3D printing income

5 Ways How to Make Money with 3D Printing – A Neat Guide – 3D Printerly

You can make money 3D printing but it’s important to know that it’s not the easiest thing to do. It won’t simply be buying a 3D printer, looking at designs and selling them.

Making money will take a bit more than that, so I’ve decided to explore how people are making money 3D printing and how you can do it for yourself.

3D printing is a dynamic industry that can quickly be adapted to fit trends in other industries. It’s main advantage is the ability to be able to create a product within a short time frame.

Some people are able to scan an item, edit the model in a CAD software and set it in their slicer ready to print in a matter of 30 minutes. There are real potentials in being able to master these abilities and if done correctly, can make you a good amount of money.

If you are able to beat other suppliers to the market, you are in a position to gain significant benefits.

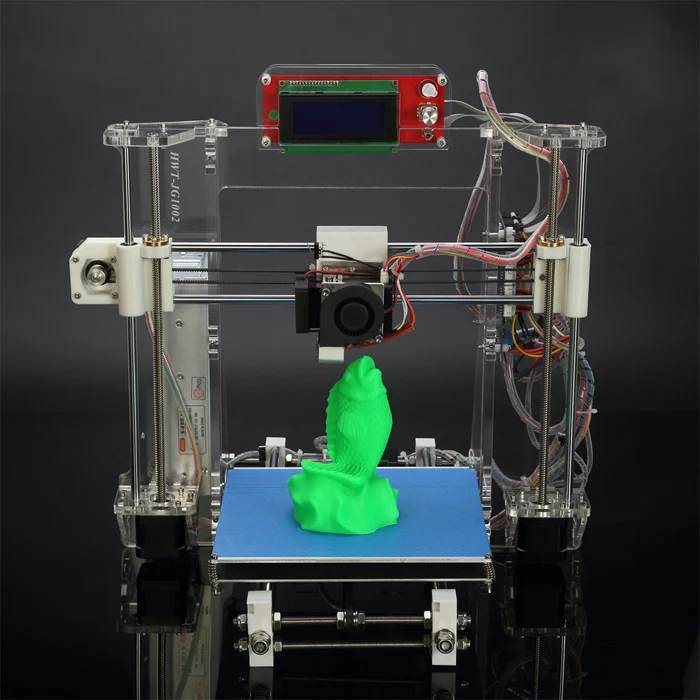

You don’t need an expensive printer to be able to create high quality items, as cheaper printers are matching the quality of premium ones.

How Much Money Can You Make With a 3D Printer?

With a standard 3D printer and a decent level of experience, you can expect to make between $4 an hour up to around $20 an hour depending on what your niche is and how well your operations are optimised.

It’s a good idea to set realistic expectations with how much money you can make.

The higher end of how much money you can make per hour will usually be for custom prototyping work. For the standard pieces such as toys, gadgets, models and so on, you’ll usually make around $3-$5 an hour so it’s not a good idea to quit your job for it just yet.

You can definitely get to a point where you have mastered your operations from designing, printing, deliveries and so on, to a point where you can expand to multiple printers and serve several regular clients.

This is where you can start to really see your profits per hour increase past that $20 mark.

Keep in mind, it’s difficult to find a market where your 3D printer will be running 24 hours at a time. The general timing of how long your printer will run, depending on what niche your in is around 3-5 hours.

The general timing of how long your printer will run, depending on what niche your in is around 3-5 hours.

Now lets jump into the main 5 ways to make money from 3D printing.

1. Printing Models on Demand

I find that the best way to make money from 3D printing on demand is to narrow down your niche. 3D printing can join up with almost every niche out there, so it’s your job to find something that solves a problem, has a demand, and makes it worth your while.

Compared to traditional manufacturing methods, 3D printing loses when it comes to manufacturing speed, unit cost, consistency in tolerances and trustworthiness because the average person doesn’t know much about the field.

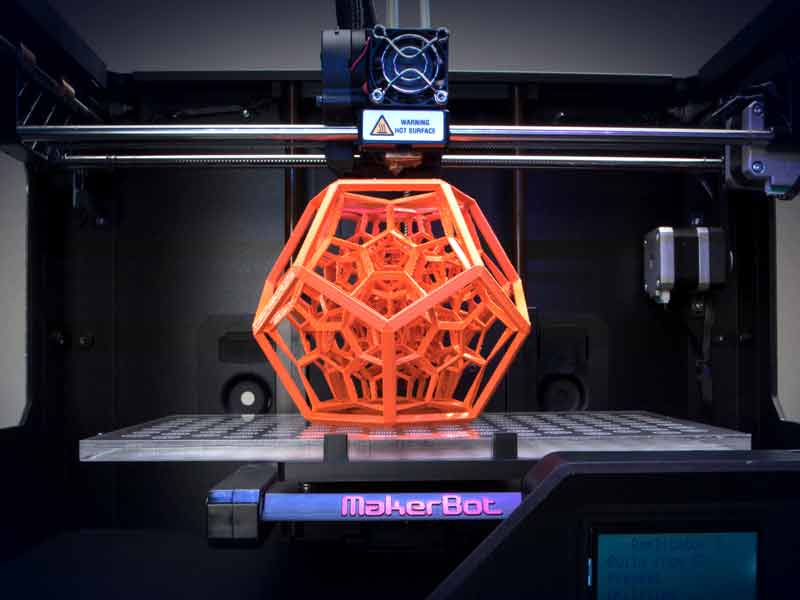

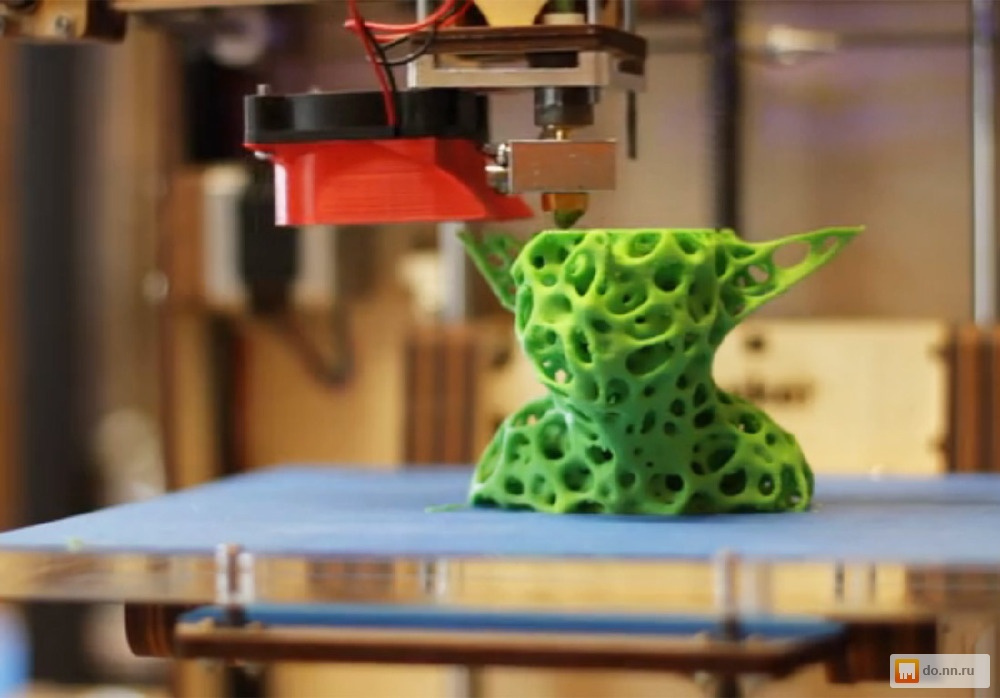

Where 3D printing does gain the advantage is design customisation, speed of a specific model rather than of each part, the range of materials used and colours available, and the fact that it’s a massively growing market.

It has massive advantages of being able to create items starting from an idea to a product in record timing.

An example of an idea that someone has used to make money 3D printing is creating and selling TARDIS (Time And Relative Dimensions In Space) rings. This is a niche product which uses a ‘Doctor Who’ concept and fan base to create a specific, low volume, highly demanded item to make money.

This is one of the main methods that people become successful making money.

There is no real benefit to 3D printing common items like holders or containers that don’t have any special function, because they are widely supplied and available at very cheap prices, unless they are custom. Basically something that people find valuable and unique to them.

How to Find People to Print For

The usual way people find others to print something in exchange for money is through online channels. This can range from Facebook groups, to forums, to online retailers and so on.

There are many designated websites which are designed exactly for this purpose and are good ways to build a reputation and rating around your work.

It’s important to focus on not just the quality of your product, but your overall customer service and experience from start to finish.

It will take some time to build up a reputation where people will start asking you to get specific work done, but once you get to that stage, you have a great potential to have a consistent income through 3D printing.

Other than online, you can always ask the people around you such as friends, family and work colleagues. This one can be a little more difficult because you’ll have to explain what services you can offer and they will have to come back to you for a project that you could help them with.

One example is where an individual had some curtains which he wanted the ability to pull back when opened. There are many options for this but he wanted a specific design which he couldn’t find.

The person who had the 3D printer in this situation had a conversation with the guy and worked on a solution for custom pullbacks for his curtain.

A few drafts were designed, which were to his liking and he printed them out for a nice amount of money, for his time, effort and the product itself.

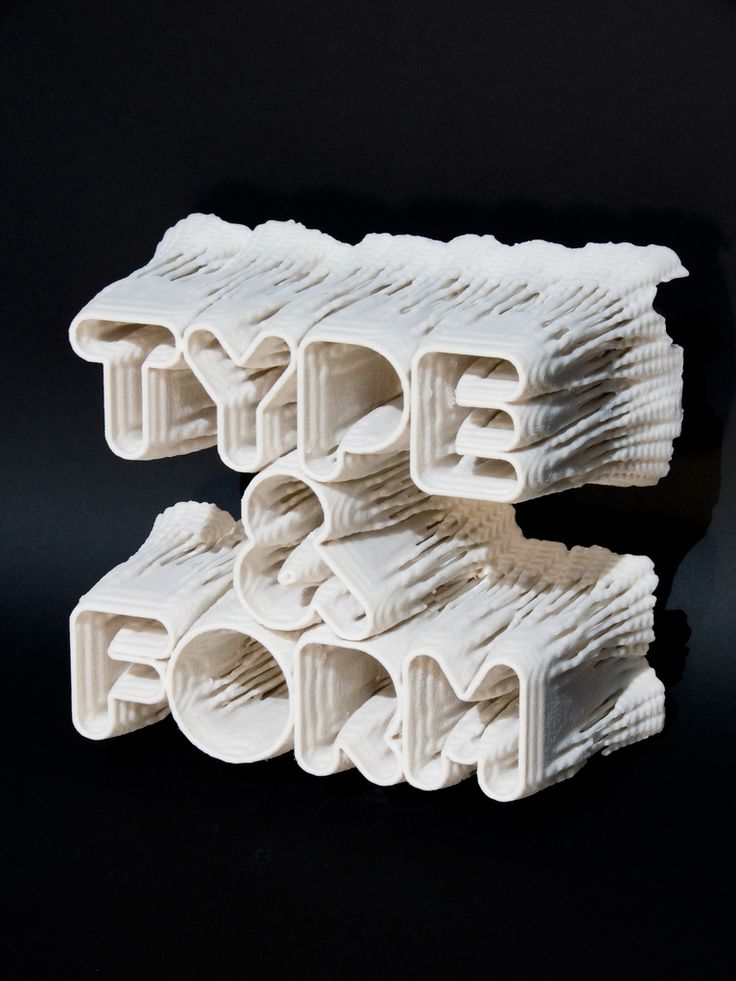

2. Sell 3D Print Designs (CAD)

This is more focused on the design process rather than the actual 3D printing but it’s still within the confines of the 3D printing process.

The simple concept here is that people have pictures of something they want to 3D print but need the actual design made through a CAD program.

You simply design the product, then sell that design to the person for an agreed upon price and profit.

The good thing about this is you have the ability to sell this more than once since it’s your own property that you created. You also don’t have the downsides of prints failing because it’s all set in one digital program which can easily be edited.

At first, you may be relatively slow at getting designs completed so it’s good to start with the basics if you don’t already have experience.

There are many beginner-friendly CAD software and video guides to get you at a good level to make marketable designs.

Websites such as Thingiverse exist as an archive of 3D designs that can be downloaded and printed.

There are archives of 3D designs which you can display for people to look at, and if they like the design, can purchase for a fee usually in the range of $1 to $30 and some in the hundreds for large, complex designs.

It’s a good idea to use some of the designs you see on these websites as inspiration and a guide on what is popular and what people are actually buying.

Creating a design just because you like it isn’t always the best idea. A bit of research should be involved before you find an actual product to create, but all the practice you can get will help your journey.

You have many channels and tutorials on YouTube and other places which you can slowly gain an understanding of how to design things.

This will take time to learn so you’ll need patience, but once you get started, you’ll only get better and more refined in your abilities, leading to you having the potential to make more money.

There are 3D printed design marketplaces all over the web where you can find people who want designs done, or sell your own designs that you think people will want to buy.

The best thing about this method is it’s ability to earn you passive income. Once your model is completed and set up on a website for people to view, the main work is done. People are free to purchase your model without you having to talk to clients, discuss licensing and all the other stuff.

Also the costs of doing this are very low, as most design software is free to use so it only costs you in time spent designing.

Best Places to Sell 3D Models Online

- Cults3D

- Pinshape

- Threeding

- Embodi3D

- TurboSquid (Professional)

- CGTrader

- Shapeways

- I.Materialise

- Daz 3D

- 3DExchange

3. Sell Your Own Niche 3D Print Creations (E-Commerce) Manufacture Your Own Product

Put simply, this is building yourself a brand through 3D printed products. Rather than print to other people’s specifications, you create your own products and market it out to your potential target audience.

Rather than print to other people’s specifications, you create your own products and market it out to your potential target audience.

There is a wide variety of products and niches you can get into. The best method is to stick to one niche that you can see growing in popularity and get better at your craft. This will allow you to build up a following and a community behind your products. Once your products are up to scratch, you find a few customers through marketing, you will be on a good path to success.

You don’t just have one way of making this work, you can take many angles.

Think of ideas that will make you unique, to the point that it’s worth that extra value and has demand.

What Can I Make and Sell With a 3D Printer?

- Customized shoes (flip flops)

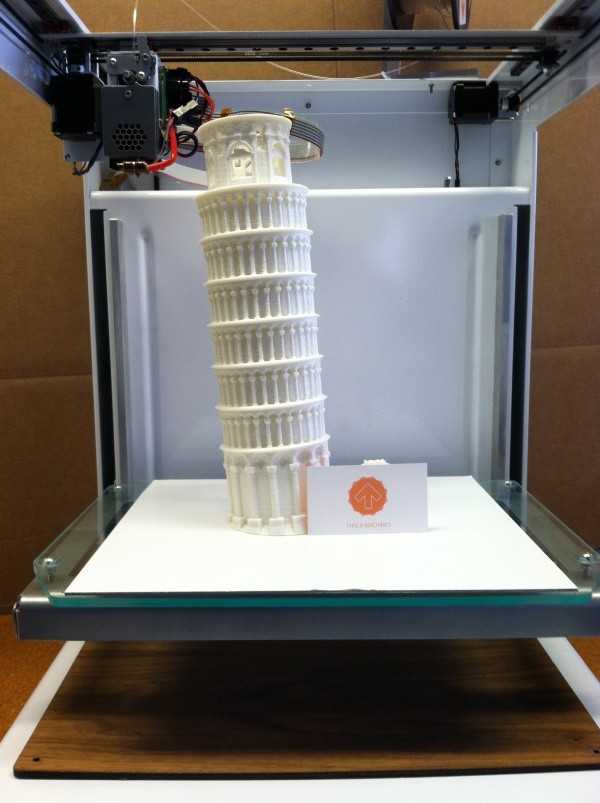

- Architecture models – produce buildings of sizes and styles

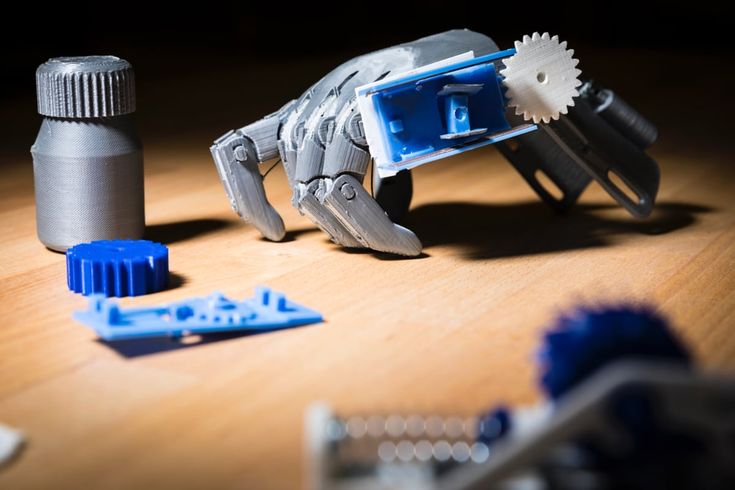

- Robotic kits

- Vases, aesthetic items

- Drone parts

- Custom buds for high end earphones

- Making fetuses come to life with the 3D files and printing them, unique product.

- Ornaments and jewelry

- Movie, theater props (keep legal in mind) – workshops or camps to be a vendor for props for them

- Nerf guns – massive gains in popularity (child toys up to office action)

- Miniatures/Terrain

- Logo stamp maker for companies or office logo decorations

- Custom cookie cutters

- Lithophane photos and cubes

- Vehicle accessories

- Personalized gifts

- Plane and train models

Where Can I Sell My 3D Printed Items?

Not everyone has the experience building a website for eCommerce so simply using one of the popular websites out there to sell your products is a good idea.

The main places where people sell their 3D printed items are Amazon, eBay, Etsy and in person. All3DP have a great article about selling your 3D printed items.

People already have trust in these big names so it reduces how much work you need to do to get products sold. You should know the demographic of your target audience and match it to specific places to sell your product.

If you get to a point where your printed product is very popular, you can demo it to distributors and retailers.

The thing to keep in mind here though, is that they will only place an order when they are aware it can be mass produced.

Tips for Creating Your Own Products

Establish a website niche where you create items that people will like, based on research, market knowledge, and history of what has worked before.

Try hopping on a trend.

An example of a trend is just like when fidget spinners were popular. The trick is to make something that’s custom or not the usual product being sold at very competitive prices.

For fidget spinners, a great idea would be using glow in the dark filament so you have unique fidget spinners that can make it worth while printing and selling to people.

Another thing you can print is drone parts, which have a big crossover with 3D printing. People realise that rather than paying a massive premium for a drone part, they can get it cheaper by getting someone to 3D print it for them.

They are usually very uniquely shaped parts which are difficult to get singularly, so there is a lot of potential here.

On top of this, you still have the ability to customize it to increase it’s value.

The bottom line is you need to find a product that people actually want, which isn’t too hard to find with a little searching around, then make it your own.

Find a high demand product that’s already out there and make it different.

Another angle you can take is the inventor side of things and catching on to the next hot product.

If you can make an adapter for some new electronic product that everyone is starting to get, you can get ahead of the curve and create that file then print it.

With a bit of marketing or sharing with people, you should be able to find your audience and start making sales.

You Will Have To Keep Motivated To Thrive

It will take time to start making money. You have to spend time in designing your product, printing it, post-processing, taking pictures of it, then appealing to the buyer enough for them to purchase.

This is more a personal journey where you’ll be making your own product in house. The way to come up with a product is by looking at where there are gaps in the market, meaning where is there a high amount of demand and a low supply.

If you hit a few of these gaps and market properly to your target audience, you can really make a good amount of money.

Once you are more established, you can reinvest your profits into more 3D printers and better material so you can boost your profits even more. When you hit a good rhythm of orders, prints and deliveries, you can really expand and look to move things into a certified business.

It’s important to not put all of your eggs into one basket when it comes to ideas. Many ideas won’t work as well as you think, so you need to be willing to fail, and try again, but not at a high cost.

Instead of jumping all in, simply try the idea on the surface with a few resources and see how far you can get it.

You should be able to see a decent potential to make money before using too many resources in an idea that may not work.

You won’t be successful with every idea, but the more experience you have, the more likely you will be to hit that golden idea.

It does take some trial and error, and you will have issues along the way, but keep focused and you’ll reap the benefits.

4. Teaching 3D Printing to Others (Education)

There are many different ways to make this method work. It can range from creating a YouTube channel to creating an E-learning course, to creating tools that educate people on learning how to 3D print.

If you have the skills and knowledge you can teach classes in your community. Some people have used their college to teach 3D printing classes to members of the local community, with a 90 minute class costing each person $15. They would have a maximum of 8 students per class and would make a neat $120 for 90 minutes of work.

This is especially great since once you have your lesson plan up to scratch, you can easily re-use it for classes in the future. You also have the option of creating a few levels of classes, beginner, intermediate and advanced if you have the resources.

If you’re delivering good quality information, you can start to market your classes and soon enough, it should spread through word of mouth or a Facebook group that’s gaining traction.

A better idea is to make this a passive type of income, where you don’t have to directly trade your time for money.

A good way to do this is to record 3D printer informational videos for an online class marketplace, good ones being Udemy, ShareTribe and Skillshare.

You create a plan and a journey for users to take where you can teach them something you think is valuable, whether it be the basics or something more advanced.

If you find an informational gap where people have trouble doing one of the main tasks for 3D printing such as 3D design or getting high quality prints you can walk people through this.

It will take some time to get the initial content created for this, but once it’s done you have a product you can sell forever and make passive regular income.

5.

3D Printer Consultant to Design Companies (Prototyping etc.)

3D Printer Consultant to Design Companies (Prototyping etc.)Put simply, this is finding people that need someone to create prototypes for them and their business and is usually at a fairly tight deadline. This isn’t a regular job but more of a side hustle to the main income.

It usually involves someone sending you a sketch, a picture, or giving you details of an idea that they have and want you to create the product for them.

It takes quite a bit of skill and experience to be able to do this as you’ll need to design the CAD product, set it in your slicer, print it at a decent quality then post-processing to make it look presentable.

If you don’t have the experience, it can definitely be gained with some practice of your own.

Try designing things that you see around you and see if you can replicate it to a good standard. You can then build up a portfolio of your designs and prints to show your skills, making it more likely that people will be interested in having you create for them.

Here you can offer your 3D printing services to specific companies that would find it valuable in their business.

Depending on what type of business it is, you can maybe offer to do all of their prototyping so they don’t have to worry about tracking down other services to get their work done.

As long as you can provide a high quality service with great prints, then you should be able to continue your work consulting for different companies.

Build up a solid portfolio and you can get up to a standard where other people will market for you, simply through word of mouth and creating a name for yourself in a specific industry.

Tips for Making Money 3D Printing

Focus on Relationships Rather Than Just the Business.

Let people know what you have going on, and whether you can be of service to them or someone else they know. People are more likely to react positively to you when you come on the angle of being helpful, rather than chasing down business opportunities.

It will make a difference to your reputation and how well you will succeed in the future. One of these previous relationships can really help to develop yourself and your business in the future, so keep this in mind.

Don’t Lie Dormant with Your Creative Abilities.

You should be thinking up new ideas daily and implementing them to see if you can truly create helpful items that give people value. This can range from items that you personally think will work, to ideas that you might think of through normal conversations with people throughout your day.

For example, if one of your friends complains about how he always drops an item of his, you can design a stand or an anti-movement product that solves this issue. It’s these small things that put you in that entrepreneurial mindset that keeps you ahead of the curve.

Focus on What Resources You Have

You shouldn’t worry about the capabilities that you don’t have, focus on what you can bring to the table with your resources and build around that.

Just because you see other 3D printer creators with expensive machines and different ways of printing doesn’t mean that’s what you need to have.

I’d be more inclined to see it as a goal to where you can be in the future, rather than having to be there now to compete. There is enough space for plenty of people to enter this market, as long as the demand is there so stay in your lane and do it well.

Once you get to the stage that you have a few orders coming in, you want to make sure you keep on top of it by having products on hand. You don’t want to get caught off-guard where you’re distracted by life activities and you are behind on delivery times.

It’s a good idea keeping at least a few products on hand and ready to ship if you have it listed.

Focus on Operations Rather Than Profit

You want to understand the ins and outs of your 3D printer and your operations. You want to know how often your prints fail, how to store filament, what materials work the best and at what temperatures.

The environment of your printing area, is it benefiting prints or making them worse. Working on each aspect of your 3D printing process will only make you more efficient and give you the ability to create higher quality products.

Once you are at a good level in your printing journey, you know you have the needed consistency to begin making profits.

It’s important to know that the items you are looking to print should be things that you have designed and not just taken from another designer.

This can land you in legal troubles depending on what licensing the designer has given out. Sometimes they allow for commercial use.

You can always consult with the designer and work out a deal, but it’s usually in your best interest to design your own work.

Turn Your Passion into a Habit

If you aren’t already into 3D printing and don’t admire the process of it, it’s unlikely that you’ll have the passion to be able to carry things on to the point where you are making money.

Being able to turn your passion of 3D printing into a habit and activity you enjoy will keep you going, past the mistakes.

It’s the dedication and passion that will keep you going, even when things seem bleak and like there is little chance of being successful. It’s the people who can get past these stages that will come out on top.

11 Ways to Make Money 3D Printing in 2022 – Clever Creations

Our site is reader-supported. When you buy via the affiliate links on this site, we will receive a commission at no cost to you. All opinions remain our own. Learn more

Ever wondered about turning your 3D printing hobby into a profitable business venture? We’re here to tell you that there are several ways to make money with 3D printing even as a beginner.

In this guide, we’ll examine the best ways how to make money with a 3D printer, which 3D printing services are most in-demand right now, and what you need to know about running a 3D printing business before you get started.

Best ways to make money with a 3D Printer in 2022

1. Design and sell 3D prints

If you want to design, print, and sell your own 3D printed items, there are a few different ways to do it. For example, you’ll need to decide if you want to stick with a set of specific designs or if you want to work on commission.

Personalized or custom items mean you have to make a new 3D model for every order. Offering only pre-designed items allows you to make items ahead of time and ship them out as needed.

There is a market for nearly every type of 3D print you can create, so choose the types of items you enjoy making. After you have decided that, figure out where the customers for those items like to shop so that you can offer your products there.

What can I make and sell with a 3D printer?

In terms of the things to 3D print and sell, your products can be anything from planters to phone cases to home décor items. Ideally, the products you sell line up with your own passions while still being in high demand from your target audience.

Some of the most popular things to make and sell are:

- (D&D) miniatures. 3D printed miniatures are very popular at the moment. Unlike store-bought miniatures, these can be fully customized to your customers’ liking. You can also paint the miniatures before shipping them out, but many customers don’t mind painting minis for themselves, or they leave them unpainted altogether. When doing this, we recommend you use a resin 3D printer for miniatures.

- Jewelry. 3D printed jewelry can be sold at a high mark-up and for more money than other items, but there is a lot of competition in this niche on sites like Etsy. For 3D printing jewelry, a resin 3D printer (or even a high resolution 4K+ resin 3D printer) is ideal.

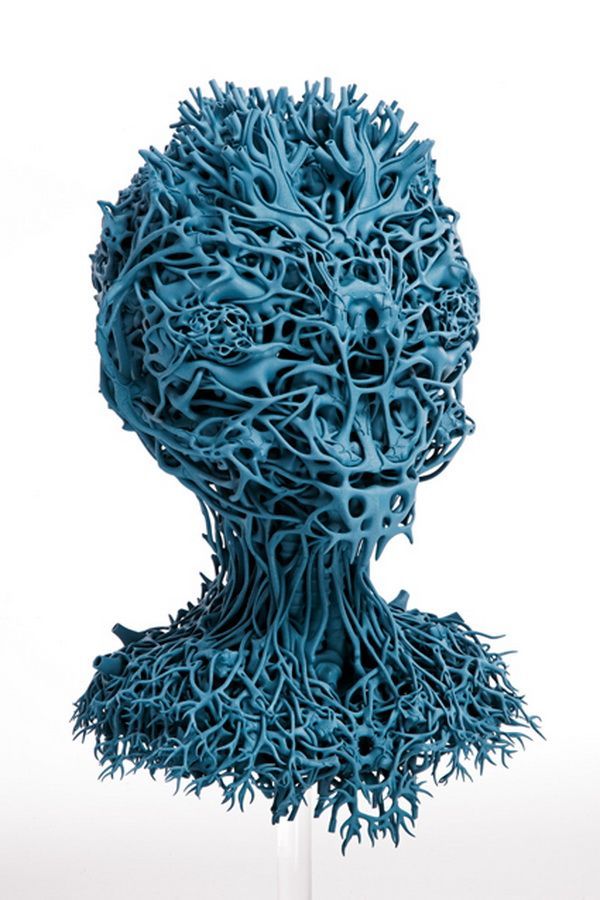

Image: xfanta via MyMiniFactory

There is a lot of demand for 3D printed jewelry- Cosplay items. Creating and selling cosplay items can be a profitable endeavor. 3D printing helmets, 3D printing armor, or all kinds of other props are valid ways of making money with a 3D printer.

- Planters. Attractive self-watering planters aren’t always easy to find in retail stores. That is one of the reasons why they are popular things to 3D print.

- Toys. Toys are easy to make on FDM printers and barely need any post-processing.

These are just a few examples, but the list is practically endless. Think key chains, customized shoes, personalized crafts, or other one-off items. You can sell designs of others (if the copyright license allows), or create your own designs and your own products.

Where to sell 3D prints?

There are many platforms you can use to sell your 3D printed items and make money with a 3D printer, both online and offline. Most sellers choose a few different platforms for selling to reach a variety of markets and audiences, as well as to bring in more money.

While it’s important to not limit yourself to one sales channel, you should also be careful not to spread yourself too thin.

Offline

You have several choices for selling your 3D printed items in person. Events like craft fairs, trade shows, garage sales, and festivals can all give you the opportunity to show off your 3D prints and gain customers. If you have access to electricity at the event, setting up your printer in your booth can be an easy way to attract people to your table.

Events like craft fairs, trade shows, garage sales, and festivals can all give you the opportunity to show off your 3D prints and gain customers. If you have access to electricity at the event, setting up your printer in your booth can be an easy way to attract people to your table.

You can also put your 3D printed items into consignment shops or set up a display in local businesses. This gives your 3D printing business local exposure without committing to a storefront.

Online

To reach a large and varied global market with your 3D printed items, you should sell online. You should ideally have your own online store at some point. In the meantime, there are several eCommerce platforms that can help you get started:

- Etsy

- eBay

- Amazon

- Fiverr

2. Start a local 3D printing business

Starting a local 3D printing business is one of the quickest ways to get customers and generate sales. You can manufacture custom parts, tools, and necessities for other local businesses. This is especially true if you live around several factories or plants. You can reach out to your local bakery about cookie cutters, or make trophies or awards for events.

This is especially true if you live around several factories or plants. You can reach out to your local bakery about cookie cutters, or make trophies or awards for events.

Recommended:

The 5 Best 3D Printers for Making Cookie Cutters

The list goes on. You will be surprised by how much you can contribute to your local community once you just start asking. If you are wondering how to make money with a 3D printer, this option offers you lots of potential.

While opening your own business sounds complicated, it’s a rather straightforward process. You should contact your local authorities or city council to double-check the ordinances. You may find that you won’t need any permits or zoning updates to run it from your house. That depends on where you live and how your local laws are set up.

What do you need to start a 3D printing business?

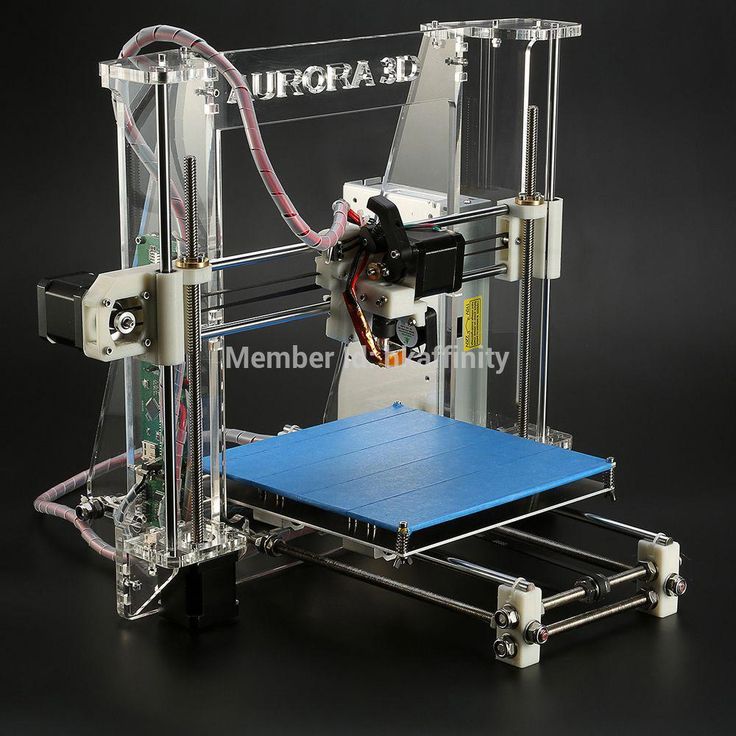

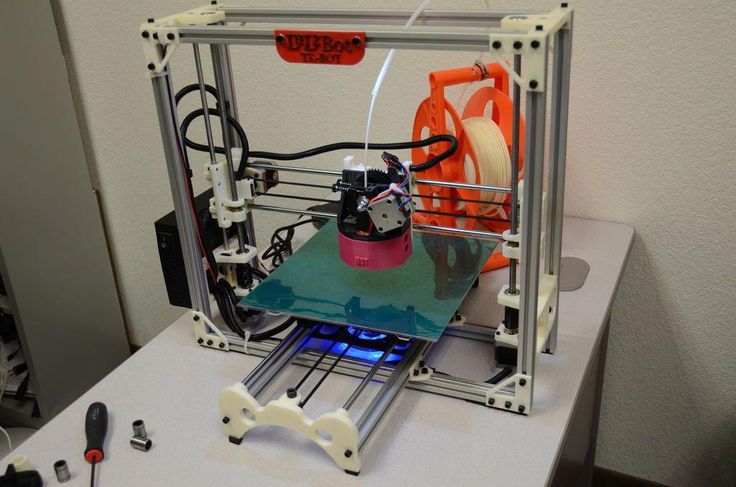

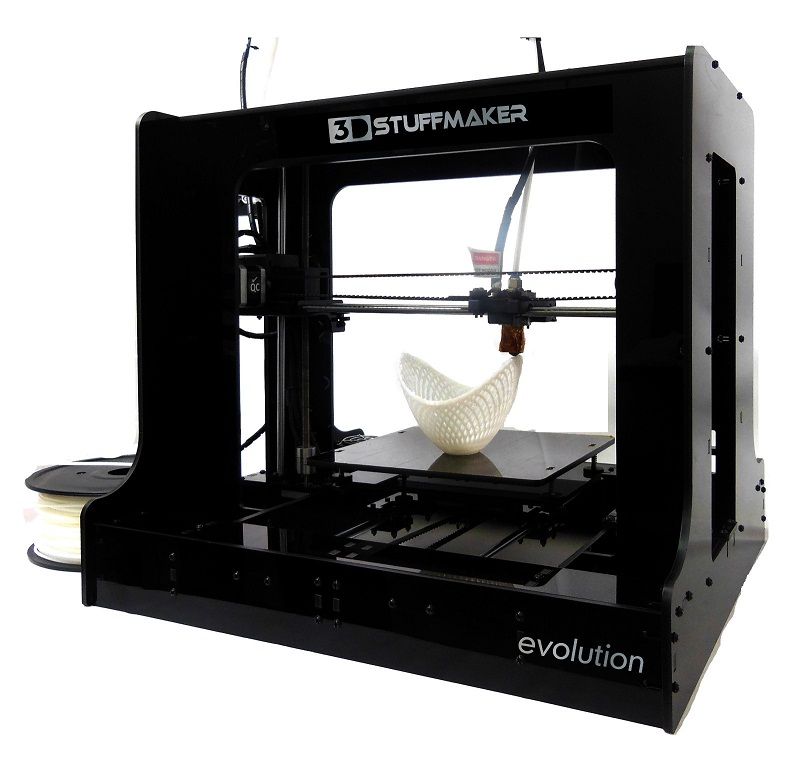

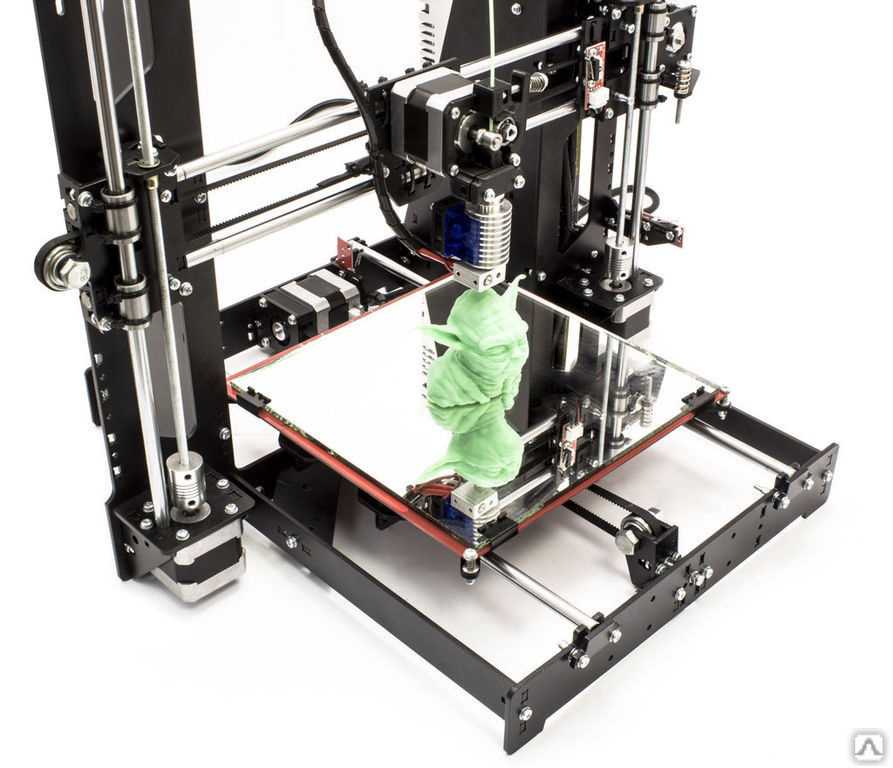

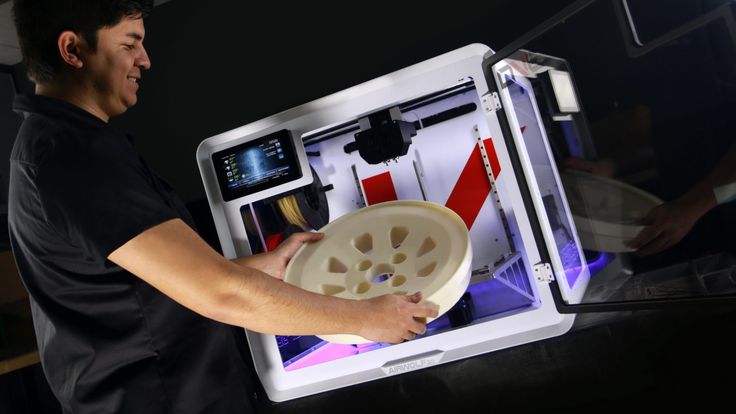

3D printer

It goes without saying that if you want to start your own 3D printing business, you need a 3D printer. In this case, it should be a reliable 3D printer that you are already familiar with and have a stock of spare parts for.

In this case, it should be a reliable 3D printer that you are already familiar with and have a stock of spare parts for.

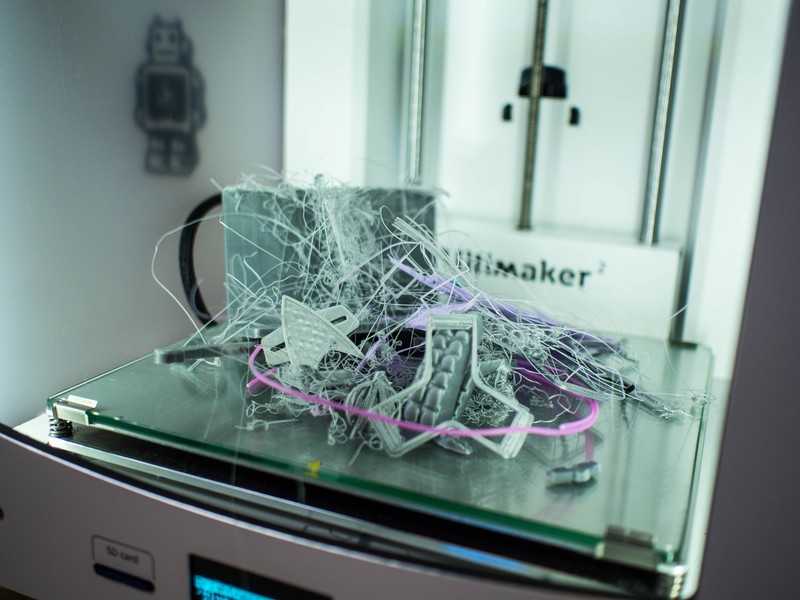

You don’t want to start taking requests from customers and have to cancel their orders a week later. Things like this happen when you’re waiting on a replacement part or because something basic went wrong and you don’t know how to fix it. Be prepared with basic troubleshooting knowledge of your machine and backup components before you start.

You don’t need a top-of-the-line printer to offer your 3D printing services. However, you should aim to have a properly working and time-efficient one. Every minute that you spend re-leveling your build plate because your printer falls out of alignment is a minute that you have to account for through higher printing fees or lost maintenance costs.

Going with a 3D printer under $1000, like the reliable Prusa i3 MK3S, is a good way to save yourself time.

On the other hand, if you decide to go with a budget 3D printer, like the Ender 3 V2, you can make use of the many Ender 3 upgrades that turn it into a more time-efficient machine. One example of this is the BLtouch leveling sensor, which removes the need for manually leveling the build plate.

One example of this is the BLtouch leveling sensor, which removes the need for manually leveling the build plate.

Business website

You need a website to inform your potential customers about your 3D printing business and to capture leads. You should have this set up by a professional web designer if possible. This will be your main touchpoint for customers to interact with your brand. As such, you want it to look good and reputable to bring in those early clients.

You should also contract a graphic designer. They will make your logo, company palette, and other branding materials. Your web designer will need them to keep your website design on-brand.

Some web designers can do both (and vice versa). Just be sure that they have a strong foundation in branding if you choose to use one person for everything.

You can go as basic or complex as you would like with your final website design. It depends on what types of services you plan to offer and how much of the pre-purchase and buying phase you want to happen online.

Premium add-ons like an online store, quote generator, appointment scheduling app, and other tools add value to your end customer. They will cost you more money in upfront design charges since they may require adding a web developer to your project as well.

3. Design and build prototypes

Using your 3D printer to design and build your own (or someone else’s) product prototypes is a great way to monetize your machine. For other people’s prototypes, you can charge them for designing and building them. For your own prototype, you can send it into production and have your own product line thanks to your 3D printer.

4. Rent out your 3D printer

Many people love the idea of 3D printing but don’t have the time, space, or money to buy their own printer. Or sometimes they just need the occasional niche print and don’t think it’s worth it to buy their own machine.

That’s where you and your 3D printer rental services come in! You can charge customers a fee for a printing service where you print their models on your printer. Doing this during your 3D printer’s usual downtime lets you make money 3D printing in moments where you don’t need to use the machine for yourself.

Doing this during your 3D printer’s usual downtime lets you make money 3D printing in moments where you don’t need to use the machine for yourself.

This seems like one of the easier options on this list to try. However, print on demand does have some complicated elements to consider. You have to be properly compensated for all time and materials involved.

That includes the cost of your time spent leveling and maintaining the printer (as well as the cost of wear and tear on your machine from additional usage). Keeping in mind the 3D printer’s electricity usage and other 3D printer costs is important too.

For your 3D printing service, you also need to consider if you will honor requests for certain colors of filament, what types of filament potential customers can order, and if you will also include services for post-processing for a fee.

Image: Mtar Einbern via MyMiniFactory

Post-processing can also include painting5. Sell digital 3D models

If you’re a skilled modeler, sculptor, or drafter, you can forgo the necessity for physical products and sell your 3D model files online. This option is more of a passive income business model that can work beside or be independent of a physical product line.

This option is more of a passive income business model that can work beside or be independent of a physical product line.

Selling digital files like 3D models lets you make money on one product several times without having to make the item more than once. It becomes even more efficient if the digital files you sell are existing assets from another project that weren’t used anymore and would otherwise have no value.

While you won’t be making money in large sums per sale for 3D models, they can still earn a higher lifetime revenue than a print and sell option of the same model. Digital files simply sell with more regularity than physical objects and have no production cost associated with each extra copy sold.

Where to sell 3D model files

The first place you should consider selling your 3D models is on your own website. If you already have one of those for your local 3D printing business, excellent. If not, start looking for a web designer ASAP.

Third-party platforms charge fees to use their services. Having your own eCommerce site ensures that you get a larger percentage of profit from each sale and increase the money you make 3D printing. The downside to this is that you have to build your audience and website traffic yourself. Most third-party eCommerce platforms bring their audience to you.

Having your own eCommerce site ensures that you get a larger percentage of profit from each sale and increase the money you make 3D printing. The downside to this is that you have to build your audience and website traffic yourself. Most third-party eCommerce platforms bring their audience to you.

Some of the best places to sell your 3D models are:

- Etsy

- MyMiniFactory

- CGTrader

- Cults3D

Image: DarkFigurines via MyMiniFactory

3D models are loaded into a slicer program to generate instructions for the 3D printer6. Start a YouTube channel

You can use your 3D printing knowledge to set up your own YouTube channel. Build your audience by posting cool and helpful 3D printing YouTube videos to your channel.

It is possible for you to earn revenue from ads, donations, affiliate programs, and brand sponsorships. If you get a large enough following, companies might also send you free products to review.

You most likely won’t make a full-time living from YouTube (especially at first). However, if you grow it as one of several monetization strategies, it can be helpful. It’s a great way to push potential customers to your website or online shop. It can also help develop your name as a knowledgeable person in the industry.

7. Start a blog

You can use a blog to write 3D printer-related content and share your knowledge with others. Like YouTube, you can monetize the content on your blog through ads, affiliate programs, and paid sponsorships. Having a blog gives you more control over the creative process. You also make a lot more from ads on your website than YouTube pre-roll ads.

You can also use your blog as a way to bring readers to your website where you sell your prints, 3D model files, and other products. Your blog content acts as a verification that you know what you’re talking about on the subject of 3D printing.

It shows that you can be looked at as a trusted source. This is called brand authority, and it makes it much easier to convert an audience member into a customer when they already trust what you’re saying.

This is called brand authority, and it makes it much easier to convert an audience member into a customer when they already trust what you’re saying.

8. Repair things in your household

A 3D printer is a great tool to have around when something in your house breaks. With basic computer-aided design (CAD) knowledge and (free) 3D modeling software, you can design replacement parts for broken appliances, furniture, and so on.

Normally when something breaks, you have to order a new part from the manufacturer. You potentially have to replace the entire thing if the manufacturer can’t help you. By doing basic repairs, 3D printing your own replacement parts, and keeping your old belongings in functional shape, a 3D printer helps you save money over time.

9. Repair 3D printers for others

There is no denying that 3D printers can be a bit temperamental sometimes. They have a large number of parts to make them operate the way they should. If someone is new to 3D printing or never learned what most of those components are meant to do, they will struggle to fix it when something goes wrong.

Put your technical 3D printer knowledge to good use and offer to fix broken printers for a fee. Most people will be happy to spend money to let someone more capable deal with it. You get paid work from a person who was likely never going to use your 3D printing services or buy your products.

10. Flip broken 3D printers

If a 3D printer is broken badly enough that the owner doesn’t want to fix it, you can still salvage it by fixing it up. After you have repaired it, you can then resell it for a profit. You can also keep it for spare parts for another 3D printer and sell that one afterward.

11. Offer 3D printing courses

If you’ve been 3D printing for a while, you probably know quite a bit about the subject. Consider using that knowledge to create an online course or series of online courses that teach new 3D printing enthusiasts the basics.

It will be a big initial investment of your time to plan the course, film it, edit it, compile it, and market it. However, you can continue to sell the course for years to come while doing little to no maintenance work on it.

However, you can continue to sell the course for years to come while doing little to no maintenance work on it.

You can host the course through an online learning platform like:

- Skillshare

- Udemy

- Domestika

- Teachable

You can also host it through your website if you have one (and use your blog to help market it.)

Frequently asked questions

Can you make money with 3D printing?

Yes, there are many ways you can start making money with a 3D printer. Selling 3D prints (like phone cases) or offering 3D printing services are some of the most popular methods, but there are many more you can choose from.

Is it legal to sell 3D prints?

As long as you follow the copyright license on any 3D model you use, you are legally allowed to sell 3D prints of the model. For any models you design yourself, you are the license holder, so you can use the models freely.

If any of the models depict copyrighted or trademarked content, that overrules the designer’s license. For example, if someone designed a 3D model of a well-known cartoon character, they still cannot sell prints of it because the character is not their intellectual property.

Image: edoyola via MyMiniFactory

Always check whether the objects you 3D print are copyrighted or notIs 3D printing a good side hustle?

Yes, 3D printing is a great side hustle if you already know a lot about the subject. If you are brand new to 3D printing and are trying to jump into starting a business with it from day one, it might be a frustrating experience.

Taking some time to learn your 3D printer, understand the settings, and be able to troubleshoot the most common issues are going to be very helpful in the long run. It will also ensure that you don’t guarantee your 3D printing service to someone before you are able to render it.

3D printing is also not much different than beginning any other side business. Starting a 3D print store or print-on-demand service requires niche market research, marketing, social media skills, and some understanding of business management. Those are all skills anyone can and should learn to increase how much money they make with their side business.

Starting a 3D print store or print-on-demand service requires niche market research, marketing, social media skills, and some understanding of business management. Those are all skills anyone can and should learn to increase how much money they make with their side business.

How long does it take to start making money with a 3D printer?

That depends on a few different factors. If you are trying a few of our suggestions on how to make money with a 3D printer, your chances of quickly connecting with new customers are higher than if you only stick to one method or sales platform.

How quickly people buy from or contract you also depends on having things like:

- A professional-looking website

- Clean and effective copy on your website and product listings

- High-quality pictures of your products

- Well-defined policies for shipping, returns, customization, etc.

- Good pricing (that doesn’t mean fighting to be the lowest)

- Accurate market research and a good strategy for your business

Not all of these factors have to be a slam-dunk every time. Online shops with terrible pictures make sales every day, while some with professional product photography do not. People stumble onto products by accident every day, even if their marketing strategy is abysmal. These are just some things that may color your timeline for profitability.

Online shops with terrible pictures make sales every day, while some with professional product photography do not. People stumble onto products by accident every day, even if their marketing strategy is abysmal. These are just some things that may color your timeline for profitability.

How long does it take to learn 3D printing?

If you have a plug-and-play 3D printer that is designed to set up and start 3D printing almost instantly (note that these are usually the more expensive machines on the market), you can start getting serviceable prints within a day.

Cheaper and more hands-on 3D printer models have a steeper learning curve and take more time to become adept with. Many of the tasks that plug-and-play printers do automatically are manual on budget printers. It will likely take you a few days to start producing quality parts. It will take a few months to have a firm understanding of all the 3D printer’s elements.

As far as being able to make your own 3D models, those skills are considerably more time-consuming to learn. You can make very basic models within a day or so by following tutorials. However, it can take months or even years to become a skilled designer who creates original and aesthetically pleasing 3D models.

You can make very basic models within a day or so by following tutorials. However, it can take months or even years to become a skilled designer who creates original and aesthetically pleasing 3D models.

Do you need a license to 3D print?

Anyone with access to a 3D printer can print 3D models for non-commercial uses. However, the rules are slightly different when you intend to sell the finished product. Any models used need to have a commercial use license.

That means only choosing ready-made models online that have the proper license. You can also contact the designer to inquire about obtaining commercial rights. Many designers are willing to charge you a licensing fee in those situations, but some will still refuse. It’s important to be respectful either way.

What software do I need?

To start 3D printing, you need a 3D modeling program and a slicer program. The 3D modeling software lets you create 3D models to print, while your slicer turns your models into lines of code that your 3D printer can read.

For help picking out a 3D modeling program, we have an in-depth comparison between the best free modeling software options.

Is 3D printing expensive?

The expenses of 3D printing depend on several factors. These include what type of material you use, what type of 3D printer you have, if you keep your printer well-maintained, and how you store your materials.

Paying attention during 3D model slicing and set up can cut down costly or wasteful mistakes. Keeping your 3D printer clean and lubricated extends the life of its parts. Storing your filaments or 3D printer resins away from moisture and light will extend its working life and help you save money.

Conclusion

There are several options to make money 3D printing, which means there is something suitable for everyone. Do you make money with a 3D printer? What do you find most challenging about running a 3D printing business or side hustle? Let us know in the comments!

Scroll to Top

Let's talk about the beginning of earnings? Business model with 3D printer

Business

Subscribe to the author

Subscribe

Don't want

9

Good day to all.

Quite often I see questions about "starting a 3D printing business". Therefore, I would like to share my thoughts on this issue. The article will not have a ready-made business plan, but there will be ground for reflection on it (I hope). In order not to be unfounded, below are the Yandex search statistics. These statistics are only from Yandex, so you can safely multiply by 2.

Actually what I'm talking about. Many people buy 3D printers in the hope of additional income from the provision of 3D printing services. Often, thoughts like: "I'll post an ad on Avito and orders will go through people's heads." Many of these businessmen simply remain alone with the printer or sell it afterwards. The competition in this area is already simply colossal and is only growing. Therefore, climbing into the service sector of this format without investing in advertising seems to me not the best idea. Moreover, almost two printer costs will have to be invested in advertising in this direction. Generally not an option. There is one way out for stuffing the client base - this is price dumping with its subsequent increase. But here, let everyone decide for himself whether he is ready, filling the base, at first to print "for 0" or even in the minus.

Generally not an option. There is one way out for stuffing the client base - this is price dumping with its subsequent increase. But here, let everyone decide for himself whether he is ready, filling the base, at first to print "for 0" or even in the minus.

The second option is already less common, but still relevant in this matter. 3d modeling + 3d printing. This format of the service is in great demand and you can already earn at least on modeling, and at the same time spend only time. Everyone should determine the price of their time for themselves, since we are all different. But even here there is more than enough competition.

Well, now actually what I want to talk about. At the time of purchase of the 3D printer, I already knew what I was going to do with it. For me, it was initially a tool to a greater extent, and not earnings. Noah understood that I could print, which would bring me some kind of income. Of course, I will not say what my projects are, but I want to share the logic of thought, or, if you like, the business model.

1st version

The beauty of a 3D printer is that there is no need to create a batch on it, to make molds or molds for casting parts. You can get by with a sample. And I think that a person who buys a 3D printer for business needs to know what he will do on it. At least roughly calculate the cost of production and the real demand for the product on the market. As an example, I can cite the sale of handles for a metal detector on Avito. I didn’t go deep into this issue, but I suspect that this thing is useful. In general, one of the options is to take as a basis a part that is in demand (perhaps some kind of automotive) on the market, learn how to print it at least well, and already post an ad on Avito or on specialized forums. This behavior can kill two birds with one stone. There is no need for advertising, since this product is already needed by someone, and Avito itself will give your ad on the Internet, including if you format it correctly (I advise you to watch a video on this topic), and there will also be no need to fight with competition, since with the right choice of product it will either not be, or will be in a minimal amount. The same wordstat from Yandex can help you with the choice. And the number of such goods is limited only by your busyness.

The same wordstat from Yandex can help you with the choice. And the number of such goods is limited only by your busyness.

2nd option.

Here you have to turn on your imagination. We must set ourselves the task of inventing a new product and promoting it. In this matter, one must understand that there is no competition at all, but there is also no advertising. Will have to look for it. Without investment, or almost without, it's real. I'll give you an example. Suppose you want to sell mini boxes with video game symbols, why not?

Let's say something like this. This idea has not been brought to mind at all and most likely it will not come to life in my hands, so you can take this idea, bring it to mind, learn how to print, make a collapsible box (that's exactly what I wanted to do), and start promoting. As marketers say, "sow demand." As an option, send it as a gift to some streamer (s), having previously made a website with possible models. Making a website as a whole is not so long and difficult. You just have to really put in the time for it. And with due diligence, you will bring a completely new product to the market, and you will receive money for it.

You just have to really put in the time for it. And with due diligence, you will bring a completely new product to the market, and you will receive money for it.

Personally, my projects worked in both cases, and I don't take printing to order (although I was just asked to do it a couple of times), but I don't rely on the orders themselves and purposefully don't look for them.

In general, this is very crumpled, and I would like to describe more, but people do not like to read long articles here)

Thank you for your attention, I will not mind discussing the article in the comments)

Even more interesting articles

avtor

Loading

06/04/2017

22395

240

Subscribe to the author

Subscribe

Don't want

Good evening, dear residents of the portal. I present to you the finished finished project of the bench model t...

I present to you the finished finished project of the bench model t...

Read more

daymon

Loading

02/24/2015

57572

165

Follow author

Subscribe

Don't want

The article is inspired by this - http://3dtoday.ru/blogs/maxbortnik/how-do-you-make-3d-printingWith the speaker...

Read more

xolodny

Loading

05/31/2022

6084

74

Subscribe to the author

Subscribe

Don't want

My hobby is mainly "engineering" - gears, brackets, housings, product prototypes....

Read more

Is it possible to make money from 3D printing? Taking off the rose-colored glasses in an interview with Oscar van Deventer / Habr

Many people are interested in the question: how to make money on 3D printing? If there are 3D printers, then there must be some way to make money from it by providing "services to the public" and not just printing prototypes.

One of the ideas: a service where anyone can upload their model, pay for printing and receive the item. Also on the service there should be a choice of models with prices. One example is shapeways.com.

This is an interview with Oskar van Deventer, engineer and puzzle designer. He made the largest Rubik's Cube: 17×17×17, which is a Guinness World Record. He is also the author of hundreds of puzzles, some of which are mass-produced, and many are presented in the form of models and can be printed on demand. It was Oscar that seemed to me the most interesting author, because:

- he loves the Rubik's cube,

- he invents something new,

- he makes money from 3D printing.

About the Rubik's Cube and other puzzles

When did you get your first Rubik's Cube and how quickly did you master it?

− I bought my first Rubik's Cube in 1980 (Oscar was born in 1965). It took me 2 weeks to solve the puzzle. Now I could solve this problem within two minutes.

Now I could solve this problem within two minutes.

Your 17x17x17 cube is in the Guinness Book of Records. Did you assemble it yourself?

− Yes, I collected it.

Direct link to the video

Do you have a favorite puzzle that you came up with?

− Always next.

Can you share some secrets about how ideas are born? This is the hardest part: coming up with something new.

- There are no secrets, I just spend a lot of time and think. For me, the task is to make a new mechanism that can do something that was not there before. See, for example, the new puzzle "Irreversible Cube".

How long does it take from an idea to a model to a 3D printed sample?

− Shapeways manufactures within 10 working days.

What programs do you use for modeling?

− Various CAD programs.

How do you test your inventions? Let your friends or family play? Maybe organize focus groups?

- First I make a prototype. Then I show it on YouTube. Be sure to submit it to the puzzle forum, which is actually a social network of collectors of complex puzzles, designers and constructors. And I show the puzzle at meetings of representatives of this community.

Then I show it on YouTube. Be sure to submit it to the puzzle forum, which is actually a social network of collectors of complex puzzles, designers and constructors. And I show the puzzle at meetings of representatives of this community.

Direct link to the video

Inventor's experience

Is working on puzzles the main job? Or do you work somewhere else?

− My main job is as a senior researcher in the field of online media.

I know about you as an inventor. How do you position yourself? Inventor? Entrepreneur?

“My entrepreneur card says “mechanical puzzle designer.” It's a hobby. Yes, I'm doing business to keep exploring new possibilities, to make puzzles to please the fans.

What is your education?

− I have a PhD in optical networks.

There are puzzles that are sold on the market and printed in industrial quantities. What are these puzzles?

- Yes, there are such puzzles. You can see here.

You can see here.

3D printing as a business

Are you satisfied with the sales of 3D models?

“Until now, selling models on Shapeways has beaten back the cost of prototypes. It's not bad anymore.

So sales aren't that great?

− Earnings provide a good additional income. But not enough to quit your regular job. Until I'm ready for it.

What sells best?

- I don't track accurately. The Hanayama metal series has been successfully sold for quite some time. Anti-Virus is doing well in Europe. And Gear Cubes are getting more and more popular.

What methods do you use to advertise? I know that you record videos for Youtube. What else?

− YouTube and puzzle fan forum. YouTube gives more viewers, but most of my buyers are on the forum.

Buyers can contact you directly. Were there any funny or weird questions from buyers?

− Sometimes, my customers don't understand the concept of 3D printing. The most interesting request was for a "Gift Cube".

The most interesting request was for a "Gift Cube".

Note: Another person suggested this idea to Oscar. An ordinary Rubik's cube, if solved, becomes a box. The top side of the red color forms a heart and is removed like a lid.

Collaboration with shapeways.com

The emergence of 3D printers is creating new markets. Shapeways.com is an example of this new way of selling. How difficult was it to conclude an agreement with them?

− At the beginning of 2008, Virsavia Grossmann told me about Shapeways. I opened my store and uploaded the models. This is a very simple and convenient service.

Have you seen their 3D printers? How do you control print quality?

− Shapeways has excellent quality control. They monitor customer complaints and feedback, and continuously improve production and delivery. If occasionally problems happen, if something goes wrong (for example, a part is missing or incorrectly printed), then everything will be corrected for you immediately.

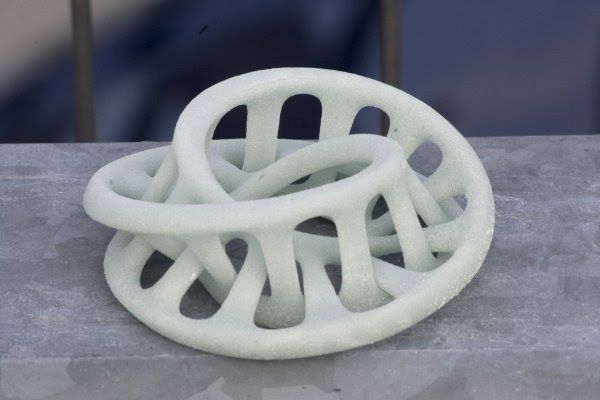

Do you choose the materials and printers that will print your puzzles? Or is it the Shapeways employees?

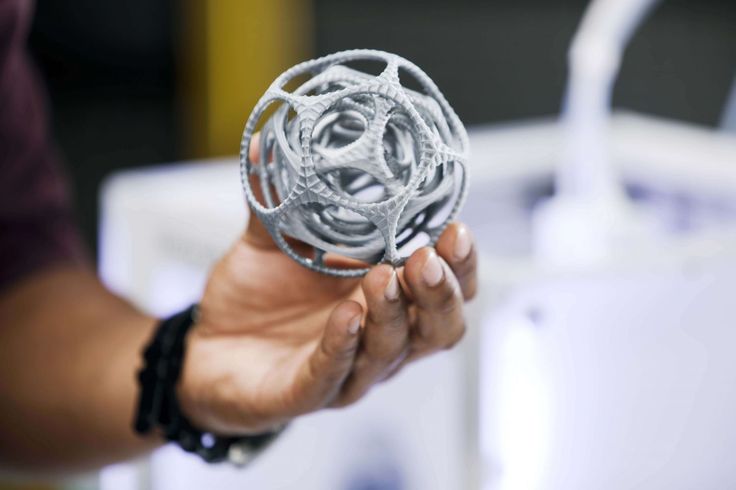

- I choose from what Shapeways offers. As a rule, I use the technology of selective laser sintering of nylon powder. Sometimes I use metal or something else.

3D printers

Do you have a 3D printer?

− No. I usually use Shaweways. I have a few friends with home 3D printers that I ask for help from time to time.

Thinking about getting your own printer?

- I'm thinking about buying Makerbot. But what stops me is the poor print quality compared to Shapeways printers and the lack of support.

Now many geeks dream of buying a 3D printer for fun. It's not necessary, but it's very desirable. Do you think 3D printers will become as commonplace as conventional printers in the future?

− No. Most homes don't have sewing machines. Most homes don't have photo printers. Why? Because it is much easier and cheaper to buy clothes and order photo printing in the laboratory.

Why? Because it is much easier and cheaper to buy clothes and order photo printing in the laboratory.

Which 3D printers do you like? What struck?

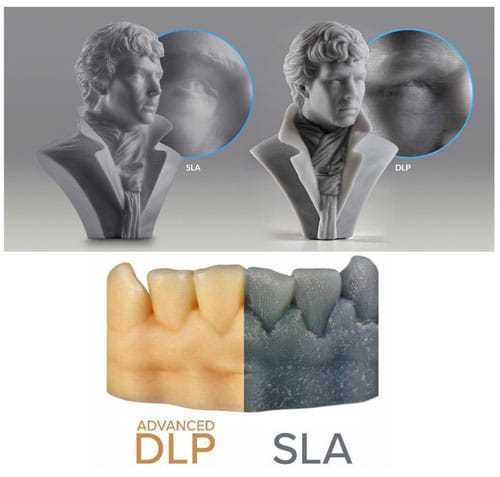

− Shapeways has the best SLS printer available today: high quality at low prices.

What do you miss about modern 3D printers? What features would you like to add?

− Every 3D printing technology is a compromise between performance, power, precision and cost. I would like a 3D printer that is able to do mass production at low prices, even for a limited edition. The Dutch company TNO is currently working in this direction.

Direct link to the video

Follow-up questions

I did not wait for additional questions from habrausers and asked them myself.

You often communicate directly with puzzle lovers. Do they have any common features?

I communicate a lot on YouTube and by email. I think it can be divided into two types:

− older generation who like traditional puzzles,

- young people who like my Rubik's Cube puzzles.

Many of them show talents in mathematics.

Now a lot of sales go through appstores for iPhones or Androids. No desire to make games for smartphones or tablets?

I have made several smartphone applications for fun, just to learn the technology. But I'm more interested in mechanical puzzles. Please note that now the development of an application, marketing costs about the same as the development of a mechanical puzzle.

Suppose I have an idea for a game. Where do I begin? Test her? Get a license? Do marketing?

You need to start by creating a working prototype. And test it on friends and family.

Links

Shapeways 3D Printing Service

Oscar's Store on Shapeways

Oscar van Deventer's official website

Oscar van Deventer's YouTube channel

Credit

5 I thank the habrausers who helped me correct the typos: encyclopedist, dimanonim, awolf, sergeyotro, dzhe.