3D printers india

Best 3D Printers in India (October 2022)

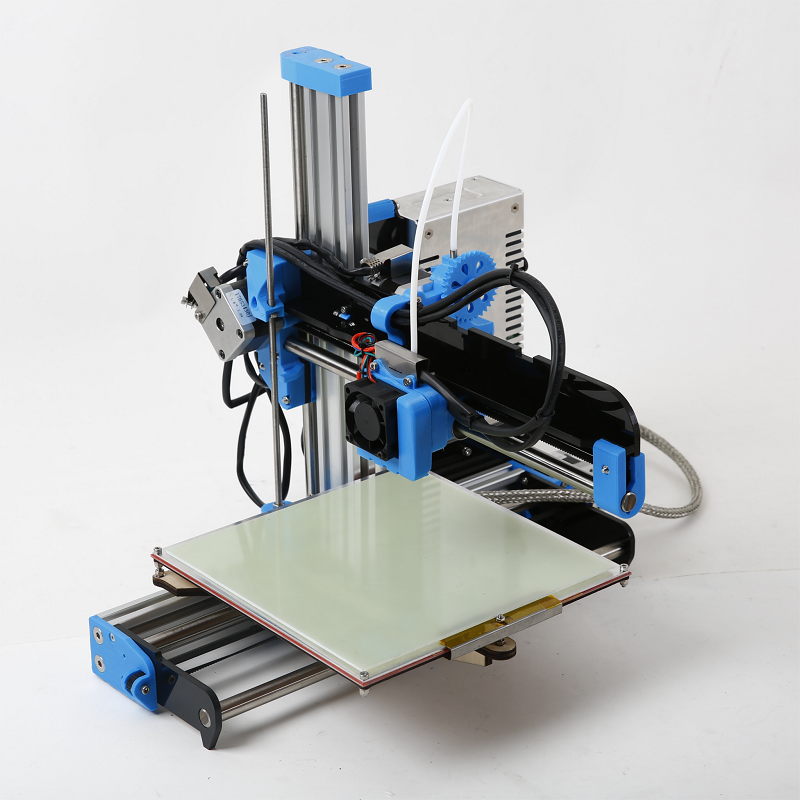

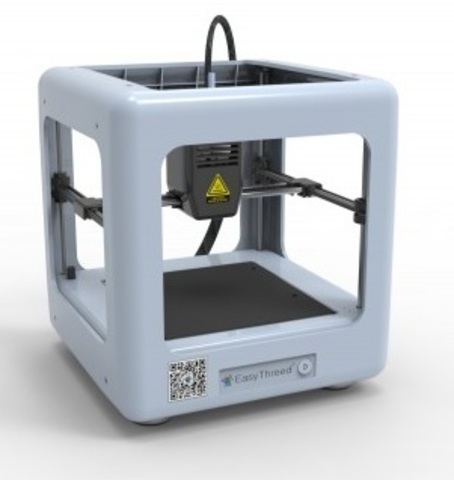

We will start with a 3D printer that is made in India and can help students stay on top of all their projects and assignments. The Pratham Mini 3D printer is an affordable printer that can come in handy in school labs and classes. It has a durable body made of metal and it comes in three eye-catching colours, red, yellow and blue.

It is fully calibrated along the XYZ axis and has undergone over 100 hours of testing to ensure that it’s safe enough to be used by students. It is very easy to set up and install so all you need to do is plug it in, load the filament and start turning your imagination into reality!

It has a print volume of 170 x 170 x 170 mm, a direct drive extruder, a nozzle (with a diameter of 0.4 mm) that can withstand temperatures up to 280 degrees Celsius and a printing speed of 40 to 120 mm per second. You can control the printer via the LCD screen. It is run by Windows and macOS and supports GCODE, STL and OBJ file types.

...Read More

| Available | ₹ 135,000 |

If you want to let your imagination run wild and create some quirky stuff at home then this 3D printer machine by Creality might become your best friend! The printer is easy to assemble as long as you refer to the user manual (it can be set up by following 12 simple steps!). It can print high-quality one-piece structures with an accuracy of 0.1 mm and a printing size of 220 x 220 x 250 mm. Its Y-axis slot ensures precise positioning of the printer head and the wheels made of POM make it easy for the nozzle to glide smoothly. Its compact design makes it easy to move around and carry. Its brass nozzle can print with various types of 1.75 mm 3D filaments including PLA, ABS, PETG and SainSmart TPU filament. Its innovative extruder design ensures minimal clogging of the nozzle for better results and even printing. The machine’s hotbed can attain temperatures as high as 110 degrees Celsius within 10 minutes and the patented MK-10 technology decreases the risk of plugging and bad extrusion, making it safe to use.

Its brass nozzle can print with various types of 1.75 mm 3D filaments including PLA, ABS, PETG and SainSmart TPU filament. Its innovative extruder design ensures minimal clogging of the nozzle for better results and even printing. The machine’s hotbed can attain temperatures as high as 110 degrees Celsius within 10 minutes and the patented MK-10 technology decreases the risk of plugging and bad extrusion, making it safe to use.

...Read More

| Available | ₹ 13,999 |

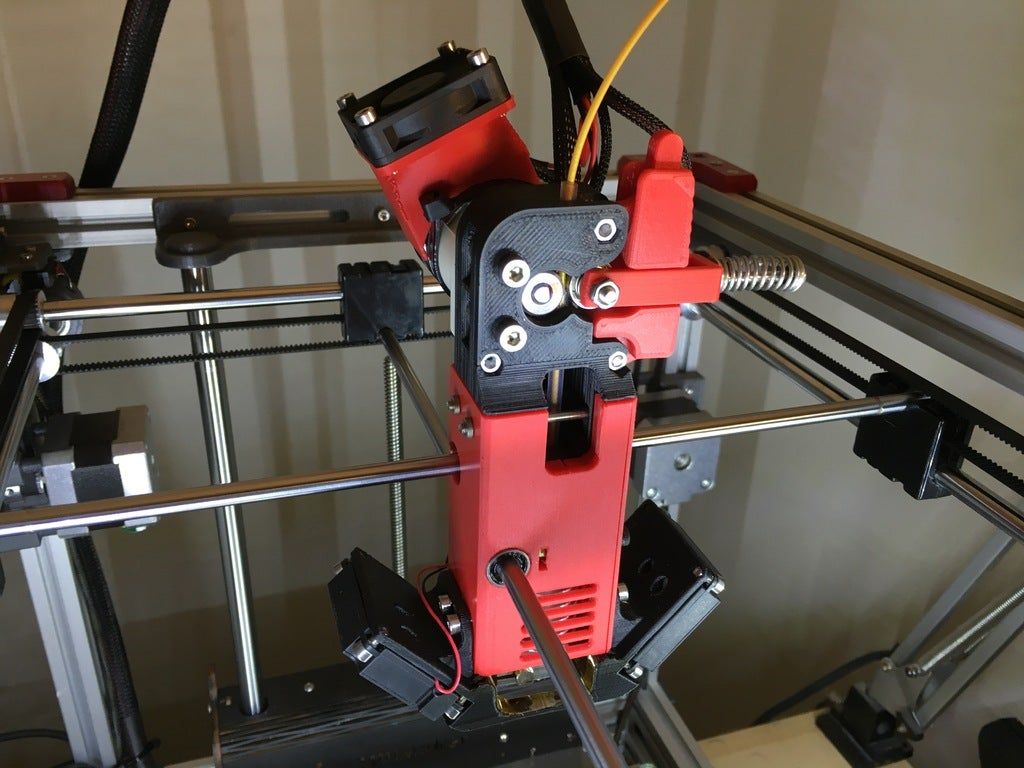

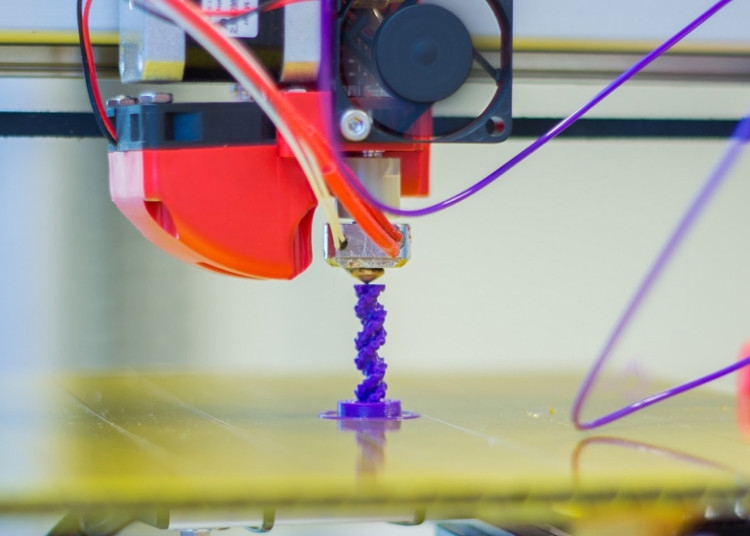

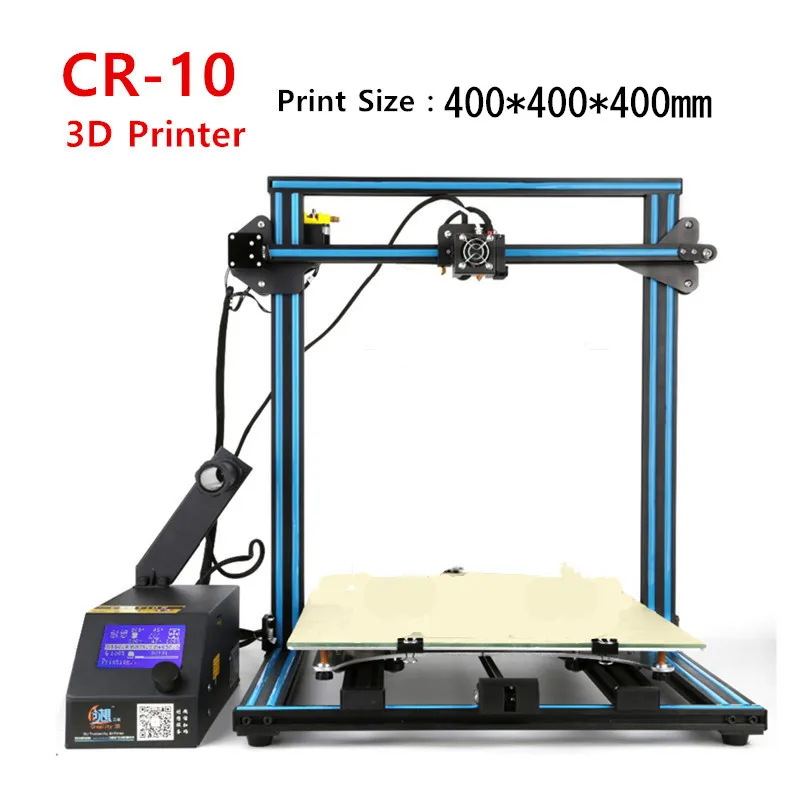

The WOL Creality 3D printer is one of the best printers that can help you create anything you want in a few minutes. It uses the Fused Deposition Molding (FDM) method to print the structures. In this process, the continuous filament is deposited on the structure via the heated printer extruder head for high precision and easily scaled structures.

It uses the Fused Deposition Molding (FDM) method to print the structures. In this process, the continuous filament is deposited on the structure via the heated printer extruder head for high precision and easily scaled structures.

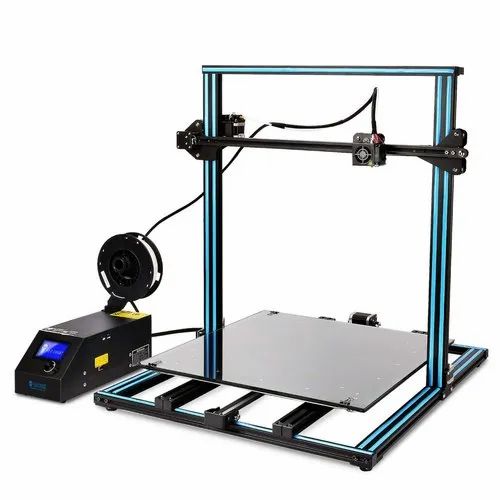

The machine’s nozzles come in two different sizes, 0.4 mm and 0.8 mm to cater to the different requirements of the users and it has a printing size of 450 x 450 x 470 mm which gives you ample space to create whatever you want. It also has an automatic bed-levelling feature and it can adjust the power supply to the motherboard and the bed depending on the need of the machine. The double belt for transmission and the dual motor ensures stable printing so you get accurate structures with every print.

The Capricorn Teflon tube installed in the machine can withstand high temperatures and ensures smooth and fast feeding and greater efficiency, which makes it faster and more accurate.

...Read More

| Available | ₹ 73,999 |

Advertisements

This 3D printer machine by Comgrow employs the FDM process for printing structures and has a printing size of 220 x 220 x 250 mm. It can print at a rate of 180 mm per second using PLA or ABS filaments with a diameter of 1.75 mm and can be used on carbon plastic and wood.

It can print at a rate of 180 mm per second using PLA or ABS filaments with a diameter of 1.75 mm and can be used on carbon plastic and wood.

Its base platform has a thickness of 0.4 mm and it has a POM wheel and a V-slot that ensure silent and smooth operation. These printers can be great for curious minds who want to create something unique with the help of these easy to use and fast 3D printing machines. You can use STL, OBJ and G-Code file formats and even resume print function from where you left off in case the machine shut down abruptly or there was a power cut. The magnetic surface plate of the printer ensures proper distribution of heat and does not stick to the printed structures so you can easily remove them once they have cooled down.

...Read More

| Available | ₹ 54,094 |

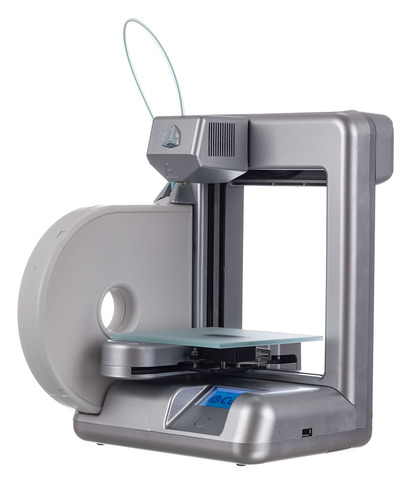

The XYZ da Vinci 1. 0 Pro 3D printer has an aluminium print bed that ensures proper heat distribution in comparison to glass ones while the innovative calibration system makes sure the bed is aligned and levelled properly for each use. It comes with adjustable temperature settings and its resolution is 20 to 400 microns and you can play around with the other settings like temperature, speed, retractions and support to make sure you get the output you desire.

0 Pro 3D printer has an aluminium print bed that ensures proper heat distribution in comparison to glass ones while the innovative calibration system makes sure the bed is aligned and levelled properly for each use. It comes with adjustable temperature settings and its resolution is 20 to 400 microns and you can play around with the other settings like temperature, speed, retractions and support to make sure you get the output you desire.

It has an output power of 350 mW (approximately) and can be used to engrave unique creative designs on all kinds of surfaces including cardboard, leather, wood and plastic.

It can connect to WiFi so you can send 3D files from your phone or PCs without connecting any cable. All XYZ printers come with free CAD and slicing software and are user-friendly so you won’t have a tough time working your way around the machine.

You can join the online community and get access to over 3,000 free models and designs (and share your work).

. ..Read More

..Read More

| Available | ₹ 94,999 |

This 3D printer by 3 Idea is an all-metal printer with a sturdy build that uses moulding technology to print 3D structures. It has an easy to use interface in English and Chinese and sports a 3.5 inches screen with high resolution and a clear display.

It can print structures with great accuracy, thanks to the 2K micron level Solid-State display system that can achieve a precision of 0.02 to 0.05 mm to deliver a smooth finish. The UV light with a wavelength of 405 nm creates a matrix that ensures up to 90% of light evenness and a stable source for a higher printing success rate.

It features a larger printing volume of 119 x 65 x 160 mm so you can print and create bigger structures without any obstructions. Its unique air filtering system includes activated carbon and double fans which deodorize the odour from resin even when you are printing indoors.

The anti-aliasing technology used by the printer masks the image with a layer over a UV light source to get 4 times or 8 times precision by interpolating the edges and smoothening them, so you can get structures with proper finish and design.

...Read More

| Available | ₹ 16,499 |

Advertisements

The WOL3D Creality CP-01 is one of the best 3D printers as this intelligent modular machine can offer 3 functionalities - 3D printing, CNC cutting and laser engraving with minimal errors and smooth finish. It is easy to assemble and can be set up in minutes. It has a large platform size, 200 × 200 × 200mm for 3D printing and cutting and a 100 × 190 mm platform for laser engraving. It can use a wide range of printing materials like PLA, ABS, TPU, PVA; CNC engraving/cutting: wood, paper, PCB, plastic, leather, etc. The full belt drive and the intersecting screw guide help increase the stability and help it attain printing speeds of 10 to 80 mm per second.

It is easy to assemble and can be set up in minutes. It has a large platform size, 200 × 200 × 200mm for 3D printing and cutting and a 100 × 190 mm platform for laser engraving. It can use a wide range of printing materials like PLA, ABS, TPU, PVA; CNC engraving/cutting: wood, paper, PCB, plastic, leather, etc. The full belt drive and the intersecting screw guide help increase the stability and help it attain printing speeds of 10 to 80 mm per second.

Its hotbed can handle temperatures up to 100 degrees and the maximum cutting speed of the CNC is 4,800 rpm. You can process the work both online and offline and adjust the power consumption of the machine depending on your needs and requirements.

...Read More

| Available | ₹ 54,499 |

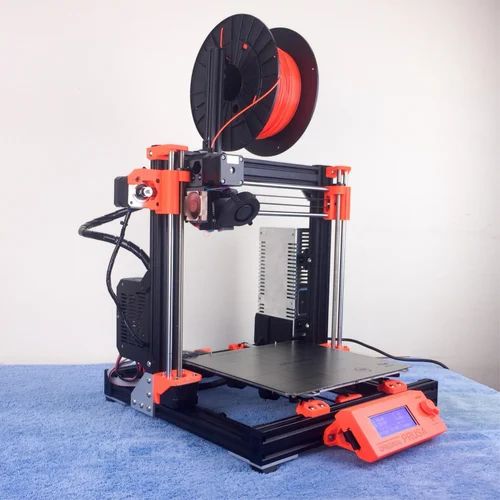

The Anet ET4 Pro is a 3D printer that has a modular robust design with a unibody aluminium frame that ensures stable printing. It comes pre-assembled so you won’t have to spend time assembling it. It features automated levelling which means (thanks to the 25 data points for enhanced accuracy) so you won’t have to struggle with bed levelling. It can save its printing progress and resume working from where it left off in case of power cuts.

It comes pre-assembled so you won’t have to spend time assembling it. It features automated levelling which means (thanks to the 25 data points for enhanced accuracy) so you won’t have to struggle with bed levelling. It can save its printing progress and resume working from where it left off in case of power cuts.

The printer will alert the user when the filament runs out of stock and will resume once the filament is changed using the easy one-click mechanism. It has a 2.67 inches coloured touch screen panel which can be used to change the settings and operate the printer. You can install upgrades by copying them into the memory card and inserting it into the slot provided. Its powerful yet silent motor driver chip (TMC2208) is ultra-quiet, has low resonance and can handle more delicate printing tasks easily. Its large build volume (220 x 220 x 250 mm) and fast (and accurate printing) make it one of the best 3D printers available right now.

...Read More

| Available | ₹ 16,995 |

If you are on the lookout for a machine that can help you print high-end 3D objects, do laser engraving or perform other activities like CNC carving or cutting, then this machine can come in handy. The printer has a tough exterior and a sturdy build and has a touchscreen display that lets you control the printer and adjust its settings with ease. It comes with several advanced features like auto-levelling, filament availability sensor, upgraded cooling system, design preview camera and a durable and firm aluminium bed which make printing, cutting and engraving extremely quick, fun, easy and precise.

The printer has a tough exterior and a sturdy build and has a touchscreen display that lets you control the printer and adjust its settings with ease. It comes with several advanced features like auto-levelling, filament availability sensor, upgraded cooling system, design preview camera and a durable and firm aluminium bed which make printing, cutting and engraving extremely quick, fun, easy and precise.

The machine allows you to carve and cut hard as well as soft materials like PCB, acrylic, POM, carbon fibre sheet, etc.

You can print almost anything you want and engrave on a plethora of materials like plywood, acrylic, cardboard, and even food items like cookies and coconuts! All these features make this one of the best 3D printer machines available in the market right now.

...Read More

| Available | ₹ 134,999 |

Advertisements

The Elegoo Saturn Photocuring 3D printer can help you build large structures as it has a printing volume of 192 x 120 x 200 mm and a monochrome 4K LCD screen with HD resolution (3840 x 2400) which makes it 60% faster than the previous models. The printer can deliver high precision printing as its Z-axis uses a double linear guideway structure for a steady motion and greater accuracy while the ethernet port at the rear and the 4GB in-built data disk allows easy data transfer.

The printer can deliver high precision printing as its Z-axis uses a double linear guideway structure for a steady motion and greater accuracy while the ethernet port at the rear and the 4GB in-built data disk allows easy data transfer.

Its light source matrix consists of 54 UV LED lights with uniform light emission. The 4.8% to 5.2% transmittance rate of light helps in faster printing and ensures low-energy consumption and heat emission which helps extend the lifespan of the Mono LCD by nearly. Its Chitubox slicer enables you to slice models with a few simple clicks and calibrate the thickness, shape and density of the object. You can use the multi-phase retract speed settings to achieve greater efficiency and increase production significantly. The 10 layers of linear transition between the bottom and regular layers ensure greater adhesion while the 8-time anti-aliasing works with an upgraded blur function to generate smooth prints.

...Read More

| Available | ₹ 59,499 |

Afrah Khan

| Product Name | Seller | Price |

|---|---|---|

| Pratham Mini 3D Printer | Amazon | ₹ 135,000 |

| Creality 3D Ender-3 3D Printer | Amazon | ₹ 13,999 |

| WOL Creality 3D CR 10 Max 3D Printer | Amazon | ₹ 73,999 |

| Comgrow WOL 3D Creality Ender 3D Printer | Amazon | ₹ 54,094 |

XYZ da Vinci 1. 0 Pro 0 Pro | Amazon | ₹ 94,999 |

| Creality 3 Idea LD-002R 3D Printer | Flipkart | ₹ 16,499 |

| WOL3D Creality CP-01 | Amazon | ₹ 54,499 |

| Anet ET4 Pro DIY 3D Printer | Amazon | ₹ 16,995 |

Snapmaker 2. 0 (A150) modular 3-in-1 3D Printe 0 (A150) modular 3-in-1 3D Printe | Amazon | ₹ 134,999 |

| Elegoo Saturn Photocuring 3D printer | Flipkart | ₹ 59,499 |

Rate this recommendation lister

Your Score

3D Print India | 3D Printing Services in Mumbai

Skip to contentis our

promise

Get a Quote

All state-of-the-art

3D Printing Services

under one-roof!

01.

3D Modelling

Obtain 3D models that would serve the unique needs of your project, at the most competitive rates. Give your ideas shape with 3D Print India.

Learn more

02.

Vacuum Casting

Get high-volume of parts fabricated to the highest standards at industry-leading turnaround time with 3D Print India. Ideal for prototypes, engineering testing, concept proofing & display demos.

Learn more

03.

Finish & Paint

Avail our finish & paint services to get your SLA, SLS or other printed parts finished and painted according to your specific requirements

Learn more

How can we help you?

I need a prototype made

- Accurate Prototype Production

- One-off Prints

- Economy or Express Turnaround

I have a STL file and looking for a quote

If you have a model ready, just upload your STL file. Our team will study the file and will quote an economical price by contacting you.

Our team will study the file and will quote an economical price by contacting you.

I am looking for low-volume production

- Low Volume Batch Production

- Order Parts when Required

- 1 – 10,000 Parts

- No Tooling Costs, No Set Up Fee

- Price Breaks for Higher Volume

I need more info and want to download brochure

Get A-Z info regarding 3D Print India, the services we offer, machines and materials we use, order processing and more…

1000+ 3D Prototypes& still counting …From plastic parts to liquid resins to metal castings, we do it all!

Check out the wide range of materials we use for our varied 3D printing services, with detailed info regarding their specific characteristics.

Explore the material range

3D Print India is India’s most reliable &

futuristic brand; low-volume production is our forte &

technical finesse is in our DNA

0+

global clients

0+

successful projects

0+

sq. ft. in-house facility

ft. in-house facility

years of expertise

Best Of US & German Technologies Under One Roof

Our industry leader Clients vouch for our

world-class quality & quick turnaround

Mitesh Shah Vice President of Sales

3D Print India is playing a key part in our business growth. When it comes to 3D printing technology for jewellery professionals, 3D Print India is the answer.

Ashok Singh Product Development Consultant

Superb turnaround time, great prices & precise prototypes! Strongly recommend!!

Rahul Sardesai Project Manager

High-quality parts that look fabulous. Great experience of working with 3D Print India.

Piyush Kadam Chief Executive Officer

Just received the parts. They look quite good and I am impressed with how the overall process has panned out. Right from the initial enquiry to today, I would like to thank 3D Print India for their great service.

Jay Goyal Sales Executive

Thank you very much for delivering the parts at such short notice. I’m really sorry for this extra pressure and appreciate your great customer service. Thanks again!

I’m really sorry for this extra pressure and appreciate your great customer service. Thanks again!

Rohit Jain Product Development Consultant

Thanks, Arpit. I just received the goods and they look perfect and of great quality. Looking forward to collaborating again.

Resources

3D Printing is Changing the World

3D printing innovations in recent years have brought a sea change in the fabrication of everything from automobile parts to jewellery.

The Ultimate Beginner’s Guide to 3D Printing

New to 3D printing? Need detailed basic information? This video should do the trick!

Why QuickCast SLA printing?

Produce investment casting patterns for high-quality parts in a fraction of the time & cost of traditional methods with QuickCast SLA printing.

Go to Top

How much does a 3D printer cost?

3D printing is a one-stop solution for a wide range of applications, from high-resolution model production to rapid prototyping, rapid tooling for traditional manufacturing processes, production of aids and end-use models.

However, when you consider investing in a 3D printer, the viability of a solution usually boils down to a simple question: Is it cost-effective for your business? How much does a 3D printer cost and how much time and money can it save your business?

3D printer prices range from $200 to $500,000 depending on the printing process, materials, and complexity of the solution.

In this guide, we'll break down 3D printing costs by technology, compare outsourcing versus in-house manufacturing, list factors to consider when calculating the cost of each model, and look at what else to look for when comparing different solutions. for 3D printing and other production methods.

Interactive

This interactive ROI tool will help you find out how much time and money you can save by 3D printing with a Formlabs 3D printer.

Calculate Your Costs

The three most well-known plastic 3D printing technologies today are Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).

Each technology has its advantages and disadvantages - take a look at the infographic:

Download this high resolution infographic here. Interested in learning more about FDM, SLA and SLS 3D printing technologies? Check out our detailed guide.

Prices for 3D printers have dropped significantly in recent years, and today all three technologies are available in compact, low cost systems.

FDM generally produces models at a lower cost if you only print relatively simple prototypes in limited numbers. SLA technology offers higher resolution and quality, as well as a wide choice of 3D printing materials at a slightly higher price. But this difference is quickly offset when you print complex designs or larger batches due to the less labor-intensive post-processing process. Finally, SLS technology is the most cost effective for medium to high volume production of high quality functional models.

Comparing the total cost of different 3D printers by price tags alone will not give you a complete picture of how the cost of a 3D printer and a printed model will compare. The cost of 3D printing materials and labor significantly affects the cost of a model, depending on the application and your production needs.

The cost of 3D printing materials and labor significantly affects the cost of a model, depending on the application and your production needs.

Let's look at the different factors and costs for each process.

FDM, also known as Fused Filament Manufacturing (FFF), is a printing method where the parts of a model are made by melting and extruding a thermoplastic filament, which the printer's nozzle applies layer by layer onto the model being made.

FDM is the most popular form of consumer grade 3D printing, fueled by the proliferation of hobbyist 3D printers. However, professional and industrial FDM printers are also popular among professionals.

The cheapest 3D printers are FDM printers. DIY kits for FDM 3D printers start at $200. However, most of these models are more like toys or DIY projects that require a significant amount of time to build, set up and calibrate. The quality of the print largely depends on the success of these operations. In addition, machines require repairs and regular maintenance to keep them working, so they are more suitable for people with a higher engineering education who have a lot of time and patience.

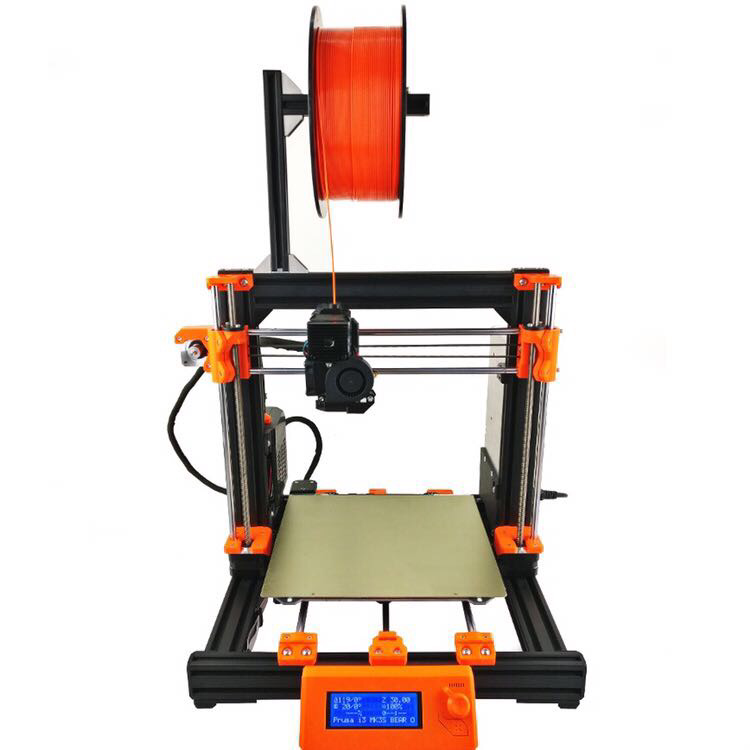

Hobbyist FDM 3D printers cost between $500 and $1,500, come pre-assembled or unassembled, require less setup, but have the same disadvantages as the cheapest 3D printers. More expensive models are capable of large print volumes and work with a wide variety of materials besides low temperature ones such as PLA.

Professional 3D FDM printers start at $2,500 and large format professional FDM printers are available from $4,000. The cost of the most modern industrial FDM printers can exceed 10,000 US dollars. Most of these printers come pre-assembled and calibrated in the box, or they can be automatically calibrated. Printers in this category offer better print quality, a wider range of media, higher print volumes, improved reliability, and ease of use and maintenance. In addition, professional 3D printer manufacturers offer customer support services for troubleshooting.

Material costs for FDM 3D printing range from $50 to $150/kg for most standard and engineering filaments, and $100 to $200/kg for auxiliary materials. There are also cheaper alternatives, but they are of lower quality.

There are also cheaper alternatives, but they are of lower quality.

In addition, FDM printing can be very labor intensive. Successful printing of complex models requires support structures that must be removed manually or dissolved in water. To obtain a high quality surface and remove layer lines, lengthy manual post-processing of models, such as sanding, is necessary.

SLA 3D printers use the process of photopolymerization, that is, the conversion of liquid polymers into hardened plastic using a laser. SLA is one of the most popular processes among professionals due to its high resolution, accuracy and material versatility.

Models printed on SLA printers have the highest precision, sharpest detail and smoothest surface possible of any plastic 3D printing technology. But the main advantage of the SLA method is its versatility. SLA polymers have a wide range of optical, mechanical and thermal properties that match those of standard, engineering and industrial thermoplastics.

SLA 3D printers can handle a wide range of resin materials for a wide variety of applications.

SLA used to be used only in large and complex industrial 3D printers costing over $200,000, but the process is now much more affordable. With the Formlabs Form 3+ Printer, businesses can now use industrial quality SLA printing for as little as $3,750. With Form 3L, large format SLA printing starts at just $11,000.

Stereolithographic 3D printers will be shipped in a box assembled and calibrated. These are professional tools that are highly reliable and require virtually no maintenance. Technical support is also always available. It provides troubleshooting in a critical situation (but its probability is extremely small).

Most standard and engineered polymers for SLA technology cost between $149 and $200 per liter.

SLA printers are easy to use and many workflow steps such as rinsing and final curing can be automated to reduce labor costs. Printed models have a high quality surface immediately after printing and require only simple post-processing to remove supporting structures.

Selective Laser Sintering (SLS) 3D printers use a high power laser to sinter fine polymer powder particles. The unsprayed powder supports the model during printing and eliminates the need for special support structures. This makes SLS ideal for complex geometries, including internal features, grooves, thin walls, and negative taper.

Models produced using SLS printing have excellent mechanical characteristics - their strength can be compared with the strength of injection molded parts. As a result, SLS technology is the most popular plastic 3D printing process for industrial applications.

SLS printed nylon models are ideal for a range of functional applications, from consumer product design to healthcare applications.

Like SLA, SLS was previously only available in large format, complex 3D printing systems costing $200,000 or more. With the Formlabs Fuse 1 stereolithography printer, businesses can now solve industrial-scale tasks with SLS technology starting at $18,500. The complete kit, which includes the post-processing and powder recovery system, costs $31,845.

The complete kit, which includes the post-processing and powder recovery system, costs $31,845.

As with SLA printers, stereolithographic printers are shipped assembled and calibrated in the box. They are reliable and can operate 24/7. The package includes in-depth training and fast technical support.

SLS nylon print materials cost about US$100/kg. SLS does not require supporting structures and unused powder can be reused, reducing material costs.

SLS is the least labor-intensive plastic 3D printing process in the production environment, because the printed models are of high quality right away, and to remove excess powder, they simply need to be cleaned.

There are several processes for 3D printing not only plastics but also metals.

Metal FDM printers are similar in design to traditional FDM printers, but use extruded metal rods held together by a resin binder. The finished parts of the model are sintered in an oven to remove the binder.

SLM and DMLS printers are similar to SLS printers, but instead of polymer powders, they fuse metal powder particles layer by layer using a laser. 3D printers based on SLM and DMLS technologies can create strong, precise and complex metal products, making this process ideal for the aerospace, automotive and medical industries.

3D printers based on SLM and DMLS technologies can create strong, precise and complex metal products, making this process ideal for the aerospace, automotive and medical industries.

Prices for metal 3D printers have also begun to decline, ranging from $100,000 to $1 million today. However, these systems are still out of reach for most businesses.

SLA 3D printing is available as an alternative for casting workflows that allow metal models to be produced cheaper and faster than traditional methods and provide greater design freedom.

Technical report

Get design guides for 3D printing samples, see the step-by-step direct investment casting process, and study guides for indirect investment casting and sand casting.

Download white paper

Different plastic and metal 3D printing processes have unique qualities that make them suitable for different applications. Below is a comparison of different printing technologies.

| Fused Deposition Modeling (FDM) | Stereolithography (SLA) | Selective Laser Sintering (SLS) | Metal FDM Printing | Selective Laser Melting (SLM) and Direct Metal Sintering (19008) 9008 | |

|---|---|---|---|---|---|

| Permission | ★☆ | ★ opa ★ ution | ★ opa | ★ opa | ★ opa ventary | Surgery | ★ opa ☆ | 1111111 ☆☆☆ | 1 ☆ | ★ opa |

| Ease of use | x 300 x 600 mm (Desktop and Workshop 3D printers) | Up to ~300 x 335 x 200 mm (Desktop and Workshop 3D printers) | Up to 165 x 165 x 300 mm (3D - workshop printers) | Up to 300 x 200 x 200 mm | Up to 400 x 400 x 400 mm |

| Price range | DIY kits for 3D printers start at $200 and hobby printers cost $500-1500. Professional 3D FDM printers start at $2,500, while large format professional FDM printers are available from $4,000. | Professional desktop printers start at $3,750 and high-volume large format desktop printers are available from $11,000. | Workshop industrial printers start at $18,500 and traditional industrial printers start at $100,000. | Metal FDM printers start at $100,000, but complete solutions including an oven are much more expensive. | DMLS/SLM solutions start at around $200,000. These printers require special infrastructure conditions, which can further increase costs. |

| Cost of materials | US$50-150/kg for most standard and engineering yarns and US$100-200/kg for auxiliary materials. | US$50-150/L for most standard and engineering polymers. | US$100/kg for nylon. SLS does not require supporting structures and unused powder can be reused, reducing material costs. | Depends on material and technology. Significantly higher than plastic. | Depends on material and technology. Significantly higher than plastic. |

| Labor | Manual removal of support structures (soluble support structures may be used in some cases). Long post-processing is required to obtain a high quality surface. | Washing and final polymerization (both can be automated). Simple post-processing to remove supporting structures. | Easy cleaning to remove excess powder. | Washing and sintering (both can be automated). It is possible to use mechanical processing and other types of surface treatment. | Stress relief, support structure removal, heat treatment, and mechanical and other surface treatments. |

| Materials | Standard thermoplastics such as ABS, PLA and their various blends. | Various polymers (thermosetting plastics). Standard, engineering (similar to ABS and PP, similar to silicone, flexible, heat resistant, rigid), injection molding, dental and medical (biocompatible). | Engineering thermoplastics - typically nylon and its composites (nylon 12 biocompatible + sterilizable). | Stainless steel, tool steel, inconel, copper, titanium. | Stainless steel, tool steel, titanium, cobalt-chromium, copper, aluminium, nickel alloys. |

| Applications | Basic experimental models, low cost rapid prototyping of simple parts. | Prototypes with a high level of detail requiring close tolerances and smooth surfaces: molds, tooling, templates, medical models and functional parts. | Complex geometries, functional prototypes, low volume production or limited trial production. | Strong and durable models, tools and production aids. | Strong and durable models with complex geometries; ideal for the aerospace, automotive and medical industries. |

When calculating the cost of one model, the cost of ownership of equipment, material costs and labor costs are usually taken into account. It is important to understand the factors that affect each of these cost components, as well as the questions to ask in order to evaluate alternative production methods and uncover hidden costs.

Hardware ownership costs are fixed costs: 3D printer price, service contracts, installation and maintenance. These amounts must be paid whether your printer is idle or produces dozens of models per week.

Add up all projected fixed costs over the lifetime of the equipment, then divide by the number of models you plan to make. As a rule, the higher the performance and efficiency of your 3D printer, the lower the cost of ownership of equipment per model.

In recent years, desktop 3D printers have shown excellent results in reducing the cost of ownership of equipment. With a price 10 to 100 times lower than traditional industrial 3D printers and the ability to produce thousands of models over a lifetime, the cost of ownership can be negligible.

Questions:

-

Are there installation, training or additional initial costs other than the cost of the machine itself?

-

Do I need to sign a (mandatory) service contract? What does it include?

-

What accessories and tools are needed to make the final models?

-

What kind of maintenance is required for the machine to function properly? What is the expected annual maintenance cost? Will it change with an increase in production volumes?

The 3D printing raw materials and consumables you need to create models at an affordable price. These costs largely depend on the number of models you produce.

These costs largely depend on the number of models you produce.

When calculating the cost of materials, determine how much material is required to create one model, and multiply this figure by the cost of the material. Count the amount of waste and any other consumables. As production grows, the cost of ownership of equipment decreases, and the cost of 3D printing materials tends to become more balanced.

Be sure to check what materials you need to create specific models, as the cost of 3D printing consumables can vary greatly. Please note that some 3D printers only work with their proprietary materials and thus limit your ability to use third party materials.

Questions:

-

What is the cost of each type of 3D printing material?

-

How much material is required to create one particular model, including waste?

-

What is the shelf life of the materials?

-

Do I need other consumables to create models?

-

Can the machine work with third-party materials?

While 3D printing can replace complex traditional manufacturing methods and provide significant time savings, depending on the 3D printing technology, it can still be quite labor intensive.

Professional desktop 3D printers are generally optimized for ease of use. DIY kits for 3D printers and hobby printers often require additional effort to adjust settings, while regular maintenance or material changes on traditional industrial machines can involve time-consuming tasks that require the assistance of a skilled operator.

Post-processing workflows vary depending on the 3D printing process, but in most cases include cleaning up models and removing support structures or excess material. However, there are solutions to automate some specific tasks. For example, Formlabs Form Wash and Form Cure simplify the wash and finish process for Formlabs SLA 3D printers, while Fuse Sift offers a turnkey post-processing and powder recovery system for the Fuse 1 SLS printer.

More complex processes such as SLA and SLS do not take long to achieve high quality models, while FDM models require lengthy manual post-processing to improve quality and remove layer lines.

Questions:

-

What is the whole model production workflow? What specific steps are required to set up printing, change materials, and post-process models?

-

How long does it take to post-process one particular model?

-

Are there any tools or devices available to automate some of these tasks?

Outsource production orders to 3rd party service bureaus or labs when you use 3D printing only occasionally or to produce large models in non-standard materials. Typically, the bureau has several in-house 3D printing processes such as SLA, SLS, FDM, as well as metal 3D printers. They can also provide advice on a variety of materials and offer additional services such as design or improved finishes.

Typically, the bureau has several in-house 3D printing processes such as SLA, SLS, FDM, as well as metal 3D printers. They can also provide advice on a variety of materials and offer additional services such as design or improved finishes.

The main disadvantages of outsourcing are the high cost and duration of production. One of the main advantages of 3D printing is its speed compared to traditional production methods. But it is noticeably reduced if the delivery of the model produced by the involved organization takes several days or even weeks. And as demand and capacity grow, the costs of outsourcing are rising rapidly.

Desktop 3D printers are the perfect solution for fast model production. Depending on the number of parts needed and the volume of prints, the investment in a professional 3D printer can pay for itself in just a few months.

With desktop and workshop printers, you can pay for the capacity that matches your business needs and scale your production by adding more devices as demand grows, without the heavy investment of a large format 3D printer. Using multiple 3D printers also allows you to print models from different materials at the same time. But if there is a need for the production of large parts or the use of non-standard materials, service bureaus can come to the rescue.

Using multiple 3D printers also allows you to print models from different materials at the same time. But if there is a need for the production of large parts or the use of non-standard materials, service bureaus can come to the rescue.

Investment, material and labor costs are relatively easy to calculate. But what about indirect costs and hard-to-calculate factors that affect your business? Let's look at some of the main considerations when comparing a desktop 3D printer to outsourcing or other manufacturing methods.

Save time: What if you could get products to market a few months faster? Or reduce the delivery time of your products by a few days or weeks? 3D printing simplifies traditional prototyping and manufacturing workflows, helping you save time and stay ahead of the competition.

Top results: 3D printing allows you to create more iterations, overcome failures faster, and produce better end products. Troubleshooting a design early on also helps avoid costly redesign and the use of additional tools.

Interaction: Having high-quality prototypes and models allows you to communicate more effectively with customers, clients, suppliers and other stakeholders. Avoid misunderstandings and costly mistakes.

Intellectual Property Protection: Do you work with confidential information? Making your own models means you don't have to transfer intellectual property (IP) to third parties, reducing the risk of IP leakage or theft.

Usually, calculating cost per part, lead time, and comparing alternatives to see if a solution is right for your business is a tedious task of creating a complex spreadsheet in an attempt to collect all of the often hidden information from a manufacturer.

Use our simple online tool to calculate cost per model and order lead time when printing with a Formlabs stereolithographic 3D printer and compare time and cost savings with other manufacturing methods.

Calculate the cost and time

Alfa-280 - ALT print

Industrial metal 3D printer - ideal for prototyping and small-scale production

Characteristics of Alfa-280 3D printer

| Working area (W x D x H) | 280 x 280 x 300 mm |

| Optical system configuration | single / double (optional) / quad (optional) |

| Type of laser used | fiber (ytterbium) water-cooled |

| Nominal laser optical power | 1 x 500 W / 2 x 500 W (optional) / 4 x 500 W (optional) |

| Laser wavelength | 1070 ± 2 nm |

| Layer thickness | 20 - 200 µm |

| Laser Beam Focal Diameter | 75 - 200 µm |

| Maximum scan speed | 10 m/s |

| Laser beam positioning accuracy | 0. 28 µm 28 µm |

| Inert gas consumption during printing | < 5 l/min |

| Power input | 6 kW |

| Power supply | ~230 V, 50 Hz |

| Dimensions (W x D x H) | 2240 x 1160 x 2110 mm |

| Weight | 970 kg |

Specification PDF Go to Alfa-150D

Benefits of the Alfa-280 3D printer

Open platform

postprocessor settings are maximally open for unlimited experiments with print parameters and modes to achieve the required quality indicators

Superior performance and stability

using a water-cooled single-mode CW ytterbium laser from a leading European manufacturer;

laser beam focal diameter of 75 - 200 µm allows you to significantly expand the working parameters of printing to achieve the required productivity and quality of products

Fully sealed build chamber

with the option of preparing the print process and unpacking finished products without the use of additional personal protective equipment

Filter regeneration system

automatically cleans the filter elements

Metal powder supply system

in continuous mode with high precision dosing during printing of products

Use of a wide range of metal powders

stainless and heat resistant steels, Inconel 625 and Inconel 718, aluminum, titanium, cobalt-chromium alloys and others

Integrated GigE Industrial Camera with CMOS sensor for continuous monitoring of high-resolution data building and archiving

Scope of supply

pre-installed software, vacuum powder transporter model APR-042, automated powder sieving station model APS-052, with which it is possible to start the 3D printing process immediately

Powder Bed Fusion

Selective laser melting is an innovative technology for the production of products of complex geometry by layer-by-layer deposition and further melting of powders of various metal alloys according to mathematical CAD models using high-power ytterbium fiber lasers as a radiation source.