Home depot 3d scanner

3D scanning used in warehouse logistics — Stibo Accelerator

Introduction:

The potential implementation of new 3 dimensional scanning technology to add value to the supply chain between The Home Depot and their suppliers.

Technology has made organisations more globally connected than ever before, and people find themselves having to collaborate across organisational and geographical borders. The fact that data is shared across borders increases the total volume of data and causes complexity for organisations. Efficient business processes in supply chains of retailer-supplier trading collaborations both ensure the sharing and quality of master data.

Several theorists join in on this point of view. Hüner et al. (2011) claim that master data itself and the sharing of it is not a key for a successful inter-organisational collaboration - the data needs a certain level of quality that makes it possible for the in- volved actors to trust and rely on it (Hüner et al. 2011). Therefore, for a supply chain collaboration to be successful, the data needs to be managed successfully, and this usually requires optimisation of business pro- cesses in the whole supply chain (Legmer & Schemm 2008). Business Process Management (after this: BPM) is a management discipline that takes changing conditions in the environment into consideration. Using Rose- mann and vom Brocke’s (2015) 6 Core Elements of BPM ensures a holistic approach to the discipline.

Since the beginning of the year 2000, an increasing amount of companies have started to manage the exchange of data in their supply chain in an electronic way. This is due to the emerging of new technologies that make such electronic exchange possible. Automation and technology, in general, can ease processes and remove the risk of expensive and fatal human errors (de Corbiére 2007).

This study revolves around a specific retailer; The Home Depot. We got access to The Home Depot and gained knowledge of one of their real challenges through the Stibo Accelerator whom we got the chance to collaborate with. The Home Depot is currently facing the challenge of not being able to rely on the packaging dimensions coming from its 8000 suppliers. Unreliable packaging dimensions cause huge costs and challenges in The Home Depot’s distribution and store planning.

The Home Depot is currently facing the challenge of not being able to rely on the packaging dimensions coming from its 8000 suppliers. Unreliable packaging dimensions cause huge costs and challenges in The Home Depot’s distribution and store planning.

To understand the causes and challenges of this, we found it necessary to investigate the whole supply chain. Therefore, we also reached out to a supplier of The Home Depot; Skylight. Skylight was familiar with this challenge of discrepant packaging dimensions and found it interesting to collaborate with us and provide us with insights from their point of view. This possibility to dive deep into the challenge from both ends of the supply chain makes us better suited to discuss how and where to implement a solution to the challenges.

Conclusion:

This thesis has covered the complexity of ensuring reliable data in trading collaborations involving several processes and crossing organisational borders.To begin with, the assumption was that The Home Depot was only facing problems relying on the packaging dimensions on non-rectangular packaging shapes such as cylinders and hexagons coming in from its suppliers through the Vendor Portal. We thought that this was caused by the fact that the suppliers were asked to enter only length x height x width regardless of the packaging shape, which makes The Home Depot ignorant about the empty space of e.g. L-shaped packages. Finally, we thought that the unreliable packaging dimensions were only causing challenges in the space planning of the stores. We decided to investigate the problem by covering both The Home Depot’s and a supplier’s perspective on it. We quickly realised that the problem was a lot more comprehensive and complex than initially expected. Not only the dimensions of non-rectangular packaging shapes were unreliable. Poor data quality applied to all packaging dimensions was caused by several things. Furthermore, the number of affected processes were higher than initially expected. This made us realise how complex and messy data can be, which enlightened the necessity of finding a solution to this problem.

We thought that this was caused by the fact that the suppliers were asked to enter only length x height x width regardless of the packaging shape, which makes The Home Depot ignorant about the empty space of e.g. L-shaped packages. Finally, we thought that the unreliable packaging dimensions were only causing challenges in the space planning of the stores. We decided to investigate the problem by covering both The Home Depot’s and a supplier’s perspective on it. We quickly realised that the problem was a lot more comprehensive and complex than initially expected. Not only the dimensions of non-rectangular packaging shapes were unreliable. Poor data quality applied to all packaging dimensions was caused by several things. Furthermore, the number of affected processes were higher than initially expected. This made us realise how complex and messy data can be, which enlightened the necessity of finding a solution to this problem.

Having analysed and identified the causes and challenges of discrepant packaging dimensions between The Home Depot and its suppliers, it was possible for us to identify 9 needs. Future initiatives should meet these needs in order for The Home Depot to minimize or eliminate the current challenges and to increase the reliability of the packaging dimensions shared and used across the supply chain;

Future initiatives should meet these needs in order for The Home Depot to minimize or eliminate the current challenges and to increase the reliability of the packaging dimensions shared and used across the supply chain;

1. “One version of the truth”

2. A mutual understanding of how to orient packages when measuring them

3. A complete set of dimensions for all packaging shapes

4. A mutual understanding of merch styles used in planogramming

5. A way of actually using the audit results in the planogramming

6. Limitation of human errors

7. Simplification of standards and access point

8. More time for the supplier to provide data

9. Motivation for the supplier to provide accurate data

Besides using the second part of the literature review to understand potential causes and challenges to be found in the case of The Home Depot, we used it to gain knowledge of actual process optimizations mentioned by the articles of the theoretical foundation or carried out by other companies. This and the informants’ own thoughts on solutions to the challenges formed the basis of an discussion of actual process optimizations. The Home Depot has recently introduced several initiatives as part of their recent supply chain orientation. These primarily focus on data exchange.

This and the informants’ own thoughts on solutions to the challenges formed the basis of an discussion of actual process optimizations. The Home Depot has recently introduced several initiatives as part of their recent supply chain orientation. These primarily focus on data exchange.

Unfortunately, smooth data exchange and high data quality do not always go hand in hand. The constantly changing conditions are also challenging the data quality. Therefore, what The Home Depot currently needs to be focusing more on is increasing the data quality while still focusing on data exchange initiatives.The following is our proposal for future initiatives at The Home Depot;

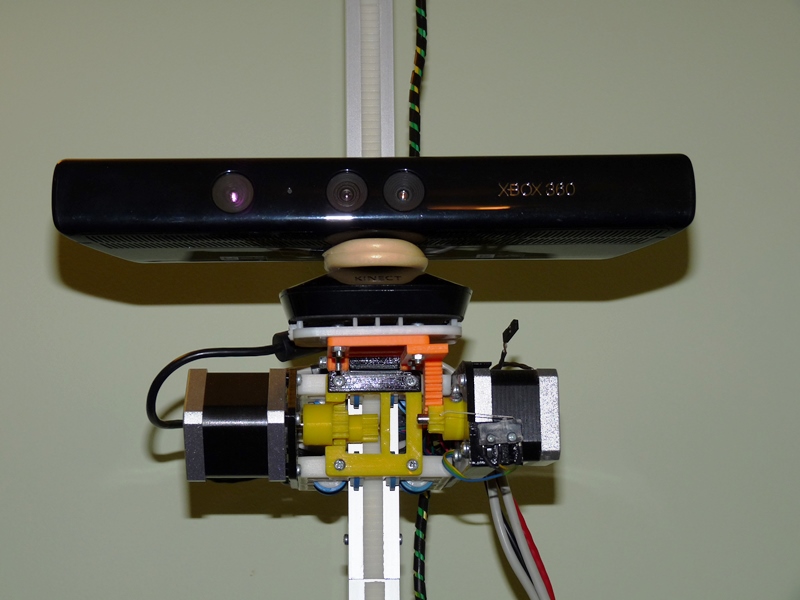

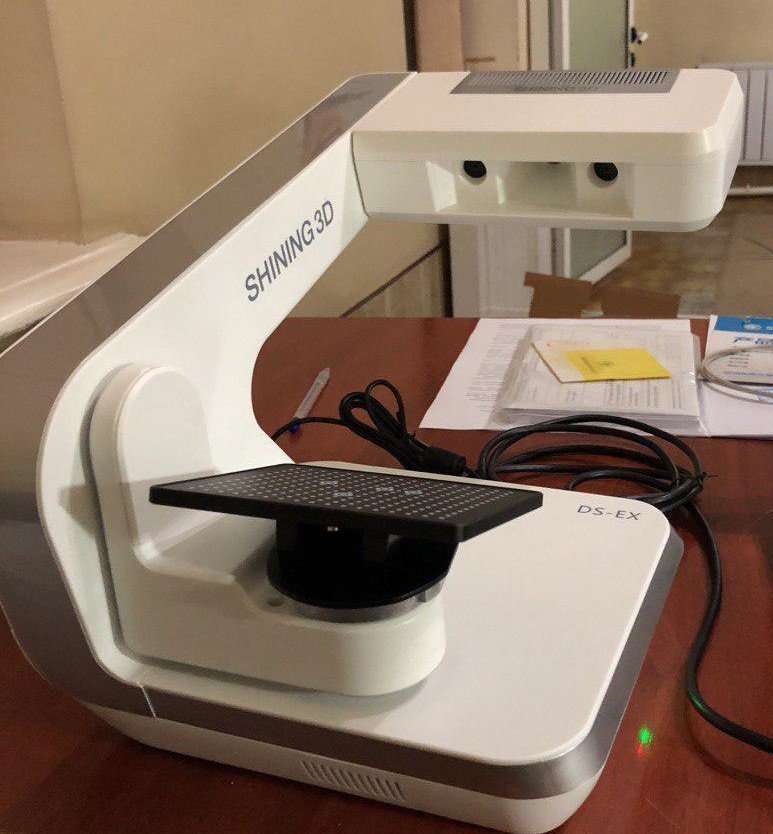

• Offering 3D object scanners to be deployed in the suppliers’ processes - directly integrated with IDM or Tagglo

• Training, especially in terms of product onboarding

• Standardisation of portals and documents containing requirements and guidelines for the suppliers

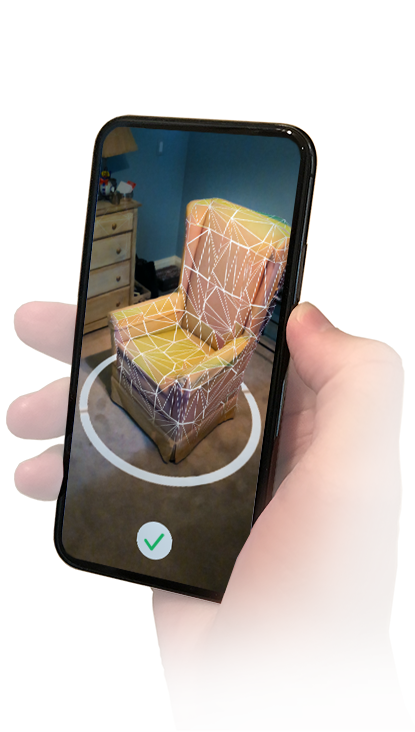

Besides this, Machine Learning used in IDM would be efficient in increasing the data quality. 3D object scanners to be deployed in the suppliers’ processes is the proposal minimising and eliminating most challenges as this initiative is capable of meeting both the need for better data exchange and higher data quality. It creates “one version of the truth” as the measurements of the packaging dimensions cannot be doubted (Need 1), a mutual understanding of how to orient the packages when measuring them is achieved as the scanner creates a visual model of the package (Need 2), a complete set of dimensions of each package is detected by the scanner (Need 3), the need for doing audits at the RDCs is minimised (partially eliminating Need 5), and human interaction with the system, in terms of packaging dimensions, is eliminated by the scanner (Need 6).Need 4 can be met by training and Need 7 can be met by standardisation of portals and documents. Need 9 should be met by changing the fining procedure and establishing a supplier “good-list”. Need 8 is not possible to meet directly with the discussed initiatives.

3D object scanners to be deployed in the suppliers’ processes is the proposal minimising and eliminating most challenges as this initiative is capable of meeting both the need for better data exchange and higher data quality. It creates “one version of the truth” as the measurements of the packaging dimensions cannot be doubted (Need 1), a mutual understanding of how to orient the packages when measuring them is achieved as the scanner creates a visual model of the package (Need 2), a complete set of dimensions of each package is detected by the scanner (Need 3), the need for doing audits at the RDCs is minimised (partially eliminating Need 5), and human interaction with the system, in terms of packaging dimensions, is eliminated by the scanner (Need 6).Need 4 can be met by training and Need 7 can be met by standardisation of portals and documents. Need 9 should be met by changing the fining procedure and establishing a supplier “good-list”. Need 8 is not possible to meet directly with the discussed initiatives. Therefore, training - not to be confused with the item onboarding training - should be used to make the suppliers understand why The Home Depot has to require the data from them at that certain point in time.

Therefore, training - not to be confused with the item onboarding training - should be used to make the suppliers understand why The Home Depot has to require the data from them at that certain point in time.

So “how can methods and information technologies support the process of exchanging product packaging dimensions between The Home Depot and its suppliers in order to ensure reliable data in the distribution and store planning?”Methods such as training and standardisation and information technologies such as 3D object scanners directly integrated with IDM and Tagglo support better and less error-prone data exchanges between the Home Depot and its suppliers. This will prevent poor data quality of the packaging dimensions, which will enable future distribution and store planning to be based on reliable data.

MakerBot and The Home Depot Bring MakerBot 3D Printers to

MakerBot and The Home Depot Bring MakerBot 3D Printers to homedepot.com and Select Stores

MakerBot Replicator 3D Printers Showcased in 12 Stores in California, Illinois and New York

BROOKLYN, N. Y. & ATLANTA — (BUSINESS WIRE) — July 14, 2014 — MakerBot and The Home Depot® announce a collaboration to bring MakerBot® Replicator® Desktop 3D Printers to customers on homedepot.com/makerbot and in 12 Home Depot stores in California, Illinois and New York beginning July 14, 2014. This is the first time The Home Depot has offered 3D printers for sale in its stores and will be a pilot program for MakerBot and The Home Depot.

Y. & ATLANTA — (BUSINESS WIRE) — July 14, 2014 — MakerBot and The Home Depot® announce a collaboration to bring MakerBot® Replicator® Desktop 3D Printers to customers on homedepot.com/makerbot and in 12 Home Depot stores in California, Illinois and New York beginning July 14, 2014. This is the first time The Home Depot has offered 3D printers for sale in its stores and will be a pilot program for MakerBot and The Home Depot.

MakerBot and The Home Depot(R) announce a collaboration to bring MakerBot(R) Replicator(R) Desktop 3D Printers to customers on homedepot.com/makerbot and in 12 Home Depot stores in California, Illinois and New York beginning July 14, 2014. This is the first time The Home Depot has offered 3D printers for sale in its stores and will be a pilot program for MakerBot and The Home Depot. (Photo: Business Wire)

MakerBot was founded in 2009 and specializes in desktop 3D printers and scanners. MakerBot is a leader in the desktop 3D printer market with more than 50,000 MakerBot 3D Printers out in the world. MakerBot sets itself apart by offering an entire MakerBot 3D Ecosystem that makes 3D printing easy and accessible for everyone. The MakerBot 3D Ecosystem includes its 3D printers and scanners, its website Thingiverse.com, the world’s largest 3D printing design community for discovering, creating, and sharing of 3D printable files, as well as software, apps, partnerships with leading companies, MakerBot Learning training programs, and its own retail stores in New York, Boston and Greenwich, Connecticut. MakerBot’s products include the award-winning MakerBot Replicator line of 3D printers which includes the MakerBot Replicator Desktop 3D Printer, the MakerBot Replicator Mini Compact 3D Printer, the MakerBot Replicator Z18 3D Printer, the MakerBot Replicator 2X Experimental 3D Printer and the MakerBot Digitizer™ Desktop 3D Scanner.

MakerBot is a leader in the desktop 3D printer market with more than 50,000 MakerBot 3D Printers out in the world. MakerBot sets itself apart by offering an entire MakerBot 3D Ecosystem that makes 3D printing easy and accessible for everyone. The MakerBot 3D Ecosystem includes its 3D printers and scanners, its website Thingiverse.com, the world’s largest 3D printing design community for discovering, creating, and sharing of 3D printable files, as well as software, apps, partnerships with leading companies, MakerBot Learning training programs, and its own retail stores in New York, Boston and Greenwich, Connecticut. MakerBot’s products include the award-winning MakerBot Replicator line of 3D printers which includes the MakerBot Replicator Desktop 3D Printer, the MakerBot Replicator Mini Compact 3D Printer, the MakerBot Replicator Z18 3D Printer, the MakerBot Replicator 2X Experimental 3D Printer and the MakerBot Digitizer™ Desktop 3D Scanner.

MakerBot 3D Printing and Scanning products will be showcased inside The Home Depot stores in specially designed kiosks that will encourage visitors to experience the wonder of 3D printing firsthand. Trained MakerBot retail staff will provide continual 3D printing demonstrations and offer 3D printed keepsakes for interested customers to take home with them, as well as help with purchase decisions.

The Home Depot stores (12) to offer the MakerBot Replicator 3D printing products and hands on demonstrations will be:

| California | Illinois | New York | ||||||

| 3838 Hollis Avenue, Emeryville | 1232 W. North Ave., Chicago North Ave., Chicago | 40 West 23rd Street, New York | ||||||

| 1781 E. Bayshore Rd., East Palo Alto | 2920 Audrey Avenue, Naperville | 980 3rd Avenue, New York | ||||||

| 1125 Old County Rd., San Carlos | 1300 S. Clinton Street, Chicago | |||||||

1675 Wilshire Blvd. , Los Angeles , Los Angeles | 2665 N. Halsted Street, Chicago | |||||||

| 22855 Victory Blvd., West Hills | ||||||||

| 7100 Warner Ave., Huntington Beach |

1 | 2 Next Page »

3D scanning of people, animals and props for VFX, gamedev, AR, VR

REALISTIC 3D avatars

for games, metaverses, movies, advertising and neural networks

Welcome to Twin3D

- We create custom realistic 3D avatars of people and characters and CG content with avatars.

- We use unique 3D head and body scanners based on photogrammetry technology with a matrix of 200 DSLR cameras. Scanning speed 0.01 sec.

- Subscribe to the company blog: analytics and news from Twin3D

Company Blog

What our 3D avatars look like in the AltSpaceVR metaverse

05/12/2022

Recently, after the AltSpaceVR talk, we got a good impression about this metaverse, and we even wrote about it. But once again we note the possibility ...

Ogilvy will unlock the value of virtual influencers for its clients

12/02/2022

International advertising agency Ogilvy launched Reality Studio to develop metaverse-related projects for its clients.

While they say...

In the morning, many Russians learned about 3D avatars — we are on Russia TV channel 1

01/12/2022

Interest in 3D avatars in Russia is growing. We come to this conclusion on the basis of more frequent inquiries to our company from the media. This time we participated…

We come to this conclusion on the basis of more frequent inquiries to our company from the media. This time we participated…

How we scan

Applications

VFX

3D scanning and digital 3D modeling of actors, extras and props. Digital stuntmen. Onsite 3D scanning.

GameDev

Complete cycle of preparing 3D character models for gamedev projects. Adaptation to VR, AR, Unreal Engine and Unity. Creation of datasets of 3D scans of people for the development of character constructors.

Metaverses

Creation of 3D celebrity avatars and metaverse characters. Mobile 3D scanners for digitizing metaverse users at events and locations. Digitization of props.

Artificial intelligence

Creation of datasets of 3D scans of people, animals and props for machine learning of neural networks.

Digital advertising and media

Development of virtual influencers, brand ambassadors and bloggers. Development of digital content with virtual influencers for digital advertising.

E-commerce

Creation of 3D models of goods for online stores, marketplaces, manufacturers in order to attract additional attention of buyers

Our projects

3D scanning of actors, extras and props.

- Movies and Series

- Rollers and clips

- Projects in production

- Games

film "My dad is the leader"

2022

Film "Major Grom: The Plague Doctor"

2021

Film "Row 19"

2021

Psycho series

2020

Side Effect Movie

2020

Goalkeeper of the Galaxy movie

2020

Ice-2

2020

Fairy

2019

Film "Ninth"

2019

Invasion movie

2019

Film "Union of Salvation"

2019

Film "Ilyinsky Frontier"

2019

Series "Godunov"

2018

Series "Fortress"

2018

The Defenders movie

2017

3D artist avatars for SODA LUV feat. EGOR KRID "Aquadisco"

EGOR KRID "Aquadisco"

2022

Citymobil commercial

2022

Citymobil commercial

2022

Husky "Outro" for Jager Music Awards

LSP. Online concert on MTS Live XR 12/19/2020

JAB "Main"

2019

Dima Bilan "Lightning"

2018

Short film Husky "Psychotronics"

2017

Film "Cheburashka"

2023

Faded AAA game

2023

Sensorium Metaverse

2022

Film "The Challenge"

2022

3D scanning of characters for the AAA game "Faded"

in production

Digitization of celebs for the Sensorium metaverse

in production

Creation of morphable 3D heads for characters in the game "King's bounty 2"

2021

Our partners

Services

3D scanning of people, animals and props

3D scanning using photogrammetry and photometric stereo technology in AAA quality. In the studio or on location.

In the studio or on location.

- 3D Scanner Matrix - 200 professional DSLR cameras.

- Scanning speed - 0.01 sec.

- 100% photorealistic.

Services

3D scanning of facial expressions and creation of blend shapes

Scanning facial expressions - emotions, phonemes and visemes for facial animation. We use photogrammetry and photometric stereo technologies for skin micro-detailing.

Read moreServices

On-site 3D scanning at the client's location

The optimal solution for creating avatars for celebrities, actors and extras.

Read moreServices

Virtual Influencers and Assistants

Creation of custom realistic virtual influencers for brands, digital bloggers and virtual assistants.

We provide a full cycle of creating a character and digital content with him.

Read moreFAQ

Here you will find answers to the most frequently asked questions. If you cannot find an answer here, please feel free to contact us.

If you cannot find an answer here, please feel free to contact us.

Do I need to make an appointment for a scan?

Scanning in the studio is carried out by appointment, at least one working day before the planned date of scanning. The most reliable option for booking a convenient date or several days is to conclude an agreement with our studio in advance with fixing specific dates and times for scanning.

What are the clothing requirements for a successful scan?

To guarantee a high-quality assembly of a 3D scan, we recommend avoiding black clothing, as well as shiny, transparent and translucent materials, elements and accessories.

Can children be scanned?

The photogrammetry technology we use is absolutely safe for health and allows you to scan instantly, in 0.01 seconds. Therefore, we can scan even very young children.

Can animals be scanned?

The photogrammetry technology we use allows you to scan instantly, in 0.01 seconds. Therefore, we can scan domestic and farm animals. Scanning of large animals, such as horses, is carried out only as part of an on-site scanning.

Therefore, we can scan domestic and farm animals. Scanning of large animals, such as horses, is carried out only as part of an on-site scanning.

When are discounts available?

We provide discounts in case of ordering more than 5 3D models, as well as on-site scanning at the location from 3 shifts. The calculation of the amount of the discount is carried out individually.

Is it possible to order scanning from you at a location with a trip to another region or country?

Our 3D scanner is mobile; The calculation of the cost of field scanning is carried out individually and includes the work of the scanner, as well as the cost of transporting equipment and the transfer of two studio employees.

Who owns the copyright for 3D models after scanning?

Intellectual property copyright - 3D models - passes to the client after full payment for our scanning or modeling services.

Still have questions?

We will tell you in detail about the stages of work and terms, we will orient you by cost

Desktop 3D printers for the home

Anet Anycubic Creality3D CreatBot Dremel Elegoo Felix FlashForge FLSUN Flying Bear Formlabs IBRIDGER imprinta MakerBot Peopoly Phrozen PICASO 3D QIDI Raise3D Tiertime Ultimaker Uniz Voxelab wanhao XYZPrinting ZENIT Zortrax

Availability

In stock

Manufacturer

Phrozen Raise3D Creality wanhao FlashForge

PICASO 3D Anycubic Formlabs Tiertime Flyingbear QIDI Uniz CreatBot Dremel DigiLab Felix Zortrax XYZprinting Ultimaker imprinta Elegoo MakerBot Anet FLSUN iBridger Peopoly snapmaker Voltera Voxelab ZENIT

Delivery

Assembled printer Assembly kit

Application

Architecture For large objects For beginners The medicine Education

Orthopedics Production prototyping Reverse engineering Advertising, exhibitions Sculpture Dentistry Hobby jewelry

Print technology

DLP/LCD/SLA FDM/FFF LFS

Thread diameter

1. 75 mm 2.85 mm 3.00 mm

75 mm 2.85 mm 3.00 mm

Material type

ABS PLA PETG Photopolymers Flex

Nylon (Nylon) ASA Carbon HIPS PC PEEK PP TPU other Metal (Ultrafuse 316L, Ultrafuse 17-4PH)

Number of extruders (print heads)

Heating table

Yes Not

Wi-Fi or other wireless network

Yes Not

Country of origin

China Russia USA Taiwan Hong Kong

Netherlands Poland

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 220x220x250 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 220x220x250 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

| Custom/Transit | Goods on the way |

| Construction area size | 220x220x250 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 235x235x250 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 220x220x250 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

| Custom/Transit | Goods on the way |

| Construction area size | 180 x 163 x 102 mm |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| On order/Transit | Goods on the way |

| Construction area size | 220x220x270 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Custom/Transit | Goods on the way |

| Construction area size | 250x250x400 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to Compare

Product added to compare Go

| Manufacturer | Creality |

| Custom/Transit | Goods on the way |

| Construction area size | 350x350x400 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

| Construction area size | 102x57x165 mm |

| Country of origin | China |

Free shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

| Custom/Transit | Goods on the way |

| Construction area size | 197 x 122 x 245 mm (5. 9 l) 9 l) |

| Chamber volume | 5.9 L |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Phrozen |

| Construction area size | 134x75x130 mm |

| Country of origin | Taiwan |

Free shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

| Custom/Transit | Goods on the way |

| Construction area size | 450 x 400 x 400 mm (capacity 72 l) |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

| Construction area size | 197 x 122 x 245 mm (print volume 5. 9 l) 9 l) |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Phrozen |

| Construction area size | 165x72x180 mm |

| Country of origin | Taiwan |

Free shipping

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Custom/Transit | Goods on the way |

| Construction area size | 198 × 123 × 210 mm |

| Country of origin | China |

3D printing is one of the most promising areas of technological development in the 21st century. Having gone a long way from bulky and heavy boxes to compact desktop devices, 3D printers have ceased to be something inaccessible to a wide range of users. The era of mass additive manufacturing has already arrived, and every home can now house a real desktop factory.