Household 3d printers

The Best Cheap 3D Printers for 2022

While we'd hesitate to call 3D printing a mature technology, you might say it has reached its teenage years. Through their first decade-and-change, 3D printers have come down in price, grown easier to set up and operate, and become more reliable. And you may pay less than you expect: Many once-high-end features have migrated down to inexpensive models.

PC Labs has been reviewing 3D printers since 2013. Today, the state of 3D printing is strong, but that wasn’t always the case. For the first several years, it was often an adventure getting one of these printers up and running, let alone successfully through our testing regimen. Issues with filament-based—aka fused filament fabrication (FFF) or fused deposition modeling (FDM)—printers were abundant.

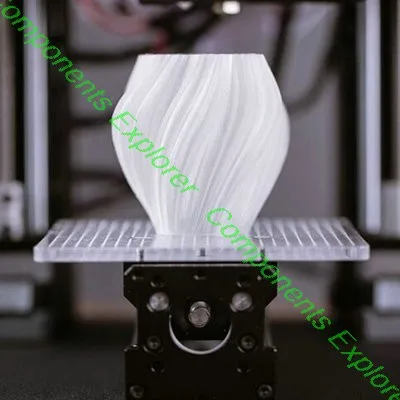

(Photo: Zlata Ivleva)

More About Our Picks

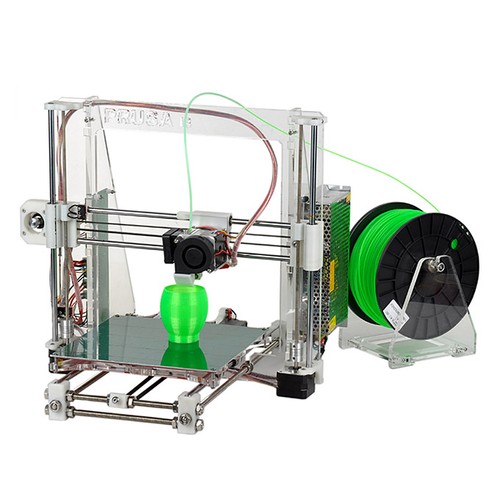

Original Prusa Mini

4.5 Outstanding

Best Overall Budget 3D Printer

Bottom Line:

It requires assembly and calibration care (plus shipping from the Czech Republic), but the Original Prusa Mini is a compact, open-frame 3D printer that consistently produces superb-quality output for a great price.

Pros

- Top-notch object quality

- Supports a variety of filament types

- Useful, professionally printed user guide

- Great support resources

- Versatile, user-friendly software

Cons

- First-layer calibration can be tricky

- Only includes starter packets of filament

- Requires monitoring if young children or pets are around

Read Our Original Prusa Mini Review

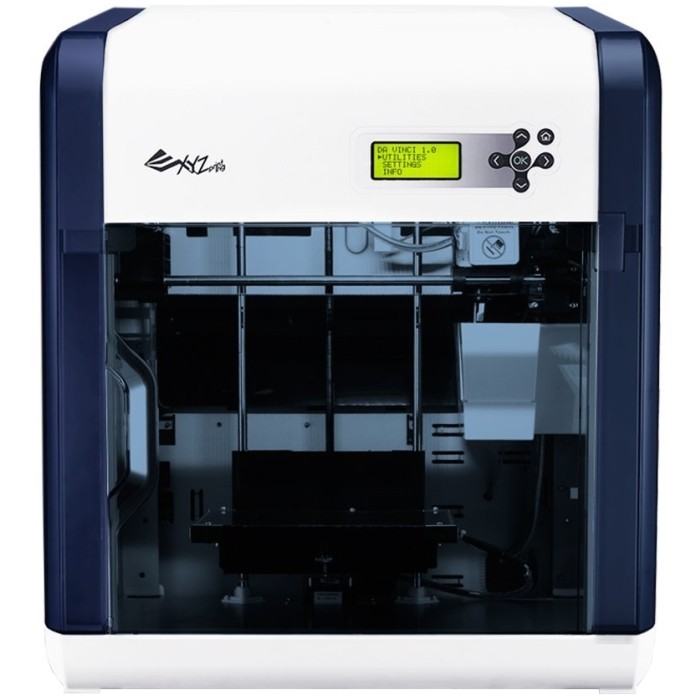

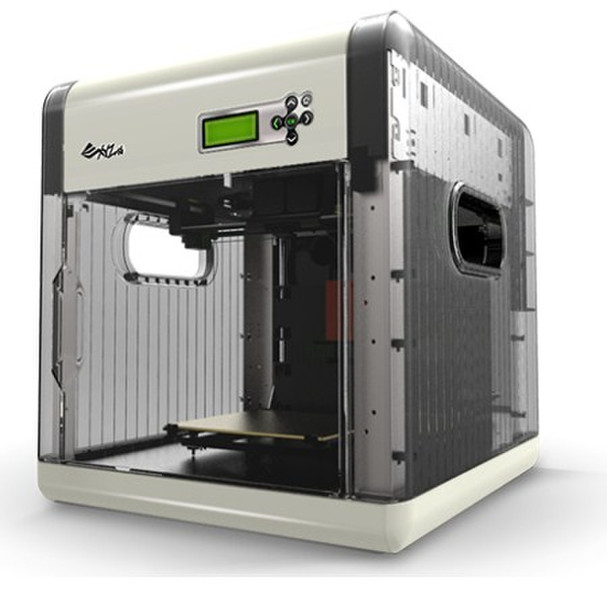

XYZprinting da Vinci Mini

4.0 Excellent

Best Budget 3D Printer for Schools, Community Centers

Bottom Line:

The XYZprinting da Vinci Mini is a consumer-oriented 3D printer that provides a winning combination of low price, ease of setup and use, solid print quality, and smooth, misprint-free operation.

Pros

- Very low price.

- Reasonably priced filament.

- Good print quality.

- No misprints in testing.

- Easy setup and operation.

- Quiet.

- Prints over a USB or Wi-Fi connection.

Cons

- Occasional problems in trying to launch prints.

- Removing printed objects from the print bed is sometimes tricky.

Read Our XYZprinting da Vinci Mini Review

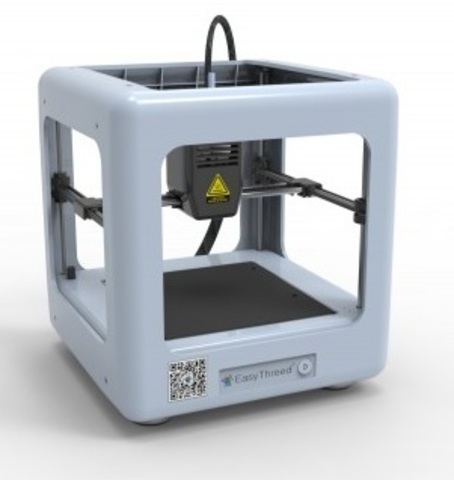

Toybox 3D Printer

4.0 Excellent

Best Budget 3D Printer for Children

Bottom Line:

The Toybox 3D Printer works well as a model designed for children, offering reliable printing from a browser or mobile device and a few thousand toys to print, plus creative options to output drawings or photos. Just bear in mind the tiny build area.

Pros

- Reliable, misprint-free printing

- Easy setup

- One-touch operation

- Well-composed help resources

- Access to more than 2,000 printable toys and projects

- Lets you create your own printable designs

Cons

- Tiny build area

- Not ideal for importing 3D files created elsewhere

Read Our Toybox 3D Printer Review

Monoprice Mini Delta V2 3D Printer

4. 0 Excellent

0 Excellent

Best Budget 3D Printer for Beginners, Non-Techies

Bottom Line:

3D printing gurus will be intrigued by the Monoprice Mini Delta V2's use of the delta rather than Cartesian coordinate system, but beginners will just enjoy its low price, ease of use, and speedy printing.

Pros

- Sub-$200 price

- Quick, nearly misprint-free printing

- Easy setup and operation

- Sturdy steel-and-aluminum frame

- Supports multiple filament types

Cons

- Tiny build area

- So-so print quality

- Mere one-year warranty

Read Our Monoprice Mini Delta V2 3D Printer Review

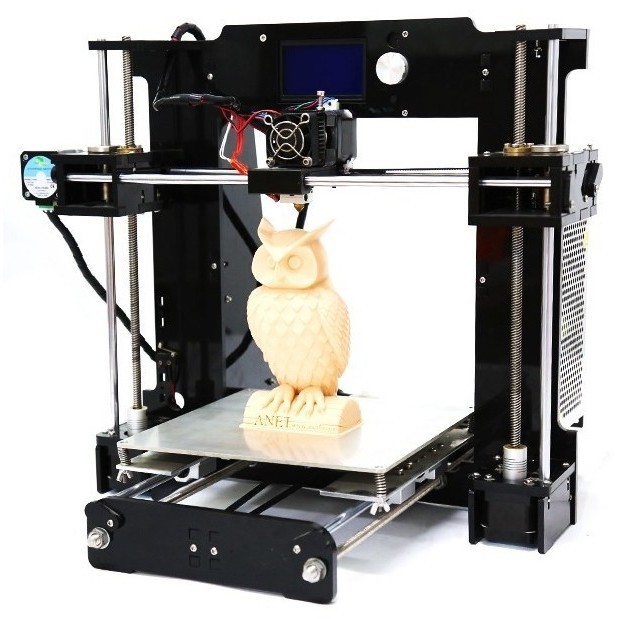

Anycubic i3 Mega S

3.5 Good

Best Budget 3D Printer With an Open Design, Big Build Area

Bottom Line:

The Anycubic i3 Mega S, an inexpensive open-frame 3D printer, produced decent-quality prints in our testing. To get the most out of it, though, may require precise calibration.

Pros

- Modestly priced

- Large build area for an inexpensive printer

- Supports a variety of filament types

- Generally solid print quality

- Uses well-known Cura software

Cons

- Finicky print-platform alignment

- Supported coils of filament are small

- Poorly placed spool holder

Read Our Anycubic i3 Mega S Review

Anycubic Vyper

3.5 Good

Best Budget 3D Printer for the Biggest Build Area Possible

Bottom Line:

Anycubic's modestly priced Vyper whips up large 3D prints on its open-frame design, and provides automatic print-bed leveling. Just know that some minor assembly is required—and printed objects may require a bit of cleanup.

Pros

- Relatively large build area

- Automatic bed leveling

- Simple assembly

Cons

- Short (one-year) warranty

- Includes only a small starter filament coil

- Using Cura software with the Vyper requires tweaking a couple of settings

- Test prints showed some "hairy" filament residue

Read Our Anycubic Vyper Review

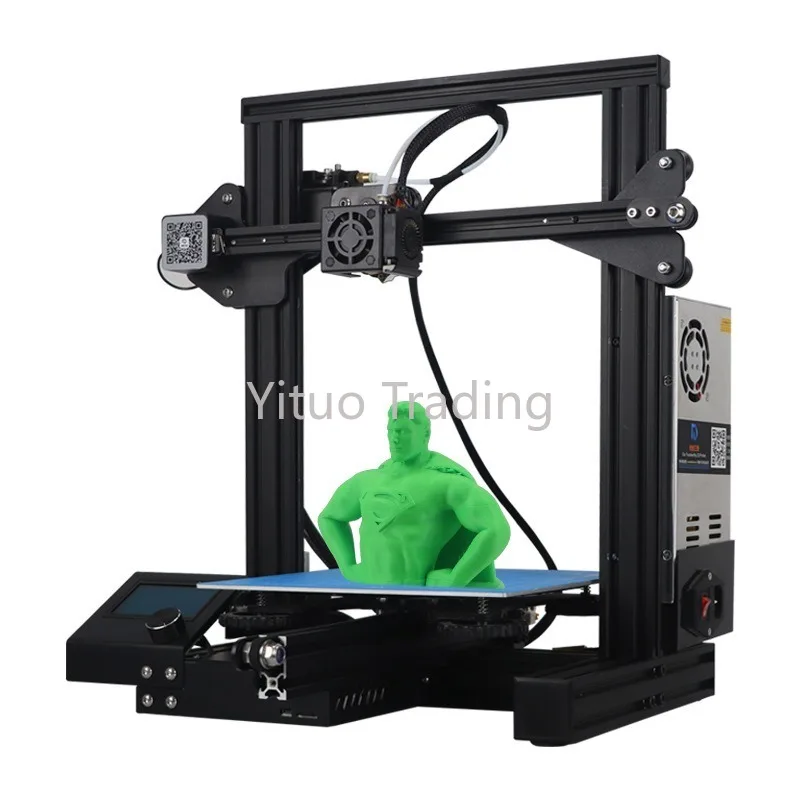

Creality Ender-3 V2

3. 5 Good

5 Good

Best Budget 3D Printer for Tinkerers and DIY Types

Bottom Line:

Hands-on tweaking defines Creality's budget-price Ender-3 V2, an open-frame 3D printer that you build from a kit. It produces generally above-par prints, but its print bed can be tricky to keep leveled.

Pros

- Inexpensive

- Slightly above-average print quality

- Good-size build area for its price

- Supports several filament types

Cons

- Manual print-bed leveling can be tricky

- Setup instructions could be deeper, more legible

- Questionable quality control on some parts

Read Our Creality Ender-3 V2 Review

Flashforge Finder 3D Printer

3.5 Good

Best 3D Printer for the Very Tightest Budgets

Bottom Line:

The Flashforge Finder 3D Printer is moderately priced and offers good print quality, but it proved tricky to get up and running in our tests.

Pros

- Quiet.

- Good print quality.

- Connects via USB 2.0 cable, USB thumb drive, or Wi-Fi.

- Reasonably priced.

Cons

- Some objects pulled off the platform during testing.

- Poor documentation.

- Modest build volume.

- Limited to printing with polylactic acid filament (PLA).

Read Our Flashforge Finder 3D Printer Review

Polaroid PlaySmart 3D Printer

3.5 Good

Best Budget 3D Printer for Dabbling in Small Objects

Bottom Line:

The Polaroid PlaySmart 3D Printer is a compact, stylish 3D printer with above-par overall print quality, but, alas, a tiny build area for the money.

Pros

- Small, lightweight for a desktop 3D printer.

- Easy to set up and use.

- Supports PLA, PETG, and wood composite filaments.

- Multiple-color support.

- Wi-Fi camera monitors print jobs.

- Prints from USB drives, SD cards, or mobile devices.

Cons

- High price for its capabilities.

- Small build area.

- Too-brief warranty.

Read Our Polaroid PlaySmart 3D Printer Review

XYZprinting da Vinci Jr. 1.0 A Pro

3.5 Good

Best Budget 3D Printer With Closed Design, Roomy Build Area

Bottom Line:

The XYZprinting da Vinci Jr. 1.0 A Pro is a moderately priced closed-frame 3D printer with a large build volume and overall good performance, but a potentially balky filament-feeding system.

Pros

- Spacious build area

- Works with third-party filaments

- Self-leveling print bed

Cons

- Build plate is not heated

- Limited to PLA- and PETG-based filaments

- Guide tube is prone to detaching

Read Our XYZprinting da Vinci Jr. 1.0 A Pro Review

Monoprice Voxel 3D Printer

3. 0 Average

0 Average

Best Budget 3D Printer for Cheap Filament

Bottom Line:

The Monoprice Voxel is an under-$400 3D printer that's easy to set up and use. It exhibits generally good print quality, but it was unable to print two of our test objects.

Pros

- Easy to set up and use.

- Budget price for printer and filament spools.

- Supports PLA, ABS, and several composite filament types.

- Versatile software.

- Prints over Ethernet or Wi-Fi, or from a USB thumb drive.

Cons

- Frequent misprints on certain test objects.

- Slightly balky touch screen.

Read Our Monoprice Voxel 3D Printer Review

Filament feeders had to be coaxed into delivering filament from the spool to the extruder. Print beds had to be manually aligned. The extruder or hot end had to be positioned just right to minimize the gap between the nozzle and the build plate (the flat surface on which the object is printed). Objects frequently stuck to the build plate, and required careful, sometimes unsuccessful, efforts to pry them off. These and other issues required painstaking effort to resolve, often combined with calls to tech support.

Objects frequently stuck to the build plate, and required careful, sometimes unsuccessful, efforts to pry them off. These and other issues required painstaking effort to resolve, often combined with calls to tech support.

Not so much anymore. While they can still be rebellious at times, 3D printers have grown up a lot, and achieving the 3D printer basics has gotten a lot less likely to end in a shouting match over small things.

What to Look for in a Cheap 3D Printer

The big difference is the change that has come to the cheaper models. Nowadays, many of those ornery 3D-printing issues have been resolved (most of the time, anyway), even for consumer and bargain-priced 3D printers. Automatic print-bed leveling is the norm, and you can usually remove 3D-printed objects from heated and/or flexible build plates with a minimum of coaxing. Most 3D printer manufacturers have either developed and refined their own software, or have adapted an open-source printing platform such as Cura(Opens in a new window).

What separates more expensive 3D printers from cheap ones ("cheap" defined as $500 or less, for the purposes of this article) is often a select group of features. These include the build volume, the type of frame, the varieties of supported filament, the software, and the connectivity mix. Let's run through those in turn.

What's the Right Build Volume for a 3D Printer?

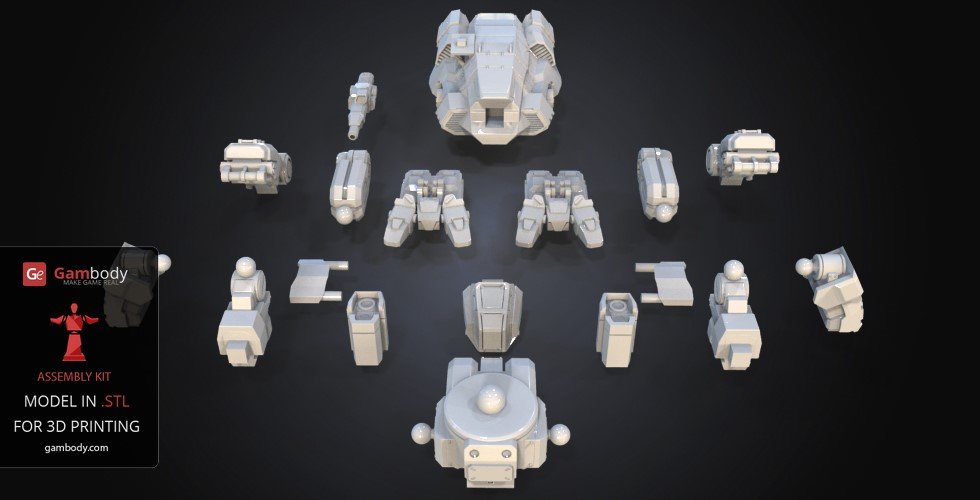

A 3D printer’s build volume is the maximum dimensions (HWD) of a part that it can print. (We say “a part” because a 3D-printed object can consist of multiple parts that are printed, then glued or otherwise pieced together.) While the smallest build volume of any 3D printer we have tested is 3.9 by 3.9 by 4.9 inches, we consider any build volume smaller than 6 by 6 by 6 inches to be small, any between that and 10 by 10 by 10 inches as medium, and any printer with at least one build dimension of more than 10 inches as having a large build volume.

(Photo: Molly Flores)

As a general rule, inexpensive 3D printers have small build volumes, while more expensive ones have larger build volumes. This depends in part on the type of printer. Closed-frame 3D printers—and most semi-open models, which have a rigid top, base, and sides but are open in front and, often, back—tend to have small build volumes, while open-frame printers, lacking as rigid a physical structure, often have relatively large build volumes for the price. You'll want to weigh the build volume against the kinds of objects you will print.

This depends in part on the type of printer. Closed-frame 3D printers—and most semi-open models, which have a rigid top, base, and sides but are open in front and, often, back—tend to have small build volumes, while open-frame printers, lacking as rigid a physical structure, often have relatively large build volumes for the price. You'll want to weigh the build volume against the kinds of objects you will print.

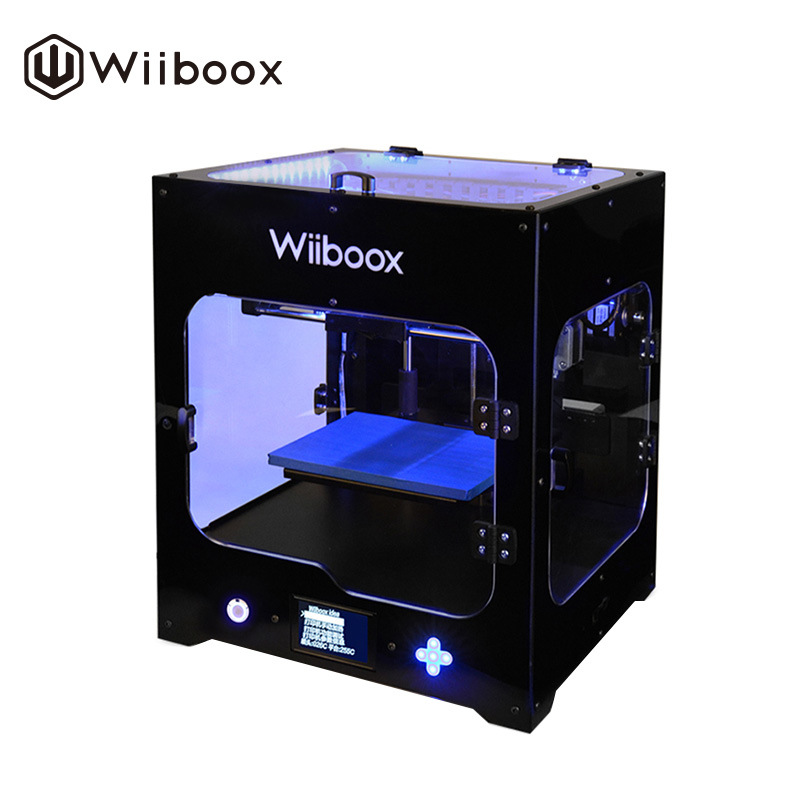

Should I Get an Open-Frame or Closed-Frame 3D Printer?

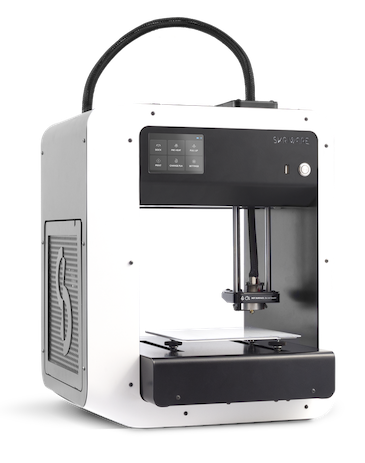

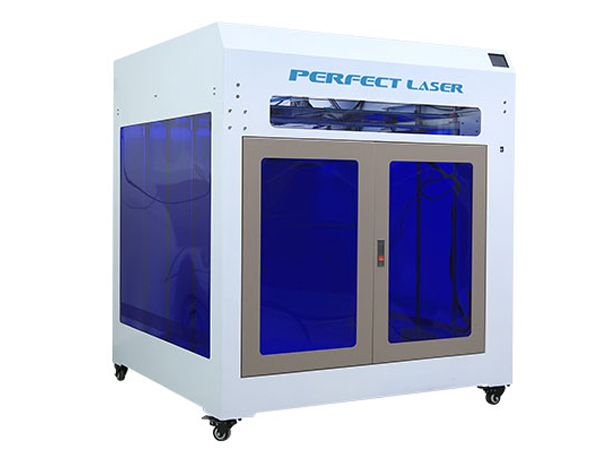

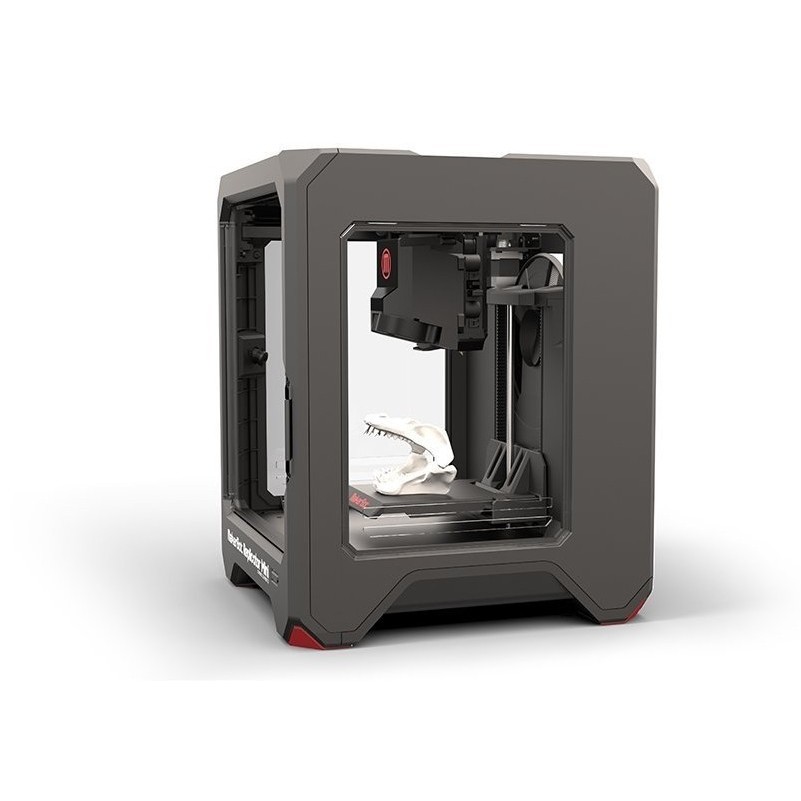

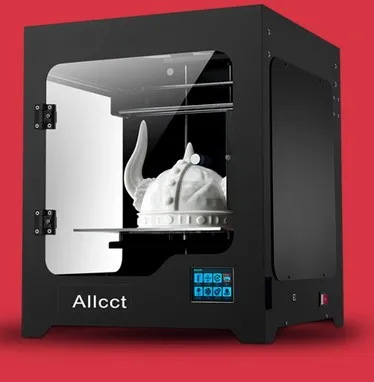

Which brings us to the frame "form factor" question: open-frame versus closed-frame. Closed-frame 3D printers are boxlike devices, with a rigid base, walls (with a see-through door in front), and top. Among their advantages? They muffle the operating noise, as well as reduce the odor from melted filament (which is potentially an issue with ABS plastic), and they provide some protection for people or pets who might inadvertently touch the hot extruder. A downside: They tend to have smaller build volumes than open-frame 3D printers, which have fewer (often, no) walls to constrict them.

(Photo: Zlata Ivleva)

Low-cost 3D printers include both open-frame and closed-frame models, as well as a few stereolithography printers. If a relatively large build volume is a priority, you’re likely to get more bang for the buck with an open-frame model. Open-frames do have some clear downsides by definition: They tend to be noisy, emit odors when certain plastics are melted, and provide little protection for someone who might touch the hot extruder.

(Photo: Molly Flores)

Also, recognize some potential negatives of open frames, depending on the model. Some require assembly, being essentially kits, and most require more setup care than a closed-frame printer, plus more maintenance to keep them running smoothly. Still, these very traits should not deter—and may even appeal to—hobbyists and DIY folks.

What Should I Look for in 3D Printer Software and Connectivity?

Gone are the days when tinkerers had to cobble together several different programs to get a 3D printer to run. Manufacturers either include their own 3D printing program or modify an existing platform such as the open-source Cura.

Manufacturers either include their own 3D printing program or modify an existing platform such as the open-source Cura.

3D printing software performs three main functions: processing an object file (resizing, moving, rotating, and in some cases duplicating it), slicing it (into virtual layers, based on your chosen resolution), and printing it. These are almost universally combined into a seamless process. Some high-end printers have software that supports a wider range of settings you can tweak, but even the basic suites work at least reasonably well.

More likely to vary among the cheaper set is the array of connection options from model to model. Nearly all have a USB Type-A port to fit a thumb drive for printing from document files. Most also have a USB Type-B port for connecting directly to a computer, and some offer Wi-Fi, too (or as an alternative), while a handful let you connect via Ethernet to share the printer across a local network.

Some printers support storing 3D files on an SD or microSD card (which may also contain the printer’s system files). Most 3D printer manufacturers (even the discount ones) have a mobile app to launch and monitor print jobs, and a few provide access to cloud services from which you can print.

Most 3D printer manufacturers (even the discount ones) have a mobile app to launch and monitor print jobs, and a few provide access to cloud services from which you can print.

While high-end 3D printers tend to have an abundance of connection choices, discount models vary widely in their choices. Some are generous and some are basic, so it pays to assess what a given model offers.

What Should I Look for in Filament Support?

Filament support tends to be a key area that separates the cheaper models from the higher-end ones. (See our guide to understanding 3D printing filaments for more particulars.) Inexpensive 3D printers tend to support a limited number of plastic filament types, some of them only PLA and/or ABS.

Recommended by Our Editors

3D Printing: What You Need to Know

3D Printer Filaments Explained

(Photo: Molly Flores)

PLA (polylactic acid) is a biodegradable, plant-based polymer, while ABS (acrylonitrile butadiene styrene) is the same tough plastic that Legos are made from. Objects printed from ABS are durable and nontoxic, though the material can be tricky to work with. ABS can emit an acrid, unpleasant odor during printing, and the bottom corners of objects being printed with it have a tendency to curl upward a bit, especially if you are using a non-heated print bed. This can lead to unsightly prints, and/or prints prematurely pulling off the build plate, ruining them.

Objects printed from ABS are durable and nontoxic, though the material can be tricky to work with. ABS can emit an acrid, unpleasant odor during printing, and the bottom corners of objects being printed with it have a tendency to curl upward a bit, especially if you are using a non-heated print bed. This can lead to unsightly prints, and/or prints prematurely pulling off the build plate, ruining them.

Many entry-level and low-price 3D printers stick exclusively to PLA. If you want to experiment with a larger variety of filaments—which include water-soluble filament, wood- and metal-laced composites, and both tough and flexible varieties—you may have to pay more, although a few discount models support a wide range of materials.

Should I Consider a 3D Printing Pen Instead?

Although they aren’t printers per se, inexpensive 3D pens are close kin to 3D printers—using the same filament types and a similar extrusion system—and we include them in the 3D printing category. Rather than tracing out a programmed pattern, you use the 3D pen much like a normal pen, except that you draw with molten plastic. You can trace a pattern or draw freehand, and even draw in three dimensions as the plastic quickly solidifies and hardens once extruded.

You can trace a pattern or draw freehand, and even draw in three dimensions as the plastic quickly solidifies and hardens once extruded.

Most 3D pens cost less than $100, and some cost $50 or less. At a glance, 3D pens may appear to be toys, but some artists and craftspeople have taken to them, as it is possible to make quite complicated and beautiful objects with them. If your aim in 3D printing is something closer to freehand design and free expression than computer-centric, structured, and repeatable output, you might give one a try.

So, Which Cheap 3D Printer Should I Buy?

Buying a budget 3D printer needn’t mean a world of sacrifice. Plenty of capable and reliable models sell at less than $500, and while they may not be as feature-rich as their more expensive cousins, there's no sense in paying for things you don’t need.

Many casual 3D-printing experimenters will be fine with printing over a USB cable or from a thumb drive, and sticking to PLA may be the best choice for a starter 3D printer. If you focus just on the features you want, you may be pleasantly surprised at what you find. Here we feature the best under-$500 3D printers we have reviewed. Also check out our guide to our favorite 3D printers overall.

Best 3D printers of 2022: top choices for work and home use

Our list of the best 3D printers contains clear and concise information on all kinds of 3D printers. (Image credit: Future)The 3D printer market is growing at an explosive rate, with new brands and styles of printing making an appearance each year. Where many 3D printers used to be huge, expensive machines, developments in technology and production now mean that many of the best options you can buy are increasingly affordable and can sit on a desk in your home without needing workshop space.

Naturally, this means there's now a massive choice of 3D printers that cater to all sorts of user needs and budgets. While this choice is excellent, picking the best 3D printer for your specific needs can be difficult. However, this guide can help, as we pick some brilliant 3D printers for all uses and budgets, with clear buying advice to help you determine which one you should buy.

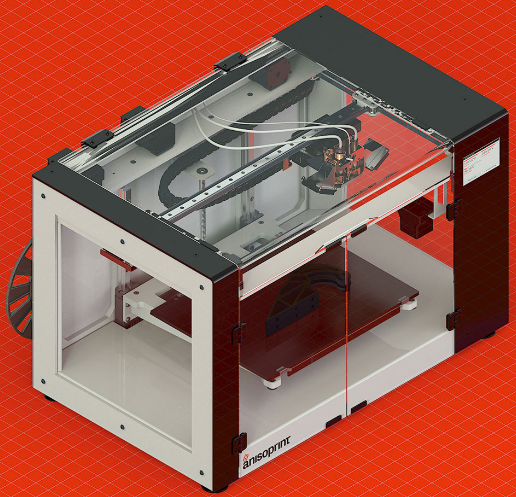

Printing hardware has taken off in recent years, so while a handful of filament printers (otherwise known as FDM printers) were all that was once available, there's now a wide variety of different styles to suit your needs across a range of budgets.

Unlike office-style printers that just print ink onto paper, 3D printers turn digital models into real-world objects made from plastic, metal, and wood. FDM printers now come in all shapes and sizes and are well suited to prototyping and crafting larger objects. At the same time, resin-based (SLA, MSLA, and DLP) allow for much greater detail, typically at a smaller scale, making them a fantastic buy for anyone looking to design jewelry or create tabletop miniatures.

You can use 3D printers to build complete products, make spare parts, or simply create things you’ll find helpful for your home, office, and workshop. And, since 3D printing technology is within the grasp of just about anyone, you don’t have to utilize one to your advantage.

And, since 3D printing technology is within the grasp of just about anyone, you don’t have to utilize one to your advantage.

Whether you’re just getting your feet wet or are an expert, here are the best 3D printers ranges to consider. Our picks wildly vary in price, size, functionality, and use case, so there should be something for you, whatever it is you’re looking for. Remember that the more expensive choices are better suited for professionals while the best cheap 3D printers are ideal for those just starting.

The best 3D printers

Original Prusa MINI (Image credit: Prusa)1. Original Prusa MINI+

Small, affordable and remarkable 3D printer

Specifications

Print technology: Fused Deposition Modeling

Build Area: 18 x 18 x 18cm

Minimum layer resolution: 50 microns

Maximum layer resolution: 200 microns

Dimensions: 33 x 33 x 38cm

Weight: 4.5kg

Today's Best Deals

Reasons to buy

+

Great value for an FDM printer

+

Easy to use

+

Supports a variety of filament types

Reasons to avoid

-

Reel sits separately

-

Imperfect print quality

-

Calibration can be tricky

This affordable open-frame 3D printer is small enough to sit on your desk and easy enough to assemble yourself without expertise. It comes in kit form and uses FDM (Fused Deposition Modeling) to turn popular modeling materials such as PLA, PETG, ASA, ABS and Flex into accurate printed products. There’s a Network LAN port and USB port for simple connectivity and a user-friendly interface. This entry-level printer should be the first choice for crafters, modelers and engineering enthusiasts. The Original Prusa MINI+ is a replacement for the Original Prusa MINI (minus the plus) the key advantage being that is now comes with a superPINDA sensor, which is not temperature dependent allowing the first layer calibration to be faster and more reliable.

It comes in kit form and uses FDM (Fused Deposition Modeling) to turn popular modeling materials such as PLA, PETG, ASA, ABS and Flex into accurate printed products. There’s a Network LAN port and USB port for simple connectivity and a user-friendly interface. This entry-level printer should be the first choice for crafters, modelers and engineering enthusiasts. The Original Prusa MINI+ is a replacement for the Original Prusa MINI (minus the plus) the key advantage being that is now comes with a superPINDA sensor, which is not temperature dependent allowing the first layer calibration to be faster and more reliable.

Read the full review: Original Prusa MINI

CEL-UK RoboxPro (Image credit: CEL-UK)CEL-UK is a leader in 3D Printer innovation, with the original Robox printers introducing many new features to the world of FDM 3D printers. The RoboxPro is Robox on a large scale with a feature set that reads like a 3D print wish list; auto filament loading, auto bed leveling, Wi-Fi, network printing and swappable tool heads. The main focus of the machine is quality and reliability, designed for anyone wanting a printer that can realize product ideas and get them to market. The enclosed design makes it an ideal choice for commercial and educational use.

The main focus of the machine is quality and reliability, designed for anyone wanting a printer that can realize product ideas and get them to market. The enclosed design makes it an ideal choice for commercial and educational use.

Read the full CEL-UK RoboxPro review .

2. CEL-UK RoboxPro

Best 3D printer for commercial printing

Specifications

Print technology: Fused Deposition Modeling

Filament Diameter: 1.75mm

Build Area: 210 x 300 x 400mm

Minimum layer resolution: 50 microns

Maximum layer resolution: 500 microns

Dimensions: 513x508x605mm

Weight: 26kg

Today's Best Deals

Reasons to buy

+

Swappable print heads

+

Dual Extruder and auto bed leveling

+

Network ready, no wired needed

Reasons to avoid

-

Large scale printer, not ideal for home use

-

Can be difficult to load filament

(Image credit: TRILAB)2.

TRILAB DeltiQ 2

TRILAB DeltiQ 2 Distinctive delta design for professional 3D printing

Specifications

Print technology: Fused Deposition Modeling (FMD)

Build area: 25 x 25 x 30cm

Minimum layer resolution: 50 microns

Maximum layer resolution: variable

Dimensions: 41 x 50 x 81cm

Weight: 10kg

Today's Best Deals

Reasons to buy

+

Elegant design

+

Easy expansion

Reasons to avoid

-

Not suitable for all materials

-

Fully open design

If you’re looking for a professional 3D printer for fairly large and complex projects, this elegant delta design should get your attention. It uses FDM technology to build 3D models from rolls of filament, but instead of the more common cartesian printers, the TRILAB DeltiQ 2 has a fixed round build plate with the extruder suspended between three arms that move the print head along three axis. It gives this model a fairly small footprint, while its high tower design ensures it is able to print some quite large pieces.

It gives this model a fairly small footprint, while its high tower design ensures it is able to print some quite large pieces.

And unlike most 3D printers, it has two extruder options, one for standard PLA and PETG and the other for flexibles. It just requires a little retooling to swap between them. The TRILAB DeltiQ 2 uses some of the best components available in its construction and the interface is a smartphone running a dedicated app. This is a handsome, high-end workshop printer that would sit well in any laboratory, studio or classroom.

Read our full TRILAB DeltiQ 2 review .

Original PRUSA SL1 (Image credit: PRUSA)3. Original PRUSA SL1S SPEED

The best MSLA printer just got better

Specifications

Print technology: Stereolithography

Build area: 320 x 450 x 500mm

Minimum layer resolution: 25 microns

Maximum layer resolution: 100 microns

Dimensions: 400 x 237 x 225 mm

Weight: 4.5kg

Today's Best Deals

Reasons to buy

+

Rapid printing

+

Great build quality

Reasons to avoid

-

High maintenance

-

Limited build volume

Prusa Research revolutionized the FDM 3D printer market and this model looks set to do the same for SLA printers. While this printer uses stereolithography technology, it's in fact a slight variant, known as MSLA. This uses a monochrome LCD and UV LED to expose the resin which is a cheaper than using precision lasers but just as accurate. The SL1S SPEED replaces the outgoing SL1 and as you might have guessed from that model name, it’s faster – around ten times faster and with a vastly improved print quality. With support from the excellent PrusaSlicer software and a huge open source community, the speedy new model looks set to lead the SLA market.

While this printer uses stereolithography technology, it's in fact a slight variant, known as MSLA. This uses a monochrome LCD and UV LED to expose the resin which is a cheaper than using precision lasers but just as accurate. The SL1S SPEED replaces the outgoing SL1 and as you might have guessed from that model name, it’s faster – around ten times faster and with a vastly improved print quality. With support from the excellent PrusaSlicer software and a huge open source community, the speedy new model looks set to lead the SLA market.

Read our full Original Prusa SL1S 3D printer review .

Anycubic Vyper (Image credit: Anycubic)4. AnyCubic Vyper

The best beginner friendly FDM 3D printer

Specifications

Print technology: Fused Deposition Modeling

Build area: 245 x 245 x 260mm

Minimum layer resolution: 100 microns

Dimensions: 508 × 457 × 516mm

Weight: 10kg

Colour

Black

Condition

New

Today's Best Deals

Reasons to buy

+

Built-in accessories drawer

+

Reliable automatic bed-leveling

+

Great value for the features you get

Reasons to avoid

-

Excessive initial stringing

-

Questionable build quality in places

-

Cura profile needs fine-tuning

If the world of 3D printing ever seemed too intimidating for you, look no further than the AnyCubic Vyper. While perfect for beginners with its auto-leveling feature and minimal assembly, seasoned printing hobbyists will also appreciate what it can offer, albeit with a few adjustments.

While perfect for beginners with its auto-leveling feature and minimal assembly, seasoned printing hobbyists will also appreciate what it can offer, albeit with a few adjustments.

As the 'automatic leveling' might imply, the AnyCubic Vyper removes the need to manually align your build plate should you want to move the machine to a different location. It's fast and accurate which saves time when setting up your first print, which makes setting up and getting started a breeze.

Read our full AnyCubic Vyper review.

Raise3D E2 (Image credit: Raise3D)5. Raise3D E2

The best workhorse 3D printer

Specifications

Print technology: Fused Deposition Modeling

Build area: 330 x 240 x 240mm

Minimum layer resolution: 20 microns

Maximum layer resolution: 250 microns

Dimensions: 607 x 596 x 465mm

Colour

Black

Condition

New

Today's Best Deals

Reasons to buy

+

High-resolution print capability

+

Innovative ouch screen interface

+

Dual Extruder system can work independently

Reasons to avoid

-

Huge and heavy, not ideal for home use

-

Careful placement of bed required

-

Needs manual assistance for filament loading

3D printing has truly come of age and machines like the Raise3D E2 bring high-end FFF printing to the home, education and business. This dual extrusion printer goes head-to-head with the RoboxPro and will fulfil most companies' design and development needs with slick business and network integration. Home and educational users will benefit from a simple interface and near faultless reliability. The only drawback of this machine is the size and weight.

This dual extrusion printer goes head-to-head with the RoboxPro and will fulfil most companies' design and development needs with slick business and network integration. Home and educational users will benefit from a simple interface and near faultless reliability. The only drawback of this machine is the size and weight.

Read the full Raise3D E review .

(Image credit: Anycubic)6. Anycubic Photon M3

Detailed 3D modelling for beginners

Specifications

Print technology: Stereolithography (SLA)

Build area: 18 x 18 x 18cm

Minimum layer resolution: 50 microns

Maximum layer resolution: 200 microns

Dimensions: 18 x 16.4 x 10cm

Weight: 7kg

Colour

Yellow

Condition

New

Today's Best Deals

Reasons to buy

+

Good value

+

Detailed models

Reasons to avoid

-

Print size is small

-

Poorly placed USB port

The Anycubic Photon M3 is the ideal entry-level resin printer to introduce you to the world of 3D printing. It’s relatively easy to set up and operate and the box includes everything you need to get started, except for the UV resin. This model is compact, which means it will fit easily on your desk in a well-ventilated room, though the build volume is somewhat limited at 180 x 163.9 x 102.4mm or 7 x 6.5 x 4-inches.

It’s relatively easy to set up and operate and the box includes everything you need to get started, except for the UV resin. This model is compact, which means it will fit easily on your desk in a well-ventilated room, though the build volume is somewhat limited at 180 x 163.9 x 102.4mm or 7 x 6.5 x 4-inches.

For printing small plastic parts or artistic pieces, this modest machine can turn out surprisingly detailed models. The interface is a 7.6-inch panel and software is included that will help you print your project and slice it. If you want to make larger models, you should consider one of Anycubic’s larger 3D printers, but for $299 (about £275 / AU$480) this is a great place to start.

Read our full Anycubic Photon M3 review .

Snapmaker 2.0 A350 (Image credit: Snapmaker)7. Snapmaker 2.0 A350

Best 3-in-1 3D printer

Specifications

Print technology: Fused Filament Fabrication, CNC, Laser

Build area: 350 x 350 x 350mm

Minimum layer resolution: 50 microns

Maximum layer resolution: 300 microns

Dimensions: 645 x 480 x 580mm

Today's Best Deals

Reasons to buy

+

3D printer, CNC, and Laser cutter in one

+

Solid design and build quality

+

Easy to understand software

Reasons to avoid

-

Switching between uses takes time

-

Enclosure purchased separately

-

Very noisy when printing

A true 3-in-1 machine makes sense, because 3D printers, CNC and Laser cutters all use the same basic mechanics and technology. The original Snapmaker has a dedicated following, so it is no surprise that the Snapmaker 2.0 builds on its predecessor's reputation and features. The A350 is the largest of three models and proves proficient at all disciplines. Swapping between the three heads and beds does take time to reconfigure and calibrate for the prince and features it's worth it.

The original Snapmaker has a dedicated following, so it is no surprise that the Snapmaker 2.0 builds on its predecessor's reputation and features. The A350 is the largest of three models and proves proficient at all disciplines. Swapping between the three heads and beds does take time to reconfigure and calibrate for the prince and features it's worth it.

Read the full Snapmaker 2.0 A350 review .

Best 3D Printers: How did we test them?

3D printers are tested using a collection of bespoke benchmarks that help show the strengths and weaknesses of each model that after time can be compared against other products. These will differ depending on printer type, but a filament printer will be tested for stringing, bridging and speed, as well as additional commentary on detail achieved and noise levels.

This will be done fairly, with dues given to different materials and printer types, with resin printers being subject to smaller, more detailed models to replace the stringing test. Design, price and performance will be also be explored as sections within the reviews.

Design, price and performance will be also be explored as sections within the reviews.

All our tests are conducted from the perspective of the printers target market where possible, so expect to see a lot of tabletop miniatures and figurines alongside the usual 'benchies' (test models that are also dubbed as 'torture tests' to see where a printer needs to be better optimized for future prints).

- We've also featured the best printers

Round up of today's best deals

Anycubic Vyper

$429.99

View

See all prices

Reduced Price

Raise3D E2

$200

$135.98

View

See all prices

Deal ends Mon, Oct 10

Reduced Price

Anycubic Photon M3

$699

$613

View

See all prices

powered by

Collin is the B2B Hardware Editor for TechRadar Pro. He has been in journalism for years with experience in both small and large markets including Gearadical, DailyBeast, FutureNet and more.

He has been in journalism for years with experience in both small and large markets including Gearadical, DailyBeast, FutureNet and more.

top 10 rating according to KP

A 3D printer opens up incredible opportunities for a person. The first prototype of such a device was born back in 1984. The idea of the invention belongs to the American Charles Hull, he received a patent for it only two years after development. The printer was a rather massive industrial installation and, despite many inaccuracies and shortcomings in operation, the technology was used.

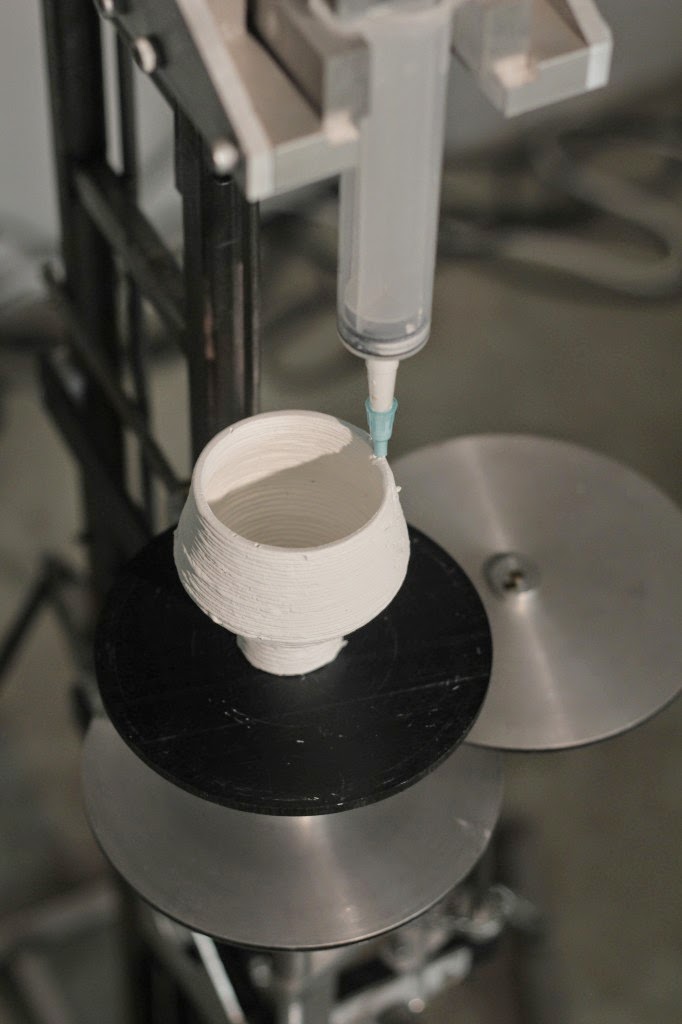

Hal co-founded 3dsystems, a leader in industrial 3D printers. However, this material is not dedicated to these large machines. 3D printing is becoming more and more part of everyday life. Thus, the technology is used to create unique toys, various models, figurines, packaging, clothes, shoes and jewelry. For these purposes, it is not at all necessary to purchase a large-sized printer. You can get by with a small device. It has a compact size, and its technology is completely identical to the industrial one. Heated plastic is fed through the nozzle (spout) of the device, which is laid out on the surface in accordance with the drawing specified in the program. And if earlier such a device was a luxury that only a few can afford, today a 3D printer is available to everyone.

It has a compact size, and its technology is completely identical to the industrial one. Heated plastic is fed through the nozzle (spout) of the device, which is laid out on the surface in accordance with the drawing specified in the program. And if earlier such a device was a luxury that only a few can afford, today a 3D printer is available to everyone.

Top 10 rating according to KP

1. Creality3D Ender 3

Creality3D Ender 3. Photo: market-yandex.ru Our rating opens with a model from the world's largest manufacturer of 3D printers. The Ender 3 features an elegant and thoughtful design, excellent print quality and a wide build area. Manufacturers have provided a good arrangement of wires that do not get confused during operation. The small control unit of the device is located to the right of the work surface. The gadget prints perfectly with various types of plastic. In particular, we are talking about varieties of ABS, PLA, TPU and PETG. The scope of this printer is quite wide. It can be used to produce minifigures, do artistic modeling, and make small prototypes of parts and functional elements.

It can be used to produce minifigures, do artistic modeling, and make small prototypes of parts and functional elements.

Main characteristics

| Print technology | fdm/fff/pjp |

| Field | PLA, Wood |

| Workspace width | 220 mm |

| Workspace height | 250 mm |

| The depth of the workspace | 220 mm |

| Features | Heated table, displays, active cooling, nozzle change, USB, Micro SD |

| Press speed | 180 mm/sec | Number of extruders | 1 |

Pros and cons

Possibility of using various types of plastic, high quality of parts, reliable design

A small display that displays only basic information

2.

FlashForge Adventurer 3 FlashForge Adventurer 3. Photo: market-yandex.ru

FlashForge Adventurer 3 FlashForge Adventurer 3. Photo: market-yandex.ru The model from the Chinese developer FlashForge took the second position in our rating. The device is equipped with a Wi-Fi receiver, a removable heated pad for printing. In addition, manufacturers have provided a built-in webcam, a closed case and a color touch-screen display. The latter, although it does not support the Russian language, is intuitively understandable. The ergonomics of the device is provided by the filament sensor: if the printer runs out of plastic, it automatically goes into standby mode and does not idle.

Pros and cons

Webcam and Wi-Fi receiver allows you to monitor the work, unusual design, simplicity from anywhere in the world in the setup, the presence of a filament sensor

Despite the rather wide functionality, this model is hardly suitable for an experienced printer or a small production due to the small area of the working space, high price

3.

FlyingBear Ghost 5 FlyingBear Ghost 5. Photo: market-yandex.ru from FlyingBear is ideal for semi-professional use. Uniform supply of filament (plastic) provides good opportunities for creating three-dimensional figures with a fairly high resolution. High productivity is achieved thanks to the transparent Dual Drive extruder with BMG double drive. The gadget has a body closed on three sides. Its walls are made of heat-resistant non-toxic ABS plastic. This protection prevents the accumulation of dust on the working parts of the device, which greatly facilitates the maintenance of the printer. The device is controlled using a 3.5-inch color TFT display.

FlyingBear Ghost 5 FlyingBear Ghost 5. Photo: market-yandex.ru from FlyingBear is ideal for semi-professional use. Uniform supply of filament (plastic) provides good opportunities for creating three-dimensional figures with a fairly high resolution. High productivity is achieved thanks to the transparent Dual Drive extruder with BMG double drive. The gadget has a body closed on three sides. Its walls are made of heat-resistant non-toxic ABS plastic. This protection prevents the accumulation of dust on the working parts of the device, which greatly facilitates the maintenance of the printer. The device is controlled using a 3.5-inch color TFT display. Main characteristics

| Print technology | fdm/fff/pjp | |||

| Field | for house/diy, initial level | |||

| Open Camera | Open Camera | Open Cam | ABS, PLA, Wood, HIPS | |

| Workspace width | 255 mm | |||

| Workspace height | 210 mm | |||

| Working space | 210 mm | |||

| Features | Heated table, display, active cooling, nozzle adjustment, temperature control | |||

| Connection | Wi-Fi, SD | , SD , SD 9001|||

| Print speed (extruder speed) | 150mm/s | |||

| Number of extruders | 1 | |||

| Printing accuracy | X, Y 0. 01 mm 01 mm | |||

| Positioning accuracy | Z 0.002 mm |

Pros and cons

Short power cord, inaccuracies in the Russian-language menu, weak airflow system.

4. Anet N4

Anet N4. Photo: market-yandex.ruThe budget model from the Chinese manufacturer Anet N4 is equipped with all the necessary functions for a small domestic production. The base of the device is made of cast aluminum alloy. The weight of the gadget does not exceed 9kg. A transparent tinted hood protects the work surface from external sources of ultraviolet radiation. It can be removed to remove the finished product and clean the printer. Also, manufacturers have provided a removable resin bath and a working platform, which greatly facilitates the use of the device.

Key Features

| Print Technology | LCD | |

| Application | Home/DIY Professional | 30 mm/h |

Pros and cons

Ability to use photopolymer resins from any manufacturer, high polymer curing speed

Small work surface, slightly inferior to competitors in some parameters

Photon Scu0bic0 Anycu0bic08 5. S. Photo: market-yandex.ru

S. Photo: market-yandex.ru In the middle of our rating is the Anycubic Photon S model. It is equipped with an advanced optical system and a large working camera. The device has a matrix light source that provides a uniform luminous flux over the entire plane of the desktop. This allows a very high curing speed of the layers to be achieved. In addition, the printer has an original function that allows you to simultaneously print eight identical models. According to the developers, the target audience for this device are orthodontists and jewelers. Most parts of the device are made of plastic. This factor significantly reduces the weight of the device and makes it convenient to transport.

Plus and minuses

High printing quality

Small worktop

6. ELEGOO Mars Pro

ELEGOO Mars Pro. Photo: market-yandex.ru

Photo: market-yandex.ru This model is significantly different from its predecessor Elegoo Mars. Thanks to the advanced Z-axis mechanics and directional UV light from the diode array, it is suitable not only for hobbies, but also for fields of activity such as dentistry and jewelry. In addition, the developers moved the USB connector to the front of the device. Now there is no need to constantly rotate the gadget in the process. The weight of the device is only 7.5 kg, which makes it very convenient for transportation. A translucent plastic cover will reliably protect against extraneous radiation and will allow you to monitor the production process.

The main characteristics

| Print technology | LCD |

| Scope | for home/diy, for medicine |

| Print speed: (layer build-up) | 22. 5 mm/h 5 mm/h |

| Print precision | X, Y 0.047 mm |

| Positioning accuracy | Z 0.125 mm |

| The wavelength of light source | 405 Nm |

PLASS AND MINCOUSS

Convenient price, LIGHT PRICE

9000 7. Two Trees Bluer Two Trees Bluer. Photo: market-yandex.ru

This is one of the most popular home models of 3D printers. It is ideal for getting acquainted with technology, various experiments, training and prototyping. Distinctive features of Two Trees Bluer are: "quiet" drivers, which are the engine of the device, a heated table, two-way airflow and a thread break sensor. The mechanics of the printer is quite simple, and at the same time very effective. The open type case will be very convenient when cleaning the work surface. The firmware of the device provides the functions of auto-calibration and automatic resumption of printing in case the power was accidentally turned off.

Pros and cons

Low price, easy and convenient to use

Lack of protection for the work surface, poor quality of spare parts

8. Wanhao Duplicator i3 Mini

Duplicator Mini i3. Photo: market-yandex.ruMiniature 3D printer does not look like other devices. However, this feature does not affect its technical characteristics. The plastic spool is located on the right side of the bracket. Wanhao branded coating is pasted over the table. There is no platform heating, so it is recommended to use PLA plastic for printing. The manufacturer clearly states in the manual that the printer is designed to work only with PLA material and nothing else. The body of the gadget is made of sheet steel. The memory card slot and all printer control elements - a monochrome liquid crystal display, a universal knob-button and a Reset micro-button - are placed on the front panel of the printer.

The main characteristics

| Print technology | FDM/FFF/PJP | ||||||||||||||||||

| Field | Educational, for House/DIY, for medicine | ||||||||||||||||||

| Openly Camera | Open | PLA | |||||||||||||||||

| Working space width | 120 mm | ||||||||||||||||||

| Working space height | 100 mm | ||||||||||||||||||

| The depth of the workspace | 135 mm | ||||||||||||||||||

| Features | displays, active cooling, speed control, temperature control | ||||||||||||||||||

| USB, SD card | ) | 70 mm/s | |||||||||||||||||

| Number of extruders | 1 | ||||||||||||||||||

| Printing precision | X, Y 0. 012 mm 012 mm |

| Print technology | FDM/FFF/PJP |

| Scope | Educational, for the house/DIY, Industrial, Professional Material |

| ABS, Flex, Nylon, PLA, PETG, SBS, CopperFILL, DuraForm TPU | |

| Working width | 220 mm |

| The height of the workspace | 250 mm |

| Dent of the workspace | 220 mm |

| Features | Heated table, Active streaming, Control adjustment, Tempension |

| USB, micro-SD | |

| Print speed (extruder speed) | 150 mm/s, |

| Number of extruders | 1 |

Pros and cons

Spacious work surface, robust housing

Little functionality for a rather high price, lack of work surface protection, few functions on the control screen.

10. Tianfour Sparkmaker

Tianfour Sparkmaker. Photo: market-yandex.ruThis model is ideal for beginners, as it does not require additional settings at all before starting work. Externally, the printer has the shape of a cylinder with a height of 27.5 cm and a diameter of 17 cm. The realistic contours and smooth curves of the figures are ensured by LCD technology. The printer works with any photopolymer resins for 3D printing with a flash length of 405nm.

How to choose a 3D printer

Choosing a 3D printer is not such a difficult task as it might seem at first glance. Despite the relentless interest in 3D printing and the incredible number of devices on the market, the basic requirements for models remain unchanged. Komsomolskaya Pravda turned to Svyatoslav Vulf, a blogger and host of a YouTube channel about modern technologies and experiments, for help in this matter. He regularly monitors new products on the 3D technology market and tests them at home.-kupit-v-soin-store.ru-1.png)

Product size

Initially, you should decide what size of products you expect to receive in the end. The required area of the working surface depends on this. Note that the price of the device also depends on the size of the latter. For work at home, there will be enough indicators: 200 × 250 × 200 (WxHxD).

Technology

Today, there are several technologies for printing on a 3D printer. They differ significantly from each other. Let's consider some of them.

SLA-technology — works on the basis of a liquid photopolymer, which under the influence of laser light changes its physical properties and hardens. It allows you to create figurines with the highest precision of microforms.

DLP technology is an alternative SLA method. However, instead of laser systems, LED projectors are used here, which significantly reduce the cost of 3D printers. When using this technology, the future prototype is formed layer by layer.

The FDM method is ideal when prototypes are required that will be actively used and not just sitting on a shelf. Here, high-strength industrial plastics will be used for production. Please note that there are other technologies, but they are very similar to the above.

Material

Before buying a printer, you should also pay attention to what materials it works with, as they have significant differences from each other. For example, ABS can take many different polymeric forms. This is a very durable plastic. It is easily sanded and processed. PLA plastic is considered more environmentally friendly. It is made from agricultural products - corn, potatoes, beets and others. In its original form, it is transparent and can be colored. PLA is just as strong but tougher than ABS. The ductility and heat resistance of SBS make it the material of choice in engineering and mechanical applications.

Noise level and drivers

An important factor when choosing a 3D printer are drivers - device engines (not to be confused with software). They affect the overall noise level of the device. For example, if you buy a printer with cheap A4988, then even neighbors will hear its work. In this case, you should pay a little more and purchase a gadget with more expensive drivers.

They affect the overall noise level of the device. For example, if you buy a printer with cheap A4988, then even neighbors will hear its work. In this case, you should pay a little more and purchase a gadget with more expensive drivers.

Self-assembly

Some manufacturers prepare the model completely before sale. The buyer can only get the printer out of the box and connect the power. However, there are some models that require self-assembly. Be sure to consider this factor before purchasing. If you are purchasing such a device for the first time, then it will not be easy for you to assemble it.

9 tips for choosing a 3D printer

A 3D printer is a unique modern tool that can turn your creative ideas into reality. Whether for work, entertainment or hobby, you will definitely need a quality model. And in order to choose one, it is important to know the main features of these devices, which we have listed in this article.

Almost a decade ago, 3D printers were huge, expensive devices designed for factories and large corporations. They were virtually unknown to the public outside the small circles of professionals who built and used them. But largely thanks to the movement RepRap open source, these exciting devices have become popular and accessible to designers, engineers, startups, schoolchildren and even curious consumers who use them in completely different ways.

They were virtually unknown to the public outside the small circles of professionals who built and used them. But largely thanks to the movement RepRap open source, these exciting devices have become popular and accessible to designers, engineers, startups, schoolchildren and even curious consumers who use them in completely different ways.

And if you suddenly found yourself thinking about the need for such an acquisition, it is important to know how these printers differ from each other, which will allow you to choose the most suitable model. Of course, they are completely different and can be optimized for performance depending on the user or type of printing. That is why before you make a purchase, it is worth considering some of the main features and answering the questions listed below.

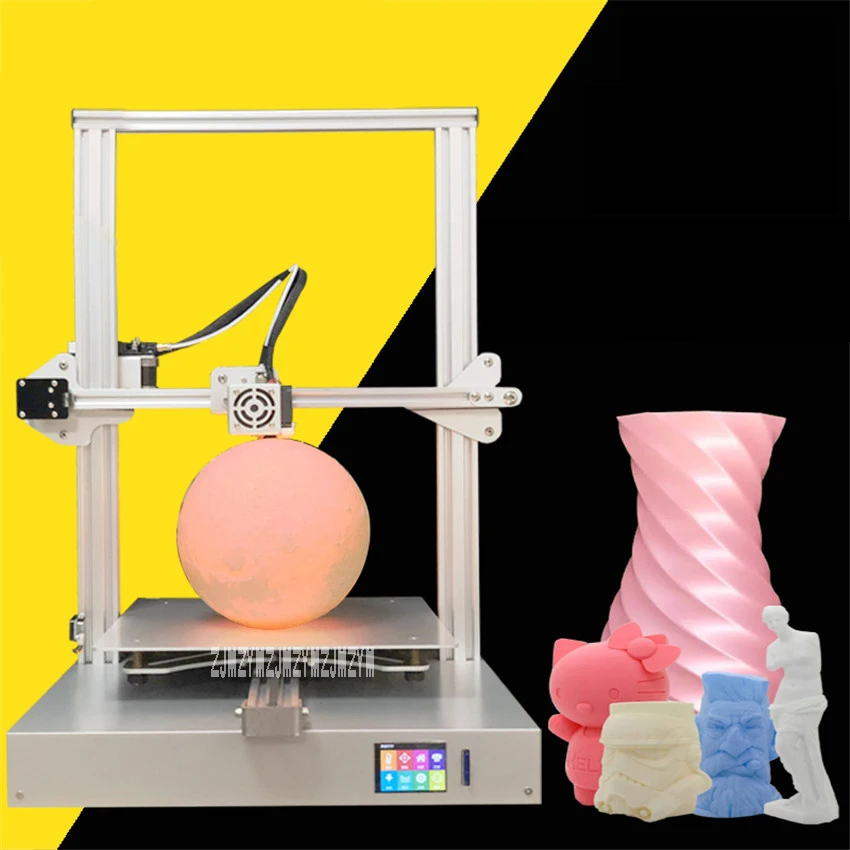

What do you want to print?

Another important question, which is closely related to the main one: Why do you need 3D printing? Do you want to print figurines, toys and more? Or maybe you are an innovator who likes to show off new things to friends and acquaintances? Maybe a teacher with aspirations to install a 3D printer in a classroom or educational center? Or a needleworker who enjoys experimenting with new technologies and projects? Or maybe a designer or architect who constantly prints various prototypes and models of parts or products? What if you're an artist looking to explore the creativity of making 3D objects? Well, or a manufacturer who needs to print plastic products in a short time?

As you can see, there are many questions and your best option will largely depend on how you intend to use the 3D printer. Regular users and schoolchildren will find a model that is easy to set up and manage, does not require serious maintenance, and has satisfactory print quality. Craftsmen and artists will certainly benefit from special features, such as the ability to print multi-color objects or the use of threads of different diameters or compositions. Designers will definitely want excellent print quality. It will be extremely convenient for producers to have a large build area that produces several objects at the same time. Well, various enterprises that want to demonstrate the features of 3D printing to their customers will need an externally beautiful, but no less reliable model.

Regular users and schoolchildren will find a model that is easy to set up and manage, does not require serious maintenance, and has satisfactory print quality. Craftsmen and artists will certainly benefit from special features, such as the ability to print multi-color objects or the use of threads of different diameters or compositions. Designers will definitely want excellent print quality. It will be extremely convenient for producers to have a large build area that produces several objects at the same time. Well, various enterprises that want to demonstrate the features of 3D printing to their customers will need an externally beautiful, but no less reliable model.

Having dealt with this, at least you will determine for yourself the main preferences that you want from the model you are looking for. Nevertheless, there are still many aspects ahead, which are also worth remembering.

Dimensions

It's simple - you need to understand the dimensions of the objects that you plan to print on a permanent basis. Make sure the build area of the 3D printer you like is large enough to fit your needs. The construction area is the maximum space in which an object can be printed using one or another printer printer, corresponding to its maximum dimensions (in theory, since it can be somewhat smaller, for example, if the printing platform itself is not perfectly flat).

Make sure the build area of the 3D printer you like is large enough to fit your needs. The construction area is the maximum space in which an object can be printed using one or another printer printer, corresponding to its maximum dimensions (in theory, since it can be somewhat smaller, for example, if the printing platform itself is not perfectly flat).

The average build area of 3D printers is usually between 8 and 12 square centimeters, but this can vary around the edges, although some of the current models are square. The main thing to remember is that the indicated dimensions of the construction area are not the dimensions of the printer itself, since the latter, of course, are larger. This is also worth considering if you are limited in the free space for its installation.

Consumables

Most budget 3D printers use FFF (Fused Filament Fabrication) technology, in which plastic filament is unwound from a spool, melted and fed through an extruder to a work surface, and then solidified to form the outline of an object. The most common types of filaments on the market (plastic filaments) are ABS plastic and polylactide (PLA). Of course, each of them has slightly different properties. For example, the former has a much higher melting point than the latter and is much more flexible, although it emits fumes during printing that are considered unpleasant by most users and needs a heated bed. Printed models made of polylactide are visually more pleasant, but, as a rule, are more fragile.

The most common types of filaments on the market (plastic filaments) are ABS plastic and polylactide (PLA). Of course, each of them has slightly different properties. For example, the former has a much higher melting point than the latter and is much more flexible, although it emits fumes during printing that are considered unpleasant by most users and needs a heated bed. Printed models made of polylactide are visually more pleasant, but, as a rule, are more fragile.

Other materials used in 3D printing are equally efficient filaments filled with polystyrene, wood, bronze and copper, photopolymers, nylon, PVA plastic and more. Each of them has a different melting temperature, which is logical, because the use of the listed threads in work may be limited by the features of your printer or devices with special software that allows user control over the temperature of the extruder.

Filament is most often supplied in several basic diameters: 1.65 mm, 1.75 mm and 3 mm. And most of the current printer models often work with them, or even with the thinnest of them. They are supplied in coils, each usually 0.75-1 kg. Even though many 3D printers accept any available spools, some companies' advanced models use only cartridges or their own patent-protected variants. It is important to make sure that the filament is the correct diameter for your printer and that the spool itself is the right size. In most cases, you can purchase or even print a spool holder yourself to fit their different sizes.

And most of the current printer models often work with them, or even with the thinnest of them. They are supplied in coils, each usually 0.75-1 kg. Even though many 3D printers accept any available spools, some companies' advanced models use only cartridges or their own patent-protected variants. It is important to make sure that the filament is the correct diameter for your printer and that the spool itself is the right size. In most cases, you can purchase or even print a spool holder yourself to fit their different sizes.

Stereolithographic printers are good at printing high quality models and prototypes of finished designs from bottled liquid photopolymer resin. It hardens by irradiation with an ultraviolet laser. Previously, the color palette of available resin colors was rather limited: mostly clear, white, grey, black or gold. Today, you can find more "exotic" colors like green, blue and orange. Working with liquid resin and isopropyl alcohol, which is used in the processing of printed parts, can create a mess.

Print resolution

The 3D printer melts successive thin layers of plastic according to the parameters pre-written in the file for a particular object. For 3D printing, resolution is equal to the layer height, in other words, it is the minimum thickness of one layer that the printer can work with. It is measured in microns, as you know, 1 micron is equal to 0.001 mm, and here the smaller the number, the higher the resolution. This is achieved by the fact that the number of layers required for printing directly depends on the thickness of the layer (less layers - more of them), and the details, respectively, are much smoother and more expressive. And, of course, in the opposite direction, everything works exactly the opposite. The thicker the layer, the coarser the print, but the process itself does not take much time, which can be useful in certain situations.

Almost all 3D printers sold today can print at 200 microns, which should produce pretty good results or better, and many can even print at 100 microns, which produces even better results with good detail. Of course, there are much more interesting models on the market that can print with a resolution of up to 20 microns. However, to do this, you may need to go beyond the preset resolutions and go deep into the user settings, allowing the resolution to be less than 100 microns.

Of course, there are much more interesting models on the market that can print with a resolution of up to 20 microns. However, to do this, you may need to go beyond the preset resolutions and go deep into the user settings, allowing the resolution to be less than 100 microns.

It is logical that the price for a higher resolution can be equivalent to premium models, which can be considered a drawback to some extent. As well as the fact that the print time at high resolution increases significantly. Decreasing the resolution will cut it by about half what is required for a particular object. But for professionals who require high quality printed objects, the extra time is well worth it. The field of consumer 3D printing for general users and craftsmen is still in its infancy. However, technology is advancing at a fairly rapid pace, making these products more and more affordable. And many have long wondered what innovations the next year will bring.

Colors

There are also 3D printers with more than one extruder and they provide the ability to print objects in multiple colors. Most of them are printers with two extruders, each with different colors of filament. The only catch here is that they can only print multi-color objects from certain multi-color files, where each color has a separate file so that the objects of different colors fit together like a (3D) puzzle.

Most of them are printers with two extruders, each with different colors of filament. The only catch here is that they can only print multi-color objects from certain multi-color files, where each color has a separate file so that the objects of different colors fit together like a (3D) puzzle.

Work Platform

The importance of the printer's work platform (the surface on which the printing process takes place) may not be entirely obvious to those new to 3D printing, but in fact it is likely to be extremely important. A quality platform allows the object to stick to it during the printing process, but should also allow it to be easily removed at the end of the process. The most common among them is a heated platform with a glass surface, sealed with blue masking tape. Objects adhere well to it, and are easily removed afterwards. The presence of a heated platform will avoid twisting the bottom corners of printed objects to the top, which is a common problem, especially when working with ABS plastic.

Glue stick is also applied to the surface of some working platforms, of course, to increase adhesion. And this, in principle, works, especially if the object can be easily removed after printing. In some cases, it is necessary to dip both the platform and the printed object in warm water to separate them. There are also models that use perforated platforms with tiny holes that fill with melted plastic during printing. The problem with this method is that although the object is securely connected, it may not be easy to detach the object afterwards. Using an awl to push the hardened plastic plugs through the holes to release the result and/or clean the platform is a laborious and unsafe process.

If the build platform tilts over time, this can make printing very difficult, especially when working with large objects. Most 3D printers offer platform calibration manuals or provide a special alignment procedure by moving the extruder to different points around the platform perimeter to determine that they are all at the same height. A small but growing number of 3D printers offer automatic build platform leveling.

A small but growing number of 3D printers offer automatic build platform leveling.

Installing the extruder at the required distance from the platform immediately before work is no less important for some printers. This z-axis calibration is most often done manually by lowering the extruder until it is close enough to the build platform that it slightly interferes with the movement of a sheet of plain paper placed between them. Here, again, there are several models that perform this calibration automatically.

Construction

This is the preferred type of 3D printer construction. Models with a closed structure have, respectively, a closed structure with a door, walls and a roof. Open models provide easy visibility into work in progress and quick access to the build area and extruder. At the same time, closed-type printers are safer, preventing children or pets (or adults) from accidentally touching a hot extruder. It also offers quieter operation, reducing fan noise and possible odor, especially when using ABS plastic, which may remind some users of the smell of burnt plastic. And he's not the most pleasant.

And he's not the most pleasant.

Connection

Most 3D printers start the printing process with a computer over a USB connection. There are also models with their own internal memory, which gives them the distinct advantage of allowing you to save a print job there and continue printing even if the USB cable is disconnected or the computer is turned off. Some printers also offer wireless connectivity, either over Wi-Fi or peer-to-peer. The disadvantage is that print files can be up to 10MB in size and can take a long time to transfer. Another connection method that is present on some models is Ethernet.

Many printers also have SD memory card slots from which you can load and print 3D files using the printer's controls and display, while others have USB ports. The benefit of printing directly from media is that you don't need a PC. As a rule, in addition to the standard connection thanks to the USB cable, models offer at least one of the listed connection options, if not several at once.

Software

Modern 3D printers come with the appropriate software available on disk or as a digital download. They are compatible with Windows and in most cases also work with macOS or Linux . Until relatively recently, all these 3D printing programs consisted of several separate softwares, including the printing program itself, which controls the movements of the extruder, “healing” software that allows you to optimize the printed file, a “cutter” that prepares layers for printing with the required resolution, and a programming language Python . All of these individual components have become widely available thanks to the RepRap open source project, which spurred the development of affordable 3D printers, but today their manufacturers have bundled them all into convenient packages. And yet, if desired, some models will give you the opportunity to use individual software components.

Conclusion

So, you have got acquainted with the main features of 3D printers, as well as with what you need to consider before buying them and in work directly.