps one of the readers will be inspired by applied engineering achievements.

Why do you need a 3D printer? Use cases

I first came across the idea of 3D printing back in the 90s when I was watching the Star Trek series. I remember how impressed I was by the moment when the heroes of the cult series printed the things they needed during their journey right on board their starship. They printed anything: from shoes to tools. I thought it would be great someday to have such a thing too. Then it all seemed something incredible. Outside the window are the gloomy 90s, and the Nokia with a monochrome screen was the pinnacle of progress, accessible only to a select few.

Years passed, everything changed. Around 2010, the first working models of 3D printers began to appear on sale. Yesterday's fantasy has become a reality. However, the cost of such solutions, to put it mildly, discouraged. But the IT industry would not be itself without an inquisitive community, where there is an active exchange of knowledge and experience and who just let them dig into the brains and giblets of new hardware and software. So, drawings and diagrams of printers began to surface more and more often on the Web. Today, the most informative and voluminous resource on the topic of assembling 3D printers is RepRap - this is a huge knowledge base that contains detailed guides for creating a wide variety of models of these machines.

Around 2010, the first working models of 3D printers began to appear on sale. Yesterday's fantasy has become a reality. However, the cost of such solutions, to put it mildly, discouraged. But the IT industry would not be itself without an inquisitive community, where there is an active exchange of knowledge and experience and who just let them dig into the brains and giblets of new hardware and software. So, drawings and diagrams of printers began to surface more and more often on the Web. Today, the most informative and voluminous resource on the topic of assembling 3D printers is RepRap - this is a huge knowledge base that contains detailed guides for creating a wide variety of models of these machines.

I assembled the first printer about five years ago. My personal motivation to build my own device is quite prosaic and based on several factors. Firstly, there was an opportunity to try to realize the old dream of having your own device, inspired by a fantasy series. The second factor is that sometimes it was necessary to repair some household items (for example, a baby stroller, car elements, household appliances and other small things), but the necessary parts could not be found. Well, the third aspect of the application is "near-working". On the printer, I make cases for various IoT devices that I assemble at home.

Well, the third aspect of the application is "near-working". On the printer, I make cases for various IoT devices that I assemble at home.

Agree, it is better to place your device based on Raspberry Pi or Arduino in an aesthetically pleasing "body", which is not a shame to put in an apartment or take to the office, than to organize components, for example, in a plastic bowl for food. And yes, you can print parts to build other printers :)

There are a lot of scenarios for using 3D printers. I think everyone can find something of their own.

A complex part in terms of drawing that I printed on my printer. Yes, it's just a figurine, but it has many small elements

Ready solution vs custom assembly

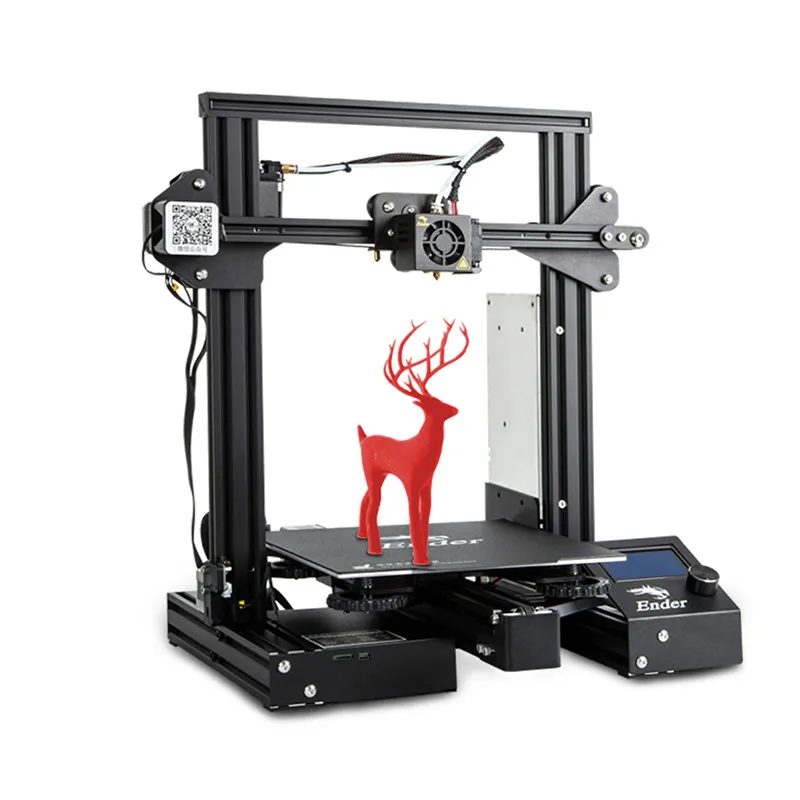

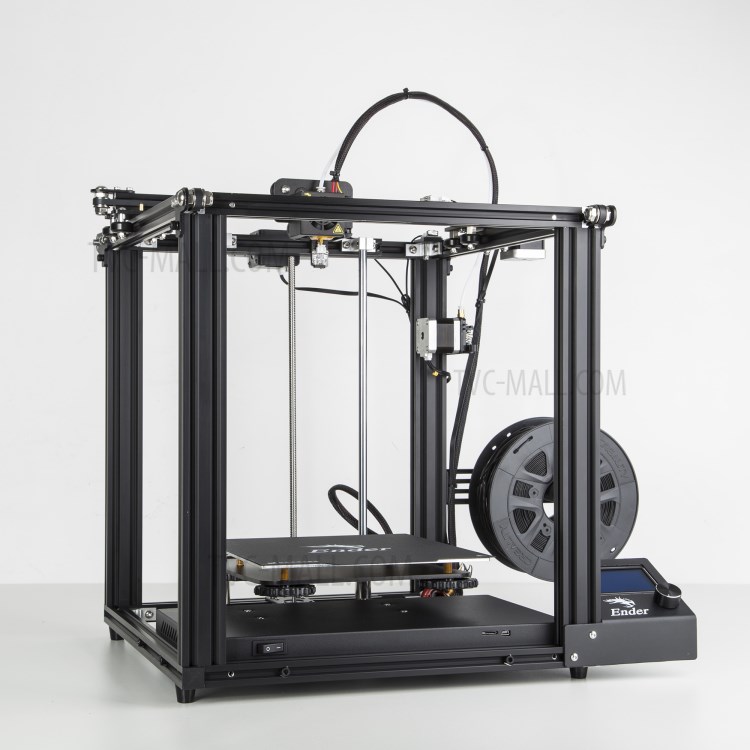

When a technology has been tested, its value in the market decreases markedly. The same thing happened in the world of 3D printers. If earlier a ready-made solution cost simply sky-high money, then today acquiring such a machine is more humane for the wallet, but nevertheless not the most affordable for an enthusiast. There are a number of solutions already assembled and ready for home use on the market, their price range ranges from $500-700 (not the best options) to infinity (adequate solutions start from a price tag of about $1000). Yes, there are options for $150, but we, for understandable, I hope, reasons, will not dwell on them.

If earlier a ready-made solution cost simply sky-high money, then today acquiring such a machine is more humane for the wallet, but nevertheless not the most affordable for an enthusiast. There are a number of solutions already assembled and ready for home use on the market, their price range ranges from $500-700 (not the best options) to infinity (adequate solutions start from a price tag of about $1000). Yes, there are options for $150, but we, for understandable, I hope, reasons, will not dwell on them.

In short, there are three cases to consider a finished assembly:

- when you plan to print not much and rarely;

- when print accuracy is critical;

- you need to print molds for mass production of parts.

There are several obvious advantages to self-assembly. The first and most important is cost. Buying all the necessary components will cost you a maximum of a couple of hundred dollars. In return, you will receive a complete 3D printing solution with the quality of manufactured products acceptable for domestic needs. The second advantage is that by assembling the printer yourself, you will understand the principles of its design and operation. Believe me, this knowledge will be useful to you during the operation of even an expensive ready-made solution - any 3D printer needs to be serviced regularly, and it can be difficult to do this without understanding the basics.

The second advantage is that by assembling the printer yourself, you will understand the principles of its design and operation. Believe me, this knowledge will be useful to you during the operation of even an expensive ready-made solution - any 3D printer needs to be serviced regularly, and it can be difficult to do this without understanding the basics.

The main disadvantage of assembly is the need for a large amount of time. I spent about 150 hours on my first build.

What you need to assemble the printer yourself

The most important thing here is the presence of desire. As for any special skills, then, by and large, in order to assemble your first printer, the ability to solder or write code is not critical. Of course, understanding the basics of radio electronics and basic skills in the field of mechanics (that is, "straight hands") will greatly simplify the task and reduce the amount of time that needs to be spent on assembly.

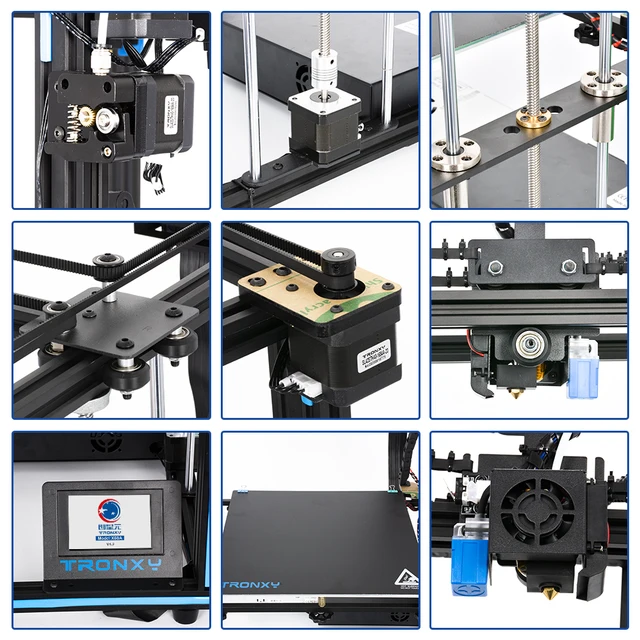

Also, to start we need a mandatory set of parts:

- Extruder is the element that is directly responsible for printing, the print head.

There are many options on the market, but for a budget build, I recommend the MK8. Of the minuses: it will not be possible to print with plastics that require high temperatures, there is noticeable overheating during intensive work, which can damage the element. If the budget allows, then you can look at MK10 - all the minuses are taken into account there.

There are many options on the market, but for a budget build, I recommend the MK8. Of the minuses: it will not be possible to print with plastics that require high temperatures, there is noticeable overheating during intensive work, which can damage the element. If the budget allows, then you can look at MK10 - all the minuses are taken into account there. - Processor board. The familiar Arduino Mega is well suited. I didn't notice any downsides to this solution, but you can spend a couple of dollars more and get something more powerful, with a reserve for the future.

- Control board. I'm using RAMPS 1.4 which works great with the Arduino Mega. A more expensive but more reliable board is Shield, which already combines a processor board and a control board. In modern realities, I recommend paying attention to it. In addition to it, you need to purchase at least 5 microstep stepper motor controllers, for example - A4988. And it's better to have a couple of these in stock for replacement.

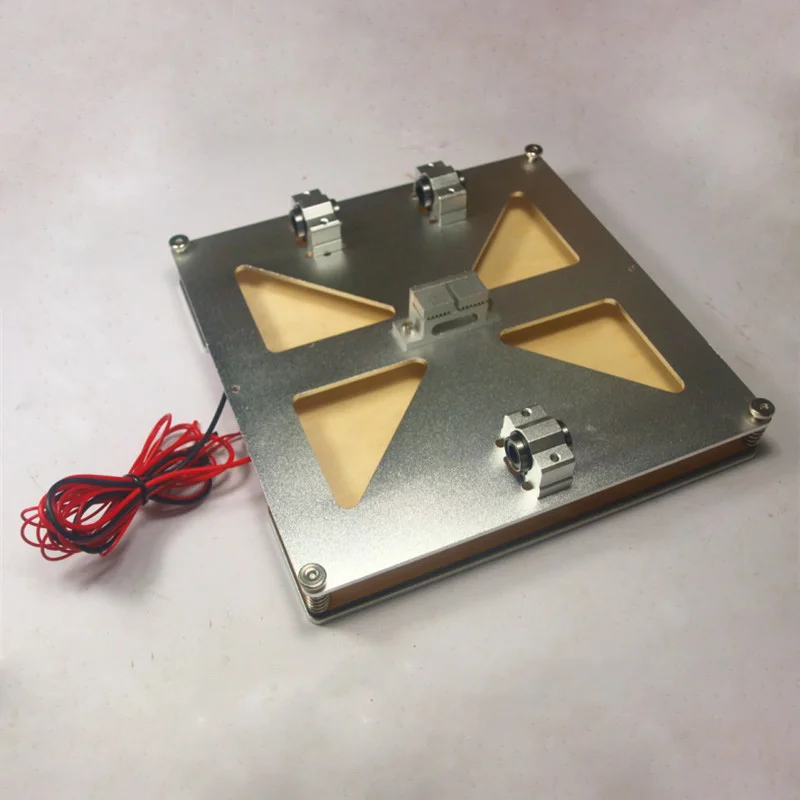

- Heated table. This is the part where the printed element will be located. Heating is necessary due to the fact that most plastics will not adhere to a cold surface. For example, for printing with PLA plastic, the required surface temperature of the table is 60-80°C, for ABS - 110-130°C, and for polycarbonate it will be even higher

There are also two options for choosing a table - cheaper and more expensive. Cheaper options are essentially printed circuit boards with preheated wiring. To operate on this type of table, you will need to put borosilicate glass, which will scratch and crack during operation. Therefore, the best solution is an aluminum table. - Stepper motors. Most models, including the i2 and i3, use NEMA 17 size motors, two for the Z axis and one each for the X and Y axes. Finished extruders usually come with their own stepper motor. It is better to take powerful motors with a current in the motor winding of 1A or more, so that there is enough power to lift the extruder and print without skipping steps at high speed.

- Basic set of plastic fasteners.

- Belt and gears to drive it.

Examples of elements appearance: 1) MK8 extruder; 2) Arduino processor board; 3) RAMPS control board; 4) motor controllers; 5) aluminum heated table; 6) NEMA 17 stepper motor; 7) a set of plastic fasteners; 8) drive gears; 9) drive belt

This is a list of items to be purchased. Hardcore users can assemble some of them themselves, but for beginners, I strongly recommend purchasing ready-made solutions.

Yes, you will also need various small things (studs, bearings, nuts, bolts, washers ...) to assemble the case. In practice, it turned out that using a standard m8 stud leads to low printing accuracy on the Z axis. I would recommend immediately replacing it with a trapezoid of the same size.

M8 trapezoid stud for Z axis, which will save you a lot of time and nerves. Available for order on all major online platforms

You also need to purchase customized plastic parts for the X axis, such as these from the MendelMax retrofit kit.

Most parts available at your local hardware store. On RepRap you can find a complete list of necessary little things with all sizes and patterns. The kit you need will depend on the choice of platform (we'll talk about platforms later).

What's the price

Before delving into some aspects of the assembly, let's figure out how much such entertainment will cost for your wallet. Below is a list of parts required for purchase with an average price.

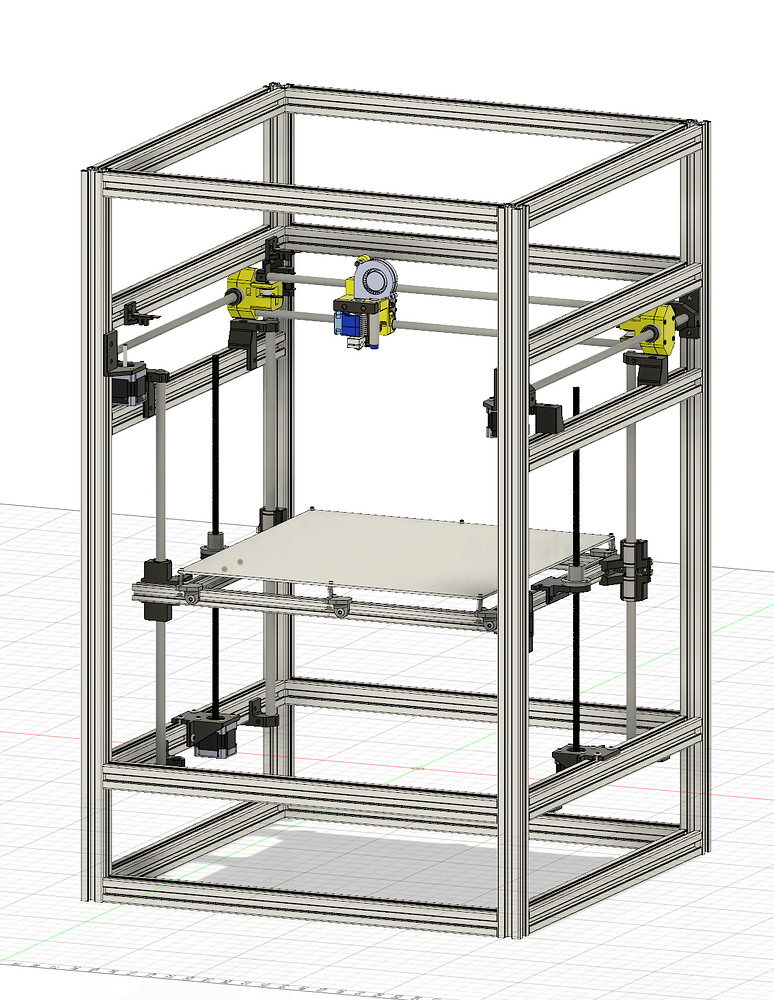

Platform selection

The community has already developed a number of different platforms for assembling printers - the most optimal case designs and the location of the main elements, so you do not have to reinvent the wheel.

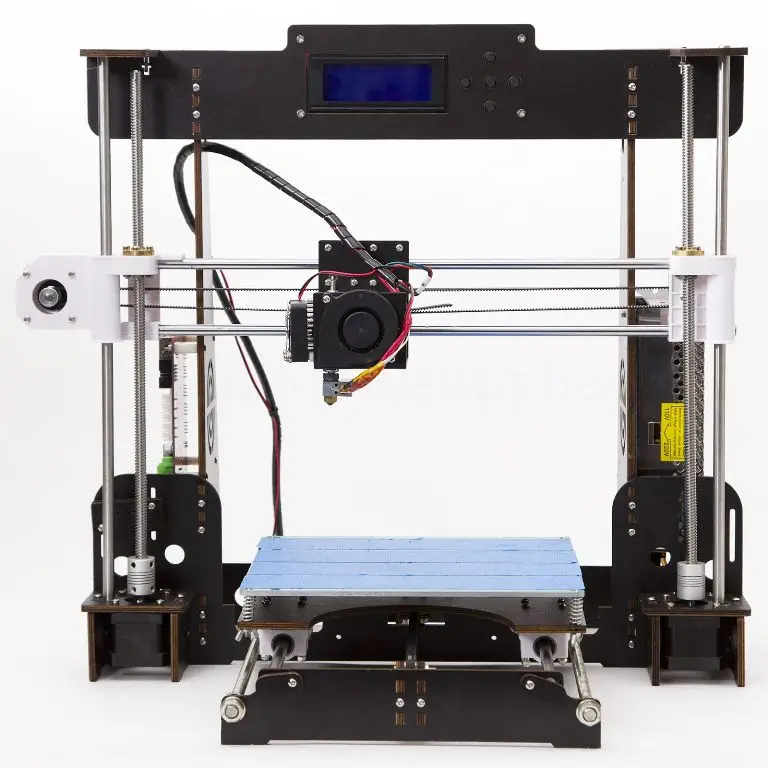

i2 and i3 are key platforms for self-assembly printer enclosures. There are also many modifications of them with various improvements, but for beginners, these two classic platforms should be considered, since they do not require special skills and fine-tuning.

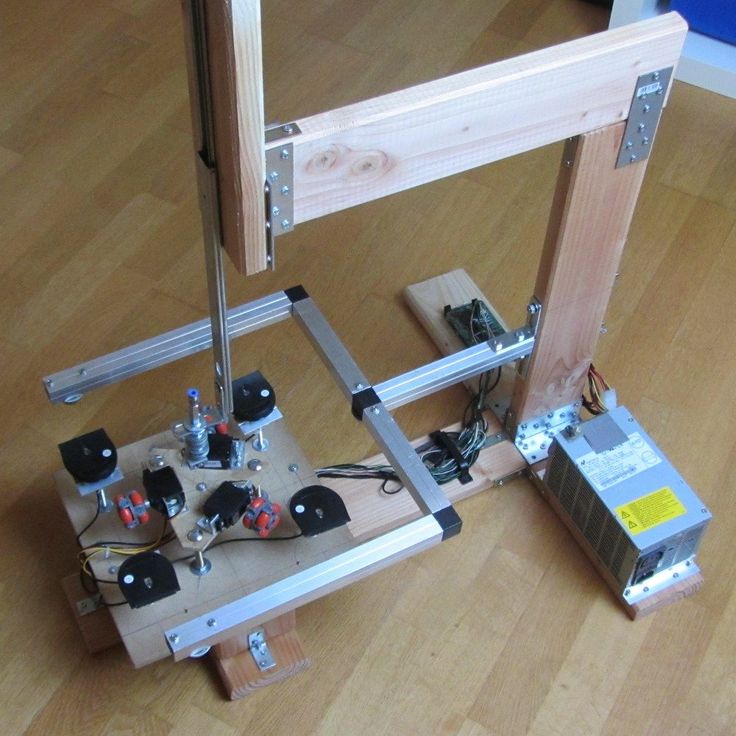

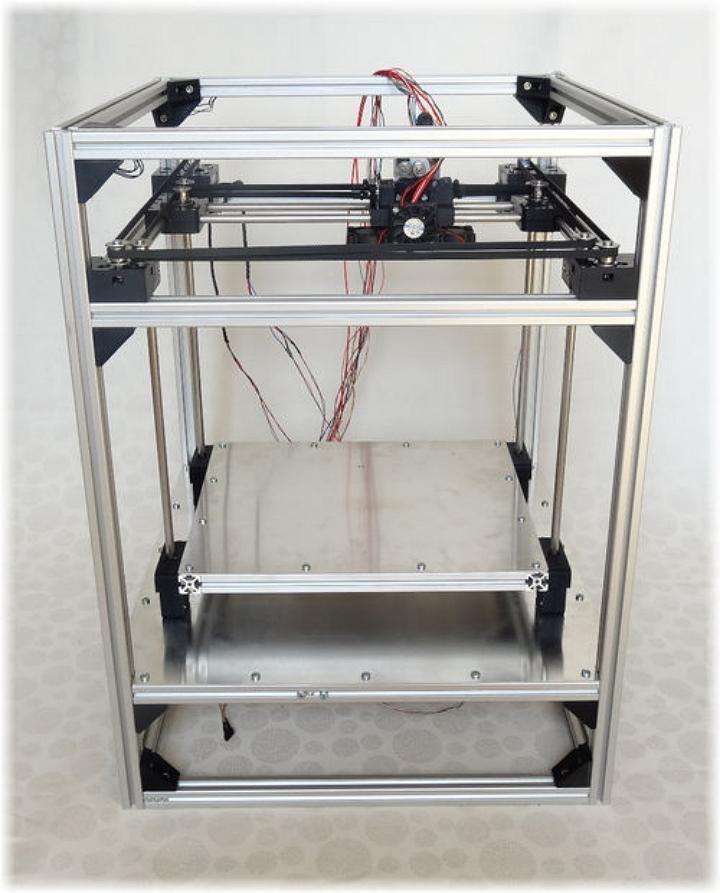

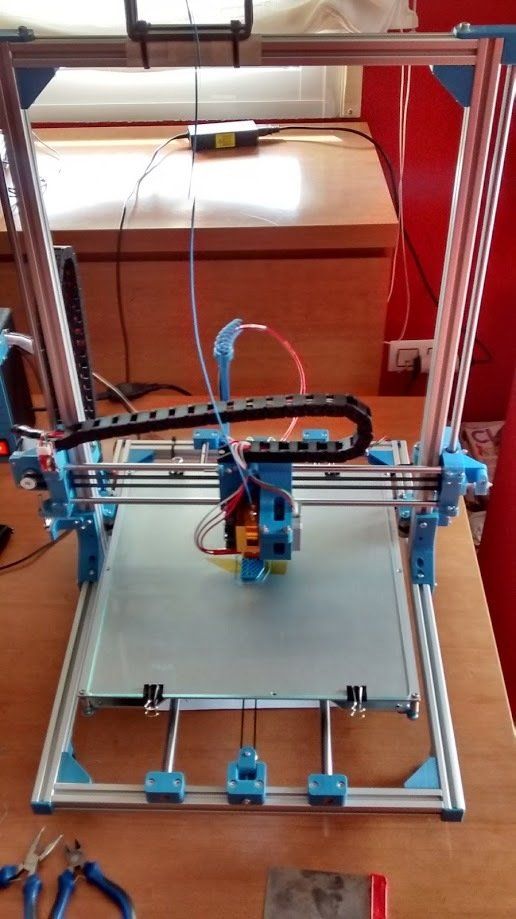

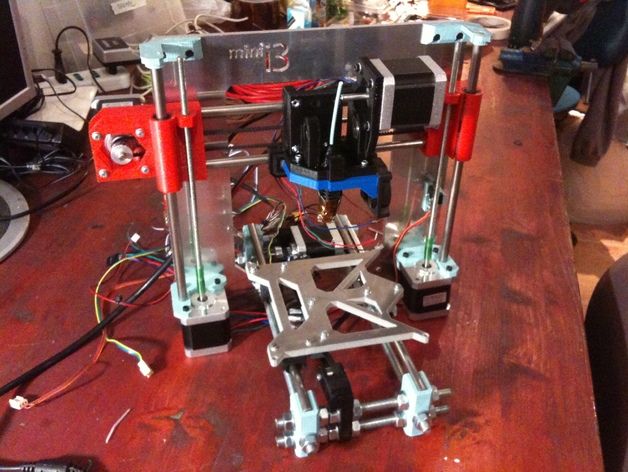

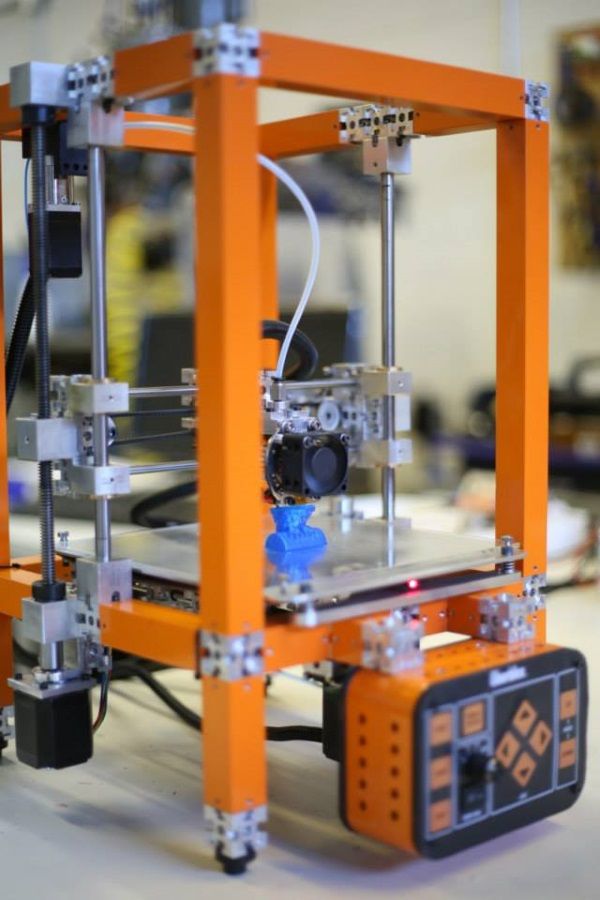

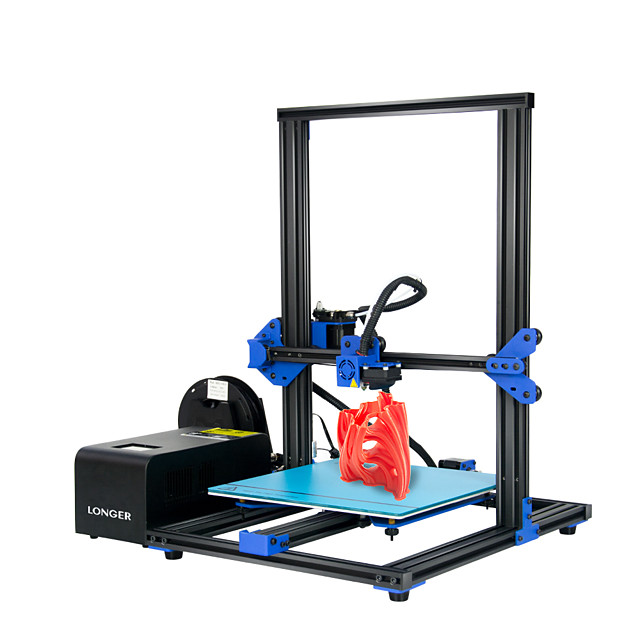

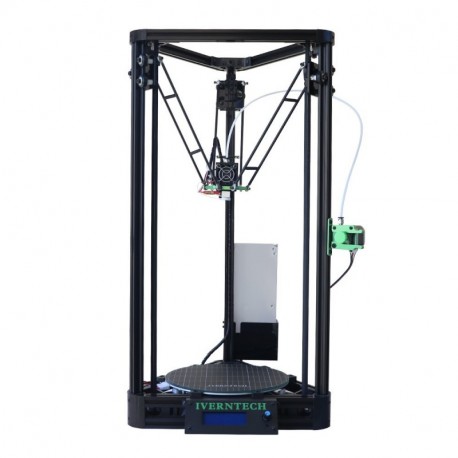

Actually, illustration of platforms: 1) i2 platform; 2) i3 platform

On the plus side of i2: it has a more reliable and stable design, although it is a little more difficult to assemble; more opportunities for further customization.

The i3 variant requires more special plastic parts to be purchased separately and has a slow print speed. However, it is easier to assemble and maintain, and has a more aesthetically pleasing appearance. You will have to pay for simplicity with the quality of printed parts - the body has less stability than i2, which can affect print accuracy.

Personally, I started my experiments in assembling printers from the i2 platform. She will be discussed further.

Assembly steps, challenges and improvements

In this block, I will only touch on the key assembly steps using the i2 platform as an example. Full step by step instructions can be found here.

The general scheme of all the main components looks something like this. There is nothing particularly complicated here:

I also recommend adding a display to your design. Yes, you can easily do without this element when performing operations on a PC, but it will be much more convenient to work with the printer this way.

Understanding how all components will be connected, let's move on to the mechanical part, where we have two main elements - a frame and a coordinate machine.

Assembling the frame

Detailed frame assembly instructions are available on RepRap. Of the important nuances - you will need a set of plastic parts (I already talked about this above, but I'd better repeat it), which you can either purchase separately or ask your comrades who already have a 3D printer to print.

The frame of the i2 is quite stable thanks to its trapezoid shape.

This is how the frame looks like with parts already partially installed. For greater rigidity, I reinforced the structure with plywood sheets

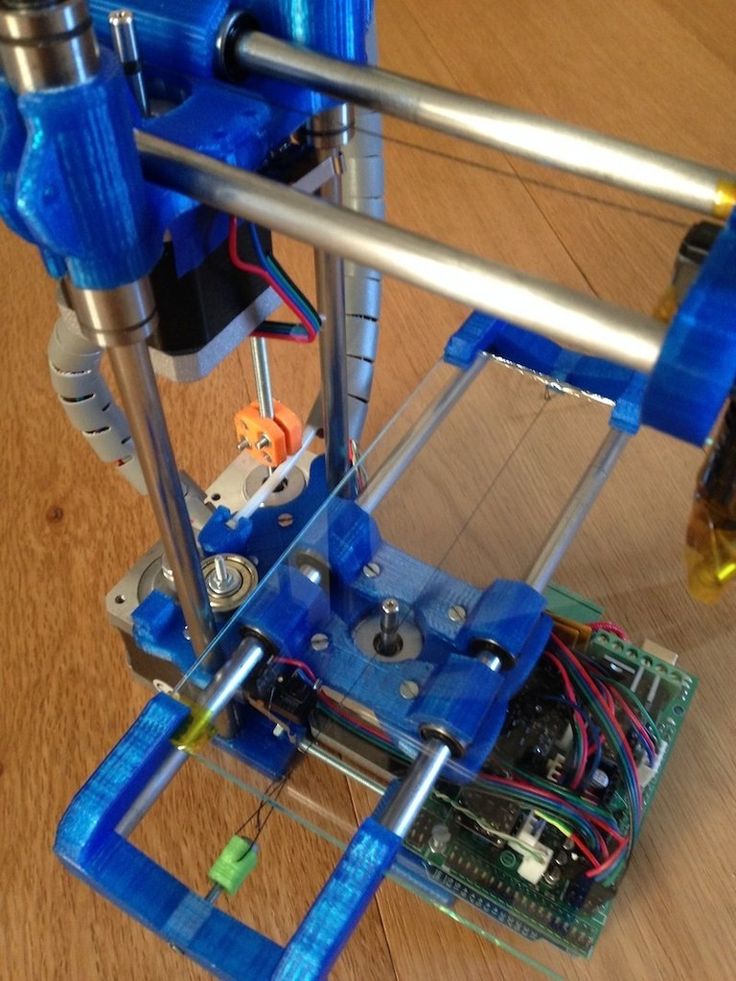

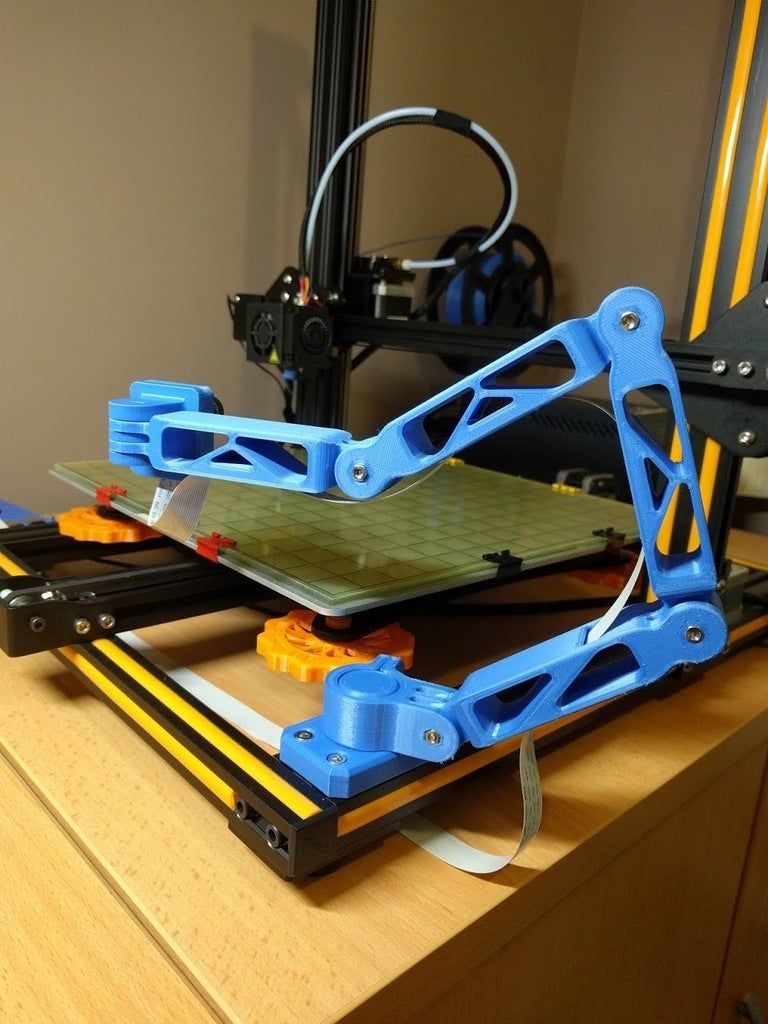

Coordinate machine

An extruder is attached to this part. The stepper motors shown in the diagram above are responsible for its movement. After installation, calibration is required along all major axes.

Important - you will need to purchase (or make your own) a carriage for moving the extruder and a mount for the drive belt. Drive belt I recommend GT2.

The carriage printed by the printer from the previous picture after it has been assembled. The part already has LM8UU bearings for guides and belt mount (top)

Calibration and adjustment

So, we completed the assembly process (as I said, it took me 150 hours) - the frame was assembled, the machine was installed. Now another important step is the calibration of this very machine and extruder. Here, too, there are small subtleties.

Setting up the machine

I recommend calibrating the machine with an electronic caliper. Do not be stingy with its purchase - you will save a lot of time and nerves in the process.

The screenshot below shows the correct constants for the Marlin firmware, which must be selected in order to set the correct number of steps per unit of measure. We calculate the coefficient, multiply it, substitute it into the firmware, and then upload it to the board.

We calculate the coefficient, multiply it, substitute it into the firmware, and then upload it to the board.

Marlin 9 firmware constants0022

For high-quality calibration, I recommend relying on larger numbers in measurements - take not 1-1.5 cm, but about 10. So the error will be more noticeable, and it will become easier to correct it.

Calibrating the extruder

When the frame is assembled, the machine is calibrated, we start setting up the extruder. Here, too, everything is not so simple. The main task of this operation is to correctly adjust the supply of plastic.

If underfeeding, the printed test item will have noticeable gaps, like test die 1. Conversely, the result will look bloated if plastic is overfed (dice 2)

Getting Started Printing

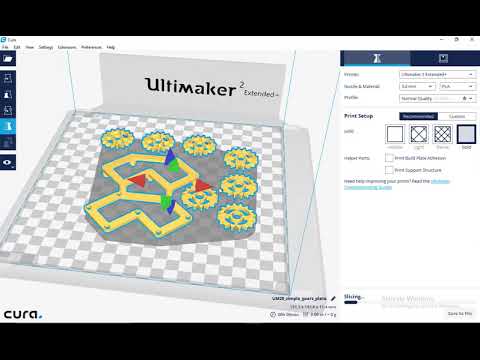

It remains for us to run some CAD or download ready-made .stl, which describe the structure of the printed material. Next, this structure needs to be converted into a set of commands understandable to our printer. For this I use the Slicer program. It also needs to be set up correctly - specify the temperature, the size of the extruder nozzle. After that, the data can be sent to the printer.

For this I use the Slicer program. It also needs to be set up correctly - specify the temperature, the size of the extruder nozzle. After that, the data can be sent to the printer.

Slicer interface

As a raw material for printing, I recommend starting with regular ABS plastic - it is quite strong, products made from it are durable, and it does not require high temperatures to work with. For comfortable printing with ABS plastic, the table must be heated to a temperature of 110-130 ° C, and the extruder nozzle - within 230-260 ° C.

Some important details. Before printing, calibrate the machine along the Z axis. The extruder nozzle should be approximately half a millimeter from the table and ride along it without distortion. For this calibration, a regular sheet of A4 paper inserted between the nozzle and the surface of the heated table is best suited. If the sheet can be moved with little effort, the calibration is correct.

Another thing to keep in mind is the surface treatment of the heated table. Usually, before printing, the surface of the table is covered with something that hot plastic sticks to well. For ABS plastic, this can be, for example, Kapton tape. The disadvantage of adhesive tape is the need to re-glue it after several printing cycles. In addition, you will have to literally tear off the adhering part from it. All this, believe me, takes a lot of time. Therefore, if it is possible to avoid this fuss, it is better to avoid it.

An alternative option that I use instead of scotch tape is to apply several layers of ordinary light beer, followed by heating the table to 80-100 ° C until the surface is completely dry and re-applying 7-12 layers. It is necessary to apply the liquid with a cloth moistened with a drink. Among the advantages of this solution: ABS plastic separates from the table on its own when it cools down to about 50 ° C and is removed without effort, the table does not have to be peeled off, and one bottle of beer will last you for several months (if you use the drink only for technical purposes :)).

After we have collected and configured everything, we can start printing. If you have an LCD screen, then the file can be transferred for printing using a regular SD card.

The first results may have bumps and other artifacts - do not worry, this is a normal process of "grinding" the printer elements, which will end after a few print cycles.

Tips to make life easier (and sometimes save money)

In addition to the small recommendations given in the text above, in this section I will also give a short list of tips that will greatly simplify the operation of a 3D printer and the life of its owner.

- Do not experiment with nozzles. If you plan to immediately print from materials that require high temperatures, then it is better to immediately take the MK10 extruder. On MK8, you can "hang" special nozzles that support high-temperature conditions. But such modifications often cause difficulties and require special experience.

It is better to avoid this fuss on the shore by simply installing the right extruder for you.

It is better to avoid this fuss on the shore by simply installing the right extruder for you. - Add starter relay for heated table. Improving the power supply system for this important printing part with a starter relay will help solve the known problem of RAMP 1.4 - overheating of the transistors that control the power of the table, which can lead to failure of the board. I made this upgrade after having to throw away a few RAMPS 1.4s.

- Select the correct filament diameter for printing. I recommend using 1.75mm plastic for MK8 and MK10. If we take plastic, for example, 3 mm, then the extruder simply does not have enough strength to push it at an acceptable speed - everything will be printed much longer, and the quality will drop. ABS plastic is ideal for MK8, MK10 will be able to produce products from polycarbonate.

- Use only new and precise X and Y guides. Print quality will be affected. It is difficult to count on good quality with bent or deformed guides along the axes.

- Take care of cooling. During my experiments with various extruders, the MK10 showed the best results - it prints quite accurately and quickly. The MK10 can also print plastics that require a higher print temperature than ABS, such as polycarbonate. Although it is not as prone to overheating as its younger brother MK8, I still recommend taking care of its cooling by adding a cooler to your design. It must be permanently enabled, this option can be configured in Slicer. You can also add coolers to keep the stepper motors at an acceptable temperature, however, make sure that their air flows do not fall on the printed part, as this can lead to its deformation due to too rapid cooling.

- Consider heat retention. Yes, on the one hand, we are struggling with overheating of the elements. On the other hand, a uniform temperature around the printer will contribute to high-quality printing (the plastic will be more pliable). To achieve a uniform temperature, you can put our printer, for example, in a cardboard box.

The main thing is to connect and configure the coolers before that, as described above.

The main thing is to connect and configure the coolers before that, as described above. - Consider insulating your desk. Heated table heats up to high temperatures. And if part of this heat leaves properly, heating the printed part, then the second part (from below) just goes down. To concentrate the heat from the table onto the part, you can perform an operation to insulate it. To do this, I simply attach a cork mouse pad to its bottom using stationery clips.

Pins

I am sure that during the assembly process you will encounter a number of difficulties specific to your project. Neither this text nor even the most detailed guides will insure against this.

As I wrote in the introductory part, the above does not claim the status of a detailed assembly manual. It is almost impossible to describe all the stages and their subtleties within the framework of one such text. First of all, this is an overview material that will help you prepare for the assembly process (both mentally and financially), understand whether you personally need to bother with self-assembly - or give up on everything and buy a ready-made solution.

For me, assembling printers has become an exciting hobby that helps me solve some issues in home and work affairs, take my mind off programming and do something interesting with my own hands. For my children - entertainment and the opportunity to get unusual and unique toys. By the way, if you have children whose age allows them to mess around with such things, such an activity can be a good help for entering the world of mechanics and technology.

For everyone, the vectors of using 3D printers will be very different and very individual. But, if you decide to devote your personal time to such a hobby, believe me, you will definitely find something to print :)

I will be glad to answer comments, remarks and questions.

What to read/see

- what can be printed;

- 3D printer forum;

- RepRap community site with model descriptions and assembly instructions;

- printer that prints electronics.

Subscribe to the Telegram channel "DOU #tech" so you don't miss new technical articles.

Topics: DIY, embedded, tech

DIY drawing threads

The appearance of the first 3D printers contributed to the accelerated development of the IT segment. The uniqueness of equipment capable of reproducing designs in three-dimensional format has become the reason for its high cost.

Extruder

Therefore, the appearance of self-made devices with similar functions did not come as a surprise. They are used in domestic conditions, and when working with them, consumables are required. It is more commonly referred to as a filamentous plastic such as ABS or PLA. A person who wants to assemble a 3D printer or its separate part (extruder) with his own hands must have the necessary knowledge and experience. He must know about extruder calibration, Cool-end and Hot-end cooling.

What will be discussed:

- Mechanical components

- Electrical components

- Block Cool-End

- Hot-End

- Extruder Assembly 9003 Heating element assembly

Mechanical components

It is possible to buy parts for assembly in a kit, but those who do not look for easy ways often decide to make their own. They will need:

They will need:

- fasteners for forming the framework;

- work platform;

- device for heating and temperature control;

- metal guides;

- gears for electric drives;

- extruder.

The main difficulty in the manufacture of a 3D printer is the correct configuration of the last three elements. Of great importance is the drive, which is installed to move the platform on one axis. The second becomes the key to moving the print head.

Parts for assembling a 3d extruder

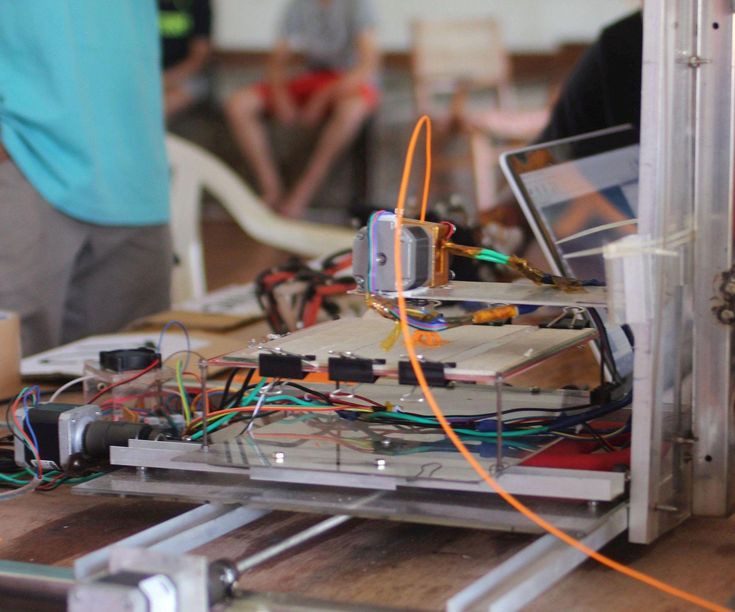

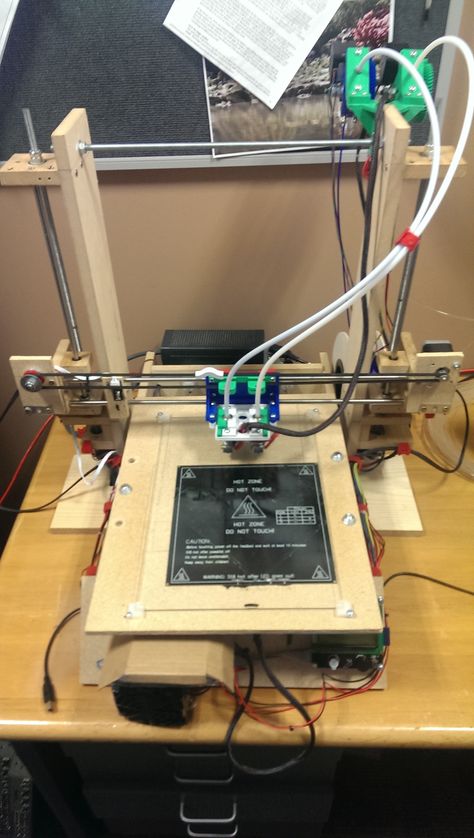

Self-assembly of the mechanical part is carried out using plywood sheets, screws of the appropriate size and clips to ensure fixation. The photo shows a standard kit for making a 3D printer with two print heads.

Electrical components

Design feature is a 3d printer filament extruder. Thanks to him, the consumable material comes out and the drawing is directly created. More often, they do not risk doing it on their own, but purchase it in specialized stores. The assembly begins with the preparation of the necessary parts.

The assembly begins with the preparation of the necessary parts.

Cool-end unit

Its functions include feeding the filament (thread made of plastic). It consists of an electric motor, rod and gears. The threads are wound on a spool provided for this purpose.

Cool-end

Hot-end

It is a duo of nozzle and heating element. The filament passes through the latter and changes its state of aggregation, turning into a viscous mass, which is then squeezed out with a nozzle. The final step is the layer-by-layer application of this composition.

hotend nozzle

The parts of this part of the dual extruder 3d printer are made of brass or aluminum alloys. As a result, heat is dissipated fairly quickly. The block consists of a wire spiral, a thermocouple (it regulates the temperature) and two resistors. The cooling of the elevator is carried out due to the thermal insulating insert. It is located between Cool-end and Hot-end. This item is shown in the photo.

Assembling the extruder

Do-it-yourself production of an extruder for a 3D printer is as follows.

The engine is selected

More often this part is replaced by a working motor from a printer or scanner, you can buy it on the radio market.

17 Stepper Motor 1.75 mm 1.7

If the motor for the extruder is too weak, an additional gearbox is required. A suitable replacement for the purchased part will be the one that was previously part of the screwdriver. Also, the reducer will need a bar extruder for a 3d printer. The engine is connected by the body, pressure roller and hot end, they must be positioned as in the photo.

Pressure roller adjustment

A well-thought-out interaction between this element and the spring is essential. The latter is set due to possible shortcomings in the calculation of the parameters of the 3D printer bar.

Too much thread adhesion to the feeder causes particles of consumable material to separate.

Making a Hot End

Much easier to get, most crafters do. For self-production, you will need drawings that can be downloaded from the Internet. The radiator needs aluminum alloy.

Extruder (hot end) radiator 3D printer

This element removes warm air from the barrel of the device, which is a hollow tube. In its functions, the connection of the heating element and the radiator. This prevents the printer from overheating.

An LED radiator is considered a good option, while the device will be cooled by a fan. The barrel of a hot-end 3D printer is a metal hollow tube. When creating an extruder, it is necessary to take into account the melting time of the threads. If they melt earlier than expected, the nozzle will become clogged.

Assembling the heating element

The first thing you need is an aluminum plate. It makes moves for attaching the thermistor, hot end and resistor.

Aluminum plate

A 3D printer may have more than one extruder, such as in the photo. This fact should be taken into account when creating a device drawing. The functionality of such equipment is an order of magnitude higher than that of standard equipment, for example, two-color printing and the manufacture of structures from soluble polymer materials.

This fact should be taken into account when creating a device drawing. The functionality of such equipment is an order of magnitude higher than that of standard equipment, for example, two-color printing and the manufacture of structures from soluble polymer materials.

The final stage of creating a 3D printer with your own hands includes calibrating the extruder, connecting electronics, adjusting the printing process, and introducing suitable software.

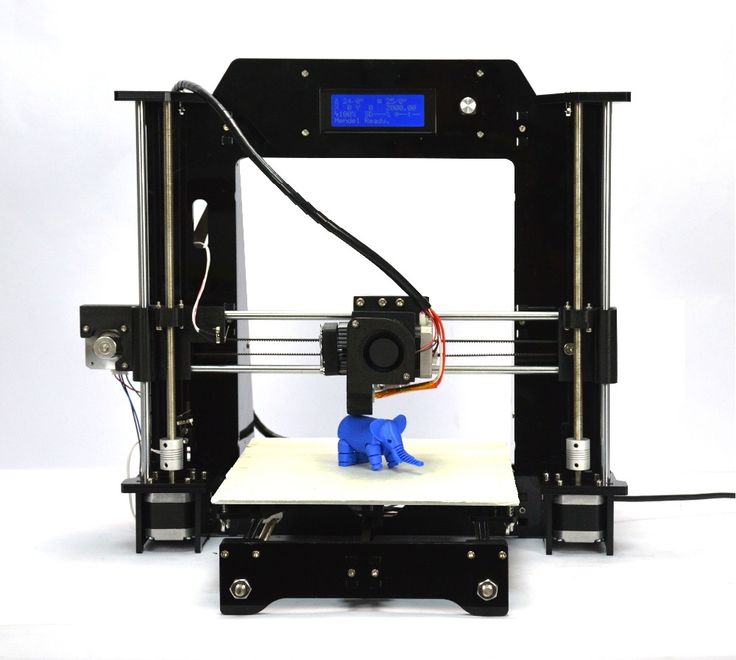

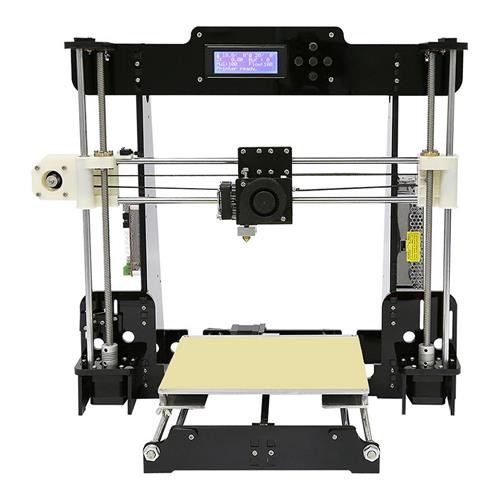

Printer Overview Bigrep One

This model is characterized by the presence of two extruders, the presence of heated working platform and impressive dimensions. Bigrep One (shown in the photo) is designed for professionals who specialize in the production of quality 3D products.

Another advantage of the Bigrep One 2 3d printer with two extruders is its cost. Against the background of prices for similar devices, it is more acceptable, therefore it is in great demand.

Bigrep One printer

The following advantages of the Bigrep One printer are noted:

- Working volume 1.

3 m3.

3 m3. - Low cost 3D models.

- No tooling required for finished products.

- Universal application.

- Economical and productive.

- Presence of a 3D printing camera.

- Extensive range of possible filaments (ABS and PLA filaments, nylon, flexible elastomers).

The Bigrep One is a new generation of printers that expands the scope of 3D technology.

Conclusion

The extruder is a significant part of a 3D printer. It affects the quality of finished items, the printing procedure itself. Malfunctions in it entail the loss of expensive plastic threads. Shortcomings in the calculation of the diameter of the bars, lack of calibration, incorrect arrangement of the axes of the body lead to negative production results. An example in the photo.

Therefore, before assembling the printer, review the possible designs of this device, determine the exact parameters of the rod and the number of extruders (one, two or more).