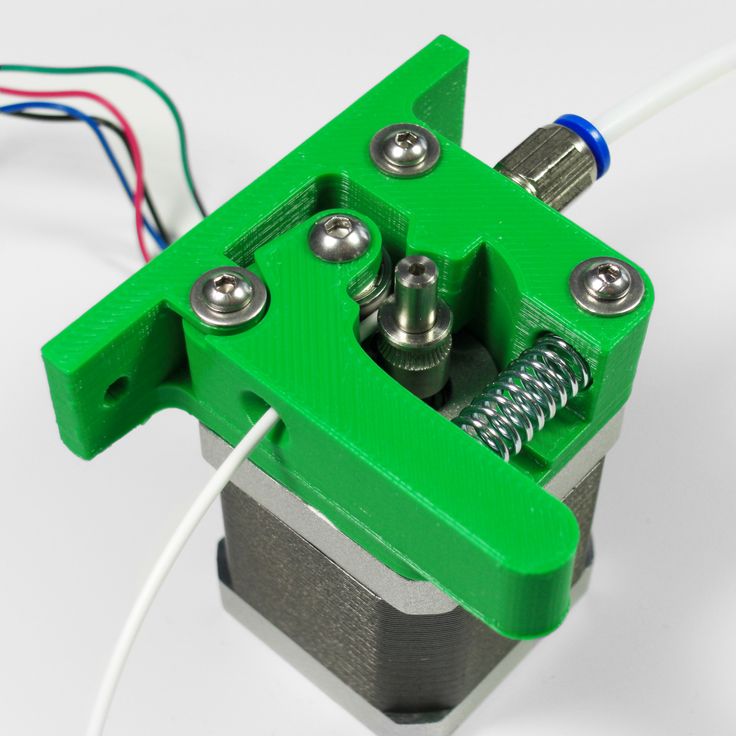

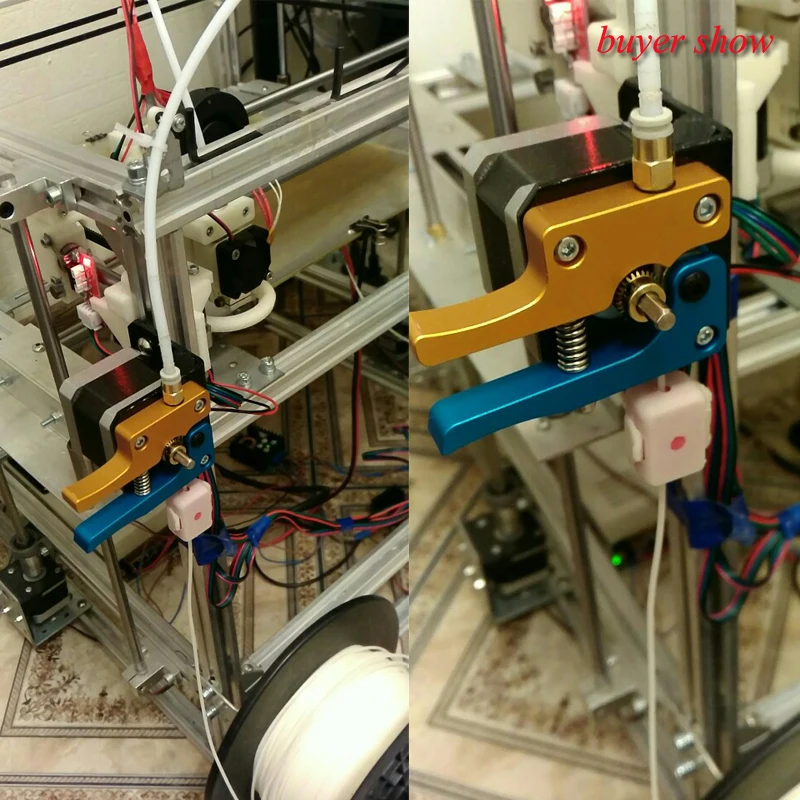

3D printing bowden extruder

Direct-drive extruder vs. Bowden extruder - Guide

These are the differences

If you deal with 3D printers, you will sooner or later be confronted with the terms “direct drive extruder” and “bowden extruder”. Both extruder variants ensure that filament is fed into the printhead, but differ in the way the filament is pushed into the hotend. Both a direct extruder and a Bowden extruder have their advantages and disadvantages, which we would like to discuss in more detail below and thus make it easier for you to choose when buying.

Direct extruderThe direct drive extruder (A) is installed with the hotend (C) and pushes the filament (B) directly into the nozzle (D). All filament processing components are therefore located in one place on the print head. This creates advantages and disadvantages that you should consider before buying a printer.

Advantages- Better extrusion

Since the extruder is located directly on the print head, the motor can simply push the filament through the nozzle.

- Faster retraction

Due to the proximity of the extruder and nozzle, the filament can be retracted quickly; in many cases, no retraction setting is necessary.

- Weaker, smaller motors are possible

Because of the short distance between extruder and nozzle, less torque is required from the motor to push the filament.

- Wider range of compatible filaments

Direct extruders are compatible with a wide range of filaments - they print reliably even with abrasive and flexible materials.

Disadvantages- More weight on the printhead

Since the extruder is mounted on the hotend, it has more weight. The increased weight has the following disadvantages:

- More power requirement

- Increased wear on toothed belts and bearings

- Printing speed is reduced

- More complex maintenance

After the feed and the hotend are built directly together, maintenance such as cleaning the nozzle proves to be more difficult.

Unlike the direct drive extruder, the Bowden extruder (A) is attached to the frame of the 3D printer and pushes the filament (B) through a long PTFE tube (Bowden tube) into the hotend (C).

Advantages- Less weight on the printhead / less moving mass

Since the printhead can work without additional weight, the following advantages result:

- Clean movements

- Increased printing speed

- Nice prints due to reduced vibration on the printhead

- More powerful motor needed

A Bowden extruder requires a more powerful motor with more torque to control the filament because it has to be pulled through the PTFE tube.

- Slower response time

Increased friction in the Bowden hose leads to a reduced reaction time. Bowden extruders require longer and faster retraction to avoid tension.

- Smaller range of compatible filaments

Flexible or abrasive filaments can wear out more in the Bowden hose and are processed more poorly than with the direct drive extruder due to the longer conveying path.

Conclusion - which extruder should you choose?Both extruder variants have their advantages and disadvantages. The biggest difference is clearly to be found in the processing of flexible filaments. If you want to print quickly and do not use flexible filament, you can use a Bowden extruder.

However, if you want to process flexible materials, a direct extruder is definitely recommended.

Buying a 3D printer - What you should consider The new BIQU B1 - Competition for the Ender 3?

Direct Drive VS Bowden Extruder – Creality 3D

May anyone confused about what is 3d printer direct-drive and Bowden drives extruder systems? What are the differences? How do they make a different effect on 3d printing? Today let’s learn the basics understanding of Direct Drive and Bowden Extruder on the FDM 3d printer. Then you will find out which kind of 3d printer extruder perfect for you?

Then you will find out which kind of 3d printer extruder perfect for you?

Before learning about the difference between Direct Drive and Bowden Extruder, it is necessary to know the common 3D printer parts and components below:

Hot-end Components: The hot-end components mainly include nozzles, heat blocks, and radiators installed on the 3D printer frame, especially on FDM 3d printer, The heating block and nozzle assembly are heated by the resistance cartridge heater. The rest of the heat sink and hot end assembly is called the cold end. Although the heat sink itself is not cold, it separates the heat sink from the rest of the components and dissipates the heat. For the purpose of this article, for the sake of brevity, we will refer to the hot end component by its name or simply "hot end".

Extruder Components: Extruder components include stepper motors, knurled bolts or drive gears, and idlers mounted on the 3D printer frame or frame. The extruder includes motors, gears, and idlers, while the assembly adds the remaining components.

PTFE Tubes: PTFE means Polytetrafluoroethylene, with its most renowned variation being Teflon. This tube is normally attached to either assembly utilizing push-fit adapters or fittings to provide a smooth change from the extruder to the hot end.

What are the differences- Direct Drive VS Bowden Extruder

Bowden Extruder

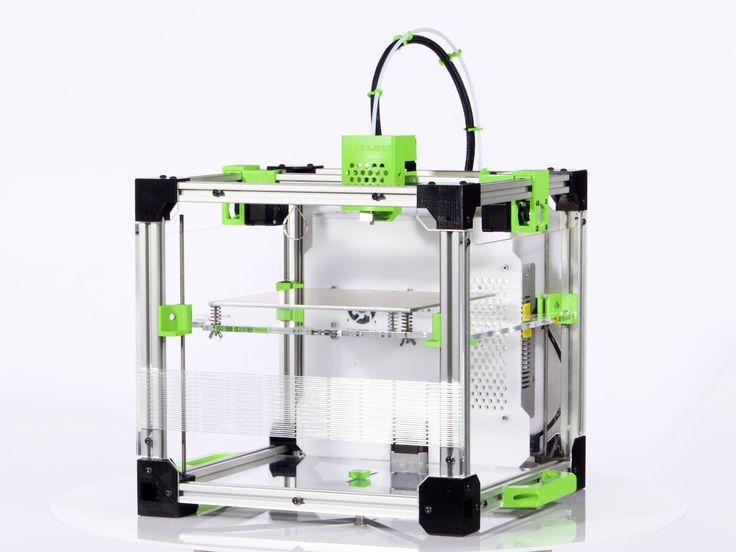

Unlike direct extrusion equipment, a Bowden extruder is placed on the printer's framework. It pushes and pulls filament with a long PTFE Bowden tube and also right into the warm end. This system likewise has pros and cons.

Pros:

Cleaner Movements: Given that a Bowden extruder is mounted on the printer's structure as opposed to on the print head, much less weight gets on the carriage. Less weight indicates quicker, quieter, as well as better prints.

Larger Build Volume: A Bowden extruder enables a smaller sized print head carriage, which, subsequently, allows for increased build volume.

Compact Dimension: Bowden extruders are normally extra compact, occupying less room than a normal straight extruder.

Cons:

1.More Powerful Electric Motor: Since a Bowden extruder is pushing and pulling filament through a lengthy tube, a particular quantity of friction exists between the two. This rubbing requires more torque to manage filament.

2.Slower Feedback Time: More friction in the Bowden tube additionally converts to reduce response time. Bowden extruders need longer and also much faster retraction to stay clear of string.

3.Smaller Sized Variety Of Products: Some flexible and rough filaments can easily bind or use in Bowden tubes.

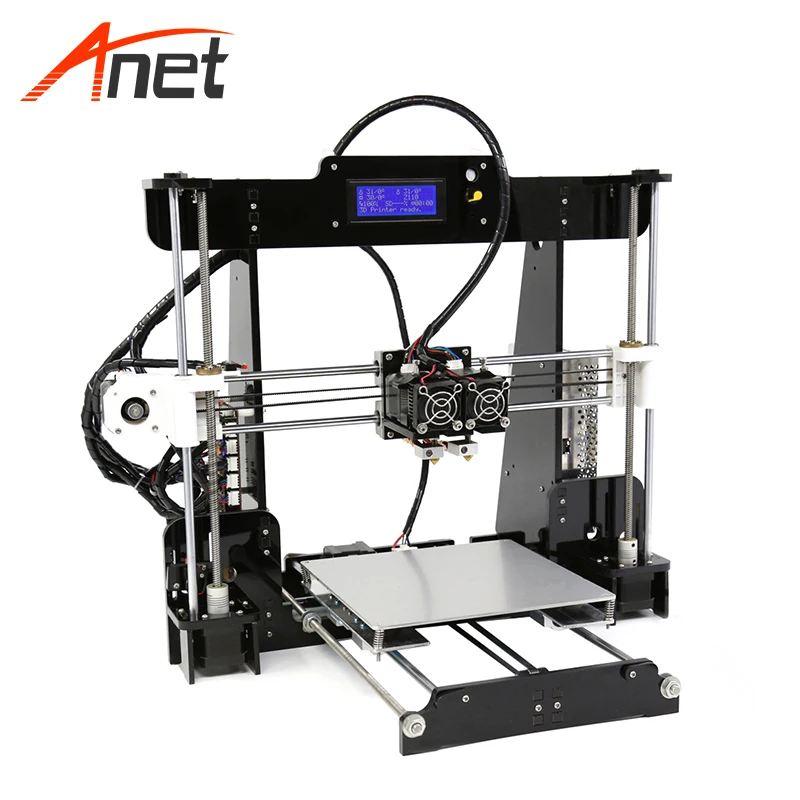

Direct drive

Direct drive also called a system of Direct extrusion, it is an extrusion method by which the extruder pushes the filament directly into the nozzle. This method is useful for many reasons, but also with some disadvantages. Let’s check.

Pros:

1.Better Extrusion: Given that a straight extruder is placed to the print head, the motor can quickly push filament with the nozzle, allowing for much better extrusion.

2.Quicker Retraction: Since the extruder is close to the nozzle, the direct extruder can rapidly withdraw filament.

3.Less Effective Electric Motor: As a result of the brief range between the extruder and also nozzle, less torque from the electric motor is required to press filament.

4.Broader Range of Filaments: A direct extruder works with a wide range of filaments. Despite having versatile and rough products, straight extrusion permits trusted printing.

Cons:

Burdened Activities: With the extruder placed to the print head, weight is obviously added. This additional weight includes rate restraints, triggering more wobble and also possibly a loss of accuracy in the X and Y axes.

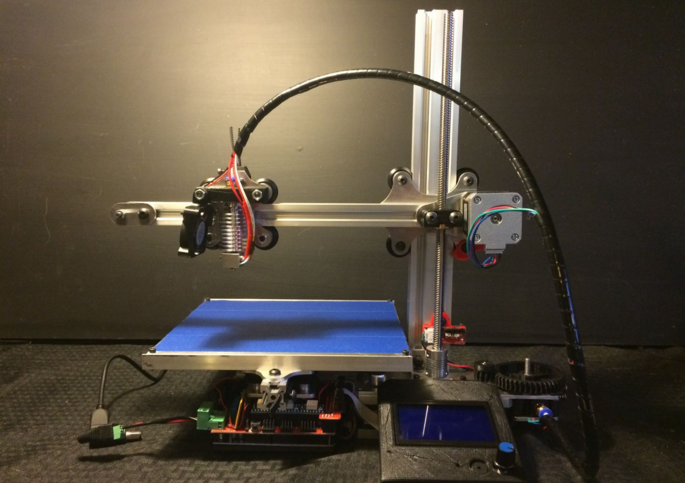

Which system is much better? It depends. Before you determine which extrusion layout to utilize for your printer, you need to take into consideration some essential elements.

The first is structure security. Delta printers, as an example, can not sustain a direct extruder. If, however, your Cartesian or CoreXY printer has a tough framework, printing with a straight extruder should be no problem. Rate is additionally a choosing variable. If your top priority is quick, accurate printing, with basic materials, Bowden extrusion will be more adequate.

Rate is additionally a choosing variable. If your top priority is quick, accurate printing, with basic materials, Bowden extrusion will be more adequate.

Finally, you must take into consideration the products you would love to print. If you're interested in versatile or abrasive filaments, a drive extrusion system is likely the one for you.

Now in the 3d printing market, most types of the FDM 3d printer are with the Bowden Extruder for normally printing with 3d filament of PLA while the enclosed 3d printer comes with direct drive mostly. Some customer is thinking about if they can change the extruder themselves on their DIY 3d printer. Typically for printing other kinds of 3d printing materials, like TPU, PETG, might be with ABS as well sometimes.

Is there a DIY 3d printer so that I can change the extruder by chance? How can I have a 3d printer with Bowden extruder and direct drive both at once?

In 2019, Creality had released a DIY 3d printer CR-10 V2 that you can add the direct-drive yourself. it comes with the normal Bowden extruder, but design a special connector on the extruder near the hot end. Some of our customers have an open box review for it, and the feedback of CR-10 V2 is quite good with precise prints. If you are interested in having the direct drive on your 3d printer, but it will good to go with buying another direct drive.

it comes with the normal Bowden extruder, but design a special connector on the extruder near the hot end. Some of our customers have an open box review for it, and the feedback of CR-10 V2 is quite good with precise prints. If you are interested in having the direct drive on your 3d printer, but it will good to go with buying another direct drive.

For better user-experience, Creality recently has this idea and decide to update the CR-10 V2 to CR-10 V3 with the direct drive so that customer can print with other kinds of filaments immediately once received the 3d printer. Especially one point I’d like to mention is that the CR-10 V3 comes with the Bowden extruder for reserved in the box as well. This decision extremely makes a difference from another 3d printer.

what is the difference and which one is better?

3DPrintStory Reviews Direct and Bowden extruder: what is the difference and which is better?

Most 3D printers use Direct or Bowden extrusion. Both designs use an extruder to force material through a heated nozzle. The difference is that in the first case, the material for 3D printing is fed directly, and in the second - through the Bowden tube. Despite the fact that these designs are similar in principle, they have significant differences. In the material below, we detail the implementation, as well as the pros and cons of these two design solutions.

Both designs use an extruder to force material through a heated nozzle. The difference is that in the first case, the material for 3D printing is fed directly, and in the second - through the Bowden tube. Despite the fact that these designs are similar in principle, they have significant differences. In the material below, we detail the implementation, as well as the pros and cons of these two design solutions.

Direct extruders

Direct extrusion is an extrusion method in which the extruder pushes the material to be 3D printed directly into a nozzle. This method is good for many reasons, but it also has disadvantages. Let's take a look.

Pros

Better extrusion : Because the printhead has a straight extruder, the motor can easily push the filament through the nozzle, which results in better extrusion.

Faster retract : Since the extruder is close to the nozzle, the straight extruder can quickly retract material and there are fewer problems with material residue between model voids.

Less powerful motor : Due to the small distance between the extruder and the nozzle, less torque is required from the motor to push the material.

Wider range of materials : The direct extruder is compatible with a wide range of 3D printing materials. Even with flexible and abrasive materials, direct extrusion ensures reliable 3D printing.

Cons

Additional heaviness when moving the nozzle : Mounting the extruder on the printhead obviously adds weight. This extra weight adds speed limits, causing more wobble and possibly loss of precision in the x and y axes.

Bowden extruders

Unlike Direct extrusion mechanisms, Bowden style extruders are mounted on the frame of the 3D printer. It pushes and pulls the filament through a long PTFE Bowden tube directly to the hot end. This system also has pros and cons.

Pros

3D Printer Carriage Movement Optimization: Since the Bowden extruder is mounted on the 3D printer frame and not on the printhead, there is much less weight on the carriage. Less weight means faster, quieter movements and (arguably) better 3D print quality.

Less weight means faster, quieter movements and (arguably) better 3D print quality.

Larger workspace : Bowden extruder allows the use of a smaller print head carriage, which in turn allows more workspace.

Compact size : Bowden extruders are usually more compact and take up less space than a conventional straight extruder.

Cons

More powerful motor : Because the Bowden extruder pushes and pulls the material through the long tube, there is some friction between them. This friction requires more torque.

Slower response time : More friction in the Bowden tube also results in slower response time. Bowden type extruders require longer infusion and higher retract speed to avoid 3D printing defects.

Smaller range of materials available : Some flexible and abrasive materials may become stuck or worn in Bowden tubes. For example, for 3D printing with flexible TPU material on the Ender 3, it is recommended to change the Bowden design to a direct plastic feed.

Pins

| |

So which system is better? Before deciding which extrusion option to use for your 3D printer, there are some important factors to consider.

First, the stability and rigidity of the frame. For example, Delta printers will most certainly not be able to support direct extrusion. However, if your 3D printer has a Cartesian coordinate system and a solid frame, 3D printing with a Direct Extruder shouldn't be a problem.

Speed is also a decisive factor. If fast and accurate 3D printing with standard materials is your priority, a Bowden type extruder can be a great choice.

Finally, you should think about the materials you want to use for 3D printing. If you're interested in flexible or abrasive filaments, you're probably better off with a direct extrusion mechanism.

Techno Print 3D Company

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

XYZprinting, best known for its daVinci line of desktop 3D printers, is bringing five new devices to the professional and industrial environment. One will use laser sintering technology, the second full color inkjet printing and three DLP machines. First of all, the novelties will be of interest to dentists and jewelers. Read more→

Cleaning the nozzle of a 3D printer is a fairly common process that any user of such a device has to deal with.