3D printing boat

Navigating the Best Examples of 3D Printed Boats

Published on July 30, 2021 by Amelia H.

Additive manufacturing is now a production method used everywhere, whether on Earth, in the air, in space or even underwater. Some players in the maritime sector are turning to 3D technologies to design components for their boats, spare parts for submarines and even components of currents turbines. We won’t go into these initiatives today, but we will focus on 3D printed boats: whether they are fully or partially 3D printed, more and more of them are incorporating additive manufacturing. From bow to stern, discover how 3D technologies are impacting the construction of our boats through some innovative applications.

The world’s largest 3D printed boat

In September 2019, the University of Maine’s Advanced Structures and Composites Center made headlines when it announced that it had made the world’s largest 3D printed boat. The 3Dirigo was printed in 72 hours by the world’s largest thermoplastic 3D printer and measures 25’ (7. 62m) long and weighs 5,000lbs (2,268kg). Beyond holding the Guinness World Record for largest 3D printed boat, it also holds a record for being the world’s largest solid 3D printed item. Though the boat will not actually be used, it was tested in a pool at the Alfond 22 Ocean Engineering Laboratory test site, with U.S. senators as well as U.S. Representative from Maine, boarding the boat for a test ride. The project is part of a partnership with the U.S. Department of Energy’s Oak Ridge National Laboratory in Tennessee (ORNL) to develop a large-format AM program based on 3D printing materials that contain wood fiber.

Photo Credits: University of Maine’s Advanced Structures and Composites Center

MAMBO, a functional 3D printed fiberglass boat

Unveiled in 2019 during the FormNext international trade show, the MAMBO boat was designed by Moi Composites, in collaboration with Autodesk, Catmarine, Micad and Owens Corning. It is 12’4″ (6.5 meters) long, 8’2″ (2.5 meters) wide and weighs about 1763. 7lbs (800 kg). The peculiarity of the project is that it turned out to be the first functional 3D printed fiberglass boat to sail in Italian waters during the Genoa boat show. For its development, the company relied on additive manufacturing technology with continuous fiber composite materials. The process involved two robots that fabricated the boat’s components to be assembled. This system allows the creation of much lighter, yet strong and durable parts, limiting material waste and without the need for molds – a successful example of the possibilities of 3D printing in the maritime sector!

7lbs (800 kg). The peculiarity of the project is that it turned out to be the first functional 3D printed fiberglass boat to sail in Italian waters during the Genoa boat show. For its development, the company relied on additive manufacturing technology with continuous fiber composite materials. The process involved two robots that fabricated the boat’s components to be assembled. This system allows the creation of much lighter, yet strong and durable parts, limiting material waste and without the need for molds – a successful example of the possibilities of 3D printing in the maritime sector!

Photo Credits: Moi Composites

Europe’s first seaworthy 3D-printed boat

A collaboration between RISE (Research Institute of Sweden) and Cipax, the owner of the boat company Pioner, resulted in Europe’s first seaworthy 3D-printed boat to be manufactured in one piece. The Pioner 14 Active Dark Line model was produced layer by layer from a plastic and glass fiber mixture using ABB robotic arms. In order for customers, such as the police or the military, to be equipped with the 3D printed boats in the future, it is still necessary to compensate for the excessive material density with floating hulls. If this goal is achieved, nothing should stand in the way of commercialization of the model.

In order for customers, such as the police or the military, to be equipped with the 3D printed boats in the future, it is still necessary to compensate for the excessive material density with floating hulls. If this goal is achieved, nothing should stand in the way of commercialization of the model.

3D printing the AC9F

The New Zealand company Yachting Developments has been building boats for a few years now, particularly with composite materials. It has developed a branch dedicated to additive manufacturing in order to accelerate the production of its ships. One of its latest projects was to 3D print all the tooling needed to build the AC9F, a boat that took part in the 36th edition of the America’s Cup, which took place from March 10 to 21. Thanks to 3D printing, the teams were able to drastically reduce the manufacturing time of the final boat.

Photo Credits: Yachting Developments / Georgia Schofield

The One Minute Boat project

Every minute, no less than 20 tons of plastic waste is dumped into the oceans. Despite the fact that they are very harmful to marine life, millions of plastic bottles are thrown into the sea every day. That’s why Searious Business, a company that specializes in the fight against plastic pollution, has developed the “One Minute Boat” project, named after the data mentioned above. The sailboat, printed in 3D, will be built from 20,000 kg of PET plastic recovered from discarded plastic bottles. In order to obtain a model of the project, Searious Business collaborated with the company Lay3rs, which 3D printed a replica of the boat with recycled PET. An initiative that proves that additive manufacturing also has a role to play in the fight against ocean pollution.

Photo Credits: Searious Business

The world’s first autonomous 3D printed boats

Roboat is the central focus of a five-year research project conducted by the Amsterdam Institute for Advanced Metropolitan Solutions and MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL). The institutes intend to manufacture the world’s first (3D printed) fleet of autonomous floating vessels. These will rely on self-driving technology set to change cities and their waterways through automation. Autonomous platforms will be integrated to form floating bridges and stages, collect waste, deliver goods, and transport people, all while collecting data about the city.

The institutes intend to manufacture the world’s first (3D printed) fleet of autonomous floating vessels. These will rely on self-driving technology set to change cities and their waterways through automation. Autonomous platforms will be integrated to form floating bridges and stages, collect waste, deliver goods, and transport people, all while collecting data about the city.

A 3D-printed version of the Livrea26

The next boat on our list is the Livrea26, prototyped by CRP Group, an industry group specializing in additive manufacturing and rapid prototyping, among other things. The inspiration for the 3D project, which is the result of a collaboration with Livrea Yacht Italia, comes from the traditional fishing boats on the Italian island of Pantelleria. Together, the partners aim to contribute to the development of innovative materials for boat building, with the goal of revolutionizing watercraft construction methods and designs. The 3D-printed version of the Livrea26, which has a scale of 1:14, is made of Windform materials. Thanks to additive manufacturing and Windform materials, the boat was built in just a few days, maintaining the most complex de-tails and strong aesthetics.

The 3D-printed version of the Livrea26, which has a scale of 1:14, is made of Windform materials. Thanks to additive manufacturing and Windform materials, the boat was built in just a few days, maintaining the most complex de-tails and strong aesthetics.

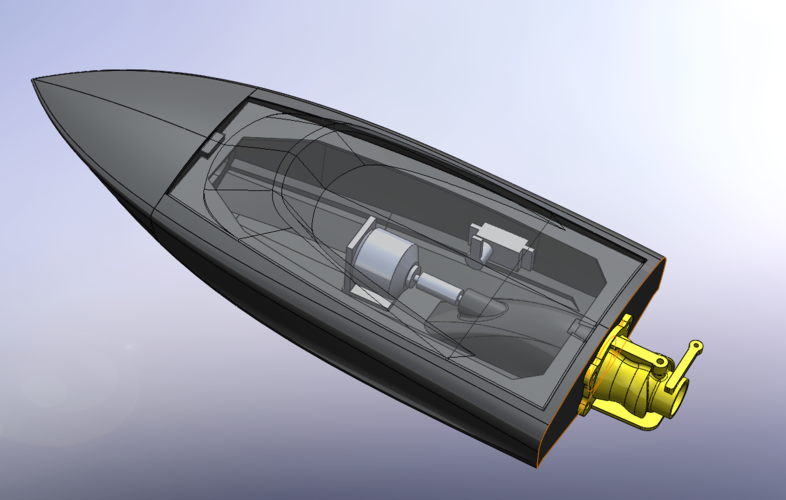

Thermwood’s 3D printed boat hull

Last year, Thermwood, a company specializing large format additive manufacturing solutions, used 3D printing to manufacture a hull mold for a 51-foot-long yacht with carbon fiber reinforced ABS. In order to do so, the company used its smallest 3D printer, the LSAM MT, which possesses a print volume of 10 x 10 feet. Thermwood then 3D printed four parts taking 65.5 hours (just under 3 days), weighing a total of 4,012 pounds (about the same as a hippo), which it later bolted together to form the whole boat hull.

Thermwood’s 3D printed hull. (Photo Credits: Thermwood)

(Photo Credits: Thermwood)

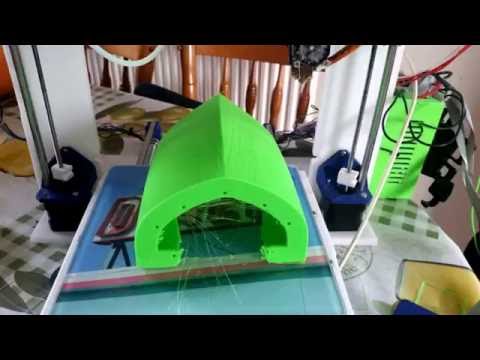

A 3D printed Kayak

Our final boat is not a prototype, nor a miniature but rather a fully functional kayak and the first of its kind. The genius behind this invention is Jim Smith of Grass Roots Engineering. He was able to create a kayak that is 5 meters long, 0.5 meters wide, and weighs about 30 kilograms, using 28 different ABS plastics. Other than that, Jim used only screws, threaded inserts and some silicone sealant. To make his project a reality, the 3D Systems engineer even created a custom, large-scale 3D printer. One thing’s for sure: no challenge could stop him from this innovation, and we can’t wait to see if more kayaks are 3D printed in the future.

Photo Credit: Grass Roots Engineering

What do you think about these 3D printed boats? Let us know in a comment below or on our Linkedin, Facebook and Twitter pages! Sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox!

University of Maine creates the world's largest 3D printed boat

Published on October 16, 2019 by Carlota V.

A team of researchers from the University of Maine revealed the largest 3D printed part in the world. It is a boat, the 3Dirigo, designed on a large-format polymer 3D printer developed by the UMaine Advanced Structures and Composites Center. The piece is 7.62 meters long and weighs 2.2 tons! The project teams were awarded 3 World Records: the largest 3D printed solid part, the largest 3D printed boat and finally the largest 3D printer. This is a promising initiative for the maritime sector, which take advantage of the benefits of additive manufacturing.

More and more additive manufacturers are turning to large-format 3D printing, hoping to create large structures in one go and avoid assembly or post-processing steps that are expensive and time-consuming. The University of Maine is therefore joining this trend, with an emphasis on the use of composite materials. Last May, its partner the Oak Ridge National Laboratory (ORNL) received $20 million to develop a large-format additive manufacturing program based on 3D printing materials that contained wood fiber. The 3D printing of the boat is therefore a significant step forward in this government-supported project.

The 3D printing of the boat is therefore a significant step forward in this government-supported project.

The large-format 3D printer, next to the 3D printed boat | Image via UMaine

3D Printed Boat: The Manufacturing Process

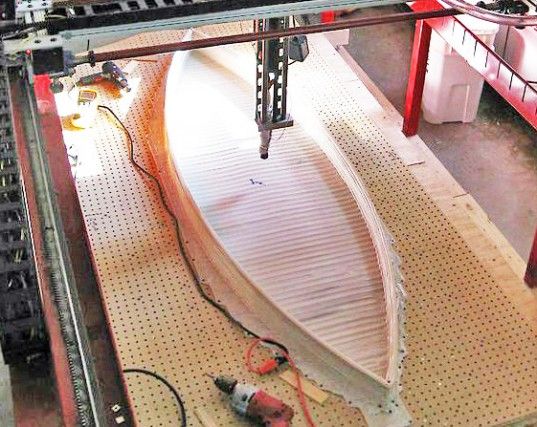

The UMaine teams worked with Ingersoll Machine Tools to develop their 3D printer, it presents a printing volume of 30 x 6.70 x 3 meters (length, width and height) and a speed of 227 kilos per hour. The print head is fixed on a gantry mounted on rails, making it easier to move along the length. As of today, the manufacturer is not offering a wide-range of compatible materials, however the machine was designed to use raw materials of biological origin, in particular cellulose from wood. Apparently, the 3D printer was designed for rapid prototyping applications for civil, defence and infrastructure applications.

In order to demonstrate the capabilities of their large format 3D printer, the teams created the 3D printed boat 3Dirigo. It was manufactured in just 72 hours from a mixture of plastic and wood cellulose. The part is 7.62 meters long and weighs 2.2 tons, making it the largest solid structure ever 3D printed.

The part is 7.62 meters long and weighs 2.2 tons, making it the largest solid structure ever 3D printed.

The boat has been tested by the Alfond W2 Ocean Engineering Laboratory test site

Other Projects

The University of Maine took the opportunity to present a second project, a 3.6-metre long 3D printed communication shelter for the US military. The university worked in collaboration with the Combat Capabilities Development Command (CCDC), a branch of the army that consists of rapidly deploying shelter systems for soldiers. Col. Frank Moore, Military Assistant at CCDC Soldier Center, explains: “The innovation that we have witnessed here at the University of Maine will revolutionize how the Army prototypes and manufactures shelters, vehicles and other large systems. The lighter yet stronger 3D printed systems will advance the state of the art in additive manufacturing, forging the future of expeditionary equipment IAW with the Army’s new policy on advanced manufacturing. ”

”

The boat took 72 hours to be 3D printed

The machine is also expected to meet the needs of rapidly deployable and logistically weak infrastructure systems. With this in mind, the teams printed a 2.2-ton, 6.4-metre-long 3D mold to make a 23-metre-long bridge girder. The bridge is expected to be built in Hampden, Maine, in the summer of 2020. Habib Dagher, Executive Director of the UMaine Advanced Structures and Composites Center concludes: “We are truly honored to be working with leaders from the Maine boatbuilding industry, Maine Forest Products Industry, the national construction industry, Maine Technology Institute, Oak Ridge National Laboratory, the U.S. Dept of Energy Advanced Manufacturing Office, the U.S. Office of Naval Research, the U.S. Army, and the U.S. Army Corps of Engineers. With this large printer, we will be able to accelerate innovation and prototype development in both the civilian and military sectors.” Find more information HERE.

What do you think of these achievements coming from the University of Maine? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!

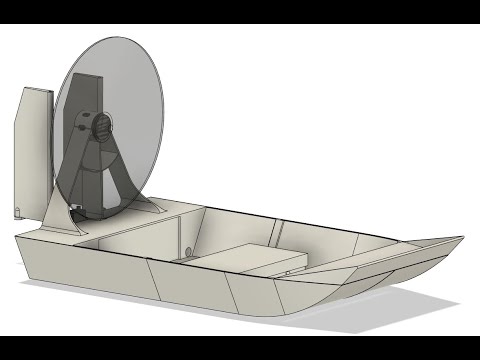

Innopolis University will print a seven-meter boat on a 3D printer

News

The motorboat is scheduled to be printed by the end of this spring, according to Inkazan. 3D printing will take about four days, and it is planned to use domestically produced ABS as a consumable. After completion of the work, the boat will be tested on the Volga. The project is being implemented by the team of the robotic laboratory of Innopolis University, which has developed a hardware and software system.

“If we are talking about a five-meter classic boat, then we will be two to three times cheaper in terms of material and equipment performance. But this is pure custom: we can make each boat unique, which is very important for boat owners,” said Artur Shimanovsky, head of the robotics laboratory at Innopolis University.

But this is pure custom: we can make each boat unique, which is very important for boat owners,” said Artur Shimanovsky, head of the robotics laboratory at Innopolis University.

Similar experiments have already been carried out abroad. In 2020, the Swedish sustainability research institute RISE printed and successfully tested a powerboat with a fiberglass polymer composite hull.

Another interesting variant called Mambo was demonstrated in the fall of 2020 at the Genoa Boat Show by the Italian startup Moi Composites, formed on the basis of the Polytechnic University of Milan. The hull of this boat is also made of composite, but on the basis of thermoplastic, not thermoplastic.

Not without a Guinness record, or rather three at once: in 2019, the University of Maine printed the largest 3D-printed boat, which turned out to be the largest one-piece 3D-printed object in general, and the largest 3D-printed object was used as production equipment. resin printer designed by Ingersoll.

resin printer designed by Ingersoll.

This boat is over seven and a half meters long. According to the director of the Center for Advanced Structures and Composites at the University of Maine Habib Daguerre, the material was a polymer filled with cellulose nanofibers, which in turn was obtained from the waste of the local woodworking industry.

Although the very possibility of 3D printing of boat hulls has been proven in practice, additive manufacturing of molding equipment still seems to be more promising. This direction has already been tested. Back in 2017, Thermwood Corporation, an American manufacturer of CNC machines, large-format 3D printers and hybrid systems, demonstrated the process of 3D printing hull master models, that is, templates for making molds, with which you can then make ordinary fiberglass boat hulls.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at news@3Dtoday. ru.

ru.

boat Innopolis

Subscribe to the author

Subscribe

Don't want

4

Even more interesting articles

5

Subscribe to the author

Subscribe

Don't want

Establishment of the center will help improve the quality and reduce the cost of engineering products...

Read more

four

Subscribe to the author

Subscribe

Don't want

Researchers from the Tomsk Polytechnic University (TPU), together with foreign colleagues, developed...

Read more

56

Subscribe to the author

Subscribe

Don't want

Dear friends!

3D printers, makers and just caring people in Russia connect. ..

..

Read more

The world's first 3D printed fiberglass boat

Technologically, our reality is evolving at a pace that our parents never dreamed of. Proof of this is the latest fiberglass motorboat, which is fully 3D printed.

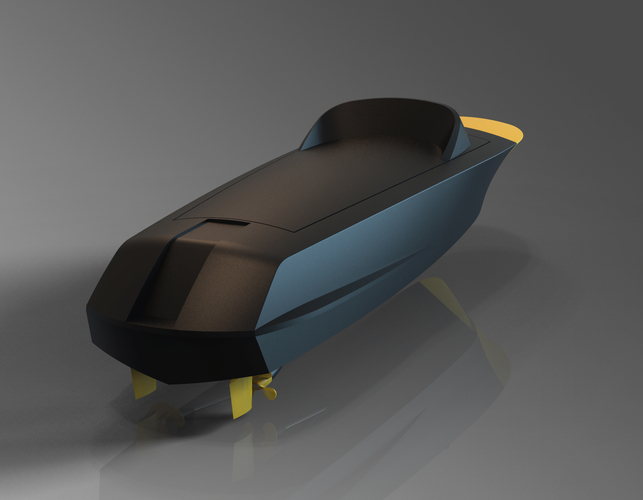

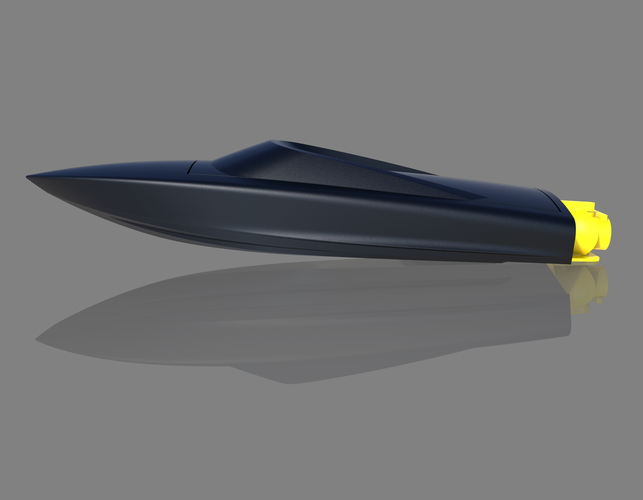

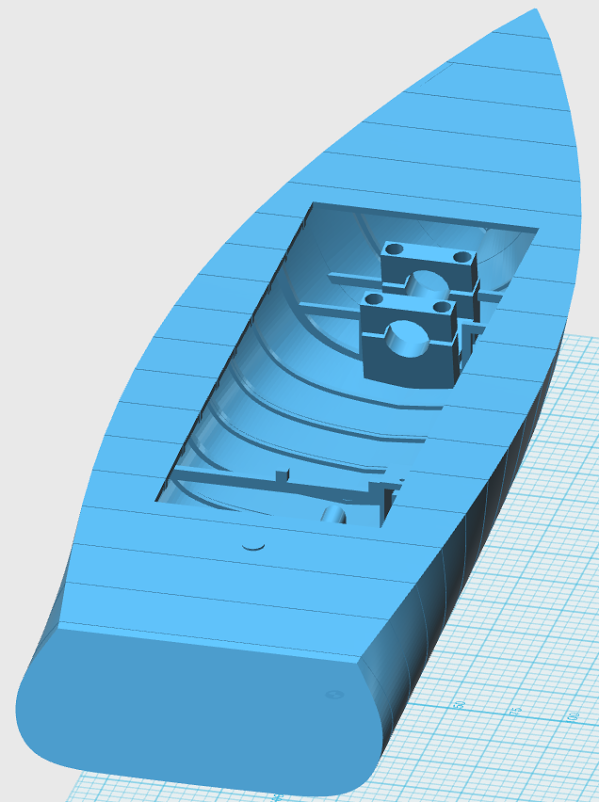

The MAMBO (Motor Additive Manufacturing Boat), designed and 3D printed by the startup team Moi Composites, using innovative robotic machines and a uniquely shaped advanced composite material, is the first boat of its kind. The boat is built using the innovative Continuous Fiber Manufacturing (CFM) technology. In this method, continuous fibers are injected into a thermosetting resin to produce a material that is as strong as traditional fiberglass but much easier to form. It is time- and money-efficient and therefore widely used, making it possible to create glass fiber reinforced products with mechanical characteristics similar to unidirectional glass fiber without the use of models, molds or other equipment.

A team from a start-up subsidiary of the Politecnico di Milano looked for ways to overcome manufacturing constraints after discovering that new designs could not be realized with existing manufacturing methods. The production of boats from composite materials is currently costly as it requires moulds, wastes time and material, and is limited to standard moulds. Since no other company could offer them the boat of their dreams, they made their own. MAMBO was developed using patented continuous fiber technology, an innovative process that combines advanced materials and 3D robot printing to produce strong, powerful, lightweight products with no waste.

The production of boats from composite materials is currently costly as it requires moulds, wastes time and material, and is limited to standard moulds. Since no other company could offer them the boat of their dreams, they made their own. MAMBO was developed using patented continuous fiber technology, an innovative process that combines advanced materials and 3D robot printing to produce strong, powerful, lightweight products with no waste.

More news in our Telegram channel Icon Life, subscribe to be the first to know!

Parts of the ship were printed using two robots: KUKA Quantec High Accuracy. Located in Milan, at the headquarters of Moi Composites, and in Birmingham, at AMF (Advanced Manufacturing Facility) Autodesk. After printing was completed, the parts were joined and laminated at the Catmarine shipyard, creating a one-piece sandwich structure with no separation of hull and deck. The tireless and passionless work of the robots, combined with the skillful and passionate craftsmanship of the shipyard craftsmen, gave birth to a new hybrid industrial system, as technological and digital as analog and manual, which today makes the impossible possible.

At 6.5 meters long and weighing 800 kg, MAMBO would be impossible to create in the traditional way. The advanced technology of Moi Composites proves that both real and fantastic products that were previously unimaginable can now be 3D printed anytime, anywhere and in any shape. MAMBO is 6.5 meters long, 2.5 meters wide, weighs 800 kg, is equipped with a 115 hp outboard motor, navigation system, cork deck and white leather sofas. The idea of the case is inspired by Sonny Levy's Archdevil, where organic forms chase each other and transform into structural and functional elements.

Gabriele Matale, CEO and co-founder of Moi Composites, said: “Finally today MAMBO was launched. We 3D printed the boat, refining the concept with a unique design created and tailored to the customer's wishes to enable everyone to understand and experience the sea in their own way. None of this would have happened without the support of our partners who, together with us, believed in this ambitious project.