3D printer pre assembled

7 Best Fully Pre-Assembled 3D Printers of 2019

3D Insider is ad supported and earns money from clicks, commissions from sales, and other ways.

The benefits of assembled 3D printers are obvious. You don’t need to spend hours putting them together from scratch. You can go from unboxing to printing in just an hour or two, with the filament loading and print bed leveling being the only tasks that might prove to be roadblocks in some cases.

Obviously, such 3D printers also come with disadvantages. For example, they are generally more expensive than DIY kits. But a lot of people are more than willing to accept those downsides in exchange for the chance to skip the assembly process and print right away. Not everyone has the time and skills to deal with DIY kits.

This guide is for beginners who are looking for the best assembled 3D printers on the market. For this guide, we set a $1,000 price limit, effectively removing 3D printers intended for intermediate users and professionals, such as the Ultimaker 3, the MakerGear M2, and the BCN3D Sigma. We assumed beginners are unlikely to spend over $1,000 on their starter 3D printer.

| Budget |

|---|

| Monoprice Select Mini v2 |

| 4.1/5.0 |

| Resolution: 100 microns |

| Filament Diameter: 1.75 mm |

| This is highly affordable and produces a decent print quality. |

| Check Amazon |

| Best Value |

|---|

| Monoprice Maker Ultimate |

| 4.3/5.0 |

| Resolution: 20 microns |

| Filament Diameter: 1.75 mm |

| Heats up fast, good print quality, and rigid metal frame. |

| Check Amazon |

| Top Pick |

|---|

| Original Prusa i3 MK2S |

4. 6/5.0 6/5.0 |

| Resolution: 50 microns |

| Filament Diameter: 1.75 mm |

| Has an outstanding print quality and generous print area. |

| Check Prusa3D |

Assembled 3D Printers Comparison Table

| Make and Model | Rating | Resolution | Build Volume | Filament Diameter | Material Type | Weight | Connectivity | Price |

|---|---|---|---|---|---|---|---|---|

| Original Prusa i3 MK2S | 4.6 | 50 microns | 9.8 x 8.3 x 8 in | 1.75 mm | ABS, PLA, Nylon, and others | 14 lb | USB, SD card | Check Price |

| Monoprice Select Mini v2 | 4.1 | 100 microns | 4.7 x 4.7 x 4.7 in | 1.75 mm | ABS, PLA, TPU, and others | 9.9 lb | Wi-Fi, USB, SD card | Check Price |

| Monoprice Maker Ultimate | 4. 3 3 | 20 microns | 7.9 x 7.9 x 6.9 in | 1.75 mm | ABS, PLA, PVA, and others | 30.6 lb | USB, SD card | Check Price |

| FlashForge Finder | 3.9 | 100 microns | 5.5 x 5.5 x 5.5 in | 1.75 mm | PLA | 44.1 lb | Wi-Fi, USB | Check Price |

| XYZprinting da Vinci 1.0 Pro | 3.8 | 20 microns | 7.9 x 7.9 x 7.9 in | 1.75 mm | ABS, PLA, PETG, and others | 50.7 lb | Wi-Fi, USB | Check Price |

| Qidi Tech X-smart | 4.1 | 100 microns | 6.5 x 5.7 x 5.9 in | 1.75 mm | ABS, PLA | 33.1 lb | USB | Check Price |

| Dremel Digilab 3D20 | 4.0 | 100 microns | 9 x 5.9 x 5.5 in | 1.75 mm | PLA | 19.5 lb | USB, SD card | Check Price |

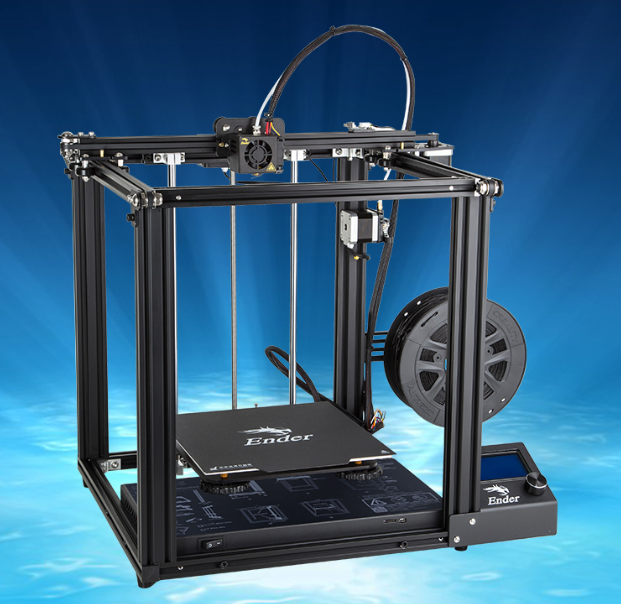

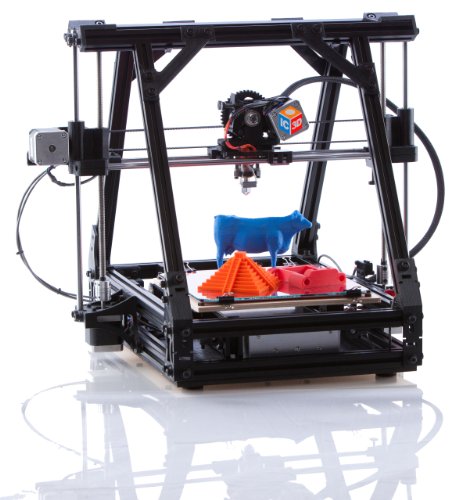

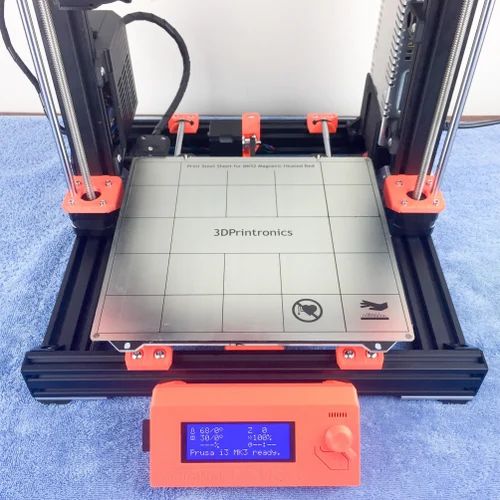

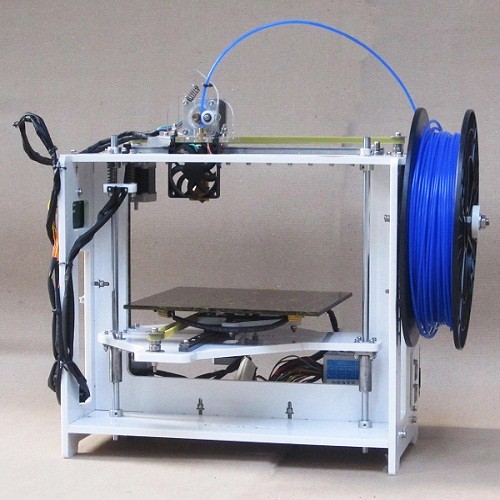

1. Best Pick: Original Prusa i3 MK2S

View on Prusa3D

Editor’s Rating: 4. 6/5

6/5

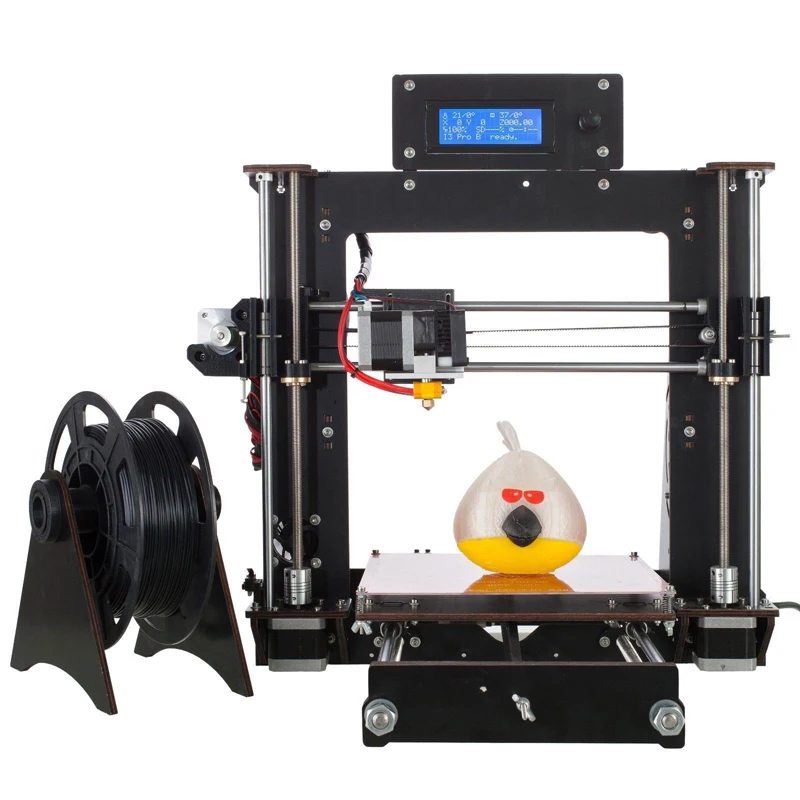

The Original Prusa i3 MK2S is one of the best and most reliable 3D printers on the market. A lot of users wouldn’t hesitate to recommend it for both beginners and enthusiasts, even with the newer model MK3 now out. You can get the fully assembled MK2S for about $900, which is around $300 more expensive than the DIY kit. It’s on the expensive side, but you won’t find many products under $1,000 that offer the same long-term value as the MK2S.

A Cartesian 3D printer, the MK2S is an open-structure 3D printer, with an integrated LCD interface and a top-mounted spool holder. It has a rigid metal frame built to withstand high-speed prints and comes with a heated print bed. Unlike with the MK3, the print bed is non-magnetic, which means you can’t easily pop it out for print removal and cleaning. Concerning build volume and machine footprint, the MK2S is identical to the MK3.

Setting up the MK2S is as simple as it can get, with the automatic bed leveling system eliminating the often daunting task of manually calibrating a print bed. No need for a significant amount of tinkering at the onset; the MK2S is ready to go as soon as you finish installing the software and loading the filament. Prusa Research includes a comprehensive manual, so the chances of you getting lost during the initial setup are slim, especially since no assembly is required.

No need for a significant amount of tinkering at the onset; the MK2S is ready to go as soon as you finish installing the software and loading the filament. Prusa Research includes a comprehensive manual, so the chances of you getting lost during the initial setup are slim, especially since no assembly is required.

What makes the MK2S worth the money is the print quality. It’s capable of producing detailed and exceptionally clean prints, the kind of results that’ll make you glad you chose to spend your money on it instead of going cheap. It’s an absolute workhorse once tuned up, producing print after print in a reliable manner. When it comes to print quality, the MK2S and the MK3 are actually not that different, one reason some owners of the older model are still not sold on upgrading to the newer model.

The MK2S offers excellent material compatibility out of the box, which can’t be said for a lot of 3D printers under $1,000. It has a well-designed print head with a very capable hotend and, as mentioned, comes with a heated print bed – both of which allow you to print with a wide selection of materials, including ABS, HIPS, Nylon, and composite filaments. The only material that will prove to be tricky to deal with is TPU, even with the direct drive setup.

The only material that will prove to be tricky to deal with is TPU, even with the direct drive setup.

In regard to community support, the MK2S will not disappoint you. It has a big community, which is sometimes more important for beginners than tech specs. It’s easy to find optimization and troubleshooting guides. The community already has you covered on some of the most common problems you might encounter down the road, as well as useful upgrades that you can check out for an even better 3D printing experience.

While not as loaded with convenient features as the MK3, the MK2S is a superb 3D printer. It’s more tried-and-tested than the MK3, with an established reputation for being one of the most reliable workhorses in the business. If you’re in the market for the best fully assembled 3D printer under $1,000, the MK2S is the first, second, and third product you should consider.

| Tech Specs |

|---|

| Resolution: 50 microns |

Volume: 9. 8 x 8.3 x 8 in 8 x 8.3 x 8 in |

| Filament: 1.75 mm |

| Type: ABS, PLA, Nylon, and others |

| Weight: 14 lb |

| Connect: USB, SD card |

| The Pros |

|---|

| Outstanding print quality |

| Automatic bed leveling system |

| Generous print area |

| Great material compatibility |

| Large community |

| The Cons |

|---|

| High price point |

| Fewer features than Original Prusa i3 MK3 |

2. Best Budget: Monoprice Select Mini v2

View on Amazon

Editor’s Rating: 4.1/5

When shopping for budget 3D printers, Monoprice is one of the first brands you should check out. It offers a solid lineup of products under $1,000, one of the most popular of which is the Monoprice Select Mini v2 – a compact desktop 3D printer that sells for about $180-200.

It offers a solid lineup of products under $1,000, one of the most popular of which is the Monoprice Select Mini v2 – a compact desktop 3D printer that sells for about $180-200.

The Select Mini v2 is a desktop 3D printer with a small footprint. It has an open structure, featuring a single extruder and a heated print bed, the latter of which might surprise some people, considering the price. It has an integrated control unit, which allows you to start prints without a computer connection. Unlike most cheap 3D printers under $200, which often come in a DIY kit, the Select Mini v2 has a clean profile, with good cable management.

Although the Select Mini v2 is fully assembled out of the box, setting it up is not as straightforward as you might expect, due in large part to the initial print bed calibration. Unlike the Original Prusa i3 MK2S, this budget 3D printer has a manual bed leveling system. While it can be frustrating to get the print bed perfectly leveled, most especially for beginners, the process won’t take more than one hour. On the plus side, leveling the print bed is a good experience, one that will prove useful in the future.

On the plus side, leveling the print bed is a good experience, one that will prove useful in the future.

The Select Mini v2 prints well for a cheap 3D printer, but don’t expect too much. It can print detailed 3D models once you get the settings right. Monoprice advertises an impressive list of materials the Select Mini v2 can print with out of the box. Sadly, almost all of them are not accessible until you make some upgrades to the core components, such as the hotend. So don’t get too excited about seeing TPU as one of the compatible materials you can print with on this desktop 3D printer.

Considering the “mini” in the product name and the machine size, it’s not surprising the Select Mini v2 comes with a small print area. Of all the products included here, the Select Mini v2 has the smallest print area, which makes it unappealing for some people, even after considering the price. If a large print area is more important to you than anything else, then this compact 3D printer is not for you.

One of the best things about the Select Mini v2 is that it has a big community. Its user groups are full of helpful people who are always happy to guide beginners, not only with troubleshooting issues but also with upgrades or mods. In regard to official support, don’t expect too much as Monoprice is not exactly known for its customer service, regardless of the communication platform.

Overall, the Select Mini v2 is one of the best 3D printers under $200. It offers multiple connection options, including Wi-Fi, comes with a heated print bed, and can produce good prints for a budget 3D printer. It’s also easy to modify, courtesy of its open structure, and comes in a portable form. If you want an assembled 3D printer but can’t afford to pop more than $300 on one, go for the Select Mini v2.

| Tech Specs |

|---|

| Resolution: 100 microns |

Volume: 4. 7 x 4.7 x 4.7 in 7 x 4.7 x 4.7 in |

| Filament: 1.75 mm |

| Type: ABS, PLA, TPU, and others |

| Weight: 9.9 lb |

| Connect: Wi-Fi, USB, SD card |

| The Pros |

|---|

| Highly affordable |

| Compact and lightweight |

| Decent print quality |

| Heated print bed |

| Large community |

| The Cons |

|---|

| Small build volume |

| Manual bed leveling can be a pain |

| Slow print speed |

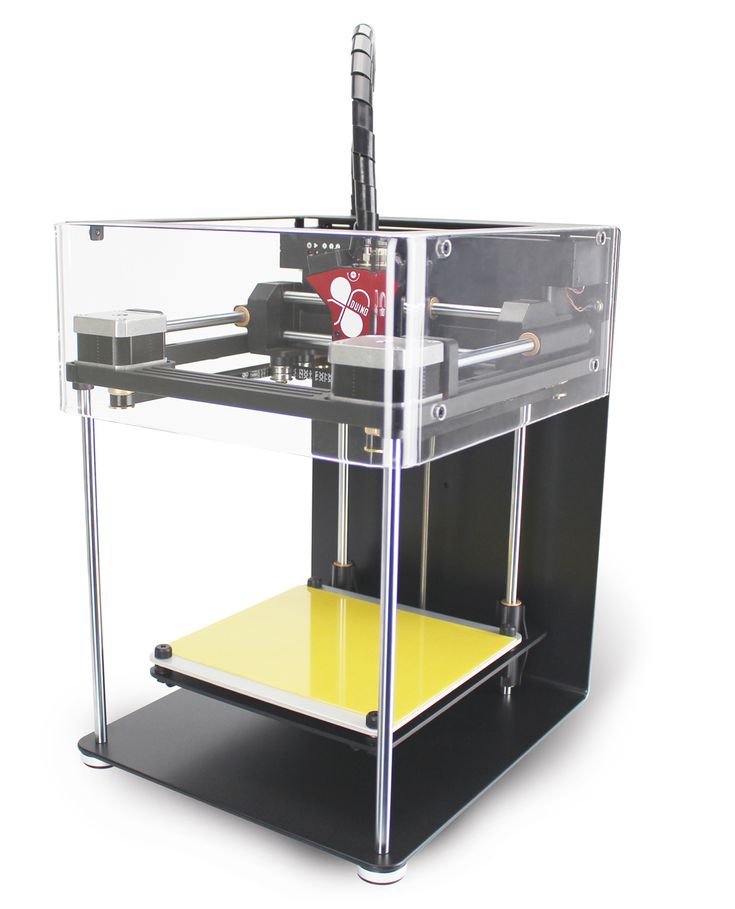

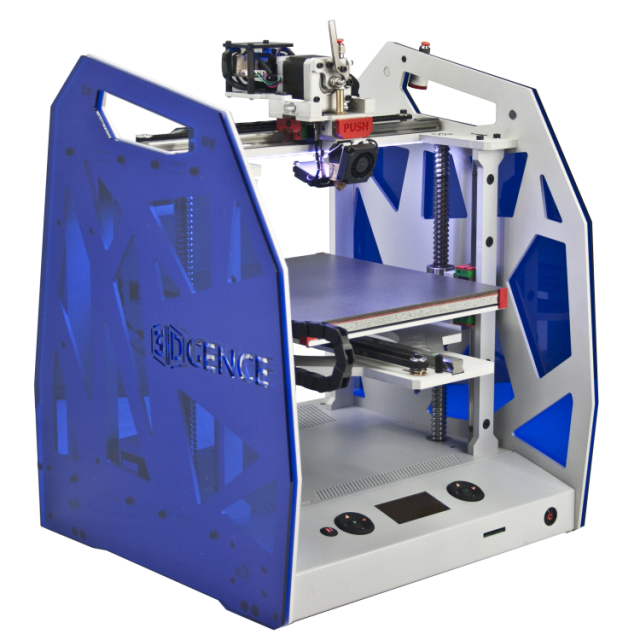

3. Best Value: Monoprice Maker Ultimate

View on Amazon

Editor’s Rating: 4.3/5

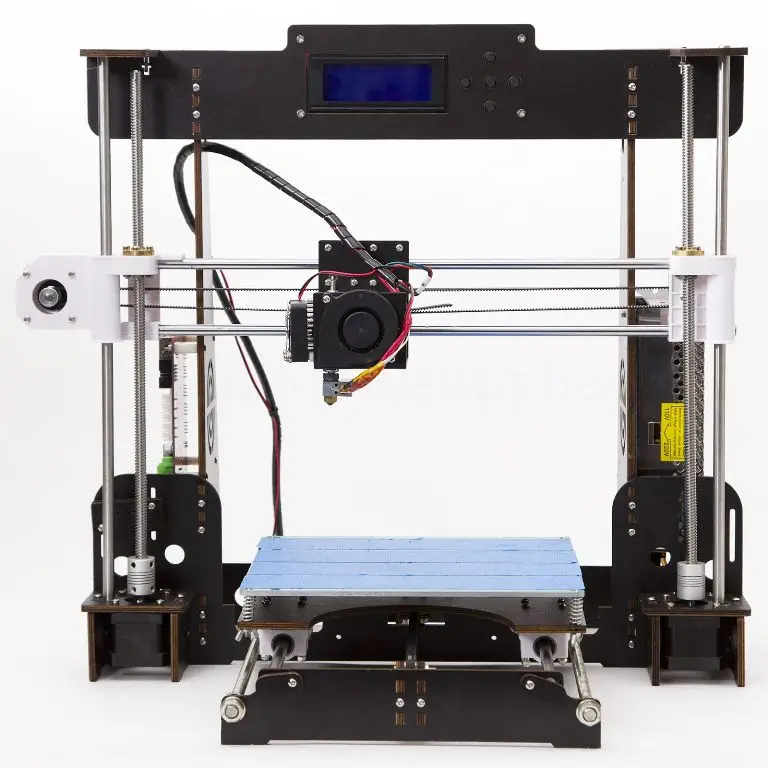

At around $600, the Monoprice Maker Ultimate is significantly more expensive than both the Select Mini v2 and the Maker Select v2. It’s a semi-enclosed 3D printer with a rigid metal frame and a single extruder. On the surface, it appears to be a combination of the Zortrax M200 and the Ultimaker 2: it has an all-black finish like the former and a dial-operated LCD like the latter.

It’s a semi-enclosed 3D printer with a rigid metal frame and a single extruder. On the surface, it appears to be a combination of the Zortrax M200 and the Ultimaker 2: it has an all-black finish like the former and a dial-operated LCD like the latter.

Enclosed with a box-shaped frame, the Maker Ultimate is Cartesian 3D printer with a print head that moves on the X and Y (Cartesian XY). The heated print bed moves up and down on the Z, instead of side to side on the Y. It has an SD card slot out front and a USB port at the rear. The spool holder is located at the back, along with the power switch.

The Maker Ultimate has a good build volume, though it would have been better if it was taller and offered more vertical space. It’s easy to set up out of the box, with all the things you need to get started included in the package, including a set of tools, a sample filament, and some test models on the SD card. The manual bed leveling process may prove to be a slight challenge, though, especially for beginners.

Concerning overall performance, the Maker Ultimate is good. It can print in high resolutions and with different materials, including ABS, PVA, and several composite filaments. It heats up fast and can handle high-speed prints well. The cooling fan can be really loud, though, so you may want to consider replacing it in the near future.

Like the Select Mini v2, the Maker Ultimate offers long-term value. It has a big community, which sort of offsets the unreliable official support, and can produce great prints with the right setup. It’s easy to upgrade as well, which means you can turn it into an even more capable 3D printer. It offers a more complete package than all the other products on this list – except the Original Prusa i3 MK2S.

| Tech Specs |

|---|

| Resolution: 20 microns |

| Volume: 7.9 x 7.9 x 6.9 in |

Filament: 1. 75 mm 75 mm |

| Type: ABS, PLA, PVA, and others |

| Weight: 30.6 lb |

| Connect: USB, SD card |

| The Pros |

|---|

| Easy to set up out of the box |

| Rigid metal frame |

| Good print quality |

| Heats up fast |

| Good community |

| The Cons |

|---|

| Loud cooling fan |

| Unreliable official customer support |

| Tricky manual bed leveling process |

4. FlashForge Finder

View on Amazon

Editor’s Rating: 3.9/5

The FlashForge Finder is a suitable starter 3D printer for beginners, both for home use and classroom use. It comes from the same company that produced the Creator Pro, one of the most reliable and most affordable dual extruder 3D printers on the market. After originally selling for over $500, the Finder now goes for less than $400, making it even more appealing to beginners.

After originally selling for over $500, the Finder now goes for less than $400, making it even more appealing to beginners.

Like the Monoprice Maker Ultimate, the Finder is a semi-enclosed 3D printer, but the frame material is different. Instead of metal, the frame is made of plastic alloy. But compared to an open-structure 3D printer with a plastic frame, such as the Anet A8, the Finder is more rigid, with no need for additional braces. Obviously, the mechanical arrangement has a big hand in that, but it’s still worth pointing out considering a lot of people assume plastic-framed 3D printers have stability issues.

The Finder is cube-shaped, with a slightly larger print area than the Monoprice Select Mini v2. It has a well-secured print head with a single nozzle and a non-heated print bed, the latter of which is what makes it an ideal 3D printer for kids. It has a touchscreen interface at the top of the frame and comes with a dedicated spool compartment, which is located at the back of the machine.

While the Finder can use filaments from other brands, the integrated spool holder is made for FlashForge-branded filaments. That means an external spool holder is required for non-FlashForge filaments, such as the ones from Hatchbox. It’s a minor inconvenience with an easy solution, but keep in mind that an external non-mounted spool holder adds to the overall machine footprint.

Other than its affordable price and fully assembled form, the Finder’s main selling point is that it’s extremely easy to use, even for complete beginners. It’s a plug-and-play 3D printer that allows you to start printing in just 30 minutes. One of the chief reasons for that is the Finder’s assisted manual bed leveling system, initialized via the onboard interface. While it can’t beat a fully automatic system, the semi-automatic bed leveling system works as intended and turns the initial bed calibration into a walk in the park.

Regarding print quality, it’d be wise not to expect a lot from the Finder. It can produce good prints but don’t count on it to produce extremely detailed and smooth prints, even in max resolution. And don’t expect to be able to experiment with different materials as well. As mentioned, the Finder is not equipped with a heated print bed, which immediately removes materials such as ABS, HIPS, and PC out of the equation.

It can produce good prints but don’t count on it to produce extremely detailed and smooth prints, even in max resolution. And don’t expect to be able to experiment with different materials as well. As mentioned, the Finder is not equipped with a heated print bed, which immediately removes materials such as ABS, HIPS, and PC out of the equation.

All in all, the Finder is a good entry-level 3D printer despite its limits. It’s extremely easy to use out of the box – which is a big plus for beginners – and comes with well-designed and well-secured components. It has an assisted manual bed leveling system and a touchscreen interface, the latter of which gives it a more modern look compared to other cheap 3D printers.

| Tech Specs |

|---|

| Resolution: 100 microns |

| Volume: 5.5 x 5.5 x 5.5 in |

| Filament: 1.75 mm |

| Type: PLA |

Weight: 44. 1 lb 1 lb |

| Connect: Wi-Fi, USB |

| The Pros |

|---|

| Plug-and-play |

| Assisted manual bed leveling system |

| Removable build plate |

| Built-in spool holder |

| Responsive touchscreen interface |

| The Cons |

|---|

| Small print area |

| Limited to PLA |

| Non-heated print bed |

5. XYZprinting da Vinci 1.0 Pro

View on Amazon

Editor’s Rating: 3.8/5

The XYZprinting da Vinci 1.0 Pro is an enclosed 3D printer that offers more long-term value than the other cheap models in the da Vinci series. On paper, it appears to be a great product, especially for beginners. But it has a number of issues that hold it back and prevent it from being more than just an entry-level 3D printer.

One of the most notable enclosed 3D printers under $500, the da Vinci 1.0 Pro has a rigid frame, with well-secured components and an easily accessible LCD interface out front. Like the FlashForge Finder, it’s a cube-shaped 3D printer with a built-in spool holder designed specifically for first-party filament spools. But unlike the Finder, it has a large print area and a heated print bed.

XYZprinting is infamous for its use of proprietary filaments, one of the biggest reasons many people stay away from the company’s lineup of affordable 3D printers. We have both good news and bad news on that front. The good news is that the da Vinci 1.0 Pro is capable of printing with third-party filaments as long as the filament diameter is a match. The bad news is that the built-in spool holder, as mentioned above, is designed for XYZprinting filament spools. For third-party filaments, you’ll need to build your own external spool holder.

The initial setup is simple. You can install the software, level the print bed, load the filament, and start printing in just 30 minutes or less, but don’t expect excellent results with the default settings. Like with other 3D printers, a fair amount of tinkering is required before the da Vinci 1.0 Pro can produce good results. Don’t get too excited about that advertised 20-micron max resolution, though; it sounds too good to be true for a cheap 3D printer.

Like with other 3D printers, a fair amount of tinkering is required before the da Vinci 1.0 Pro can produce good results. Don’t get too excited about that advertised 20-micron max resolution, though; it sounds too good to be true for a cheap 3D printer.

When it comes to overall performance, the da Vinci 1.0 Pro is good but not exactly a standout. It can produce good prints at decent speeds with both ABS and PLA, the two most common materials used in 3D printing. But despite being equipped with a heated print bed and a full enclosure, the da Vinci 1.0 Pro has a disappointing material compatibility overall. It needs at least a hotend upgrade before it can print with more advanced materials.

If you’re in the market for a fully enclosed 3D printer that comes assembled, the da Vinci 1.0 Pro is a solid option. It has a large build volume, accepts third-party filaments (which is notable for a 3D printer from XYZprinting), and features an easy bed leveling process. It’s also highly affordable, selling for just around $350 on a regular day.

| Tech Specs |

|---|

| Resolution: 20 microns |

| Volume: 7.9 x 7.9 x 7.9 in |

| Filament: 1.75 mm |

| Type: ABS, PLA, PETG, and others |

| Weight: 50.7 lb |

| Connect: Wi-Fi, USB |

| The Pros |

|---|

| Full enclosure |

| Good build volume |

| Easy to set up and use |

| Heated print bed |

| Open filament system |

| The Cons |

|---|

| External spool holder required for third-party filaments |

| Limited material compatibility |

| Not easy to mod |

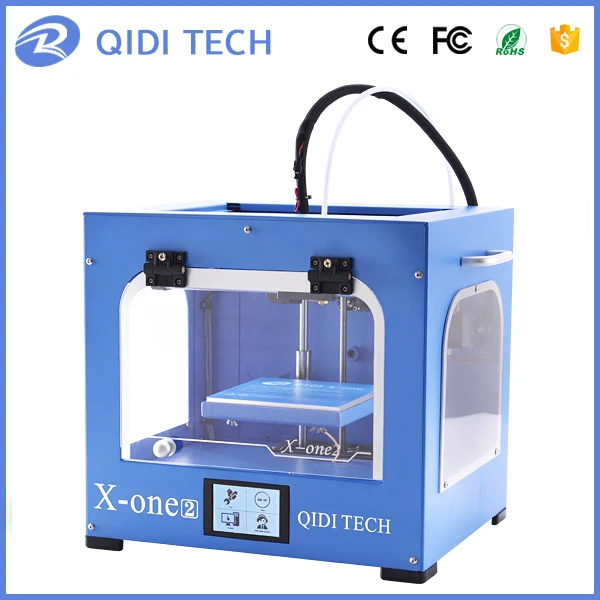

6.

Qidi Tech X-smart

Qidi Tech X-smartView on Amazon

Editor’s Rating: 4.1/5

With so many products on the market, there are many good 3D printers that get overlooked. The Qidi Tech X-smart is a good example. It’s an enclosed 3D printer with a rigid metal frame and a number of features not normally seen on budget products.

In design, the X-smart is like the Qidi Tech I, but smaller and more limited. It has a smaller build area and comes with a single extruder. It’s protected on all sides, featuring a hinged front door, a couple of side panels, and a top cover. The full enclosure is a two-way defense. It protects you against fumes and protects the 3D printer from dust and other fine particles. The side panels and top cover can be easily removed, allowing you to quickly switch to an open setup.

The X-smart has a spool holder at the back and a touchscreen interface, the latter of which is uncommon for a budget 3D printer. It has a heated print bed, connected to a leadscrew-driven motion system. The build platform is removable and bendable, which allows for easy removal of completed prints. Additionally, the removable nature of the built plate makes it a lot easier to clean. The print bed is easy to level and doesn’t go out of alignment after just a few prints, both of which are not surprising for a 3D printer set in a Cartesian XY mechanical arrangement.

The build platform is removable and bendable, which allows for easy removal of completed prints. Additionally, the removable nature of the built plate makes it a lot easier to clean. The print bed is easy to level and doesn’t go out of alignment after just a few prints, both of which are not surprising for a 3D printer set in a Cartesian XY mechanical arrangement.

When it comes to print quality, the X-smart is good for a budget 3D printer. It can produce clean and surprisingly detailed 3D models when the settings are on point, though it struggles a bit with more complex objects. It can print with both ABS and PLA, with the heated print bed making the former possible.

Unlike most cheap 3D printers, the X-smart has the ability to recover from a power failure. It automatically creates a save point when interrupted in the middle of a print, allowing you to resume the print progress as soon as the power returns. It’s also possible to manually create a save point, a useful feature if you don’t want to sleep with a running 3D printer in another room.

The best thing about the X-smart is that Qidi Tech provides outstanding customer service, which is rare these days. The company attends to inquiries and customer issues in a friendly and timely manner, the latter of which is even more impressive once you remember Qidi Tech is in a different time zone. This is what separates Qidi Tech from other China-based 3D printer companies.

All in all, the X-smart is a great starter 3D printer for beginners. It can be used for both home use and classroom use. It has a rigid metal frame, a full enclosure, a power loss recovery feature, and a removable build plate, all of which instantly makes it better than many 3D printers in the same price range. The cherry on top is the exceptional Qidi Tech customer support.

| Tech Specs |

|---|

| Resolution: 100 microns |

| Volume: 6.5 x 5.7 x 5.9 in |

Filament: 1. 75 mm 75 mm |

| Type: ABS, PLA |

| Weight: 33.1 lb |

| Connect: USB |

| The Pros |

|---|

| Outstanding customer service |

| Touchscreen interface |

| Easily removable side panels and top cover |

| Removable built plate |

| Power loss print recovery |

| The Cons |

|---|

| Small build volume |

| Limited connectivity options |

| Practically non-existent community |

7. Dremel Digilab 3D20

View on Amazon

Editor’s Rating: 4/5

The Dremel Digilab 3D20 is another fully enclosed 3D printer designed for beginners. It’s from an established brand of power tools, selling for about $600, a more accessible figure than its original price of $1,000. It has a sturdy frame, with a touchscreen interface out front and an internal spool holder.

It has a sturdy frame, with a touchscreen interface out front and an internal spool holder.

The 3D20 has a well-designed structure, with all the moving parts safely secured inside the full enclosure, making it a recommended 3D printer for classroom use in which kids are involved. It’s got a single extruder setup and comes with a non-heated print bed. It has a slightly larger build volume than the Qidi Tech X-smart, featuring a lengthier build plate.

Compared to the X-smart, setting up the 3D20 can be a bit tricky, especially for beginners, because of the manual bed leveling process. It can take several tries before you can get the print bed perfectly leveled. The good news is that you don’t have to go through that process on a regular basis as the print bed stays level for a long time. Other than the initial print bed calibration, there are no other technical roadblocks during the initial setup.

While the 3D20 can produce good prints, it doesn’t offer a lot of room for experimentation. It can only print with PLA, the most basic material. High-temperature materials such as ABS, HIPS, and ASA are not possible, considering the print bed is non-heated. TPU and other flexible filaments, which don’t strictly require a heated print bed, are also out of the equation, simply because the extruder is not built for them.

It can only print with PLA, the most basic material. High-temperature materials such as ABS, HIPS, and ASA are not possible, considering the print bed is non-heated. TPU and other flexible filaments, which don’t strictly require a heated print bed, are also out of the equation, simply because the extruder is not built for them.

Speaking of material compatibility, the 3D20 can use third-party filaments, though Dremel encourages everyone to use its own expensive filaments. But for third-party filaments, you need to build your own spool holder. Before you print with a non-Dremel filament, make sure you understand that doing so will mean forfeiting the product warranty.

Overall, the 3D20 is a fully assembled 3D printer that will make for a good starter 3D printer for beginners. It has a decent build volume, comes with a full enclosure for safety, and produces good prints at acceptable print speeds. The price is a letdown, though, considering its limits. But at least the product warranty is for real, unlike with most other budget 3D printers.

| Tech Specs |

|---|

| Resolution: 100 microns |

| Volume: 9 x 5.9 x 5.5 in |

| Filament: 1.75 mm |

| Type: PLA |

| Weight: 19.5 lb |

| Connect: USB, SD card |

| The Pros |

|---|

| Full enclosure |

| Touchscreen interface |

| Can produce good prints |

| Decent build volume |

| Comes from an established brand |

| The Cons |

|---|

| Limited to PLA |

| Non-heated print bed |

| Stock spool holder only fits Dremel spools |

Contents

- Assembled 3D Printers Comparison Table

- 1.

Best Pick: Original Prusa i3 MK2S

Best Pick: Original Prusa i3 MK2S - 2. Best Budget: Monoprice Select Mini v2

- 3. Best Value: Monoprice Maker Ultimate

- 4. FlashForge Finder

- 5. XYZprinting da Vinci 1.0 Pro

- 6. Qidi Tech X-smart

- 7. Dremel Digilab 3D20

5/51 rating

Warning; 3D printers should never be left unattended. They can pose a firesafety hazard.

The Best Cheap 3D Printers for 2022

While we'd hesitate to call 3D printing a mature technology, you might say it has reached its teenage years. Through their first decade-and-change, 3D printers have come down in price, grown easier to set up and operate, and become more reliable. And you may pay less than you expect: Many once-high-end features have migrated down to inexpensive models.

PC Labs has been reviewing 3D printers since 2013. Today, the state of 3D printing is strong, but that wasn’t always the case. For the first several years, it was often an adventure getting one of these printers up and running, let alone successfully through our testing regimen. Issues with filament-based—aka fused filament fabrication (FFF) or fused deposition modeling (FDM)—printers were abundant.

Issues with filament-based—aka fused filament fabrication (FFF) or fused deposition modeling (FDM)—printers were abundant.

Filament feeders had to be coaxed into delivering filament from the spool to the extruder. Print beds had to be manually aligned. The extruder or hot end had to be positioned just right to minimize the gap between the nozzle and the build plate (the flat surface on which the object is printed). Objects frequently stuck to the build plate, and required careful, sometimes unsuccessful, efforts to pry them off. These and other issues required painstaking effort to resolve, often combined with calls to tech support.

Not so much anymore. While they can still be rebellious at times, 3D printers have grown up a lot, and achieving the 3D printer basics has gotten a lot less likely to end in a shouting match over small things. And they've gotten a lot more affordable, too, for curious DIY-ers and hobbyists to try.

If you're in the market for a beginner or low-cost 3D printer, it's important to know how lower-end models differ. Read on for mini-reviews of the top budget 3D printers we've tested. After that, we go into more detail on understanding the 3D printer specs and tech relevant to beginning buyers. Ready to take the plunge? Read on.

Read on for mini-reviews of the top budget 3D printers we've tested. After that, we go into more detail on understanding the 3D printer specs and tech relevant to beginning buyers. Ready to take the plunge? Read on.

Original Prusa Mini

Best Overall Budget 3D Printer

4.5 Outstanding

Bottom Line:

It requires assembly and calibration care (plus shipping from the Czech Republic), but the Original Prusa Mini is a compact, open-frame 3D printer that consistently produces superb-quality output for a great price.

PROS

- Top-notch object quality

- Supports a variety of filament types

- Useful, professionally printed user guide

- Great support resources

- Versatile, user-friendly software

CONS

- First-layer calibration can be tricky

- Only includes starter packets of filament

- Requires monitoring if young children or pets are around

| Sold By | List Price | Price | |

|---|---|---|---|

| Prusa Research | $399. 00 00 | $399.00 | See It (Opens in a new window) |

Read Our Original Prusa Mini Review

XYZprinting da Vinci Mini

Best Budget 3D Printer for Schools, Community Centers

4.0 Excellent

Bottom Line:

The XYZprinting da Vinci Mini is a consumer-oriented 3D printer that provides a winning combination of low price, ease of setup and use, solid print quality, and smooth, misprint-free operation.

PROS

- Very low price.

- Reasonably priced filament.

- Good print quality.

- No misprints in testing.

- Easy setup and operation.

- Quiet.

- Prints over a USB or Wi-Fi connection.

CONS

- Occasional problems in trying to launch prints.

- Removing printed objects from the print bed is sometimes tricky.

| Sold By | List Price | Price | |

|---|---|---|---|

| Walmart | $199. 95 95 | $199.95 | See It (Opens in a new window) |

| Amazon | $199.95 | $199.95 | See It (Opens in a new window) |

Read Our XYZprinting da Vinci Mini Review

Toybox 3D Printer

Best Budget 3D Printer for Children

4.0 Excellent

Bottom Line:

The Toybox 3D Printer works well as a model designed for children, offering reliable printing from a browser or mobile device and a few thousand toys to print, plus creative options to output drawings or photos. Just bear in mind the tiny build area.

PROS

- Reliable, misprint-free printing

- Easy setup

- One-touch operation

- Well-composed help resources

- Access to more than 2,000 printable toys and projects

- Lets you create your own printable designs

CONS

- Tiny build area

- Not ideal for importing 3D files created elsewhere

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $299. 00 00 | $299.00 | See It (Opens in a new window) |

| Toybox Labs | $379.00 | $299.00 | See It (Opens in a new window) |

Read Our Toybox 3D Printer Review

Monoprice Mini Delta V2 3D Printer

Best Budget 3D Printer for Beginners, Non-Techies

4.0 Excellent

Bottom Line:

3D printing gurus will be intrigued by the Monoprice Mini Delta V2's use of the delta rather than Cartesian coordinate system, but beginners will just enjoy its low price, ease of use, and speedy printing.

PROS

- Sub-$200 price

- Quick, nearly misprint-free printing

- Easy setup and operation

- Sturdy steel-and-aluminum frame

- Supports multiple filament types

CONS

- Tiny build area

- So-so print quality

- Mere one-year warranty

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $179. 99 99 | $179.99 | See It (Opens in a new window) |

Read Our Monoprice Mini Delta V2 3D Printer Review

Anycubic i3 Mega S

Best Budget 3D Printer With an Open Design, Big Build Area

3.5 Good

Bottom Line:

The Anycubic i3 Mega S, an inexpensive open-frame 3D printer, produced decent-quality prints in our testing. To get the most out of it, though, may require precise calibration.

PROS

- Modestly priced

- Large build area for an inexpensive printer

- Supports a variety of filament types

- Generally solid print quality

- Uses well-known Cura software

CONS

- Finicky print-platform alignment

- Supported coils of filament are small

- Poorly placed spool holder

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $229. 98 98 | $229.98 | Check Stock (Opens in a new window) |

Read Our Anycubic i3 Mega S Review

Anycubic Vyper

Best Budget 3D Printer for the Biggest Build Area Possible

3.5 Good

Bottom Line:

Anycubic's modestly priced Vyper whips up large 3D prints on its open-frame design, and provides automatic print-bed leveling. Just know that some minor assembly is required—and printed objects may require a bit of cleanup.

PROS

- Relatively large build area

- Automatic bed leveling

- Simple assembly

CONS

- Short (one-year) warranty

- Includes only a small starter filament coil

- Using Cura software with the Vyper requires tweaking a couple of settings

- Test prints showed some "hairy" filament residue

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $429. 99 99 | $429.99 | See It (Opens in a new window) |

| AnyCubic | $369.00 | $319.00 | See It (Opens in a new window) |

Read Our Anycubic Vyper Review

Creality Ender-3 V2

Best Budget 3D Printer for Tinkerers and DIY Types

3.5 Good

Bottom Line:

Hands-on tweaking defines Creality's budget-price Ender-3 V2, an open-frame 3D printer that you build from a kit. It produces generally above-par prints, but its print bed can be tricky to keep leveled.

PROS

- Inexpensive

- Slightly above-average print quality

- Good-size build area for its price

- Supports several filament types

CONS

- Manual print-bed leveling can be tricky

- Setup instructions could be deeper, more legible

- Questionable quality control on some parts

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $299. 00 00 | $246.00 | See It (Opens in a new window) |

Read Our Creality Ender-3 V2 Review

Flashforge Finder 3D Printer

Best 3D Printer for the Very Tightest Budgets

3.5 Good

Bottom Line:

The Flashforge Finder 3D Printer is moderately priced and offers good print quality, but it proved tricky to get up and running in our tests.

PROS

- Quiet.

- Good print quality.

- Connects via USB 2.0 cable, USB thumb drive, or Wi-Fi.

- Reasonably priced.

CONS

- Some objects pulled off the platform during testing.

- Poor documentation.

- Modest build volume.

- Limited to printing with polylactic acid filament (PLA).

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $729.00 | $729.00 | Check Stock (Opens in a new window) |

Read Our Flashforge Finder 3D Printer Review

Polaroid PlaySmart 3D Printer

Best Budget 3D Printer for Dabbling in Small Objects

3. 5 Good

5 Good

Bottom Line:

The Polaroid PlaySmart 3D Printer is a compact, stylish 3D printer with above-par overall print quality, but, alas, a tiny build area for the money.

PROS

- Small, lightweight for a desktop 3D printer.

- Easy to set up and use.

- Supports PLA, PETG, and wood composite filaments.

- Multiple-color support.

- Wi-Fi camera monitors print jobs.

- Prints from USB drives, SD cards, or mobile devices.

CONS

- High price for its capabilities.

- Small build area.

- Too-brief warranty.

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $699.00 | $699.00 | See It (Opens in a new window) |

Read Our Polaroid PlaySmart 3D Printer Review

XYZprinting da Vinci Jr. 1.0 A Pro

Best Budget 3D Printer With Closed Design, Roomy Build Area

3. 5 Good

5 Good

Bottom Line:

The XYZprinting da Vinci Jr. 1.0 A Pro is a moderately priced closed-frame 3D printer with a large build volume and overall good performance, but a potentially balky filament-feeding system.

PROS

- Spacious build area

- Works with third-party filaments

- Self-leveling print bed

CONS

- Build plate is not heated

- Limited to PLA- and PETG-based filaments

- Guide tube is prone to detaching

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $299.95 | $199.95 | See It (Opens in a new window) |

| Best Buy | $449.95 | $449.95 | Check Stock (Opens in a new window) |

Read Our XYZprinting da Vinci Jr. 1.0 A Pro Review

Monoprice Voxel 3D Printer

Best Budget 3D Printer for Cheap Filament

3. 0 Average

0 Average

Bottom Line:

The Monoprice Voxel is an under-$400 3D printer that's easy to set up and use. It exhibits generally good print quality, but it was unable to print two of our test objects.

PROS

- Easy to set up and use.

- Budget price for printer and filament spools.

- Supports PLA, ABS, and several composite filament types.

- Versatile software.

- Prints over Ethernet or Wi-Fi, or from a USB thumb drive.

CONS

- Frequent misprints on certain test objects.

- Slightly balky touch screen.

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $449.99 | $329.46 | See It (Opens in a new window) |

| Walmart | $429.99 | $369.26 | See It (Opens in a new window) |

Read Our Monoprice Voxel 3D Printer Review

Buying Guide: The Best Cheap 3D Printers for 2022

How to Buy a Cheap 3D Printer

The biggest changes to 3D printers over the last few years have come to the cheaper models. Nowadays, many of those classic, ornery 3D-printing issues have been resolved (most of the time, anyway), even for consumer and bargain-priced 3D printers. Automatic print-bed leveling is the norm, and you can usually remove 3D-printed objects from heated and/or flexible build plates with a minimum of coaxing. And most 3D printer manufacturers have either developed and refined their own software, or have adapted an open-source printing platform such as Cura(Opens in a new window).

Nowadays, many of those classic, ornery 3D-printing issues have been resolved (most of the time, anyway), even for consumer and bargain-priced 3D printers. Automatic print-bed leveling is the norm, and you can usually remove 3D-printed objects from heated and/or flexible build plates with a minimum of coaxing. And most 3D printer manufacturers have either developed and refined their own software, or have adapted an open-source printing platform such as Cura(Opens in a new window).

(Credit: Zlata Ivleva)

What separates more expensive 3D printers from cheap ones ("cheap" defined as $500 or less, for the purposes of this article) is often a select group of features. These include the build volume, the type of frame, the varieties of supported filament, the software, and the connectivity mix. Let's run through those in turn.

What's the Right Build Volume for a 3D Printer?

A 3D printer’s build volume is the maximum dimensions (HWD) of a part that it can print. (We say “a part” because a 3D-printed object can consist of multiple parts that are printed, then glued or otherwise pieced together.) While the smallest build volume of any 3D printer we have tested is 3.9 by 3.9 by 4.9 inches, we consider any build volume smaller than 6 by 6 by 6 inches to be small, any between that and 10 by 10 by 10 inches as medium, and any printer with at least one build dimension of more than 10 inches as having a large build volume.

(We say “a part” because a 3D-printed object can consist of multiple parts that are printed, then glued or otherwise pieced together.) While the smallest build volume of any 3D printer we have tested is 3.9 by 3.9 by 4.9 inches, we consider any build volume smaller than 6 by 6 by 6 inches to be small, any between that and 10 by 10 by 10 inches as medium, and any printer with at least one build dimension of more than 10 inches as having a large build volume.

(Credit: Molly Flores)

As a general rule, inexpensive 3D printers have small build volumes, while more expensive ones have larger build volumes. This depends in part on the type of printer. Closed-frame 3D printers—and most semi-open models, which have a rigid top, base, and sides but are open in front and, often, back—tend to have small build volumes, while open-frame printers, lacking as rigid a physical structure, often have relatively large build volumes for the price. You'll want to weigh the build volume against the kinds of objects you will print.

Should I Get an Open-Frame or Closed-Frame 3D Printer?

Which brings us to the frame "form factor" question: open-frame versus closed-frame. Closed-frame 3D printers are boxlike devices, with a rigid base, walls (with a see-through door in front), and top. Among their advantages? They muffle the operating noise, as well as reduce the odor from melted filament (which is potentially an issue with ABS plastic), and they provide some protection for people or pets who might inadvertently touch the hot extruder. A downside: They tend to have smaller build volumes than open-frame 3D printers, which have fewer (often, no) walls to constrict them.

(Credit: Zlata Ivleva)

Low-cost 3D printers include both open-frame and closed-frame models, as well as a few stereolithography printers. If a relatively large build volume is a priority, you’re likely to get more bang for the buck with an open-frame model. Open-frames do have some clear downsides by definition: They tend to be noisy, emit odors when certain plastics are melted, and provide little protection for someone who might touch the hot extruder.

(Credit: Molly Flores)

Also, recognize some potential negatives of open frames, depending on the model. Some require assembly, being essentially kits, and most require more setup care than a closed-frame printer, plus more maintenance to keep them running smoothly. Still, these very traits should not deter—and may even appeal to—hobbyists and DIY folks.

What Should I Look for in 3D Printer Software and Connectivity?

Gone are the days when tinkerers had to cobble together several different programs to get a 3D printer to run. Manufacturers either include their own 3D printing program or modify an existing platform such as the open-source Cura.

3D printing software performs three main functions: processing an object file (resizing, moving, rotating, and in some cases duplicating it), slicing it (into virtual layers, based on your chosen resolution), and printing it. These are almost universally combined into a seamless process. Some high-end printers have software that supports a wider range of settings you can tweak, but even the basic suites work at least reasonably well.

More likely to vary among the cheaper set is the array of connection options from model to model. Nearly all have a USB Type-A port to fit a thumb drive for printing from document files. Most also have a USB Type-B port for connecting directly to a computer, and some offer Wi-Fi, too (or as an alternative), while a handful let you connect via Ethernet to share the printer across a local network.

Some printers support storing 3D files on an SD or microSD card (which may also contain the printer’s system files). Most 3D printer manufacturers (even the discount ones) have a mobile app to launch and monitor print jobs, and a few provide access to cloud services from which you can print.

While high-end 3D printers tend to have an abundance of connection choices, discount models vary widely in their choices. Some are generous and some are basic, so it pays to assess what a given model offers.

What Should I Look for in Filament Support?

Filament support tends to be a key area that separates the cheaper models from the higher-end ones. (See our guide to understanding 3D printing filaments for more particulars.) Inexpensive 3D printers tend to support a limited number of plastic filament types, some of them only PLA and/or ABS.

(See our guide to understanding 3D printing filaments for more particulars.) Inexpensive 3D printers tend to support a limited number of plastic filament types, some of them only PLA and/or ABS.

Recommended by Our Editors

3D Printing: What You Need to Know

3D Printer Filaments Explained

(Credit: Molly Flores)

PLA (polylactic acid) is a biodegradable, plant-based polymer, while ABS (acrylonitrile butadiene styrene) is the same tough plastic that Legos are made from. Objects printed from ABS are durable and nontoxic, though the material can be tricky to work with. ABS can emit an acrid, unpleasant odor during printing, and the bottom corners of objects being printed with it have a tendency to curl upward a bit, especially if you are using a non-heated print bed. This can lead to unsightly prints, and/or prints prematurely pulling off the build plate, ruining them.

Many entry-level and low-price 3D printers stick exclusively to PLA. If you want to experiment with a larger variety of filaments—which include water-soluble filament, wood- and metal-laced composites, and both tough and flexible varieties—you may have to pay more, although a few discount models support a wide range of materials.

If you want to experiment with a larger variety of filaments—which include water-soluble filament, wood- and metal-laced composites, and both tough and flexible varieties—you may have to pay more, although a few discount models support a wide range of materials.

Should I Consider a 3D Printing Pen Instead?

Although they aren’t printers per se, inexpensive 3D pens are close kin to 3D printers—using the same filament types and a similar extrusion system—and we include them in the 3D printing category. Rather than tracing out a programmed pattern, you use the 3D pen much like a normal pen, except that you draw with molten plastic. You can trace a pattern or draw freehand, and even draw in three dimensions as the plastic quickly solidifies and hardens once extruded.

(Credit: 3Doodler)

Most 3D pens cost less than $100, and some cost $50 or less. At a glance, 3D pens may appear to be toys, but some artists and craftspeople have taken to them, as it is possible to make quite complicated and beautiful objects with them. If your aim in 3D printing is something closer to freehand design and free expression than computer-centric, structured, and repeatable output, you might give one a try.

If your aim in 3D printing is something closer to freehand design and free expression than computer-centric, structured, and repeatable output, you might give one a try.

So, What Is the Best Cheap 3D Printer to Buy?

Buying a budget 3D printer needn’t mean a world of sacrifice. Plenty of capable and reliable models sell at less than $500, and while they may not be as feature-rich as their more expensive cousins, there's no sense in paying for things you don’t need.

Many casual 3D-printing experimenters will be fine with printing over a USB cable or from a thumb drive, and sticking to PLA may be the best choice for a starter 3D printer. If you focus just on the features you want, you may be pleasantly surprised at what you find. Below, check out a spec breakdown of the best under-$500 3D printers we have reviewed, paralleling our picks above. Also, for a look at the broader market, see our guide to our favorite 3D printers overall.

How are 3D printers changing the real estate market right now?

LonGrad

Your next home can be printed

Several new homes across California are selling unusually fast. In the last two months, 82 houses have been sold out, and another 1,000 are on the waiting list. However, the wait doesn't have to be long: while a typical brick home can take weeks to build, Palari Homes and Mighty Buildings can build one in less than 24 hours. This is due to the fact that their objects are assembled from pre-assembled components at the factory. The idea itself is not new, but in this case the components are obtained in an unusual way: they are printed.

In the last two months, 82 houses have been sold out, and another 1,000 are on the waiting list. However, the wait doesn't have to be long: while a typical brick home can take weeks to build, Palari Homes and Mighty Buildings can build one in less than 24 hours. This is due to the fact that their objects are assembled from pre-assembled components at the factory. The idea itself is not new, but in this case the components are obtained in an unusual way: they are printed.

Plan of a five-acre 3D printed development in Rancho Mirage, California.

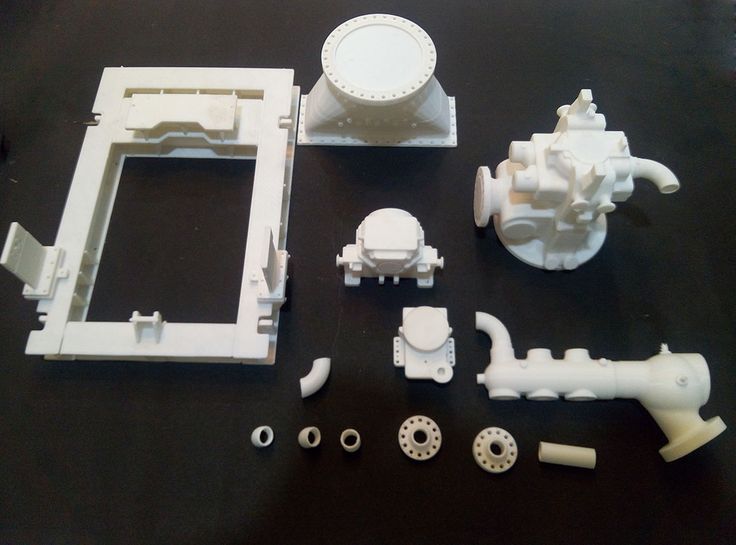

3D printing has been around since the early 1980s but is now gaining momentum. It is already being used to make everything from orthopedic implants to aircraft components.

Details vary between products and processes, but the basic principle remains the same: a layer of material is laid and fixed, another one is placed on top of it, and then another and another. By changing the shape and sometimes the composition of each layer, it is possible to create objects that would be difficult or impossible to make with more traditional methods. In addition, unlike traditional manufacturing processes, there is no waste of materials.

In addition, unlike traditional manufacturing processes, there is no waste of materials.

3D printing houses is the greenest way to build

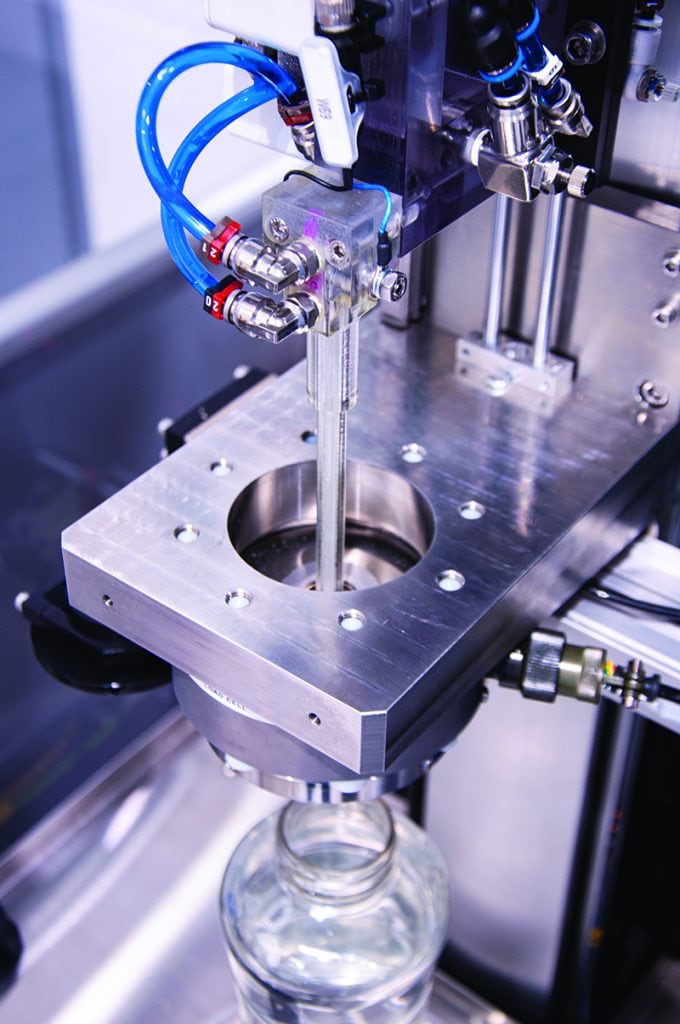

In the case of Palari Homes and Mighty Buildings, the printers are much larger than those required for artificial knees and airplane wings, and the materials are somewhat rougher. But the principle remains the same. The nozzles extrude a paste (in this case, composite), which then hardens under the influence of ultraviolet light. This allows Mighty Buildings to print details such as cornices and ceilings without the use of reference forms - as well as simpler things like walls. They are then assembled on site and attached to a permanent foundation by the builders of Palari Homes.

Not only does 3D printing provide versatility and faster construction, it also promises a lower cost and more sustainable approach than traditional construction methods currently offer. This could be the answer to two of the problems the world is currently facing: housing shortages and climate change. About 1.6 billion people - more than 20% of the world's population - do not have adequate housing. And the construction industry accounts for 11% of global anthropogenic carbon dioxide emissions. At the same time, the industry does not show success in reducing its carbon footprint.

About 1.6 billion people - more than 20% of the world's population - do not have adequate housing. And the construction industry accounts for 11% of global anthropogenic carbon dioxide emissions. At the same time, the industry does not show success in reducing its carbon footprint.

Automation brings huge cost savings. Mighty Buildings says computerizing 80% of the printing process means the firm only needs 5% of the workforce it would otherwise have. It also doubles the rate of production. This is good news for the construction industry, which has struggled for years to increase its productivity. According to the McKinsey consulting firm, over the past two decades, the industry has grown by only a third of the overall level of productivity in the global economy as a whole. Digitization is slower than almost any other industry. In many places, the industry also suffers from a shortage of skilled labor. And it is expected that the situation will not improve further. In America, for example, about 40% of construction workers are expected to retire within the next decade.

3D printer at Mighty Buildings headquarters.

The environmental benefits come in many ways, but the important thing is that you don't have to move a lot of heavy objects. For example, Palari Homes estimates that assembling its products reduces the number of truck rides needed to build a home by as much as two tons of carbon dioxide emissions per home are reduced.

Palari Homes and Mighty Buildings are not alone in their endeavors: similar projects are being launched everywhere. The vast majority of structures are printed using concrete. 14Trees, a joint venture between Holcim (the world's largest cement producer) and CDC Group, the UK government's development finance organization, operates in Malawi. Its representatives claim that it is possible to print a house in just 12 hours for less than $10,000. 14Trees notes that this process is not only cheap and fast, but also environmentally friendly. Holcim says that by applying the exact amount of cement needed and thus reducing waste, 3D printing generates only 30% of the carbon dioxide produced by fired clay bricks.

Meanwhile, in Mexico, the homeless charity New Story partnered with 3D printing firm ICON to build ten 46-square-meter houses. Each of these houses was printed in about 24 hours (although those hours were spread over several days), with the final elements collected by Échale, another local charity. In Europe, the first 3D-printed house on the continent was built in Eindhoven, the Netherlands - the keys to it were handed over to tenants on July 30.

First 3D printed house in Europe. Based in Eindhoven, The Netherlands.

Layer cake

The house in question, the first of five detached two-bedroom houses in a project coordinated by the Eindhoven municipal government and the City University of Technology, is the result of a collaboration between several firms. The Dutch division of the French building materials company Saint-Gobain developed the required concrete mortar. Construction firm Van Wijnen erected the structure, while consultant Witteveen + Bos was in charge of the design. The building is leased by its owner Vesteda, a Dutch residential property investor.

The building is leased by its owner Vesteda, a Dutch residential property investor.

3D printed house project in Eindhoven, The Netherlands

However, using cement in these projects is not an environmentally friendly process. It converts calcium carbonate in the form of limestone to calcium oxide and carbon dioxide, and this process is believed to account for about 8% of anthropogenic emissions of this gas. So a group at Texas A&M University, led by Sarbajit Banerjee, developed a way to do without cement.

Dr. Banerjee's new building material was inspired by a project he initiated years ago. It was a program to build access roads to remote areas of the Canadian province of Alberta using materials at hand. The crushed stone he invented combined local soil with wood fiber mulch and was held together with liquid or water-soluble silicates, which then hardened and acted like cement. To build houses, he uses clay and stone debris that lie under the top layer of soil near the construction site, grinds them into powder and mixes with silicates. The resulting mixture can be squeezed out through a nozzle, after which it will quickly harden and gain strength to maintain its shape and withstand the weight of the next layer. This makes the process doubly "green": it eliminates both the cement and the need to transport to the construction site, often over long distances, the sand and aggregates used in conventional concrete.

The resulting mixture can be squeezed out through a nozzle, after which it will quickly harden and gain strength to maintain its shape and withstand the weight of the next layer. This makes the process doubly "green": it eliminates both the cement and the need to transport to the construction site, often over long distances, the sand and aggregates used in conventional concrete.

Benefits of cement

There are limits to building 3D printed houses. To begin with, it is necessary to create a legislative framework for the construction of such houses. To this end, UL, one of America's largest certification agencies, collaborated with Mighty Buildings to develop the first 3D printing standard. Its principles will be incorporated into the new International Housing Code, which is in use or has been adopted by every US state except Wisconsin. While this is a welcome move for a young industry, most governments have yet to develop country-specific standards. There are also questions about the quality and finish of houses built on 3D printers.

There are also questions about the quality and finish of houses built on 3D printers.

Nevertheless, the prospects look promising. Last year, Germany approved plans to 3D print an apartment building. The three-story structure of the German construction company Peri is assembled from parts made using printers developed by the Danish company Cobod. This building will have five apartments. The use of the technology is also expanding in the Middle East and Asia. The Dubai government wants a quarter of the country's new buildings to be 3D printed by 2030 and is dedicating an entire area on the outskirts of the capital to house 3D printing companies and their warehouses. Saudi Arabia plans to use 3D printing to build 1.5 million homes over the next decade. India's Ministry of Housing and Urban Development wants to use 3D printing to solve the country's housing shortage.

If successful, 3D printed construction could expand beyond the residential sector: warehouses, offices and other commercial buildings have good prospects. The US space agency NASA is exploring the use of 3D printing to build landing sites, living quarters and roads on Mars and the Moon. There is no soil on these two celestial bodies, only crushed rock called regolith. Dr. Banerjee's group, which works with NASA, says their 3D printing approach also works well with this material. “Ultimately we would like to have real estate on Mars and the Moon, but we won't be able to carry concrete with us there,” says Dr. Banerjee. "We'll have to work with the regolith."

The US space agency NASA is exploring the use of 3D printing to build landing sites, living quarters and roads on Mars and the Moon. There is no soil on these two celestial bodies, only crushed rock called regolith. Dr. Banerjee's group, which works with NASA, says their 3D printing approach also works well with this material. “Ultimately we would like to have real estate on Mars and the Moon, but we won't be able to carry concrete with us there,” says Dr. Banerjee. "We'll have to work with the regolith."

If you are interested in options for alternative construction methods in order to increase the return on investment, then contact us! Longrad has been actively working with developers who build prefabricated houses for several years. These technologies are several times faster than traditional methods, which helps to achieve significantly higher returns. You can get a free consultation by phone +447792174059 (WA, Telegram), via email info@longrad. com or by filling out the form below. We will be glad to work with you!

com or by filling out the form below. We will be glad to work with you!

You may also be interested

Billionaires invest in luxury real estate during the pandemic

In total, in the first 6 months of 2021, wealthy buyers from around the world spent 13.8 billion on the super premium real estate market

Why is Fulham attracting homebuyers during the pandemic?

The small-town atmosphere and the desire of many during the pandemic to live in a spacious house has rapidly increased the attractiveness of Fulham over the past year.

You may also be interested

Billionaires investing in luxury property during the pandemic

The UK property market is expected to slow down after the end of preferential holidays

Stamp duty when buying property in England in 2021

Save yourself £

1000for a free consultation

Who creates the best work as a 3D printer customer?・Cults

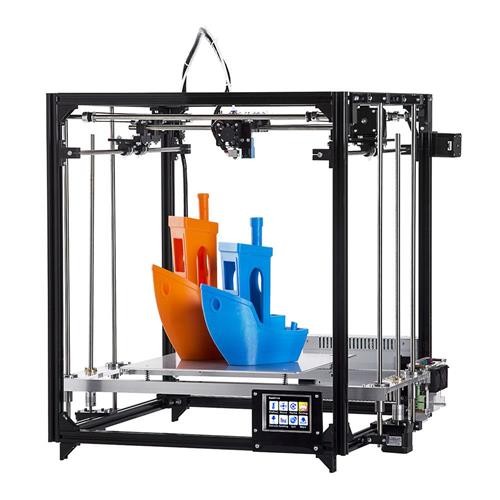

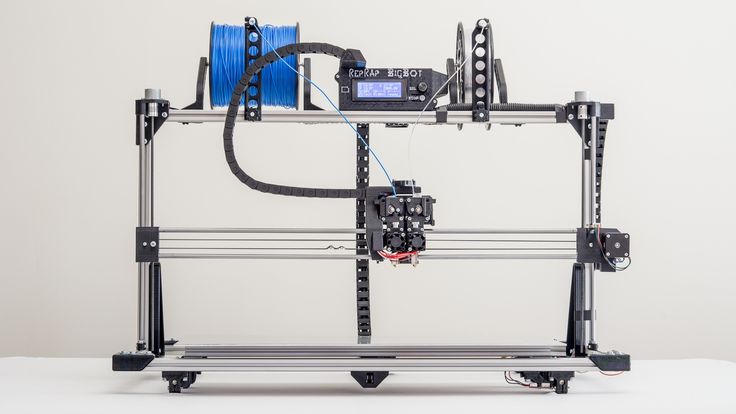

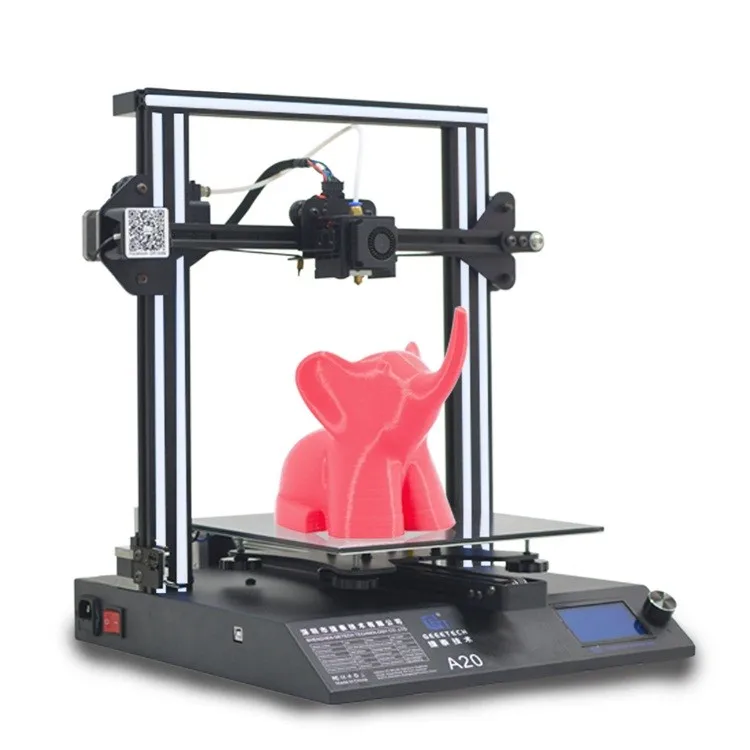

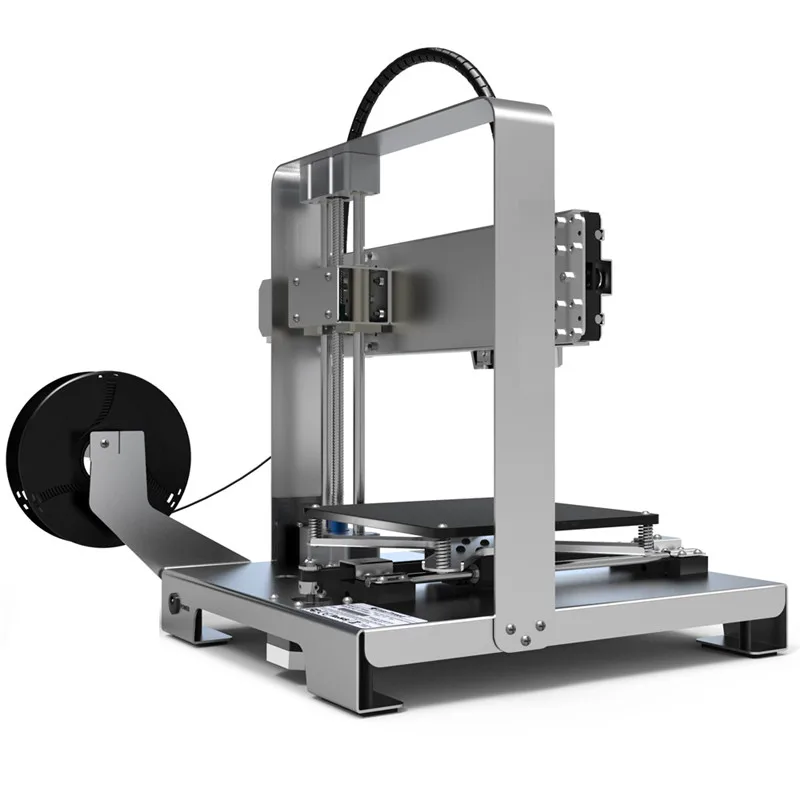

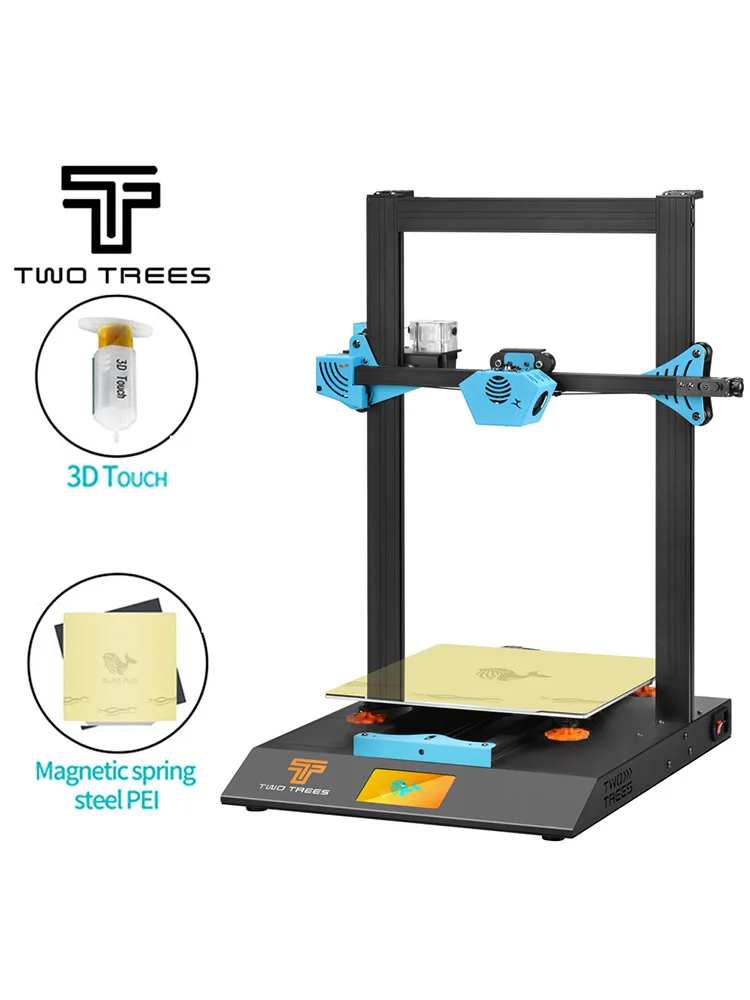

The BLU-5 is one of the most affordable desktop 3D printers we've ever made. It offers the largest print area of any TwoTrees 3D printer, the most consistent performance, and is suitable for users of all skill levels.

It offers the largest print area of any TwoTrees 3D printer, the most consistent performance, and is suitable for users of all skill levels.

Its all-metal base and frame provide durable performance. Simple, elegant design combined with outstanding performance makes the BLU-5 a toy for DIY enthusiasts, as well as a professional printing machine for designers and factories.

Here is a video review made by Aurora Tech, you can search for other video reviews of the BLU-5 printer on Youtube (formerly known as BLUER Plus).

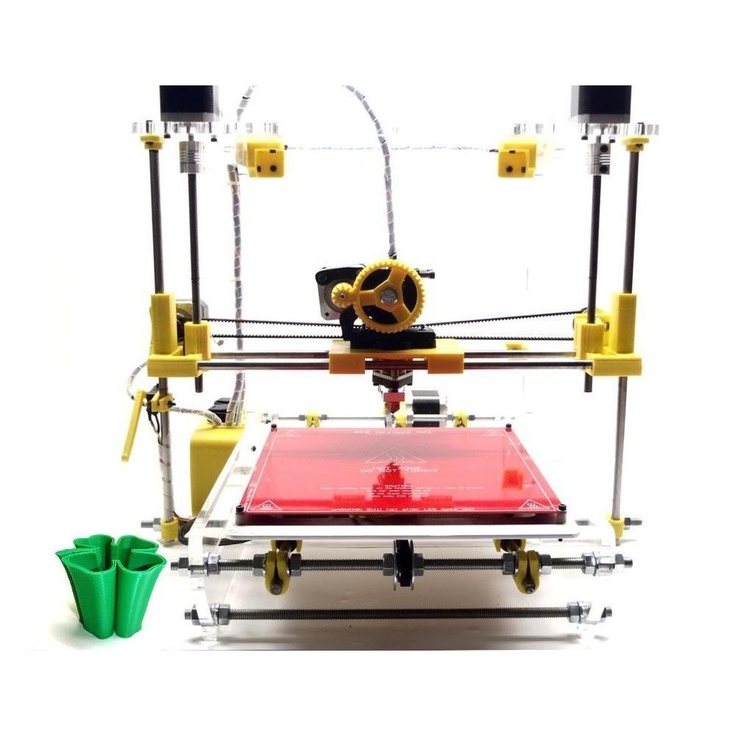

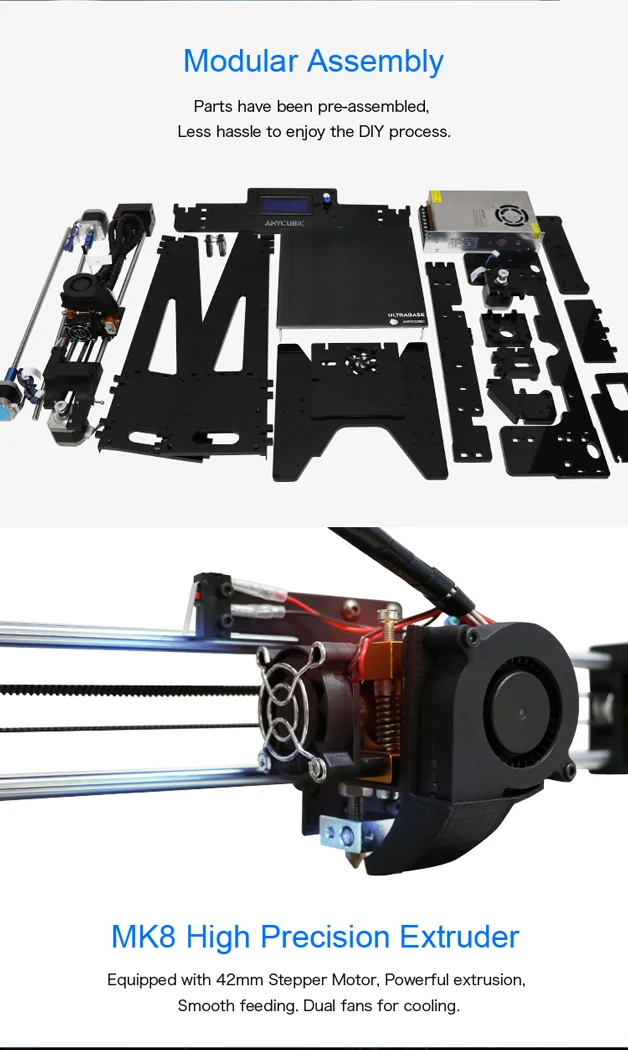

90% pre-assembled, easy to install

BLU-5 comes with 90% pre-assembled parts that require minimal installation. Most installations can be easily done with hex wrenches.

To ensure that users receive devices without printing problems, each device is assembled for a 3D cube printing test prior to delivery. Few factories test the print before shipping as it is time consuming and labor intensive.

Few factories test the print before shipping as it is time consuming and labor intensive.

90% Finished Desktop 3D Printer

3D Smart Touch Sensor and Auto Leveling

The BLU-5 also has a built-in 3D touch sensor that allows the printer to check if the print platform is level and make adjustments if necessary.

After checking that each part is installed correctly, alignment is recommended and required before printing. The alignment and leveling function in Tool Settings (on the touch screen) allows you to move the nozzle and 3D touch sensor around multiple points and register the position of each one. If the distance between the dot, nozzle and print bed differs from other dots, the software automatically starts the alignment process.

Built-in 3D touch sensor

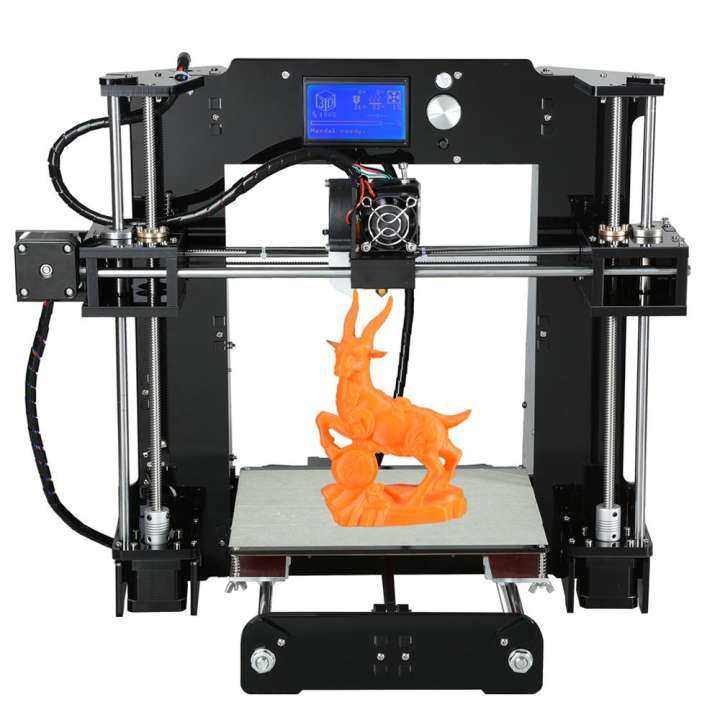

Large print area for more options

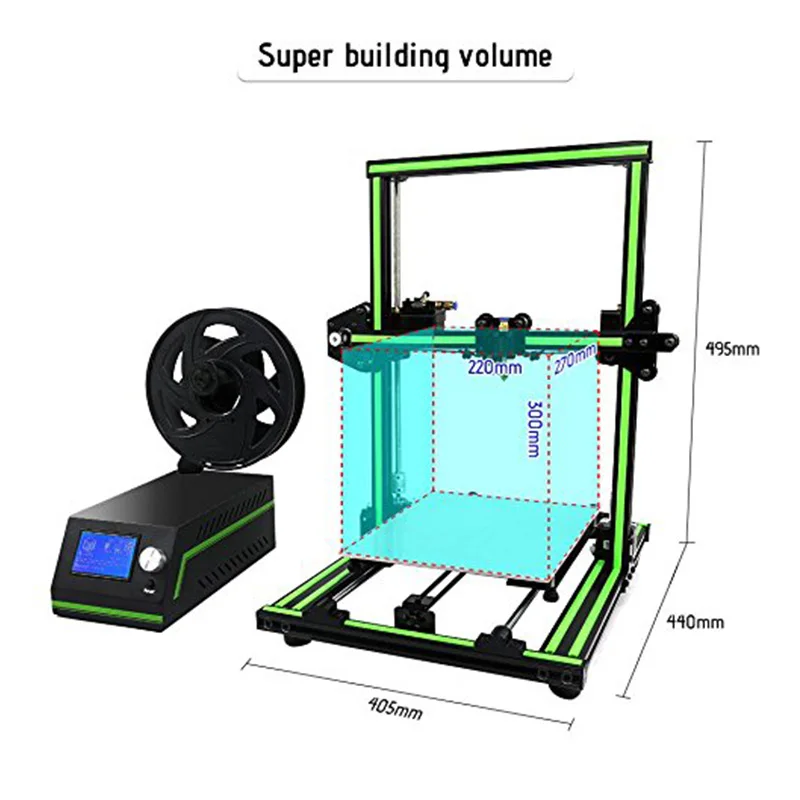

Compared to other TwoTrees consumer 3D printers, BLU-5 is the largest 3D printer with 300*300*400mm print area. It is also one of the best large-scale 3D printers available in the consumer market. The print size of 300*300*400mm provides enough space for most DIY projects and allows users to complete printing of multiple models in one print. If you're not sure what size you need, the BLU-5 is a good budget option if you take everything into account.

It is also one of the best large-scale 3D printers available in the consumer market. The print size of 300*300*400mm provides enough space for most DIY projects and allows users to complete printing of multiple models in one print. If you're not sure what size you need, the BLU-5 is a good budget option if you take everything into account.

Large 3D Printer

Patent Development: Automatic Space Adjustment Function

The basic working principle of FDM 3D printing requires that the print head and print platform move synchronously and according to the design file. Since 3D printing is extremely demanding on precision, any imperceptible defect can cause the print to fail or become distorted.

Patented auto-spacer kit with spring kits greatly reduces motion-induced vibration for high precision and smooth printing.

Auto interval function

Silent operation: TMC2209 mute driver

One of the main disadvantages of using FDM 3D printers is annoying noise.

TMC2209 mute driver reduces running motor noise and makes 3D printing an enjoyable experience.

Dual Z-Axis and Synchronous Belt

Instead of a single Z-axis lead screw, the BLU-5 uses two lead screws with a synchronous belt for smoother movement and faster response.

This unique setting effectively reduces vibration and improves print accuracy and speed.

Z-Axis Dual Guide Screws

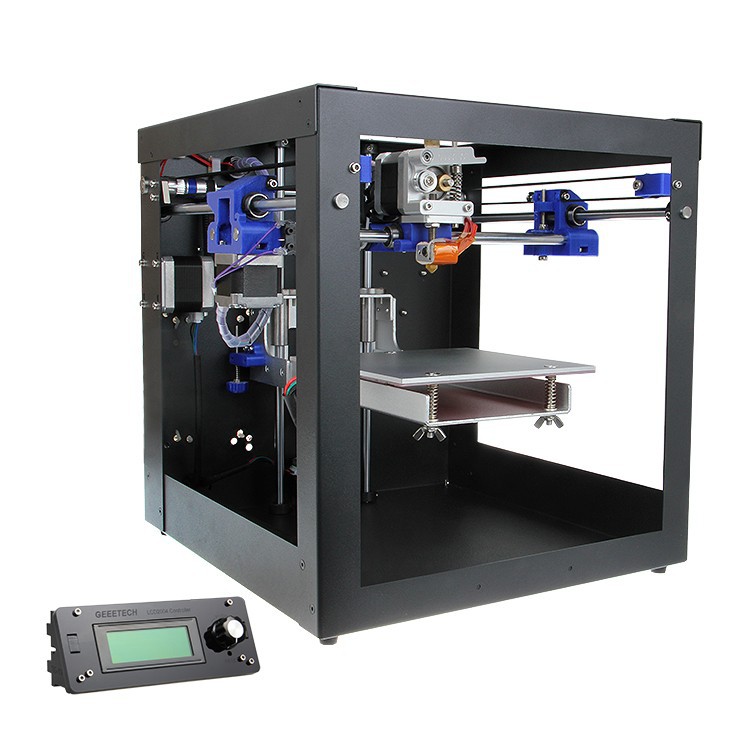

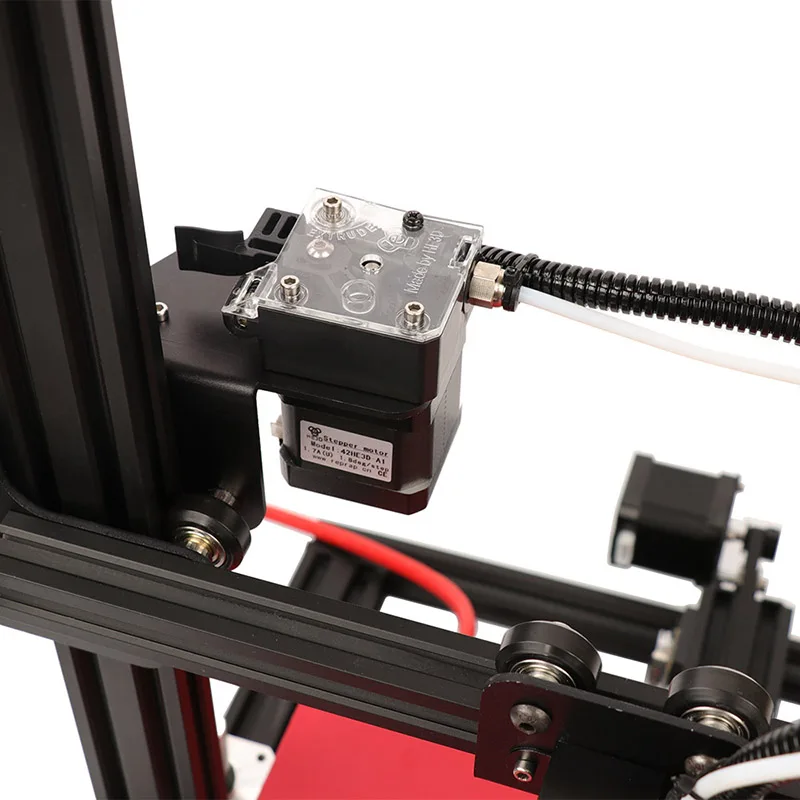

Transparent Dual Stage Extruder

Compared to 3D printers with single stage extruders, the BLU-5 uses dual stage extruders to provide greater stretching force to achieve more stable and smooth extrusion.

Transparent housing allows users to observe and control the entire process with the naked eye.

Packed PEI greenhouse

Although the PEI greenhouse is a basic accessory for 3D printers, users usually have to pay extra for it from most vendors.

To provide users with a print-ready desktop 3D printer, a PEI greenhouse is included with the BLU-5 printers.

Thanks to the elastic and wear-resistant surface, you can easily remove printed models.

RJ45 jack

Instead of using other jacks, the BLU-5 uses the common RJ45 interface for connection, which is much more readily available in local stores and easier for users to find replacements on demand.

RJ45 is also more reliable and efficient in signal transmission.

RJ45 jack

Filament running out detection function and printing resume when power on

It is quite normal when filaments run out during printing, and restarting wastes a lot of time and money on filaments. To solve this problem, all TwoTrees 3D printers are equipped with an intelligent low filament sensor and a restart function.

Whether printing is interrupted due to a power failure or a broken filament, the printer will resume printing at the exact layer or position where it left off.

Thread flow detection

- X and Y belt tensioner allows users to make proper adjustments without the need for additional tools.

- Removable motherboard service cover makes motherboard replacement much more convenient.

- The 4.3-inch touch screen control panel provides a clear, simple interface and fast response to every touch.

- All-metal base and frame make the 3D printing machine strong and durable for long-term use.

Click to use promo code

(coupon code automatically added at checkout).

Established in 2017 as a manufacturer of 3D printer accessories, TwoTrees is rapidly growing into one of the most trusted companies in the world in developing, manufacturing and marketing desktop FDM 3D printers. In addition, TwoTrees is the pioneer of self-developed laser engraving machines in China. Today, our business includes FDM 3D printers, filaments, resins, as well as laser engraving machines and related accessories that have a global reach.

With R&D teams and a specialized experimental studio, we promise to always maintain a customer-oriented concept to provide more cost-effective innovative products.