3D printer facts

Check out these 17 outstanding 3D printing facts

Posted By Lucie Gaget on Oct 30, 2019 |

You may already use 3D printing but here are some great facts you may not know about 3D printing. Indeed, as a 3D printing service, we can see every day that people have misconceptions about this cutting-edge technology! That is why we made this article for you, about the incredible and diverse applications of additive manufacturing, showing you the full potential of this technology.

Are you ready to see what 3D printing can produce? Discover some amazing 3D printing facts and get inspired to give life to your own 3D printing projects!

3D printing is older than you think

Additive manufacturing is often seen as a really new manufacturing technique. But this technology is actually not that new. We can say that 3D printing made kind of a buzz in the 2000s when the general public discovered FDM (Fused Deposition Modeling) technology and nylon filament. But the birth of additive manufacturing is way older than that! First 3D printing experiments and patents appeared in the ’80s

3D printing is a French invention

Indeed, the creation of 3D printing kind of started in France. Jean-Claude André, Alain le Méhauté and Olivier de Witte registered the first patent for this game-changing technology in 1984, but everything didn’t go as expected, and we often credit the American Charles Hull for this innovation. To read the full story, check out our interview with Jean-Claude André, one of the 3D printing creators.

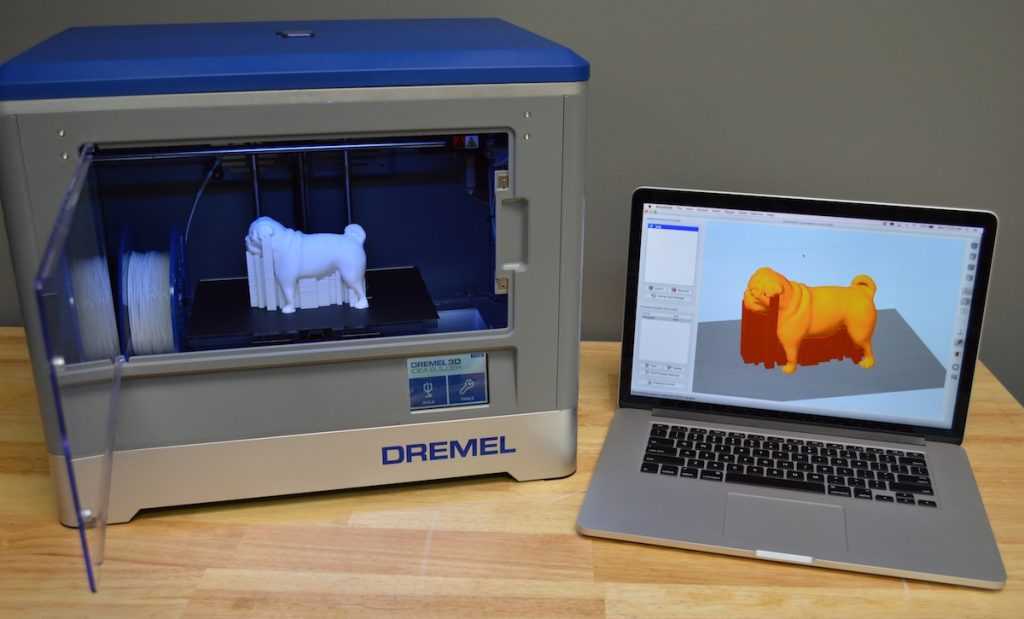

There are numerous 3D printing techniques

People often associate 3D printing with FDM technology and desktop 3D printers, but there are actually various types of 3D printing processes. But that is not the only 3D printing technology. As you can see on our online 3D printing service, we are offering multiple technologies such as SLS (Selective Laser Sintering), HP Multi Jet Fusion, DMLS (Direct Metal Laser Sintering), SLM (Selective Laser Melting), DLS (CLIP), etc.

From plastic to metal and resin, there are different 3D printing processes and even more 3D printing materials available on the market.

3D printing is not only a prototyping technique

3D printing is mainly seen as a prototyping technique. And indeed, it is a very good way to make some rapid prototyping and create functional prototypes, but not only! Additive manufacturing is more and more used for production. Each year, we study the evolution of the uses of additive manufacturing by companies, with the biggest report of the additive manufacturing industry, the State of 3D Printing.

In this report we can notice that year after year, 3D printing is used for more and more different applications by companies. And we can clearly see that a growing 51% of respondents apply 3D Printing technologies for production. This technology is actually more and more used for production purposes!

3D printing materials are more numerous that what you think

We just told you about the numerous 3D printing techniques actually available in the industry. But the industry is also flourishing on the material side. If plastic, metal, and resin, are offering great opportunities. Researchers are developing new material, so this technology can answer all needs possible. 3D printed wood, ceramics or 3D printed meat. Yes, materials possibilities are endless.

But the industry is also flourishing on the material side. If plastic, metal, and resin, are offering great opportunities. Researchers are developing new material, so this technology can answer all needs possible. 3D printed wood, ceramics or 3D printed meat. Yes, materials possibilities are endless.

Additive manufacturing saves lives

3D printing is taking more and more space in the medical industry. This manufacturing technique is actually helping surgeons and doctors in their daily job. That is why we can say that 3D printing is helping to save lives on different levels.

Applications of additive manufacturing in the medical sector are numerous. 3D printing is making it possible to create perfectly adapted devices: from casts to prosthetics. But it also becomes possible to make implants, adapted tools for surgeons, and to print a 3D model to prepare a complex surgery. Indeed, it is becoming common in hospitals to 3D print models of kidneys or hearts and prepare some complex surgeries.

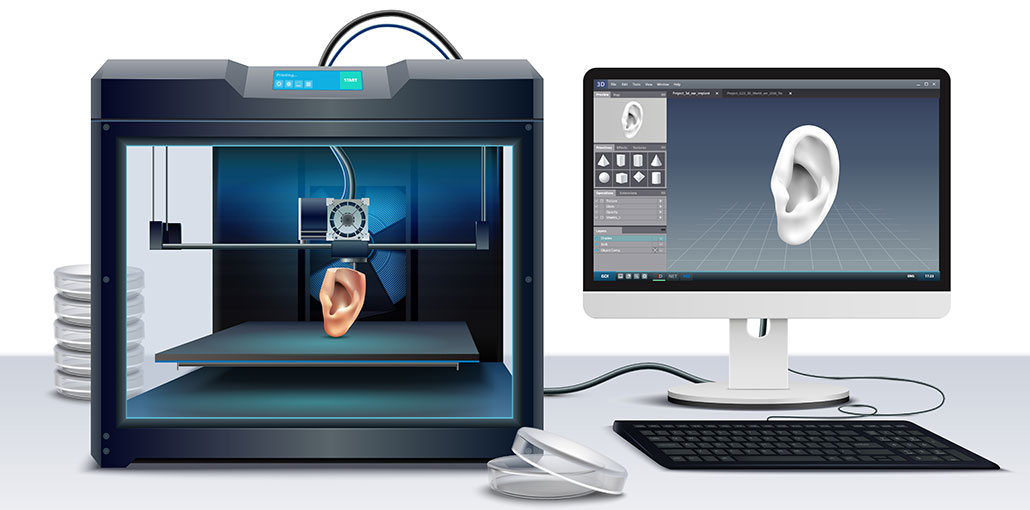

It is possible to print living tissues

Here is an outstanding material that is now 3D printable: Living tissue, or organ parts. It is a kind of part of the new experiments made in the medical industry to save lives.

3D Bioprinting allows creating various tissue structures, such as kidney tissue or skin tissue. Even blood vessels and bones are now becoming 3D printable using this technology. This is definitely offering new possibilities in terms of tissue engineering and regenerative medicine

Another benefit of this great bioprinting technology to create living tissues: it is a great way for medical researchers to make laboratory tests. For example, instead of testing on animals, it is becoming possible to test directly on human tissue or organs as these prints have the exact same properties and reactions.

3D printing is not only possible on earth

Additive manufacturing is not only dedicated to use on earth, and astronauts know it! This game-changing technology is offering great advantages in space, but which ones? 3D printing in space can be used for several projects from creating adapted tools to a 3D printed habitat to live on Mars, or on the Moon. Additive manufacturing and 3D printing without gravity are actually offering brand new possibilities.

Additive manufacturing and 3D printing without gravity are actually offering brand new possibilities.

You can lower your costs using 3D printing

People often see 3D printing as an expensive manufacturing technique, but it could actually help you lower your costs by accelerating your product development. As you know, in business, time is money. Using additive manufacturing is a great way to reduce costs and save time. It can help you with prototyping as it is faster and cheaper than many traditional processes. You only need to create a 3D model of your idea to print it.

3D printing can help to build houses

Additive manufacturing is also helping to build at an architectural scale! The first big advantage of this manufacturing technique for architecture is that it saves time. 3D Printing in the construction industry means reduced production time. Indeed, machines themselves are very fast, some of them are capable of manufacturing a 600 to 800-square-foot (55 to 75-square-meters) home in just 24 hours.

Additive manufacturing is really seen as a new way to create affordable housing. This new construction method can be used for social housing, but also to face the housing shortage in developing countries. But this technology actually offers possibilities for a large variety of architectural projects and buildings.

Are you ready to live inside a 3D printed home?

You can wear 3D printed parts

Clothes, shoes, jewelry, bags, glasses, watches, all of these elements can be 3D printed! Indeed 3D printed fashion is now a real thing.

Additive manufacturing is widely used by sneaker brands: Nike, Adidas, New Balance, or Reebok to name a few, major brands have tried it out with varying degrees of success. 3D printed glasses are also becoming a big thing. In the eyewear industry, this technology has been used more and more to create 3D printed glasses since it opens a broad range of possibilities to create 3D printed glasses frames totally custom-made.

Optimization of production processes, cost optimization (storage with on-demand printing, manufacturing as there are no material scraps, but also for prototyping …), customization possibilities or creation of complex shapes… 3D printing opens new creative fields for the fashion industry.

3D printing can improve your tooling process

When talking about the benefits of 3D technology, improving a tooling process is certainly not the first that comes to our mind. If your manufacturing process can be improved by a better prototyping or production process thanks to 3D printing, that is not all. Additive manufacturing can help you create tools perfectly adapted to your work.

This technology allows customizations. Surgeons, doctors, are more and more making the most of this technology to create tools adapted to their job, making them more convenient for their use. We had an example on our blog with Marc Soubeyrand. This surgeon is using 3D printing to create his own tools with plastic materials for orthopedic surgeries!

3D printing tools can also be a great way for your business to save money. For example, Volkswagen Autoeuropa, the car manufacturer, is using 3D printing to manufacture some of its tools. The company estimates that thanks to 3D printing they saved 250,000€ in 2017. Reducing your tooling investment thanks to 3D printing could be the perfect solution.

For example, Volkswagen Autoeuropa, the car manufacturer, is using 3D printing to manufacture some of its tools. The company estimates that thanks to 3D printing they saved 250,000€ in 2017. Reducing your tooling investment thanks to 3D printing could be the perfect solution.

3D printing might be part of your favorite movie

A lot of movies now have 3D printed parts in it, the film industry is obviously making the most of all the advantages of additive manufacturing! It can be used to work on the designs of monsters or creatures or to directly manufacture props. You might not know it, but Iron Man’s suit is 3D printed, stormtroopers in Star Wars movies also have some 3D printed parts. 3D printing can also be used in animation film to create 3D printed parts and universes.

In the Black Panther movie, 3D printing actually helped to push the limits of design to create Queen Ramonda’s look, by mixing traditional African culture together with new-age technology.

Marvel Studios’ BLACK PANTHER to R: Shuri (Letitia Wright) and Ramonda (Angela Bassett)Ph: Matt Kennedy©Marvel Studios 2018

Mass-production is possible with additive manufacturing

Additive manufacturing can be used for production, yes, we just saw that. But do you know that this technology can go even further and can also be used for mass-production? Mass producing goods is no longer a problem for 3D technology, and mass manufacturers are already using it. Companies such as Airbus are seeing the full potential of additive manufacturing to mass-produce parts!

You can 3D print food

Do you know that even food is 3D printable? It is already possible to 3D print steaks and vegan steaks. Moreover, the chocolate 3D printer will be the perfect investment for your next Easter.

Regarding meat 3D printing, Giuseppe Scionti, an Italian bioengineer worked on some bioprinting projects, such as creating synthetic tissues, like artificial corneas and 3D printed artificial skin. As you can imagine, working on regenerative medicine can definitely help to recreate meat products. This Italian scientist is on his way to find a way to produce meat and help reduce greenhouse gas emissions from livestock, at the same time.

As you can imagine, working on regenerative medicine can definitely help to recreate meat products. This Italian scientist is on his way to find a way to produce meat and help reduce greenhouse gas emissions from livestock, at the same time.

Chocolate 3D printing is also becoming quite interesting for chefs working in pastry. 3D printers are actually helping them create chocolate designs that are complicated to achieve only using hands.

Actually, you can 3D print anything… even a 3D printer

Everything is 3D printable, even 3D printers! You could 3D print a 3D printer by yourself. Some self-replicating 3D printers are already available on the market. But, these types of 3D printers can’t do the whole job themselves, there is still some assembly that can’t be done automatically. And there are still a few parts of a 3D printer that can’t be 3D printed, such as electronic components. So you can 3D print a 3D printer, but not totally for now.

This also stands for plastic 3D printing only. Other types of 3D printers such as metal 3D printers, a liquid resin or ceramic 3D printing can’t be 3D printed!

Other types of 3D printers such as metal 3D printers, a liquid resin or ceramic 3D printing can’t be 3D printed!

The first self-replicating 3D printer was invented by Dr. Adrian Bowyer through the RepRap project and was unveiled in 2008.

4D printing is on its way!

You read it right. 4D printing technology might be the next revolution. But what is 4D printing exactly, how is this different from 3D printing? 4D Printing is referred to as 3D printing transforming over time. For these objects, a fourth dimension is added: time. The big breakthrough about 4D printing over 3D printing technology is its ability to change shape over time.

Are you ready to get 4D printed projects?

Applications of 3D printing are numerous, as you can see. Have you discovered some interesting 3D printing facts in this blog post? Share your discoveries with us. Are you ready to use 3D printing for your own projects?

Try to upload your 3D file on our online 3D printing service and get your 3D objects in a few days. As we just saw, this technology could help you improve both prototyping and production processes, but could also help you go through brand new challenges.

As we just saw, this technology could help you improve both prototyping and production processes, but could also help you go through brand new challenges.

8 Interesting Facts about 3D Printing | 3D Printing Blog

8 Interesting Facts about 3D Printing

by Billy | August 27, 2014

Everyone seems to have heard some stories about 3D printing already. But there’s are still some exciting facts about 3D printing that you probably didn’t know about so far. So sit back, relax, and let us present 8 basic but important facts about 3D printing you haven’t heard of before!

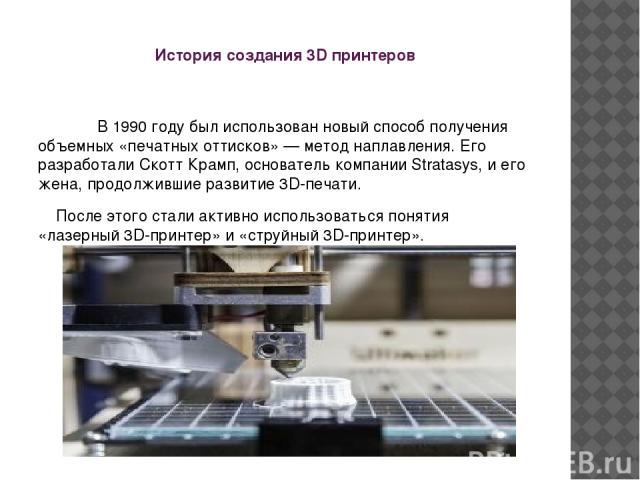

1. 3D Printing Started in the ‘80s.

Yepp, 3D printing is onlder than you might think. In fact, 3D printing has its roots in the 1980s. In 1984, Chuck Hull, invented a process called “stereolithography” which used UV lasers to solidify photopolymer that created 3D parts layer by layer. In 1985, Materialise CEO Fried Vancraen was a young man making his own non-computer “FDM” models. Five years later, he founded Materialise, one of the first 3D printing companies.

Five years later, he founded Materialise, one of the first 3D printing companies.

In 1985, our CEO was invited to meet his girlfriends’ parents. He created a statue of his birdwatching girlfriend and her dog using FDM (Fumbling Deposition Modeling.) This non-computer technique preceeded 3D printing.

2. 3D printing was primarily used for prototyping, but is now being used for production-ready pieces.Taking its roots in manufacturing, 3D printing was primarily used for prototyping products. In fact, large corporations continue to use rapid prototyping to save millions of dollars. For example, Ford is currently using 3D printing to make large selections of its car parts for testing. According to Ford, the company can save up to $493,000 a month of work with this production method.

Getting back to the point though, 3D Printing is increasingly being used to create finished projects. Since 2003, our friends at .MGX by Materialise have been working together with top designers to create lamps and other design objects – objects that are now included in the permanent collections of Museums and art galleries worldwide.

And now, we see that designers and individuals worldwide are also turning to 3D printing to bring their own creations to life, both for personal use and for the enjoyment of others.

3. 3D printers print a model in layersAdditive manufacturing works a lot like your inkjet printer at home. The ink jet printer puts a single layer of ink on top of the page in order to get the job done, while a 3D printer adds new layers on top of each layer before it, until the object is completed. Check out 3D printing in action via the video below:

Because of this layer-by-layer printing process, an escape hole is usually necessary to properly print and clean your models. For more basic 3D printing tips, click here!

For more basic 3D printing tips, click here!

4. You can already print in titanium, ceramics, wood, etc!

Now this 3D printing fact might be surprising: pretty much anything can already be 3D printed. Since the 80s, many new materials for 3D printing have entered the market, including gold, silver, titanium, wood, and ceramics. And these materials are not limited to an elite of industrial giants. Each and everyone can upload 3D designs to online 3D printing services like i.materialise and receive these kind of prints.

Over the last year alone we have seen 3D printed houses, drones, dresses, jewelry and table wear being printed. You might have heard about 3D printed prosthetics used to treat wounded soldiers, or seen the 3D printed race car that now rests in the lobby of i.materialise/Materialise’s HQ!

3D printing in wood is possible: the ‘Hexa-Phone Amplifier’ by James Novak

5. 3D printing can lower production costs.

Traditional manufacturing models require a lot of upfront costs, storage fees and uncertainty from investors. Machines have to be set up, space rented, and fingers crossed that the manufactured product sells. 3D printing takes a more fluid approach: you can print orders on-demand. If you’re a maker or an entrepreneur trying to get a small business off the ground, this can home in handy. The additive process wastes very little material, and you can print as the orders come in. This makes it less financially risky and translates into a low cost of production.

Machines have to be set up, space rented, and fingers crossed that the manufactured product sells. 3D printing takes a more fluid approach: you can print orders on-demand. If you’re a maker or an entrepreneur trying to get a small business off the ground, this can home in handy. The additive process wastes very little material, and you can print as the orders come in. This makes it less financially risky and translates into a low cost of production.

For instance read more about how 3D printed footwear is taking over racetrack and runways.

3D printed rubber-like shoes. Many shoe companies now use 3D printing.

6. 3D printing is in the movies you watch.

3D printing fun fact: 3D printers are already being used for movies. Props can take hours of hard work to create and apply. With 3D printing, many of those props can be created and re-created faster, easier, and without starting from scratch. 3D printing techniques have been featured in movies such as IronMan, The Hobbit, Jurassic Park, Avatar, The Muppets, Terminator Salvation, Real Steel, Paranorman, The Avengers and Paranorman.

7. 3D printing is launching into space.

NASA researches are currently working on figuring out how to bring 3D printing technology to space. The idea is to send robots ahead of astronauts to construct buildings and infrastructure on lunar surfaces. We’ve also compiled a list of interesting 3D printing facts & figures of NASA-driven projects in this blog post.

8. 3D printing is being used for education.

3D printing is a growing training area in schools, and is also being used to integrate students with disabilities in programs that has traditionally excluded them (and often still does.) Personalized, 3d printed medical solutions can empower a person with arm injuries to become a musician, a person without legs to play soccer, and students who are blind to “see” microscope slides.

For younger students, art, design, entrepreneurship and engineering are unlocked with increasingly simple 3D modeling tools. These tools empower children to turn their ideas into objects they can hold. As the expansion of 3D printing in schools continues, so will the growth of the next generation of entrepreneurs, artists, designers and makers raised on 3D printing. The first community college in Texas is now offering 3D printing classes this fall and educational programs are available for those wanting to introduce the biomedical applications of this technology into their curriculums.

As the expansion of 3D printing in schools continues, so will the growth of the next generation of entrepreneurs, artists, designers and makers raised on 3D printing. The first community college in Texas is now offering 3D printing classes this fall and educational programs are available for those wanting to introduce the biomedical applications of this technology into their curriculums.

This is an example of a 3D printed “tactile learning object,” made to be used by students who are blind and studying STEM fields.

Would you like to be part of the future and create your own 3D prints as well? It’s easy to get started now. We’ve put together a list of good 3D modeling tools for your first projects. Once you have a 3D file, you can upload it here and we’ll print it on industrial high quality printers for you – in more than 18 different materials.

20 fun facts about 3D printing

Zefirka > Science and technology > 20 fun facts about 3D printing

Having appeared relatively recently, 3D printing has burst into the most diverse areas of human life, pushing the horizons of possibilities. Medicine, cooking, space - this is not a complete list of industries where 3D printers can successfully work. And experts are sure that this is only the beginning of a long journey of 3D printing.

Medicine, cooking, space - this is not a complete list of industries where 3D printers can successfully work. And experts are sure that this is only the beginning of a long journey of 3D printing.

1.

3D printing will become more and more affordable

Printers are getting cheaper.

Today, a small 3D printer can be purchased for $1,375. Printers are getting cheaper every year.

2.

It's hard to believe, but the history of 3D printing began in the 1980s

Stereolithography.

It all started with stereolithography technology in 1984, which used UV lasers to harden a photopolymer to create 3D objects layer by layer. The process was invented by Chuck Hill. nine0003

3.

Artificial organs are already being created with this technology

Ear prostheses.

For example, for babies who, due to genetic defects, were born without ears, prosthetic ears are printed precisely on 3D printers.

4.

Things are printed layer by layer

The printing process is similar to printing on a conventional printer.

The printing process itself is somewhat similar to printing an image on a regular home or office printer, but one layer of ink is applied there, and the 3D printer adds more and more material in layers. nine0003

5.

Many materials can already be printed.

Ceramic, wood, titanium and gold.

Including ceramics, wood, titanium and gold. In fact, you can print anything dresses, prosthetics, houses, drones, bicycles, cars and much more...

6.

Nokia Lumia 820 case was printed

Case printout.

The Makerbot printer took less than a day to complete.

7.

3D printing is used to create unusual weapons

Tiny weapons.

Experts say a 3D printer could make a weapon so tiny that it would be very difficult to detect.

8.

Someday it will be possible to print people

Human organs.

Scientists already know how to print human organs, skin, bones, any tissue. Therefore, it is not surprising that some suggest that soon it will be possible to print the whole person. nine0003

9.

Micro and nano structures can be printed.

Small structures. The

3D printer can create very small structures that are about the thickness of a human hair.

10.

Production costs will soon be reduced due to advances in technology

Fewer materials and virtually no waste.

The release of any product requires a lot of money literally at every stage of the production chain. 3D printing allows you to make products to order, according to current requirements. It's ideal for small businesses - fewer materials are required and there is virtually no waste. nine0003

11.

Any house can turn into a factory

Home factory.

Everything that used to be made only in factories can now be made right at home: toys, guitars, ceramics, bicycles …

12.

The technology is already used in films

Props for filming.

Thanks to 3D printing, making props for filming has become much easier and faster than before. For example, 3D printed products can be seen in films such as Iron Man, The Hobbit, Jurassic Park, Avatar, Terminator, Real Steel, Paranorman and The Avengers. nine0003

13.

Products will become cheaper

Due to the development of 3D printing, the prices of many goods will fall.

In fact, with the development of 3D printing, prices for many products will fall. There will be no costs for logistics, human and machine labor (of course, with the exception of the work of the 3D printers themselves).

14.

Technology will go into space

Robots instead of people.

It is planned to send robots to the Moon instead of humans to build infrastructure on the surface of the Earth satellite. nine0003

nine0003

15.

3D printers can work in conjunction with tomographs to produce a tumor clone for medical examination.

Examine the tumor before surgery.

If the tumor is examined before surgery, it will be easier to remove.

16.

NASA will use lunar dust to print the moon base

lunar dust to make duplicates.

This same technology is already being used by astronauts to repair or duplicate broken equipment. nine0003

17.

Technology already applied to education

3D modeling will enable young students to realize their original ideas.

Students with disabilities now have the chance to get a comprehensive education like everyone else and maybe become musicians, engineers or doctors. 3D modeling will allow young students to realize their original ideas.

18.

Model Dita Von Teese is the first star to wear a 3D printed dress

3D printed dress.

The dress consisted of 3000 parts and favorably emphasized Dita's magnificent forms.

19.

HP is going to release

HP and 3D printers.

A company made famous by conventional printers is testing a new 3D printer and is about to launch it on the market soon.

20.

3D printing has revolutionized and people still don't understand its full potential

Press the button you will get the result.

Technology can change literally everything. After all, it will not be necessary to spend a lot of effort and money to get what you want, but it will be enough just to press a button.

Source: www.novate.ru

Science and Technology February 9, 2016 13 064 views

Interesting facts about 3D printing and 3D printers - 3DDevice

Interesting facts about 3D printing and 3D printers

3D printing technology is very versatile and often used for quite unusual purposes. Of course, this leads to interesting results that attract a lot of attention. But all events cannot be covered, and some achievements remain behind the scenes. We believe that this is wrong and in this section we want to list interesting facts about 3D printing that you may not have known. We will tell you about something that goes beyond the usual applications of 3D printing, but, nevertheless, is of great practical value. nine0003

Of course, this leads to interesting results that attract a lot of attention. But all events cannot be covered, and some achievements remain behind the scenes. We believe that this is wrong and in this section we want to list interesting facts about 3D printing that you may not have known. We will tell you about something that goes beyond the usual applications of 3D printing, but, nevertheless, is of great practical value. nine0003

Interesting facts about 3D printing

Let's start with some interesting facts about 3D printing. Of course, many more points can be attributed here. It all depends on the awareness of people. Indeed, today everyone already knows that with the help of a 3D bioprinter it is possible to create artificial organs and living tissues, as well as a lot of other similar information. Therefore, we have chosen revolutionary techniques that are only gaining popularity and are of particular interest and value in certain circles. nine0003

1. 3D printed all-in-one pills

In the US, 3D printed pills for epilepsy can already be found in pharmacies. And scientists do not intend to stop at the production of only one drug. Currently, new methods for 3D printing of medicines are being developed, and researchers pay special attention to SLA technology. The main advantage of using 3D printing for this purpose is the possibility of gradual release of active substances. That is, such a tablet can be programmed for sequential dissolution over a certain time. If you need to take several different medications a day, this can be a real breakthrough in treatment. nine0003

And scientists do not intend to stop at the production of only one drug. Currently, new methods for 3D printing of medicines are being developed, and researchers pay special attention to SLA technology. The main advantage of using 3D printing for this purpose is the possibility of gradual release of active substances. That is, such a tablet can be programmed for sequential dissolution over a certain time. If you need to take several different medications a day, this can be a real breakthrough in treatment. nine0003

2. 3D food printing

You probably already know about this, but this fact is worth talking about in more detail. To date, this branch of 3D technology is not too developed, but progress is moving forward rapidly. There are already several 3D printed food restaurants operating around the world, and some culinary specialists are using 3D printing to bring their creative ideas to life. On top of that, 3D printed products represent a real possibility for astronauts. Indeed, with the help of 3D printing, it is possible to endow food with the maximum amount of useful substances and serve it in the most convenient way. nine0003

Indeed, with the help of 3D printing, it is possible to endow food with the maximum amount of useful substances and serve it in the most convenient way. nine0003

3. 3D printing of living tissues

Interesting facts about 3D printing are simply unthinkable without this item. 3D bioprinting is a real panacea in the world of medicine. With its help, scientists intend to create full-fledged living tissues suitable for implantation into the human body. Experiments are now being actively conducted on the manufacture of artificial organs, bones, blood vessels and even hair using living cells. And such initiatives are extremely successful! Of course, mass 3D printing of full-fledged organs is still a long way off, but we are definitely moving in the right direction. nine0003

4. Space

3D printing promises to be a major technology in space. With its help, people will not only conquer the expanses of the universe, but also explore new territories. 3D printing is used to produce parts for rockets, satellites and other spacecraft, and the ISS even has its own 3D printer that works in zero gravity. Moreover, 3D printing is being considered as a potential technology for creating human settlements on the Moon and Mars. Who knows how far 3D technology will take us. nine0003

Moreover, 3D printing is being considered as a potential technology for creating human settlements on the Moon and Mars. Who knows how far 3D technology will take us. nine0003

Also don't miss:

Interesting facts about 3D printers

The facts about 3D printing don't stop there, but we decided to highlight some of them in a separate paragraph. Here we will write interesting facts about 3D printers that you might not know.

1. Industrial robots-manipulators

This approach is increasingly used in production: industrial robots-manipulators adapted for 3D printing are used as 3D printers. This is interesting primarily because the construction area in such cases is practically not limited by either the dimensions or the X, Y, Z axes. Some companies are even touting the approach as "5D printing" while the work platform is also in motion. And recently, a presentation of the concept of a 3D printer with six axes took place, which allows printing products without supports. nine0003

nine0003

2. 3D printer tattoo machine

Tattoo artists immediately noticed the possibilities of 3D printing and decided to use it for their own purposes. Today, there are several projects for the use of 3D printers as tattoo machines at once, and their results are quite successful. Needless to say, such an application is extremely specific and is unlikely to be widely used. But the idea is interesting.

3. Huge 3D printers and smartphone printers

3D printing technology is more extreme than ever. This is due to the huge functionality of the technique, which allows it to be applied in a variety of directions. 3D printers print houses, huge metal structures and other large-scale structures. But in parallel with this, the developers also take care of the production of smaller parts. So, the whole world is waiting for a 3D printer for smartphones, the concept of which rocked Kickstarter some time ago. And scientists print microscopic structures and full-fledged electronics, giving odds to professional manufacturers.