3D printer filament extruder machine

Felfil Filament Maker | Make your own 3D printing filament with Felfil Evo

Felfil Evo Extruder

The Perfect Match for your 3d printer

order now

Felfil Shredder

Crush your Plastic Wastes

order now

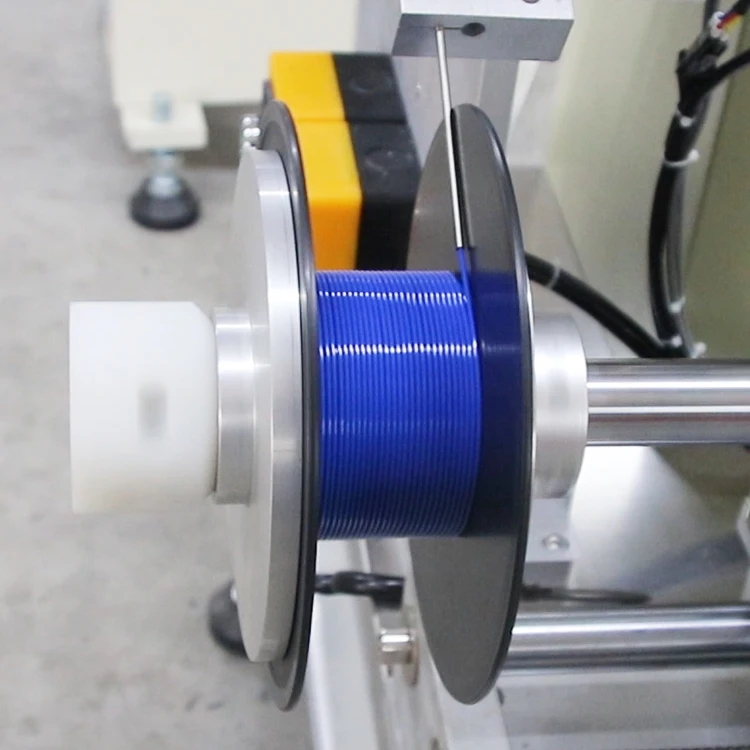

Felfil Spooler

Easier way to extrude

order now

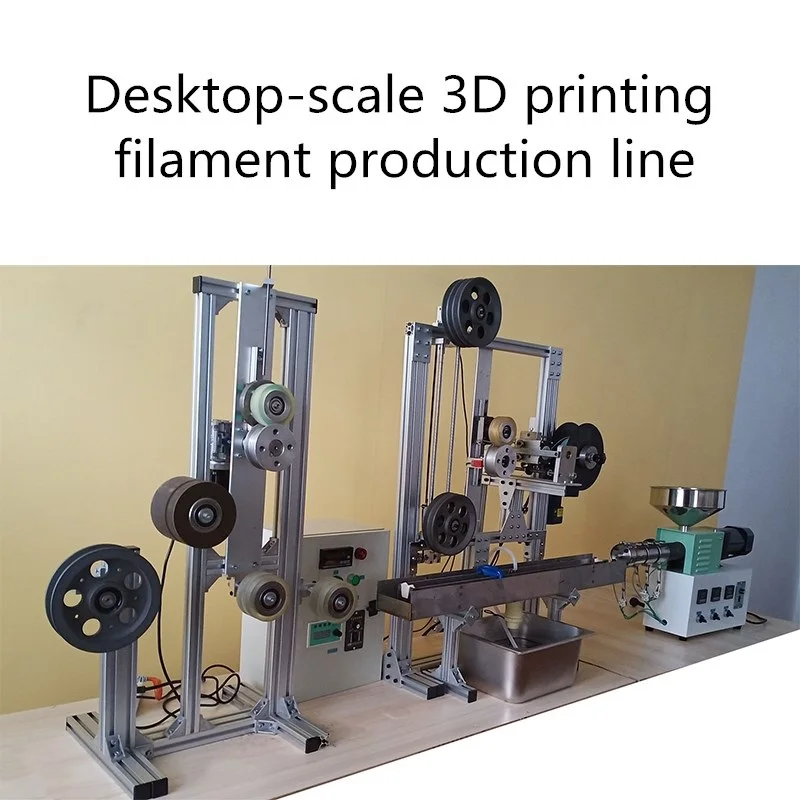

Our filament maker system

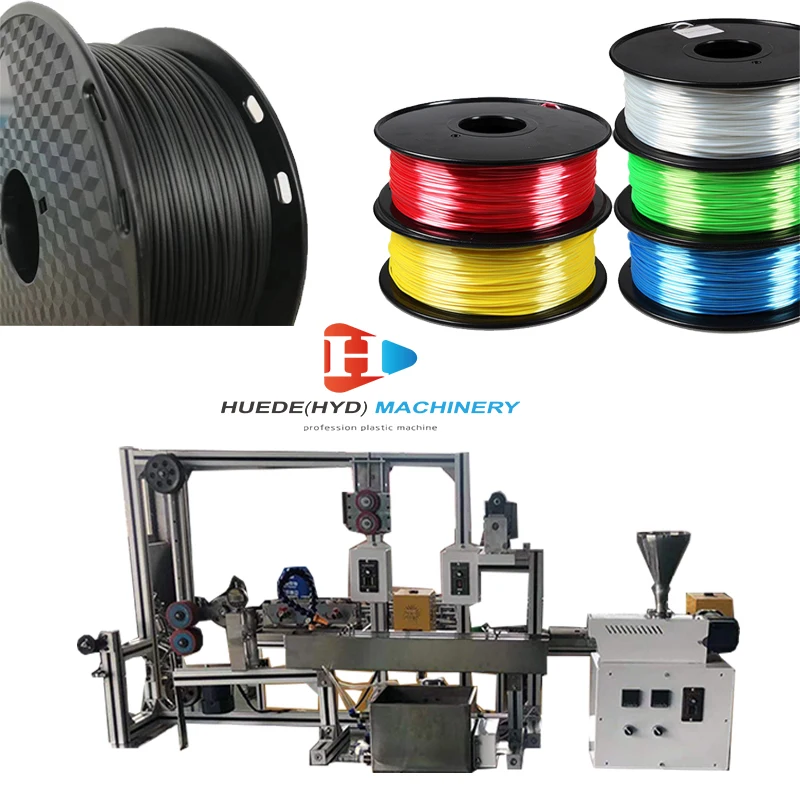

The Felfil filament extrusion line is composed by Felfil Evo, a 3d printer plastic extruder machine, Felfil Spooler which is a winding machine and Felfil Shredder that is a small plastic shredder. This extruding system allows anyone to make custom 3D printing filaments at home or in a lab, starting from industrial pellet or chopped wrong 3D prints, old models and plastic waste.

Using our desktop filament maker you will be able to choose your filament color, diameter and material, day by day, according to your creativity and your needs. In this way you will save over 80% of the price of filaments spools and help to protect the environment.

Recycle

Use failed 3D prints or plastic waste to create your filament

Save money

Save up to 80% of the spool costs starting from our pellets

Experiment

Make your custom 3D printing filament for any 3D printer

Get Your Desktop Filament Extruder

Choose between our different models and start to make your own filament

request a quote

This is the complete filament maker system by Felfil, that includes Felfil Evo Assembled and Felfil Spooler.

You will receive all assembled, ready to make your custom and DIY 3d filament.

A complete solution to make your own filament directly on your desktop.

That’s the full recycling system by Felfil. It includes a plastic shredder, the extruder and the winder. All arrives already assembled and tested.

All three products can be placed on your desktop, and you can start immediately to recycle your old 3d prints or plastic wastes.

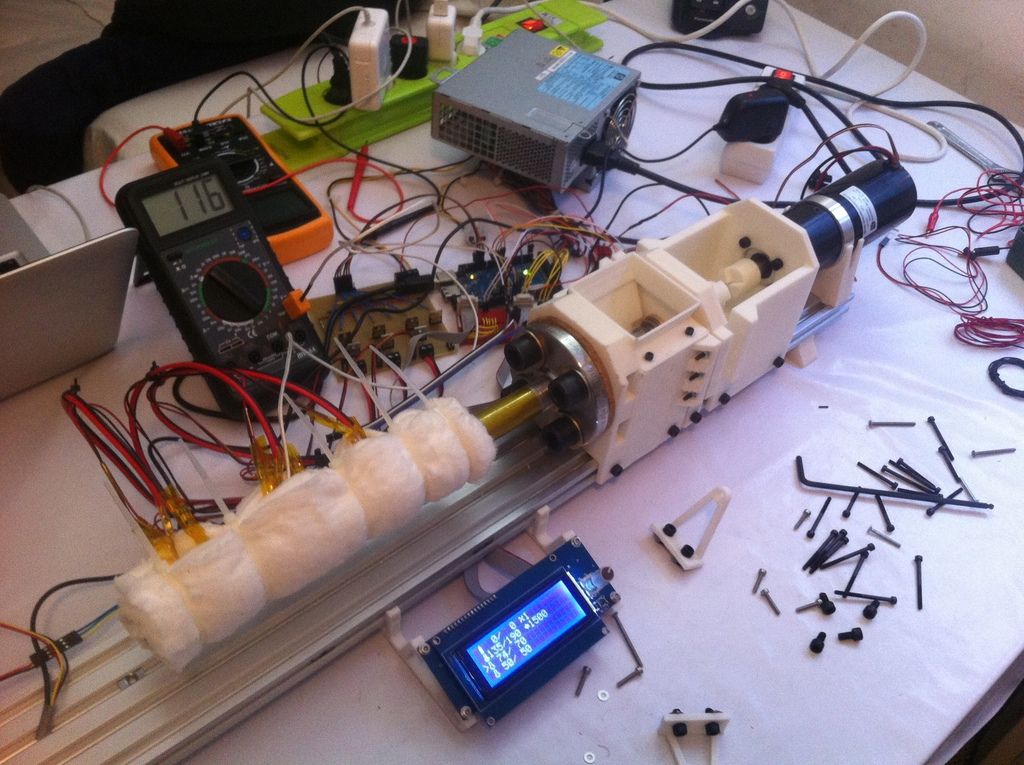

The Felfil Evo Complete Kit is the solution for who want to build their own extruder, step by step. Then, it is shortly to begin to extrude.

Buying this package you will get all the components of Felfil Evo, you just have to assemble them following the instruction manuals.

This is the complete filament maker system by Felfil, that includes Felfil Evo Assembled and Felfil Spooler.

You will receive all assembled, ready to make your custom and DIY 3d filament.

A complete solution to make your own filament directly on your desktop.

This solution is perfect for who want to try immediately our extruder! An ideal choice for those who want to begin to extrude easily.

You will receive the filament maker already assembled, ready to make your custom and DIY 3d filament. You have just to unbox it and connect the plug.

The Felfil Evo Complete Kit is the solution for who want to build their own extruder, step by step. Then, it is shortly to begin to extrude.

Then, it is shortly to begin to extrude.

Buying this package you will get all the components of Felfil Evo, you just have to assemble them following the instruction manuals.

ONE SYSTEM, SEVERAL APPLICATIONS

Our filament extruder system is easy to use and suitable for different applications, find out yours

Fablab /Makers

Felfil Evo is an open source project and it is perfect for FabLabs and MakerSpace users: amatorial 3D printers and experts.

It is studied to help Makers recycle plastic waste from 3D printing activities, to save money and try different materials in order to stimulate creativity and innovative ideas.

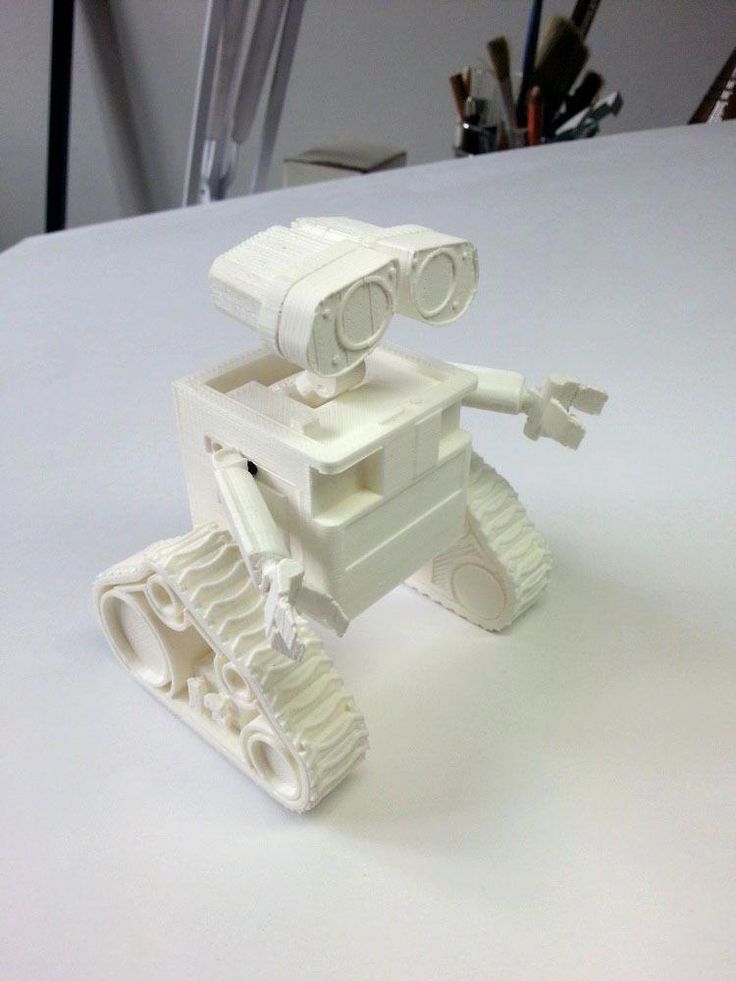

You can create incredible and original objects from your old 3D prints.

Lean more

Laboratories

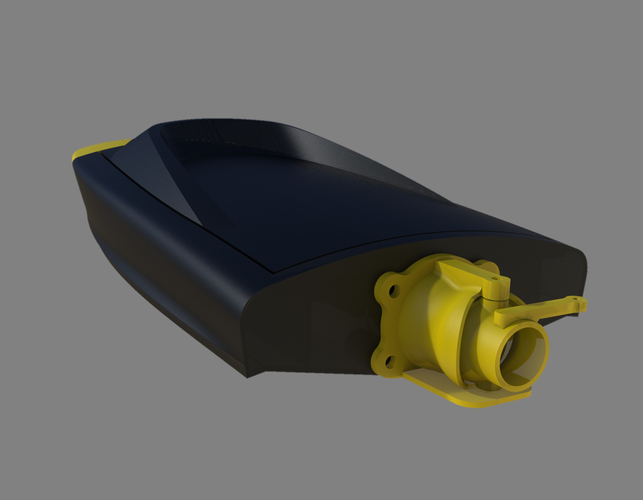

With our system it is possible to experiment new material, test their features and study their application. Felfil Evo and Felfil Spooler can be used in many sectors for prototyping activities.

Felfil Evo and Felfil Spooler can be used in many sectors for prototyping activities.

With our desktop filament maker, research laboratories can be independent creating and testing small quantities of filament and have an immediate experience with the new materials.

Lean more

Education

Felfil helps students to learn about new technologies and additive manufacturing.

Thanks to our filament recycler system it is possible to learn about plastic materials for 3D printing and their potential for reuse culture.

The educational potentials of Felfil project concerns recycling and reuse, maker philosophy and application sectors of 3D printing.

Lean more

Our Clients

Born as open hardware but ready to make filament easily and safely at home. It’s a desktop 3d printer filament extruder able to produce custom filaments for your 3D printer.

Meet Felfil Evo

Meet

Make your choice

You can choose between three different version of Felfil Evo filament maker

DIY Project

Discover how to customize Felfil Evo

More

Filabot EX6 Filament Extruder - Standard Series

- Description

- Specs

- Videos

The Filabot EX6 extruder is our professional-level system, designed to be the best system for developing new polymers and for production of filament. The EX6 features a three-stage extrusion screw made from hardened and polished high-carbon stainless steel. The screw can be easily removed for cleaning and can be swapped out with the various other screw profiles to match the processing requirements of the polymer. With this new system, screws with different characteristics can be used as needed for each specific polymer, allowing screw designs to be tested and polymer output and consistency optimized. All screws have a 24:1 L/D ratio giving greater versatility and control compared to other extruders.

All screws have a 24:1 L/D ratio giving greater versatility and control compared to other extruders.

Click here to learn about the other available screws.

The EX6 features extrusion speed control and a 4 zone temperature control system. The speed control board includes an automatic, variable voltage control module that is engineered to regulate the precise RPM of the screw. The temperature zones are independently controlled allowing for a polymer specific heat profile.

The Filabot EX6 comes with a full one-year warranty on all parts.

Extrudable Plastics: 4043D PLA, 3D870 PLA, 3D850 PLA, Magnum 8391 ABS, and HIPS. Click here for EX6 Extrusion settings. The EX6 is also capable of processing ABS Flame Retardant, PC, PP, PS, ULTEM, PEEK, NYLON, HDPE, PETG, and WAX. Low to Higher Melt Flow Polymers. If you don't see a material listed send us a sample we can test. Click here to see our testing services.

Extrusion Rate: Over 10 pounds per hour (4. 5kg per hour) - Dependant on polymer properties, filament output speed may be less. Output test is done with 4043D PLA for mass flow rate at the nozzle.

5kg per hour) - Dependant on polymer properties, filament output speed may be less. Output test is done with 4043D PLA for mass flow rate at the nozzle.

Filament Sizes: 1.75mm and 2.85mm

Material Input Size: 1/8in (3.18mm) pellets to powder

Material Capacity: Hopper - 195 cubic in (3195.5 cubic cm)

Screw Void - 2.37cubic in (38.8 cubic cm)

Feed Port - 195 cubic in (3195.5 cubic cm)

Temperature Control: 4 Independently PID controlled heat zones, all with active fan cooling for consistent heating

Feed Screw and Drive:

0-100rpm Speed Control

24:1 L:D Ratio Screw

16.28" Length (45.31cm)

5/8” Diameter (16mm)

1/2” Pitch (13mm)

Removable and up-gradable screw

Stainless Steel and Hardened

Click here for Screw Specs.

EX6 Includes

1. Removable Screw

1. 2.85mm Nozzle

1. 1.75mm Nozzle

1. User Manual

User Manual

1. Power Cord

1. Packet of Anti-Seize

2. Packages of Purge

1. Brass wire wheel,

1. Brass pipe cleaner,

1. 10’ of copper gauze and an extension rod for the pipe cleaner

1. Screw removal tool,

1. Pair of oven mittens.

Extrusion Pressure:

3D870 running 365 - 435 psi

Max (plugged nozzle) 765 psi

Universal Power Input: 110 VAC or 220 VAC - 50 to 60hz - 1550 watts MAXIMUM

Physical Characteristics: Weight 50lbs (23kg) and dimensions of 29.7in x 9.1in x 8.4in (75.44cm x 23.11cm x 21.34cm)

Full 1 Year Warranty

Click Here for the EX6 Dimensions

Click Here for the EX6 G Dimensions

Click Here for the EX6 User Manual

Click Here for the Ink Bird Temperature Control Manual

Check out our YouTube channel to see our systems in action!

3d filament extruders in Russia

- Home

- Sale

- Extruders and extrusion lines

- 3d filament extruder

You can quickly compare 3d filament extruder prices and choose from over 5885 offers

AFE25 3D filament production line

Condition: New Manufacturer: China

Characteristics: Model: AFE25 Raw material used: PAL ABS Productivity: 1 - 2 kg/hour 3D filament diameter: 1.75 mm, 3 mm (can be customized according to customer requirements) 3D filament accuracy: ±...

09/02/2022 Moscow (Russia)

Line for the production of 3D thread AFE28

Condition: New Manufacturer: China

Characteristics: Model: AFE28 Raw material used: PAL ABS Productivity: 3 - 5 kg/hour 3D thread diameter: 1. 75 mm, 3 mm (can be customized according to customer requirements) 3D thread accuracy: ±...

75 mm, 3 mm (can be customized according to customer requirements) 3D thread accuracy: ±...

02.09. 2022 Moscow (Russia)

Filament extruder for 3D printer

Condition: New Year: 2014

In stock

Extrusion line for the production of filaments for a 3D printer, new, fully equipped, ready for operation, consisting of an extruder, a dryer, a cooling bath, a water tank with pumps, a head ...

17.05.2015 Omsk (Russia)

1,500,000

PP thread extruder

Condition: Used Year: 2000 Manufacturer: Taiwan

PP thread production area: 1. Extruder brand CH-100 W made in Taiwan with a head for the production of PP film - 1 pc.2. Mixer PP granules - 1 pc.3. PP film cooling bath – 1 pc.4....

11/19/2019 Cheboksary (Russia)

3,000,000

Thread extruder

Condition: Used Year: 2015 Manufacturer: SJPL (China)

I sell equipment Made in China. Productivity is 150kg/hour. 2015 release. In excellent condition.

Productivity is 150kg/hour. 2015 release. In excellent condition.

06/01/2018 Krasnoyarsk (Russia)

7 000 000

Line for production 3D GSD-45

Status: New Manufacturer: China

Characteristics: Model: GSD-45 FEAL: 220/380 / 480 V. , 50 / 60 Hz, 3 fTotal power: 30 kWActual power: 20 kWAir pressure: 0.6 - 0.7 MPa Average output: 15 - 30 kg/h ±...

06/21/2022 Moscow (Russia)

Line for the production of 3D thread GSD-35

Condition: New Manufacturer: China

Characteristics: Model: GSD-35Used material: ABS, PLA, PS, PA Productivity: 8 - 15 kg/h Dimensions: 9920 x 1023 x 1989 mm Weight: 3100 kg

11/10/2022 Moscow (Russia)

Flat thread extruder

Condition: used Year of issue: 2012 Manufacturer: Taiwan (Taiwan)

We sell an extruder for rafi. Auger 80. It turns out a thread from 600 to 1900 den. Number of winders 88 pieces Other information by phone.

Auger 80. It turns out a thread from 600 to 1900 den. Number of winders 88 pieces Other information by phone.

09/06/2021 Tolyatti (Russia)

6,800,000

Wanhao i3 3D printer

Condition: New Manufacturer: Wanhao (China)

In stock

Wanhao Duplicator i3 3D printer is a special DIY printer. It comes assembled, configured and tested! Without exception, all components are made of metal, and not with...

12/07/2021 Samara (Russia)

29 000

Picaso Designer Classic 3D printer

Condition: New

In stock

Designer Classic is a basic 3D printer for an easy introduction to 3D printing technology. Clear management and customized profiles for popular materials will help you easily learn new technology....

12/13/2022 Kazan (Russia)

3D printer Picaso 3D Designer X

Condition: New

In Stock

3D printer Picaso 3D Designer X is a novelty from the Russian manufacturer Picaso 3D, which combines industrial-level technologies and the availability of a desktop device. This gadget is built on...

This gadget is built on...

12/13/2022 Kazan (Russia)

3D printer Picaso 3D Designer X Pro

Condition: New

Available

D printer Picaso 3D Designer X Pro is the latest development of the famous Russian brand Picaso 3D, presented in November 2016. The process of creating this printer is marked by another...

12/13/2022 Kazan (Russia)

3D printer Picaso 3D Designer XL

Condition: New

Picaso 3D Designer XL is a desktop 3D printer that combines all the advantages of an industrial machine with the simplicity of a personal machine. The main distinguishing feature of the device from all ...

12/13/2022 Kazan (Russia)

3D printer Picaso 3D Designer XL PRO

Condition: New

Designer XL PRO - ease of maintenance, minimum calibrations and maximum printing - this is one of the key ideas that we kept in our head when we created Designer XL PRO. That is why we...

That is why we...

12/13/2022 Kazan (Russia)

3D printer Hercules Strong 19

Condition: New

Available

Hercules Strong 19 is a version of the 3D printer that has become larger and more accurate. The printable area has grown by an additional 10 cm in height, making it easier to print large models without...

12/13/2022 Kazan (Russia)

3D printer Hercules G2

Condition: New

Hercules G2 - a characteristic feature of this model is an extruder that heats up to 410 degrees Celsius, thanks to which the device is able to print with the widest range of...

13.12.2022 Kazan (Russia)

Imprinta Hercules Strong Duo 3D printer

Condition: New

The Imprinta Hercules Strong Duo 3D printer is an improved version of the large-format Hercules Strong. From the previous model, it has a print chamber of the same volume (36 l), but mechanics and electronics...

From the previous model, it has a print chamber of the same volume (36 l), but mechanics and electronics...

12/13/2022 Kazan (Russia)

Zenit Z1 3D printer

Condition: New

Available

The Zenit 3D printer is a Russian-made Zenit printer that meets all modern requirements for quality and convenience of 3D printing, has extensive functionality and is used for...

Kazan (Russia)

3D printer Zenit Z DUO

Condition: New

Available

The Zenit DUO 3D printer is a Russian-made device that meets all modern requirements for quality and convenience of 3D printing, has extensive functionality and is used for...

12/13/2022 Kazan (Russia)

3D printer Zenit DUO SWITCH

Condition: New

In Stock

The Zenit DUO SWITCH 3D printer is a Russian-made device that meets all modern requirements for quality and convenience of 3D printing, has extensive functionality and is used for. ..

..

12/13/2022 Kazan (Russia)

Popular categories0014

3d filament extruder video

Portable rod extruders. Filament manufacturing. How to make your own 3D printing consumables

- 1 Description

- 2 Filabot Original

- 3 Filabot Wee

- 4 Filastruder

- 5 Lyman Extruder

- 6 OmniDynamics Struder

- 7 STRUdittle

- 8 Filabot Reclaimer

- 9 Fila Maker

Description

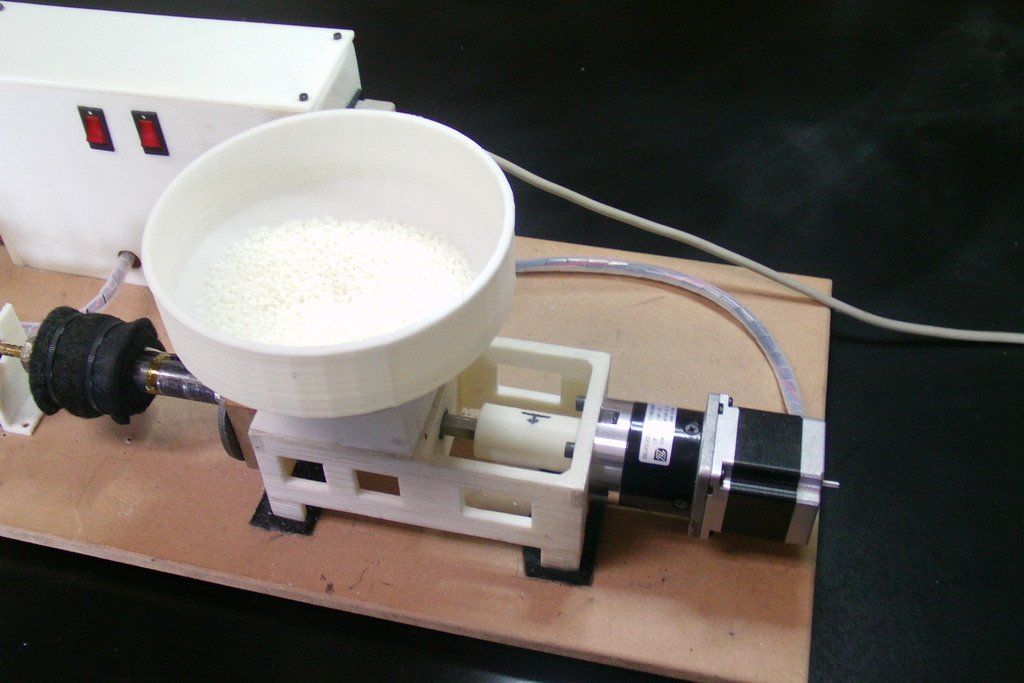

One of the limiting factors in the development of FDM printing is the relatively high cost of consumables. Although most plastics are quite affordable for an ordinary user, the difference between raw materials and finished thread is very significant - often the cost of a rod exceeds the cost of granules of the same weight by dozens of times. Thus, it is not surprising that portable, desktop devices for home production of filament from granules and plastic waste have appeared.

Extruder device

Such installations can significantly reduce the cost of printing and, of course, improve the environment. In this section, we'll take a look at some of the most well-known home rod making practices, including filament extruders and plastic waste shredders.

Filabot Original

The most well-known development with high performance. The device is designed to work with ABS, PLA and HIPS. Granulated plastic is used as a consumable, but plastic waste can also be used, provided that the particle size does not exceed 5 mm.

Filabot Original is the most famous device for home bar production

The company offers a choice of seven colors of granulated dyes for ABS plastic, allowing you to give the finished material the desired shade. Dyes are supplied in packs of 25g. One or two packs are required to paint one kilogram of ABS. For best results, the use of colorants with white ABS granules is recommended.

In addition, ABS, PLA and HIPS can be blended with carbon fiber for stronger and more durable materials. To obtain such a composite, it is only necessary to mix plastic with carbon fiber granules and, if necessary, dye, and then load the finished mixture into a hopper.

Filabot Original has the highest performance among similar devices. It takes about five hours to extrude one kilogram of bar. The temperature range during heating is 40°C-400°C, which allows you to experiment with a wide range of materials, including composites with wood filler, electrically conductive additives, etc.

Bar diameter can be 1.75mm or 3mm depending on nozzle. The extrusion speed is 250-750mm per minute depending on the diameter of the bar to be produced.

The auger rotates at 35 rpm. The power consumption of the device reaches 300W depending on the extrusion temperature. The extruder is equipped with a filter to remove contaminants just before extrusion.

The device is equipped with a durable metal case and has fairly compact dimensions, comparable to a computer system unit: 431x178x203mm.

Factory selling price: $899.

Filabot Wee

Filabot Wee is a more affordable option, not inferior to the Filabot Original

Version of the original Filabot extruder, equipped with a wooden body. This option is positioned as a budget version and is available both in assembled form and as a kit for self-assembly.

The budget version is slightly inferior to its more expensive counterpart in terms of performance: the extrusion speed varies from 125mm to 500mm per minute. The extrusion temperature varies from 40°C to 350°C.

The device is primarily intended for the production of HIPS, ABS and PLA rod, although other materials suitable for extrusion temperatures are also possible.

Due to the use of granular dyes, a wide range of colors can be achieved - when using dyes, the use of white ABS plastic or a material with slight color shades is recommended.

The addition of granulated carbon fiber results in a higher strength end product. Carbon fiber can be used in combination with any of the calculated plastics.

The maximum power consumption is 300W. The device comes with interchangeable nozzles that allow the production of two of the most popular bar diameters: 1.75mm and 3mm.

Filabot Wee dimensions are similar to Filabot Original: 431x178x203mm.

Filabot has released the Filabot Wee drawings to the public. Those wishing to build an extruder with their own hands can download the necessary files here and here.

Factory selling price: $749for an assembled extruder, or $649 for a self-assembly kit.

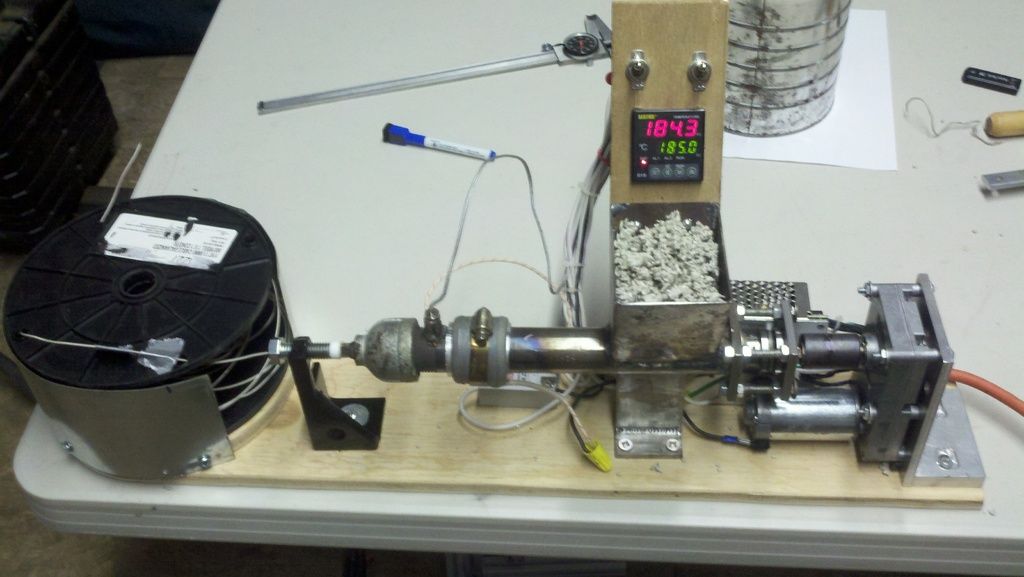

Filastruder

A relatively inexpensive extruder designed by two University of Florida students, Tim Elmore and Allen Haynes.

Filastruder - a relatively inexpensive but very efficient extruder

Filastruder allows you to produce one kilogram of filament in 12 hours of operation of the device, or from 150mm to 600mm per minute, depending on the diameter of the nozzle, extrusion temperature and the material used. The developers tested the extruder with ABS plastic, but they allow the use of PLA, HIPS, nylon, polyethylene and other plastics. The maximum extrusion temperature reaches 225°C.

The developers tested the extruder with ABS plastic, but they allow the use of PLA, HIPS, nylon, polyethylene and other plastics. The maximum extrusion temperature reaches 225°C.

The extruder is quite economical - the maximum power consumption is 60W with an average of 50W.

Filastruder is available with 1.75 or 3mm nozzles.

Filastruder extruder sells for $300 without hopper or $310 with printed hopper.

Lyman Extruder

Lyman Extruder - the pioneer of desktop filament mills

Named after the inventor, Hugh Lyman. The original development is probably the first homemade bar extruder. It was this design that won the top prize at the Desktop Factory Competition in 2013.

The design of the extruder was simplified as much as possible, which was the result of the main condition of the competition: the total cost of the components used in the design should not exceed $250.

The Lyman extruder is not commercially available and is not available at retail. The developer posted instructions for creating an extruder in the public domain. The required files can be downloaded here.

OmniDynamics Struder

OmniDynamics Struder is designed for safety and ease of use

A compact device announced on Kickstarter in May 2014. The goal of the developers is to create a portable, convenient and safe device to use.

Delivery of the first batches of the extruder is scheduled for September 2014. The retail price of the device has yet to be announced, but the Kickstarter pre-order price is £149.

Extruder designed to work with any thermoplastic used in 3D printing including ABS, PLA, PET, HDPE, HIPS, etc. The device is equipped with a full-fledged control module with a color LCD display.

STRUdittle

STRUdittle is a promising extruder with compact dimensions and high productivity

Another interesting development that received the necessary funding on Kickstarter.

Designed for high compactness and good affordability while maintaining high performance.

According to the developers, the device is capable of producing up to 600mm bars per minute. The extruder is designed to work with ABS plastic. Filament diameter deviations do not exceed 0.03 mm when using a winder or 0.05 mm if the bar is simply extruded onto the floor. Customers can specify the required nozzle diameter: 1.75mm or 3mm.

Kickstarter pre-order price is $385 for extruder with winder.

Filabot Reclaimer

The Filabot Reclaimer can handle all kinds of plastic waste. At the same time, FDM printers in combination with desktop extruders have great potential for recycling plastic waste into new products. Thus, to use plastic waste as consumables, a device is required that can crush plastic to obtain small particles - usually no more than 5 mm. Filabot has developed a simple yet effective shredder designed for just this purpose. The device was called the Filabot Reclaimer.

The device was called the Filabot Reclaimer.

The Filabot Reclaimer features a strong, welded metal frame and hardened steel serrated rollers. The device is not equipped with an electric drive - the rollers are driven manually using a lever.

Almost any thermoplastic used in 3D printing can be used as raw material.

The Filabot Reclaimer lets you recycle bad models, 3D print scraps, and just plain old plastic items. The size of the neck and, accordingly, the processed pieces of plastic reach 50x90mm. Due to the robust metal construction of the fixture, the weight of the Filabot Reclaimer is an impressive 11kg. The installation dimensions are quite modest, reaching 255x255x380mm.

The Filabot Reclaimer retail price is $439. Despite the relatively high cost, the device quickly pays for itself, allowing, together with the extruder, to save up to 90% of the cost of the bar.

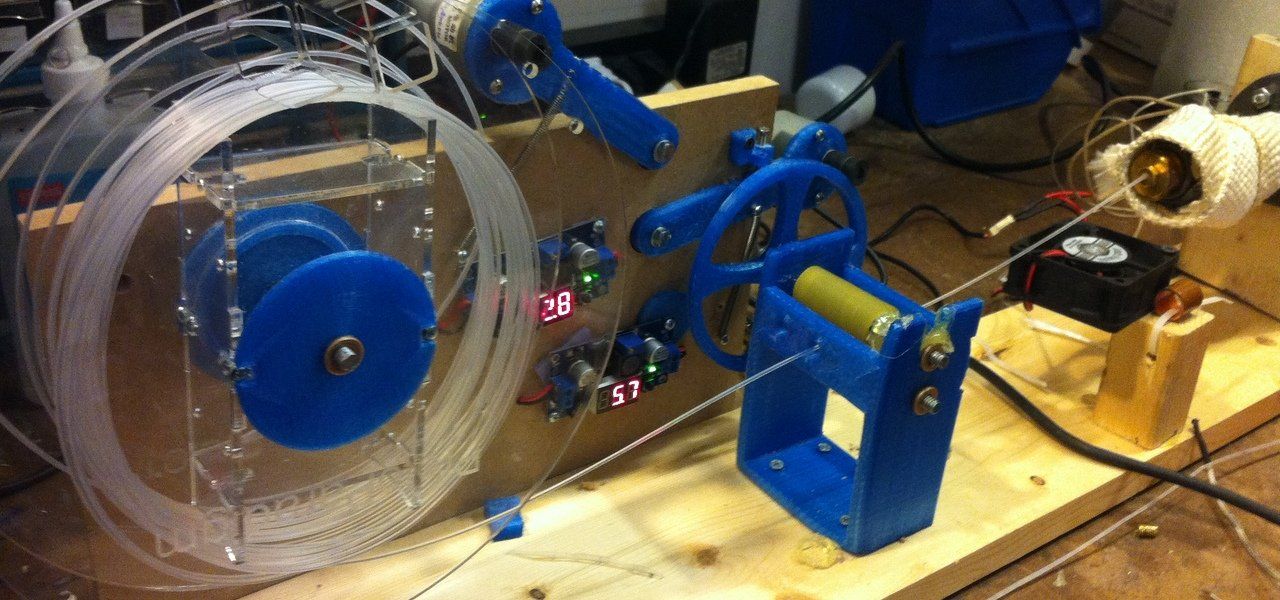

FilaMaker

FilaMaker combines crusher and extruder functionality

FilaMaker combines crusher and extruder functions in one device.