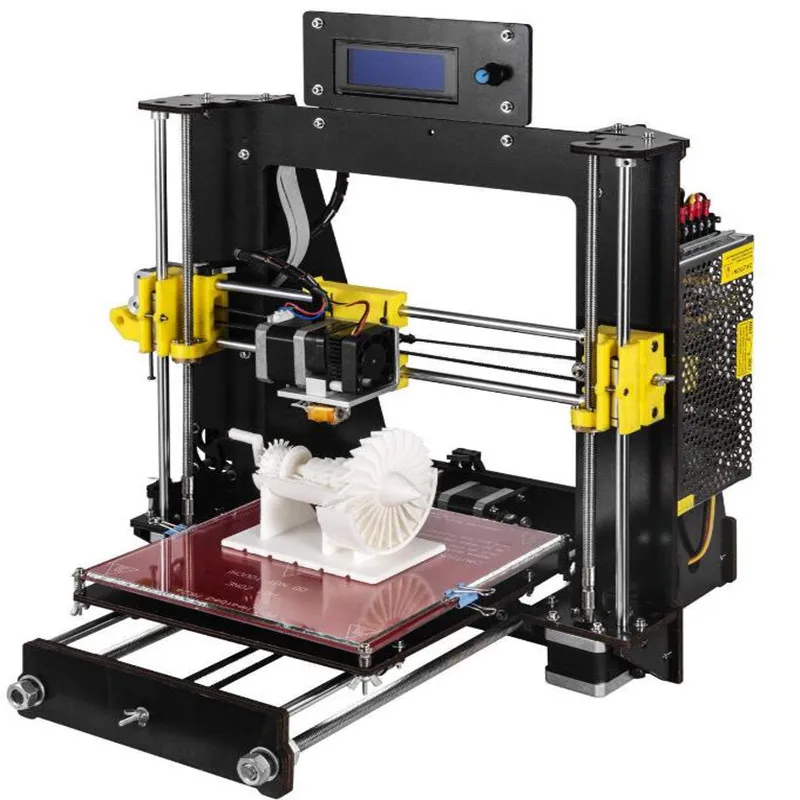

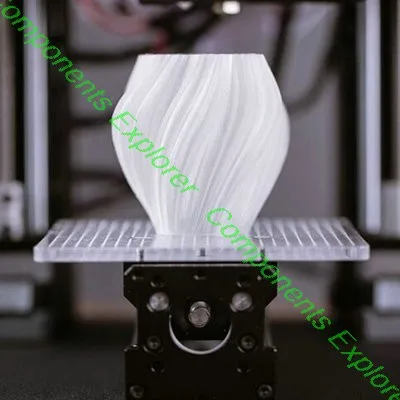

3D printer trinus

Project Updates for TRINUS - The Affordable All-Metal 3D Printer on BackerKit Page 1

Trinus Virtual LCD - Kodama Trinity Public Release

over 2 years ago – Fri, Jul 03, 2020 at 02:12:17 AM

Dear Trinus lovers,

One of our Dutch Kickstarter backers, with the help of a group of beta testers, has created Virtual LCD software for Trinus. Designed in The Netherlands, this software is free for download and use, and will be an enhancement for every Trinus out there. This is a great example of the community we’re building together, and we’re very proud to see the innovations that our fellow creators and makers continue to develop.

WHAT EXACTLY IS KODAMA TRINITY?Kodama Trinity is a support application for Bardo-based Trinus printers equipped with or without a physical LCD screen. Connecting your printer through USB to your computer, you can control Trinus in the same manner as users who have a physical LCD screen on their printers, but with the convenience of doing it right from your computer (Windows or Mac).

Kodama Trinity is a companion application on your desktop for the Trinus printer, whether or not you have the physical LCD. Conveniently, it also checks if there are firmware updates for your Bardo board and/or LCD screen.

In case of firmware updates for Bardo, it allows automatic installation from Trinity for you. No more messing around with downloading the hex-files and finding a tool that works for your computer to flash it to Bardo, it's now all integrated. And as you start Trinity it will immediately check if new updates have been published! Convenience and ease of use is the key here.

As with the LCD and Bardo updates, Trinity will also check itself for updates and notify you when they are available. So after you have installed Trinity, you shouldn't miss out on any updates again.

WHERE CAN I DOWNLOAD KODAMA TRINITY?

You can download the application from the direct download link for Windows and Mac , which holds the most recent releases.

We hope you enjoy this enhancement, and can’t wait to see the next collaborated innovation for Trinus!

Have fun, stay safe, and keep creating,

Team Kodama

New: Bardo PCBA release, Marlin2, free LCD upgrade

about 3 years ago – Fri, Nov 22, 2019 at 11:54:01 PM

Dear Backers,

The wait is finally over!

Our Bardo PCBA is finally out and available for purchase from our online stores.

3D Printers have a much longer lifetime than other consumer technologies such as smartphones, where you’re forced to upgrade to the latest model every year or two.

Our Trinus printer is the best testament to this: originally launched in 2016, the mechanics are superb to this day, making this printer a reliable workhorse that supports your creations and needs little to no maintenance.

But we still wanted to see whether we could further upgrade things.

Thanks to your support, Trinus has gathered a large user base, and we want to make sure they can always have the best machine: we don’t take our customers for granted. With the release of Bardo, makers can now use the printer in stealth mode (TMC), open-source Marlin2, enable auto bed leveling, and much more.

With the release of Bardo, makers can now use the printer in stealth mode (TMC), open-source Marlin2, enable auto bed leveling, and much more.

To make it a remarkable upgrade, we are also adding the option to upgrade the existing LCD screens free of charge—this multiplies the amount functionalities available…in the same machine!

Here are some of the main upgrades that Bardo brings to Trinus:

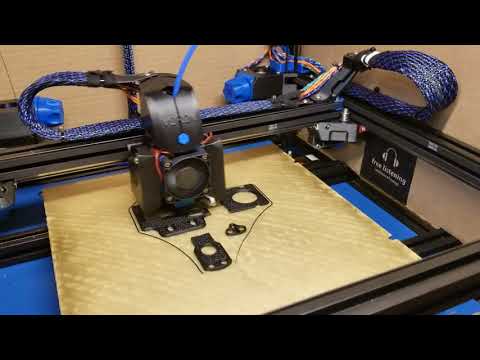

Here you can see stealth mode in action: our old PCBA with A4988 stepper drivers vs our new Trinamic (TMC, stealth mode).

The first batch of Bardos has been produced and is now on its way to our warehouses in the US and EU (and our temporary fulfilment centre in Hong Kong, open for this week only to cater to our customers based in Asia).

This is a big release for us, and we wanted to update you on our progress: we keep moving forward and improving our machines, and we will keep you updated and part of the journey as always – your support is what makes our mission possible!

Stay tuned for more information and have a great weekend.

Michael and Team Kodama

The evolution of Trinus

almost 5 years ago – Sat, Mar 03, 2018 at 07:43:02 PM

This post is for backers only. Please visit Kickstarter.com and log in to read.

Trinus and Beyond, Obsidian, and new Kodama Filament

over 5 years ago – Thu, Jun 29, 2017 at 01:11:47 AM

Dear Backers,

Thank you for trusting us and giving us the opportunity to deliver Trinus to you. It’s been an amazing journey and along the way we’ve learned some major lessons and have been hard at work making sure Trinus lives on and continues to live on to what we envisioned for it: An all-in-one combination 3D printer and more. As some of you already know, we just launched another Kickstarter, and we want to explain what this means for Trinus.

Since launching Trinus, we’ve made several tweaks to it wherever we saw a need to improve its quality and user experience: A bed leveling system, a hot end silicone sleeve, a filament guide to make loading filament easier, a switch, etc. This has not stopped. There were many modifications prototyped but not OK’d for production, and some still pending approval: tungsten nozzles, carbon fiber beds, enhanced laser, a new LCD screen, open firmware, and more. One thing we get many questions about is new modules.

This has not stopped. There were many modifications prototyped but not OK’d for production, and some still pending approval: tungsten nozzles, carbon fiber beds, enhanced laser, a new LCD screen, open firmware, and more. One thing we get many questions about is new modules.

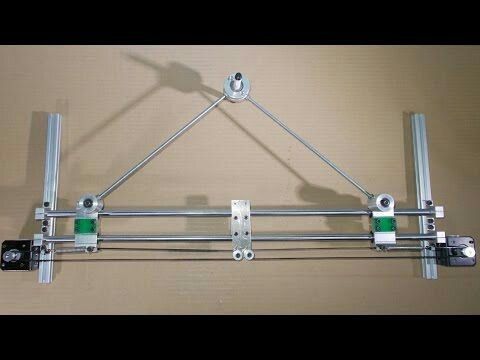

We’re very excited to announce something we said we’d dedicate R&D to since the campaign: A CNC head. Our CNC module is more than just a carver or surface scratcher, it can completely drill through wooden workpieces and even needs its own 48V PSU to achieve this. We have a CNC expert and former watchmaker working on just the CNC module full time, hands off any other Kodama project, as there is a degree of engineering challenge in making a precise yet strong CNC attachment for a Trinus form factor while controlling for stability. For now we can tell you that it can mill wood and acrylic work pieces just fine. We’ll reveal more about its capabilities later on. See some of our early prototype results for yourself:

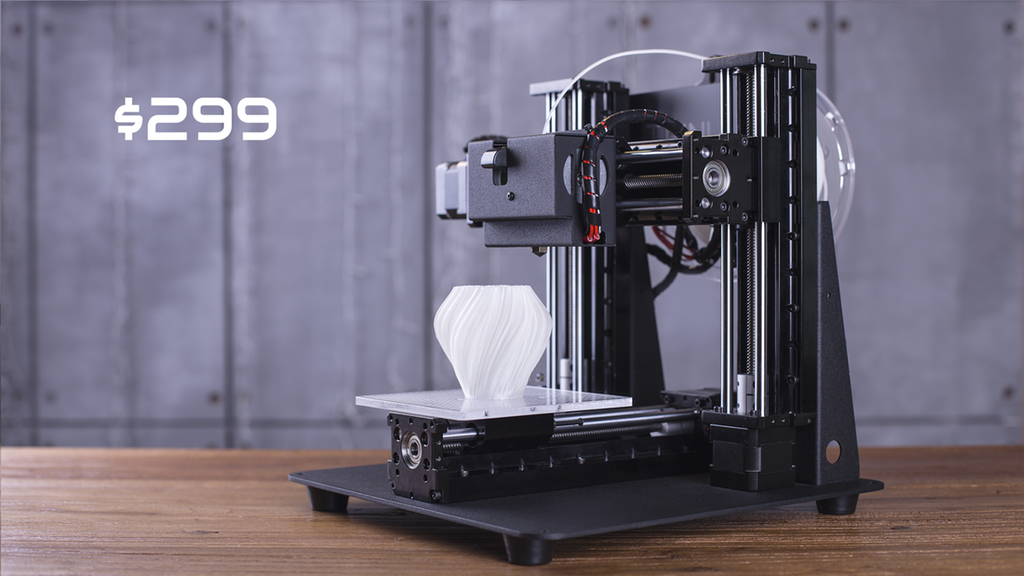

Obsidian was built in house by Kodama and is an out of the box fully-assembled plug and print 3D printer, and it starts at $99. We believe that Obsidian takes the ease of use of Trinus several steps further, and helps us achieve our goal of making 3D printing accessible and affordable to everyone, regardless of skill level. We used the print quality of the Trinus as a benchmark for Obsidian, and we think it makes a great companion to Trinus as a dedicated 3D printer or as a gift you can give to your friends and family to introduce them to 3D printing. You’ll also see some new features in Obsidian that will make their way back to Trinus later on. You can see our campaign by clicking this link.

In the spirit of making 3D printing affordable and accessible to everyone, we’ve also tested hundreds of different filament types and colors from various sources with the goal of providing high quality filament at a great price. Some of you may have already seen it for sale on our website. Every other month we’ll be releasing new filament colors and types that we find interesting and intriguing. If you can’t decide which spool you want, you can also purchase our sample pack. This month we’re offering hickory wood, pearl white, translucent white, lime green, and emerald green. You can find it in the filament section of kodama3d.com

Some of you may have already seen it for sale on our website. Every other month we’ll be releasing new filament colors and types that we find interesting and intriguing. If you can’t decide which spool you want, you can also purchase our sample pack. This month we’re offering hickory wood, pearl white, translucent white, lime green, and emerald green. You can find it in the filament section of kodama3d.com

- Team Kodama

All Kickstarter orders delivered. Getting ready for the future.

over 5 years ago – Sat, Apr 29, 2017 at 01:00:54 AM

Dear Backers,

Less than one year ago you helped us to make a dream come true. With your support and your pledges, you helped us deliver close to 4,000 Trinus machines (incl. pre-orders) to 80+ countries around the globe.

Already last month we have shipped the last batch of Kickstarter Trinuses, utilizing various express courier services for every corner of the world. And with also this batch successfully completed, we can proudly say that nearly 100% of all our backers have received their machines! In some countries and with some logistics companies it’s not possible to track all orders down online until the last mile. But even counting in backers who didn’t get back to us with updated addresses, deliveries in question account for less than 0.5% of all KS pledges. (So if for some reason you’ve really not heard anything from us in the last 4 weeks, then please send us an e-mail to the dedicated inbox [email protected] so we can investigate your specific case immediately).

And with also this batch successfully completed, we can proudly say that nearly 100% of all our backers have received their machines! In some countries and with some logistics companies it’s not possible to track all orders down online until the last mile. But even counting in backers who didn’t get back to us with updated addresses, deliveries in question account for less than 0.5% of all KS pledges. (So if for some reason you’ve really not heard anything from us in the last 4 weeks, then please send us an e-mail to the dedicated inbox [email protected] so we can investigate your specific case immediately).

Kodama started lean and has stayed lean – with all the advantages and disadvantages this entails: A Kickstarter campaign brings you a large lump sum of money, and a lot of hype and enthusiasm. When you beat your initial funding goal by an order of magnitude, it feels like nothing can go wrong. Some may start thinking about getting a bigger team, a nice office, or spending on non-necessities. This is a very vulnerable time, and in our industry and business environment suppliers are all too happy to take their cut of your enthusiasm. Showing market demand for your product is one thing, but starting working relationships with manufacturers, suppliers, distributors, and couriers is a necessary and very difficult side of the business. Moreover, amounts that seem like a lot of money on Kickstarter turn out to not be very much in the world of tech giants, when you’re competing with established, multinational, and/or investor-backed firms.

This is a very vulnerable time, and in our industry and business environment suppliers are all too happy to take their cut of your enthusiasm. Showing market demand for your product is one thing, but starting working relationships with manufacturers, suppliers, distributors, and couriers is a necessary and very difficult side of the business. Moreover, amounts that seem like a lot of money on Kickstarter turn out to not be very much in the world of tech giants, when you’re competing with established, multinational, and/or investor-backed firms.

We expected delays and there were many, we expected manufacturing errors and even then there were some that caught us off guard. We negotiated hard for every piece of your Trinus kits and learned the hard way how to better judge our partners. Our community got impatient at times, but we take their critiques as tough love and a roadmap for improvement. We welcome our competitors and already see new campaigns inspired heavily by ours./i.s3.glbimg.com/v1/AUTH_08fbf48bc0524877943fe86e43087e7a/internal_photos/bs/2017/B/6/WLnbAoRvqNzuwzQV46rw/3d-printer.jpg) This validates our vision and reminds us that this industry is just getting started. We won't be sleeping while they start the hard part. We’ve worked tirelessly, every day of the week and during holidays to make this happen.

This validates our vision and reminds us that this industry is just getting started. We won't be sleeping while they start the hard part. We’ve worked tirelessly, every day of the week and during holidays to make this happen.

This project doesn’t end with the delivery of the machines. Trinus users should expect to hear from us more often in the coming weeks. We are providing ongoing support, both for technical and general inquiries. With all of the shipping done we can now also concentrate on our backlog (including missing items cases: “We have not forgotten you!”). Support tickets are attended to by our team day and night. But we know that we still weren’t able to resolved all cases. So if you feel that there is something wrong with your ticket and you require more attention, then please help us to help you - with kind reminder (or maybe even two…) in good faith.

One side effect of the batch shipment method and of the ticketing system which we employed is that feedback from earlier batches helped us anticipate what kind of support the last batches would need. So we continuously brainstormed, designed and prototyped ways to improve and upgrade the Trinus.

So we continuously brainstormed, designed and prototyped ways to improve and upgrade the Trinus.

(Now available in our US and EU stores; by mid May also in ANZ and ROW)

1. We’ve designed a silicon sleeve that insulates and protects the hot end.

2. Our leveling system for both heated and non-heated print beds, improved for months and with the help of dozens of beta-testers.

3. We're stocking a 144W power supply as deluxe users have been requesting a beefier power adapter. We recommend this power supply for users powering multiple add ons at once.

(Enclosure panel tool for cases of too thick laser safety panels. Available for 0.01$ in all our shops - or entirely for free if you open a new support ticket with a quick note and your latest shipping address.)

Trinus has been designed with a modular structure, and will experience a series of incremental upgrades and new add ons.

Kodama’s supply chain: After our first batch trial and error, we hedged our bets by using multiple different logistics partners to deliver our batches. Two different partners delivered to the US, a different one to Canada, one of the US distributors shipped to Australia and another one from the UK delivered to Europe. We used a variety of partners for the rest of the world as well. We learned how to deal with regulatory authorities, certification agencies, and a host of other bureaucratic processes that should be much more streamlined in the future.

Two different partners delivered to the US, a different one to Canada, one of the US distributors shipped to Australia and another one from the UK delivered to Europe. We used a variety of partners for the rest of the world as well. We learned how to deal with regulatory authorities, certification agencies, and a host of other bureaucratic processes that should be much more streamlined in the future.

We are transitioning from backerkit to regionally-fulfilled e-commerce for ongoing Trinus sales. You can access our pages at:

https://us.kodama3d.com

https://eu.kodama3d.com

https://anz.kodama3d.com

https://asia.kodama3d.com

If you are from the US, Canada or Mexico, select United States.

If you are from the European Union, Switzerland & Norway, select European Union. If you are from Australia or New Zealand select Australia/New Zealand. Asia includes East Asian and Southeast Asian countries – but will soon be open also for “rest of the world”.

Here you can purchase available stock, reserve backordered stock, and sign up to receive e-mail notifications when something you want is back in stock.

So thank you again for supporting us all along this way. You will hear a lot more from Kodama in the next weeks and months (or might already have heard something…).

As a special offer to you, we are offering the silicon sleeves for US$4.99 (€4.99) instead of US$8.99 and Kodama blue filament for US$10 (€10) instead of US$15 for the next 3 days!

At the same time we will greatly appreciate if you stock up on Kodama or Polymaker filaments now with your order of leveling system, silicon sock, etc. Don’t forget to combine this with your 10% backer discount code for our online shops!

Best regards

Your Kodama Team

Michael, Arturo, Maxim, Yunkai - not in the picture: Danny, Leo, Lukas, Roi

Kodama Trinus 3D Printer Review by 3D Printed Aspie

3D Printers

Disclaimer: I would like to say that I have no affiliation with Kodama in any business sense and although they sent me the Kodama Trinus free of charge for the purpose of this review I will be completely honest with how I feel about this 3D printer. Michael was kind enough to give me this opportunity and I will do everything in my power to give it the best I can.

Michael was kind enough to give me this opportunity and I will do everything in my power to give it the best I can.

The purpose of this review is to inform you, the readers/viewers, of this product so you can make your own decision on whether it will fit into both your budget and your needs as a possible printer.

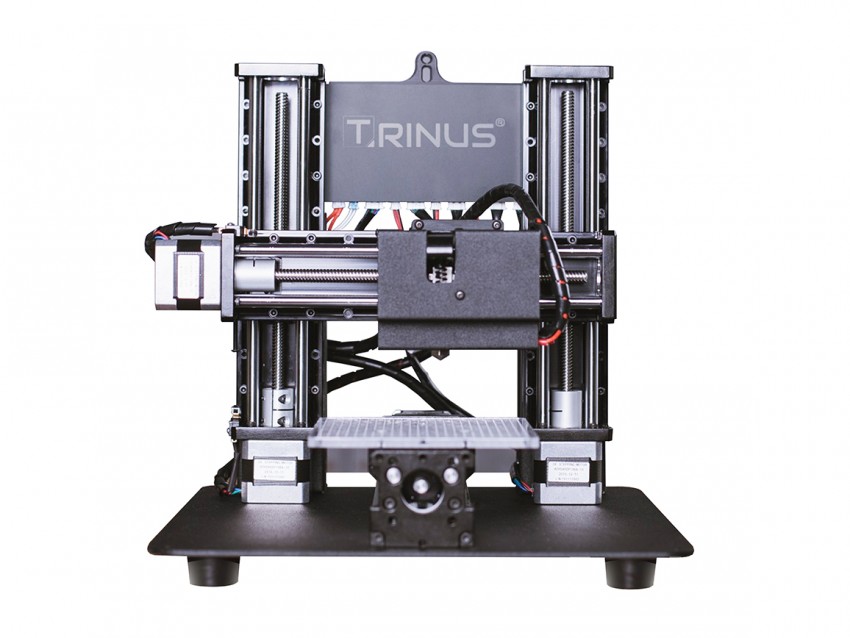

Kodama Trinus Specifications

Printer Type – FDM (Fused Deposition Modelling)

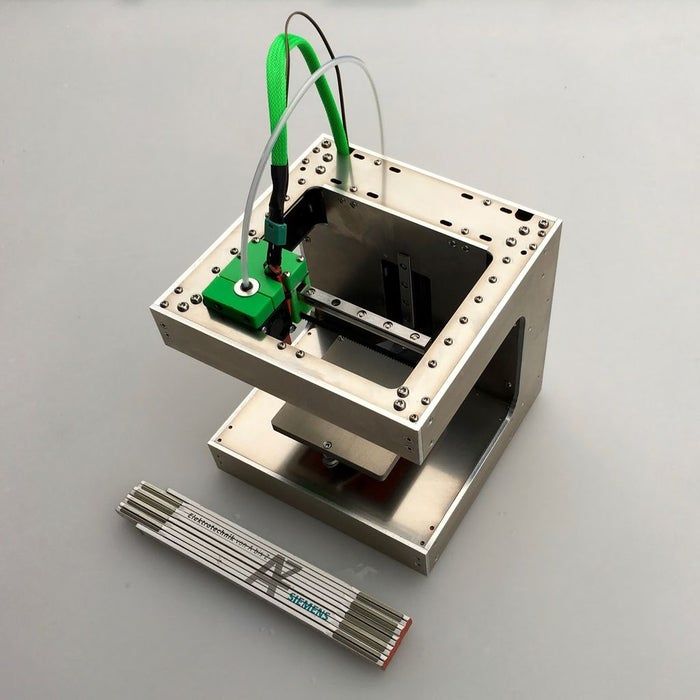

Build Materials – Aluminium and Steel Machined Modules

Print Bed – 120x120x125mm Grid Machined Plastic

Print Speeds – Up to 70mm/s

Nozzle Size – 0.4mm (other sizes available)

Filament Size – 1.75mm

Layer Height – 0.05mm – 0.5mm

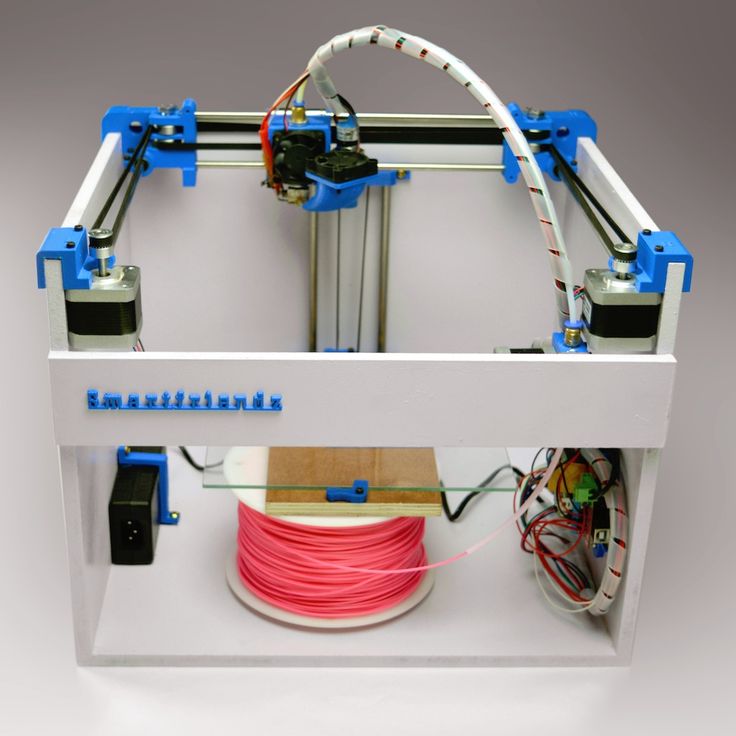

First off, you may think that the Trinus isn’t the largest printer you will find up for the offer. Don’t be fooled and do not underestimate this little machine because what it lacks in size it makes up for in build quality and its ability to just print and print very well. The 3D printer kit I received from Kodama was the standard base unit with no extras.

3D Printer Kit

(Image: Kodama)

1 x Trinus Control Board

1 x Enclosed Extruder Assembly

1 x Steel Extruder Mounting Plate

4 x Colour Coded Axis Modules

1x 3mm Steel Base Plate

1x 5mm Print Bed4 x Rubber Feet

2 x Z-Axis Motor Covers and all the necessary hardware needed to put it together.

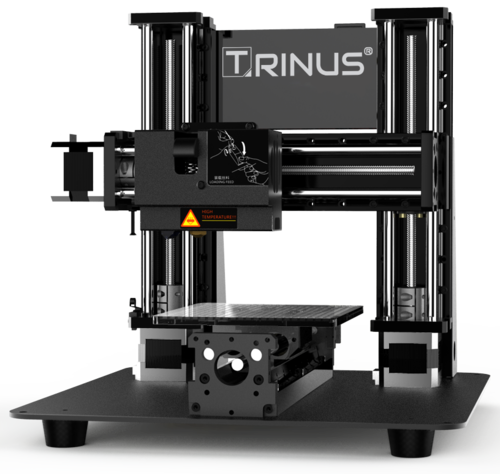

Kodama Trinus – Build Quality

As you can see from the picture above the Trinus is designed in a modular fashion. Each axis has its own module and apart from the Z-Axis that has two all have a unique colour assigned to make the assembly a breeze and effortless.

The board also has colour coded ports again making it easy and intuitive besides making a breeze to find a particular axis if you ever need to problem solve.

Let us look at these modules in more detail so you can see what you are getting when you order this kit. Each axis slider module consists of a machined body with 2 stainless steel smooth rods and an 8mm lead screw.

(Image: Kodama)

They all come pre-assembled with a Nema 17 stepper motor and a machined mounting carriage that rides on what I believe to be LM8UU bearings.

The lead screw is supported by a machined end cap that houses the guide bearing that seems to fit perfectly to the lead screw.

I say “seems” to fit because I have heard talk of some people having issues with the bearings coming loose although I haven’t had any issue personally.

As a reviewer, it is my job to provide you as much information as I have been able to find out about this printer.

Now following on from this look at the axis modules I can tell you that each of the 4 modules I received was as perfect as you could ask for. The powder coated/ anodized surface finish was flat and I saw no blemishes in the colouring.

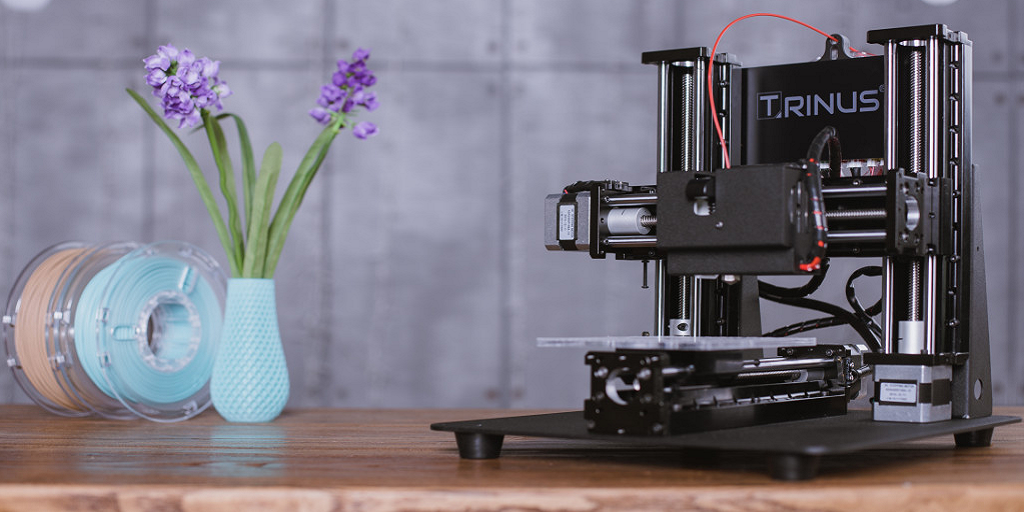

Quality and rigidity seems to be the main goal with the Trinus with less focus on flashy features and more focus on producing a small scale machine that is built like a tank.

Fully assembled the Kodama Trinus weighs around 40kg owing to the fact that not only are the axis modules solid machined they sit on a very solid 4mm plate of powder coated steel. From the base to the board the Trinus is built to last.

From the base to the board the Trinus is built to last.

Kodama Trinus – Setup and First Print

So after a pretty painless build process that you can find on my YouTube channel. I came to the setup and first print.

https://youtu.be/aHGrF8O-HIA

Reading and re-reading the Quick Start guide I was a bit skeptical about the instructions a really simple 3 step process.

I’ve built 3 printers at this point and none of them has been this simple something was telling me in the back of my mind that this sounded too good to be true. Oh, how wrong I was. I followed the instructions.

Plugged in – Check.

Lights Working – Check.

Load Filament – Check.

Insert SD Card – Check.

The double beeps sounded and the red indicator light to tell me the extruder was heating up started flashing. NO WAY!

After a few minutes, it went through the homing sequence and extruded a small amount of filament to purge the nozzle that I quickly had to grab still half in shock that it was really that simple. Then away it went printing its very first print.

Then away it went printing its very first print.

First impressions as it laid down the first layers of Royal Blue PLA goodness were very good. The layers looked even and consistent, it was at that point I noticed something strange.

Strange in a good way if any of you are reading this and familiar with FDM printing you will know that most slicers print a raft that normally follows the general shape of the model being printed but this was different.

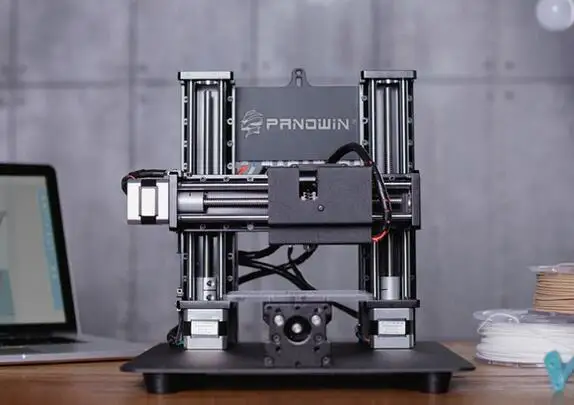

Kodama uses a slicing software called PangoWin and the software uses a hexagonal raft system that looks cool as hell. It builds hexagonal rafts that interlock with each other like honeycomb the same for the supports too. Hexagonal crystalline structures that barely touch the print surface and leave no residue or nasty gunk when you remove them.

Kodama Trinus – Print Quality

This was the result of that very first print and I should let this speak for itself but what kind of reviewer would I be if I did that. The file they had chosen to show off what the Trinus could do was a cute little Bulbasaur and I have to say I am very very happy with the results. As far as first prints go you couldn’t ask for more.

As far as first prints go you couldn’t ask for more.

(Photo: 3DPrintedAspie)

No calibration, no bed levelling, no glue/hair spray nothing that you normally have to do to get a print to stick to the bed. If you also take into account that the stock Trinus has a static bed with no adjustment options. No fancy 12 point probe levelling system no heated bed just a very well designed simple print surface that screws directly to the Y-Axis carriage mount.

I’d say the Trinus stacks up really well to its competitors who are few and far between in the same price range and you definitely won’t find one for the same price with the same level of build quality. I have looked.

(Photo: 3DPrintedAspie)

Ever since owning the Kodama Trinus it has been used to print almost non-stop with only a few minor errors that were no fault of the Trinus itself and more user errors. Mainly trying to print with specialised filaments without a heated bed that leads to the prints warping terribly and after realising my mistake a quick swap of the filament back to PLA and it was off and printing perfectly.

Now I don’t mean perfect in a sense that the Trinus prints perfect models without layer lines. I mean perfect in a sense that once you slice a file in Pango and send it to the Trinus it Beeps-Heats-Prints, every time without failure as of the time I wrote this review.

(Photo: 3DPrintedAspie)

Now I know a great many people will be turned off because of the size of this printer but if like me you just love watching a well-designed machine just doing what it was designed to do then the Trinus might just be the perfect printer for you.

Let me explain my reasoning for recommending this 3D printer to anyone that asks me about it.

The kit I have is a standard bare bones kit. Meaning no luxury features. No heated bed, no auto-levelling, no adjustable bed, no LCD screen and do you know what?

It doesn’t need any of those things to be an absolutely outstanding machine. Yes, it can be enhanced by adding such features as a heated bed or the LCD screen but it doesn’t “need” them to make it a great 3D printer.

(Photo: 3DPrintedAspie)

Kodama Trinus – Summary and Final Thoughts

To summarise the Kodama Trinus I’m going to ask a few questions I normally ask anyone who comes to me for advice on what printer to buy.

Q1) What is your budget?

Under £500 as a low-income family. Kodama has seen to this need as the Trinus base unit is £332.56 or $379.00 at the time of writing this review. Add-ons and extra modules can be bought such as a TFT screen, laser engraver, heated bed, levelling system, enclosure. They aren’t needed as I mentioned earlier as the base unit while limited to mostly PLA will handle prints without issue.

Q2) What do you want to use the 3D printer for?

To print my digital sculpts and toy prototypes. Is the Trinus suited to achieve this goal? Yes without question. It is my personal opinion that although limited by its size the Trinus build quality and print quality will compete with most printers on the market under the £/$1000 price bracket. In fact, it might even compete with a few £/$1000+ machines too.

In fact, it might even compete with a few £/$1000+ machines too.

Q3) How well do you know your way around basic everyday tools?

Personally, I am confident using hand tools you would find in most workshops. Again the Kodama Trinus 3D printer scores high on this aspect too. The modules fit together effortlessly and the module based design makes it an exceptionally easy build. I would go as far as to say that with a bit of guidance only due to the weight of the parts, The Trinus would be a perfect first kit for a child looking to get into 3D printing. (Testing with my children to follow at a later date)

Q4) Would I suggest the Kodama Trinus to others?

Yes, I would and I do on a regular basis. For me, it’s not about having the biggest machine on the block or the fastest or the most advanced. It’s about having a machine that will work when you want it to without a 10 step process of faffing and messing around. I would take a printer with no LCD that prints tethered or via SD card every time over a printer with a full-colour touch screen that only prints half the time.

Q5) Who would I recommend this printer for?

I would suggest this printer to anyone that is interested in the technology and want to get started in 3D printing. In fact, for the price and the quality of the Trinus, I would say that it would be a perfect addition to any workshop. Small enough to fit on or under a desk, even on a strong shelf. The print quality isn’t perfect but with some simple settings tweaks, it will print to a 0.3mm tolerance so even small mechanical prototypes can be achieved with little to no fussing. Add on an enclosure and heated bed and you upgrade it to be capable of printing a wider choice of materials.

Q6) What I didn’t like about the Trinus?

Honestly, nothing. It’s small perhaps but even that is a stretch.

STL Files:

Unicorn https://www.thingiverse.com/thing:2316291

Smiling Owl Pot https://www.thingiverse.com/thing:2125599

Kodama Tree https://www.thingiverse.com/thing:2243196

Pinkie and Brain https://www.thingiverse.com/SparkyFace5

High Poly Bulbasaur https://www. thingiverse.com/thing:1576163

thingiverse.com/thing:1576163

Source Links:

Trinus UK – https://eu.kodama3d.com/collections/trinus/products/trinus-3d-printer

Trinus US – https://us.kodama3d.com/collections/trinus/products/trinus-3d-printer

Twitter – https://twitter.com/3DPrintedAspie

Thingiverse – https://www.thingiverse.com/3DPrintedAspie

(Image: 3DPrintedAspie)

Up to 54% Off

Christmas Deals & Products from Popular Brands

Anycubic >>

Creality >>

Elegoo >>

Polymaker >>

Snapmaker >>

MoreLess

AUTHOR

3D Printed Aspie

I’m Ryan the 3D Printed Aspie I am a massive Geek, Nerd, Gamer, Maker, Builder, Tinkerer and I want to share my knowledge with you all. I am formally trained and have a degree in Computer Games Design but my passion was always creating Characters and Models in 3D. Twitter: @3DPrintedAspie

2 postsTRINUS - modular DIY 3D printer

- home

- Blogs nine0004

- TRINUS - Modular DIY 3D Printer

The original modular 3D printer was developed by Californian engineers. TRINUS comes as a 11-piece DIY kit – according to the authors of the novelty, even an inexperienced user can assemble the device in just 30 minutes.

Home 3D printer is in no way inferior to professional counterparts in terms of its characteristics. TRINUS is made of high-quality materials that provide excellent 3D printing accuracy, while the novelty does not require frequent calibration - it is enough to adjust the system before the first use.

The maximum print speed of the new 3D printer is 150 mm/sec, while the minimum thickness of the applied layer is 50 microns. In addition, TRINUS has interchangeable heads - for example, in just 60 seconds, the user can turn the printer into a laser engraver. In the future, the developers plan to equip the device with additional features. The 3D printer works with almost all modern materials, including PLA, ABS, wood, aluminum and bronze. nine0011

Another DIY 3D printer was recently introduced by a Luxembourg startup. TRIUM DELTA has a simple design and a minimum number of elements.

Articles, Articles

Tags: 3d printer , engraver , trium delta , diy kit , news

Other posts from blogerMG

- Wiring in the garage: connection options, wiring diagrams, installation 0

- Nozzles, tools and accessories for an electric drill 0 nine0004

- Tool overview.

Renovator 0

Renovator 0 - How to seal a thread or how to choose the perfect sealant 0 nine0007 Mechanic lessons. Extend the life of your wrench 0

No matter how rich the experience of a specialist, and no matter how confident he is, sometimes he needs to consult with someone. Communication on the Internet has long become familiar to us. A variety of netizens - be it a professional or a highly knowledgeable amateur - can post life hacks (simple useful tips on various topics) that can be usefully applied to your home. nine0011

Communication on the Internet has long become familiar to us. A variety of netizens - be it a professional or a highly knowledgeable amateur - can post life hacks (simple useful tips on various topics) that can be usefully applied to your home. nine0011

What are the benefits of using forum resources?

- A constant stream of interesting information about new building ideas.

- Simple and useful tips for building.

- Opportunity to communicate with interesting people, experienced craftsmen.

- Advice on the choice of tools or materials.

- Also a nice plus is the lack of advertising, because users are the same consumers as you are. nine0004

Our forum contains all the latest construction news, because our specialists always keep abreast of construction events. Here you will find useful information for the operation of the premises, equipment and so on. Many consider it useful to do more for the house with their own hands, because it is good for health, economically profitable, and provides some moral comfort. And the logical question arises: “How to do it yourself?” Answers can be obtained by looking through our website. It is after visiting this forum that you will fully experience all the pluses. On this Internet resource you will find information for arranging a cottage with your own hands. But many of those recommendations can be taken into account when arranging an apartment. For the implementation of household projects of various sizes, inventory is needed. For general consultation of site visitors, an overview of tools is created, where information is presented simply and clearly. nine0012

Many consider it useful to do more for the house with their own hands, because it is good for health, economically profitable, and provides some moral comfort. And the logical question arises: “How to do it yourself?” Answers can be obtained by looking through our website. It is after visiting this forum that you will fully experience all the pluses. On this Internet resource you will find information for arranging a cottage with your own hands. But many of those recommendations can be taken into account when arranging an apartment. For the implementation of household projects of various sizes, inventory is needed. For general consultation of site visitors, an overview of tools is created, where information is presented simply and clearly. nine0012

3D printers - Page 17 of 41

Is bioprinting possible with plant cells? Perspectives and methods

3D printing, 3D printersAuthor: Anna TextOk

Is bioprinting possible with plant cells? Prospects and Methods The introduction of 3D printing into various fields of activity has contributed to the fact that innovative technologies have been used in the most unexpected, at first glance, aspects. Today, with the help of 3D Print, you can print living biocells, create tissues and entire organs. Most often, animal biocells are used for bioprinting. Plant tissue is used very rarely, ...

Today, with the help of 3D Print, you can print living biocells, create tissues and entire organs. Most often, animal biocells are used for bioprinting. Plant tissue is used very rarely, ...

NEVA Delta Printer available for $349

3D Printer News affordable NEVA devices based on the delta robot principle. This device differs from any other devices for three-dimensional printing by the simplest control, which is carried out using just one power button. Using the same control, you can launch, ...

Laser engraving on leather

3D printing, 3D printers, CNC machinesAuthor: Anna TextOk

3D printed weapons seized in the Swedish city of Malmo

3D printing, 3D printersAuthor: Anna TextOk

3D printed weapons seized in the Swedish city of Malmo purposes. Additive manufacturing allows not only to produce high-quality products for various purposes, but also helps to realize creative ideas. Unfortunately, attackers can also take advantage of 3D printing, and the more affordable the equipment for the masses, the…

Additive manufacturing allows not only to produce high-quality products for various purposes, but also helps to realize creative ideas. Unfortunately, attackers can also take advantage of 3D printing, and the more affordable the equipment for the masses, the…

WinSun revolutionized construction 3D printing

3D printing, 3D printersAuthor: Anna TextOk

WinSun revolutionized construction 3D printing complex architecture. They can do today what we only read about a couple of years ago in science fiction novels and at the same time their work has an affordable price. The Chinese company WinSun is the specialists who managed to supply…

Cura 2.6 slicer beta released

3D printing, 3D printers, 3D printer softwareAuthor: Anna TextOk

Cura 2.6 slicer beta released which came out as 2.6. So far, the program is presented as a beta version and its creators ask users to send feedback and comments regarding stability and functionality. What's new in Cura 2.6? The program is now installed in a separate folder, which saves ...

What's new in Cura 2.6? The program is now installed in a separate folder, which saves ...

Fashion and medicine: 3D corset will save you from scoliosis!

3D printing, 3D printersAuthor: Anna TextOk

Fashion and medicine: 3D corset will save you from scoliosis! The world-famous company UNYQ, which develops and creates high-quality prostheses, has announced the creation of a supporting corset for patients with scoliosis, printed on a 3D Printer. Soon, according to the company's specialists, the 3D corset will appear before the eyes of the public at the Smithsonian Museum of Innovative Design Projects, which displays other equally interesting exhibits from ...

How 3D scanning helps save one of the world's oldest ships

3D printing, 3D printersAuthor: Victoria

How 3D scanning helps save one of the world's oldest ships Auckland, is diligently committed to preserving New Zealand's history through digital scanning and modeling. She's doing her next project, and it's going to be a huge project. Using 3D scanning technology, the team digitally preserves what may very well be the oldest…

She's doing her next project, and it's going to be a huge project. Using 3D scanning technology, the team digitally preserves what may very well be the oldest…

Kodama accepts orders for Obsidian 3D printers under $100

3D Printers, 3D Printer NewsBy Victoria

Kodama accepts orders for Obsidian 3D printers under $100 We already reported a breakthrough last year , which Kodama has implemented with its Trinus multi-functional machine, is a metal 3D printer that not only provides high-precision 3D printing, but can also turn into a laser engraver in just 60 seconds through the use of interchangeable parts.…

Erasable ink for 3D printing

3D printing, 3D printersAuthor: Anna TextOk

Erasable ink for 3D printing Discoveries in this industry occur, if not daily, then certainly very often. For example, not so long ago, scientists from the famous Institute of Technology - Karlsruhe pleased the world with a new discovery.