3D printed space shuttle

Teardown: 3D Printed Space Shuttle Lamp

Since the very beginning, the prevailing wisdom regarding consumer desktop 3D printers was that they were excellent tools for producing prototypes or one-off creations, but anything more than that was simply asking too much. After all, they were too slow, expensive, and finicky to be useful in a production setting. Once you needed more than a few copies of a plastic part, you were better off biting the bullet and moving over to injection molding.

But of course, things have changed a lot since then. Who could have imagined that one day you’d be able to buy five 3D printers for the cost of the crappiest Harbor Freight mini lathe? Modern 3D printers aren’t just cheaper either, they’re also more reliable and produce higher quality parts. Plus with software like OctoPrint, managing them is a breeze. Today, setting up a small print farm and affordably producing parts in mass quantities is well within the means of the average hobbyist.

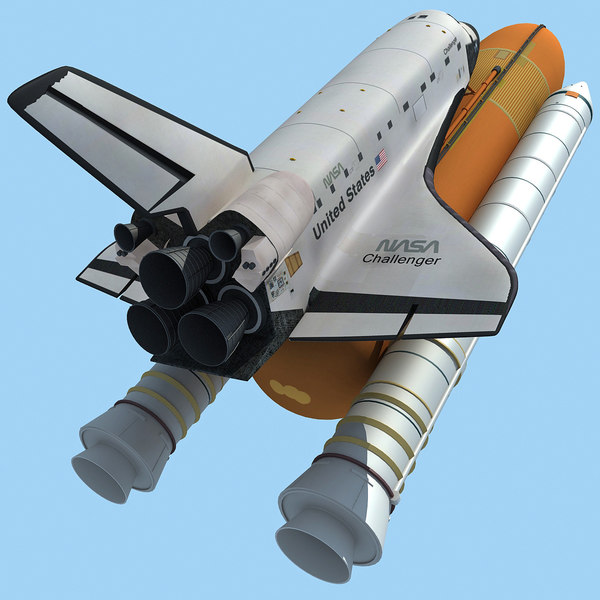

Flickering LEDs provide a sense of motionSo perhaps I shouldn’t have been so surprised when I started seeing listings for these 3D printed rocket lamps popping up on eBay. Available from various sellers at a wide array of price points depending on how long you’re willing to wait for shipping, the lamps come in several shapes and sizes, and usually feature either the Space Shuttle or mighty Saturn V perched atop a “exhaust plume” of white PLA plastic. With a few orange LEDs blinking away on the inside, the lamp promises to produce an impressive flame effect that will delight space enthusiasts both young and old.

As a space enthusiast that fits somewhere in between those extremes, I decided it was worth risking $30 USD to see what one of these things looked like in real life. After waiting a month, a crushed up box arrived at my door which I was positive would contain a tiny mangled version of the majestic lamp I was promised — like the sad excuse for a hamburger that McBurgerLand actually gives you compared to what they advertise on TV.

But in person, it really does look fantastic. Using internally lit 3D printed structures to simulate smoke and flame is something we’ve seen done in the DIY scene, but pulling it off in a comparatively cheap production piece is impressive enough that I thought it deserved a closer look.

Now it’s always been my opinion that the best way to see how something was built is to take it apart, so I’ll admit that the following deviates a bit from the rest of the teardowns in this series. There’s no great mystery around flickering a couple LEDs among Hackaday readers, so we already know the electronics will be simplistic in the extreme. This time around the interesting part isn’t what’s on the inside, but how the object itself was produced in the first place.

The Star of the Show

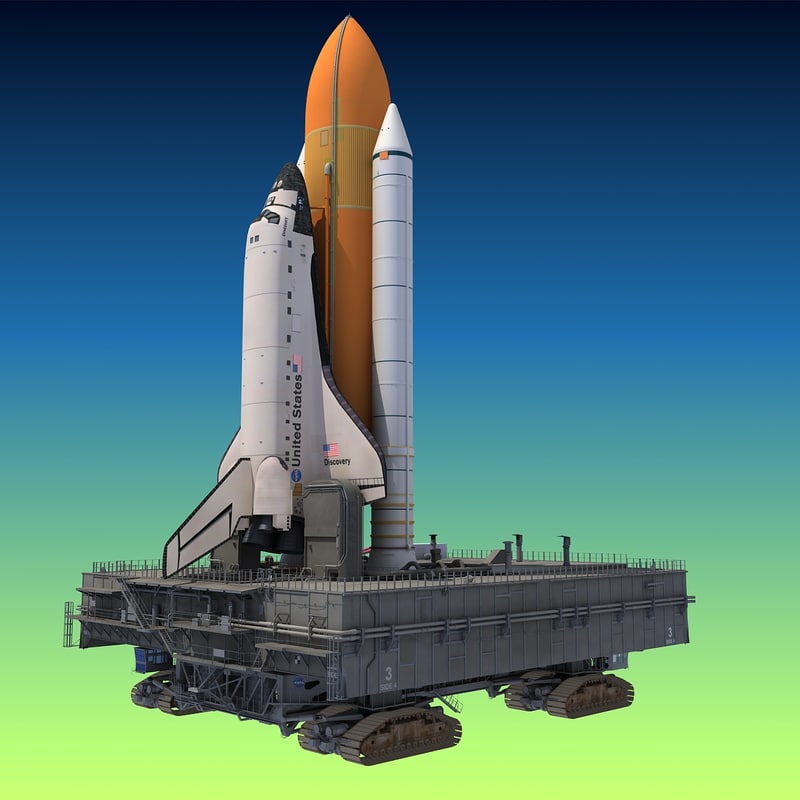

I picked the Space Shuttle version of his lamp over the Saturn V because it’s by far the harder of the two to produce. I knew the iconic orbiter, along with its orange external tank and side-mounted boosters, would make for a more difficult FDM print than the cylindrical Apollo rocket. The Shuttle would almost certainly be printed in multiple pieces and glued together, and I wanted to see what kind of build quality could be expected in the worst case scenario.

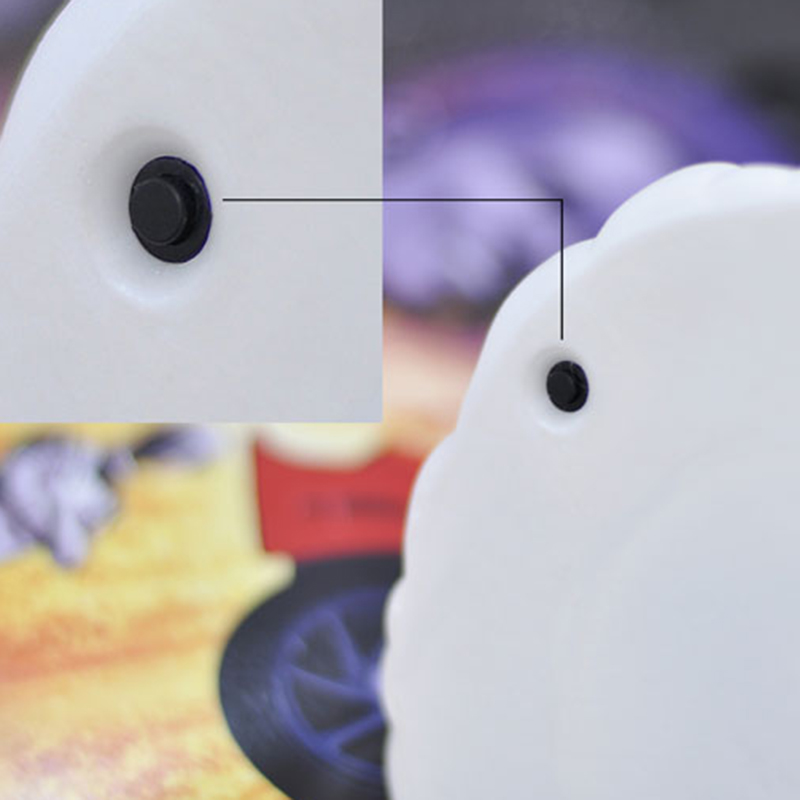

But even upon close examination of the roughly 120 mm (4. 7 inch) spacecraft, I have to admit they’ve done a pretty good job. Clearly a lot of finish work went into the piece, especially on the external tank and boosters, but the printer used to produce the Shuttle is obviously pretty well dialed in. You can see faint layer lines on the orbiter itself, but in my experience, they’re always hard to hide on white surfaces. Also note that the windows aren’t just painted on, but are actually tiny indentations in the print surface, as are the RCS thrusters on the nose.

7 inch) spacecraft, I have to admit they’ve done a pretty good job. Clearly a lot of finish work went into the piece, especially on the external tank and boosters, but the printer used to produce the Shuttle is obviously pretty well dialed in. You can see faint layer lines on the orbiter itself, but in my experience, they’re always hard to hide on white surfaces. Also note that the windows aren’t just painted on, but are actually tiny indentations in the print surface, as are the RCS thrusters on the nose.

In terms of production, it seems that the orbiter was printed separately from the tank and boosters, and then glued on after the parts had been painted. It’s also clear that all the parts were printed vertically, which is somewhat surprising, as the logical print orientation for the orbiter would be to have it laying flat on the bed.

Considerable support material must have been used to print the orbiter vertically, the remnants of which can be seen in the stepped surface on the back of the wings. I’m not sure why they would have taken this more difficult route, though it’s possible they’re printing them vertically to maximize how many can fit on the bed at once.

I’m not sure why they would have taken this more difficult route, though it’s possible they’re printing them vertically to maximize how many can fit on the bed at once.

While the 3D printer owner in me is impressed by the quality of the final piece, the space nerd in me has to say that this isn’t a particularly good rendition of the Space Shuttle. The wingtips are all wrong, there are no OMS thrusters on the back, and the nose looks more like a sad cartoon dog than the legendary spaceplane NASA flew for three decades. Of course, the kid who’s room this lamp would probably end up in won’t know any of that.

Cranking Out Clouds

While the Space Shuttle itself was quite impressive, the plume of PLA it rides on is decidedly less so. Painting the plastic would have reduced the glowing effect, but the downside of leaving it unfinished is that even small surface inconsistencies are obvious. A close examination shows clear signs of under-extrusion, often a hint that the print speed has exceeded the extruder’s ability to melt the required volume of plastic.

Things are only worse on the inside. The plume was printed without an internal support structure to save time and material, and while that’s worked fine for the most part, there are a few areas where the print came quite close to failing. One patch near the bottom deformed so badly that it looks like it may have been scraping against the extruder, as there’s hints of discoloration and charring.

In general, my impression is that the plumes are being printed at a much faster rate than the Shuttle itself. It could even be that they are printed on a second set of less stringently maintained and calibrated printers, as they don’t need to have anywhere near the detail of the “hero” spacecraft they get mated to.

Lighting the Candle

As you probably suspected, the electronics inside the lamp aren’t anything to get excited about. The small PCB has eight LEDs (four red, four yellow) being driven by an unmarked 8-pin IC, and is hot glued directly to the top of an 800 mAh pouch cell.

A smaller board is responsible for charging the cell with a standard micro USB cable, and features the LTH7 battery management IC which regular readers may recall we last saw used in the power supply circuit of some very bloated restaurant pagers. The charging module looks like it might be repurposed from some other device, but the one-trick nature of the LED board makes me think it’s purpose built for these lamps.

Money Talks

It seems pretty clear to me that all the parts for this lamp have been produced using standard consumer 3D printers, as there’s nothing here that couldn’t be accomplished on an entry-level Ender 3. But what about the material costs? Well, this particular style of lamp weighs in at approximately 160 grams, and since we know from the included documentation that it was printed in PLA, we can easily calculate some interesting metrics.

3D Printing Cost CalculatorNamely, running each one off consumes slightly north of 52 meters of filament, at a cost of roughly $3. 20 USD given current consumer PLA prices of ~$20 per kilogram. While this doesn’t take into account the support material which would have been required when printing the Shuttle, we can also bet that the companies printing these lamps aren’t paying full retail price for their filament. Even with the occasional failed prints skewing the number, it’s safe to say the material cost for each of these lamps is well under $4.

20 USD given current consumer PLA prices of ~$20 per kilogram. While this doesn’t take into account the support material which would have been required when printing the Shuttle, we can also bet that the companies printing these lamps aren’t paying full retail price for their filament. Even with the occasional failed prints skewing the number, it’s safe to say the material cost for each of these lamps is well under $4.

Given China’s infamously low cost of labor, and the minimal cost of the simplistic electronics required to kit them out, there’s quite a profit to be made on each lamp at $30. Such an operation could quickly recoup the cost of the initial print farm, at which point the only ongoing expenses would be a fresh supply of PLA, batteries, and LEDs.

In short, it looks like we were all wrong. Or at least, not imaginative enough to predict the quantum leaps that desktop 3D printing would make in a decade’s time. While it might be a stretch to say that it’s an ideal solution, products like this are proof positive that print farms of consumer 3D printers can not only churn out production-ready parts, but that they can potentially make you a hell of a lot of money doing it.

3D-Printed Rockets Set To Blast Off

Relativity Space stage 1 3D-printed rocket being installed at Cape Canaveral, Fla.

Trevor Mahlmann/Relativity SpaceIf this summer's Terran1 launch from Cape Canaveral is a success, Relativity Space will be the first aerospace manufacturing company to send an entirely 3D-printed rocket into space. Soon after, a California start-up called Launcher will deploy its Orbiter satellite platform powered by 3D-printed rocket engines after getting a boost into space from a SpaceX.

It's hard to overestimate the impact 3D printing – also called additive manufacturing – has had on the space industry. No other technology has enabled so many companies to enter this industry and deliver vehicles, engines, and rockets in so short a time at such low costs. And now, the number of start-up rocket manufacturers is poised to boom as more commercially available 3D printers prove up to the task of churning out space-worthy components.

For example, UK-based aerospace company Orbex hopes its 3D-printed rockets, made with the latest metal 3D printer from German manufacturer EOS, will blast off from Scotland by the end of the year. And in the U.S., young rocket engine maker Ursa Major is taking orders now for its new Arroway propulsion engine designed to displace the now-unavailable Russian-made propulsion sources. It’s also 3D printed using available metal 3D printers.

“I don’t think our company would exist without 3D printing,” says Jake Bowles, director of advanced manufacturing and materials at Ursa Major, who spent five years at SpaceX. “Our evolution was strongly tied to the existence and the maturity of 3D printing.”

Render of Ursa Major’s 3D-printed Arroway heavy-launch engine.

Ursa MajorMORE FROMFORBES ADVISOR

Ursa Major set out to bring an engine to market at a much faster pace than it had been done before, in months not years, which was only possible by prototyping and manufacturing with 3D printers, says Bowles.

While Relativity Space and others have developed proprietary 3D printing technology for their rockets, Bowles says using new commercial 3D printers enabled Ursa Major to keep costs under control and iterate on designs rapidly, without having to stumble through the early technology development required with homegrown 3D printers.

“Our team is constantly evaluating new 3D printer companies coming out with innovations because there's a lot of competition for a share of the aerospace and space launch market,” says Bowles. The global aerospace 3D printing market size is predicted to reach $9.27 billion by 2030, according to Strategic Market Research.

Companies are racing to offer the most powerful, most flexible, and cheapest options to companies, such as AmazonAMZN , that are looking to put satellites into orbit to deliver global broadband, capture high-resolution images of activity on earth, and even establish private space station hotels for the ultra-wealthy.

The combustion chamber of the Launcher E-2 rocket engine is fully 3D-printed in copper alloy on an . .. [+] AMCM version of an EOS printer while the rocket's injector was 3D printed on a Velo3D Sapphire.

.. [+] AMCM version of an EOS printer while the rocket's injector was 3D printed on a Velo3D Sapphire.

3D Printing Fueling the Race to Commercialize Space

With additive manufacturing technology cutting launch costs by as much as 95% compared to the NASA space shuttle program, the door is open for more services from orbit driving stiff competition among rocket makers. Launcher’s company slogan reads like a Walmart ad: “Anywhere in space at the lowest cost.”

Chipping millions off the cost of deploying satellites recently garnered Launcher funding from the U.S. Space Force to further develop its E-2 3D-printed, high-performance liquid rocket engine for the Launcher Light launch vehicle, scheduled to fly in 2024. U.S. Space Force said: “Launcher’s E-2 liquid rocket engine has the potential to significantly reduce the price to deliver small satellites to orbit on dedicated small launch vehicles, which is a key capability and priority for the Space Force. ”

”

To cut costs and speed production, Launcher also uses 3D printers from EOS as well as California-based Velo3D.

“Rocket engine turbopump parts typically require casting, forging, and welding,” says Max Haot, founder and CEO of Launcher. “Tooling required for these processes increases the cost of development and reduces flexibility between design iterations. The ability to 3D print our turbopump, including rotating Inconel shrouded impellers, thanks to Velo3D’s zero-degree technology, makes it possible now at a lower cost and increased innovation through iteration between each prototype.”

With traditional manufacturing methods for aerospace, it’s common to hear of nine- to 12-month lead times and huge expenses in tooling to build and test, something like a pump-fed oxygen-rich staged combustion engine, says Eduardo Rondon, a senior propulsion analyst at Ursa Major, another SpaceX veteran. “Additive manufacturing allows us to put a new design on the test stand, decide to make a change, work on an alternate architecture, print it, and get it on the stand in weeks. ”

”

Orbex 3D prints its rockets on the same printer type as Launcher, the AMCM M4K-4 metal printing platform from EOS, which came out in 2021. The company has also used metal 3D printers from German company SLM Solutions.

In June, U.K.-based aerospace company Orbex unveiled Prime, a prototype of its 3D-printed ... [+] small-satellite launching rocket powered by seven 3D-printed engines.

Orbex3D Printing Not Just for Start-Ups

3D printing has a long history in space ever since SpaceX unveiled its 3D-printed SuperDraco rocket engine in 2013.

Aerospace giant Aerojet RocketdyneAJRD redesigned its Bantam rocket engine family in 2017 take full advantage of additive manufacturing capabilities that reduce the total design and manufacturing time from more than a year to a couple of months while lowering the cost by about 65% compared to conventional manufacturing methods.

"These engines, which would normally be composed of over 100 parts, are built from only three additive-manufactured major components: the injector assembly, the combustion chamber, and a monolithic throat and nozzle section," the company says.

Rocket Lab, another pioneer in commercial satellite launches, first launched its lightweight 3D-printed rocket engine, the Rutherford, in 2017. Its combustion chamber, injectors, pumps, and main propellant valves are all 3D-printed and have already powered 27 launches, including the one this week.

On Tuesday, Rocket Lab’s Rutherford engine powered the company’s Electron rocket from New Zealand with a NASA payload bound for the moon.

Despite the fact that NASA and seasoned launch veterans have tested, validated, and incorporated additive manufacturing into their programs for years, today’s commercial 3D printing technology and advanced metal alloy materials have matured so rapidly that companies like Launcher, Ursa Major, and Orbex can get from prototype to launch in less time for less money.

“We started from day one designing around 3D printing, and taking advantage of capabilities that it offers,” says Bowles. “This has allowed us to build internal know-how on how to optimize designs for 3D printing, which we can then apply to new engines that we need to develop and sell to meet market demand. And by already knowing how to do that we can get to market faster.”

And by already knowing how to do that we can get to market faster.”

3D printing in space - Zelenyikot

Now 3D printing has lost its halo of novelty and innovation, becoming one of the technological operations of modern industry. Astronautics is a rather conservative industry, but there is also a search for the use of 3D printers. Plastic printing has already gone into space as an experiment, and metal powder sintering is used in rocket science.

At large enterprises in the space industry, 3D plastic printing has found application in prototyping and mold making. Selective laser sintering of metal powder has not yet earned the trust of rocket scientists, and still does not compete with casting, stamping and milling. Metal 3D printing technology is still perceived as an experiment, often carried out at public expense. For example, in 2015, a combustion chamber for a rocket engine was printed with copper using NASA funds.

Further experiments were carried out with different alloys and manufacturing techniques. One of the engines with a 3D printed combustion chamber was tested at the stand, but the engines for rockets produced under a government contract were left unchanged.

One of the engines with a 3D printed combustion chamber was tested at the stand, but the engines for rockets produced under a government contract were left unchanged.

Private space companies are more open to innovation and bolder in introducing advanced technologies into mass production. RocketLab, a New Zealand company, has mastered 3D printing technology in the manufacture of elements of the Rutherford rocket engine. One of the key elements of a rocket engine is printed - a combustion chamber and a nozzle with a cooling jacket, where rocket fuel must circulate during engine operation. Rutherford was tested first on the bench, then during the space launch. The first rocket launch failed due to a failure in the communications system, and the second, in January 2018, was successful.

True Rutherford from RocketLab is quite light, has a thrust of about 2. 5 tons and a weight of about 25 kg. Nine of these engines are required in the first stage of the Electron rocket to launch a payload of just 200 kg into low Earth orbit.

5 tons and a weight of about 25 kg. Nine of these engines are required in the first stage of the Electron rocket to launch a payload of just 200 kg into low Earth orbit.

Several 3D printed metal elements are used in the much more powerful Merlin engines on SpaceX's heavy Falcon 9 rocket. However, the key elements of this engine are made using other technologies; milling, injection molding, hot forming, etc.

American startup Relativity Space has gone the farthest. Its founders propose to produce a fully 3D printed rocket. Although we are talking about the mass use of parts created using selective laser sintering technology using a specially designed 3D printer based on Kuka robots.

According to the authors of the project, they managed to reduce the total number of rocket parts from 100,000 to 1,000. A small parabolic antenna, a solar array deployment mechanism, elements of an imaging system, a small CubeSat satellite body. Three-dimensional printing reduces the mass of elements, reduces the total number of parts, opens up new possibilities in the design of parts based on topological optimization, allows you to replace wire loops with conductive threads stretched directly through the walls of the structure.

Although the products were never launched into space, relying on previously mastered technologies. Although, it is possible that the results obtained will find application in future satellite platforms.

With regard to 3D printing, the conservatism of space technology manufacturers affects, because it is not enough to develop a new structural element, it is necessary to conduct its multiple tests on Earth, then launch it into space and see there the direct benefits that the novelty will provide compared to analogues of previous years. Therefore, it is easier for private beginners to use new technologies, because their development and so require a full test.

A separate area of 3D printing that has not yet got out of the experimental stage is printing in space. This direction is considered as a promising opportunity to realize the dreams of the theoreticians of astronautics of the last century, and start production in space. At first, such production could cover the needs in space, and then on Earth, opening up the possibility of moving into space the most environmentally hazardous industries. However, 3D printers are still far from solving global problems.

However, 3D printers are still far from solving global problems.

An experiment on 3D printing with ABS plastic in microgravity was carried out onboard the ISS. The astronauts were able to successfully print a ratchet key from a file transmitted from Earth, confirming the fundamental possibility of creating new products in orbit.

The company that equipped the ISS with a 3D printer - Made In Space - hopes to develop technology and create printers capable of creating structural elements of spacecraft and orbital stations directly in a vacuum.

In 2013, Deep Space Industries, a private company, set out to develop a 3D printer that could print metal in zero gravity. The company aims to extract minerals from asteroids, so it is planned to use the main material of metal asteroids, iron-nickel alloy, as a raw material. However, today all references to this development have been removed from the DSI website.

Another company that has set its sights on asteroids, Planetary Resources, also sees a future in using space resources in orbital manufacturing. As an experiment, the company printed a small design in an earth laboratory using a powdered metal meteorite as a material. (Header photo).

As an experiment, the company printed a small design in an earth laboratory using a powdered metal meteorite as a material. (Header photo).

The Russian company Anisoprint is developing a technology for 3D printing from composites and is considering printing composite elements of spacecraft in orbit as a possible application.

Another Russian startup 3D Bioprinting Solutions plans to conduct an experiment on the Russian segment of the ISS, with the biofabrication of body tissues. It is assumed that microgravity conditions will allow the formation of stable three-dimensional structures and full-fledged tissues and even organs, the creation of which on Earth is prevented by gravity. The equipment for the experiment has already been sent to the ISS.

On Earth, 3D printers can already handle not only small items, but entire houses. Similar experience is proposed to be applied in the creation of extraterrestrial settlements or scientific bases. In the USA, Russia and other countries, developments and experiments are being carried out in this direction.

The European firm Foster and Partners, commissioned by ESA, carried out design work on the design of a lunar base printed from regolith. As a confirmation of the proposed technology, the company ordered the printing of one block of volcanic basalt using a D-Shape construction printer.

Samara State Technological University is developing a lunar lander that could sinter building blocks from regolith. It is supposed to use sunlight as a source of energy, which is concentrated by deployed reflectors.

Unfortunately, most 3D printing projects in space remain on Earth for the time being. This is partly due to the imperfection of the technology, partly to the insignificant benefits that the new technology promises. Much depends on economies of scale here: while the entire industry is based on the use of earlier technologies, therefore, the novelty turns out to be more expensive and riskier than repeating the past. Although 3D printers are able to give a certain benefit, we should expect an increase in their popularity in the space industry.

Prepared for Nplus1.ru published in the author's edition.

3D-printed Lunar landing pad prototype tested

It is almost impossible to imagine space exploration without using local resources. Lunar base projects were buried under the surface, sprinkled with soil, or surrounded by printed walls. But less attention was paid to the buildings of the lunar cosmodrome - at best, flat areas are drawn in the illustrations. They will have a minus - the engine exhaust will corrode the surface and raise dust. To address these potential challenges, a team of students from ten US universities and colleges, with support from NASA and 3D printing company ICON, designed, built, and successfully tested a large-scale prototype of the Lunar PAD airstrip.

Photo: ICON

In the summer of 2019, a team of students from NASA's L'SPACE Virtual Academy won a round of NASA NPWEE's 12-week Technology Concept Proposal course and received funding to develop their concept for protecting landers from lunar dust using robotic construction. The goals of both L'SPACE and NPWEE are to expand the pool of high-quality proposals of new concepts and technologies that can then be useful to NASA. In 2020, the team submitted a revised concept to an online technology readiness review and received funds to build and test a scale model. After spending hundreds of working hours consulting with NASA experts, the students went from idea to implementation of a model of the potentially important task of creating a safe reusable landing site for the Moon. In autumn, a scale model was built at Camp Swift, Texas, and successfully tested by a geophysical rocket engine in early March.

A team of students at work, photo ICON

The project, originally named Dust Devil ("dust whirlwind"), is eventually called Lunar Plume Alleviation Device ("Lunar device for mitigating exhaust") or, for short, Lunar PAD (playing on the fact that in English "pad" also means "a platform for launch / landing"). Structurally, the Lunar PAD consists of two levels: the upper one is a flat platform with small slots for exhaust gases to drain.

Ready site with test rocket engine installed, photo ICON

The lower level combines load-bearing structures and gas ducts for exhaust gases to the sides. A feature of the project is the use of 3D printing. First, a 3D construction printer forms a frame, which, as is often the case in additive manufacturing, uses complex surfaces and looks aesthetically pleasing.

Frame and student team, photo ICON

Printing process, top view, photo ICON

The printed frame is then filled with filler. The test mock-up used a cement-based material, but for lunar conditions, it would be logical to produce a hardening or sintering regolith building material in situ. The structure built is strong enough to withstand the takeoff and landing of the lunar modules, and produces less dust by diverting engine exhaust into the gas ducts.

Even at the construction stage, sensors were installed in the model to determine temperatures, loads and gas flow. In early March, a geophysical rocket team from Texas A&M University delivered a solid rocket motor to a test site. It was installed above the site, launched and looked at the information recorded by the sensors. The tests were successful - the Lunar PAD pad successfully withstood the takeoff / landing simulation, the data obtained do not contradict the calculated ones.

In early March, a geophysical rocket team from Texas A&M University delivered a solid rocket motor to a test site. It was installed above the site, launched and looked at the information recorded by the sensors. The tests were successful - the Lunar PAD pad successfully withstood the takeoff / landing simulation, the data obtained do not contradict the calculated ones.

Site inspection after testing. Pay attention to the side along the edges, reflecting the exhaust up. Photo ICON

The project has already published its first scientific publication in the AIAA SciTech Forum materials, and a very diverse group of college and university students scattered throughout the United States can take part in a full-fledged and successful scientific and technical project, potentially in demand in future lunar base projects.

It is also interesting to note that ICON, which provided the gantry 3D printer for the project, is also 3D printing houses and other structures.