Multoo 3d printer

Multoo MT2X 3d printer

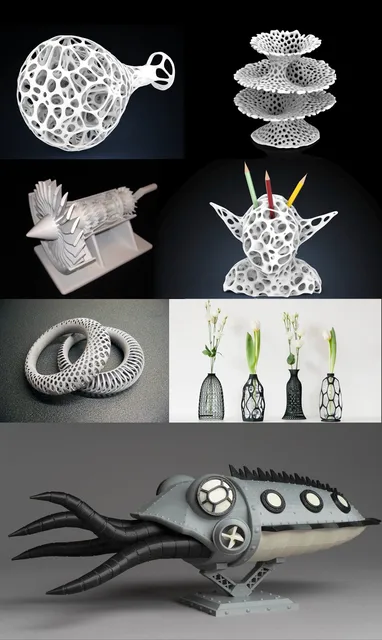

Simple setup, high uptime, and reliable dual extrusion. Push your 3D printing workflow to a whole new level. Optimized for the widest range of materials.

Check price here!

Technical Specifications:

- Printing Technology: LCD-based SLA Printing, Fused Deposition Modeling(FDM), Fused filament fabrication(FFF)

- Light-source

- Feeder type

- Exposure screen

- XY DPI

- Y axis resolution

- Display

- Layer resolution

- Printing speed

- Rated Power

- Print head

- Printer size

- Printing volume

- Printing material

- Connectivity: USB

- Package Weight

- Build Area

- Printing accuracy

- Light source

- Safety Protected Power Supply

- Print Materials: UV Resin, PLA, ABS, HIPS, PETG, Wood and TPU

- Illuminant: Diffusion, Matrix, None

- Excellent print quality

- Smooth & reliable operation

- Axis Z: Single, Double

- More info

- Easy to assemble.

Great print quality. Accurate printing results.

Build volume | Printing speed | Printing accuracy | Layer thickness| Operating noise| Nozzle temperature | Heated bed temperature | Machine Dimension | Machine Weight

Compare 3D printers by price, print technology, technical specs, and ratings.

Check price here!

ADVERTISE YOURBUSINESSHEREclick for details

Firmware

# Download the latest firmware update here.

Please check out the information page of your printer before upgrade.

If problem occurred please contact our tech support.

Extract the firmware package to obtain the .bin files.

Copy these .bin files to an empty USB flash drive.

Insert the USB flash drive into the 3d printer.

It will take about a few minutes to upgrade.

Please visit our web site for technical support.

Marlin... RepRapFirmware... Repetier... Smoothie... Klipper... Prusa... MK4duo... MakerBot...

grbl... Sprinter... BFB... FiveD... Machinekit... Redeem... Teacup... Yaskawa...

Where to buy Multoo MT2X 3d printer

Get the best deal from the largest online selection. New or used.

Slicer

Windows 10 / Mac OS X / Linux

Debian / Ubuntu / Linux Mint

openSUSE

Oracle Linux, CentOS, RedHat or Fedora

Arch or Manjaro

Show the part of mesh on the ground

Change model interior color

.exe

.dmg

.deb

.rpm

.pkg.tar.xz

Slising software installation

Manipulate 3d model in slicer

Model importing

View changing

Model changing

Support Settings

Shape editing

Raft

Slice Settings Multoo MT2X 3d printer

Redesigned UI interface. More convenient to operate.

Download 3D model files to test the latest slicing improvements. ..

..

Drivers

# Download the latest drivers for Multoo MT2X 3d printer.

Windows 10, Mac OS, Linux

Recovery guide

# Download the Recovery guide for Multoo MT2X 3d printer here.

Remove all files exceprt for the firmware files from the USB flash drive to avoid crashes.

Safety instruction

Always follow the safety instruction during assembly and usage, to avoid any unnecessary damage to the Multoo MT2X 3d printer or individual injury.

Download the latest Multoo MT2X 3d printer manual pdf here.

Please contact our customer support if you have any issues

In case of emergency, immediately cut off the power of 3d printer and contact the tech support

Multoo MT2X 3d printer includes moving parts that can cause injury

Use protection glasses when cleaning/sanding the printed models

Keep 3d printer and its accessories out of the reach of children

Vapors or fumes may be irritating at operating temperature.

Always use the 3d printer in an open and well ventilated area.

Build Manual

# Download the Build Manual for Multoo MT2X 3d printer here.

Assembly and Leveling instructions

Unpack the machine and then remove the protective film outside

Plug in the power and turn on the power switch

Set the current Z height as the Zero position

Arabic, English, French, German, Greek, Hebrew, Italian, Korean, Punjabi, Spanish, Swedish

Software

# Software for Multoo MT2X 3d printer.

Windows 10 / MacOS / Linux

Compatible with Mac or Windows computers...

Brings more accuracy for leveling

Support anti-aliasing function

Fixed the crash when file fold has incorrect file format

Optimized the stability of reading

Uninstall the previous version before installing

print preparation software

printer management software

Plugin integration: SolidWorkds, Autodesk

Supported file types: STL, OBJ, X3D, 3MF, BMP, GIF, JPG, PNG

Printable formats: G, GCODE, GCODE. gz, UFP

gz, UFP

64-bit

Easy to use. Simply choose speed and quality settings, and you can start printing. Prepare your 3D model for print in minutes with recommended settings.

The best way to prepare, manage, monitor, and share your 3D print files.

Parts

# Parts List

Resin

Scraper

Tool set

USB Drive

Gloves

Resin Vat

User manual

Funnel

Power cord

USB cable

Srews

ADVERTISE YOURBUSINESSHEREclick for details

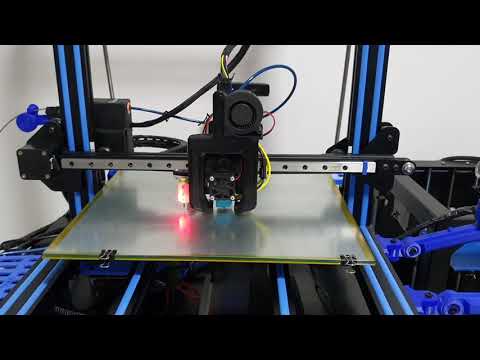

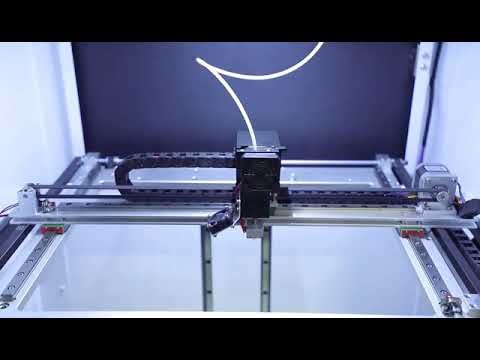

How to use Multoo MT2X 3d printer

Step by step for beginners. Printing more quantity and bigger model at once.

This tutorial teaches you how to 3D print using the computer.

A quick how to video explaining the steps to use a 3D printer.

Learn how to 3D print your models in this video!

G-Code Commands for 3D Printing

G-code stands for "Geometric Code". Its main function is to instruct a machine head how to move geometrically in 3 dimensions.

There are a few different ways to prepare G-code for Multoo MT2X 3D printer.

G0 - Rapid Move.

G1 - Linear Move.

G90 - Set to Absolute Positioning.

G91 - Set to Relative Positioning.

G-Code Examples...

M106 - Fan on

Multoo MT2X 3d printing resin cost

Standard SLA resins...

Resin or filament...

The price of a DLP 3D printer generally starts around...

Here is the price list...

Best 3D Printing Materials for Multoo MT2X

Buy 3D Printing Resins

Resin 3D printers, whether by laser, LCD or DLP, can produce some of the highest-quality 3D prints...

Best Budget Resin is...

You can find here the best SLA or DLP 3D printer resin for your 3D printer...

Buy 3D Printing Resins here!

3D Printer Filament PLA... various kinds and colors of filaments, which has even and smooth output, giving you more choices for your creativity.

Suitable for micropavè, engravings, filigree, engagement ring, dental works. ..

..

Multoo MT2X 3d printer settings

Maximum volumetric speed

Layer height

Desired resolution

Infill

Infill Patterns

Support material

Brim width

How to connect Multoo MT2X 3D printer to a computer

Connecting via USB...

Installing the driver software...

Microsoft Standard Driver for Multoo MT2X 3D Printer...

Multoo MT2X 3D printer that does not extrude

No filament comes out of the extruder. Extruder problems may have different causes. Knowing when the failure occurred is often the first thing you’ll need to consider to properly diagnose the problem.

- Out of filament

- Initial nozzle height is too close to bed

- Overheated extrusion motor

- Clogged nozzle

- The extruder needs to be primed

- Extrusion Motor is Heated More than Needed

- Filament is Stripped

The 500 x 500 x 500 mm 3D Printer Buyer's Guide (Under $1,000)

Ever wanted to make that large print, but found yourself put off because of all the parts that will need assembling after? With a 500 x 500 x 500 mm 3D printer, the build area is large enough to send your imagination into overdrive and opens up tons of possibilities.

We’ve selected the best 500x500x500mm 3D printers for every budget, but first, let’s consider the advantages of going big.

What does 500x500x500mm 3D printer mean?

The 500x500x500mm simply means that the build volume of the 3D printer is 500 x 500 x 500 mm. That is, each axis — X, Y, and Z — all have a maximum 500mm cubed build area.

Most 3D printers have substantially smaller build areas than this, especially home desktop printers. This is because it can be more difficult to maintain accuracy with larger build areas due to the complexity and size that the gantry systems need to encompass such wide areas, and as you get less compact, vibrations and other factors can reduce print quality as strength and stability declines.

For generally larger printers, we also have a buyer’s guide for large 3D printers

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

Despite this, there are a number of reasons why you’d want to buy a printer:

Why Buy a 500 x 500 x 500 mm 3D Printer?

Frees Up Time

When printing and project, you are at the mercy of the print time. Not just the print time, but the time spent setting up the printer for each print, selecting your model and print settings. Maybe you’ve been commissioned to make a large comic book character bust?

Not just the print time, but the time spent setting up the printer for each print, selecting your model and print settings. Maybe you’ve been commissioned to make a large comic book character bust?

Being able to print the entire project in one print is a massive bonus. Larger 3D printers can be left to finish the project without interruption, freeing up more time.

Print large pieces at once, or have fewer pieces to assemble

Being able to print larger parts greatly reduces any post-processing you need to do. If you’re stuck with a smaller 3D printer and need to glue many pieces together to form your larger model, these welded are weak points that can break easily.

For example, cosplay enthusiasts seeking to wow fellow convention-goers who 3D print entire cosplay outfits or armor can print their dream outfit in fewer parts on a 3D printer 500x500x500mm large.

We took a deeper dive into cosplay 3D printing, check out our recommendations here

Huge models just look more impressive, and a 500 x 500 x 500 mm build volume means you can make a full-size stormtrooper helmet, or similar-sized prints, without the need to assemble multiple parts.

Printing a whole batch at once

A batch of hobby pieces can be tricky with a small print bed. Having to reprint a series is time-consuming. With a large print bed you can print all these pieces at once because they all fit within the print bed’s area.

Print Speed

You could be forgiven for wondering if large 3D printers take longer to print, but with the right hardware, this isn’t the case. Investing in a larger nozzle will greatly affect how quickly a large printer can finish a project.

This, and taller layer heights can quicken the process — but you need to decide if you’re comfortable with the quality trade-off.

The Best 500 x 500 x 500 mm 3D Printers

With something to suit every budget, we have scoured the market for the best models that can take on larger projects. We list printers with exact 500 x 500 x 500 mm printing dimensions, as well as some that come close, but are also great options if you don’t need exactly 500mm³ dimensions.

Starting with one of the most popular in the world of 3D printing:

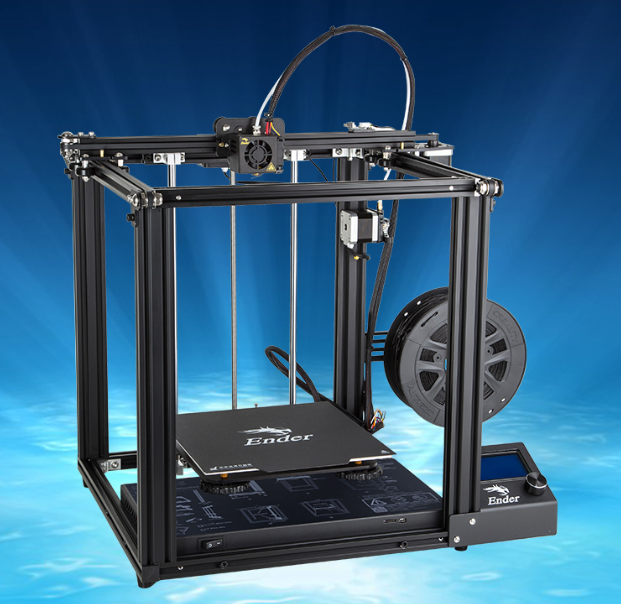

Creality CR-10 S5 – Best Under $1,000

- Price: $719 — Available on Creality Store here / Available on Amazon here

So big it will need a dedicated space, the sheer size of the Creality CR-10 S5 will get the creative juices flowing.

Larger projects mean more filament, so strength is key. The build plate rests over two rails and boasts powerful motors that make it feel sturdier than the smaller CR-10 (and its smaller 300 x 300 x 400 mm build volume). These rails retain print quality, but also reduce noise so those day-long prints are less likely to disturb the rest of the house.

A generally considered downside to purchasing a larger 3D printer is that assembly can take longer. However, this isn’t such an issue with the CR10 S5. It comes in only a few sections that are easy to assemble, with clear instructions and clearly labeled wires. All in all, you’ll only need around 10 minutes to get it up and running.

The hot end can take on a multitude of filaments including ABS, PLA, TPU, wood, carbon, and copper. This means you can easily switch between printing projects like a large-scale anime character, and a carbon fiber model airplane.

It requires a little patience as the printing bed takes a little longer to heat up. The CR10 S5 needs around 30 minutes to get to 80C, but this is understandable given the size of the printer.

It also boasts a lot of the common features you want with any 3D printer for general quality of life improvements. These include a print resume function in case there is a power cut, and a filament detector that pauses the print when you’ve run out, so you can resume after replacing your filament without ruining your print.

Some neat added extras include a mini SD card and USB which is where you will find the instructions and test models to get you started. All in all, this is an excellent 3D printer 500x500x500mm by any standards, especially given the attractive price point.

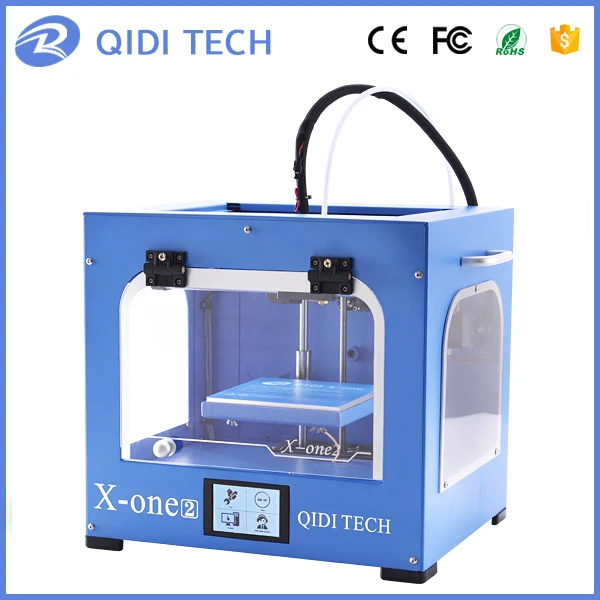

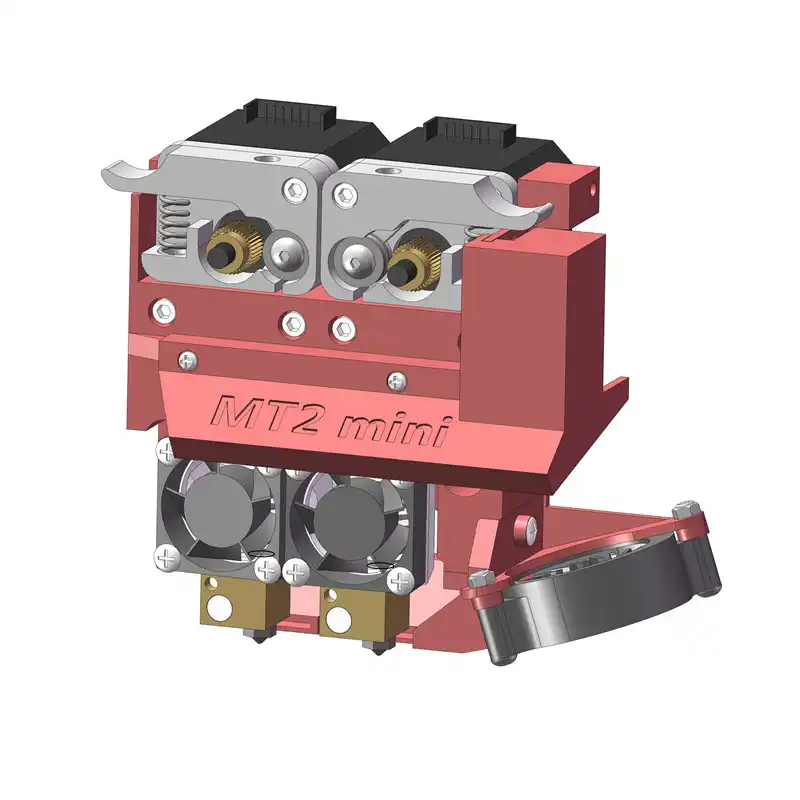

Multoo MT2X – Another great 500x500x500mm build area 3D printer

- Price: $1,299

The Multoo MT2X is a versatile 500 x 500 x 500 mm 3D printer with automatic leveling. This will be an advantage as adjusting the print bed between every project can be tricky, especially with large-scale prints.

We also have a ranking of the best auto-leveling 3D printers

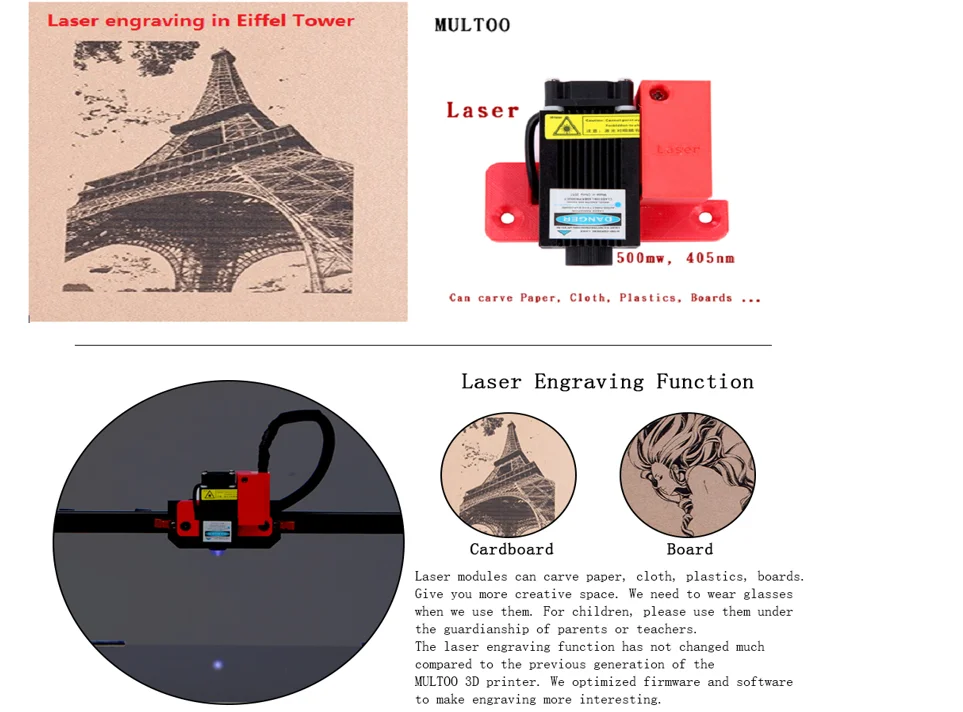

You can also upgrade it to function as a laser engraver, for just $50 extra, and is a great feature that you don’t always get with 3D printers. With this you can engrave a design onto a leather belt, personalize a wooden coaster, or make a huge range of other projects.

Even more impressive is the fact that the Z-axis can be adjusted to reach 800mm — if 500mm doesn’t satisfy you, it can get even bigger! Those full-size models are going to need more room after all.

The auto-resume feature picks up where you left the project in the event of a power cut, and its dual extruder means it can be used for single, dual, and parallel printing. This makes it possible to print up to 5 objects in one sitting, reducing the time spent managing projects.

This makes it possible to print up to 5 objects in one sitting, reducing the time spent managing projects.

We also have a ranking of the best dual extruder 3D printers

Because large projects can be time-consuming (we’re looking at you, full-size figurines), efficiency is a priority. Dual extruders allow the Multoo MT2X to print parallel projects at the same time. It also opens up the opportunity to print two colors, or different materials at the same time.

The 5mm thick glass of the heat plate makes it stable. This also helps to keep the print warmer, reducing warping and ensuring the project can get off the ground in no time.

Not quite 500x500x500mm 3D printers, but alternatives with similar build area

Anycubic Chiron – Affordable Alternative

- Price: $439 — Available on Anycubic Store here / Available on Amazon here

- Build volume: 400 x 400 x 450 mm

Although this is not strictly a 500 x 500 x 500 mm 3D printer, we have included it as a budget-friendly option that still has a large build area.

At 400 x 400 x 450 mm, there is still plenty of room to take on larger projects; it is an affordable option that has seen more people get into 3D printing. The sacrifice is in the manual leveling, but working out the settings is made easy by the strong community support. This is a popular 3D printer after all.

The Ultrabase Pro print bed offers great adhesion, and also makes prying the finished print off the platform easy once the model has had time to cool.

The high-quality extruder makes printing trickier filaments like TPU a breeze, extrudes more smoothly, and reduces the likelihood of that hundred-hour print going wrong.

There are plenty of neat features that stand out for a model at this price. They include a full-color touch display, a filament sensor that alerts you if anything has gone wrong or it has run out, and a print speed that ranges from 20 to 100 mm/s a second.

Assembly should take between 30 to 60 minutes which only means one thing – there is more time to spend on the fun part – printing.

3D printing in cartoon production

Implementation stories

Art and design

Author: Semyon Popadyuk

Author: Semyon Popadyuk

“Sad”, “beautiful”, “witty”, “each character is charming and original in its own way”: and these are not just words that are usually used to describe puppets in an animated film created using the stop-motion technique. We are not afraid to say: the full-length cartoon "Anomalise" has not yet been equal. Thanks to high-resolution full-color 3D printing on the 3D Systems ProJet CJP 660 printer, the creators of the picture managed to reflect the entire range of human emotions of the characters.

Starburns Industries, a full-service production company based in Burbank, California, used a 3D printer to render thousands of different facial expressions with life-like detail - wrinkles, smiles, furrowed brows, lines of concern and bags under the eyes.

Michael and Lisa, the main characters of "Anomalise"

Aesthetics and performance: two in one

In recent years, additive technologies have become widely used in the film industry to print prototypes, props and objects that are difficult to create using traditional methods. However, Anomalisa sets a precedent for the use of 3D printing in the entertainment industry in terms of such a large amount of work and realism in conveying emotions.

Director Duke Johnson, who co-created the film with Charlie Kaufman (Being John Malkovich, Eternal Sunshine of the Spotless Mind), noted the role of 3D printing in conveying the inner feelings of the characters and reproducing the smallest nuances.

While the ProJet CJP 660 did an excellent job of aesthetics, it was chosen primarily for its performance: this 3D printer is fast, reliable, and capable of producing true-to-life colors.

The ProJet CJP 660 3D printer produces full color 3D images in a single cycle without the need to change palettes. The build area of the printer (254 x 381 x 203 mm) allowed Starburns to create dozens of faces with different facial expressions in one cycle of work for several hours.

The build area of the printer (254 x 381 x 203 mm) allowed Starburns to create dozens of faces with different facial expressions in one cycle of work for several hours.

“Color is the most important factor for us, along with the speed and performance of the machine,” says Brian LaFata, head of production at Starburns Industries. “ProJet worked for us practically non-stop for a year and a half while Anomalisa was being created, printing countless faces.”

Thousands of facial expressions

3D printer makes it possible to render thousands of different facial expressions with believable details

Starburns modeled and printed three basic head patterns for Anomaliese: one for each of the lead characters, Michael and Lisa, and one for a character referred to as the "face of the world" which is modeled after at least 20 faces of the studio's employees. . "Face of the World" was used for all characters except Michael and Lisa.

The faces of the characters are divided into upper and lower parts. Starburns Studio has modeled and printed thousands of facial expressions. Thanks to this, the animators have the opportunity to choose almost any facial expression for a particular scene.

Starburns Studio has modeled and printed thousands of facial expressions. Thanks to this, the animators have the opportunity to choose almost any facial expression for a particular scene.

“We had whole racks of faces to choose from at any time,” says LaFata. “It could take a lot of face models just to find the right smile.”

Keep Feeling

Maintaining a visible border between the upper and lower parts of the face without the use of digital retouching was a conscious decision by the directors of Anomaliese.

James A. Fino, executive producer and partner at Starburns, explains the decision in an article on the Producers Guild of America website: “In recent animated films, these lines are usually retouched, but in Anomalys we took a different approach. The stitches on the characters' faces are not so much distracting as they gently but insistently highlight the incredible artistry displayed in the cartoon."

In an article by Mekado Murphy in The New York Times, Kaufman's co-director explained it this way: “We didn't want to hide the fact that the film was shot in stop motion. We wanted the viewer to have a sense of the invisible presence of the animators."

We wanted the viewer to have a sense of the invisible presence of the animators."

Starburns also did minimal post-processing on the characters' faces to keep them feeling like they were just printed on a ProJet 660 3D printer. Once again, this was a conscious choice by the directors.

“We used it (3D printing) for a very specific task – to give faces the desired realism, and it was impossible to achieve the desired textures and shades by freehand painting,” says Caroline Kastelik, Starburns puppet maker, in an interview with IndyWire. – And, in fact, that is why the faces have a very beautiful texture ... I find it aesthetically ideal. It also saved us a lot of time."

"Anomalisa" is called a masterpiece of puppet animation

Local support

Creating thousands of faces, dozens of body models, and realistic props for cartoons like Anomaliese requires teamwork; it involved not only about 200 studio employees, but also third-party partners.

LaFata would like to thank 3D Systems partner 3D Rapid Prototyping, next door in Garden Grove, California, for making regular supplies to Starburns and even printing face models when needed.

“We did a lot of faces, often 24/7, and Billy Craig (President and CFO of 3D Rapid Prototyping) and his team were always there to help us out,” he adds.

Big future in 3D printing

While the behind-the-scenes stories of the use of technology in films can be fascinating, the measure of success is how the film is received by the public. In the case of Anomaliza, 3D printing is not just a special effect or a highlight; it is an integral part of the game characters.

Everyone seemed to like this approach: apart from the Oscar and Golden Globe nominations, Anomalisa became the first animated film to receive a special jury prize at the 72nd Venice Film Festival. In his 5-star review in Rolling Stone, Peter Travers calls Anomalisa "a masterpiece of puppet animation. "

"

Brian LaFata does not consider "Anomalisa" an isolated phenomenon. “The scale and speed at which you can produce full color models on a 3D printer like the ProJet CJP 660 is definitely a big advantage,” he says. “I think 3D printing has a great future in terms of stop-motion filmmaking.”

English translation

Do you need to print a layout, a souvenir or a prototype using full-color 3D printing technology? Contact us! Send an online application or call: +7 (495) 223-02-06.

Article published on 10/11/2017, updated on 07/04/2022

Be-Be-Bears online | Episode 218 | 3D printer

Be-Be-Bears online | Episode 218 | 3D printer - Tlum.ru✖

- Articles

- Tests

- cartoons

- Watch online

- City of numbers

- Shop Mult

- Promo codes

- Mugs