3D print yourself uk

3D Selfie Figurine | Scan & print a sculpture of yourself in 3D

Our Mini-You sculptures are of the best possible quality. The greatest care is taken in all the stages of production from the initial scan through to the final 3D colour print. You and your family will be delighted with this most modern of portraits.

Step 1

The session takes less than 20min. Our photo scanning booth captures your likeness with amazing accuracy and detailStep 1

And our 3D design gurus will create your Mini-You BustStep 2

We will print your sculpture on a 3D printer using advanced, full-colour print technologyStep 3

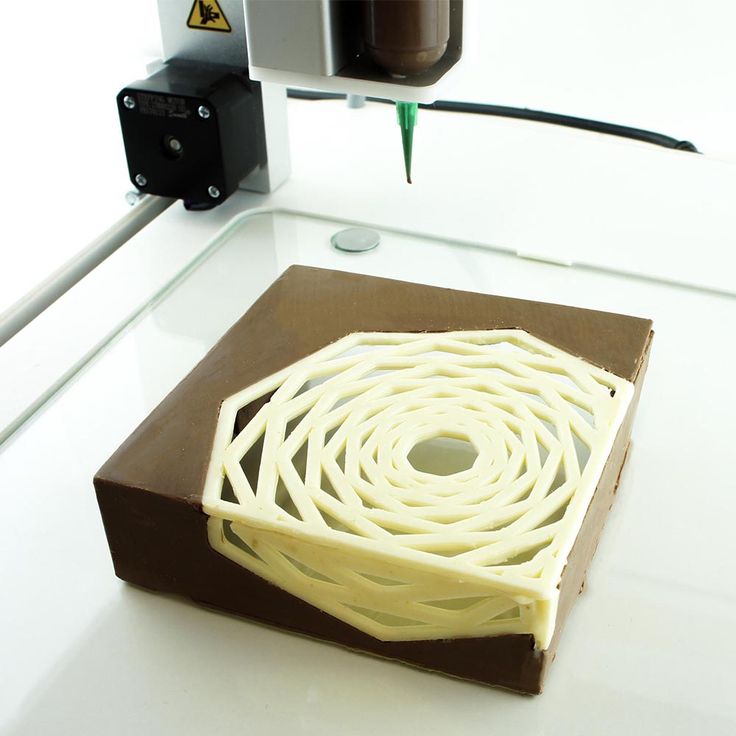

Your figurine will be ready within 14 working days and you can collect it from our store in Wells Street or have it delivered. Introducing the chocolate selfie: It’s the year’s quirkiest Mother’s Day gift – a 3D model of yourself that’s good enough to eat. www.dailymail.co.uk

Travelling alone means you end up with lots of beautiful shots of scenery and places, but no pictures of yourself. Unless you particularly like the ‘selfie’. Instead I opted for creating my very own mini-you with iMakr, which I have taken everywhere with me. Each day I will compose a shot with my mini-Rachel wherever I am and upload it to my website WhereIsRachelToday.com. It’s a great way of making sure I’m in all the pictures, while also recording my journey.

Mini-Rachel creates lots of attention when I take her out – it’s a great way to start a conversation with the locals. They all want their picture taken with her.

Rachel Le Feuvre

This was awesome! Great service!

Mads

Can’t wait to see it! Eficient, friendly, exciting!!! Stephane Maupin

Looks awesome! Thank you and the rest of your team for the stunning work!

You’ll hear from us again 🙂

Jorge De Castro

What’s the ultimate selfie? Getting your head 3D printed in chocolate… It’s the ultimate way to give someone a piece of your mind. Susannah Butter gets her head 3D printed in chocolate.

Susannah Butter gets her head 3D printed in chocolate.

www.standard.co.uk

Can’t wait to see the finished piece! Best birthday present.

P.S. Make it scary!

Eva

3D printing is a pretty amazing invention and Clerkenwell-based 3D specialists iMakr are leading the way by creating impressive ‘Mini You‘ bust or full body models in sandstone.

Time Out London

Nice nice experience! Mini factory is a cozy place and I’m looking forward to seeing my mini-me! Cristiana Buzzelli

I am clearly recognisable and think everyone has done a great job Sam Rimmer

I have received the mini me. Many thanks for delivering such a quality product. It has received many comments thus far and I have passed along your info. Conor O'donnell

Conor O'donnell

iMakr’s mini-you service is just the tip of the iceberg for what’s possible. iMakr on Clerkenwell Road has just celebrated its first birthday, and prides itself on catering to all comers, from 3D printing pros to interested newbies. It’s done a roaring trade in 3D miniatures, estimating that they’ve scanned and printed over a thousand people to date. www.Londonist.com

Good service-magnificient. 48 cameras!! good coffee, had fun doing this! must try. I can’t wait to see the result next week! #excited!! Barbara Pels

Tim Dowling has written the ultimate guide to being a perfect husband. So what happened when we decided to turn him into a real model? He explains how he met his mini-me with the help of 3D printers iMakr.

The Guardian

Great! Looking forward to see the result! K. Shinne

Shinne

Nonnonwenon – a 3D printed me! thanks guys #runlikeelleElle Hankinson

Fin Gray

January 2019

Pedro is a dedicated fastidious professional who settles for nothing but the best with regard to his clients. He understands completely that he’s handling people’s memories and he takes this seriously. It’s refreshing to see such professionalism and dedication in small business in the 21st century.

As long as Pedro remains in charge of the team at Mini-you I have no hesitation in recommending this business unequivocally. You are in good hands with Pedro at the helm.

Leonard O’Finchley

March 2019

The statuette that we ordered was much better than we could have hoped for. It was truly a mini me of the person for whom we bought it.

Blake O’Donnell

January 2019

Great service! They make your ideas and concepts a reality. Can’t recommend highly enough.

Can’t recommend highly enough.

Hamusa Sesay

March 2019

iMakr were great from start to finish, they are a very professional and friendly company. Pedro in particular was a delight to work with, he talked me through all of the steps in the 3D printing process and ensured that I was kept updated every step of the way.

Jeremy Hunt

January 2019

Needed a body scan to be made for a 3D project I was working on. Scan process went smoothly and was sent a very good quality result. Pedro cleaned up and prepared the file very professionally and when downloaded I was able to utilise it straight into my digital workflow. Would recommend.

Jeremy Hunt Design, London.

Pierre Micottis

January 2019

Pedro did a fantastic job all along and sent us lots of pictures during the design process to ensure we were happy with the shape, texture and colours. The 3D sculpture really looks like our late Mischa…

Sandra Sollitt

January 2019

Excellent customer service and attention to detail. Pedro worked with us tirelessly to get the 3D model just right. We visited store to work directly with him and also worked over video conference calls to finalise details. Pedro has an excellent eye for anatomy and detail, we can’t thank you enough. Very highly recommended

Pedro worked with us tirelessly to get the 3D model just right. We visited store to work directly with him and also worked over video conference calls to finalise details. Pedro has an excellent eye for anatomy and detail, we can’t thank you enough. Very highly recommended

Ditto

January 2019

These guys have 3D scanned many people for us on various projects and they have always done a great job. Highly recommended!

Laura Winters

February 2019

All reviews

3D Portraits - BACKFACE

Figures & Busts

Fun, Creative and Unique Gifts

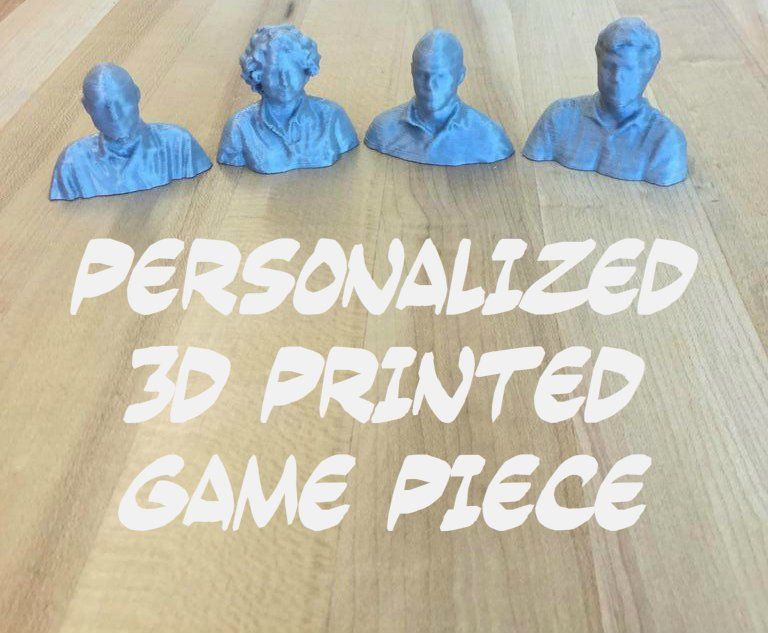

Using our custom built, high resolution 3D scanner we can create a stunning miniature figure of you or your loved one. The initial 3D scan is captured in the blink of an eye using a photographic scanning technique, perfect for excitable children and adults alike! The final figures are created from a composite of British gypsum and after being cured and finished they feel a lot like ceramic.

Single Figure or Bust

3D photographic scan session and 3D printed figure or bust. Ideal for a family gift or celebrate a special occasion such as graduation, birthday or sporting competition win. Also available as a gift card.

Pair of Figures

3D photographic scan session for two and two 3D printed figures. Ideal for wedding cake toppers, couples, BFFs or children. Also available as a gift card.

Group of figures

3D photographic scan session for a group of 3 or more. Ideal for families, a sports club, pub quiz team, work colleagues or band.

The Perfect Portrait

How we create the perfect 3D printed portrait

Using our high resolution body scanner our design team take an initial scan and a number of photographs. After processing the scan data, our artists get to work touching up and finishing the design before they’re sent to our full colour 3D printer. Once printed, cured and after some finishing work your 3D model is ready to be collected or delivered.

Standard Figure Sizes

We produce our figures in three standard sizes. 15cm, 20cm and 25cm, although we’re happy to print any size up to 35cm tall.

If you’re booking to have scans and figures made of more than one person, we’d recommend scaling the figures so they are in proportion with one another – that way they’ll look even better when displayed together. Generally we’ll average the sizes between the figures – so one is slightly larger than the chosen size and one slightly smaller. We’ll discuss this during your shoot.

We’ve produced some great figures to be displayed alongside collectable toys – if you’re looking to have this done too, let us know and we can do our best to try and match the style of the base.

Props and cosplay aren’t usually a problem, but there may be an additional charge for complicated or large items. Please let us know when booking.

Want to surprise someone? Gift Vouchers now available!

Gift Vouchers

Shop NowSome things scan better than others

What to Wear?

The type of scanning we do uses a technique known as photogrammetry, it works by matching millions of different points on a person and plotting their position in 3D space. The more points our algorithms can match, the better and more accurate the result. We’ve got various tricks to make almost anything work, but it’s helpful to keep in mind the following when choosing what to wear.

The more points our algorithms can match, the better and more accurate the result. We’ve got various tricks to make almost anything work, but it’s helpful to keep in mind the following when choosing what to wear.

Black

Black and other very dark, plain fabrics don't scan well. So try to avoid any dark, creaseless trousers

Shiny

The scanner finds it hard to identify points from different angles if clothes are shiny. Try to avoid shiny materials like PVC or polished, creaseless leather.

Tight Plain Clothing

Very skin-tight plain clothing is tricky to scan. Try to avoid wearing skin tight, plain leggings or a tight t-shirt if it doesn't have a pattern.

Patterns

Patterns of all kinds are great to scan, plus they add extra detail to a miniature figure. Floral dresses or a patterned t-shirt is a good choice.

Textures

Fabrics with lots of texture like wool or denim scan extremely well. Jeans and wooly jumpers make for very accurate models.

Creases

Creased clothing makes for a great scan and really helps add to the realism of a figure in miniature. A badly ironed shirt or trousers that bunch up work really well.

Book an appointment and get your own figure made

Ready to go?

Book NowDMC brings silicone 3D printing back to the UK

You are here

Home

The 3D printing service bureau Digital Manufacturing Center (DMC) or "Digital Manufacturing Center" has introduced a process in the UK called silicon additive manufacturing (SAM). The technology, developed by the Swiss company Spectroplast, is intended for the automotive, industrial and medical sectors.

High quality elastomeric parts are still quite rare in 3D printing compared to hard materials. This is due to the limited range of elastomers that can be processed with various 3D printing technologies. In extrusion engineering, thermoplastic polyurethane (TPU) is a key resource. The same applies to powder bed sintering, where there are even more restrictions on the types of raw materials that can be worked with.

In extrusion engineering, thermoplastic polyurethane (TPU) is a key resource. The same applies to powder bed sintering, where there are even more restrictions on the types of raw materials that can be worked with.

As a thermosetting resource, silicone is rare in the industry, but exhibits physical properties not available with TPU and other thermoplastic elastomers. In particular, its resistance to chemicals, a wide range of temperatures and UV radiation is useful for certain applications such as sterilizable medical equipment.

Spectroplast is a subsidiary of the renowned Swiss public research university ETH Zurich. The specifics of the SAM technology have yet to be revealed, but the firm describes it as a process that is similar to SLA using a concentrated light source. DMC explains that printing silicone molds on a 3D printer involves selectively exposing liquid silicone to a light source to form very thin, solid layers that coalesce to create the finished object.

Photo: https://spectroplast. com/

com/

In addition, parts made using SAM are described as isotropic. This means they exhibit uniform physical properties in all directions, unlike most 3D printed items. This suggests that silicone additive manufacturing includes the option of continuous DLP technology, which is confidential information.

The company currently offers four types of silicone with hardness A20, A35, A50 and A60 respectively. All four options are considered biocompatible and comply with ISO DIN EN109 standards93-05/10. This means that the compound is not only safe for skin contact, but can also be implanted, allowing the material to be used in medical devices, prostheses and more. With temperature resistance ranging from -50 to +200°C, SAM products can be used as gaskets, seals, bushings, dampers and pipes for industrial applications. The achievable layer thickness is currently 0.1mm and the working volume of the current platform is 120x130x75mm, but Spectroplast is working on increasing the printable area to 200x440x300mm.

DMC is now developing this technology in the UK. DMC opens a subsidiary of the engineering company KW Special Projects with a production area of 2000 sq.m., which has been offering 3D printing services since the first quarter of this year. The company is setting up work on printing three-dimensional objects, including mass production of parts.

Although DMC claims to be the first to offer silicone 3D printing in the UK, Picsima developed the silicone 3D printing method around 2014. Unfortunately, the organization announced the sale of its patents in 2020 as the founder began his teaching career.

Meanwhile, Wacker Chemie, an international silicone company, has developed its own method for 3D printing silicone. Its 3D printing department continues to operate using inkjet technology, so UK customers can order parts from that organization as well. However, compared to what Spectroplast and DMC offer, the possibilities of Wacker Chemie are very limited.

Now that there are several players involved in silicone 3D printing, maybe Picsima will return to the game . ..

..

Source

Other materials:

- Big Challenges 2021. The projects of young innovators from Pyatigorsk participate in the All-Russian competition

- THE FIRST EDITION OF THE DRAFT NATIONAL STANDARD

- RECEIVED IN THE SECRETARIAT OF TK 182

- BASF launches a grade of polyamide for the automotive industry with heat resistance up to 190°C

Attention!

We accept news, articles or press releases

with links and images. [email protected]

How 3D printing can make the UK a world leader in the fourth industrial revolution

How 3D printing can make the UK a world leader in the fourth industrial revolution

The Industrial Digitalization Review, a UK government commissioned review on industrial digitization, suggested that the UK could add £455bn ($600bn) to its budget and create 175,000 new jobs by leveraging Industrial 4. 0 technologies such as 3D seal.

0 technologies such as 3D seal.

With the UK leaving the European Union, many economists predict a potentially bleak future for the UK. The country is looking for any way it can reduce the damage caused by leaving the European Union. One such way is to use futuristic technology and modernize the manufacturing sector, a tactic that has been strongly recommended by initiatives such as the UK's National Supplement Strategy.

AM UK's National Strategy was only published a month ago, but the scheme's goals are now being reaffirmed by another government-backed initiative: the Industrial Digital Processing Survey.

Conducted by leading business actors on behalf of the UK Government, The Industrial Digitalization Review aims to "assess how manufacturing in the UK can benefit from increased digitalization and technological change" by making a concerted effort to bring technology into the industry 4.0

The review was first announced in January and was published today. It contains some impressive numbers regarding the potential growth in the UK if it decides to continue developing areas such as 3D printing , artificial intelligence and various other futuristic technologies that could improve the manufacturing sector.

It contains some impressive numbers regarding the potential growth in the UK if it decides to continue developing areas such as 3D printing , artificial intelligence and various other futuristic technologies that could improve the manufacturing sector.

These figures include a projection that the UK could generate £455bn ($600bn) through Industry 4.0 and also create 175,000 new skilled jobs for workers who can use 3D printers and other related equipment.

The numbers are not just plucked out of thin air. The review was led by Juergen Mayer, the British and Irish boss of the German engineering company Siemens, a company that knows a thing or two about technology such as additive manufacturing.

"The business and academic community has conceptualized the far greater ambition needed for Britain to become a global leader in the fourth industrial revolution," Mayer said.

Thankfully, the 246-page review should help this organization as it neatly compiles expert advice from industry leaders like Rolls-Royce and Accenture, as well as academic institutions like the universities of Cambridge and Newcastle.