Cost to run 3d printer

How Much Does It Cost To Run A 3d Printer At Home? – Home 3d Prints

Running a 3d printer at home does cost you some money. There is the cost of electricity to run the machine, and there’s the cost of the material being used to produce the model. For some printers, there’s other consumables, like paper towels, isopropyl alcohol or other cleaners and rubber gloves. Plus, there’s a bunch of up-front costs, like the printer itself and any accessories and tools that you use.

All in, a 3d printer can cost as much as $12.00USD per day in consumable materials (that’s including the plastic or resin to make the model you’re printing). If you aren’t printing 100% of the time during a day, then the price falls below that. Operating a printer for 8 hours may only cost $4.00 to $5.00USD for the working day.

DLP resin printers have different operating costs to FDM filament printers. Let’s have a look at the differences so that you can understand the costs of printing objects at home.

Many 3d prints that you do are going to be running for eight hours or more. It’s even common with FDM filament printers to have a print that will take two or even three days to complete. That means that on some of your printing days, you’re actually running the printer for the entire 24 hour period with no break.

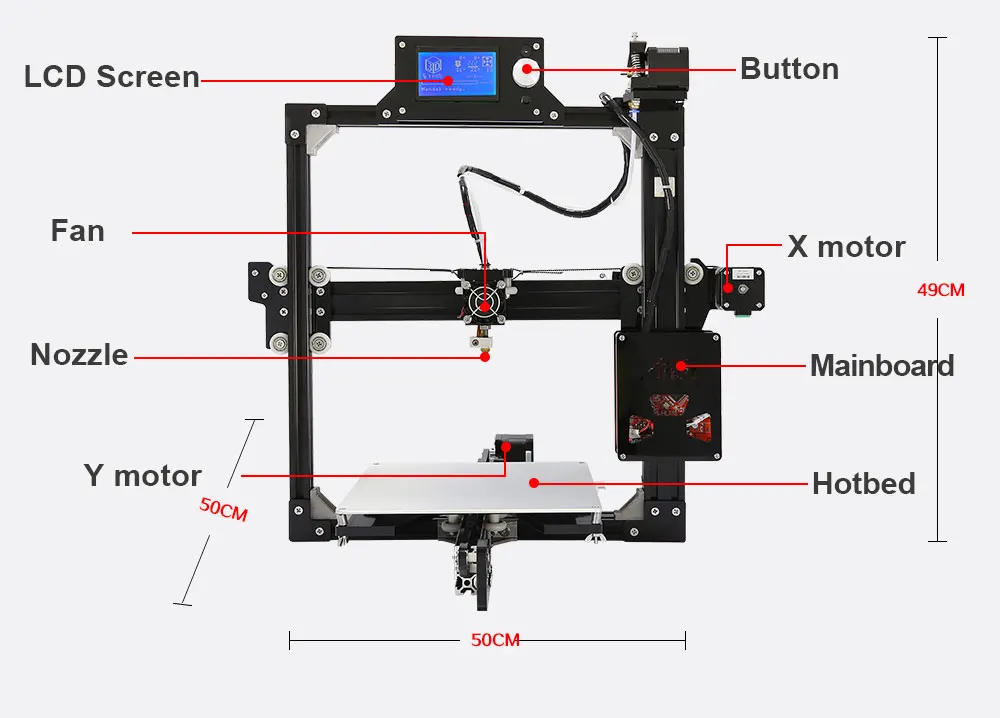

Most 3d printers consume around 50 watts per hour, even with a heated bed. Others, to get the bed to heat up quickly, use 120 volt power to heat the bed (the Artillery Sidewinder X1 is an example) and at peak, it can consume 600 watts per hour, but it won’t sustain that, and should drop to 50 to 80 watts per hour once it’s up to temperature.

50 watts per hour is around 1¢ per hour. So estimating double that, and running 24 hours a day, will get you a cost of under 50¢ per day in electricity. For a DLP resin printer, the only thing drawing power is the low wattage UV light source, the tiny control computer and the small amount of power that the z-axis motor requires. For an FDM filament printer, you’re powering the control computer, and the x-, y- and z-axes motors. They really are rather efficient in their electrical use.

For an FDM filament printer, you’re powering the control computer, and the x-, y- and z-axes motors. They really are rather efficient in their electrical use.

The obvious cost of a 3d printer is the stuff that you’re making the 3d printed part out of. That’s either filament or liquid resin, depending on the type of printer that you have. The examples below are for PLA filament or standard UV resin. If you use other materials, then likely your costs will be higher. Instead of $50.00USD for standard resin, you may decide to go with AnyCubic’s ECO resin that is safer, lower odor and made from plants. It goes for roughly $75.00USD for a liter, and you can find other resins, depending on your need, for even more money. Filament is the same. Generic PLA can be quite cheap, but different material properties will likely cost a lot more.

Cost of Filament for An FDM Printer

Cura Slicer (when printing with an FDM filament printer) will provide you with a rather good estimate of the length of filament a model will use when it slices a model. For example, this model building will take XX.XX meters of filament. Your 1kg spool of PLA will have around 330 meters of filament on it. At $25.00 for a spool from Amazon.Com, your cost is 7.6¢ per meter.

For example, this model building will take XX.XX meters of filament. Your 1kg spool of PLA will have around 330 meters of filament on it. At $25.00 for a spool from Amazon.Com, your cost is 7.6¢ per meter.

A typical “benchy” model (a fairly standard test print) takes about 25 cubic centimeters, or 10 meters of filament. At 7.6¢ per meter, your cost would be around 76¢ for the model in filament cost. If you printed a larger model, your amount of filament used would, of course, go up as well. If a print took longer than 24 hours, using PLA, with a layer height of 0.2mm, you would use somewhere around 120 meters per day, at a cost of around $9.12USD. So, rounding up, if you estimated $10.00USD per day for a full day (24 hours) of printing using PLA, you’d be pretty close.

Cost of Resin for a DLP PrinterAs with the Cura Slicer, the ChiTuBox Slicer I use for DLP resin printing will calculate the volume of the resin used and, if you enter the price of the resin in the settings, will calculate the price for the entire print run. I use a price of $50.00 in the settings (and my resin is usually cheaper than that!) I have printed pair of large tanks for a resin cost of $2.35 for the print run.

I use a price of $50.00 in the settings (and my resin is usually cheaper than that!) I have printed pair of large tanks for a resin cost of $2.35 for the print run.

Remember, just like with the FDM printer, changing the layer height of the print will increase the time, but not the volume of material used. It may look better and have great detail, but it won’t be any more volume (and thus material cost) to one done with less detail.

Other Consumables and Their CostsFor a FDM filament printer, you’ll want some isopropyl alcohol to clean off the build plate (to remove finger oils and other residues). Other than that, repair or replacement parts are the only thing you’ll potentially need. Replacement Bowden tubes and connectors, replacement hot end nozzles and replacement hot end insulating sleeves are generally under $10.00USD each for a set of replacements (enough for several replacements, not just one).

For a DLP resin printer, you’ll need a little more. Any time you interact with liquid resin, you’ll need to wear Nitrile rubber gloves. This specific type of rubber glove will keep your hands safe from the caustic chemicals of UV resin. You’ll also need a cleaner to clean off your prints. Many recommend isopropyl alcohol to clean the prints, but I use Mean Green cleaner at full strength. It’s cheaper, smells better and isn’t flammable! Water is the second step of the cleaning process, but it’s at least free from the tap.

Any time you interact with liquid resin, you’ll need to wear Nitrile rubber gloves. This specific type of rubber glove will keep your hands safe from the caustic chemicals of UV resin. You’ll also need a cleaner to clean off your prints. Many recommend isopropyl alcohol to clean the prints, but I use Mean Green cleaner at full strength. It’s cheaper, smells better and isn’t flammable! Water is the second step of the cleaning process, but it’s at least free from the tap.

For any one print, you’ll need a pair of Nitrile rubber gloves. A box of 100 is less than $10.00USD, so a pair is 20¢ and you’re likely doing no more than two prints per day. You’ll go through 3 sheets of paper towel per print (likely) so that adds another 10¢ per print (348 sheets for $11.00USD comes out to 3.2¢ per sheet, or 10¢ for three). So, with two sets of gloves and 6 paper towel sheets, you’re at a whopping 50¢ for a hard day’s printing.

Non-Consumables For 3d PrintersWhen you start out, you’ll run into all sorts of one-time purchases that will make your life easier with a 3d printer. Check out the Recommended 3d Printer Gear page here on Home3dPrints.Com: https://home3dprints.com/recommended-3d-printing-gear/. FDM filament printers have less to add, but there are some good recommendations for DLP resin printers: pickle jars to clean the finished prints, parts for a UV curing station and some good side cutters come to mind).

Check out the Recommended 3d Printer Gear page here on Home3dPrints.Com: https://home3dprints.com/recommended-3d-printing-gear/. FDM filament printers have less to add, but there are some good recommendations for DLP resin printers: pickle jars to clean the finished prints, parts for a UV curing station and some good side cutters come to mind).

If you’re going to start a 3d printing business with your printer, then understanding your costs is a must. The more it costs, the more you’ll want to charge for your service or product. But don’t forget time. It’s our most precious resource, and don’t sell yourself short. 3d printing is an advanced technical skill, and should be paid for accordingly. Not everyone is up to the challenge of 3d printing. You are, and that’s worth something.

Time pricing is much more viable than materials pricing. If you were to print at 0.4mm layer height, you could finish a print far faster than printing at 0. 1mm layer height. But the material amount would be the same. So an estimate by time is far more useful than an estimate by just how much material is used. Multiply this by the your rate, and you have a good estimate for your product or service price.

1mm layer height. But the material amount would be the same. So an estimate by time is far more useful than an estimate by just how much material is used. Multiply this by the your rate, and you have a good estimate for your product or service price.

Can you make money with a 3d printer?

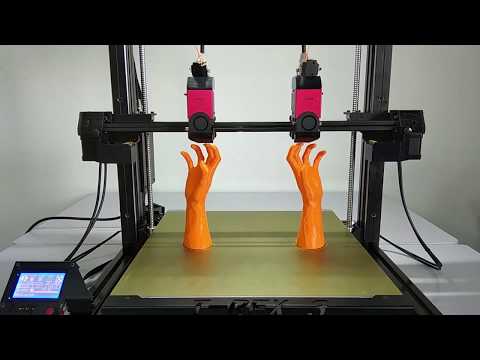

To make money with a 3d printer, you have two main options. You can charge a service fee to print models for customers and ship it to them, or you can produce items for sale in an online or physical shop. Either way will work, but one printer does not have enough capacity to make a full-time living from. It may be a great way, however, to supplement an existing income.

What can I make with a 3d printer at home?

Anything that you can think of that’s plastic and as small as the print bed on your printer can be printed at home. For home-sized DLP resin printers, the items are quite small. The AnyCubic Photon, for example, can produce items to a maximum dimension of 115mm x 65mm x 155mm. FDM filament printers tend to have larger print volumes. For example, the Ender 3 can make objects to a maximum dimension of 220mm x 220mm x 250mm.

FDM filament printers tend to have larger print volumes. For example, the Ender 3 can make objects to a maximum dimension of 220mm x 220mm x 250mm.

You could print specialty kitchen utensils or tools, models for gaming or displaying, holders, replacement knobs for drawers or phone cases. There are so many things that can be made. Have a look at Thingiverse.Com to see the literally hundreds of thousands of downloadable files for 3d printing. Download and print something today!

Tweet

Complete 3D Printing Costs Breakdown; Updated 2022! – 3D Solved

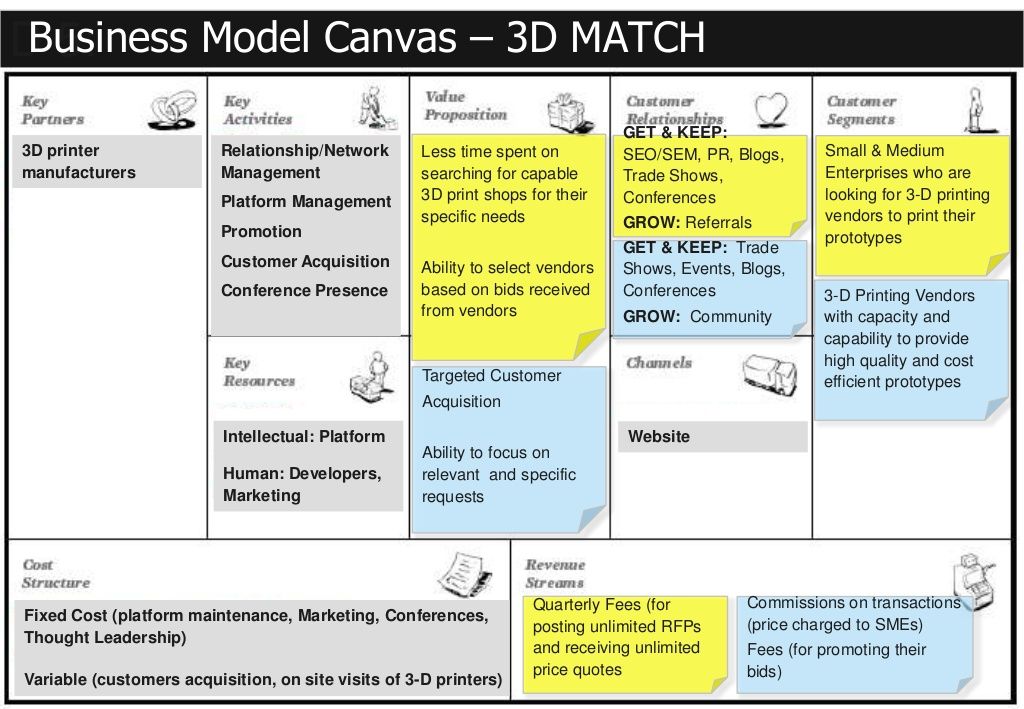

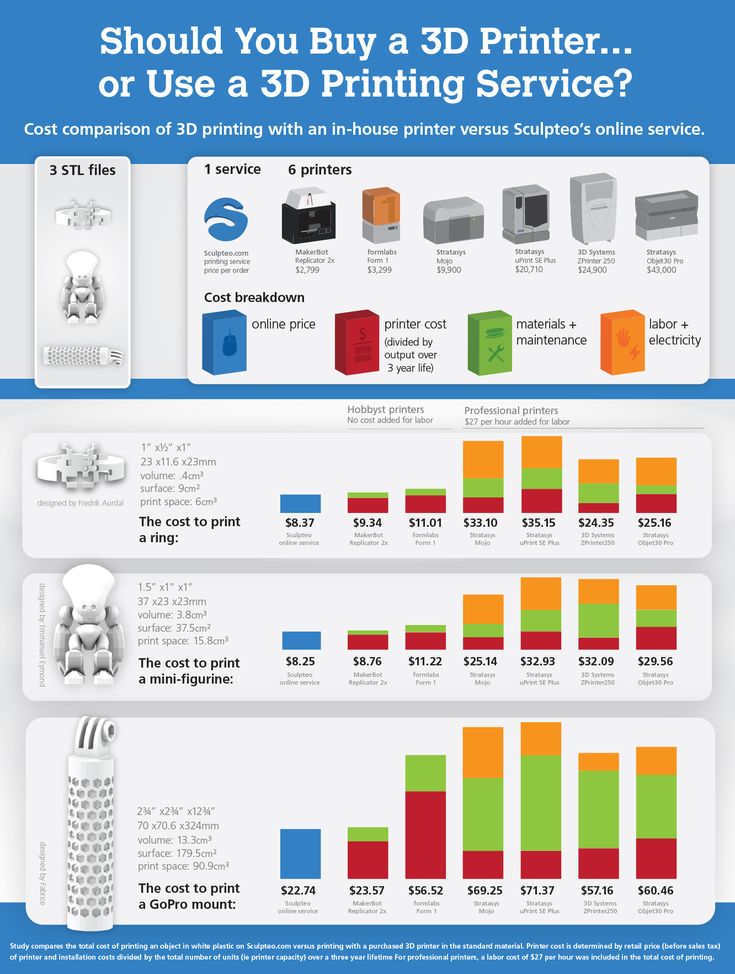

To ensure that you’re getting the most bang for your buck when using 3D printing technology, sometimes, calculating printing costs will be needed, especially if the aim is to market the printed pieces.

The printer’s price can vary a lot because of the wide range of applications that exists. But comparing printer prices won’t always tell you the full story about how much your printed piece will cost.

In this article, we will explore many other factors that will end up impacting the final cost of running a 3D printer, such as material costs for different 3D printing technologies, as well as electricity costs, post-processing materials, and costs related to the previous design of the model.

An active 3D printer costs roughly $0.35 per hour. This not only includes filament consumption (15 cents per hour), but also electricity costs (1.58 cents per hour), nozzle replacement (1 cent per hour), and the amortization of the machine ($0.17 per hour). Conservatively, if you operate the machine 8 hours per day during working days (252 days/year), this translates to a yearly cost of $695.

Once you’ve read this article you will be able to calculate the cost of your production ensuring that you have found a balance between lowering costs and keeping high quality.

Price of the 3D Printer

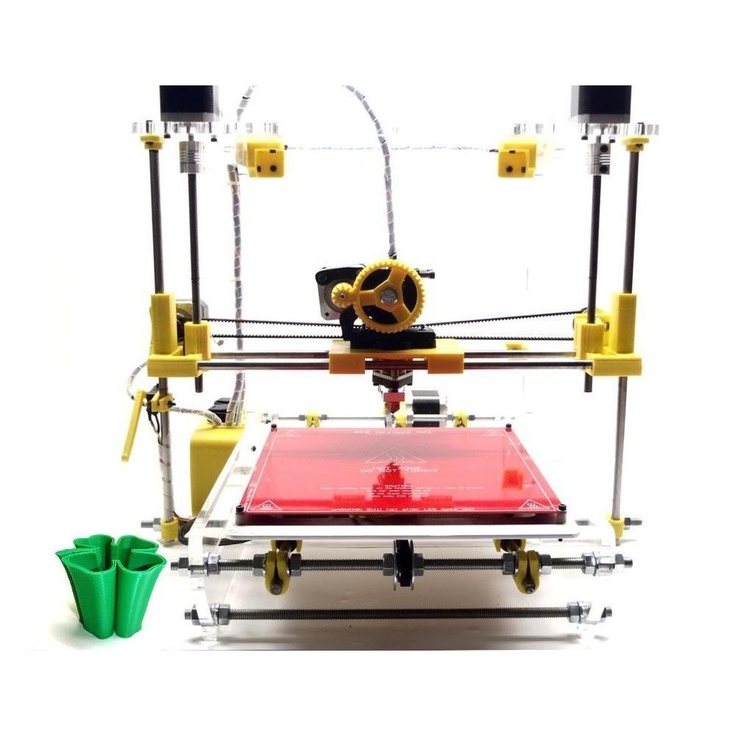

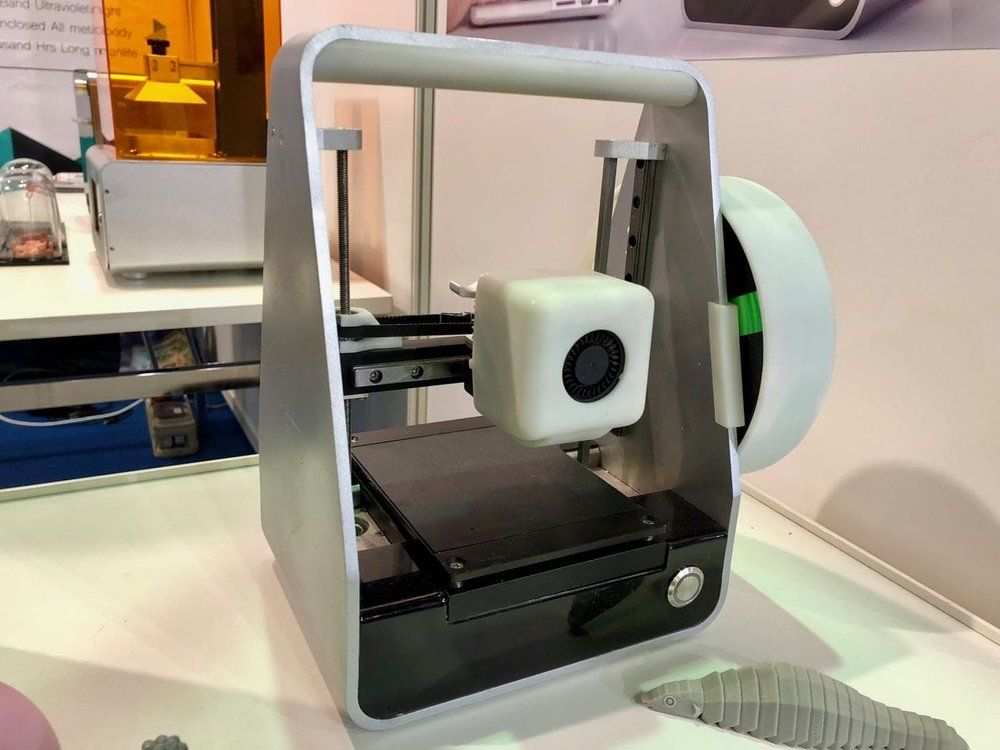

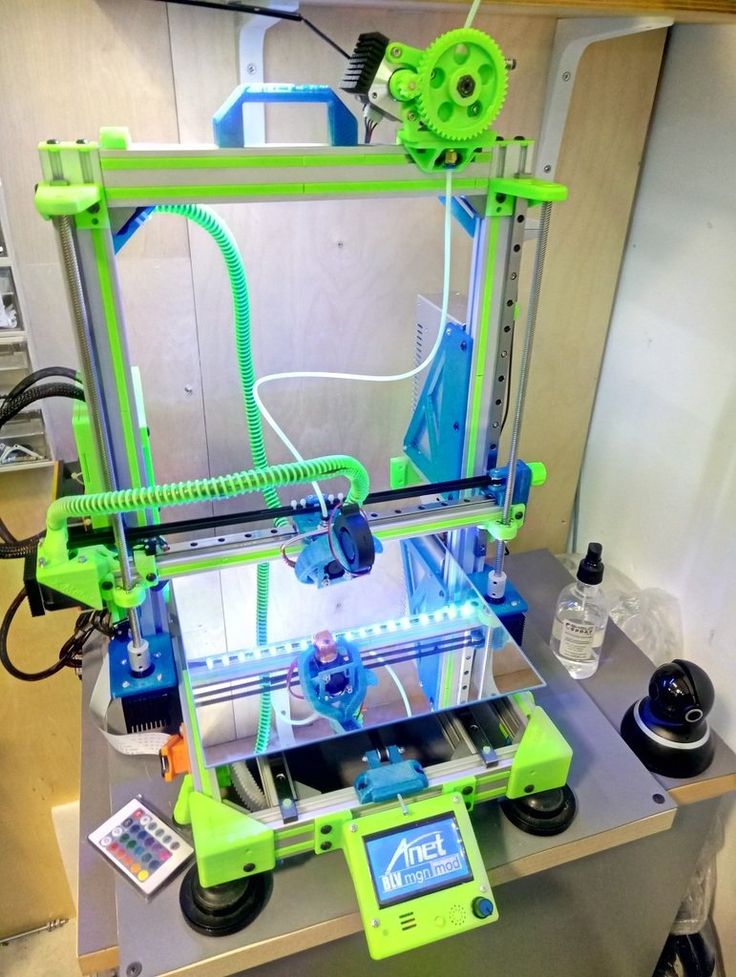

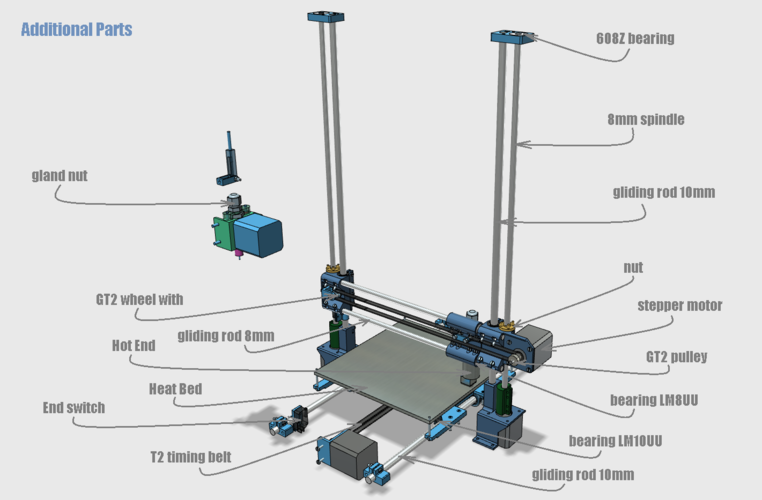

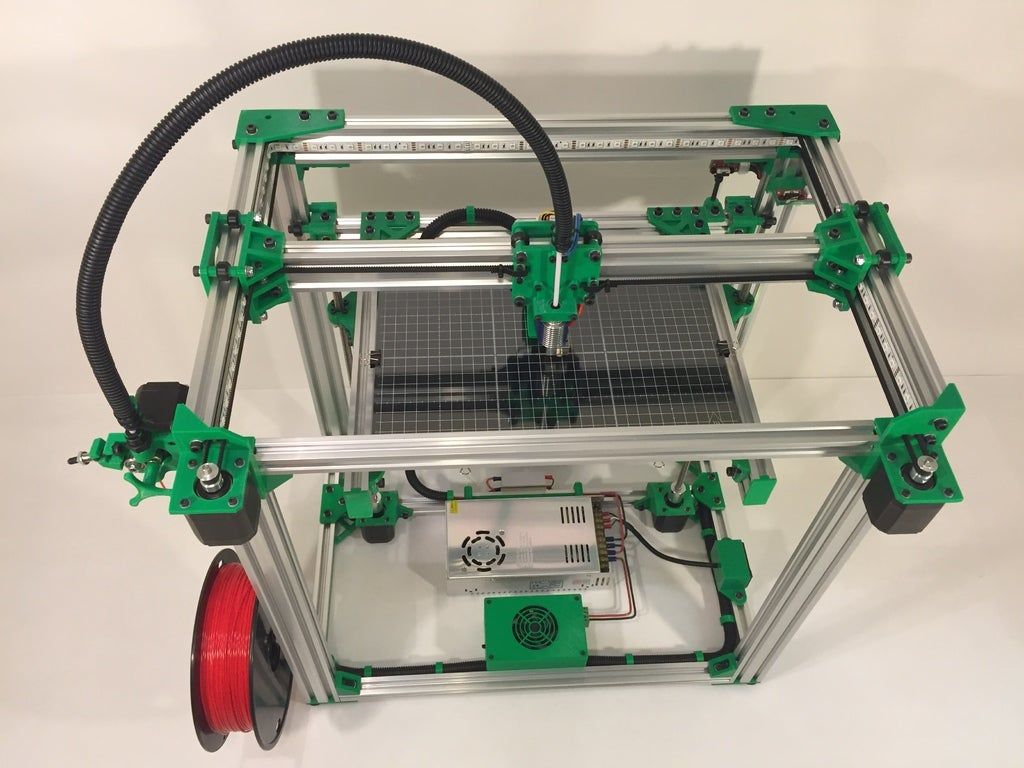

There are different kinds of printers. Fused deposition modeling (FDM) and stereolithography (SLA) are the two most popular and widespread types of 3D printers you can find on the market these days.

While FDM printers work by extruding and depositing layers of melted thermoplastic filament on a print bed, SLA printers use a laser to selectively cure liquid polymer resin, layer by layer, in a process called photopolymerization.

Despite the fact that there exists a wide price range, the lowest cost 3D printers are most often than not FDM ones. This is probably why it is the most widely used 3D printing method among hobbyist 3D printers and for such cases where only relatively simple prototypes in limited numbers are printed. Higher-performance professional and industrial FDM printers are also popular with professionals. Naturally, their costs are significantly higher.

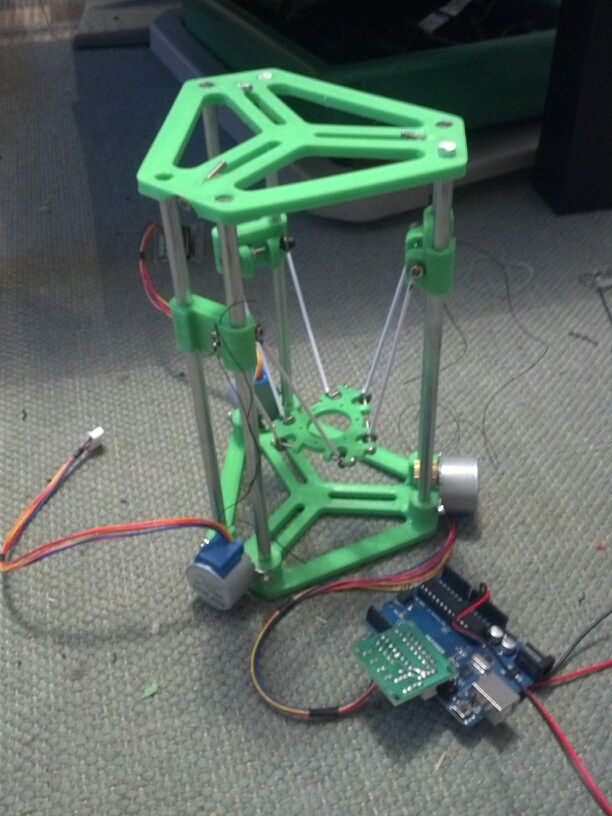

Here are some estimated prices for the different FDM 3D printers categories available:

- DIY 3D printer kits: about $200

- Hobbyist printers: $500-$1,500

- Professional FDM 3D printers: start at around $2,500

- Large-format professional FDM printers: start at around $4,000.

SLA technology used to be available only for the expensive industrial-grade segment, but fortunately, the process has become much more accessible nowadays.

Professional SLA desktop printers start at $3,500 and large-format benchtop printers which offer a bigger build volume are about $11,000. Having said that, it is possible to get high-quality hobbyist SLA printers such as the Elegoo Mars 2 Pro for around $200.

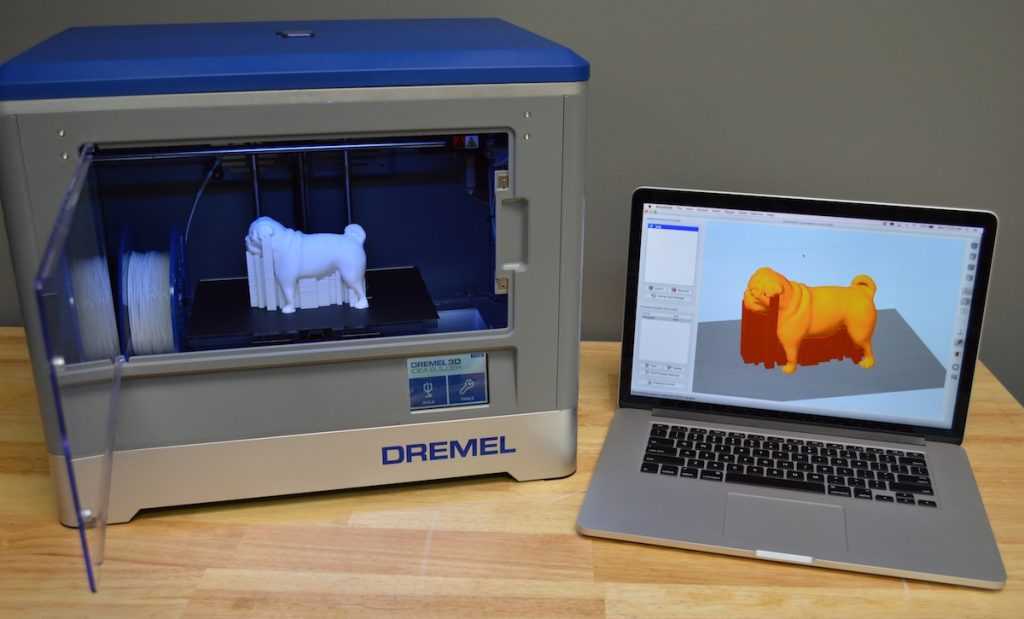

Difference in Print quality between FDM and SLA Printers

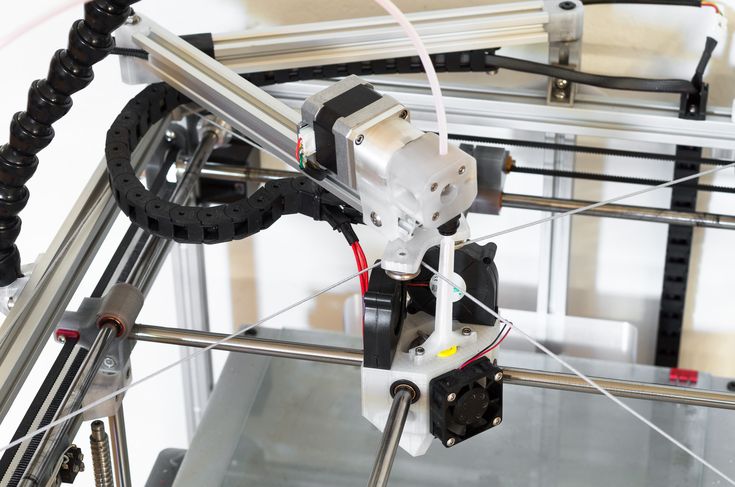

Same part printed with an FDM Printer (left) and an SLA printer (right)FDM printers build pieces by layering molten filament on a print bed. This process makes the resolution defined by the size of the extrusion nozzle since there are voids in between the rounded lines at each layer.

Furthermore, FDM printing produces a mechanical bond between layers. This constructive characteristic affects strength since the interface between layers becomes weak points.

On the other hand, SLA technology uses a different process where liquid resin is cured by a laser to form each layer. This process enables us to achieve much finer details and is more reliable in repeatedly achieving high-quality results. In consequence, we will obtain smooth surfaces, high part precision, and accuracy.

This process enables us to achieve much finer details and is more reliable in repeatedly achieving high-quality results. In consequence, we will obtain smooth surfaces, high part precision, and accuracy.

Unlike FDM printers, SLA ones create chemical bonds resulting in fully dense parts which provide high degrees of lateral strength, turning out in isotropic parts.

Costs of Running a 3D Printer

Contrary to what might be thought, the costs of running a 3D printer are not only a matter of how much your 3D printer costs.

This won’t tell you the full story about how much a printed part will cost.

Printing material, electricity consumption, machine maintenance, and post-processing additional materials are some of the factors that will significantly influence the final cost per part.

3D Printing Material Cost (Filament, Resin)

One of the main things to be taken into account when calculating printing costs is the material cost. This, in turn, depends on the cost of the 3D printing material itself, how much material is required to create a given part (including waste), what the shelf life of the material is, and if there are other elements required for printing the parts.

The usual cost for each PLA, ABS, or PETG is about $20 for a 1Kg spool of 1.75 mm filament.

ABS and PETG are characterized by their durability and impact resistance and PLA by its easy way to use, and its multitude of applications.

Unlike SLA printers, where you need to consider many additional costs (like Gloves, Isopropyl alcohol, and more), there are no hidden costs when using an FDM printer.

The resin price can vary anywhere from $15 to $45 for 500ml of material, and for 1000ml the price range is between $28 and $80.

For an extensive comparison between filament and resin costs check out this article I wrote on the subject.

Electricity costs

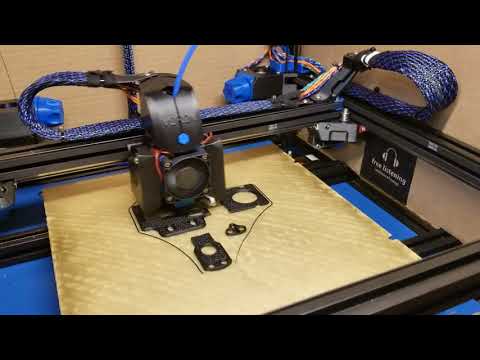

Using an Electricity Usage Monitor to measure the consumption of our Ender 3 v2The electric power that a printer uses depends primarily on the printer’s brand and size, the temperature of the heated bed and nozzle, as well as the size of the printed piece. As a reference, the average cost per kWh in North America is 12. 69 cents, which is similar to Europe (12.3 cents), Asia (14.65 cents), and South America (15.18 cents). Electricity costs have a greater impact if you’re located in Oceania, where the cost per kWh is 26 cetns.

69 cents, which is similar to Europe (12.3 cents), Asia (14.65 cents), and South America (15.18 cents). Electricity costs have a greater impact if you’re located in Oceania, where the cost per kWh is 26 cetns.

For instance, printers with larger heated beds or those which can print at higher temperatures, tend to consume more power.

Comparing it with the price of the filament or resin, electricity doesn’t add that much to the overall cost. However, it might become significant in those cases where you need to print batches or you have a larger amount of machines working.

As an example, in this article, you will find an analysis of how much power an Ender 3 consumes, made by using an Electricity Usage Monitor.

General Maintenance

3D printers are no different from other machines; they all need preventive maintenance and eventually the need for some part replacement.

Proper-maintained machines will perform as intended, and periods of downtime can be avoided.

However, you still can’t save some parts from wear and tear.

An example of this is the nozzle. They have a major impact on the print’s quality, this is why it is important to keep them clean and replace them when necessary.

In these articles, you will find information about how often you should replace a nozzle, how to replace it, and how to clean an unclogged one.

Other parts that will need replacing over time might be stepper motors, maybe the mainboard at some point, belts, bed springs, ABL sensors, etc.

Additional Materials

There may be other factors affecting the final cost of a specific part. These aren’t strictly related to printing the model but post-processing.

3D printed parts usually require some post-processing treatment. This can include practices like cleaning or fixing the piece, surface finishing, and coloring.

When calculating costs, you should consider the price of all the materials involved and the time it takes to perform those treatments.

Within post-processing materials, we can count sandpaper, acetone, paint, brushes, spray paint, etc.

Post-processing can become costly, especially when it’s done by hand and it might be unsustainable in large series production because of the time it takes and the fact that costs of part breakage are included here too.

Software Costs (CAD and Slicers)

Slicers such as Cura or Prusa Slicer are generally free, but Simplify3D, for example, isn’t. You will most probably don’t need to acquire Simplify3d, but just as a reference, its license costs roughly $150.

When trying to learn how to slice and print models, free software like Cura is a great way to start learning the basics and they are also capable of producing high-quality prints.

Becoming experienced with this software, you might require a more comprehensive set of features that may justify an investment.

It’s worth noticing that the quality advantage that paid slicers used to have in the past is continuously getting smaller, and nowadays it is only advisable to pay for a license in very specific cases.

Then there’s CAD software to design the models and those can also be free, but the best ones are generally paid (yearly or monthly payments).

In the following articles, you will find information about different slicers and CAD software.

- Best slicers for 3d printing

- Is Tinkercad good for 3d printing?

- Is fusion 360 good for 3d printing?

- How to create models for 3d printing?

- Is Simplify3d worth the cost? Comparing it with Cura and Prusaslicer

Designs you can find online (not always free)

Designing a part from scratch may not always be the best option. There is a large number of digital design files already available online which will save you a lot of time.

Most of them, such as the ones found on Thingiverse (a website dedicated to the sharing of user-created digital design files), are free. You should also check out our own search engine, which aggregates the most relevant results from the most popular sources: https://www. 3dsolved.com

3dsolved.com

But if you want to print something specific then you might need to pay for the STL file. If this is the case, then consider that the cost per part will be less affected the larger the number of pieces you need to print.

How to calculate the cost of 3D Printing

In this section, we will study an example of how to calculate the cost of owning and running a 3D printer.

Let’s take as an example the Prusa I3 MK3S+ FMD 3D printer whose price is around $1.000. Let’s say you run it for 8Hs a day for two years. Thus, 8 hs * 365 days * 2 years = 5840hs gives us the total number of hours the printer will be running. This is of course a very conservative estimate and does not mean that your printer won’t be usable from there on, but it just serves as a depreciation schedule.

Having done so, you can calculate how much it costs to own the printer per hour (without including electricity, and filament) by dividing the price by the total of hours: $1. 000 / 5840 hs= 17 cents/hour

000 / 5840 hs= 17 cents/hour

To calculate filament cost for a specific model, use Cura to slice the model and it will tell you how much filament you’re going to need, then just calculate the cost based on how much the spool cost. As a ballpark figure, a 3D printer consumes approximately 7.5g of filament per hour when printing at a 0.2mm layer height and at a conservative speed. Assuming that the filament spool costs $20 for 1Kg, this results in a filament cost of 15 cents per hour.

Nozzles should be replaced about every two months if you’re printing for 8hs a day, so you should include that cost. Each brass 0.4 mm diameter nozzle costs $5.78 (average of a few reliable brands). Following the previous example, you would need 12 nozzles in 2 years, which translates to $69.36. Dividing this by the total of hours, you get a 1 cent cost per hour approximately.

Electricity depends on the country you’re in, and you can check out the full-length article I wrote on the topic. As an example, let’s take the electricity cost in North América which is about 12.69 cents per kWh. This gives us an estimate of 1.58 cents cost per hour and 12.64 cents per day.

As an example, let’s take the electricity cost in North América which is about 12.69 cents per kWh. This gives us an estimate of 1.58 cents cost per hour and 12.64 cents per day.

General repairs & maintenance depend a lot on the printer, but it shouldn’t be too much unless something like the mainboard gets fried.

The following list sumarises some average 3D printing costs:

- Average 3D printing costs per hour: printer_depr. + fil_cons. + nozzle_repl. + elect_costs = 34.58 cents / hour

- Average 3D printing costs per day: $2.76

- Average 3D printing costs per year: $695

- Cost of 3D printing a small object (10-15g of filament): 67.5 cents

- Cost of 3D printing a Phone Case: 27 cents

Use the Prusa Calculator

This calculator is mostly designed to let you know how much to charge your clients for a printed piece.

You just have to load a gcode file or input the print time and filament weight manually, and it will answer questions like: How much should you charge when 3D printing on demand? Is electricity a major factor in the calculation? What about the return on the total investment and your time?.

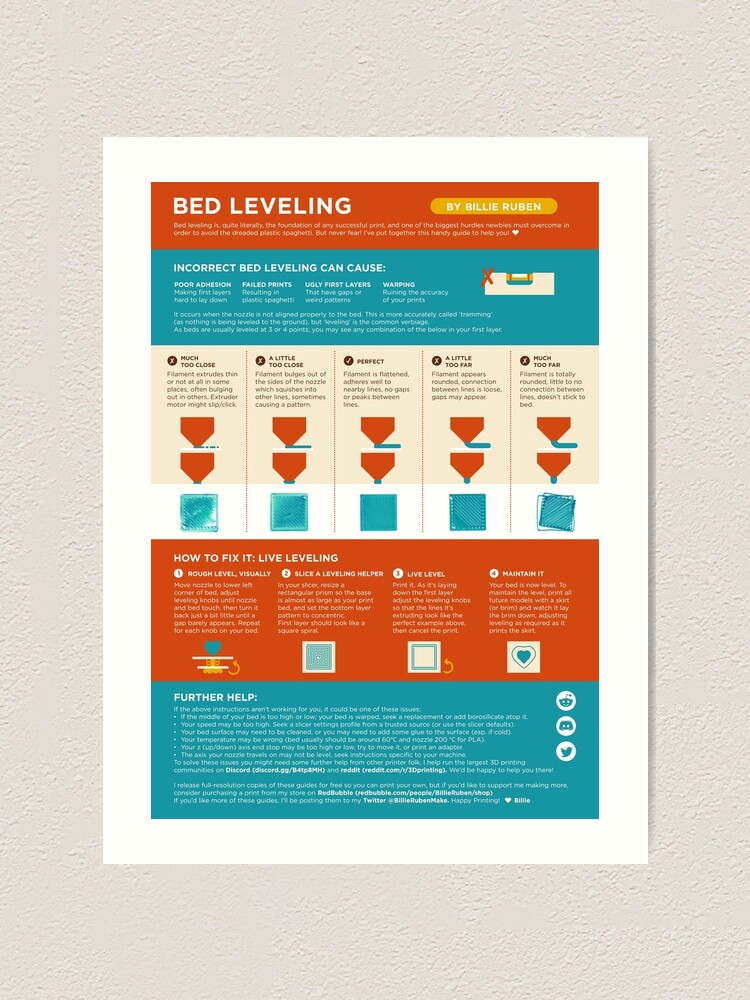

How to lower the cost of 3D printing with Slicer Settings

If you’re looking to lower the cost of your prints while also achieving high print quality, you might want to make sure you’re always using the optimal print settings.

Only use Supports when actually needed

In those projects where support structures are needed, you will have to add to the calculation the price of material and the time needed to build those structures, also consider the time and tools that will be needed to post-process the piece.

Sometimes, just reorienting your object inside of the slicing software can help in reducing the need for unnecessary plastic in your print.

Another way of avoiding unnecessary support structures is to increase the angle at which the Slicer starts introducing supports. If you know your printer, you may get by printing 60-degree overhangs without any supports (Cura usually enables them at 45 degrees).

If you know your printer, you may get by printing 60-degree overhangs without any supports (Cura usually enables them at 45 degrees).

Reduce the infill density

By reducing the infill density, not only will you save more material, but your prints will also finish much faster, which means less printer wear and tear, less electricity consumption, and more output per hour.

You can save material if you completely hollow out the inside of your design. But you must be careful because the printing material you use will require a minimum wall thickness to maintain hull integrity.

Reduce the number of shells/walls

Same as the case of reducing infill density, reducing the number of walls will not only reduce the amount of material used but the processing time too.

Always try to keep a balance between infill and walls number reduction to maintain structural integrity and keep the strength and quality of the piece high.

Print faster

Always trying to avoid neglecting quality and strength printing faster not only will save you time but will also reduce the time that the nozzle and bed are hot, which are the ones that consume the most energy.

Reduce the Bed temperature

Since bed print heating is performed by long traces of cooper acting as a resistor, higher temperatures mean higher amounts of electricity consumption. As seen this will affect the final cost of the pieces.

Then, only if adhesion is not a problem (mainly working with PLA), you should consider reducing the bed temperature.

Costs of Outsourcing the printing process

The printing farm of Voodoo Manufacturing.You might not be interested in buying, operating, and maintaining your own 3d printers. In that case, you might consider outsourcing your prints!

This could be a good option if you’re looking to save some time, or maybe if you just need a once-in-a-lifetime print. Outsourcing also has the advantage of giving you access to industrial printers that you could otherwise most probably not be able to use.

3D printing services can be really expensive because besides all the costs we have already mentioned, they have to account for the industrial printers they use, which are significantly more expensive, and they also have to add profit margin on top of that cost.

Then, if you’re just printing for fun, buying a 3D printer would be the best choice in the long run.

How much does a 3D printed house cost?

3DPrintStory News How much does a 3D printed house cost?

Every new innovation comes to market with a price. For example, large concrete 3D printers had a fairly high price when they first launched. But as with most technology, prices are falling as new, better, and more affordable products are developed. New innovative concrete mixtures also contribute to lower prices. nine0005

Since there are a number of 3D printed building projects around the world, it is impossible to give an exact price for a 3D printed house. Instead, we'll take a look at some of the most recent and promising projects and their prices.

However, in general, jumping ahead a bit, you will see that a 3D printed house can cost as little as $10,000, sometimes less. Let's take a look!

Example 1. House Apis Cor

One rather promising project from Russia. Apis Cor is a Russian company that specializes in the development of a mobile 3D construction printer capable of printing entire buildings on the spot.

Apis Cor built a 410 square foot home to showcase the potential and capabilities of its mobile 3D construction printer. The 3D-printed house cost the company about $10,150 - an incredibly low amount for building a house. nine0005

Here is a more detailed list of costs, according to the company's website:

- Foundation: $277

- Walls: $1624

- Floor and roof: $2434

- Wiring: $242

- Windows and doors: 3

- Exterior: $831

- Interior (including stretch ceiling): $1,178.

The company even decorated the house both inside and out. The outside of the house is painted, but inside there is a refrigerator, a large-screen TV, a sofa and other furniture. True, furniture is clearly not included in the price. Apis Cor just wanted to showcase what a finished home could look like. nine0005

The outside of the house is painted, but inside there is a refrigerator, a large-screen TV, a sofa and other furniture. True, furniture is clearly not included in the price. Apis Cor just wanted to showcase what a finished home could look like. nine0005

Example 2. Is ICON a home for less than $4,000?

Look at the picture above. This house was 3D printed by Texas-based ICON.

ICON specializes in low cost building solutions, so their main project is a 3D printed house.

In partnership with the non-profit organization New Story, ICON plans to build an entire block of these affordable 3D printed houses in El Salvador. The goal is to provide housing for people who, unfortunately, do not yet have adequate housing conditions. nine0005

A prototype 3D printed house cost about $10,000, but the company says it can bring that down to $4,000, which is amazing and impressive news. The approximate assembly time for such a house from ICON is approximately 24 hours.

Example 3 Winsum - 10 houses in one day

Winsun from Shanghai became famous in 2014 by reaching the 3D printing milestone of 10 houses in just one day!

Winsun used large concrete 3D printers, 10 meters wide and 6.6 meters high. The company said that each 3D printed house costs $4,800, which is surprisingly low for 2014! nine0005

Although Winsun's 3D houses are not so exquisite, they have generated a lot of public interest. This project has definitely contributed to the increase in the number of houses made with 3D printers and the development of 3D printers themselves for their production.

Winsun is also known for producing one of the most advanced 3D printed buildings to date, which we will discuss in the next section...

Example 4 Office Building in Dubai in the world, printed on a 3D printer. What it is? Beautiful and futuristic office building in Dubai. nine0005

The entire 3D printing process took Winsun only 17 days. Up to this point, we have mentioned fairly cheap 3D printed houses, but this building was clearly more expensive - around $140,000. However, compared to what it would have cost had it not been 3D printed, the final price is impressively low.

However, compared to what it would have cost had it not been 3D printed, the final price is impressively low.

Conclusions

As we mentioned above, it is difficult to give an exact price for 3D printing at home, since the price depends on the size and complexity of the design. nine0005

But keep in mind that these days you can 3D print a house for as little as $4,000. This price covers the frame of the house (base, walls, roof) and, in some cases, wiring.

As you may have noticed, the cost of an office building in Dubai is quite high compared to cheaper and smaller 3D printed houses. For high-tech concrete 3D printed projects, expect construction costs to be around $100,000, which is actually quite low compared to the cost of building the same building using traditional building techniques. nine0005

Over time, more and more companies will implement 3D printing of buildings. This, coupled with advances in technology, is sure to drive prices down and quality up.

How Relativity Space prints rockets on a 3D printer

Relativity Space co-founder, CEO Tim Ellis / Relativity Space / AFP

Relativity Space is printing a metal space rocket on a 3D printer that it invented specifically for this purpose. Almost all: printed 95%, and the remaining 5% are electronics, seals and some other items. 3D printing has many advantages. She's cheaper. She's faster. It is made on the spot, no need to wait until the parts are brought from another factory. It is stronger: fewer places for fastening parts. “The Shuttle had 2.5 million parts,” says Relativity Space co-founder Tim Ellis. “According to our estimates, SpaceX and Blue Origin have reduced this number to 100,000 per rocket. We have a thousand - less than in your car.

3D printing is used by many space companies, but only for individual components. Skeptics insist that no one knows how the printed rocket will behave during takeoff and in space. So far, the startup's first rocket, Terran 1, has successfully passed all ground tests. The first copy for a real flight is collected slowly and carefully checked. Now it is ready for 85%. A test flight is scheduled for the end of this year. But investors believe in the idea. Last November, Relativity Space completed a series funding round and raised $500 million. After that, according to research company Pitchbook, with a business valuation of $2.3 billion, Relativity Space became the second most valuable venture capital-funded space company in the world. In 1st place, of course, SpaceX (however, Pitchbook does not include Blue Origin in the rating, which is fully funded by Jeff Bezos). nine0005

The first copy for a real flight is collected slowly and carefully checked. Now it is ready for 85%. A test flight is scheduled for the end of this year. But investors believe in the idea. Last November, Relativity Space completed a series funding round and raised $500 million. After that, according to research company Pitchbook, with a business valuation of $2.3 billion, Relativity Space became the second most valuable venture capital-funded space company in the world. In 1st place, of course, SpaceX (however, Pitchbook does not include Blue Origin in the rating, which is fully funded by Jeff Bezos). nine0005

Since then, Relativity Space has raised another round, raising $650 million, based on a company-wide valuation of $4.2 billion. reusable. After all, competitors do not sleep. Relativity Space is just one of more than a dozen rocket companies created in the last 10 years.

Launch from Mojave

Ellis was born in 1990 in Texas. He is the eldest of three children of an architect father and a dentist mother. As a child, Ellis was fond of Lego and persuaded his parents to buy about 200 sets. He immediately threw away the instructions from them and collected the spaceships he invented himself. Until now, the thumb of his right hand, when at rest, arched back more than his left - Ellis assured the Los Angeles Times that this was the result of long hours when he assembled and disassembled the parts of the designer. nine0005

As a child, Ellis was fond of Lego and persuaded his parents to buy about 200 sets. He immediately threw away the instructions from them and collected the spaceships he invented himself. Until now, the thumb of his right hand, when at rest, arched back more than his left - Ellis assured the Los Angeles Times that this was the result of long hours when he assembled and disassembled the parts of the designer. nine0005

As Ellis got older, he began making amateur films with friends, mostly action films, where the characters were often confronted by zombies. He entered the University of Southern California to become a screenwriter. But already in his first year, he became interested in the profession of an aerospace engineer and joined the Rocket Propulsion Lab at the university, which was engaged in the development of rockets.

The University of Southern California is known for its space program. Its alumni include Apollo 11 commander Neil Armstrong, astronaut and former head of NASA Charles Bolden, and Dana Rohrabaker, chairman of the House Space and Aeronautics Subcommittee. There are several laboratories where students create real rockets and satellites. “I was amazed,” Ellis recalled in an interview with the university website about the first time he went to test the rocket engine he designed and built with his comrades in the Mojave Desert. – I always advise students: take part in practical classes. So you will understand why you need to study this or that differential equation, scheme or line of code. nine0005

There are several laboratories where students create real rockets and satellites. “I was amazed,” Ellis recalled in an interview with the university website about the first time he went to test the rocket engine he designed and built with his comrades in the Mojave Desert. – I always advise students: take part in practical classes. So you will understand why you need to study this or that differential equation, scheme or line of code. nine0005

They wanted to be the first student group to launch a rocket into space. But, having carried out dozens of successful launches, they did not even achieve a suborbital flight - this was done by their successors in 2019, having developed more powerful engines.

Why leave Bezos and Musk

At Rocket Propulsion Lab, Ellis met and became friends with classmate Jordan Noone. Then their paths diverged for a while. Noon went to SpaceX, where he worked, among other things, on the Dragon 2 spacecraft. His emergency rescue system uses a 3D printed SuperDraco engine. nine0005

nine0005

Ellis interned for three summers at Bezos' Blue Origin, and after graduating, he was hired full-time. He convinced Bezos to create a metal 3D printing division (by then many competitors, including Boeing, were doing it). He also created it from scratch. The traditional way of producing parts is turning on a lathe, stamping or casting with a mold. In 3D printing, robotic arms deposit layer upon layer of molten metal. A printed rocket has fewer parts, and therefore, places to connect them using welding, rivets, etc., and therefore fewer vulnerabilities. Skeptics object that if defects are found, the entire part has to be discarded and its manufacture must be started anew. But Ellis says that Relativity Space has developed a way to restart the printing process from the right place. “3D printed rockets are the future of rocketry and space exploration,” he told Inc. magazine. nine0005

Ellis and Noon often called each other and talked about rockets, although they worked for different space companies. They put together a rough cost structure to understand why rockets are so expensive. “80 to 90% goes to wages,” Noon told Bloomberg. 3D printing can dramatically reduce these costs.

They put together a rough cost structure to understand why rockets are so expensive. “80 to 90% goes to wages,” Noon told Bloomberg. 3D printing can dramatically reduce these costs.

Ellis once mentioned that he was going to start a startup to 3D print entire rockets. He later admitted to Inc. that he tried to get Bezos to print more parts for the rocket, but his suggestions were never fully implemented. Then he decided to take up rocket science himself. Noon liked the idea. Both left in December 2015 to create startup Relativity Space. nine0005

"I've never seen him give up, give up, or fail to solve a problem, even a really difficult one," Ellis told the Los Angeles Times of Noon. “I knew our startup was going to have a lot of problems, and he was the right person to make it all work.” And Noon noted: “I am strong in technical and practical aspects, and Ellis is strong in creative thinking and non-standard solutions.”

For 1 kg of satellite

Relativity Space received its first money from venture investor Mark Cuban. Ellis and Noon made about 20 attempts to guess Cuban's email address, as Cuban preferred texting to other forms of communication. Some of the letters were returned with a note that such an address does not exist, some got to other people. But one of the addresses turned out to be correct, and Cuban read the letter with the headline "Space Is Sexy: 3D Printing of an Entire Rocket." Ellis and Noon asked for $100,000. Cuban, after five minutes of texting them, agreed to invest $500,000 (although they had to wait two months to check if they were fraudsters). “They are smart, resourceful, driven and always learning,” Cuban wrote in an email to The Times. “These are exactly the traits I look for in innovators.” nine0005

Ellis and Noon made about 20 attempts to guess Cuban's email address, as Cuban preferred texting to other forms of communication. Some of the letters were returned with a note that such an address does not exist, some got to other people. But one of the addresses turned out to be correct, and Cuban read the letter with the headline "Space Is Sexy: 3D Printing of an Entire Rocket." Ellis and Noon asked for $100,000. Cuban, after five minutes of texting them, agreed to invest $500,000 (although they had to wait two months to check if they were fraudsters). “They are smart, resourceful, driven and always learning,” Cuban wrote in an email to The Times. “These are exactly the traits I look for in innovators.” nine0005

First, the startup needed to create a huge 3D printer - there were no models on the market suitable for their purposes. A lot of effort was put into this. But now the latest generation printer is able to print a part up to 32 feet (almost 10 m) high, while the height of the Terran 1 rocket is 115 feet (35 m). Ellis and Noon say that even if the rocket venture fails, they can always cash in on the sale of industrial 3D printers.

Ellis and Noon say that even if the rocket venture fails, they can always cash in on the sale of industrial 3D printers.

Terran 1 /Relativity Space

Created with Cuban's money, the first printer could print parts half the size of the last generation. But the working rocket engine printed on it made an impression on investors. First, they invested almost $10 million in the startup, then another $35 million, and in October 2019d. - another $ 140 million. Ellis and Noon planned to stop there. They did not want to dilute their share, and the funds raised should have been enough for the time before the first commercial launch, if they worked without haste. But in November 2020, another $500 million round of funding was raised. As Ellis explained to CNBC, “the development and scaling of the project needs to be accelerated.” That summer, the startup moved to a new 11,000-square-meter headquarters in Long Beach, California. m, where there will be a site for the production of rockets (the most important thing is that their new printer climbed there in height). Over the past year and a half, the company has more than doubled the number of employees. She now has 400+ people and plans to hire 200 more this year.

Over the past year and a half, the company has more than doubled the number of employees. She now has 400+ people and plans to hire 200 more this year.

Ellis told Inc. that they already have $1 billion in launch contracts from government and commercial entities. Terran 1 can carry up to 1250 kg of payload. This is smaller than SpaceX's Falcon 9, but larger than Rocket Lab's Electron. Relativity Space is targeting a mid-sized satellite niche, much like a car, Ellis said. Its competitors are the Russian Soyuz-2-1V and the European Vega. Or the same Electron, if Terran 1 displays several small satellites at once. nine0005

The launch cost of Terran 1 is $12 million, i.e. just under $10,000 per 1 kg. Last year, Roscosmos CEO Dmitry Rogozin announced a more than 30% reduction in the price of launch services for a number of satellites to the level of SpaceX: to $15,000-17,000 per 1 kg instead of $20,000-30,000.

Target - Mars

The competitive advantage of Relativity Space is not only in cost, but also in the fact that it can print a rocket to customer requirements, changing both the diameter of the rocket and the shape of the fairing for the satellite - of course, within the limits allowed by aerodynamics, Forbes explained. And she can do it quickly. Once the technology has been proven in practice, Relativity Space is going to print the rocket in 30 days and take another 30 days for pre-launch tests, Ellis told Scientific American. According to him, even SpaceX takes 12 to 18 months to build a conventional rocket. But Musk claims that his reusable rocket is ready for a new flight 51 days after the previous launch. nine0005

And she can do it quickly. Once the technology has been proven in practice, Relativity Space is going to print the rocket in 30 days and take another 30 days for pre-launch tests, Ellis told Scientific American. According to him, even SpaceX takes 12 to 18 months to build a conventional rocket. But Musk claims that his reusable rocket is ready for a new flight 51 days after the previous launch. nine0005

So in June, Relativity Space raised another $650 million from investors to accelerate the development of its own reusable Terran R rocket (almost entirely printed on a printer, of course). Its first launch is scheduled for 2024. It will be larger than the first one - 216 feet (66 m) high and designed for 20 tons of payload.

For Ellis and Noon, the main thing is that this project is another step towards interplanetary flights. Musk is looking for a way to get colonists to Mars, and Ellis and Noon are hoping to help them settle on the Red Planet. "If you believe - and I believe - that Elon [Musk] and NASA will send people to Mars, then <.