At home metal 3d printer

Desktop Metal Studio 3D Printer

DESKTOP METAL

STUDIO SYSTEM 2™An End-to-End Solution to 3D Print Complex Metal Parts In-HouseIntroducing the new Desktop Metal Studio 2 for metal 3D printing. The first end-to-end affordable solution for 3D printing complex metal parts in-house in a variety of metal alloys including stainless steel, copper and tool steels.

View Video Brochure Request Demo Request A Quote

- Overview

- Key Features

- Advantages

- How it Works

- Materials

- Applications

- Request a Quote

Accessible Metal 3D Printing

The Studio System 2 from Desktop Metal was created to enable engineers and design teams to produce complex metal parts faster, more accurately, and in a safe operating environment without the need for special facilities or dedicated operators. Just print and sinter; A two-step process that doesn’t require solvent debinder or tooling as in the case of MIM (metal injection molding).

Explore the Desktop Metal Studio by watching the video

Sophisticated Software

Powerful software creates build and sinter plans for every project and material. Automative supports and control parameters ensure a seamless 3D printing experience.

Maximize Productivity

3D print up to 24 cubic inches per day in a wide variety of metal materials. Maximum resolution for the printer is 50 μm

Built to Perform

The motion control system was built with encoded balls screws instead of belts, and combined with auto leveling and a heated build area you get excellent geometric fidelity and build success rates.

Affordable

Safe & Simple

Separable Supports

Precise, High-Quality Parts

Make Metal Work Faster

No more waiting for machined or cast parts. Iterate faster by printing highly complex metal parts–without leaving the office.

Iterate faster by printing highly complex metal parts–without leaving the office.

REQUEST INFO

How It WorksA metal 3D printing process in 3 easy-to-manage steps

Step 1 – Prepare your files

Secure, web-based software fabricates from STL or CAD files, automatically generating supports and control parameters based on part geometry and material.

Step 2 – 3D Print

Layer by layer, a green part is shaped by extruding bound metal rods—metal powder held together by polymer binders—in a process called Bound Metal Deposition™.

Step 3 – Sinter

Once printed, parts are placed in the furnace. As the part is heated to temperatures near melting, the binder is removed and metal particles fuse together causing the part to densify up to 98%.

Introducing the new, swappable 250μm printhead that includes supporting software profiles. This enables new geometries and applications, resulting in achieving smaller parts and fine features with an improved surface.

There are camera’s everywhere, so why not put one in the in-chamber build plate? This camera captures live footage of the part as it prints, and is accessible in your web browser. Users now have complete insight of their part, and have the ability to monitor print success.

Stackable shelving is a new feature that increases part capacity of the debinder and furnace, giving greater throughput. Increased workload volume addresses bottlenecks typical at the debind sinter stages.

To achieve high quality parts, a new retort box design has been added to support thermal uniformity.

Eliminate some cost of consumables and achieve lower cost-per-part with external gas connections.

Studio Fleet is a custom and configurable metal 3D printing hardware solution for producing complex metal parts in low-mid volume.

MaterialsThe metallurgy behind the Studio System™ is built upon the material science and established powder supply chain of the metal injection molding (MIM) industry. When combined with Desktop Metal’s expansive in-house expertise in material processing, binder compounds, and metal 3D printing, the result is high-quality metal parts with affordable material costs.

When combined with Desktop Metal’s expansive in-house expertise in material processing, binder compounds, and metal 3D printing, the result is high-quality metal parts with affordable material costs.

17-4 Stainless Steel

(Studio System)

Material: 17-4 PH Stainless Steel

17-4 Stainless Steel is a precipitation hardening steel used in a wide range of industrial applications including those with mildly corrosive environments and high-strength requirements.

Specs- XY axis

- As sintered:

- Yield Strength: 695 MPa

- Ultimate Tensile Strength: 925 MPa

- Elongation at Break: 5.3%

- Hardness (HRC): 26

- Density (g/cc): 7.56

- As sintered:

- Manufacturing machinery

- Chemical processing

- Food processing

- Pump components

- Valving

- Fasteners

- Jigs and fixtures

- Bound Metal Deposition™

Learn more

316L Stainless Steel

(Studio System 2)

Material: 316L Stainless Steel

Characterized by its corrosion resistance and performance at both high and low temperatures, 316L stainless steel is a fully austenitic steel ideal for harsh environments.-kupit-v-soin-store.ru-2.png)

- Sintered:

- Ultimate Tensile Strength: 533 MPa

- Yield Strength: 169 MPa

- Elongation: 66%

- Hardness (HRB): 66

- Density (relative): 97%

- Chemical and petrochemical processing

- Food processing

- Laboratory equipment

- Medical devices

- Marine

- Jewelry

- Power generation

- Petroleum refining

- Water treatment

- Pulp and paper manufacturing

- Bound Metal Deposition™

Learn more

h23 (Studio System 2)

Material: h23 Tool Steel

h23 tool steel is hot work steel with great hot hardness, resistance to thermal fatigue cracking, and stability in heat treatment. This makes it an ideal metal for both hot and cold work tooling applications.

Specs- Yield Strength:

- Sintered: 650 MPa

- Heat-treated: 1250 MPa

- Wrought, heat-treated: 1525

- Ultimate Tensile Strength:

- Sintered: 1325 MPa

- Heat-treated: 1720 MPa

- Wrought, heat-treated: 1950 MPa

- Elongation at Break:

- Sintered: 2.

3%

3% - Heat-treated: 5.8%

- Wrought, heat-treated: 9%

- Sintered: 2.

- Hardness:

- Sintered: 35

- Heat-treated: 45

- Wrought, heat-treated: 54

- Density:

- Sintered: ≥93.5%

- Wrought, heat-treated: 100%

- Extrusion dies

- Injection molds

- Hot forging dies

- Die casting cores, inserts and cavities

- Bound Metal Deposition™

Learn more

4140 Chromoly Steel

Studio System 2

Material: 4140 Chromoly Steel

One of the most versatile steels, 4140 steel is characterized by its toughness, high fatigue strength, and abrasion and impact resistance.

Specs- Yield Strength:

- Heat Treated: 1060 MPa

- Wrought (heat-treated): 1500 MPa

- Ultimate Tensile Strength:

- Heat Treated: 1450 MPa

- Wrought (heat-treated): 1990 MPa

- Elongation at Break:

- HeatTreated: 5.

5%

5% - Wrought (heat-treated): 10%

- HeatTreated: 5.

- Hardness (HRC):

- Heat Treated: 40

- Wrought (heat-treated): 52

- Density:

- Heat Treated: 95%

- Wrought (heat-treated): 100%

All-purpose steel industrial applications such as:

- Jigs and fixtures

- Automotive

- Bolts/Nuts

- Gears

- Steel couplings

- Bound Metal Deposition™

Learn more

Copper (Studio System 2)

Material: Copper

Copper is characterized by its electrical and thermal conductivity and ductility, and it is ideal for electrical equipment, plumbing, and heat transfer applications.

Specs- Sintered:

- Ultimate Tensile Strength: 195 MPa

- Yield Strength: 45 MPa

- Elongation: 37%

- Density (g/cc): 8.75

- Consumer and industrial electronics

- Heat exchangers

- Antennas

- Inductors

- Bound Metal Deposition™

Learn more

Ti64 (Studio System 2)

Material: Titanium Alloy

Ti64 is an alloy of titanium, aluminum, and vanadium with a high strength-to-weight ratio and corrosion resistance.

- Ultimate Tensile Strength:

- Sintered: 845 MPa

- Yield Strength:

- Sintered: 730 MPa

- Elongation:

- Sintered: 17%

- Density (Relative): 97.5%

A wide variety of high-performance applications such as:

- Specialty automotive components, including connecting rods and gearboxes for racing

- Prototyping of medical devices, including tweezers, forceps, clamps, suture instruments and more

- Consumer goods, including sporting goods and jewelry

- Bound Metal Deposition™

Learn more

IN625 Nickel Alloy (DM Studio System)

Material: Nickel Alloy Inconel 625

Inconel 625 is a high nickel super alloy ideal for harsh environments in or out of water, characterized by its excellent strength, heat & corrosion resistance.

SpecsMechanical Properties [as sintered]:

- Ultimate tensile strength (Xy): 725 MPa

- Yield strength (Xy): 303 MPa

- Elongation at Break: 34%

- Hardness (HRB): 83.

5

5 - Young’s Modulus: 199 GPa

- Density: 8.2 g/cc

- Defense

- Aerospace

- Chemical

- Nuclear

- Bound Metal Deposition

Learn More

D2 Tool Steel (DM Studio System)

Material: Corrosion Resistance Tool Steel

D2 tool steel is a versatile material that provides tooling grade strength while also offering corrosion resistance, a key benefit for conformally cooled applications.

SpecsMechanical Properties (After Quench & Temper):

- Transverse Rupture Strength (GPa): 3.1, ASTM B528

- Hardness (HRC): 56.5, ASTM E18

- Density: 7.5 g/cm³

Application

- Cutting components

- Conformally cooled injection molding inserts and cavities

- Cold forming tooling components

Learn More

Superior Properties

Similar to metal injection molding (MIM), the Desktop Metal Studio System leverages bulk sintering to achieve densities greater than 98%. Part performance is similar to wrought alloys and it is possible to tune part density with closed-cell infill.

Part performance is similar to wrought alloys and it is possible to tune part density with closed-cell infill.

Materials Available

17-4 PH Stainless

316L Stainless

h23 Tool Steel

4140 Chrome Moly

Copper

Inconel 625 Superalloy

Kovar F-15

Additional Materials: By enabling the use of metal powders from the MIM industry, our systems have access to a wide range of existing materials—from steels and aluminum to superalloys and titanium.

Near-Net-Shape Parts

The Desktop Metal Studio system produces near-net-shape metal parts with the accuracy and layer resolution needed for functional prototyping and a variety of other applications. A seamless 3D printing experience, from printing through to sintering, is created with powerful software and automatic support generation.

Tight Tolerances

± .002 in/in (geometry dependent)

Remove Supports by Hand

The Desktop Metal Studio system does not require any wire EDM or machining to remove support structures. Proprietary separable supports make it possible to remove support by hand because it is no bonded to the part. As a result, highly complex parts and print-in-place assemblies can be easily printed and put to use.

Proprietary separable supports make it possible to remove support by hand because it is no bonded to the part. As a result, highly complex parts and print-in-place assemblies can be easily printed and put to use.

Bring Affordable Metal 3D Printing In-House

SEE COMPATIBLE ALLOYS

The HardwareThe Desktop Metal team designed the Studio 3D Printer to be the most accessible metal 3D printing solution to date.

With powerful web-based software, hand-removable support material, and fast material changes the

Studio System was designed from the ground up for seamless integration into your product development workflow.

The Studio Desktop Metal 3D printer extrudes bound metal rods similar to a plastic FDM system. Unlike laser-based DMLS 3D printers that selectively bond metal powders the Studio system does not require any special safety or facility requirements and creates the opportunity to produce closed-cell infill for lightweight structures as well as work with a wider range of metal alloys.

| Build Volume | 300 x 200 x 200 mm (12 x 8 x 8 in) |

| Build Chamber | Heated |

| Extruder Assembly | Dual quick-release print heads |

| Layer height (in green state) |

|

| Nozzle diameter (Build media) |

|

Download Spec Sheet

The Furnace

The Studio System 2 furnace is designed to be the easiest to use furnace ever made. It first heats parts to remove all binders, then increases the temperature to near-melting point to deliver industrial-strength sintering in an office-friendly package. Built-in temperature profiles tuned to every build and material ensure uniform heating and cooling without the residual stresses introduced in laser-based systems.

| Atmosphere | Partial-pressure sintering (vacuum-enabled) |

| Heating | SiC heating elements (4 sides) |

| Max Temperature | 1400 °C (2552 °F) |

| Workload surface area | 3,000 cm2 (465 in |

| Workload envelope | 300 x 200 x 170 mm (11.8 x 7.9 x 6.9 in) |

Download Spec Sheet

Software-Controlled Workflow

The Desktop Metal Studio system was designed as a complete workflow, with no third party equipment required. Every stage of the 3D printing process is fully automated and managed by software, making it simple to go from CAD to metal part.

Quick Material Changes

Compared to laser based systems, where material changes can pose safety risks and can take a week or more, the Studio 3D printer was designed to have swappable, safe-to-handle material catridges and quick release print heads.

Office-Friendly Sintering

A first of its kind, the sintering furnace has swappable aluminum gas canisters and optional hook ups for simple to manage gas. Built-in effluent filters, binder cold traps, safety fail safes, and detection systems make this system safe to use on the shop floor.

Expert Metallurgy Built-In

The Desktop Metal sintering oven combines unique materials profiles with part data to construct sintering plans for every part. With closed loop thermal control, real-time heating regulation throughout the sintering cycle is enabled ensuring every part is uniformly heated and cooled.

Low Volume Production with

Studio Fleet

LEARN MORE

Stainless steel, copper, and tool steels are some of the many critical allows the Studio System brings to 3D printing. Every alloy goes through meticulous qualification by world-leading materials scientists, and our core materials consistently meet or exceed industry standards.

17-4 PH Material datasheet

| 17-4 PH Stainless steel for strength and corrosion resistance | AISI 4140 low alloy, mid-carbon steel for high strength and toughness | h23 tool steel for hardness and abrasion resistance at elevated temperatures |

| 316L Stainless steel for corrosion resistance at high temps | Copper for thermal and electrical conductivity | Inconel 625 superalloy for strength and corrosion resistance at high temperatures |

Easy two-step process

Printed parts are placed directly in the furnace. No need for a solvent debind, just print and sinter.

Safety First

Odor-free and environmentally safe due to no solvent debind phase. No need for additional ventilators or respirators. Studio System 2 allows users to get the system up and running in no time.

High Quality Parts

Difficult geometry (which requires tall, thin, complex supports) is now possible thanks to new material formulations and print/sinter profiles.

Software Controlled Workflow

No metallurgist or machinist experience is required with an automated print to sinter workflow powered by Fabricate software

ApplicationsMachine Bracket

Jigs & Fixtures Titanium 64 (Ti64) Alloy

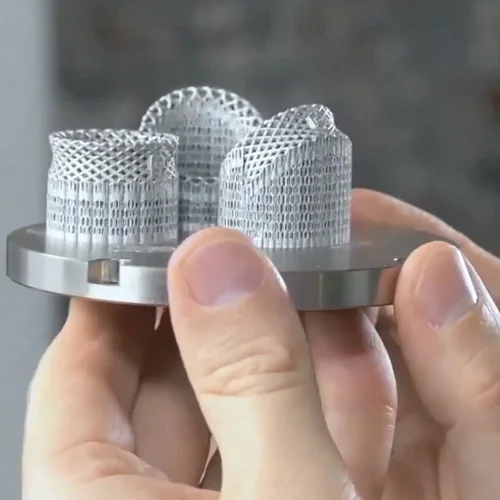

This machine bracket has been designed by using a gyroid lattice infill and titanium in place of 17-4PH stainless steel in order to reduce weight and material while maintaining the required functional strength and stiffness.

Full DescriptionIt would be impossible to produce this part’s geometry using conventional manufacturing processes due to its complexity. Moreover, 3D printing this new design on the Studio System 2 in Ti64 leads to reducing the part’s weight by 59 percent.

Ti64 for Studio System 2 produces lightweight 3D printed parts due to its high strength-to-weight ratio, thus becoming ideal for countless applications from key industries such as aerospace and defence, automotive, oil and gas, and medical.

- Estimated saving in part weight: 55-60%

- Bound Metal Deposition (BMD)™

Flower Nozzle

Industrial Equipment 316L Stainless Steel

This flower nozzle was 3D printed with Desktop Metal Studio System 2™ and it is used to atomize fluid in industrial equipment.

Full DescriptionDue to the complex geometry, this type of part would typically be cast followed by extensive secondary machining. With the Studio System 2™, the nozzle can be 3D printed without the lead times and setup costs of casting, enabling one-off and small-batch orders.

Specs- Size (mm): 123 x 123 x 45

- Cost to print ($): 184.00

Bound Metal Deposition™

Lathe Gear

Industrial Equipment 17-4 PH Stainless Steel

This part is a replacement gear for a vintage lathe. Metal 3D printing allows for the fabrication of legacy parts at a much lower cost.

In some cases, replacement parts are no longer available, either off the shelf or from the OEM (Original Equipment Manufacturer). Fabricating custom gears via hobbing and broaching is often expensive. With metal 3D printing, the manufacturing of such parts is possible at lower costs and reduced lead times.

Specs- Size (mm): 82 x 82 x 27

- Cost to print ($): 58.00

- Cost to machine ($): 260.67

- Savings vs. machining: 77.70%

Bound Metal Deposition™

APG Thread Checker Fixture

17-4 PH Stainless Steel (Studio System)

This fixture pushes a thread checker into a part on a manufacturing line. It stands for repeated use and must be easily produced to keep the manufacturing line up.

Full DescriptionThe fixture must be regularly replaced as it wears out. Printing the part with the Studio System eliminates CNC lead time and frees up the machine shop for more critical work.

- Size (mm): 47 x 28 x 15

- Cost to print: $14.00

- Bound Metal Deposition™

Tri Manifold

Manufacturing Alloy 625

This part converges three flow paths into one via internal channels. These channels would be impossible to machine and instead would need to be drilled as straight holes and plugged.

Full DescriptionPrinting on the Studio System allows these channels to be designed for their function rather than their manufacturing method. This part can be produced in just a few days with very little hands-on work.

Specs- Size (mm): 108 x 101 x 98

- Cost to print: ($) 906.00

- Cost to DMLS ($): 4069.28

- Savings vs. machining: 77.74%

Bound Metal Deposition™

Generative Piston Head

Generative Design, Prototyping 4140

Prototype piston head for a reciprocating engine, optimized with generative design. Typically CNC machined from aluminum alloy, pistons can be time-consuming and difficult to rapidly prototype and test.

Typically CNC machined from aluminum alloy, pistons can be time-consuming and difficult to rapidly prototype and test.

It often takes months or even years to move from design to production. With the Studio System, various piston designs can be easily prototyped and tested—speeding up product development timelines, reducing time to market, and introducing new opportunities for optimization, including generative design—all while avoiding CNC backlog and lead times.

Specs- Size (mm): 105 x 105 x 54

- Cost to print ($): 271.00

- Cost to machine ($): 568.13

- Savings vs. machining: 52.30%

Bound Metal Deposition™

YE6 Burner Tip

Tooling and Machinery 316L Stainless Steel

This burner tip was originally cast in the 1950s. With the Studio System, the company was able to recreate the part with properties similar to the original cast part, with no tooling cost or long lead times.

The quote for new tooling is usually in the tens of thousands of dollars. Thus, Studio System 2, a printer that was designed from the ground up for simple installation and use, allows for significant cost savings, especially when it comes to manufacturing obsolete parts at low costs and without compromising part quality.

Specs- Size (mm): 139 x 139 x 86

- Cost to print ($): 193.46

- Cost to machine: ($) 694.00

- Cost reduction: 72.00%

Bound Metal Deposition™

Helical Heat Exchanger

Manufacturing Copper

This heat exchanger enables a much higher heat transfer rate than a traditionally manufactured part. Used in chemical processing to cool a hot gas as it flows through a pipe.

Full DescriptionThe Studio System allows for the complex geometry of the heat exchanger to easily be printed as a single component. It would not be manufacturable as one component via CNC machining due to its thin external fins and a complex, internal helical cooling channel.

- Size (mm): 78 x 64 x 58

- Cost to print ($): 443.00

- Cost to machine ($): 2138.00

- Cost reduction: 79.28%

Bound Metal Deposition™

Zipper Mold

Material: h23 Tool Steel

This part is an injection mold insert for manufacturing zinc zippers.

Full DescriptionThe 3D printing of the mold inserts shortens production run lead time and allows rapid iteration and refinement of zipper designs. Using a high-resolution printhead allows for smaller parts with finer features, requiring less post-processing.

SpecsSize (mm): 46 x 27 x 18

Cost to print ($): 16.00

Bound Metal Deposition (BMD)™

😲 Metal 3D Printing at home!

😲 Did you know that you can print 100% metal parts on your home 3D filament printer?

A hint: it’s not like making a mold to cast molten metal – much easier!

We show you how to print metal with your FDM printer and introduce you to all the 3D metal printing technologies that exist.

📖 What do you want to read?

Filament for printing metal parts

You may have noticed that some manufacturers sell filament with metal dust. These are materials that imitate the metal finish on your printed pieces.

But we are not talking about this, we are talking about filament that is printed in 3D and used to make 100% metallic printed parts.

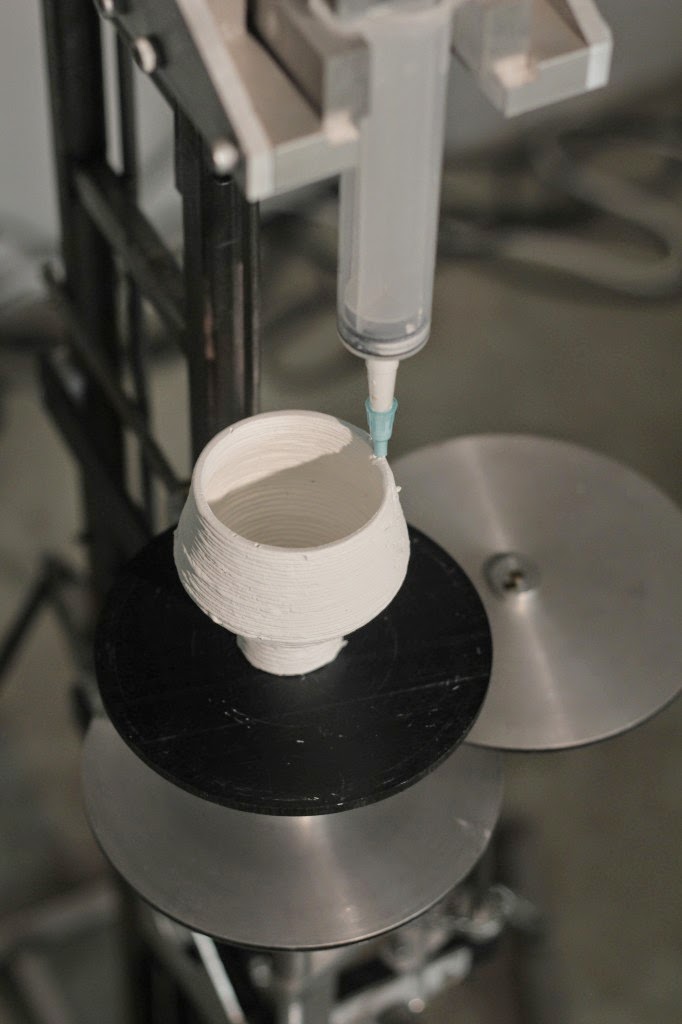

What material is it? It is the BASF Ultrafuse filament from the German company BASF. It is a filament with a large amount of metallic dust that is printed with a conventional FDM 3D printer. After printing, the pieces have to follow a chemical washing and sintering process in an oven so that the metal powder is fused into a single solid metal piece.

Here is a video where you can see what results can be achieved with this type of 3D metal printing.

What is the filament made of? The content of the BASF Ultrafuse 316L filament is, as its name suggests, 316L stainless steel, a very popular steel used in applications where corrosion resistance is a critical feature, as it is more expensive and stronger than the most common stainless steel (304).

The filament coil contains 90% metal by mass; the rest of the material is the thermoplastic which makes it remain in thread form and flow through the printer extruder.

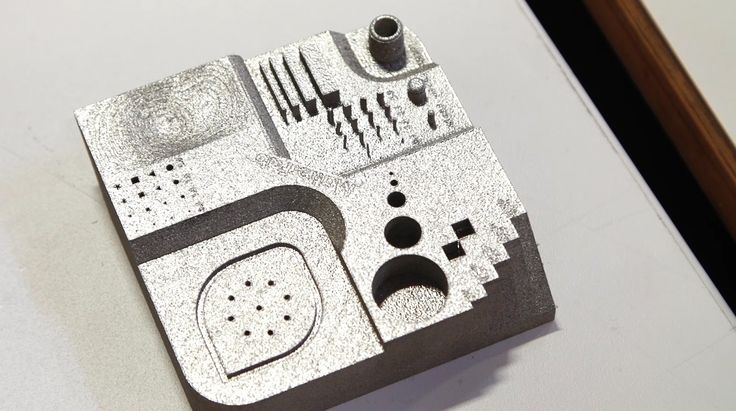

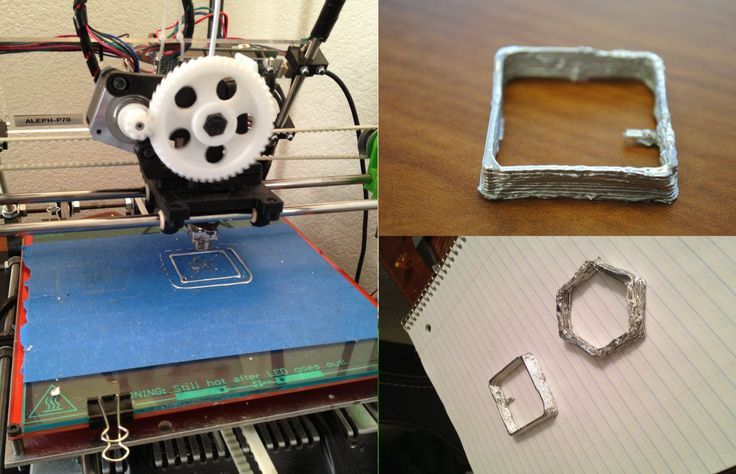

Examples of parts made with this filament

As you can see, the parts that go through the whole post-processing process have the characteristic lines of 3D layered printing and some filament sticking. The pieces can be sanded both in green (this is what the piece is called before it is washed and sintered) and in its final metallic form. They can also be polished, shot-blasted, etc.

The post-processing of the metal filament

As we said, with this filament we need a post-processing to obtain the final metal part.

The post-processing is usually done in an external company. Usually when you buy the coil it includes in its price the post-processing of the parts you manufacture with it. The technologies for post-processing of powder metal and plastic parts already exist for MIM (Metal Injection Molding) manufacturing, so it is possible to find suppliers who focus on these phases.

The process that the part goes through until it is a steel mass is as follows:

- Printing (green part). Printed on a conventional FFF printer with an abrasive resistant tip

- Washing/Debinding (brown part). The printed part is immersed in an atmosphere of vaporized nitric acid (HNO3) and heated to remove the plastic from the part so that only the metal dust remains.

The result is the phase known as the brown part.

The result is the phase known as the brown part. - Sintering. The brown part is placed in an oven where it is subjected to high temperatures without melting it so that the powder particles are completely fused and almost 100% desiccated. During this process the part shrinks, so it is necessary to print it with a margin that is established in the design process.

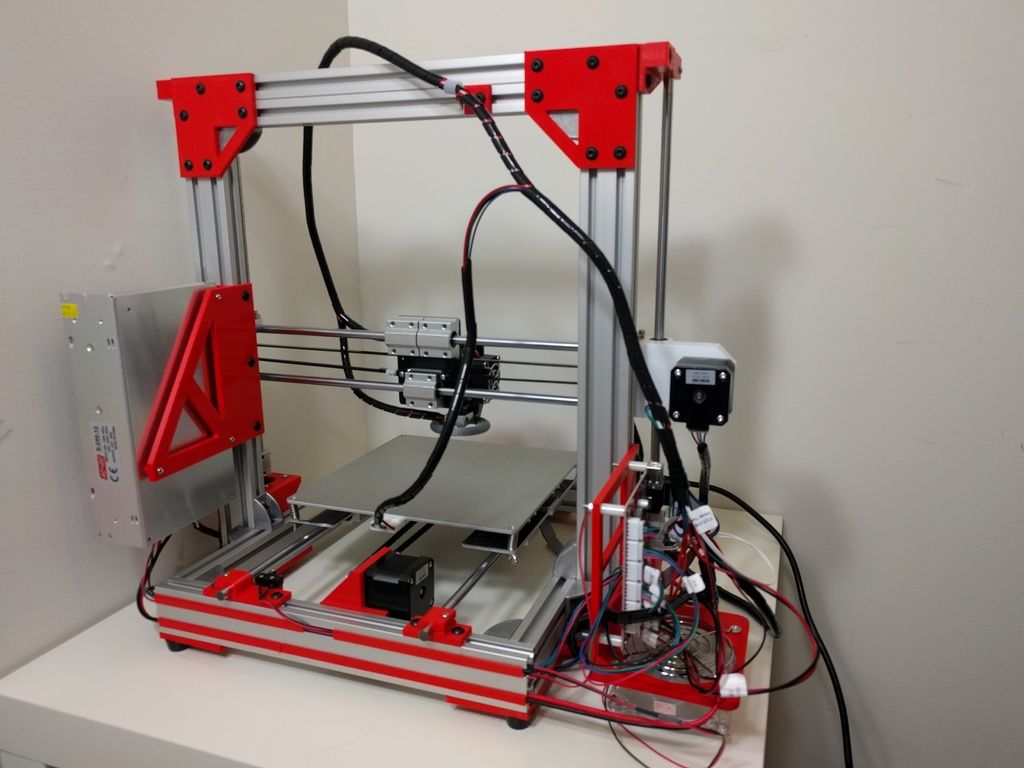

👉 How to print metal on your own printer

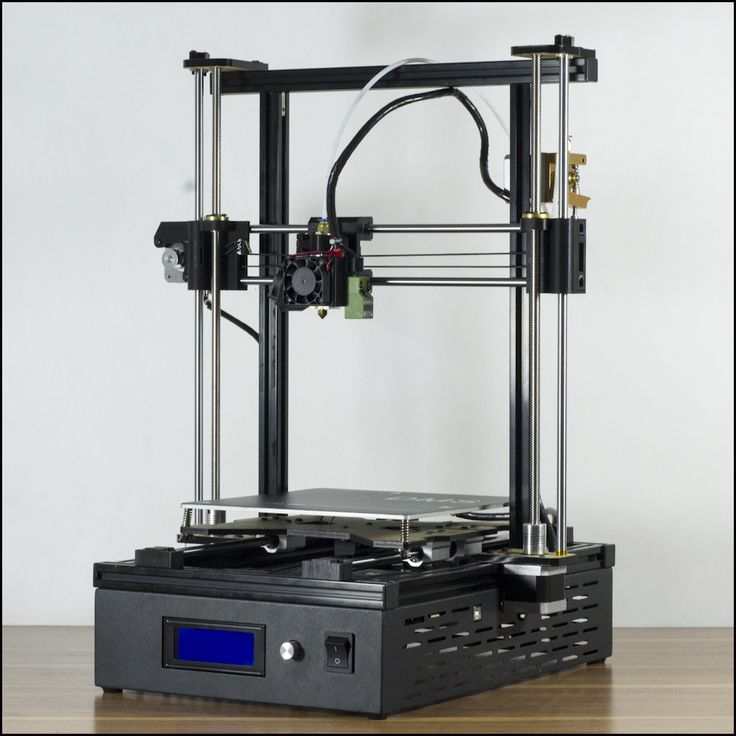

Now the most important question: can I use any printer to print it? Yes, you can print with conventional FDM desktop printers: Ultimaker, BCN Sigma… in 1.75 and 3mm filament. The only thing you need is a steel nozzle to resist the abrasion of the metal filament.

These are the printing parameters of the BASF Ultrafuse 316L filament, judge for yourself:

How to print on metal? Just follow the manufacturer’s instructionsAnd how much does it cost? It’s starting to be distributed and can be found at Matterhackers for $465 a reel.

¿Do you want to try 3D metal printing?

We have not yet been able to get hold of a BASF Ultrafuse coil to test it, but we are very interested in starting to print metal parts. If you want to ask us for a quote for this or any other project, just leave us a message and we will help you make it happen:

Home metal 3D printer is already a reality

3D printing

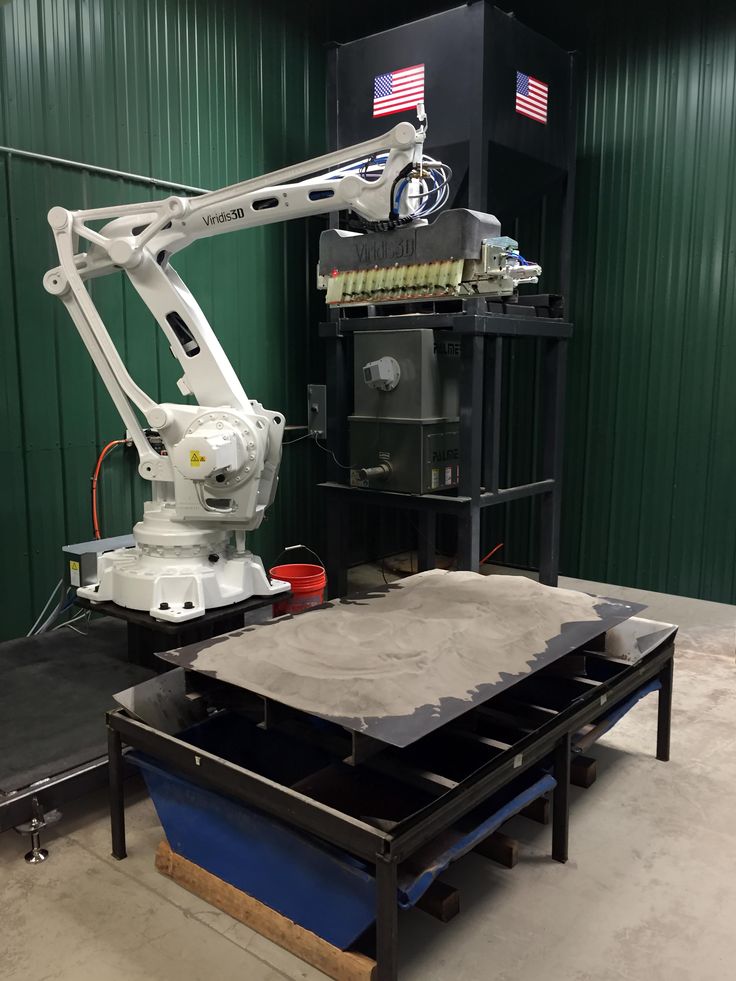

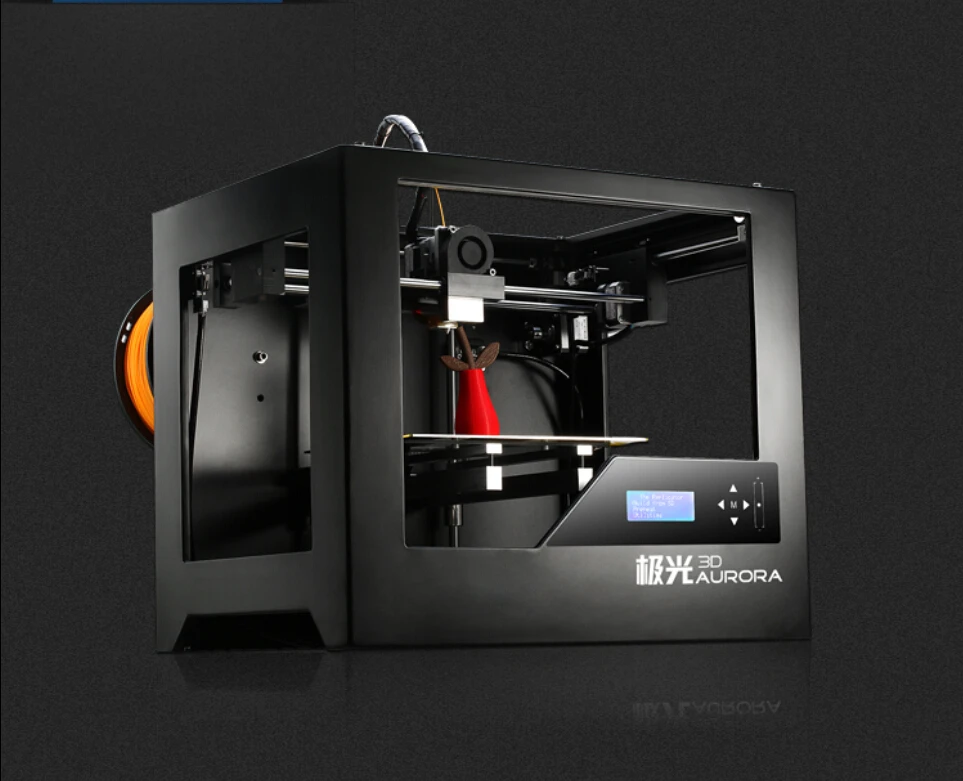

It is extremely rare for a 3D printer to appear in the 3D printing industry, the principle of which is based on a completely new approach. Today we can print products from hundreds of different materials, but when it comes to metals, the prices for 3D printers become simply sky-high. Only very large companies can afford "metal" 3D printers because they start at $250,000. But progress does not stand still, and someday anyone will be able to purchase such a miracle of technology and print metal products without leaving home.

The first steps have already been taken. Take, for example, the project of the Argentine engineer Gaston Accardi. Accardi has been into 3D printing for over 12 years and was one of the first to bring the technology to South America. Somehow he had an idea to make a completely new 3D printer, but due to a busy schedule, he put off work on the project for five years. And a couple of weeks ago, he finally managed to find time.

Take, for example, the project of the Argentine engineer Gaston Accardi. Accardi has been into 3D printing for over 12 years and was one of the first to bring the technology to South America. Somehow he had an idea to make a completely new 3D printer, but due to a busy schedule, he put off work on the project for five years. And a couple of weeks ago, he finally managed to find time.

“This is a 3D electroplated metal printer,” says Accardi. – Layer-by-layer deposition of metal in the right places occurs due to an electrochemical reaction. A wide variety of metals can be used, as well as alloys, conductive materials, and semiconductors. But most importantly, it is a very cheap method.”

By "cheap" Accardi means "very cheap". The fact is that he assembled a working prototype of the printer for just ... $ 2 (no, no, this is not a typo). So how does this unique 3D printer work?

So, galvanization is the process of coating one metal with another by means of electrolysis. There is no hint of laser sintering, stereolithography, or fused filament technology in Accardi's 3D printer. Instead, the most common electrical plating is used here.

There is no hint of laser sintering, stereolithography, or fused filament technology in Accardi's 3D printer. Instead, the most common electrical plating is used here.

In fact, galvanization becomes possible with a power supply and two poles. One field is connected to the part you want to plate, the other is connected to the metal that will be electrodeposited. You will also need an electrically conductive solution, usually sulfuric acid or lemon juice is used for this purpose. If galvanizing is done with copper, then for best results it should simply be added to the solution.

“A few minutes after you start running current through the solution, the copper starts to coat the piece,” explains Accardi. “Both of the electrodes you use must be electrically conductive.”

Accardi's 3D printer is based on the galvanization method, but he has further improved it. He took a marker, pulled out a rod from it and poured a solution of acid copper into it. Then he brought one field (copper electrode wire) inside the marker. Under the influence of an electric current, copper ions are released from the acid in the marker, pass through its tip and settle on the surface of the printing platform, which is coated with conductive silver and connected to another field. The result is a layer of metal.

Then he brought one field (copper electrode wire) inside the marker. Under the influence of an electric current, copper ions are released from the acid in the marker, pass through its tip and settle on the surface of the printing platform, which is coated with conductive silver and connected to another field. The result is a layer of metal.

“You can actually write with brass,” says Accardi. “And if you keep writing the same letters over and over again, they gradually grow in height and become voluminous.”

The marker can be filled with almost any conductive and semi-conductive metal, be it titanium, gold, iron, platinum, nickel, chromium or alloys such as bronze. Accardi said he bought a 4-axis CNC machine and plans to install his electroplating system on it. As a result, he should get something like a regular FFF 3D printer, only metal will be used here instead of molten plastic.

Although the prototype cost only $2, Accardi is looking for investors to help him create a more advanced device worthy of buyers' attention.

“I'm a multi-disciplinary inventor,” he says. “Life is like a puzzle. You have to find as many pieces of the puzzle as you can and then start putting them together."

Accardi believes that $100,000 will be enough for him to implement his idea and then put the printer into production and sale. If he succeeds, then the cost of a 3D printer will fluctuate around $ 1,000-2,000.

Accardi plans to build a device with multiple markers that can print with different metals at the same time. He also wants to try filling one of the markers with conductive silver ink so that the printer can print metals on non-conductive surfaces as well. We decipher: a plastic object is taken and placed inside the printer; conductive silver paint is applied to it; Different metals are applied to silver paint through a process of galvanization.

Accardi believes that his printer will help people create unique electronic devices, such as "smart prostheses" that will detect temperature and pressure. Although this printer has enormous potential, it has one significant drawback: it is very slow. Accardi's prototype is now growing 0.2 mm in the Z-axis per hour. At the same time, the power consumption is quite high - about 17 V.

Although this printer has enormous potential, it has one significant drawback: it is very slow. Accardi's prototype is now growing 0.2 mm in the Z-axis per hour. At the same time, the power consumption is quite high - about 17 V.

Electroplating has long been known, but the idea of using it to make metal products could revolutionize the world of 3D printing. This is an absolutely safe technology that can be used at home. Such a printer can be afforded by small companies that have long dreamed of moving into the production of metal products, as well as ordinary users who can not wait to experiment with metals.

Follow the author

Subscribe

Don't want

8

Homemade metal 3D printer, but something went wrong / Sudo Null IT News

Hello everyone, my name is Sergey. In this article, we will talk about 3D printing with metal, more precisely, about my attempt to implement 3D printing with metal.

In this article, we will talk about 3D printing with metal, more precisely, about my attempt to implement 3D printing with metal.

Quite often, people who are interested in or engaged in any activity, no matter what, stumble upon something completely new and previously unknown to them, something that can help develop/improve their main activity. A similar situation happened to me.

Surfing the expanses of your Internet, I came across a wonderful technology for vacuum deposition of metals on various materials. On Habré there is an interesting article about this technology. In addition, on many other resources it was said that the evaporated metal moves towards the target in a straight line.

Lots of resources0003

And then I thought, what if I spray metal in the place I need, gradually increasing the thickness? I looked for information about whether someone did this - I did not find it.

Registered on a forum where sprayers are clustered together and began to disturb them with questions like: is it possible to build up a “film” with a thickness of 1 or more millimeters. To which I caught a lot of misunderstanding what it was for, but received a positive answer.

General information received, you can begin to prepare for experiments.

It is known from various articles and documents that a vacuum of no more than 10⁻² Pa is required. For comparison, the order of magnitude - the pressure that gives a household vacuum pump (Value and others) - about 4 Pa (measured value), i.e. pressure is 400 times greater than necessary. How to deal with it and what to do? To achieve low pressures, turbomolecular vacuum pumps are used, they work in parallel with the foreline pump and, literally by molecules, capture the remaining air from the chamber. The process is not fast. The pump looks like this.

We installed a pump, it pumps out air and everything seems to be fine, but how to find out the pressure? For this I chose an ionization vacuum gauge.

In fact, nothing else is needed, except for the chamber and evaporator. I did not find a ready-made affordable (in terms of finances) camera, therefore, I decided to make my own. It is of a small volume (about 8-10 liters) in order for the air to be pumped out faster. Usually, the chambers have a spherical shape, in my case it is, on the contrary, elongated, in order to be able to set the “target” (the place where the metal is deposited) at different distances from the evaporator. In addition, the camera has a lot of flanges for connecting all kinds of inputs/outputs and sensors. I modeled the camera in a well-known CAD program, drew drawings and transferred it to production.

Current leads and conductors I made from a brass bar and a brass rod, bought on the local market. (Juno, who is from St. Petersburg).

In the photo below, a tungsten boat is fixed between two conductors.

The bottom part looks like this. The photo shows the cooling tubes of the current leads. Subsequently, I abandoned them, due to the simplification of the system.

Subsequently, I abandoned them, due to the simplification of the system.

Assembling the camera did not take much effort and complexity. It is much more difficult to achieve vacuum retention in this chamber. To do this, I polished the flanges and all mating surfaces to avoid the slightest leakage through the rubber seal (in the photo below, I processed only the top flange).

As it turned out later, the weld is not airtight at all (meaning for low vacuum). I, out of inexperience, assumed that by pumping a pressure of 300 kPa into the chamber and immersing it in a bath of water, I would carefully find all the leaks and eliminate them. Yes, at the first stage I did just that, but the pressure in the chamber did not fall below 10-2 Pa, there were leaks. Interestingly, before the start of the test, at a pressure in the chamber of 300 kPa, bubbles emerged from the welds with an intensity of approximately 1 bubble (diameter 2-3 mm) in 30-40 seconds. And those were big losses that I eliminated. But what to do with minimal vacuum losses that cannot be tracked in "kitchen" conditions?

But what to do with minimal vacuum losses that cannot be tracked in "kitchen" conditions?

The solution was close. To do this, all you need is a mass spectrometer.

The idea is simple – the investigated chamber or container is connected to the vacuum chamber of the spectrometer. Air is pumped out, on the graph they look for extraneous peaks of any gases. After that, helium is supplied locally, to the places of possible leakage. It is helium, because its penetrating power is higher and the helium peak can be easily tracked on the spectrum. As soon as helium enters the chamber through a micro-hole, it is immediately visible on the spectrum.

I drove twice and looked for leaks twice. Now the chamber with the installed pump is hermetic and it is possible to carry out experiments further, having previously assembled all the components of the system on the rack.

General view of the incredible installation.

Starting up the plant and checking it comes down to maintaining the lowest possible pressure. The foreline pump is started first.

The foreline pump is started first.

The pressure after the operation of the foreline pump can be seen in the picture below.

After the pressure is established (does not change). You can launch "heavy artillery" - a turbomolecular pump. It reduces the pressure by another 3 orders of magnitude.

The time has come for experiments, what I have been going for so long and what I have been waiting for so long.

The first experiment.

Place a small amount of silver into the boat fixed between the conductors. Above the boat I install a steam conduit - a soldered tin cylinder, which, as I thought, should limit the spread of metal through the chamber. Above the steam conduit there is a lid with a hole of 2 mm, behind the lid there is a target on which the metal should condense. It is a pity that there are no photos left, but the vacuum chamber was completely dusty. There was not a single place where there was no applied layer of metal. In the photo below, it’s not a different planet at all, but silver sprayed onto the inner surface of the wall.

In the photo below, it’s not a different planet at all, but silver sprayed onto the inner surface of the wall.

Second experiment.

I thought it was because of the large gaps between the boat and the steam line. The solution was born immediately and quickly. I took two boats and combined them so that a shell was obtained. I placed silver inside, and cut a hole with a diameter of 2 mm in the upper half.

And he began to heat up the whole thing. But, I did not take into account the rigidity of the boats and the rigidity of the current leads. The shells parted a little and a gap formed between them, through which steam also flew in all directions.

As a result - spraying in the entire volume of the chamber. In the photo below there is a viewing window, the boat in which was slightly above half, but the window was completely dusty.

Third experiment.

After a little thought and grief, I thought that the container with the evaporated metal should be airtight and with only one outlet, but how and what to make it. From tungsten - very expensive and difficult to process. The way out has been found! Graphite is an excellent material for making a crucible, let's call it that. On the ad site, I found an ad for the sale of graphite bars from the contact whiskers of a trolleybus, cut out a bar with a hole in the center and made a cover for it. In the photo below - just a bar with a hole for the material (without a cover).

From tungsten - very expensive and difficult to process. The way out has been found! Graphite is an excellent material for making a crucible, let's call it that. On the ad site, I found an ad for the sale of graphite bars from the contact whiskers of a trolleybus, cut out a bar with a hole in the center and made a cover for it. In the photo below - just a bar with a hole for the material (without a cover).

And in this photo already in the chamber with the lid installed (the hole in the lid is 1 mm in diameter).

Under the spoiler are a few photos with a short period of time, from which you can see how dusty the viewing window is.

Loss of transparency

It is obvious that in this case, too, there was no success, to my great regret. All three experiments were carried out with a gradual increase in temperature from the state when evaporation does not occur.

A small video in which the information is presented in a slightly different way, in a different form and volume.