3D printing help reddit

gettingstarted - 3dprinting

- Getting Started

- Why 3D Printing?

- Getting started with 3D Printing

- Where to get a model printed

- What printer to get

- Where to find models

- Material Choices

- Slicers

- Printing and Troubleshooting

- Post Processing

- How to make models

- Further Info

| If you're new around here, welcome! We thought we'd put a few links together to springboard your foray into the fabulous (and sometimes frustrating!) world of 3D printing. :) |

|---|

| If you are contributing to this wiki please keep this page incredibly concise and extremely high level, keep further detail for the Detailed Info pages. |

Why 3D Printing?

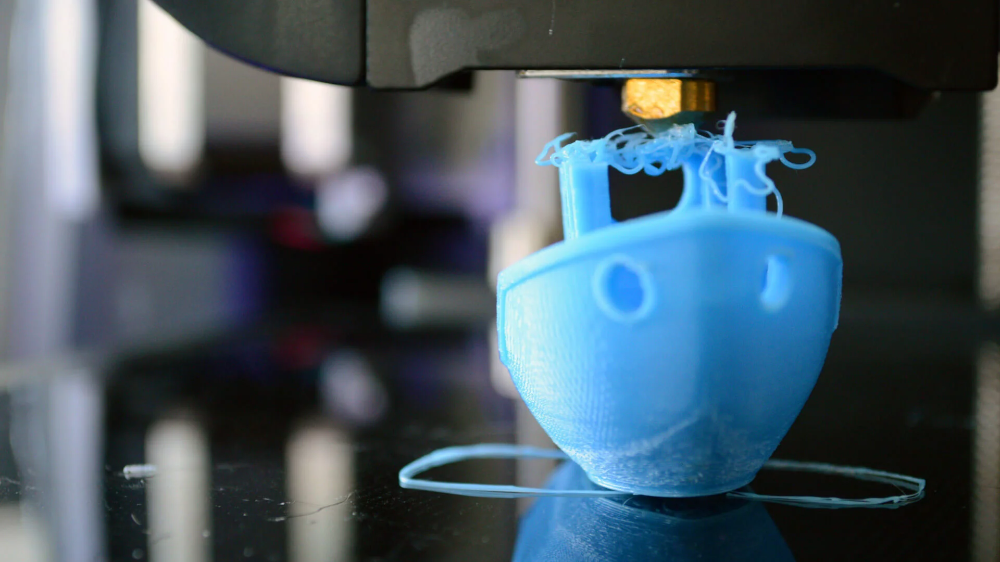

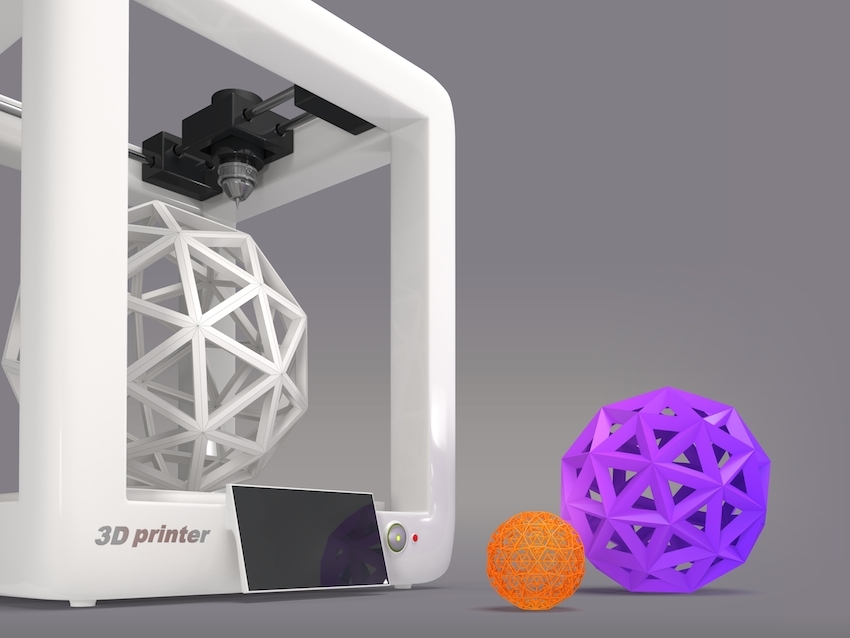

3D printing (a.k.a Additive Manufacturing) is now pretty well established in industry as a prototyping tool, and is becoming more common as a process for creating finished custom or low-run parts.

In the home, printers can be a marvelous tool for solving practical household problems for example by repairing items, or creating new items that are fully customised for their position or use case. They also can be used for fun, and are popular for making tabletop gaming minis, and toys.

For inspiration browse the top posts of this subreddit.

Getting started with 3D Printing

The various types of 3D printing technologies all create real-world three-dimensional objects from digital models via the addition of material. These processes are able to produce novel structures that other manufacturing techniques cannot. Usually the 3D printing process looks like this:

Get a digital 3D model (by downloading or making one)

Slice it (use a program to generate instructions for the printer)

Print it (and troubleshoot it)

Post-process it (remove support material, clean up areas, paint etc)

Where to get a model printed

If you don't want to buy a printer (and you just want to have something printed), you can engage the help of a 3D printing service. Some popular choices include:

Some popular choices include:

For a full list of service-providers (including design and model hosting services), please see the Services page.

What printer to get

If you're totally new to printing, the best place to ask for help when deciding what printer is right for you is our stickied monthly Purchase Advice Megathread.

Generally personal printers come in two main categories;

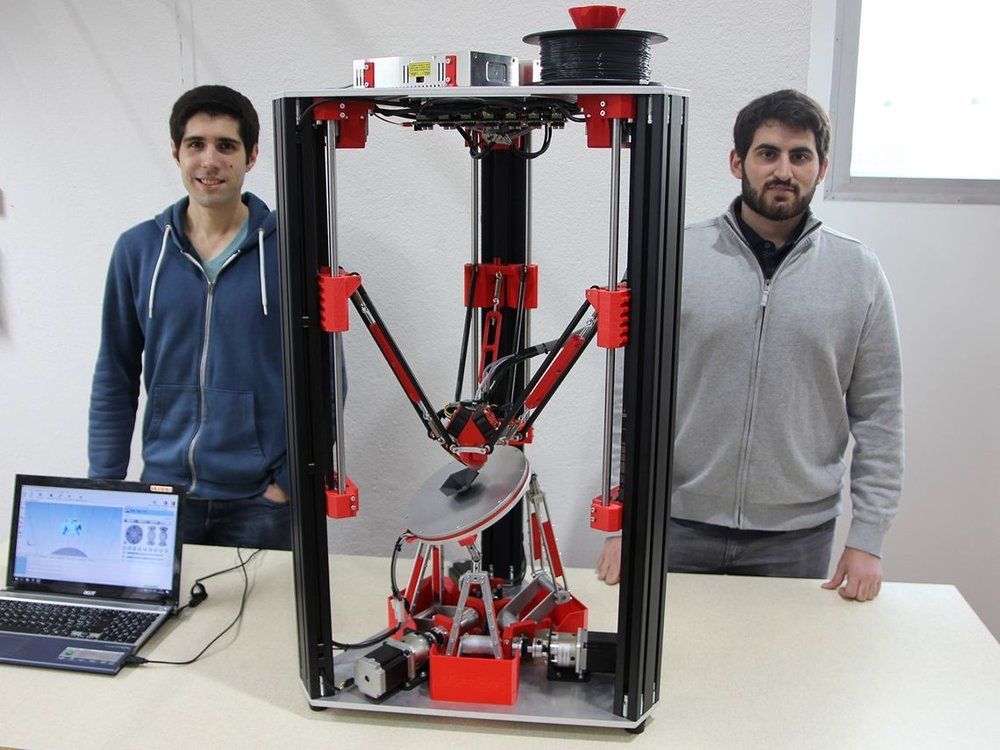

FDM (FFM) printers are best suited to larger objects and functional parts and work a bit like a like a hot glue gun that moves around, extruding plastic filament and building up an object layer by layer.

DLP (Layer Masking) printers are best suited to extremely detailed prints, and use light to cure resin in layers, masking it with an LCD screen.

There are, however, many other types of 3D printing technologies, which are explained here.

Where to find models

If you don't want to make your own models to print, there are many sites that host models for download. The more popular ones are:

The more popular ones are:

Printables: upcoming and community-focused, feature-rich

Thingiverse: biggest model host, often buggy

Thangs: free models, which can be searched by geometry

My Mini Factory: free and paid models, guaranteed to print

GrabCad: functional/ technical models

YouMagine: Open source models

pinshape: free and paid models

yeggi: 3D model aggregator/search

CGTrader: free and paid models, not all of them made to be printed

A community-curated list of model host services can also be found on the services page.

The RepRap foundation also keeps a list of printable model-host services here.

When selecting a model you need to ensure they are manifold, here's an explanation of what that means and guide on fixing them. You can also try these free, automated services; Netfab, and Microsoft's tool

Material Choices

When you are just starting out with FDM 3D printing PLA is the recommended choice. It's very easy to work, relatively strong, with and comes without many of the safety concerns of other materials. A deeper discussion of materials can be found here.

It's very easy to work, relatively strong, with and comes without many of the safety concerns of other materials. A deeper discussion of materials can be found here.

If you are starting on a resin printer, check out our Resin Info page.

Slicers

Slicing software takes a 3d model and turns it into instructions for the 3D printer. The instructions are generally exported in GCode which essentially is a list of locations to move to, amount of filament to extrude, etc.

The popular choices for slicing software are:

Ultimaker Cura: free, open source, highly customisable. Getting Started, Full Manual

Prusa Slicer (Based on Slic3r), Beginning with Prusa Edition (old version)

There are, however, many other options, most of which are discussed here

Be sure to check the layer preview to see if it makes sense in your slicer before printing (no unsupported overhangs, no parts missing, etc). More info on the Slicers Page

Printing and Troubleshooting

Follow your manufacturer's instructions in setting up your printer and starting your first print. It's a good idea to print a test print first (usually printers come with one).

It's a good idea to print a test print first (usually printers come with one).

If it succeeds congrats on your first print! You can now start slicing and printing your own models or some calibration prints

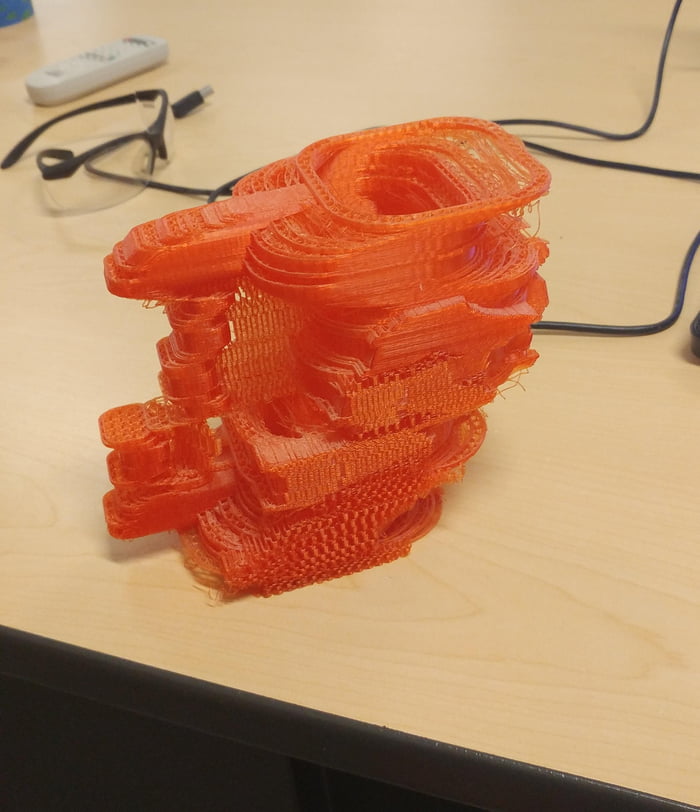

If your print fails you can begin troubleshooting.

This video helps you get to know the parts of your machine, so you know what we're talking about! :)

By far the most common reason for prints failing is an issue with levelling/tramming:

Full-resolution printable copy can be found here.

This visual reference, and this video may also help.

Once you have your prints sticking and printing, these guides can help you identify and solve any other issues you're experiencing:

Our Troubleshooting and Calibration wiki page

A Printa Pro PrintaGuide

rigid.ink poster and visual guide

Matterhackers Troubleshooting Guide

Simplify 3D Visual Troubleshooting Guide

Ultimaker Visual Troubleshooting Guide

RepRap Wiki Pictorial Troubleshooting Guide and Descriptive Troubleshooting Guide, these are a bit more technical/ advanced

It's also worthwhile seeking information from the manufacturer of your machine.

You can try searching for similar issues that other folk have experienced in the following communities: /r/3Dprinting, /r/FixMyPrint, the 3D Printers Discord

If the above suggestions don't solve your issue then it's time to seek help from the community:

This video is a great overview on how to seek help with prints.

The best places to ask for help are here on /r/3Dprinting, /r/FixMyPrint, the 3D Printers Discord. When asking for help be sure to provide the following:

- A highly descriptive title (even if you don't know exactly what everything is officially called, please do your best to describe the issue in plain English. This not only helps you get the help you want, but also helps the rest of the community by keeping the sub searchable, so others can benefit from the help you receive.)

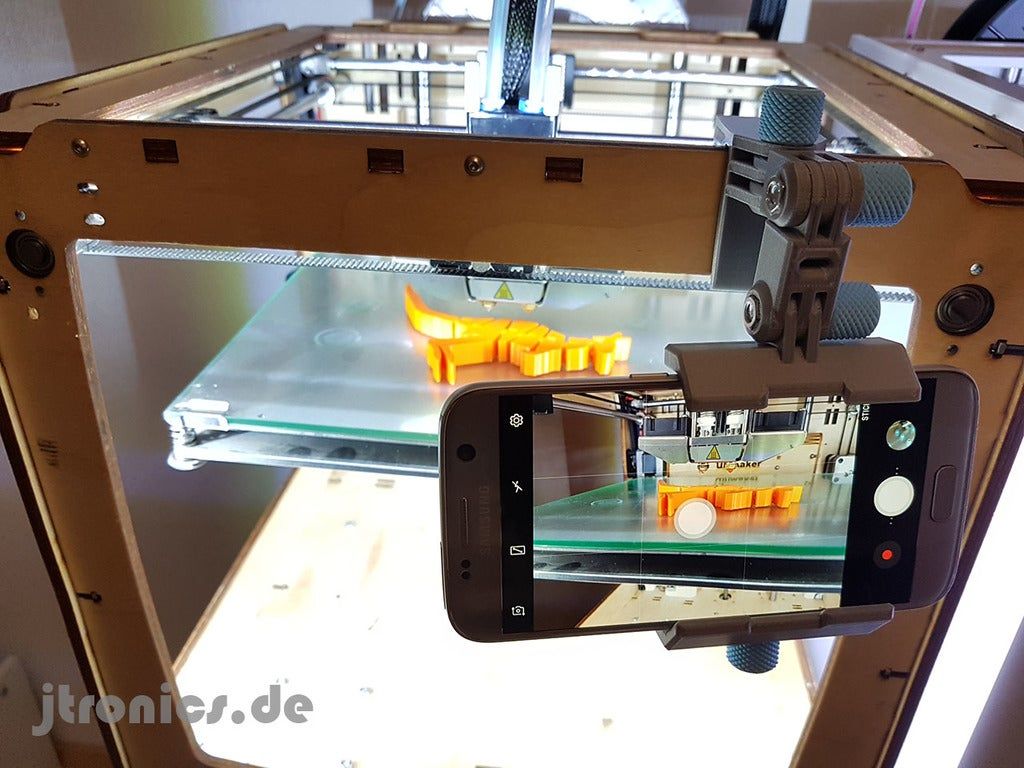

- Photos of the issue, screengrabs of the layer view in your slicer, screengrabs of the model itself.

- A description of what the machine was doing as it produced this issue.

- Your basic settings such as: nozzle and bed temperature, speed, nozzle/line width and later height, the printer you're using and the material you're printing in. Or better yet, a screengrab or an export of your settings (you can upload files free without an account here)

- Any other information you think could be relevant such as modifications or hypotheses.

Post Processing

Most prints need some work after they come off the printer to turn them into a finished part. Supports need to be removed, and surfaced may need to be smoothed. Here are some tutorials:

- How to finish 3D Prints guide

More info on the Post Processing page

How to make models

Can't find what you want online? Why not design and make it? Model-making software is split into 4 main categories, depending on your goal:

Full-resolution, printable copy here

These are just the top picks, model making is discussed in more depth on the Making Models page

More communities:

/u/Devtholt keeps a Multireddit of all 3d printing subreddits including some specifically for help, or tailored to certain printers or printer manufacturers.

Also has some subs that are related to 3D printing peripherally, such as /r/lasercutting and /r/CNC

Also has some subs that are related to 3D printing peripherally, such as /r/lasercutting and /r/CNC3D Printers Discord great platform for troubleshooting and socialising.

RepRap Forums

troubleshootingandcalibration - 3dprinting

troubleshootingandcalibration - 3dprintingLooks like you're using new Reddit on an old browser. The site may not work properly if you don't update your browser ! If you do not update your browser, we suggest you visit old reddit .

Press J to jump to the feed. Press question mark to learn the rest of the keyboard shortcuts

Search all of RedditFound the internet!

Feeds

Popular

Topics

ValheimGenshin ImpactMinecraftPokimaneHalo InfiniteCall of Duty: WarzonePath of ExileHollow Knight: SilksongEscape from TarkovWatch Dogs: Legion

NFLNBAMegan AndersonAtlanta HawksLos Angeles LakersBoston CelticsArsenal F. C.Philadelphia 76ersPremier LeagueUFC

C.Philadelphia 76ersPremier LeagueUFC

GameStopModernaPfizerJohnson & JohnsonAstraZenecaWalgreensBest BuyNovavaxSpaceXTesla

CardanoDogecoinAlgorandBitcoinLitecoinBasic Attention TokenBitcoin Cash

The Real Housewives of AtlantaThe BachelorSister Wives90 Day FianceWife SwapThe Amazing Race AustraliaMarried at First SightThe Real Housewives of DallasMy 600-lb LifeLast Week Tonight with John Oliver

Kim KardashianDoja CatIggy AzaleaAnya Taylor-JoyJamie Lee CurtisNatalie PortmanHenry CavillMillie Bobby BrownTom HiddlestonKeanu Reeves

Animals and PetsAnimeArtCars and Motor VehiclesCrafts and DIYCulture, Race, and EthnicityEthics and PhilosophyFashionFood and DrinkHistoryHobbiesLawLearning and EducationMilitaryMoviesMusicPlacePodcasts and StreamersPoliticsProgrammingReading, Writing, and LiteratureReligion and SpiritualityScienceTabletop GamesTechnologyTravel

Create an account to follow your favorite communities and start taking part in conversations.

Join Reddit

r/

3Dprinting

r/3Dprinting

- Troubleshooting and Calibration

- First Steps

- Troubleshooting

- Solutions for specific issues

- Calibration

- Seeking help

- Specific Printer Guides

This page is incomplete. You can help by expanding upon it. You can help by expanding upon it. |

|---|

| If you've not contributed to this wiki before, some guidance and help can be found on this page: How to contribute to this wiki. |

First Steps

It will help you to have a basic understanding of the parts of your 3D printer and how it works.

50 parts in 5 minutes This video helps you get to know the parts of your machine, so you know what you're talking about! :)

Your hot end explained. This one help you understand how one of the most important parts of your printer (and likely the one you'll encounter most of your issues with) works, and how to treat it well. :)

Troubleshooting

These guides can help you identify and solve any issues you're experiencing:

rigid.ink poster

Ultimaker Visual Troubleshooting Guide

Simplify 3D Visual Troubleshooting Guide

RepRap Wiki Pictorial Troubleshooting Guide and Descriptive Troubleshooting Guide, these are a bit more technical/ advanced

all3DP common problems

It's also worthwhile seeking information from the manufacturer of your machine.

You can try searching for similar issues that other folk have experienced in the following communities: /r/3Dprinting, /r/FixMyPrint, the 3D Printers Discord

Solutions for specific issues

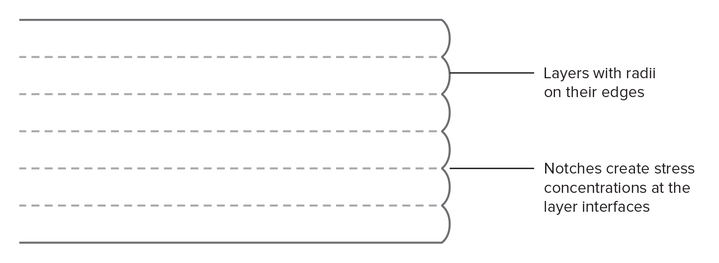

Full-resolution printable copy can be found here.

Leveling (tramming (AKA My first layer wont stick!!!)) is by far the most common reason for prints failing. The following guides will assist you:

- Written Guide/Assistance GCode/Complementary videos

- Written Guide

- Infographic/Poster

- Visual reference

- Video

Clearing clogs

- Video

- Video

- Video

Adjusting Eccentric Nuts Eccentric Nuts can be hard to understand if you are new to the hobby. If anything on your printer has play, its probably due to the Eccentric Nuts not being properly calibrated. Check out this video on how to properly adjust the eccentric nuts and remove wobble

Under-extrusion if you see this issue (described in the above image guides) check for the following:

- Incorrect filament diameter set in the slicer

- Mismatched volumetric extrusion settings between printer and slicer (whether extrusions are written/read in distance (mm) or volume (mm³))

- Printing too cold (note that optimal temperatures can vary even within brand and material)

- Extruder hobb getting gummed up so it no longer grips the filament well

- Incorrect tension on extruder leading to insufficient grip (can be due to a broken extruder arm)

- Loose hobb set/grub screw (motor spins but the hobb slips)

- Resistance on the filament, if the spool doesn't spin freely enough or something else holding the filament back

- Coasting with too high coasting volume set in slicer

- Partially clogged nozzle

- E-steps needing calibration (note that this can mask other causes, and most non-DIY printers (including kits) already have this correctly calibrated)

- Stepper motor driver dying

- Glitching stepper motor connections

- Moisture in filament (you will likely hear popping in the hotend.

maybe not technically underextrusion, but looks similar)

maybe not technically underextrusion, but looks similar)

Calibration

Once your printer is functional it's time to start calibrating!

Let's Print 3D has a great written guide about 5 Calibration Tests to Achieve the Perfect 3D Prints

Hobby Hoarder has a good video explaining how to calibrate a 3D printer and first things you should print

Triffid Hunter has made a nice calibration guide on the reprap wiki

Desi Quintan's guide on tuning flow rate (or extrusion multiplier in some slicers): Calculating flow rate for your 3D slicer

Musings on retracts

Improved Temperature Tower Script

Seeking help

If the above suggestions don't solve your issue then it's time to seek help from the community:

This video is a great overview on how to seek help with prints.

The best places to ask for help are here on /r/3Dprinting, /r/FixMyPrint, the 3D Printers Discord.

When asking for help be sure to provide the following:

When asking for help be sure to provide the following:- A highly descriptive title (even if you don't know exactly what everything is officially called, please do your best to describe the issue in plain English. This not only helps you get the help you want, but also helps the rest of the community by keeping the sub searchable, so others can benefit from the help you receive.)

- Clear photos of the issue, screengrabs of the layer view in your slicer, screengrabs of the model itself.

- A description of what the machine was doing as it produced this issue.

- Your basic settings such as: nozzle and bed temperature, speed, nozzle/line width and later height, the printer you're using and the material you're printing in. Or better yet, a screengrab or an export of your settings (you can upload files free without an account here)

- Any other information you think could be relevant such as modifications or hypotheses.

Specific Printer Guides

Guide for new Creality Ender 3 Owners (contains advice, mods, and more)

Flashforge Resources

Critical safety upgrades for an Anet A8

Last revised by

167488462789590057

-

1 month ago

About Community

/r/3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

Created Mar 4, 2010

Useful Links before Posting

Before Posting for Help, consider searching if your issue hasn't already been answered, or look for answers in our Wiki sections

r/3dprinting Rules

Posts must be 3D-printing-related

Requests for purchase advice must go in the stickied megathread

Less than 10% self-promotion

Community Behavior

Monday is Meme Day. You can only post Memes on Monday

First layer Fridays, Spaghetti Saturdays

No Karma/Repost Bots

Filter by Flair

News

Project

Discussion

Troubleshooting

Meta

Question

No File

Paid Model

Meme Monday

Moderators

Moderator list hidden. Learn More

ImpressumReport NetzDG Content

helpTransparency report

User AgreementPrivacy policy

Content policyModerator Code of Conduct

Reddit Inc © 2022. All rights reserved

All rights reserved

Reddit and its partners use cookies and similar technologies to provide you with a better experience.By accepting all cookies, you agree to our use of cookies to deliver and maintain our services and site, improve the quality of Reddit, personalize Reddit content and advertising, and measure the effectiveness of advertising.By rejecting non-essential cookies, Reddit may still use certain cookies to ensure the proper functionality of our platform.For more information, please see our Cookie Notice and our Privacy Policy .

Advertisement

Examples of positive and negative applications of the 3D printer

Every year 3D printing becomes more and more popular. The 3D printer, as a tool for turning a digital model into a physical object, is gaining popularity, outperforming other production methods in many ways due to its affordability.

But do not forget that a 3D printer is just a tool. A lot depends on how this tool will be used.

Available 3D printing technologies

All 3D technologies can be conditionally divided into 4 types.

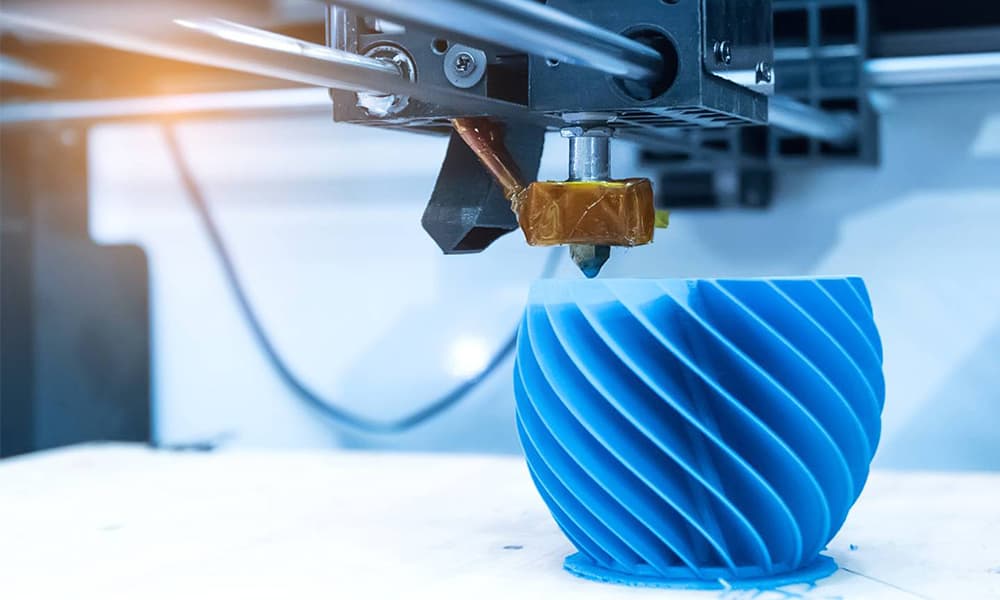

Layer by layer welding with molten material.

The principle of operation is similar to the familiar glue gun. The print media is melted to a semi-liquid state in the print head and applied with a nozzle to the print surface where it solidifies. This is how the finished 3D model “grows” layer by layer on the printing table. Not only thermoplastics can be used as consumables, but, for example, chocolate, icing, concrete, etc.

This is the most common type of printer. Inexpensive FDM printers are often used as home assistants. This is facilitated by an inexpensive price and a variety of consumables.

Selective curing of resin (photopolymer printers).

The material used is a photopolymer resin that hardens under the influence of UV radiation. As a source of UV radiation, a thin laser beam, a DLP projector or an LCD screen with a UV matrix, or any other design can be used. For example, some industrial 3D printers apply a photopolymer using thin nozzles and immediately illuminate it with a UV lamp.

For example, some industrial 3D printers apply a photopolymer using thin nozzles and immediately illuminate it with a UV lamp.

Previously, these printers were quite expensive. Today, with advances in technology, photopolymer 3D printing has become affordable and photoresin printers have become popular as home hobby printers.

Selective bonding of powdered material.

On the print head of the printer there are several nozzles through which a binder is supplied, which is selectively applied to the powdered material. Various materials can be used as a material: for example, gypsum or metal powders. But gypsum is most often used.

Since dye can be added to the "glue" during printing, such printers are usually used for the production of color demonstration models or souvenirs.

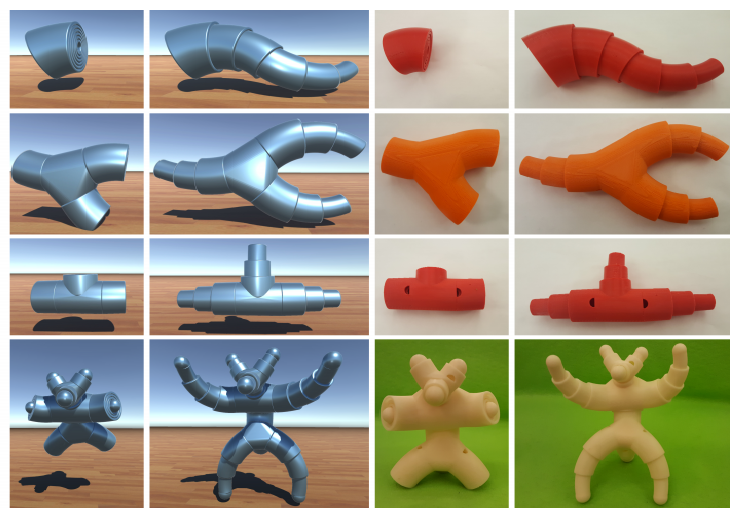

Laser sintering of powdered materials.

The youngest technology, but with great potential for use in large-scale production. With the help of a laser or a heated print head, selective sintering of the metal powder occurs in an environment filled with an inert gas.

These are already serious industrial printers that are used for the production of functional metal assemblies and parts. Currently, such 3D printers are actively used in the aerospace industry.

Unethical use

3D piracy

Where there is duplication of objects, there are always disputes about copyright and piracy.

The production of any product is a long and painstaking work, and often more than one person. Before you get a finished decorative product, for example, a figurine, you need to think through everything to the smallest detail. Usually, before modeling, the artist draws a lot of sketches, the details of clothing and accessories are thought out. Only after that the 3D modeler gets to work and begins painstakingly recreating the 3D model.

Functional models are often redesigned by engineers after the prototype has been made. There can be a very long way between the initial idea and a stable working mechanism. And it’s very disappointing when such work is simply copied and posted in the public domain.

LEGO

It was one of the first mass manifestations of "3D piracy". At that time, 3D printing was only gaining popularity, and many users, having printed a dozen figurines, were looking for a useful application for a 3D printer. Given the low plastic consumption, the printed LEGO blocks were very inexpensive.

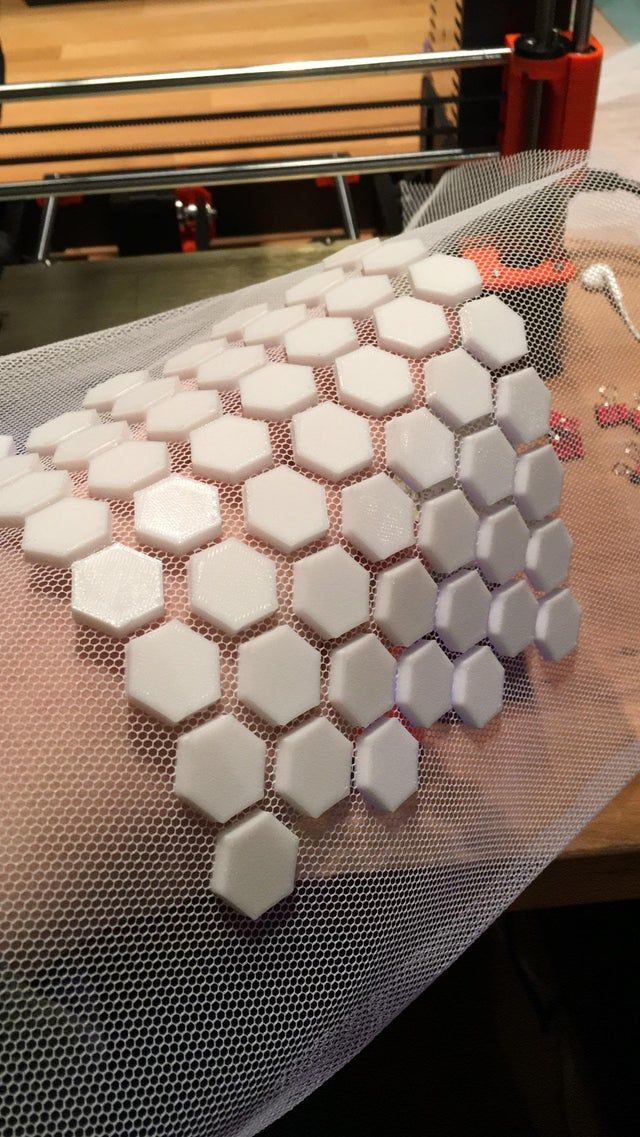

3D printed LEGO bricks

Despite the far from ideal surface, many were satisfied with such a copy. Some have argued that the accuracy of a home FDM printer is not enough for the bricks to fit well with the original LEGO, but for most users everything fit perfectly.

At the moment, LEGO is actively removing models that copy the original sizes of the famous bricks and men from the network. On popular sites, only custom elements of LEGO-men and LECO are left that are not the original size.

Custom heads for LEGO men

Games Workshop

Games Workshop, which produce the most expensive table soldiers in the world, sued Thomas Valenti (USA) back in 2012. Thomas has modeled, printed and made publicly available several miniatures based on the Warhammer universe. The court sided with Games Workshop and the models had to be removed.

Thomas has modeled, printed and made publicly available several miniatures based on the Warhammer universe. The court sided with Games Workshop and the models had to be removed.

3D Printed Chaplain

Chaplain 3D model from Warhammer 40k

Games Workshop went one step further by banning fans from creating art and other work based on the original settings and characters. As a boycott, users of the Warhammer 40,000 section on Reddit are proposing to abandon the company's products as much as possible - print game figures on 3D printers, use paints from other companies, or switch to other universes.

Hollywood

The production of modern films is not a cheap pleasure, and film companies try to recoup their costs not only by showing them in cinemas, but, for example, by producing souvenirs.

DreamWorks has an entire consumer goods division that helps recoup the cost of a movie if it fails at the box office. Film companies recognize that fan-made productions often surpass the official "souvenir" in accuracy and detail.

Film companies recognize that fan-made productions often surpass the official "souvenir" in accuracy and detail.

DC Universe Batman fan model

Many film companies are closely following the development of 3D printed merchandise, but do not yet know how to respond. For example, Paramount Pictures, Marvel Studios and Warner Bros. They themselves began to upload models for 3D printing to the network, before the release of new films.

Weapon Seal

Seal of weapons

24-year-old law student Cody Wilson was the first to make a gun on a 3D printer. Cody designed and 3D printed a combat pistol on his own. After 8 years, the idea of making firearms using 3D printing has not only not died out, but flared up with a bright fire.

It started in Texas in 2012. It was there that the company Defense Distributed was registered, the ideology of which was the development of models of firearms that anyone could make on a home 3D printer.

Guns

Liberator

The first “swallow” was the Liberator - a compact plastic pistol printed on a 3D printer from ABS plastic. The only thing that could not be made on a 3D printer was the striker, which was successfully replaced by an ordinary nail. The first printed pistol was made on a Stratasys Dimension SST 3D printer.

Liberator - the name is borrowed from a cheap pistol that was developed in 1942 in the USA.

The Liberator fired a fairly weak .380 ACP round and could only last a dozen rounds at most.

Failed Liberator

Zig Zag

In the spring of 2014, a video appeared on the Internet with a man shooting from a plastic revolver with a huge drum. The video greatly stirred up all of Japan.

Zig Zag

Unknown was Yoshitomo Imura (Yoshitomo Imura) - 28-year-old employee of the Shonan Institute of Technology. Despite Imuru's claim that he fired blanks on the tape, he was arrested and sentenced to 2 years in prison.

Despite Imuru's claim that he fired blanks on the tape, he was arrested and sentenced to 2 years in prison.

The Zig Zag design was a reimagining of revolvers popular in the 19th century, which used a rotating .38 caliber barrel block mounted on a pistol grip.

Washbear

In 2015, mechanical engineering student James Patrick posted a video online showing a 3D printed PM522 Washbear in operation.

PM522 Washbear

The PM522 visually resembled a children's pistol from a science fiction movie, but at the same time the pistol had a strong and rigid frame. Washbear is also safer than its predecessors. At rest, the firing mechanism was not in line with the primer, so the PM522 was protected from accidental firing, for example, when dropped. The only metal part was the nail that replaced the striker.

Rifle

Grizzly

Canadian with the nickname CanadianGunNut, ThreeD Ukulele or simply Matthew, inspired by the Liberator project, designed and posted his project - Grizzly. Grizzly is an ABS+ plastic rifle. It took the Canadian 3 days to design the rifle and another 27 hours to manufacture it using a Stratasys Dimension 1200es industrial 3D printer.

Grizzly is an ABS+ plastic rifle. It took the Canadian 3 days to design the rifle and another 27 hours to manufacture it using a Stratasys Dimension 1200es industrial 3D printer.

Grizzly 9 Rifle0063

The first version of the Grizzly had a smooth and straight .22 barrel. But this turned out to be not a very good decision, and the barrel cracked after the first shot. Subsequently, Matthew replaced the barrel with a tapered barrel with rifling inside.

Plastic “cutting” could not affect the ballistics of the bullet in any way, but added strength to the barrel.

Shotgun

Liberator 12k

The Liberator 12k is a 12-round shotgun made by a well-known, in narrow circles, enthusiast in the world of 3D printing - Jeff Rodriguez.

Liberator 12k

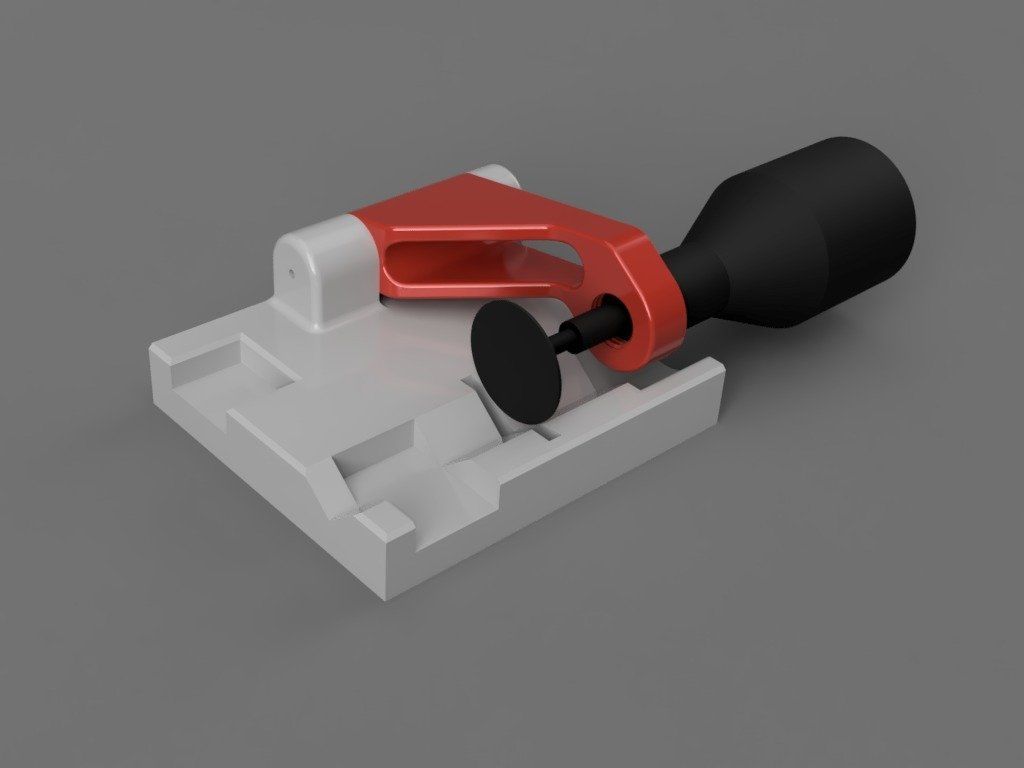

Rodriguez managed to create a simple and at the same time reliable design, "mixing" a pistol and a pump-action shotgun in the design of the Liberator 12k. A huge plus for manufacturing and reliability was the absence of small parts in the shotgun mechanism.

A huge plus for manufacturing and reliability was the absence of small parts in the shotgun mechanism.

Since the plastic was not strong enough, Rodriguez reinforced the design of the Liberator 12k with metal pins and added metal tubes inside the barrel and drum. The metal parts were purchased from a regular hardware store, so anyone could easily make a Liberator 12k with their home 3D printer.

Semi-automatic weapons

Shuty-MP1

The first sign was the Shuty-MP1, a semi-automatic pistol made by an amateur gunsmith with the nickname Derwood, in April 2017.

Shuty-MP1

Shuty AP-9

The Shuty AP-9 still uses a pistol barrel, but the trigger and return spring are taken from the civilian version of the M16. This improved the reliability of the rifle.

Ethical use

Despite the negative examples of application, 3D printing is actively used in many areas, helping to save time and create products that cannot be produced by other methods.

Medicine

Implants

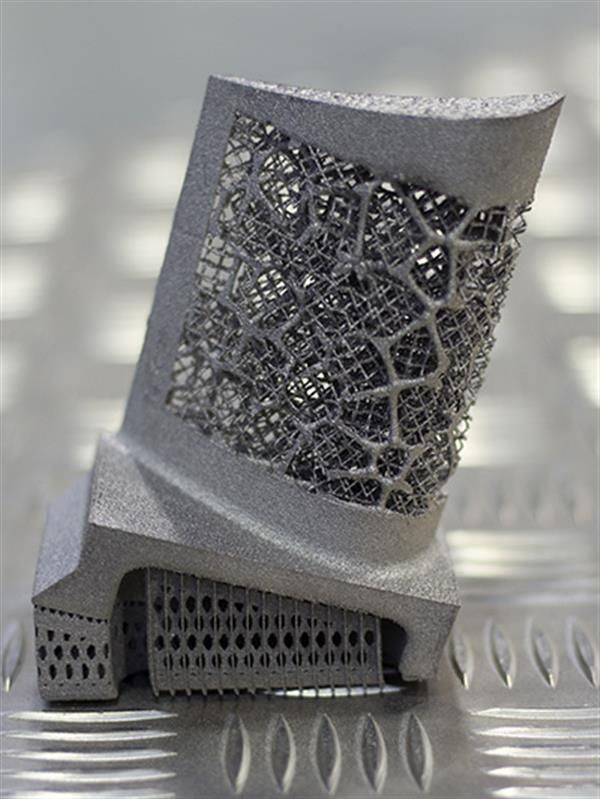

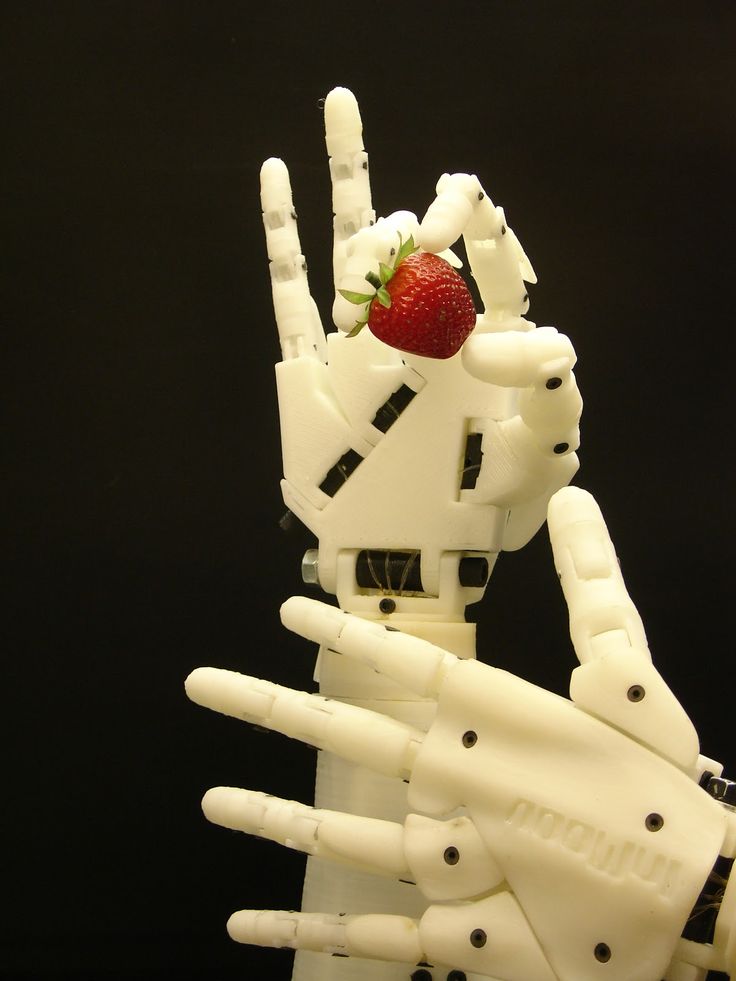

Metal-printing 3D printers are actively used in medicine for the manufacture of titanium implants. For example, a patient needs to have a hip joint implant made. According to the results of CT, the necessary area of bone tissue replacement is agreed with the doctors and a prosthesis model is created that is ideal for this patient. After all approvals, the finished model is sent for printing.

3D model of implant

The main areas of 3D printing of implants in medicine are maxillofacial surgery, traumatology, orthopedics, oncology and veterinary medicine. A big advantage over classical methods of manufacturing implants is the ability to create a cellular or porous structure. This allows for better integration of the prosthesis into the bone tissue.

Samples of printed implants and pins

Dentures

The manufacture of even a relatively simple traction prosthesis is a rather laborious and lengthy process. 3D printing has reduced costs and accelerated the production of prostheses. In addition, it became possible to customize the prosthesis.

3D printing has reduced costs and accelerated the production of prostheses. In addition, it became possible to customize the prosthesis.

Customized child prostheses

Some enthusiasts are modeling and posting models and detailed instructions for assembling traction prosthetic hands and fingers in the public domain so that any user can print and make a prosthesis at home.

Simple Traction Hand Model

Production

Building custom drones

Aerialtronics is a small Dutch company that specializes in building unique, customized drones. Aerialtronics manufactures and develops unique drones, the characteristics of which can vary depending on the needs of the customer.

Initially, a basic concept model was designed, which consists of a platform and a set of elements that can be changed at the request of the customer. Changes can affect almost any part of the drone. The customer can choose the number of motors and their power, payload, flight time, supported software and much more.

The customer can choose the number of motors and their power, payload, flight time, supported software and much more.

Aerialtronics base model

But any, even minor changes in the characteristics and design of the drone required the manufacture of new elements and design changes. Classical manufacturing methods turned out to be quite laborious and long. To save time and money, a Stratasys uPrint SE Plus 3D printer was purchased.

Drone Assembly

Thanks to 3D printing, it was possible not only to speed up production, but also to devote more time to improving individual components, because the finished model is ready the next morning. Rapid manufacturing allows you to print a part, test it, make the necessary changes to the 3D model and make a new sample. Aerialtronics engineers manage to manufacture and test 8-10 variants of a part in a few days in order to achieve maximum quality.

Prototyping

Gas turbine prototyping.

Prototyping by traditional methods is often time consuming and expensive. Because of this, the price of an error in calculations and 3D modeling can be very expensive.

For example, the production of turbine engine parts is usually based on careful preparatory calculations, but even this does not always prevent errors in the production of a test prototype. After all, even the most modern software methods cannot replace physical tests. But due to the high cost (over $20,000), it becomes impossible to produce multiple prototypes for testing.

Turbine Technologies (Wisconsin, USA) and its subsidiary Kutrieb Research have found a way out - 3D printing. Thanks to the 3D Systems ProJet 3D printer, it was possible to reduce the cost of prototyping by about 10 times to $2,000.

3D model and printed part of turbine

A turbine model is printed on a wax 3D printer, tested and then cast from metal. In addition to the cost, it was possible to significantly speed up production. After all, the production of traditional stencils with filling in molds took up to 5 weeks, and the 3D printed model is ready by the morning.

After all, the production of traditional stencils with filling in molds took up to 5 weeks, and the 3D printed model is ready by the morning.

Totals

Despite the unethical side of 3D printing, there are still more positive use cases. 3D printers have become indispensable assistants in various industries - from home hobbies to serious industries. With the help of 3D printers, unique products are made that could not be obtained using other machines.

Popularization of 3D printers is a matter of time. But do not forget that 3D printing is just a tool, just like a drill or a hammer. It depends only on the user how it will be used.

Why mass-produced 3D printing hasn't become a trend yet

Photo: asharkyu / Shutterstock, Chris McGrath / Getty Images

The production of goods with individual characteristics is one of the trends in the consumer market. However, personification has not yet become a popular phenomenon. Is this idea promising for business development?

When the problem of shortage of personal protective equipment (PPE) for doctors became acute, the owners of 3D printers united in the volunteer movement #3Dfor doctors. They began to print adapters, which made it possible to connect diving masks with virus-bacterial filters. Manufacturers were able to quickly develop and release adapters in various configurations for popular types of masks found in stores, quickly covered burning needs and saved many lives - and then began to make full-fledged protective masks and shields.

They began to print adapters, which made it possible to connect diving masks with virus-bacterial filters. Manufacturers were able to quickly develop and release adapters in various configurations for popular types of masks found in stores, quickly covered burning needs and saved many lives - and then began to make full-fledged protective masks and shields.

Adapters for masks - example of a customized product (made to order. - RBC Trends ), that is, adapted to different types of masks. How quickly manufacturers were able to design and release a new product with unique characteristics demonstrates the main advantages of 3D printing.

3D printing allows you to create products based on the preferences or personal characteristics of the buyer - personalized goods. This idea arose in the early 2000s, but so far, contrary to forecasts and the rapid development of additive technologies, has not become a mass phenomenon.

Personalization challenges

Since 2012, Nike and Adidas have been experimenting with 3D printing in the production of sneakers. The goal is to create sports shoes in the presence of the buyer according to the individual characteristics of his foot. For example, Adidas announced in 2015 that a consumer could walk into a store, spend a couple of minutes on the treadmill, and immediately receive a printed pair of running shoes that take into account the contours of the foot and pressure points while running. At the same time, Nike announced the possibility of printing shoes directly at the customer's home. To do this, you just need to download the file with the parameters of the sneakers and the characteristics of the foot from the corporation's website to your home 3D printer.

However, by 2020, these opportunities remained unrealized. In practice, everything turned out to be more difficult.

The point is the high cost of such products: the consumer is not ready to pay for customized sneakers many times more expensive when you can choose the right model from thousands of more affordable options.

Customization does not take root among automakers either. For example, in 2017, BMW launched the MINI Yours Customized service, which allows you to customize a new or previously purchased MINI car using decorative elements printed on a 3D printer. For example, it was possible to order individual side body inserts, trim parts, LED door sills and LED door projectors. However, the service is currently unavailable.

Where personification has taken root

So far, 3D printing is most actively used in medicine, where it is vital to take into account the individual characteristics of a person. First of all, the technology is useful in orthopedics and dentistry for the manufacture of prostheses and implants. Customization is especially in demand in the production of prosthetic limbs. With the help of 3D scanning, the parameters of the patient are determined, a digital model of the prosthesis is created, which is printed on a 3D printer. In this case, you can create a unique design of the artificial limb. For example, they produce children's prostheses stylized as favorite movie characters.

In this case, you can create a unique design of the artificial limb. For example, they produce children's prostheses stylized as favorite movie characters.

Another area where 3D printing is being used to customize products is in the jewelry and fashion jewelry industry. There are enterprises that produce mass products using 3D printing, for example, the American brands LACE, Nervous System and others. Customization is carried out, first of all, by small studios and workshops offering exclusive jewelry. They print digital models created according to customer sketches or cast them from precious materials using 3D printed molds.

Economics of innovation Living hand: who creates bionic prostheses in Russia

As for the majority of goods, the price works here in 99% of cases. Especially when the share of online sales is growing. You type in Google "buy a fountain pen is the cheapest" - and no matter where you are, you buy this fountain pen cheaper. This is where mass production wins.

This is where mass production wins.

You can think of many products that could be customized. But you need to be clear about who you will sell them to. Are there enough people willing to overpay for customization to keep your business alive? “In your calculations, you need to take into account real consumer demand, and not the desire to make money on hype,” says Vlasov. “The conclusion is simple: personalized production is possible when it will give approximately the same price as mass production.”

Denis Alekseev, Head of R&D and Production at JSC ROBBO (educational robotics, Skolkovo resident), is sure that personalized production will become a popular trend of the future. But in order to attract the mass consumer to this segment, it is necessary to overcome a number of technical and organizational issues. For the end user, the process of ordering a customized product should be as simple as possible: with a few steps, order what he wants, while receiving the finished product quickly and conveniently. The cost of individual products may be higher, but this increase must be of value to the customer.

The cost of individual products may be higher, but this increase must be of value to the customer.

Main disadvantages of 3D printing:

-

low production rate;

-

often low quality products;

-

high cost of the product when trying to mass production.

How to reduce the cost of a customized product?

The cost of the finished product primarily depends on the materials for 3D printing. One way to cut costs is to produce consumables yourself.

Another option to reduce the cost of consumables is possible with the development of additive technologies and the development of new printing materials.

The main question is: who will buy it?

Entrepreneurs who will find the answer to the question: who will buy them will be able to develop the production of personalized goods? Businesses that already operate in a particular market and feel the needs of their audience can feel the demand.