3D printing breakthroughs

Breakthrough in metal 3D printing could revolutionize manufacturing

Chief Scientist Andy Bayramian makes modifications to the laser system on Seurat's 3D metal printer. Photo courtesy of Seurat Technologies.

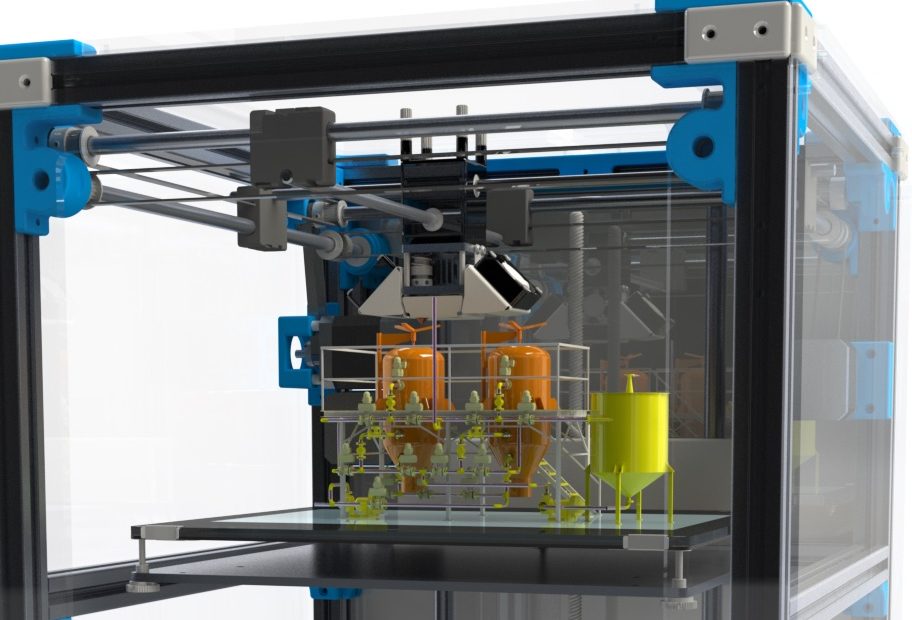

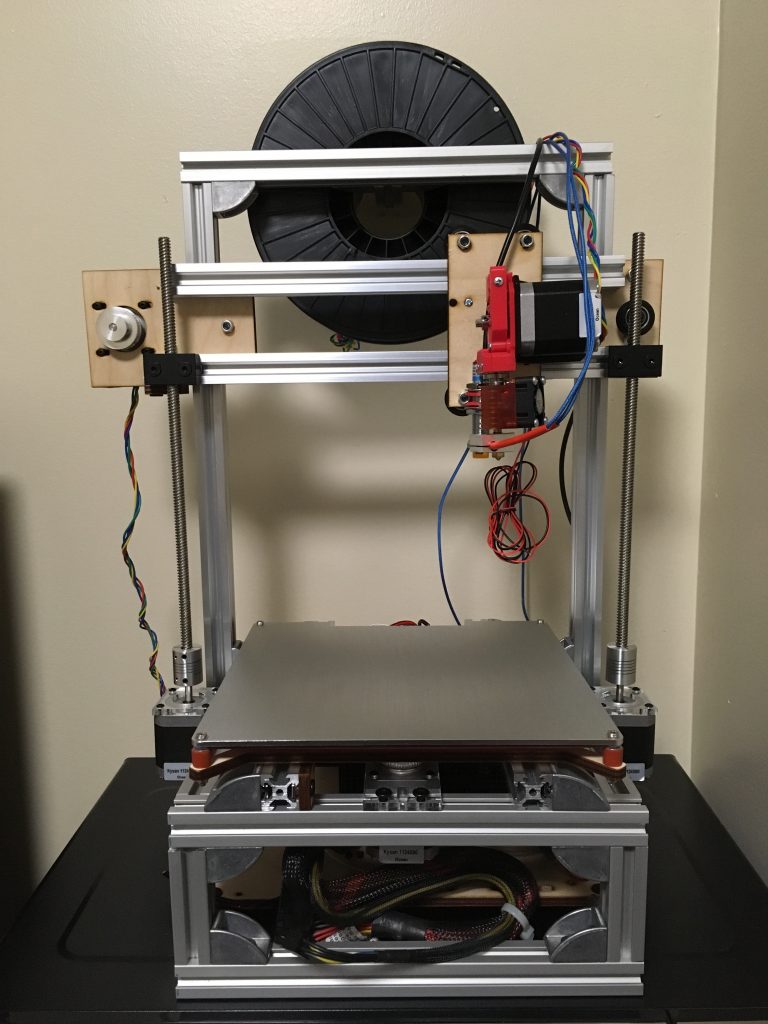

A new metal 3D printing technology could revolutionize the way large industrial products like planes and cars are made, reducing the cost and carbon footprint of mass manufacturing.

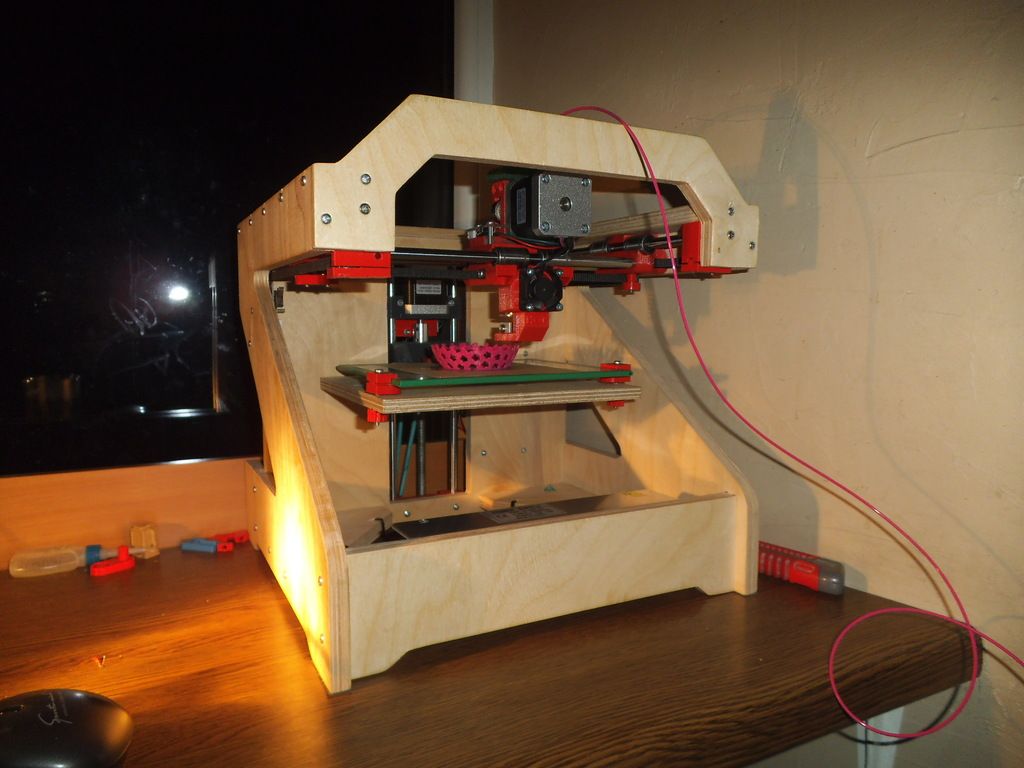

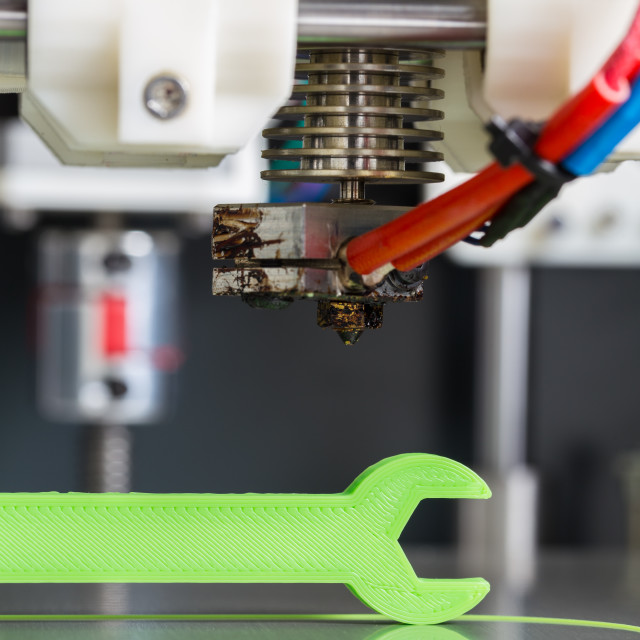

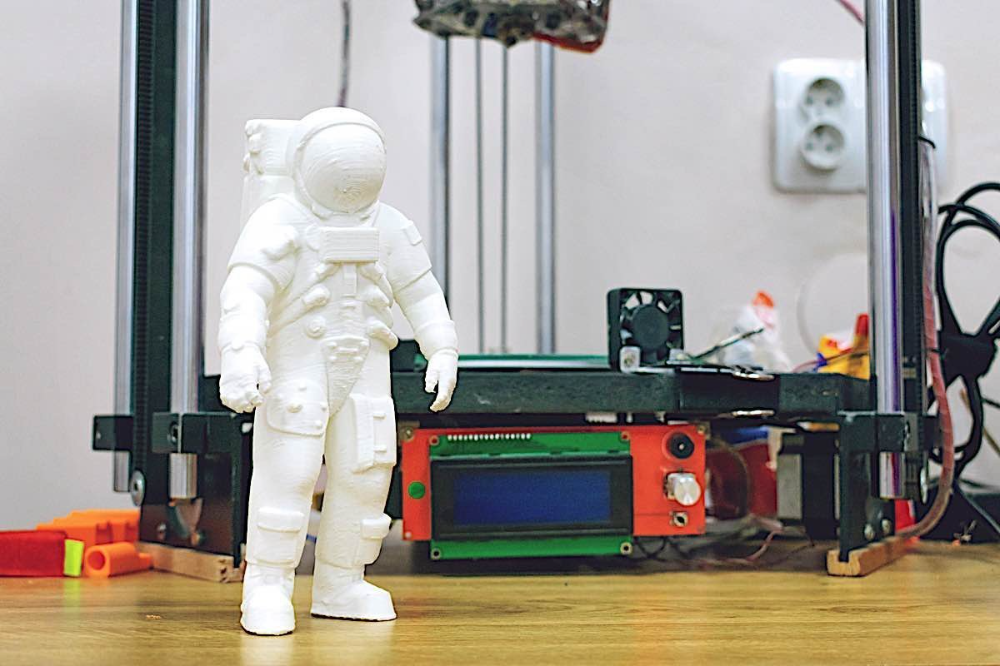

Why it matters: 3D printing — also called additive manufacturing — has been used since the 1980s to make small plastic parts and prototypes. Metal printing is newer, and the challenge has been figuring out how to make things like large car parts faster and cheaper than traditional methods.

- A new method from a startup called Seurat Technologies — using a powerful laser technique — could be the breakthrough the industry has been waiting for.

- If Seurat's method can be used on a large scale, fragile U.S. supply chains could be reimagined using low-cost “print depots” to manufacture parts domestically, at high volume, where and when they're needed.

Context: Today's metal 3D printing works by shining a laser onto a thin layer of metal powder, melting it and welding it to the layer below.

- The digital design gradually takes shape as the layers accumulate and the object grows.

- It's an extremely slow process, however. Even with multiple lasers, 3D metal printing hasn't accelerated fast enough to produce auto parts and consumer electronics in high numbers.

What's new: The technology from Seurat — named for the painter Georges Seurat, who studied the science of light and pioneered the style known as pointillism — speeds things up by splitting a single, high-powered laser beam into as many as 2.3 million beams of light.

- A 30 kW laser is patterned with high-resolution images that can be programmed to block or let light through each of its pixels.

- Every pixel defines its own laser spot, so the system can weld a large area of metal powder in an instant — allowing a multi-layered object to take shape 10 times faster than today's 3D printing technology.

- "And it's not even the beginning of what we can do," Seurat CEO and co-founder James DeMuth tells Axios.

- Seurat's technology, he says, is to 3D printing what the printing press was to pen and paper.

The backstory: The idea of pixelating a laser beam can be traced to the U.S. Department of Energy's Lawrence Livermore National Laboratory more than a decade ago, as DeMuth writes in a blog post.

- He and other researchers were working on an entirely different problem — energy fusion — but the challenge was to design a reaction chamber that could withstand the extreme temperature swings that happen when lasers are used to produce energy.

- After much trial and error, they adapted a patterned light method that was already in development at Livermore Labs for other purposes.

- By 2015, DeMuth and Erik Toomre — a co-founder of Seurat — had proved that the technology would work for metal 3D printing, too. The company licensed the technology from Livermore Labs in January 2016.

What's next: Seurat, based in Wilmington, Massachusetts, says it has deals with seven of the world’s largest automotive, aerospace, energy and industrial companies to begin commercializing the technology this year.

- The company has raised $78 million — including a $21 million Series B round extension announced Wednesday.

- Its newest investors are Xerox Ventures and SIP Global Partners, which joined Capricorn’s Technology Impact Fund, DENSO, True Ventures, GM Ventures, Porsche Automobil Holding SE, Siemens Energy and Maniv Mobility.

Editor's note: This story was originally published on Jan. 19.

Go deeper

3D printing breakthrough enables custom tablets to be produced in just seven seconds

0Shares

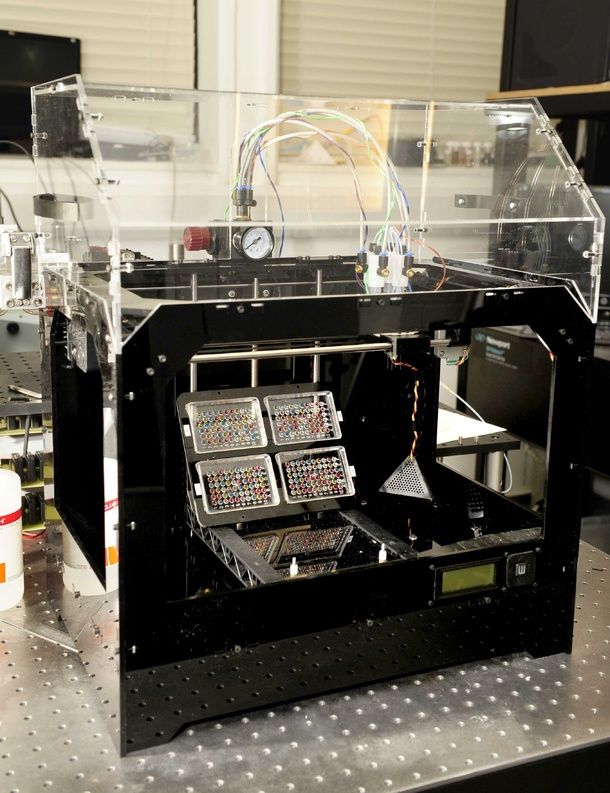

Researchers at the University of Santiago de Compostela, MERLN Institute University College London (UCL) and UCL spin-out FabRx, have come up with a way of 3D printing tablets inside of seven seconds.

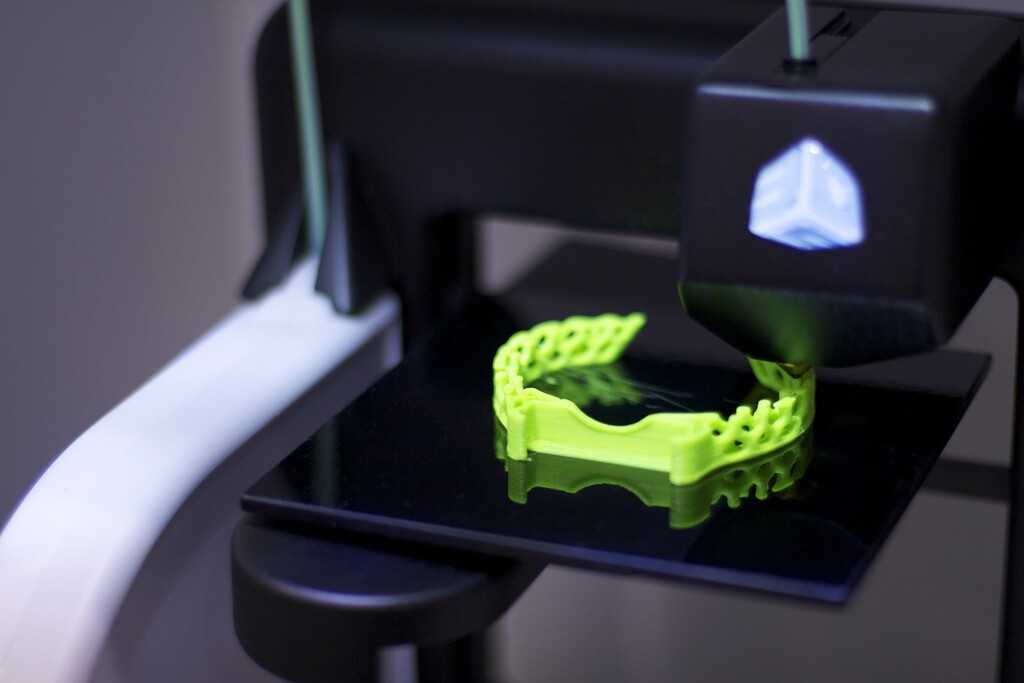

As opposed to the normal vat photopolymerization process, which can be used to print pills layer-by-layer, the team’s volumetric printing approach is capable of curing full vats of resin in a single run. In doing so, the scientists say their technology has the potential to ramp up the rate at which custom medication is produced, a USP that could prove vital to making end-use clinical 3D printing more viable.

“This could really be a game-changer for the pharmaceutical industry,” Alvaro Goyanes, one of the UCL scientists behind the project told the i newspaper. “Personalized 3D printed medicines are evolving at a rapid pace. They are starting to reach the clinic for trials and in a best case scenario they could be used in the health service in three to five years.”

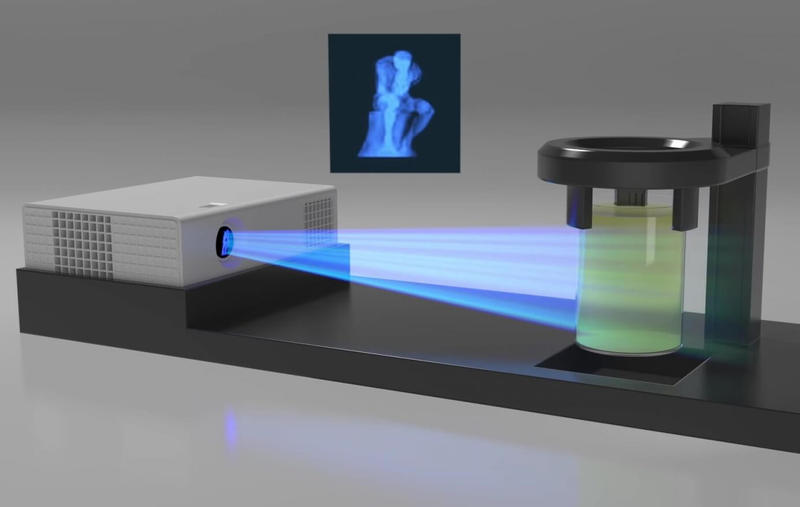

A diagram depicting the methodology behind the team’s approach. Image via UCL.FabRx’s custom medication drive

Since 2016, when Aprecia established itself as an early leader in additive manufactured medicine with the launch of fast-dissolving Spiritam, the first FDA-approved 3D printed drug, it’d be fair to say that the technology has come on leaps and bounds.

By 2020, for instance, researchers in Pakistan had proved it possible to 3D print antibiotics with optimized drug-release rates, via fused deposition modeling (FDM) technology and precise infill control. Earlier that year, a team based at St. John’s University also took a similar approach to 3D printing egg-shaped capsules, designed to be difficult to crush by those trying to abuse prescribed opioids.

More recently, FabRx itself has made advances in the field of tailored medicine as well, developing a means of Selective Laser Sintering (SLS) braille-patterned printlets for the visually impaired, as well as launching its M3DIMAKER system.

Marketed as the ‘first pharmaceutical 3D printer for personalized medicines,’ the machine features a multi-nozzle setup that allows users to switch heads and change from FDM to Direct Powder Extrusion production. The start-up also boasts that the system is supported by software that allows it to create prescribed pills on-demand, but this progress hasn’t stopped it iterating upon its technology.

In fact, working with colleagues at Universidade de Santiago de Compostela and UCL late last year, FabRx managed to develop its own smartphone-powered tablet 3D printer. Built around a modified M3DIMAKER, the team’s revised setup proved capable of producing customized blood-thinning capsules, and it was thought at the time that it could be used to improve access to prescribed medication.

The researchers’ previously-developed smartphone-powered LCD 3D printer. Image via UCL.Vat polymerization’s speed limit

So, given FabRx’s track record of relative success in 3D printing drugs with custom release profiles, shapes and sizes, why hasn’t it managed to achieve greater traction in the pharmaceutical sector? Well, aside from issues such as gaining regulatory approval and passing the relevant testing procedures, there’s also a commercial drawback to adopting 3D printing in this way: throughput.

According to the UCL-led team, “existing 3D printing technologies don’t afford the speeds required for the on-demand production of medicines in fast-paced clinical settings. ” However, the scientists add that volumetric printing “exploits the threshold behavior” that occurs in polymerization to cure masses of resin, hence it may offer a solution to this.

” However, the scientists add that volumetric printing “exploits the threshold behavior” that occurs in polymerization to cure masses of resin, hence it may offer a solution to this.

Now, building on the work carried out in their previous study, the researchers have found a way of putting this approach into practice, by manipulating light in such a controlled way, that it can solidify vats of resin simultaneously. This is said to have been achieved by tweaking the intensity of emitted rays and applying them at various angles, until the full mass of material can be polymerized in one go.

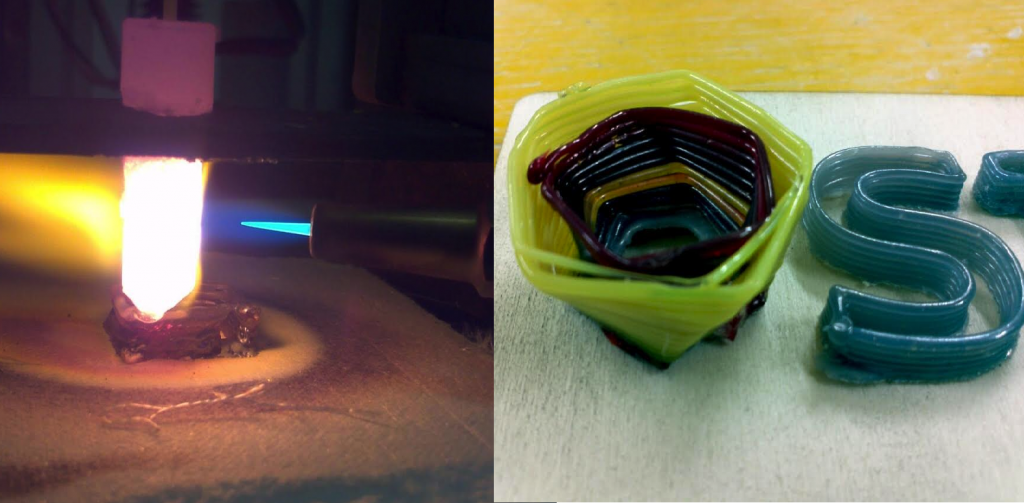

The UCL team’s 3D printed pill prototypes. Photo via UCL.Volumetric 3D printing in-action

During their study, the researchers deployed a modified 3D printer to assess the efficacy of their revised approach, and produce tablets from six different photoinitiator-loaded resins, with paracetamol being used as a model drug. Initial results from these tests showed that the team were able to produce tablets with tunable drug release profiles, at a rate of anything from 7 to 17 seconds per pill.

With further development, the scientists say that their approach could be used to create ‘polypills’ at pace, the likes of which incorporate tailored doses or multiple medications, but tend to come with longer lead times. One application the technology is currently reportedly being trialed in, involves 3D printing cancer therapy and anti-side-effect drugs inside the same pill at a French hospital.

“To reduce the risk of recurrence, many women with early-stage breast cancer are treated with hormone therapy for five years, often with additional treatments to manage side effects,” Maxime Annereau, the Gustave Roussy hospital pharmacist leading the project explained to the i newspaper. “Taking all of these treatments in a single 3D printed tablet with a personalized dose should make it easier to complete the treatment.”

Another potential application of the technology lies in the production of more appetizing medication for poorly kids, especially given that London’s Great Ormond Street Children’s Hospital is said to be weighing up installing a 3D printer at its pharmacy, with its team of specialists there believing that the technology could, in future, become an essential piece of kit.

“I am already looking to put a 3D printer in the pharmacy at GOSH to support trials of use of 3D medicines,” Steve Tomlin, Chief Pharmacist at the Great Ormond Street Children’s Hospital also told the i newspaper. “Knowledge of genetic differences in people’s responses to medicines (pharmacogenomics) means that we know that for many drugs one size does not fit all.”

The researchers’ findings are detailed in their paper titled “Volumetric 3D printing for rapid production of medicines.” The study was co-authored by Lucía Rodríguez-Pombo, Xiaoyan Xu, Alejandro Seijo-Rabina, Jun Jie Ong, Carmen Alvarez-Lorenzo, Carlos Rial, Daniel Nieto, Simon Gaisford, Abdul W. Basit and Alvaro Goyanes.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a diagram depicting the methodology behind the team’s approach. Image via UCL.

Tags Alvaro Goyanes aprecia FabRx Gustave Roussy M3DIMAKER Maxime Annereau MERLN Institute for Technology-Inspired Regenerative Medicine St Johns University Steve Tomlin University College London University of Santiago de Compostela

Paul Hanaphy

Paul is a history and journalism graduate with a passion for finding the latest scoop in technology news.

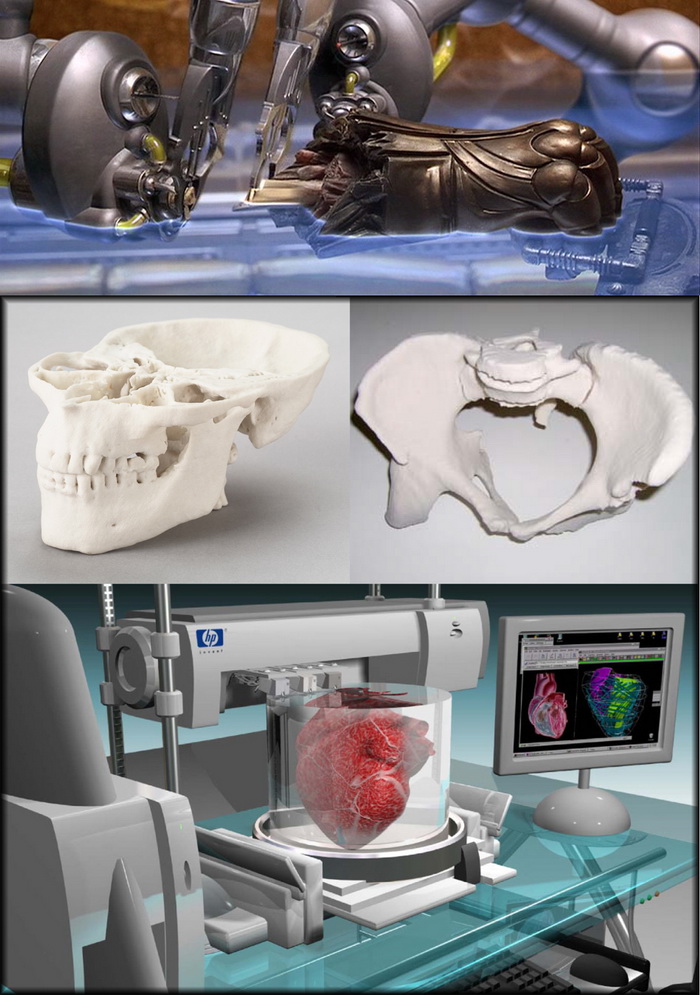

3D printing - a breakthrough in medical technology uMEDp

3D printing is definitely the technology of the year.

With the help of 3D printers, this technology has penetrated many different areas of life. 3D printers are used to create accessories, dishes, designer models and even weapons. Printers for private use and professional tools are already on the market. And recently there has also been a trend in the use of this technology in medicine.

Printers for private use and professional tools are already on the market. And recently there has also been a trend in the use of this technology in medicine.

Both experts and non-specialists agree that 3D printing is quite capable of changing the life of society, as people with its help get the opportunity to actually create things that are necessary in everyday life. 3D printing may not be a common feature of everyday life for a long time, but in medicine this technology has already begun to make breakthroughs.

According to Ashkhen Hovsepyan, director of SIU System, the official distributor of the American corporation 3D Systems: “Medicine is one of the most important and most promising areas for the development of 3D technologies. 3D printing can be used in transplantology, traumatology, prosthetics, plastic surgery, dentistry and many other areas.”

3D technologies in modern medicine are used in different ways - some are used partially so that they can be modified for various tasks, and some technologies have fully entered the workflow.

Dentistry

3D technologies are used most actively in this area. Align Technology introduced 3D printed aligners to the market back in 1999. Mouthguards are a convenient alternative to braces that do not cause any inconvenience, as they are transparent and therefore invisible on the teeth. The company currently produces over 650,000 caps per day. To create a cap, the patient's jaw is scanned in all angles. Then individual mouthguards are created - they have to be printed again every two weeks, since changes have occurred in the dentition during this time.

As A. Hovsepyan says: “Many people are embarrassed to wear braces: such designs look unaesthetic. Clients prefer to stay with a malocclusion for life, so mouthguards are ideal for these people. Some Moscow dentists are already using this method to create a Hollywood smile.”

With the help of 3D printers, it is also possible to create an impression of the jaw and teeth much cheaper, easier and faster. This approach is used, for example, at the Moscow State University of Medicine and Dentistry. There, students are already being taught the use of 3D technologies in dentistry using specially purchased equipment.

This approach is used, for example, at the Moscow State University of Medicine and Dentistry. There, students are already being taught the use of 3D technologies in dentistry using specially purchased equipment.

Hearing aids

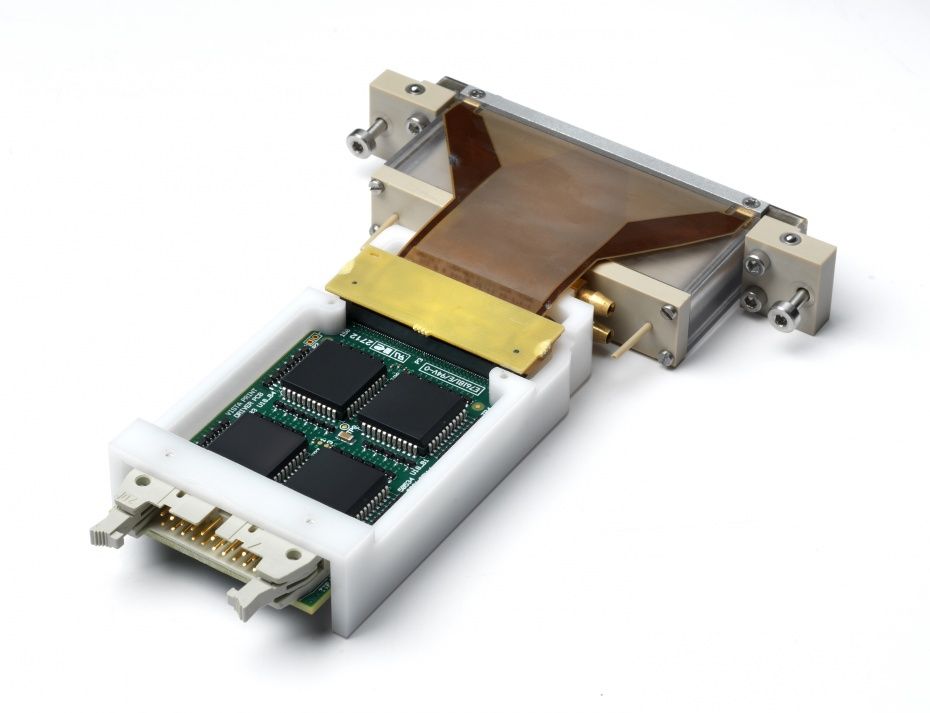

Widex has been using proprietary hearing technology since 2012. First, liquid silicone is injected into the auricle, on the basis of which an impression is created. The 3D impression model is then processed on a 3D scanner and reproduced by a 3D printer. The hearing aid is inserted into the model and the result is a miniature and precise ITE.

In'Tech took a different approach. In 2001, they started working with the Viper SLA printer. It allows you to make a shell for hearing devices that can be inserted inside the ear. The sheath accuracy can be adjusted within a millimeter.

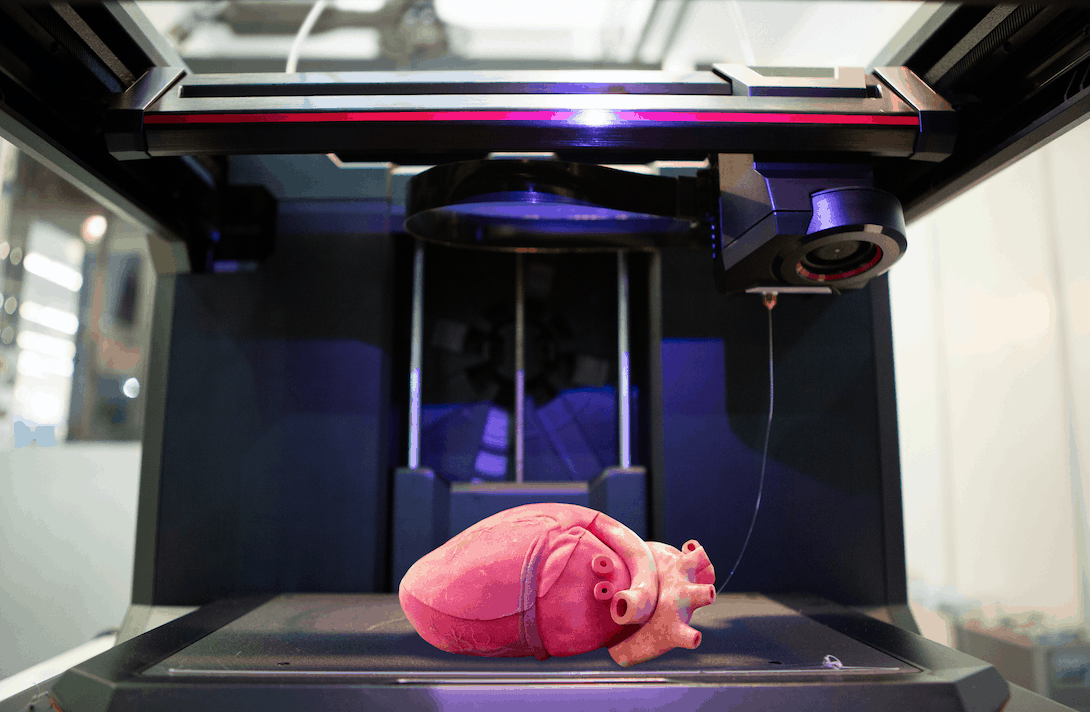

Transplantology

What once seemed like science fiction is now becoming a reality - 3D printing can create organ parts for transplants. In 2012, a Belgian woman was first transplanted with a jaw created in this way. Although there is no talk of creating a complete organ yet - 3D printing, of course, is not able to recreate full-fledged kidneys, heart valves or a liver.

In 2012, a Belgian woman was first transplanted with a jaw created in this way. Although there is no talk of creating a complete organ yet - 3D printing, of course, is not able to recreate full-fledged kidneys, heart valves or a liver.

However, a 3D printer is quite capable of replacing parts and components of the body. In the United States, exoskeleton elements have already been printed on a 3D printer for a two-year-old girl Emma, who suffers from arthrogripposis. This is a disease of the musculoskeletal system, in which the joints and muscles are underdeveloped, and deformity and contraction of the limbs occur. But the auxiliary exoskeleton helped the child move his arms, which means he could draw and play. In 2013, scientists have already created a whole exoskeleton for the girl Amanda Boxtel (Amanda Boxtel), who, due to paralysis after a fall on skis, could not walk for 22 years.

“The developers of 3D Systems have been able to put a woman on her feet. Her spine, lower legs and thighs were 3D scanned, after which a complete exoskeleton was printed. Amanda was able to get up and move around on her own again. Control units and complex mechanical drives provided by EksoBionics specialists were combined with elements printed on a 3D printer,” says Hovsepyan.

Amanda was able to get up and move around on her own again. Control units and complex mechanical drives provided by EksoBionics specialists were combined with elements printed on a 3D printer,” says Hovsepyan.

Russian science does not lag behind American colleagues. In 2013, a private laboratory for biotechnical research "3D Bioprinting Solutions" was opened on the basis of Skolkovo - here the methods of three-dimensional organ bioprinting are studied from all sides. In addition to titanium implants, 3D printing can also create bone models that are as similar in structure to real ones as possible. Such technology would make transplant operations safer and easier.

Oncology

Can 3D printing help people with cancer? Scientists expect to use 3D models not only for rehabilitation after surgery, but also to prevent the development of tumors. There are already examples of this from practice: the patient had the left side of his face completely removed due to a malignant tumor. But 3D printing has helped surgeons implant a facial prosthesis that allows patients to eat properly.

But 3D printing has helped surgeons implant a facial prosthesis that allows patients to eat properly.

The prospect of cancer prevention with 3D technology is just beginning to develop. In DNA, there is a sequence of G-quadruplex molecules that cannot be depicted in two-dimensional space. Scientists from the University of Alabama have created a model of such a molecule on a 3D printer. This model is expected to help understand how to influence such molecules in order to stop the division of cancer cells in the pancreas.

Prosthetics

Customized prostheses that take into account all the characteristics of the patient - not the exclusive prerogative of 3D printing, but much cheaper. Initially, prosthetics were tested on animals. In 2012, a bald eagle was shot dead by a poacher in the United States. A nylon beak model was created for the bird, and the eagle was fed and watered by hand before the prosthesis was transplanted. The artificial beak allowed the bird to feed on its own.

The artificial beak allowed the bird to feed on its own.

In 2013, engineer Ivan Owens launched the Robohand project, which creates inexpensive prosthetic hands. The carpenter from South Africa Richard Van As, who himself lost four fingers on his hand as a result of an accident, participated in the creation of the project. Now, Owens and Van As's prostheses cost an average of $15 each, while traditional prostheses can cost upwards of $10,000.

Earlier on our portal, we already wrote about unique face restoration operations. Briton Stephen Power surgeons literally restored the "skeleton" of the face. In another case of 3D printing, little American Garrett Peterson was 3D-printed to create a biopolymer splint to fit his trachea.

Breakthrough in 3D printing of stem cells

10/23/2015

It is likely that medicine is indeed the area of human activity within which advances in 3D printing seem to be the most significant. A striking example of the use of 3D printer in medicine is a technology for printing transplantable cell structures and the ability to provide an individual approach in the process of creating drugs. Moreover, another revolutionary development in the field of medicine is worth paying attention to: scientists at Heriot-Watt University in Edinburgh recently reported a real breakthrough in the field of 3D printing of k stem cells, which will enable individual approach to the development of drug regimens, and would also reduce the need for medical testing on animals.

A striking example of the use of 3D printer in medicine is a technology for printing transplantable cell structures and the ability to provide an individual approach in the process of creating drugs. Moreover, another revolutionary development in the field of medicine is worth paying attention to: scientists at Heriot-Watt University in Edinburgh recently reported a real breakthrough in the field of 3D printing of k stem cells, which will enable individual approach to the development of drug regimens, and would also reduce the need for medical testing on animals.

This fantastic achievement was achieved by a team of scientists led by Dr. Wil Shue in collaboration with the Scottish company Roslin Cellab, which is engaged in contract research and development of new products, while often collaborating with scientific institutions. As the authors of the project report to the journal Biofabrication, they managed to create a 3D printer, with which induced stem cells can be obtained from the cells of the patient himself.

The use of stem cells has been controversial in the past. Now there are very few opponents of this innovation, since the patient's own cells can now serve as the material for printing. It is known that the original 3D printer was used to print tissue using embryonic stem cells. Now, one of the main achievements in this field is that scientists have discovered a new type of stem cells, now known as pluripotent stem cells (iPS). In the future, they can be used to print entire organs and even brain cells.

Although the use of the new cell type is much less controversial, it also presents many challenges because they are much more fragile than embryonic stem cells. However, Dr. Shu and his team have learned how to handle them. “This is the first study that demonstrates that induced stem cells, that is, those that can be obtained from adult stem cells, can be 3D printed without affecting their biological properties; the capabilities of our 3D printing technology allow us to do this,” says Dr.

Shu. “We were able to demonstrate that printed stem cells can be turned into liver cells.” Thus, this is the first time that pluripotent stem cells have been created using a bioprinter without losing their biological properties.

This method could have many different applications, our initial goal is to 3D print human body tissue samples, which will later be used for drug testing. This, in turn, means that the need for animal testing will be significantly reduced, another of the controversial issues in medicine. In addition, in the future, this method will help to provide an individual approach in the development of drug treatment regimens, which will greatly reduce the risk of side effects. “The features of the 3D printing technology we have developed allow us to preserve the pluripotency of stem cells, that is, their ability to develop with the formation of tissues of various types. On the other hand, it is possible to make stem cells form more self-similar cells.

In other words, we are on the way to creating organoids, that is, ensembles of cells of various types that can be obtained from the patient's own cells, the researcher explains. “Going forward, this would completely eliminate the need for animal research, as well as make medical care more personalized.”

However, many applications may be found in the future. It is hoped that 3D printing of stem cells will open up new possibilities in the field of organ transplantation, since it will be possible to grow them for transplantation from the patient's own cells. Moreover, according to Jason King, a representative of Roslin Cellab, this technology will soon prove indispensable in the field of tissue engineering, namely, in the fight against certain diseases. Thus, it is already being used to treat heart defects and neurodegenerative diseases such as Parkinson's syndrome. Some progress has already been made, and this is very encouraging.

Thus, it is difficult to overestimate the importance of research by scientists from Heriot-Watt University for the development of personalized medicine.