3D printing advances

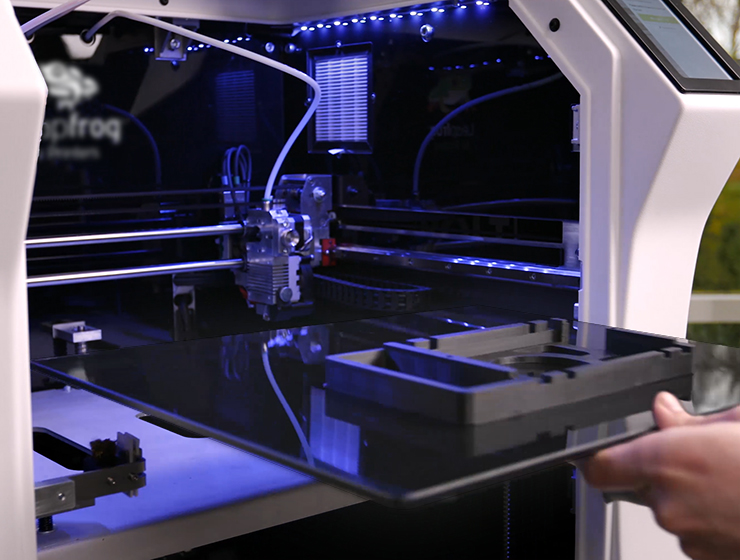

New 3D printer promises faster, multi-material creations

Stanford engineers have designed a method of 3D printing that is 5 to 10 times faster than the quickest high-resolution printer currently available and is capable of using multiple types of resin in a single object.

By Laura Castañón

Advancements in 3D printing have made it easier for designers and engineers to customize projects, create physical prototypes at different scales, and produce structures that can’t be made with more traditional manufacturing techniques. But the technology still faces limitations – the process is slow and requires specific materials which, for the most part, must be used one at a time.

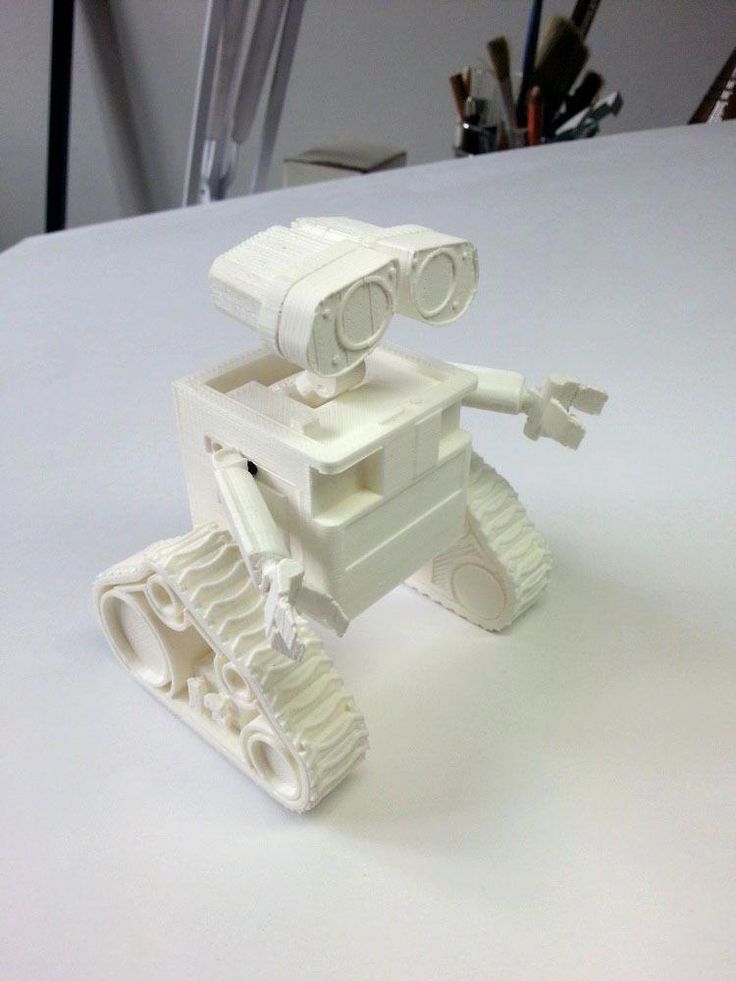

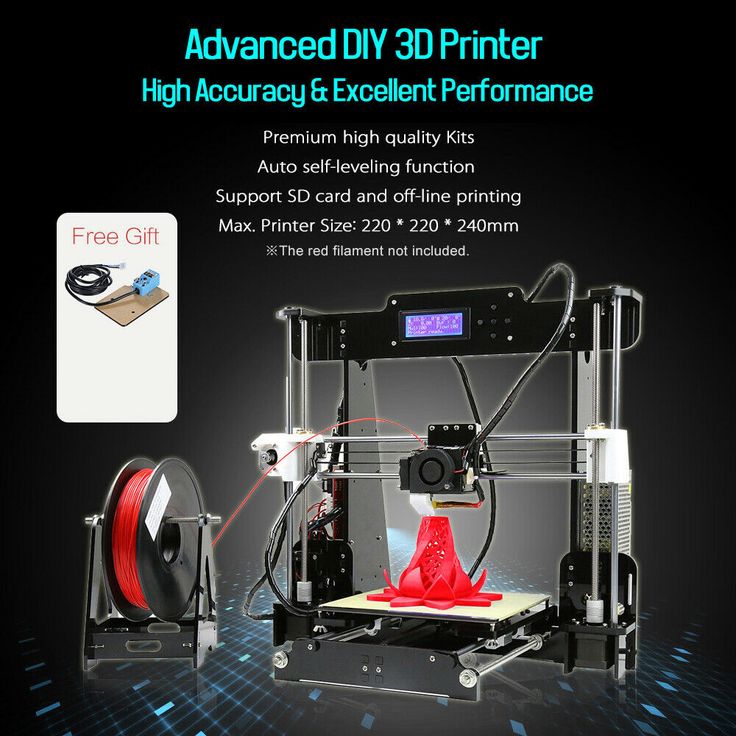

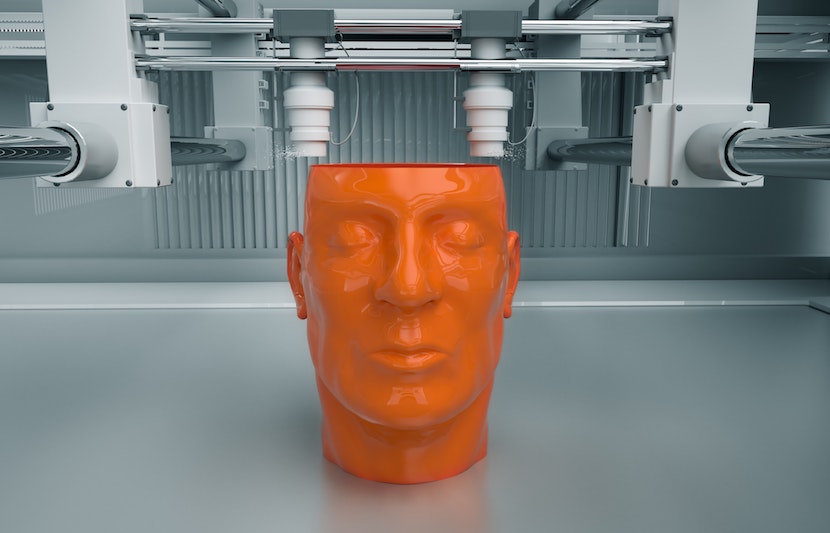

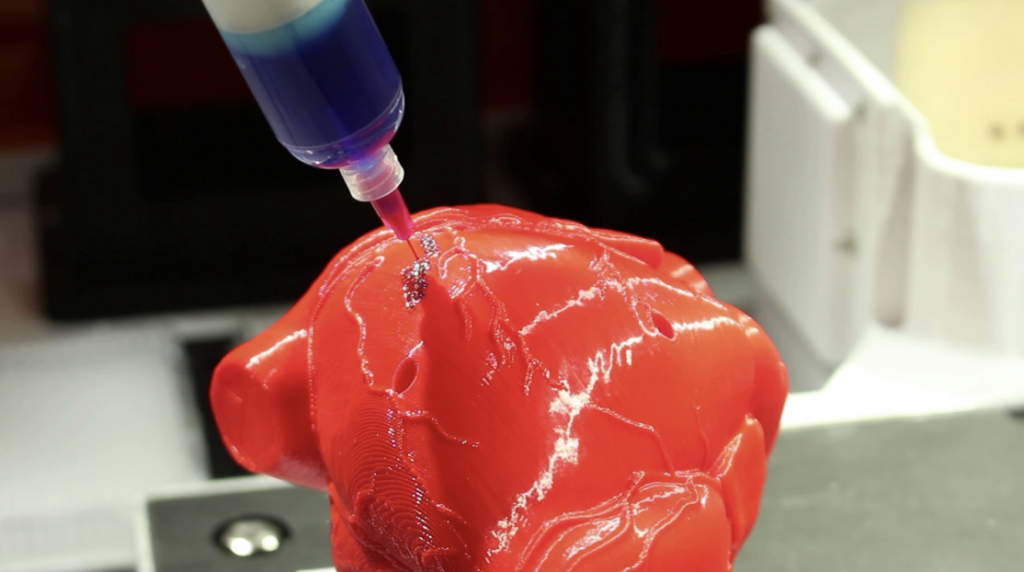

A model of Kyiv’s Saint Sophia Cathedral in the blue and yellow of the Ukrainian flag, made using the iCLIP method for 3D printing, which allows for the use of multiple types – or colors – of resin in a single object. (Image credit: William Pan)

Researchers at Stanford have developed a method of 3D printing that promises to create prints faster, using multiple types of resin in a single object. Their design, published recently in Science Advances, is 5 to 10 times faster than the quickest high-resolution printing method currently available and could potentially allow researchers to use thicker resins with better mechanical and electrical properties.

“This new technology will help to fully realize the potential of 3D printing,” says Joseph DeSimone, the Sanjiv Sam Gambhir Professor in Translational Medicine and professor of radiology and of chemical engineering at Stanford and corresponding author on the paper. “It will allow us to print much faster, helping to usher in a new era of digital manufacturing, as well as to enable the fabrication of complex, multi-material objects in a single step.”

Controlling the flow of resin

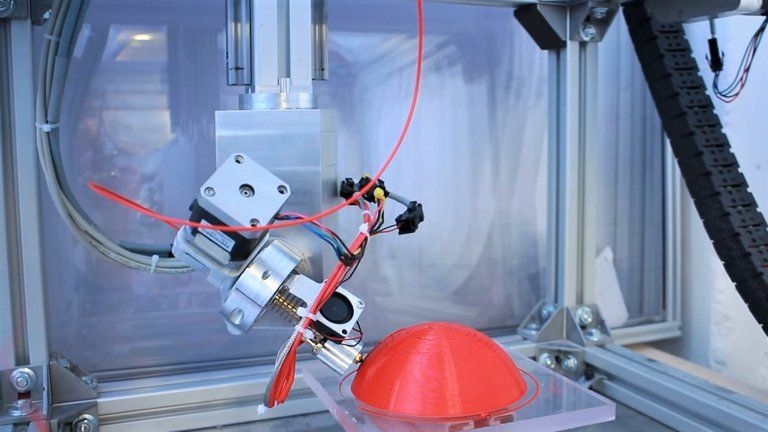

The new design improves on a method of 3D printing created by DeSimone and his colleagues in 2015 called continuous liquid interface production, or CLIP. CLIP printing looks like it belongs in a science fiction movie – a rising platform smoothly pulls the object, seemingly fully formed, from a thin pool of resin. The resin at the surface is hardened into the right shape by a sequence of UV images projected through the pool, while a layer of oxygen prevents curing at the bottom of the pool and creates a “dead zone” where the resin remains in liquid form.

CLIP printing looks like it belongs in a science fiction movie – a rising platform smoothly pulls the object, seemingly fully formed, from a thin pool of resin. The resin at the surface is hardened into the right shape by a sequence of UV images projected through the pool, while a layer of oxygen prevents curing at the bottom of the pool and creates a “dead zone” where the resin remains in liquid form.

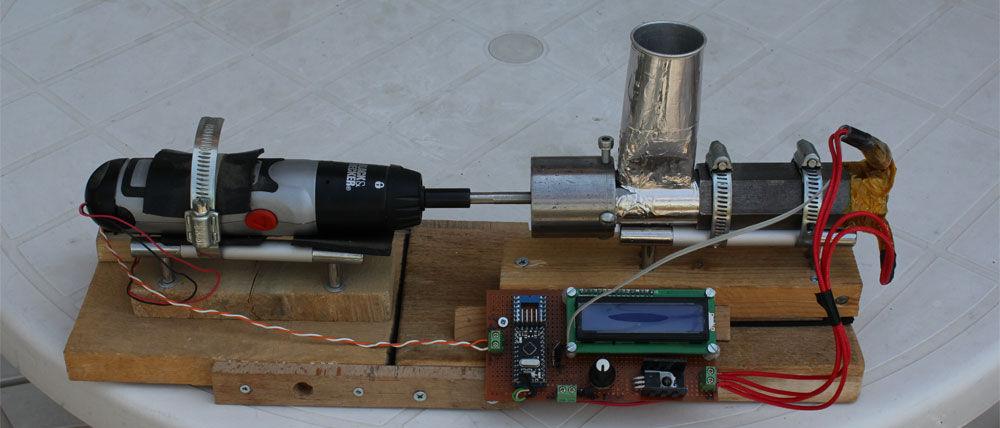

The dead zone is the key to CLIP’s speed. As the solid piece rises, the liquid resin is supposed to fill in behind it, allowing for smooth, continuous printing. But this doesn’t always happen, especially if the piece rises too quickly or the resin is particularly viscous. With this new method, called injection CLIP, or iCLIP, the researchers have mounted syringe pumps on top of the rising platform to add additional resin at key points.

“The resin flow in CLIP is a very passive process – you’re just pulling the object up and hoping that suction can bring material to the area where it’s needed,” says Gabriel Lipkowitz, a PhD student in mechanical engineering at Stanford and lead author on the paper. “With this new technology, we actively inject resin onto the areas of the printer where it’s needed.”

“With this new technology, we actively inject resin onto the areas of the printer where it’s needed.”

The resin is delivered through conduits that are printed simultaneously with the design. The conduits can be removed after the object is completed or they can be incorporated into the design the same way that veins and arteries are built into our own body.

Multi-material printing

By injecting additional resin separately, iCLIP presents the opportunity to print with multiple types of resin over the course of the printing process – each new resin simply requires its own syringe. The researchers tested the printer with as many as three different syringes, each filled with resin dyed a different color. They successfully printed models of famous buildings from several countries in the color of each country’s flag, including Saint Sophia Cathedral in the blue and yellow of the Ukrainian flag and Independence Hall in American red, white, and blue.

“The ability to make objects with variegated material or mechanical properties is a holy grail of 3D printing,” Lipkowitz says. “The applications range from very efficient energy-absorbing structures to objects with different optical properties and advanced sensors.”

“The applications range from very efficient energy-absorbing structures to objects with different optical properties and advanced sensors.”

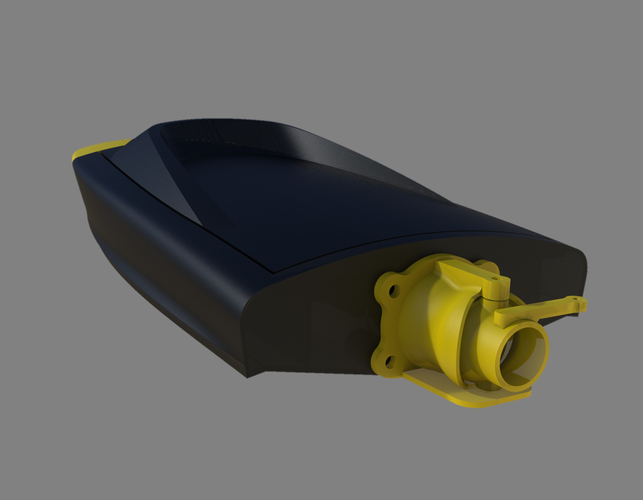

Having successfully demonstrated that iCLIP has the potential to print with multiple resins, DeSimone, Lipkowitz, and their colleagues are working on software to optimize the design of the fluid distribution network for each printed piece. They want to ensure that designers have fine control over the boundaries between resin types and potentially speed up the printing process even further.

“A designer shouldn’t have to understand fluid dynamics to print an object extremely quickly,” Lipkowitz says. “We’re trying to create efficient software that can take a part that a designer wants to print and automatically generate not only the distribution network, but also determine the flow rates to administer different resins to achieve a multi-material goal.”

DeSimone is a member of Stanford Bio-X, the Wu Tsai Human Performance Alliance, and the Stanford Cancer Institute; he is a faculty fellow of Stanford’s Sarafan ChEM-H; and he holds appointments in the departments of Radiology and Chemical Engineering.

Additional Stanford co-authors of this research include Eric S. G. Shaqfeh, the Lester Levi Carter Professor in the School of Engineering and professor of chemical engineering and of mechanical engineering; senior research scientist Maria T. Dulay; postdoctoral scholars Kaiwen Hsiao and Brian Lee; graduate students Tim Samuelson, Ian Coates, and Harrison Lin; and undergraduate student William Pan. Other co-authors are from Sungkyunkwan University and Digital Light Innovations.

This work was funded by the Precourt Institute for Energy at Stanford, the Stanford Woods Institute for the Environment, and the National Science Foundation.

To read all stories about Stanford science, subscribe to the biweekly Stanford Science Digest.

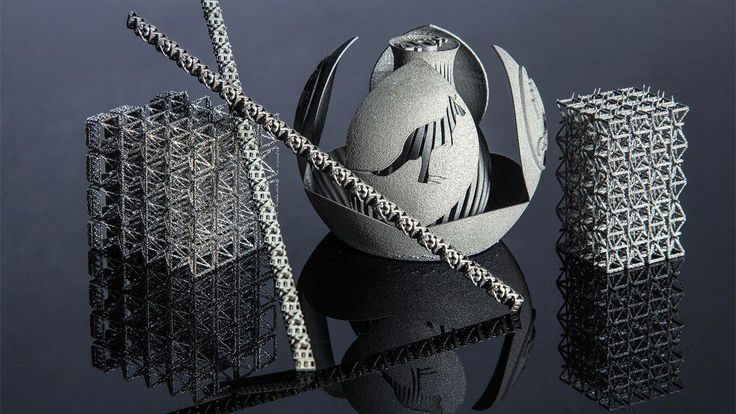

3D printing gets bigger, faster and stronger

As a metal platform rises from a vat of liquid resin, it pulls an intricate white shape from the liquid — like a waxy creature emerging from a lagoon. This machine is the world’s fastest resin-based 3D printer and it can create a plastic structure as large as a person in a few hours, says Chad Mirkin, a chemist at Northwestern University in Evanston, Illinois. The machine, which Mirkin and his colleagues reported last October1, is one of a slew of research advances in 3D printing that are broadening the prospects of a technology once viewed as useful mainly for making small, low-quality prototype parts. Not only is 3D printing becoming faster and producing larger products, but scientists are coming up with innovative ways to print and are creating stronger materials, sometimes mixing multiple materials in the same product.

The machine, which Mirkin and his colleagues reported last October1, is one of a slew of research advances in 3D printing that are broadening the prospects of a technology once viewed as useful mainly for making small, low-quality prototype parts. Not only is 3D printing becoming faster and producing larger products, but scientists are coming up with innovative ways to print and are creating stronger materials, sometimes mixing multiple materials in the same product.

Sportswear firms, aviation and aerospace manufacturers and medical-device companies are eager to take advantage. “You’re not going to be sitting in your home, printing out exactly what you want to repair your car any time soon, but major manufacturing companies are really adopting this technology,” says Jennifer Lewis, a materials scientist at Harvard University in Cambridge, Massachusetts.

The latest techniques could be lucrative for researchers, many of whom — Lewis and Mirkin among them — are already commercializing their work. They’re also fundamentally exciting, says Iain Todd, a metallurgist at the University of Sheffield, UK. “We can get performance out of these materials that we didn’t think we could get. That’s what’s really exciting to a materials scientist. This is getting people used to the new weird.”

They’re also fundamentally exciting, says Iain Todd, a metallurgist at the University of Sheffield, UK. “We can get performance out of these materials that we didn’t think we could get. That’s what’s really exciting to a materials scientist. This is getting people used to the new weird.”

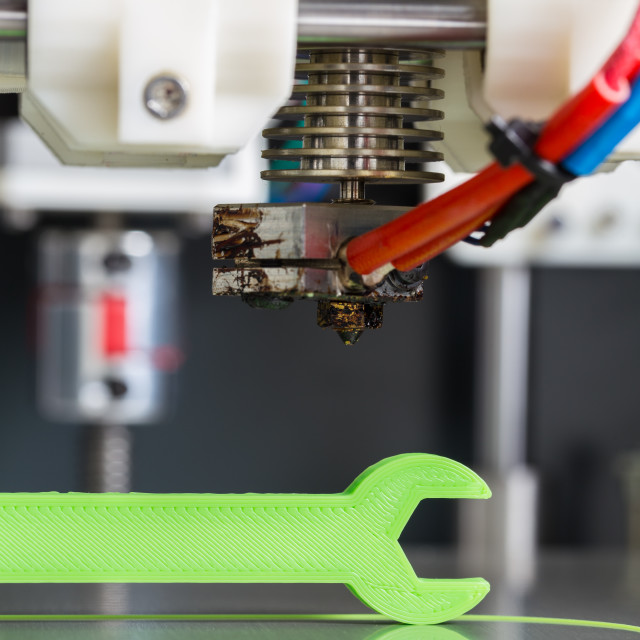

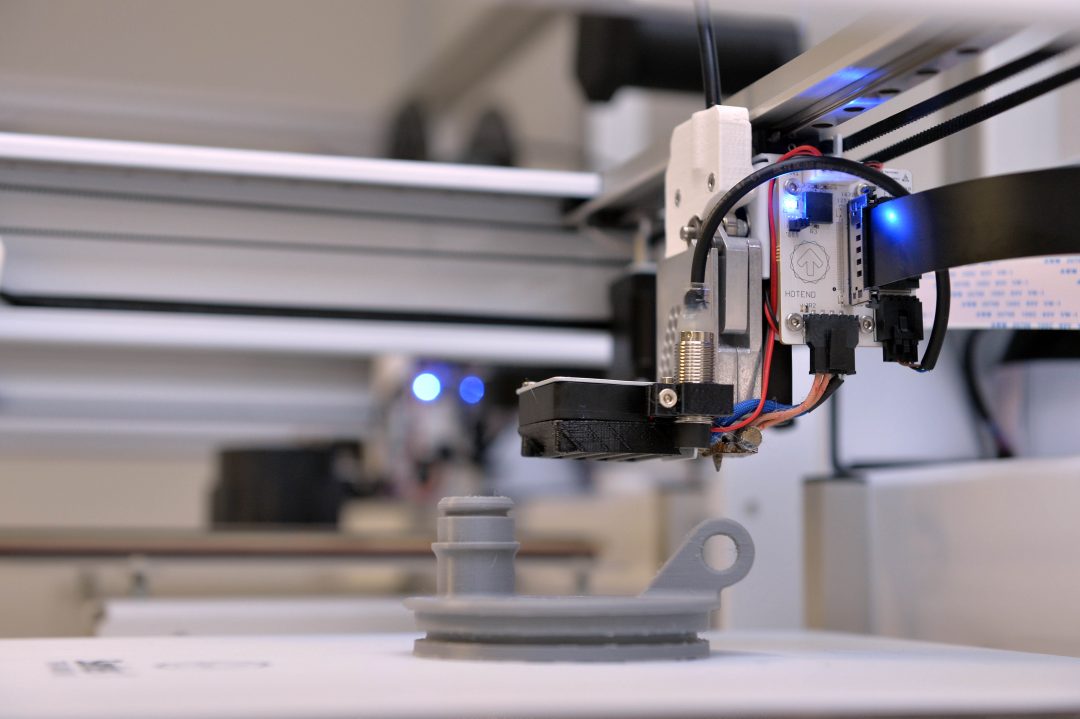

The 3D printing technique is also referred to as ‘additive manufacturing’, because instead of chopping or milling a shape out of a larger block, or casting molten material in a mould, it involves building objects from the bottom up. Its advantages include less waste and an ability to print custom designs, such as intricate lattice structures, that are otherwise hard to create. Low-cost hobbyist machines print by squeezing out thin plastic filaments from heated nozzles, building up a structure layer by layer — a method known as fused deposition modelling (FDM). But the term 3D printing encompasses a much wider range of techniques. One of the oldest uses an ultraviolet laser to scan across and solidify (or ‘cure’) light-sensitive resin, layer by layer. That concept was described as far back as 1984, in a patent filed by Charles Hull2, the founder of a company called 3D Systems in Rock Hill, South Carolina.

That concept was described as far back as 1984, in a patent filed by Charles Hull2, the founder of a company called 3D Systems in Rock Hill, South Carolina.

The latest techniques — including Mirkin’s — still use light-sensitive resin, but are faster and larger-scale, following improvements reported in 2015 by a team led by Joseph DeSimone, a chemist and materials scientist at the University of North Carolina at Chapel Hill3. Early printers were slow, small-scale and prone to producing layered, imperfect and weak structures. These found a niche in rapid prototyping, making plastic model parts as mock-ups for later production by conventional methods. As an area of research, this kind of printing wasn’t thrilling, says Timothy Scott, a polymer scientist at Monash University in Melbourne, Australia: “Basically making trinkets and knick-knacks. For a polymer chemist, it was pretty dull.”

In 2015, Joseph DeSimone at the University of North Carolina at Chapel Hill unveiled a technique to speed up 3D printing. Credit: Carbon 3D Inc.

Credit: Carbon 3D Inc.

Then DeSimone unveiled a way to print light-sensitive resin up to 100 times faster than conventional printers3. It uses a stage submerged in a vat of resin. A digital projector shines a pre-programmed image up at the stage through a transparent window in the floor of the vat. The light cures an entire resin layer at once. DeSimone’s advance was to make the window permeable to oxygen. This kills the curing reaction and creates a thin buffer layer, or ‘dead zone’, just above the window’s surface so that the resin doesn’t stick to the bottom of the vat each time a layer is printed. The stage rises continually, pulling the completed part up through the liquid as new layers are added at the bottom.

Other labs were working on similar concepts at the time, says Lewis. But perhaps most impressive about DeSimone’s resins was that they could undergo a second reaction in a post-print heat treatment to strengthen the finished product. “It opens up a much broader array of materials,” says Lewis.

Forget everything you know about 3D printing — the ‘replicator’ is here

Many research groups and firms have since built on the work. Mirkin’s printer pumps a layer of clear oil across the bottom of the vat to inhibit the polymer’s reactions. This also acts as a coolant, removing heat that can deform a printed part — and it means that the equipment is not limited to printing with resins that are inhibited by oxygen. He says the printer produces material ten times faster than DeSimone’s. And last January, Scott and his colleague Mark Burns at the University of Michigan in Ann Arbor reported a printer that inhibits the reactions by mixing into the resin a chemical that can be activated by a second lamp emitting a different wavelength of light4. By varying the ratio of the strength of the two light sources, the researchers can control the thickness of the photo-inhibited zone, allowing the creation of more complicated patterns, such as surfaces embossed with seals or logos.

Inventions in 3D printing often have rapid commercial potential: some researchers start forming companies before they publish their advances. On the same day DeSimone’s paper was published, for instance, he showcased it at a TED talk in Vancouver, Canada, and officially launched his start-up firm Carbon 3D in Redwood City, California, although he had quietly registered the company two years earlier. The firm is now one of the biggest start-ups in 3D printing; it has already raised US$680 million in publicly disclosed funding rounds, and is reportedly valued at $2.4 billion. It has high-profile contracts with Adidas to make rubber-like midsoles for athletic shoes, and with sports-gear firm Riddell to manufacture customized helmet padding for American-football players.

Carbon 3D’s technology is used to print Adidas shoes (left) and padding for American football helmets (right).Credit: Carbon 3D Inc.

Mirkin and his colleagues James Hedrick and David Walker have also launched a start-up, Azul 3D in Evanston, Illinois, to commercialize their technique, which they have dubbed HARP (high-area rapid printing). And Scott and Burns are preparing a commercial prototype printer with their Ann Arbor-based start-up Diplodocal, a name derived from the Greek for ‘double beam’.

And Scott and Burns are preparing a commercial prototype printer with their Ann Arbor-based start-up Diplodocal, a name derived from the Greek for ‘double beam’.

New resin-printing techniques are still emerging. One begins with a small spinning glass holding liquid resin. As the glass rotates, a projector shines a loop of video onto it that corresponds to 2D slices of the desired object. Within seconds, the final object solidifies inside the liquid resin — no layers necessary5. The method is inspired by X-rays and computed-tomography scans, which image a cross-section of a solid object. This is the inverse: back-projecting cross-sections to form a 3D object.

A projector shines a video loop onto liquid resin, causing an entire object to be created at once, rather than layer by layer.Credit: UC Berkeley

Even in this fast-moving field, the technique turned heads for what Lewis calls “the gee-whiz factor”. It has significant limitations: the resin used must be transparent, and the printed object must be small enough for light to pass through it to cure it. But it also has a potential advantage: it can handle highly viscous resins, which other resin-based printers struggle to suck through the narrow dead zone. That means it could make stronger materials and more accurate prints.

But it also has a potential advantage: it can handle highly viscous resins, which other resin-based printers struggle to suck through the narrow dead zone. That means it could make stronger materials and more accurate prints.

The approach has garnered substantial interest from industry, says Christopher Spadaccini, a materials and manufacturing engineer at Lawrence Livermore National Laboratory (LLNL) in California. Spadaccini was a member of the team that published the work last January5. A group at the Swiss Federal Institute of Technology in Lausanne (EPFL) independently developed the same concept, and has also reported a demonstration of it6. Spadaccini thinks the technology has tremendous commercial potential because it has modest hardware requirements. “In the end, really, what you need is a halfway-decent projector and a rotating stage,” he says.

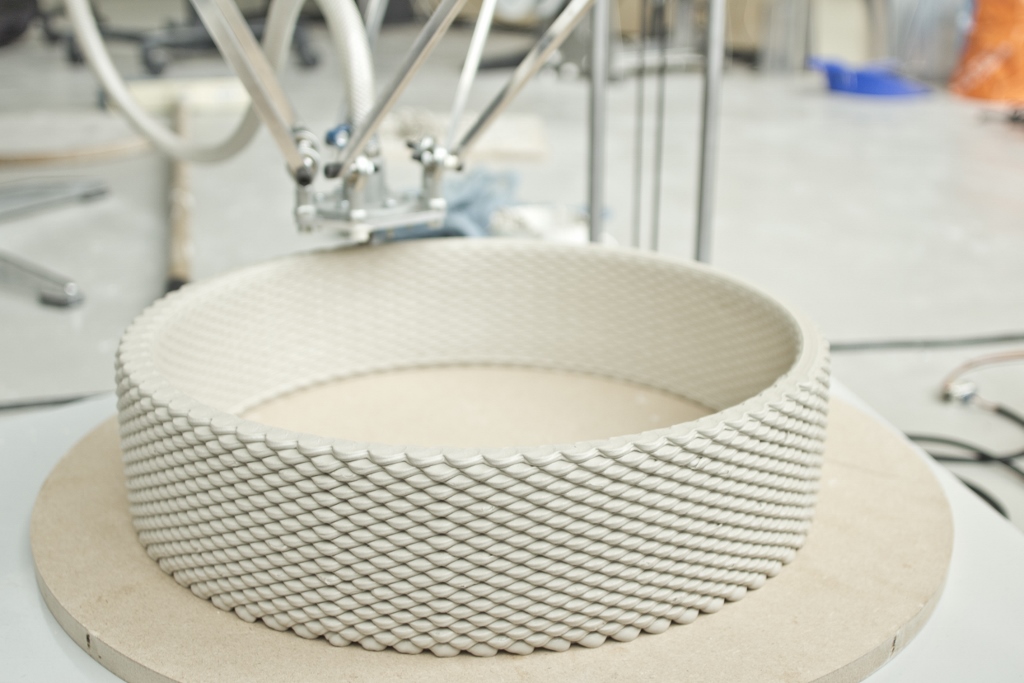

Going bigWhile chemists work on smarter ways to 3D-print intricate resins, engineers are pushing boundaries in 3D printing of concrete — using computers and robots to precisely automate the pouring process.

A 3D-printed concrete pedestrian bridge developed by Tsinghua University.Credit: Imaginechina/Shutterstock

The world’s first 3D-printed concrete pedestrian bridge was made by researchers at the Institute for Advanced Architecture of Catalonia in Barcelona, Spain, and installed in a park in Alcobendas, near Madrid, in 2016. Twelve metres long, the bridge features a lattice structure designed with algorithms that maximize strength and reduce the amount of material needed. Other teams have made similar structures, including a 26-metre-long bridge in Shanghai, China, produced by engineers at Tsinghua University in Beijing. And teams and companies in China and the Netherlands have 3D printed demonstration houses.

Those structures aren’t constructed in one print job, however: separate segments are printed and then connected. By producing bridges and houses more cheaply and efficiently, 3D printing could reduce concrete’s carbon footprint — but it could also just encourage engineers to build more.

It’s not just concrete that is going big: Amsterdam firm MX3D has printed a bridge from stainless steel. First displayed publicly in 2018, the bridge is now being tested and having sensors installed ahead of a planned installation over an Amsterdam canal.

A view of MX3D’s printer during the process of printing a metal bridge.Credit: Olivier de Gruijter/MX3D

And California start-up firm Relativity Space in Los Angeles says it is constructing a nearly fully 3D-printed rocket. The rocket is designed to lift 1,250 kilograms into low Earth orbit, and its first test launch is slated for 2021. Printed metal doesn’t always have the same heat-dissipating performance as non-printed metal, says Relativity Space’s chief executive, Tim Ellis, but the printing process can add cooling channels in geometries that can’t usually be manufactured. Because rockets are used only once or perhaps a few times, they don’t have to be as strong in the long term as do alloys in aeroplane parts, which must resist failure over tens of thousands of pressure cycles, Ellis says.

A metal printer at start-up firm Relativity Space, which aims to test a mostly 3D-printed rocket in 2021.Credit: Relativity Space

These large-scale metal-printed projects are built with robot arms that feed a thin metal wire to a laser that welds the material into place. Other established ways to print metal use a laser or a beam of electrons to melt or fuse a bed of powder into layers of finished product. Another technique binds a bed of powder with liquid glue, then sinters the structure in a furnace. And printers designed in the past few years extrude molten metals through nozzles, in much the same way as in FDM.

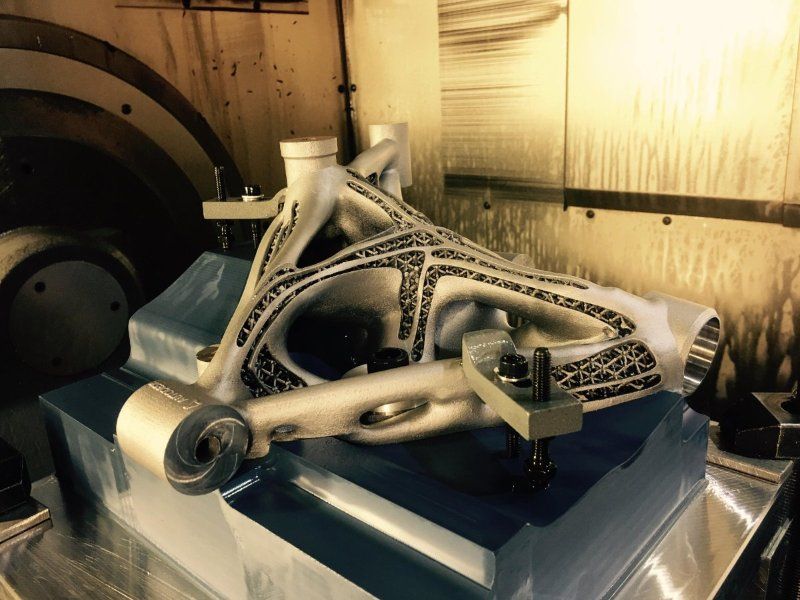

Aviation firms such as Boeing, Rolls Royce and Pratt & Whitney are using 3D printing to make metal parts, mainly for jet engines. It can be cheaper than milling metal blocks, and the intricate components often weigh less than their conventionally made counterparts.

But 3D-printed metals are prone to defects that can weaken the final products. Spadaccini and others are trying to use arrays of sensors and high-speed cameras to watch for irregularities such as hotspots of heat or strain — and then make adjustments in real time, he says.

Five innovative ways to use 3D printing in the laboratory

Many scientists are also hoping to improve the intrinsic strength of printed metals, sometimes by controlling the microstructures of the materials. For instance, in October 2017, a US team reported that the intense heat and rapid cooling used in 3D-printing stainless steel could alter the metal’s microstructure such that the product is stronger than those cast conventionally7. And two months ago, researchers in Australia and the United States reported a titanium–copper alloy with similar strength advantages8. As they solidified, previous 3D-printed titanium alloys tended to form grains that grew in column-like structures. The copper helps to speed up the solidification process, which results in grains that are smaller and sprout in all directions, strengthening the overall structure.

Mark Easton, a materials engineer at RMIT University in Melbourne and one of the leaders of the alloy work, has already had conversations with aerospace companies interested in exploring uses for the material. He says it could also be used in medical implants such as joint replacements.

He says it could also be used in medical implants such as joint replacements.

Many of the printing techniques that work for metals can also be applied to ceramics, with potential applications that include making dental crowns or orthopaedic implants. Moulds for these objects are already made by 3D printing, with the material cast in the conventional way. But 3D-printing the entire object could save time at the dentist or surgeon’s office.

However, it is harder to control the microstructure of 3D-printed ceramics, says Eduardo Saiz, a materials scientist and ceramicist at Imperial College London. And nearly all practical ceramic printing techniques involve extensive post-print sintering that can warp or deform the part. “In my opinion, ceramics is way behind polymers and metals in terms of practical applications,” he says.

Change over timeThe field’s future could also lie in ‘4D printing’ — 3D-printed objects that also have the ability to perform some mechanical action, akin to artificial muscles. Often, these incorporate shape-memory polymers, materials that can react to changes in their environment such as heat or moisture.

Often, these incorporate shape-memory polymers, materials that can react to changes in their environment such as heat or moisture.

In May 2018, researchers at the Swiss Federal Institute of Technology (ETH) in Zurich and the California Institute of Technology in Pasadena reported printing a submarine that propels itself forward using paddles that snap backwards when placed in warm water9. The work could lead to microrobots that can explore the oceans autonomously. But for the moment, the paddles must be reset after each stroke. Such devices could use battery power to reset themselves, but that makes the machine less efficient than one made conventionally, says Geoff Spinks, a materials engineer at the University of Wollongong in Australia. “There are still some big challenges with 4D printing,” he says.

Another approach to 4D-printed devices involves triggering the action with a changing external magnetic field. US researchers have 3D-printed lattice structures filled with a liquid that changes stiffness in response to a magnetic field10 — which could perhaps be used to help car seats stiffen on impact.

A fluid that stiffens in response to a magnetic field is injected into the hollow struts and beams of a 3D-printed lattice. The material can be made stiff or flexible.Credit: Julie Mancini/LLNL

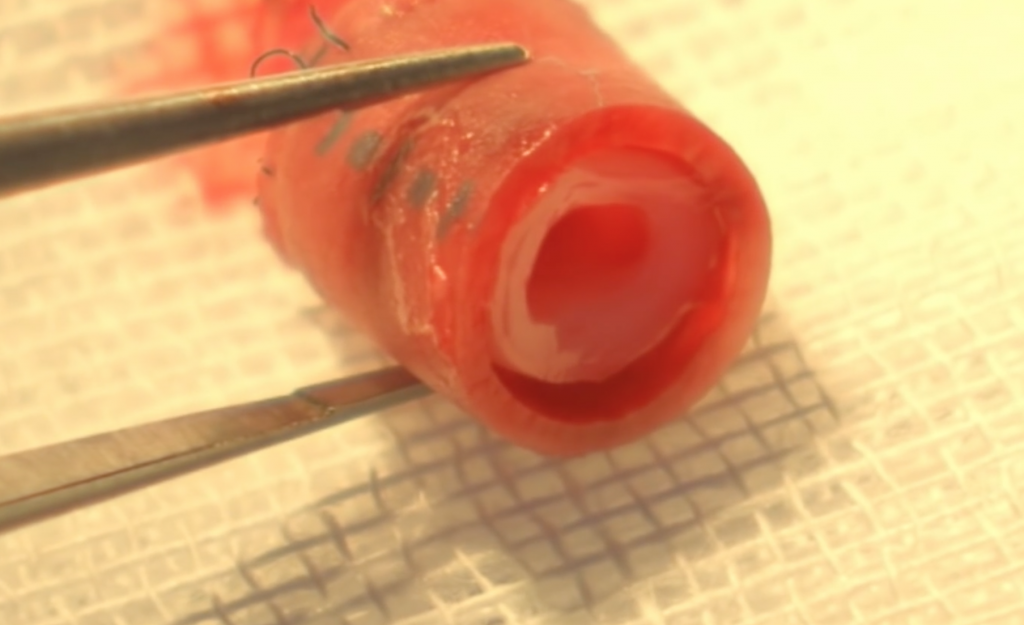

Other, more passive potential 4D printing applications include stents, which could be compressed to be implanted then expanded on reaching the desired site in a blood vessel to prop it open. Last July, researchers in Switzerland and Italy described a 4D-printed stent that is just 50 micrometres wide11, much smaller than conventional ones. The devices are so small, the team says, they could one day be used to treat complications in fetuses, such as strictures in the urinary tract, which can sometimes be fatal.

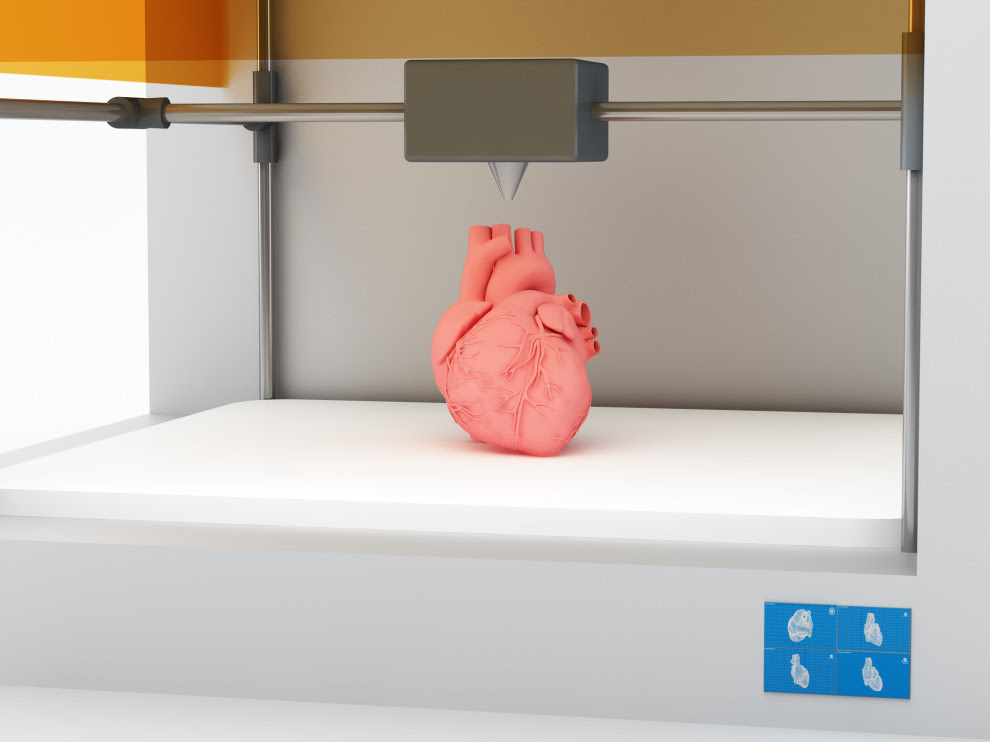

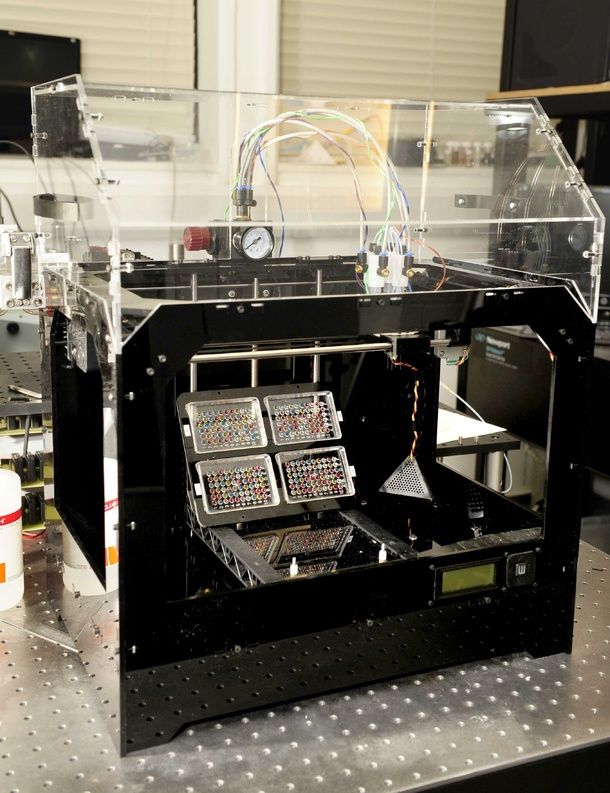

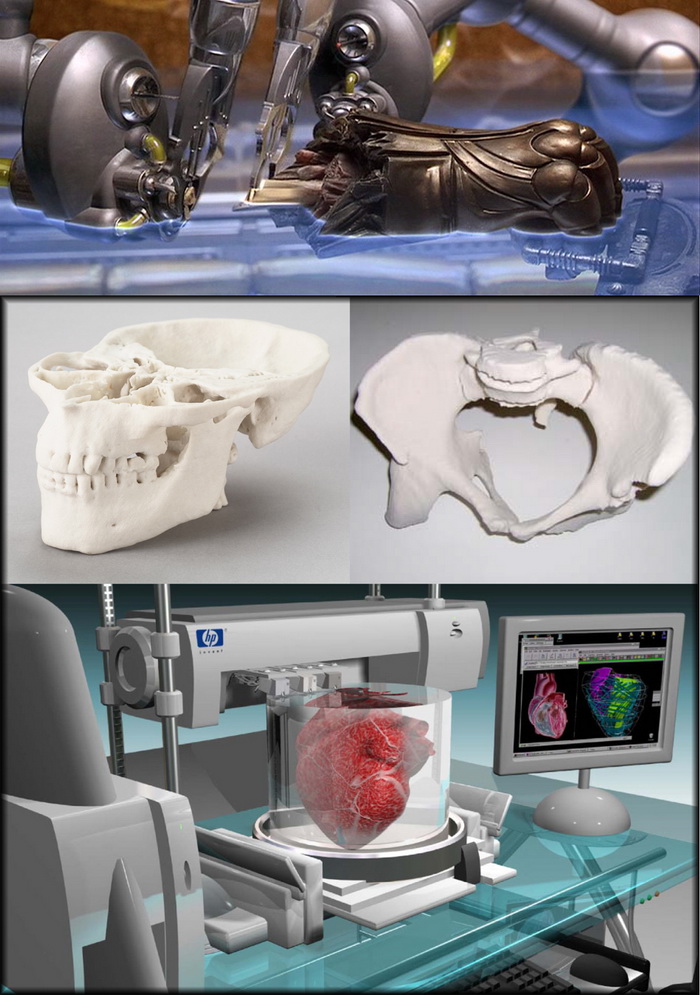

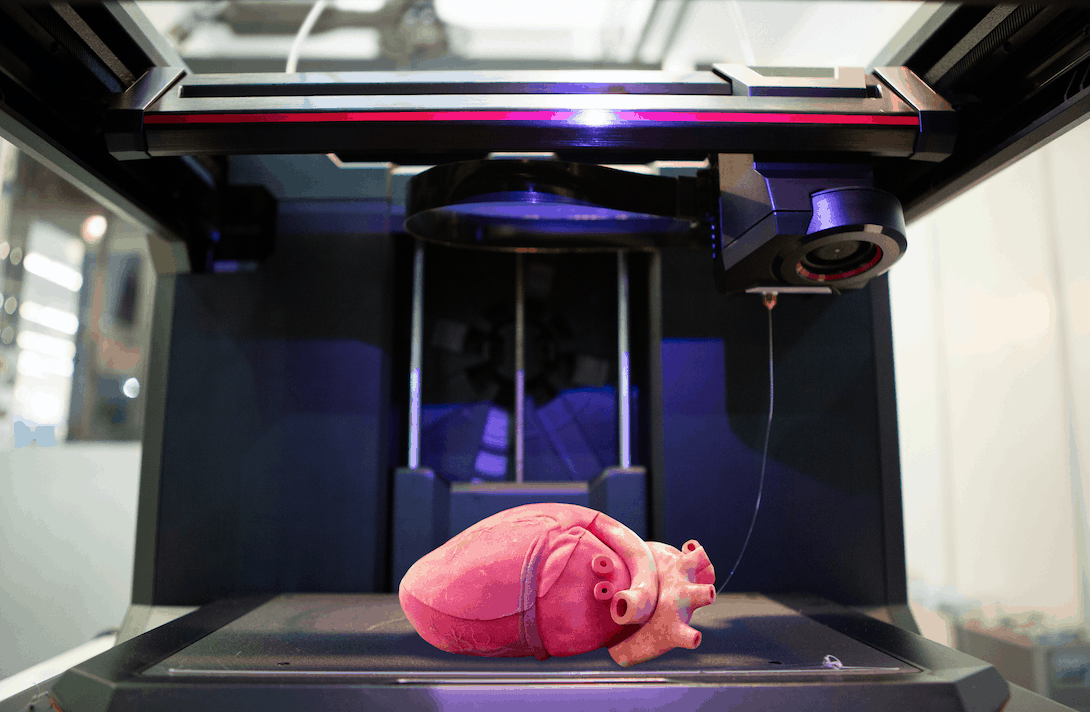

Perhaps the most ambitious example of 4D printing is matter that not only moves, but is alive. Currently, techniques for such bioprinting can print tissue, such as human skin, that is suitable for lab research, as well as patches of tissue for livers and other organs that have been successfully implanted in rats. But such techniques are still far from ready to integrate into a human body. Researchers dream of printing fully functioning organs that could alleviate long wait lists for organ donors. “I personally feel we’re a decade-plus away from that, at least, if ever,” says Lewis.

But such techniques are still far from ready to integrate into a human body. Researchers dream of printing fully functioning organs that could alleviate long wait lists for organ donors. “I personally feel we’re a decade-plus away from that, at least, if ever,” says Lewis.

Many inventive ideas about printing matter that moves or changes rely on printing multiple materials together. “That’s absolutely where the field is heading,” says Scott.

Last November, Lewis and her lab described a printer that can rapidly switch between different polymer inks or mix them as it prints a single object12. This means objects can be printed with both flexible and rigid parts. Lewis has spun off previous work on multi-material printers into a firm called Voxel8, a start-up in Somerville, Massachusetts. Her multi-material printer could help with the athletics wear that Voxel8 is developing, says Lewis. Wearable devices need to be flexible around joints while also having rigid parts to house electronics. Saiz calls the printer “beautiful work”, adding wistfully: “There’s nothing like that for ceramics or metal.”

Her multi-material printer could help with the athletics wear that Voxel8 is developing, says Lewis. Wearable devices need to be flexible around joints while also having rigid parts to house electronics. Saiz calls the printer “beautiful work”, adding wistfully: “There’s nothing like that for ceramics or metal.”

And in March 2018, a team led by Jerry Qi, a materials engineer at Georgia Institute of Technology in Atlanta, unveiled a four-in-one printer. This combines a nozzle that extrudes molten polymer with one that prints light-sensitive resin, ready to be cured by ultraviolet lamps or lasers, and two that print wires and circuitry from tiny dots of metal13. The print heads work together to make integrated devices with circuits embedded on a rigid board or inside a flexible polymer enclosure. Qi says his group is now collaborating with electronics companies interested in printing circuit-board prototypes faster than conventional methods.

It wasn’t as simple as bolting four different printers into one platform: the researchers also needed to develop software that would allow each print head to communicate with the others and keep track of the progress.

The field is still far from delivering on early visions of bringing mass manufacturing into people’s homes. For now, sophisticated printers are too expensive to appeal to non-specialists. But 3D printing has come a long way in the past 20 years. Todd remembers people touring his lab in the early 2000s to see his technique to fuse specks of metal dust together to grow parts. Compared with the conventional milling machines and metal-cutting systems in neighbouring labs, his 3D-printing machines struck visitors as a complete oddity. “It was like we were some sort of a dog playing a piano in a bar,” he recalls. Now, for many firms, that trick is standard practice.

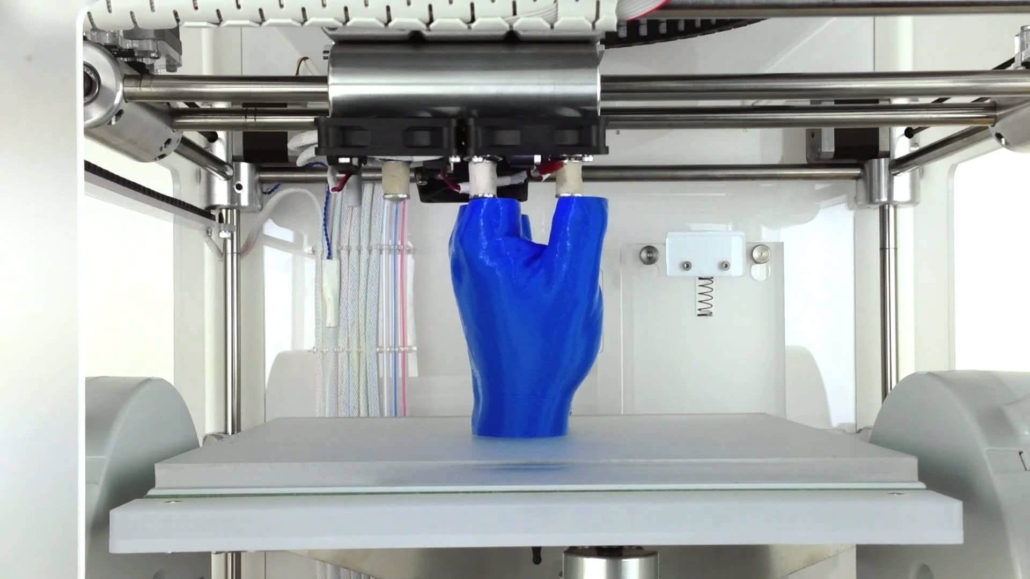

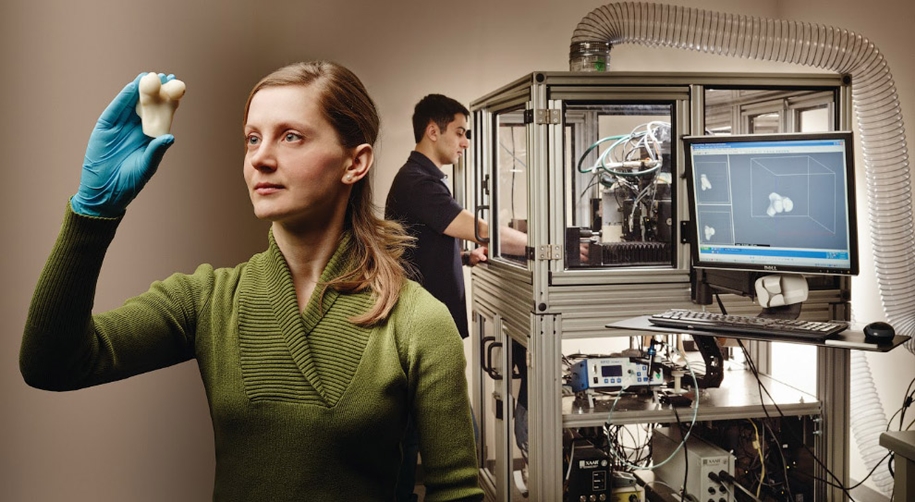

| 3DNews Technologies and IT market. Interesting news from the world of high-tech Achievements of 3D printing: from artificial ... The most interesting in the reviews 07/05/2014 [08:00], Dmitry Prikhodko The modern development of 3D printing has reached the level when using high-tech printers it became possible to create implants, comfortable and functional prostheses, rather large units of industrial equipment and even confectionery. One of the clearest examples of the close relationship between modern medicine and innovative technologies is the successful operation to remove a tumor in a 5-year-old patient. The diagnosis of neuroblastoma required an urgent and extremely complex surgical intervention to remove a malignant tumor in the abdomen. In order not to hurt the vital blood vessels, it was decided to practice on a mock-up, which was made on a 3D printer using several materials with different properties. Since the first two attempts to remove the tumor without training on a mock-up were not very successful, an artificial analogue, exactly repeating the location of arteries and organs, became the only salvation for the child and a way out of this situation for doctors. In total, specialists together with doctors printed two models. It took 1.5 weeks to practice using the printed organs, after which the tumor was removed. The patient is reported to be recovering rapidly. And all this is due to the skillful actions of surgeons and the capabilities of a 3D printer to accurately recreate any element. Continuing the medical theme: scientists from the University of Illinois managed to construct a biorobot whose body is an artificially created muscle tissue. And although the movement of the robot cannot be called human-like, since it is more like the characteristic movements of a crawling earthworm, the miniature device is a very serious step in the development of biotechnology. Making such a complex mechanism 1 cm long and only 1 mm thick, which is an imitation of a human muscle fragment, has become a reality thanks to 3D printing technology. Another case concerns the animal kingdom, which also found a place for the use of 3D-printed prostheses. To help the bald eagle, who suffered from the actions of a poacher, it was decided to implant an artificial beak. The most important thing is that the body of the sea eagle did not reject the artificial organ and the bird quickly got used to it. 3D printing is also relevant in many other areas. Leading companies are trying to rationalize their production and take care of their subordinates, using quite original solutions not only in mechanisms and apparatus, but also in the equipment of workers. So, for example, the German automobile concern BMW issued individual gloves with a special fingertip to employees working on an assembly line in Munich. 3D printed thumb cap designed to reduce stress on joints when inserting plugs and other manual and forceful operations. The fingertip itself, which is individually made for the specific hand of each worker, is an orthopedic device like a splint. During fastening work, it evenly distributes the applied force over the entire surface of the thumb. After a few hours of work, a factory employee will not experience discomfort or pain in the joints, which can later lead to very expensive treatment. Sources: If you notice an error, select it with the mouse and press CTRL+ENTER. Related materials Permanent URL: https://3dnews.ru/823424 Headings: News Hardware, interesting things from the world of hi-tech, on the cutting edge of science, 3D technologies, Tags: hardware, 3d printing, 3d printer, medicine, technology, manufacturing ← В past To the future → |

Achievements of the 3D industry in 2019

Analytics and business

Top topics

Experts recommend

Author: Olga Gorobets

Author: Olga Gorobets

Some statistics | Highlights of 2019: Most Impressive Success Stories | What the experts say

2019 is coming to an end… another year marked by the rapid growth of the 3D market. According to Wohlers Associates Inc., if in 2018 global sales of products and services were estimated at more than $8.5 billion, then in 2020 these figures should increase by 86%, reaching $15.8 billion. The market is expected to grow by 2024 to $35.6 billion (3.6 times compared to 2018).

According to Wohlers Associates Inc., if in 2018 global sales of products and services were estimated at more than $8.5 billion, then in 2020 these figures should increase by 86%, reaching $15.8 billion. The market is expected to grow by 2024 to $35.6 billion (3.6 times compared to 2018).

Global 3D Printing Market Growth Forecast / Source: Wohler Associates Inc., 2019

Businesses are gaining more confidence in 3D technologies – they are beginning to fully understand the benefits of 3D printing and are using it more actively than before. According to Sculpteo's 2019 State of the 3D Printing Market, based on a survey of professional users around the world, 51% of respondents use additive manufacturing in manufacturing, while 3D printing was previously considered only a prototyping method.

iQB Technologies experts recommend:

Results-2020 and forecasts: the 3D printing market will grow by 25% annually

What awaits 3D printing in 2022? Trends and expert forecasts

Presentation of the new version of the Materialise Magics software at the Formnext exhibition, November 2019 / Photo: iQB Technologies

The State of the 3D Printing Market provides, among other things, the following data on key issues related to additive manufacturing:

- The percentage of people using 3D printing for manufacturing increased from 38% to 48% over the past year;

- 80% report that 3D printing has had a significant impact in accelerating innovation;

- 63% believe that 3D printing will play an important role in the context of manufacturing and business;

- 70% of companies plan to increase investment in 3D printing.

The majority of participants in the study "State of the 3D printing market 2019» reported significant improvements in terms of successful 3D printing adoption

What is the best way to sum up the year? We thought the picture would be complete enough if we talked about some of the most interesting projects using 3D printing and 3D scanning, covering a wide variety of industries. And at the same time, we tried to look into the future: to do this, we asked Russian and foreign experts to tell us how they see the prospects for the development of the 3D industry in the coming years.

Highlights of 2019: Most Impressive Success Stories

Largest SLM Rocket Engine

SLM Solutions, a leading manufacturer of metal additive systems, has produced what it claims to be the world's largest 3D printed rocket engine for British aerospace company Orbex.

Printing was performed on a large-format 3D printer SLM 800, the construction chamber of which has a size of 260x500 mm and allows printing parts up to 800 mm high. The motor was printed from a nickel alloy and additive manufacturing allowed Orbex to spend 90% less time and cut costs by more than 50% compared to traditional CNC machining.

The motor was printed from a nickel alloy and additive manufacturing allowed Orbex to spend 90% less time and cut costs by more than 50% compared to traditional CNC machining.

This way of manufacturing the engine also made it possible to make the Prime rocket 30% lighter and 20% more efficient than any other launch vehicle in this category. The first launch of the Orbex Prime rocket with a 3D printed engine is scheduled for 2021.

Read more in the blog

First 3D printed human heart

Israeli scientists have created a human heart with blood vessels and cells on a 3D printer. It was made in miniature, but the same technology could be used to print a regular-sized heart, the researchers said. The printed organ consists of the patient's fat cells that have been converted into cardiovascular muscle stem cells, then mixed with connective tissue and placed in a 3D printer.

The heart, created in an Israeli laboratory, can already contract, but so far it is not able to pump blood. Project leader Tal Dvir hopes that in 10 years the best clinics in the world will have 3D printers that can print human organs, and that this procedure will become commonplace.

Project leader Tal Dvir hopes that in 10 years the best clinics in the world will have 3D printers that can print human organs, and that this procedure will become commonplace.

Source: Euronews

Creaform 3D scanners in the largest fusion reactor project

Creaform's handheld 3D laser scanning technology is part of the largest energy project in history, the International Thermonuclear Experimental Reactor (ITER).

Inside the Tokamak facility, designed to generate energy from a thermonuclear reaction, there is a toroidal vacuum chamber of 9 sectors. Welding of sectors should be carried out at the installation site of the Tokamak plant, in a very limited space with access only from the inside. On-site assembly operations are extremely important, and therefore they were tested on a model.

“Using the highest precision Creaform MetraSCAN 750 Elite and HandySCAN 700 3D scanners, we scan every element of the space and get the exact geometry in the CAD program. These 3D scanners have the reliability you need for a project. In addition, they are compact and easy to handle,” comments José María Sanchez, CTO of AsorCAD, which is responsible for this phase of the work. The 3D scan data is reverse engineered and then used in precision machining. This allows you to get finite elements that exactly match the size of the gaps.

These 3D scanners have the reliability you need for a project. In addition, they are compact and easy to handle,” comments José María Sanchez, CTO of AsorCAD, which is responsible for this phase of the work. The 3D scan data is reverse engineered and then used in precision machining. This allows you to get finite elements that exactly match the size of the gaps.

Read more in the blog

Scientists have created a method for 3D printing of composite diamonds

Specialists from the Swedish company Sandvik Additive Manufacturing have announced the development of a composite diamond that is superior in properties to natural minerals and can be used in industry. This result was achieved through the use of a matrix material in which the diamond is sealed for optimal preservation of the required characteristics.

Thanks to laser stereolithography (SLA) technology, a solution of diamond dust and polymer materials is fed and evenly distributed over the surface layer by layer. UV radiation makes it possible to layer-by-layer form the composition into complex shapes. The final processing by a special patented method gives the material properties such as increased density and rigidity.

UV radiation makes it possible to layer-by-layer form the composition into complex shapes. The final processing by a special patented method gives the material properties such as increased density and rigidity.

Scientists say that the new diamond is not only cheaper and easier to manufacture than conventional synthetic diamond, but also three times more durable and thermally conductive. With the help of further research, it is planned to increase its coefficient of thermal expansion, thermal conductivity and corrosion resistance.

Source: home.sandvik

3 Guinness World Records in one project

The Center for the Development of Advanced Structural and Composite Materials at the University of Maine (USA) completed a unique 3D printing project: a boat more than 7 meters long was created on a polymer 3D printer. Thus, the university set three Guinness records at once: the largest 3D printer, the largest printed solid object and the largest printed boat. The 3D printing process lasted three days, after which the boat was immediately launched, bearing the weight of six people.

The 3D printing process lasted three days, after which the boat was immediately launched, bearing the weight of six people.

Source: 3dprintingindustry.com

Volkswagen improves production using 3D printing and artificial intelligence

The Volkswagen Group has begun using artificial intelligence (AI) and 3D printing to produce automotive parts. In its Innovation and Engineering Center, the company recently introduced a state-of-the-art electrical version of the updated Microbus 1962 years old. This is the first car to be assembled using AI-designed and 3D-printed parts.

Autodesk's generative design software can help engineers train AI by focusing on the core features of a car. With its help, it is possible to develop lightweight, but at the same time reliable and safe structures.

Going forward, the company has big plans to use the technology to create a closed-loop recycling system that will allow a manufacturer to make new plastic parts from used ones. This will not only save fuel, but also lead to a reduction in waste generated.

This will not only save fuel, but also lead to a reduction in waste generated.

VW has proven that AI and 3D printing in automotive design make it possible to create more flexible structures and advanced lightweight parts, all at a much lower cost than traditional production methods.

Source: mobilesyrup.com

Ski helmet prototype in 3 days

Laser stereolithography is one of the most widespread 3D printing technologies, providing undeniable advantages in prototyping compared to traditional production methods. ProtoFab, one of the leaders in the market of SLA equipment, materials and 3D services, implemented a complex project in a short time to create a high-quality model of a ski helmet. First, several parts of the product were printed on a ProtoFab 3D printer from Formula W white opaque photopolymer, then sanding, polishing, coating selection, painting, varnishing and assembly.

A separate problem was polishing - due to the complex texture of the surface on the upper side of the helmet. The application of paint also required special care. In order to ensure an absolutely uniform coating, three separate polishing and painting cycles were carried out.

The project was completed in just 3 days. ProtoFab specialists managed to fulfill all the requirements of the client: eye-catching lines, uniform coloring, clear color contrast, stylish and attractive appearance.

Read more in the blog

3D laser scanner helps restore Notre Dame de Paris

On April 15, 2019, the whole world watched with bated breath the largest fire in history at Notre Dame Cathedral. The next day, when the fire was extinguished, a discussion began on how to restore the masterpiece of medieval architecture.

The French company Art Graphique & Patrimoine teamed up with FARO, the world leader in 3D measurement technology for BIM, to save Paris' top landmark.

In one day, using the most advanced 3D scanners of the FARO Focus S series, color scans were obtained from more than 300 positions and containing from 30 to 40 billion points. Together with data collected before the fire, AGP now has the most complete and accurate 3D map of Notre Dame in its history, consisting of 50 billion points. The wooden frame and the spire destroyed by the flames are especially accurately recreated.

Read more in the blog

Russia's first propeller produced by method 3 D-print

The United Shipbuilding Corporation (USC) presented at its booth during the NEVA-2019 exhibition the first domestic propeller produced by 3D printing.

The unique equipment is the propeller of the propulsion-steering column DRK 1500, obtained by direct laser growth. The propeller was made by specialists from the Institute of Laser and Welding Technologies (ILIST) of St. Petersburg State Marine Technical University (SPbGMTU).

Petersburg State Marine Technical University (SPbGMTU).

The technology of direct laser growth makes it possible to create complex-profile and thin-walled parts with a diameter of up to 2 m and a weight of up to 500 kg.

Source: sudostroenie.info / photo: SPbGMTU

Bentley recreates a rare model with 3D technology

Bentley announced its intention to produce 12 modern replicas of the Blower 1929 years, which will be created using additive technologies and 3D scanning. The Blower was once unparalleled in European racing and today tops the list of most desirable Bentleys for collectors.

The company plans to use detailed scans of original parts, which will require engineers to disassemble and scan parts of Tim Birkin's pre-war sports car 4 1/2-Liter Team Blower. Also, a 3D scanner will allow you to recreate the engine of the car in order to most fully restore the performance of the original.

Both the external design of the car and its internal structure will be almost identical to the original. All 12 models will be equipped with a four-cylinder 16-valve engine with an aluminum crankcase with a capacity of about 240 hp, cast-iron liners and non-removable cast-iron cylinder heads.

Source: 3dprinting.com

The largest plastic-printed bridge opened in Shanghai

A pedestrian bridge printed on a 3D printer was opened in the central park of Taopu district (Shanghai). This is the first such project in China, and the largest in the world in the field of 3D plastic printing. The curved bridge measuring 15.25 m long and 3.8 m wide was printed in just 35 days from photopolymer and composite materials. The structure is designed for operation for 30 years, can withstand a load of up to 250 kg per square meter. m, resistant to prolonged exposure to sun and rain. According to local authorities, the project is an innovative way to popularize 3D printing and its implementation in urban planning.

Source: 3ders.org

Russian Helicopters will start introducing additive manufacturing of parts from 2020

“This year we have to complete the reengineering of about 30 parts and structures that will be produced using additive technologies. The current technology of their manufacture is different - it is casting, stamping, machining. It will be necessary to transfer them to the 3D printing method. According to plans, their introduction into production will begin in 2020. We are talking about serious, power elements of structures, units and systems of our helicopters. By the end of the year, we will make a decision whether we are ready to install part of the parts on mass-produced aircraft, ”said Andrey Shibitov, head of the delegation of the Russian Helicopters holding, Innovation Director, during the 10th International Industrial Exhibition Innoprom-2019".

Each unit will undergo constructive processing, strength testing, testing in terms of all modern production technologies. Then, as part of the tests, it will be necessary to confirm that the part made using additive technology is equal to or superior in its characteristics to the replacement counterpart. Only after such a thorough analysis will new parts be able to get on board serial helicopters. To date, a total of 80 parts are undergoing reengineering.

Then, as part of the tests, it will be necessary to confirm that the part made using additive technology is equal to or superior in its characteristics to the replacement counterpart. Only after such a thorough analysis will new parts be able to get on board serial helicopters. To date, a total of 80 parts are undergoing reengineering.

Source: rostec.ru

What the Experts Say

Andrey Trofimov, Director of Strategic Planning iQB Technologies:

A common trend common to all additive technologies is working with new materials. To a lesser extent, this manifested itself in 3D printing with metals and very clearly in polymer technologies. SLA, SLS and FDM technologies are very susceptible to new materials, and the principle of working with them, unlike metals, is quite simple. With the advent of even more advanced polymers, new types of products will become available to these technologies. But the breakthrough to be expected will obviously be related to composites. The development of the chemical industry in the near future will be determined by the improvement of the properties of composite materials.

The development of the chemical industry in the near future will be determined by the improvement of the properties of composite materials.

Damien Plougastel, EMEA Channel Manager, Creaform:

We, Creaform, see several trends in the 3D market, which are determined by the development of 3D scanning technology. First, with the advent of more and more efficient tools, the pace of production is accelerating, so 3D measurement devices, which include scanners, must meet these changes. Secondly, Creaform products will obviously need to meet the growing need for automation as our customers seek to outsource repetitive tasks to robots. It will also respond to a growing shortage of qualified personnel, which in turn will affect measuring equipment: it must be made available to unskilled labor.

Ilya Krupennikov (iQB Technologies) and Damien Plougastel (Creaform) at the booth of our company at Testing & Control 2019 / Photo: iQB Technologies

Kevin Lin, ProtoFab Director of Sales and Marketing:

In the coming years, 3D printing technologies such as SLS and SLM will play a decisive role due to their clear advantages over traditional methods. They will become more accessible and more widely used, and materials with improved characteristics will appear. Many companies invest heavily in the development of these technologies and involve leading specialists in their development - so does ProtoFab. In the summer of 2020, we will be launching our new SLS and SLM machine lines, which were introduced at the just held Formnext.

They will become more accessible and more widely used, and materials with improved characteristics will appear. Many companies invest heavily in the development of these technologies and involve leading specialists in their development - so does ProtoFab. In the summer of 2020, we will be launching our new SLS and SLM machine lines, which were introduced at the just held Formnext.

Bart Van der Schuren, CTO of Materialize:

In recent years, 3D printing has made progress in many important areas - more productive machines, new materials, more post-processing capabilities. And today we see how all these achievements come together to create an inspiring environment for innovation. All this will lead to the development of fundamentally new applied solutions that were previously impossible and unimaginable [cit. by 3dprintingindustry.com - ed.].

Thorsten Brecht, Senior Director 3D Design & 3D Manufacturing EMEA, FARO Europe GmbH & Co. KG:

The main perspective opened up by additive technologies is the ever-greater freedom in design.

Achievements in the field of medicine deserve special attention. Surgical operations are now carried out not only with the use of "smart glasses" like Google Glass, but also with the help of 3D printers.

Achievements in the field of medicine deserve special attention. Surgical operations are now carried out not only with the use of "smart glasses" like Google Glass, but also with the help of 3D printers.  The second model was a version of the first product, almost identical in its structure, but without a tumor. This was done so that doctors could see the final result of the future operation and understand for sure that they carried it out to the end, completely removing the neuroblastoma.

The second model was a version of the first product, almost identical in its structure, but without a tumor. This was done so that doctors could see the final result of the future operation and understand for sure that they carried it out to the end, completely removing the neuroblastoma.  The biorobot has all the characteristic features of the muscle tissue of a living organism. When an electrical impulse is applied to the brainchild of American scientists, the artificial muscle begins to contract in a similar way to a human one.

The biorobot has all the characteristic features of the muscle tissue of a living organism. When an electrical impulse is applied to the brainchild of American scientists, the artificial muscle begins to contract in a similar way to a human one.