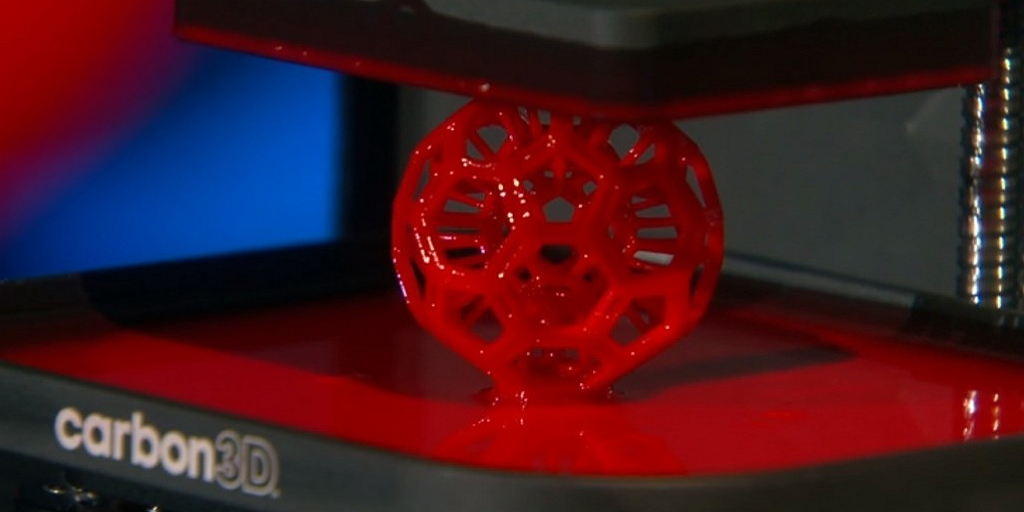

Carbon3D 3d printer

Who We Are - Carbon

Carbon’s Mission

Light and Oxygen

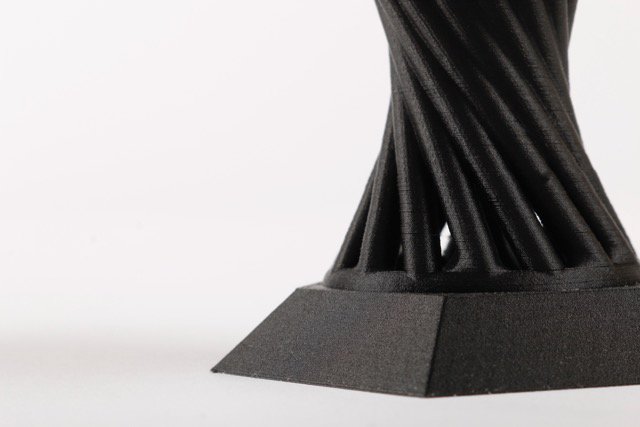

The Carbon DLS™ process combines versatile printers, advanced software, and best-in-class materials to deliver functional parts with end-use performance and aesthetics, helping engineers and designers to create products that outperform. From prototyping and low-volume production to production-at-scale, hundreds of global organizations, including adidas, Ford, and Becton Dickinson, use the Carbon process to create a wide range of functional end-use parts and print them reliably wherever and whenever they need them through our production network partners.

Learn about DLS

Latticed Bike Saddle

Read our customer stories

TED Talks

The talk that introduced us to the world

Science Magazine

The science behind Carbon technology, on the cover of Science

Our Leadership Team

With senior leaders from Silicon Valley, scientific, and business communities, we’re bringing together the best in hardware and software engineering, molecular science and service.

Craig Carlson

Office of the CEO

Craig is a member of the Office of the CEO, and most recently the CTO responsible for short and long term technology needs of the company as it scales and continues to introduce industry-leading software and hardware capabilities. He joined Carbon in 2014 from Tesla Motors, where he was VP of Software and Electrical Integration, with responsibility for all low-voltage electronics and all software that powers the Model S – from battery and motor control firmware, to the hardware and software that run the Model S in-car displays, to the Tesla mobile apps and server-based systems that connect to Teslas on the road. Craig joined Tesla in 2007 to lead the firmware organization, beginning with delivery of the first Tesla Roadsters in 2008. Before Tesla, Craig spent 15 years at Intuit, joining when Intuit acquired his small startup to start and lead development of QuickBooks. Craig was VP of Software Development for QuickBooks and then started, built, and launched QuickBooks Online. Craig received his BS in Electrical Engineering and Computer Science from Stanford University.

Craig received his BS in Electrical Engineering and Computer Science from Stanford University.

Philip DeSimone

Office of the CEO

Phil is a member of the Office of the CEO. He was part of the founding team at Carbon in 2013, and most recently the Chief Product and Business Development officer responsible for Carbon’s product strategy and strategic partnerships. Most recently, Phil led the go-to-market strategy and managed Carbon’s most strategic partnerships and customer relationships. Prior to Carbon, Phil co-founded and was the VP of Business Development at Buystand, an ecommerce company. Phil received his BA in business and econometrics from Ursinus College.

Ellen J. Kullman

Executive Chair

Ellen is the Executive Chair of Carbon, previously serving as President & CEO. Prior to joining Carbon, Ellen was Chairman and CEO of DuPont. She was the nineteenth executive, and the first woman to lead the company in its 212-year history. As a business leader, Ellen led double-digit growth of the company’s Safety and Protection business portfolio, started two successful high-growth businesses known today as DuPont Industrial Biosciences and DuPont Sustainable Solutions. During her seven years as CEO, Ellen led the company’s focus on growth in emerging international markets and championed the power of DuPont science and global market knowledge to transform industries. She decisively positioned the company for its next generation of growth, executing a strong plan that is delivering results today while positioning DuPont for future growth.

During her seven years as CEO, Ellen led the company’s focus on growth in emerging international markets and championed the power of DuPont science and global market knowledge to transform industries. She decisively positioned the company for its next generation of growth, executing a strong plan that is delivering results today while positioning DuPont for future growth.

Ellen is co-chair of the Paradigm for Parity coalition and a board director of Dell Technologies, Amgen, and Goldman Sachs. She is a member of the National Academy of Engineering and past president of the U.S. China Business Council. She serves on the board of trustees of Northwestern University. Ellen has been named as one of the “50 Most Powerful Women in Business” by Fortune and one of the “World’s Most Powerful Women” by Forbes. Ellen holds a B.S. in mechanical engineering from Tufts University and an MBA from the Kellogg School of Management of Northwestern University.

Colleen Martin-Garcia

SVP of Finance

Colleen Martin-Garcia is the SVP of Finance, responsible for Carbon’s overall financial activities and global finance organization, including accounting and controllership, financial planning and analysis (F,P&A), reporting, tax, treasury, and sales operations. Leading into this role, Colleen was VP, Corporate Controller for more than three years at Carbon. Colleen is an experienced financial leader with more than 25 years of experience in Accounting and Finance. Colleen worked as the VP, Corporate Controller at Polycom, a global communications company and the Corporate Controller at Plantronics, a maker of audio solutions. She also spent nearly 10 years in the assurance practice at KPMG LLP. Colleen is a CPA and holds a BS degree in Economics from UC Santa Cruz and a Masters in Accounting from San Jose State University.

Leading into this role, Colleen was VP, Corporate Controller for more than three years at Carbon. Colleen is an experienced financial leader with more than 25 years of experience in Accounting and Finance. Colleen worked as the VP, Corporate Controller at Polycom, a global communications company and the Corporate Controller at Plantronics, a maker of audio solutions. She also spent nearly 10 years in the assurance practice at KPMG LLP. Colleen is a CPA and holds a BS degree in Economics from UC Santa Cruz and a Masters in Accounting from San Jose State University.

Vincent Rerolle

SVP of Corporate Development

Vincent is the Senior Vice President of Corporate Development at Carbon. He brings over 30 years of software and technology experience in startups and public companies. Vincent is responsible for corporate strategy, mergers and acquisitions, innovation, and strategic alliances. He was recently Chief Commercial Officer at Nauto. Prior to Nauto, he served as a strategic advisor to several technology start-ups and previously held senior corporate development and general management roles at Lunera, Acquia, Cavium, Wind River (acquired by Intel), and Mercury Interactive (acquired by HP). Vincent received his MBA from INSEAD and his Masters in Electrical Engineering from and Computer Science from Télécom Paris.

Vincent received his MBA from INSEAD and his Masters in Electrical Engineering from and Computer Science from Télécom Paris.

Shay Canty

VP of People

Shay Canty is the Vice President of People, responsible for leading the Carbon people team in attracting, engaging, and developing a diverse employee base committed to fulfilling the company’s mission. Prior to joining Carbon, Shay held several recruiting and HR leadership roles in Fortune 500 companies including TiVo, Brocade, and AMD, where she led efforts to grow and establish global teams. Shay holds a B.A. in Psychology and Sociology from the University of California, Santa Cruz.

Jason Rolland, PhD

SVP of Materials

As SVP of Materials, Jason is tasked with creating the broadest possible range of materials for growing 3D objects with Carbon DLS technology. Previously, he was Senior Director of Research at Diagnostics for All, and co-founded Liquidia Technologies. Jason holds a BS in chemistry from Virginia Tech, a PhD in chemistry from UNC Chapel Hill, and has over 25 current and pending patents.

Hardik Kabaria

VP of Software

Hardik Kabaria is the Vice President of Software, responsible for leading the development of software products that empower successful manufacturing of various parts at scale spanning from midsoles to dental models using Carbon DLS technology and materials. He led the development of Carbon Design Engine, a software product that enables lattice structure-based design for Carbon DLS. Hardik holds a BS in Mechanical Engineering from BITS, Pilani, as well as an MS and Ph.D. in Mechanical Engineering from Stanford University.

Greg Dachs

SVP of Engineering

Greg Dachs is the Senior Vice President of Engineering, responsible for leading the development of Carbon’s print and process technologies. Under his leadership, the Engineering team has successfully launched the L1 and M3 printers, developed techniques to print midsoles and numerous other products at scale, and relentlessly improved the product suite with innovations in algorithms, hardware, and process. Prior to Carbon, Greg was a Manager of Mechanical Engineering at Intuitive Surgical, where he developed surgical instruments and robotic actuators. Greg holds a M.S. in Mechanical Engineering and Robotics from Purdue University and a B.S. in Mechanical Engineering from Rice University.

Prior to Carbon, Greg was a Manager of Mechanical Engineering at Intuitive Surgical, where he developed surgical instruments and robotic actuators. Greg holds a M.S. in Mechanical Engineering and Robotics from Purdue University and a B.S. in Mechanical Engineering from Rice University.

Chris Van Wert

SVP of Operations

Chris is the Senior Vice President of Operations at Carbon. He leads the supply chain, operations engineering, facilities, environmental health and safety, planning, and inventory functions, building infrastructure and processes to redefine digital manufacturing. Chris brings more than 20 years of experience leading cross-functional teams at companies including Stryker and Berkeley Process Control. Prior to Carbon, Chris was Director of Product Excellence at Tesla, where he managed all aspects of product excellence teams, including Quality Engineering, Supplier Quality, and Inspections. Chris received his MSc in Mechanical Engineering from Stanford University and his BSc from the University of California, Davis.

Tim Avila

SVP of Marketing

Tim is the Senior Vice President of Marketing at Carbon. He leads the marketing, communications and product marketing, and customer education functions building Carbon’s brand and driving growth. Tim brings more than 25 years of experience leading growth-focused marketing teams at companies including Yahoo!, BrightRoll and United Business Media. Prior to Carbon, Tim was Vice President of Marketing and Business Development at Intellimize, the pioneer in machine learning-based website optimization. Tim received his MBA from Santa Clara University with Beta Gamma Sigma honors.

Board of Directors

Executive Chair

Ellen J. Kullman

Member, Board of Directors & Co-Founder at Carbon

Joseph DeSimone, PhD

Former CEO, Ford Motor Company

Alan Mulally

Partner, Sequoia Capital

Jim Goetz

Managing Director, Silver lake

Bryce Lee

Former KPMG Managing Partner

Deborah M. Messemer

Messemer

Group CIO, Adidas

Andreas Hubert

Granville Capital

Bobby Long

Executive VP and GM of the Client Computing Group at Intel Corporation

Michelle Johnston Holthaus

Founders

Member, Board of Directors & Co-Founder at Carbon

Joseph DeSimone, PhD

Office of the CEO, Carbon

Philip DeSimone

Launch CEO & Co-founder

Steve Nelson

Advisor & Co-founder, Carbon

Ed Samulski, PhD

Chief Innovation Officer & Co-founder, Carbon

Alex Ermoshkin, PhD

Co-founder

Nikita Ermoshkin

Best 3D Printer Models to Lease

A Carbon 3D Printer for Every Budget

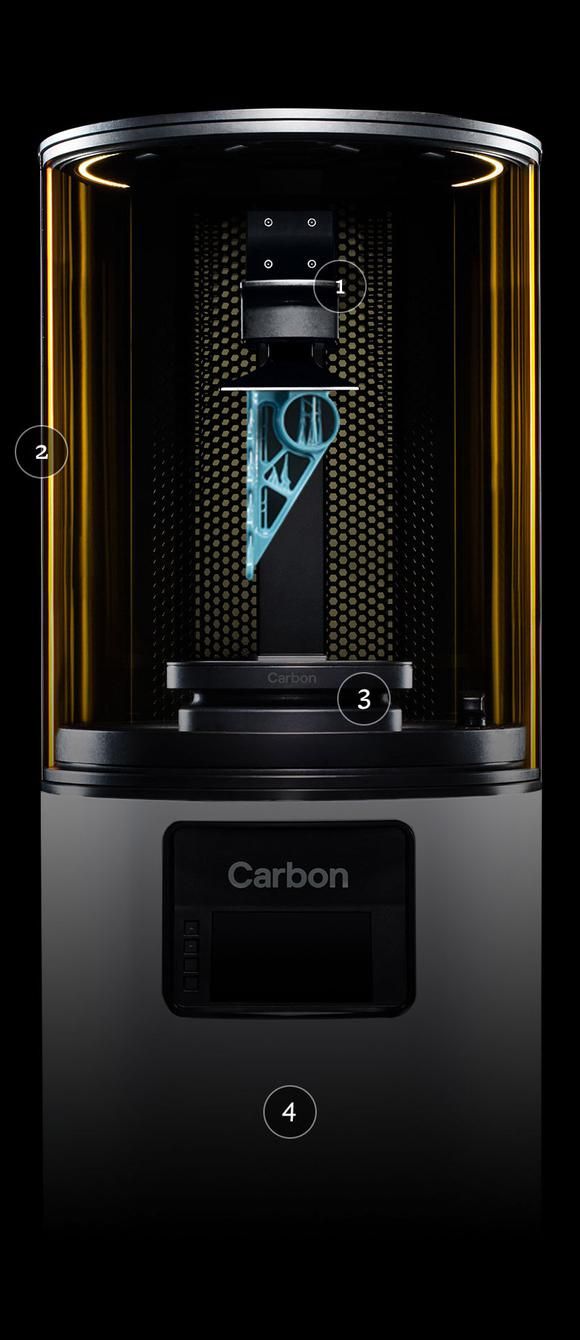

All Carbon 3D printers utilize the groundbreaking Carbon Digital Light Synthesis™ (Carbon DLS™) 3D printing process. Additionally, Carbon printers come in a variety of models with build volumes and price points to suit your needs.

M1The printer that pioneered the Carbon DLS process. Ideal for companies starting to explore 3D printing for prototyping and low volume production. Great for small batch sizes and fast cycle times. | M2Workhorse 3D printer that scales a wide range of applications from prototyping to mass production. Offering the same high resolution as the M1, the M2 is ideal for smaller parts with intricate features such as threading or internal channels. | M3The M3 printer is the cutting edge of DLS printing, ideal for customers looking for faster printing, a simpler print experience, an expanded design space, and a more consistent surface finish. | M3 MaxThe M3 Max printer offers the benefits of next-gen DLS printing with a true 4K light engine, enabling double the build area with the same pixel size and density. | L1Revolutionary large-format 3D printer leveraged by leading brands for the serial production of next-generation end-use products. Great for consistent, high-volume production of large parts or many small parts. | ||

| Explore M1 | Explore M2 | Explore M3 | Explore M3 Max | Explore L1 | ||

| Build Volume (X x Y x Z) | 141 x 79 x 326 mm 5.6 x 3.1 x 12.8 in | 189 x 118 x 326 mm 7.4 x 4.6 x 12.8 in | 189 x 118 x 326 mm 7.4 x 4.6 x 12.8 in | 307 x 163 x 326 mm 12.  1 x 6.4 x 12.8 in 1 x 6.4 x 12.8 in | 400 x 250 x 460 mm 15.7 x 9.8 x 18.1 in | |

|---|---|---|---|---|---|---|

| Technology | Carbon DLS 3D printing process Gen 1 DLS | Carbon DLS 3D printing process Gen 1 DLS | Carbon DLS 3D printing process Gen 2 DLS | Carbon DLS 3D printing process Gen 2 DLS | Carbon DLS 3D printing process Gen 1 DLS | |

| Layer Thickness | Layerless, isotropic parts | Layerless, isotropic parts | Layerless, isotropic parts | Layerless, isotropic parts | Layerless, isotropic parts | |

| XY; Z Resolution* | 75 µm; 25, 50 or 100 µm | 75 µm; 25, 50 or 100 µm | 75 µm; 25, 50 or 100 µm | 75 µm; 25, 50 or 100 µm | 160 µm; 25, 50, or 100 µm | |

| General Accuracy** | Up to ±70 μm + 1 μm per mm dimension size Up to ±0.  003 in + 0.001 in per in dimension size 003 in + 0.001 in per in dimension size | Up to ±70 μm + 1 μm per mm dimension size Up to ±0.003 in + 0.001 in per in dimension size | Up to ±65 μm+ 1 μm per mm dimension size Up to ±0.0026 in + 0.001 in per in dimension size | Coming Soon | Up to ±70 μm + 1 μm per mm dimension size Up to ±0.003 in + 0.001 in per in dimension size | |

| Production Repeatability Accuracy** | Up to ±40 μm Up to ±0.002 in | Up to ±40 μm Up to ±0.002 in | Up to ±37 μm Up to ±0.002 in | Coming Soon | Up to ±40 μm Up to ±0.002 in | |

| Materials Selection | Single-cure prototyping resins | |||||

| Dual-cure engineering resins | Excludes resins that require a heated cassette (e.  g. RPU 130). g. RPU 130). | |||||

| Third-party dental resins | Validation of third party resins in progress. | Validation of third party resins in progress. | ||||

| Software*** | Print preparation | |||||

| Online fleet management | ||||||

| Print analytics | ||||||

| Access to new materials | ||||||

| Optimized print planner | ||||||

| Automated Post-processing Solutions |

|

|

|

|

| |

| Service & Support | Integrated service package with real-time customer support and preventative maintenance for optimized machine uptime. | |||||

| Pricing | Carbon 3D printers start at $25k per year and are available with a variety of packages suited to your needs. Contact us for printer-specific pricing details. | |||||

| Case Studies | Delphi leverages the M1 for Prototyping and Final Part Production Carbon’s M1 Printer Used to Manufacture High Quality Audio Parts for Motorcycles | ARaymond Uses Carbon DLS to Reduce Product Development from 8 Weeks to 3 Days Nakanishi Dental Lab Increases Manufacturing Volume by 54% with Carbon | What Our Customers Have to Say (Video) | What Our Customers Have to Say (Video) | How OECHSLER Went From Design to Serial Production of Riddell Helmet Liners in 100 Days Making Industrial Drone Flight Possible with Digital Aerolus | |

| Explore M1 | Explore M2 | Explore M3 | Explore M3 Max | Explore L1 | ||

* Z resolution is adjustable from single digit microns to multiple hundred microns, and can be optimized through working with Carbon on your target application.

** For more information about accuracy, please refer to Carbon DLS accuracy guidelines for engineering materials and dental materials.

*** Included in your subscription with regular OTA software updates about every eight weeks.

† Compatible via the Smart Part Washer basket.

Get a Free Sample Part

There’s no substitute for holding a 3D printed part in your hand. Experience the quality of Carbon DLS-printed parts by requesting a free sample part below.

Request a Free Sample Part

Get Your Parts Made

Not in the market for a printer but still want Carbon DLS-printed parts? Find a certified Carbon production partner to get your parts made. These manufacturers are certified experts in the Carbon DLS 3D printing process––from design to production.

Find a Carbon Production Partner

Find a Carbon Dental Outsource Partner

MATERIALS

Prototype and produce high-performance functional parts with the mechanical properties you require. Carbon’s best-in-class 3D printing materials include rigid and elastomeric polymers that are proven across a wide range of industries, from automotive to medical devices.

Carbon’s best-in-class 3D printing materials include rigid and elastomeric polymers that are proven across a wide range of industries, from automotive to medical devices.

Explore Materials Library

Carbon® Design Engine

Design high-performance conformal lattices to improve product performance and speed print time.

Explore Carbon Design Engine

SERVICE & SUPPORT

Stay productive and minimize downtime with Carbon’s industry-leading customer service and support – included in our subscription model.

3D printers Carbon extrudes 3D objects from polymer

No products were found matching your request.

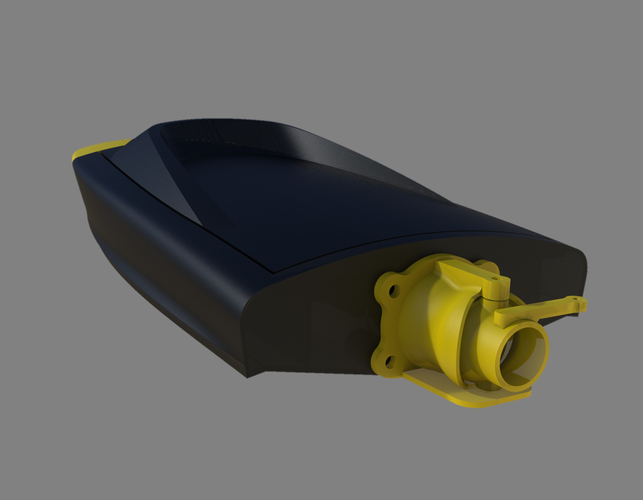

Introducing the revolutionary 3D printer - Carbon 3D, developed by VOX under the direction of Joseph Stromberger. This printer revolutionizes how desktop 3D printers work.

Read more…

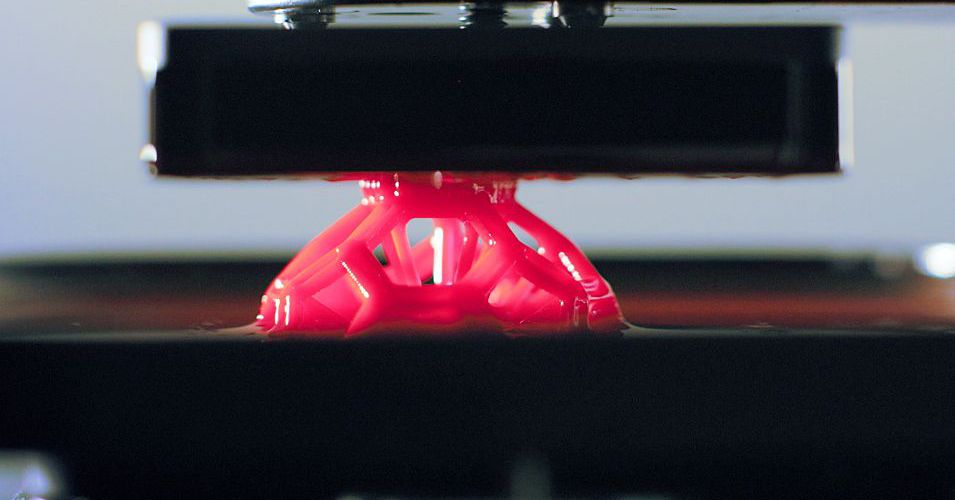

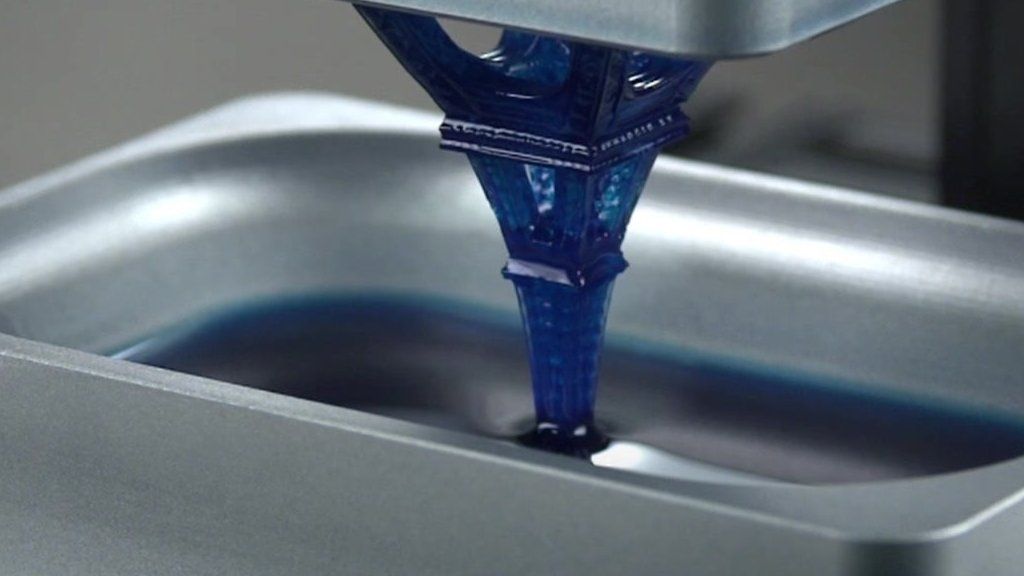

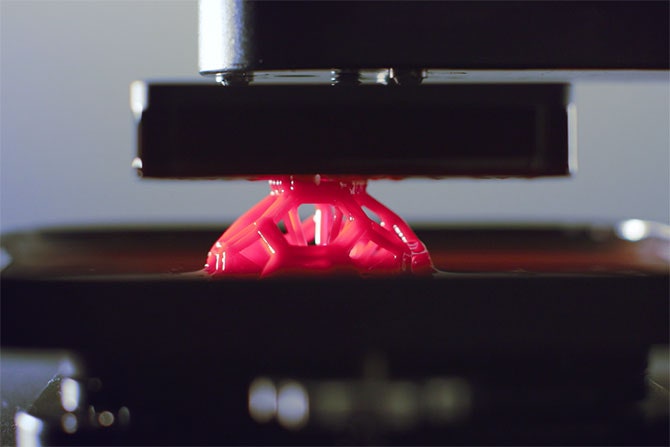

Carbon 3D extrudes three-dimensional objects from a polymer in a liquid state. There is no usual extruder in the device, but there is a powerful ultraviolet emitter, under the influence of which the plastic is cured. 3D printing on this revolutionary printer looks like a terminator from a movie is being pulled out of the molten material in a tank.

Carbon 3D printers have the following features:

- printing speed is 30-100 times faster than standard 3D printers;

- high precision and print quality;

- low cost of a 3D object;

- high performance;

- wide range of uses, from souvenir making to industry.

3D printer manufacturer Carbon has developed a completely new algorithm for creating 3D models. CLIP technology (roughly translated as "continuous liquid printing") has an important feature: the material hardens under the influence of light and gradually the desired object is obtained, which gradually grows upwards to the desired size.

Benefits of new technology for 3D prototyping

- Very hard 3D objects result;

- The accuracy of the model in the future allows you to use it as a prototype;

- High speed of operation, which exceeds the performance of competitors' analogues by 25 - 100 times.

In what industrial areas such 3D printing can be useful? The list is long and constantly updated with new industries that use the possibilities of additive manufacturing for their work.

CLIP technology used in Carbon M1 and Carbon M2 printers

The Carbon M1 has a wide print area. The body is assembled from aluminum parts. For 3D modeling, the device uses 7 different types of resins, from hard materials to rubber plastics.

The developers calculated that the model is designed for industrial use with payback in the region of 45 thousand units of goods. Such a forecast makes it a strong competitor for industrial lines. Additional benefits include ease of use and maintenance. The foot control of the built-in door completely frees your hands.

Another useful feature is the ability to connect to the Internet. It is very easy to download the latest updates or files to work.

3DMALL offers professional and consumer 3D modeling and printing equipment using the latest technologies: FDM, FFF, SLA, DLP and PolyJet. The range includes printers, scanners and consumables from European and domestic manufacturers Flashforge, Photocentric, EnvisionTEC, Wuhan CTS, TsTKAT and many others. All goods can be ordered with delivery in Moscow and the Russian Federation. In Moscow, products are delivered free of charge, the cost of transportation to the regions of Russia depends on the value of the order.

The range includes printers, scanners and consumables from European and domestic manufacturers Flashforge, Photocentric, EnvisionTEC, Wuhan CTS, TsTKAT and many others. All goods can be ordered with delivery in Moscow and the Russian Federation. In Moscow, products are delivered free of charge, the cost of transportation to the regions of Russia depends on the value of the order.

Gizmo 3D will release a printer that is as fast as the new Carbon 3D

There has been a standing ovation in the media about the company Carbon 3D, which, thanks to its know-how - the mysterious CLIP technology - was able to achieve from 25 to 100 times acceleration in 3D printing. But another Australian company, Gizmo 3D, has appeared on the horizon, saying it is also working on a similar technology based on stereolithography that could rival Carbon's discovery.

Gizmo uses a modified DLP 3D printing technology that, using a special LED projector, affects a photopolymer resin that hardens when irradiated with light. Cobus du Toit, the founder of the company, explains that all SLA printers that use the bottom-up model construction method have problems with the absorption of photopolymer under the part, which is why the guys from Carbon are trying to solve it by creating an air gap under the product, they are fighting nature and spend some money on it. Gizmo's 3D printer uses a top-down model, so it doesn't have these problems.

Cobus du Toit, the founder of the company, explains that all SLA printers that use the bottom-up model construction method have problems with the absorption of photopolymer under the part, which is why the guys from Carbon are trying to solve it by creating an air gap under the product, they are fighting nature and spend some money on it. Gizmo's 3D printer uses a top-down model, so it doesn't have these problems.

The main feature of the technology offered by Cobus du Toit is the method of illumination of the photopolymer. For traditional DLP printers, it is performed stepwise: the image of the first layer is projected, turns off, the platform goes down one layer (or up), the second layer is illuminated, turns off ...

In Gizmo's company, there are no gaps between the first and second images - the change occurs smoothly, as when watching a cartoon. Accordingly, the platform moves smoothly, and the resin polymerizes continuously, which can have a certain effect on both the smoothness of the surface and its strength. It seems incredible why they didn’t think of this before, because it’s so natural! Gizmo hasn't decided what they'll call their technology yet, and is vacillating between "continuous printing" and "animated printing," leaning toward the latter.

It seems incredible why they didn’t think of this before, because it’s so natural! Gizmo hasn't decided what they'll call their technology yet, and is vacillating between "continuous printing" and "animated printing," leaning toward the latter.

The developers say that a model measuring 150x80x26 mm with a layer thickness of 50 microns can be printed by their printer in just 6 minutes. An example of work can be seen here:

Cobus du Toit believes that there is another difference between their invention and Carbon printers. The fact is that the continuous printing method is only great for creating thin walls (1-2 mm). Therefore, the company plans to make it possible to switch between printing methods and the machine will automatically (or manually) switch from standard to "animated" DLP printing in order to select the most suitable method.

For all the seeming simplicity of the invention, there are certain subtleties that Cobus du Toit does not disclose until they are patented and he himself admits this.