3D printer safety

3D Printing Safety at Work | NIOSH

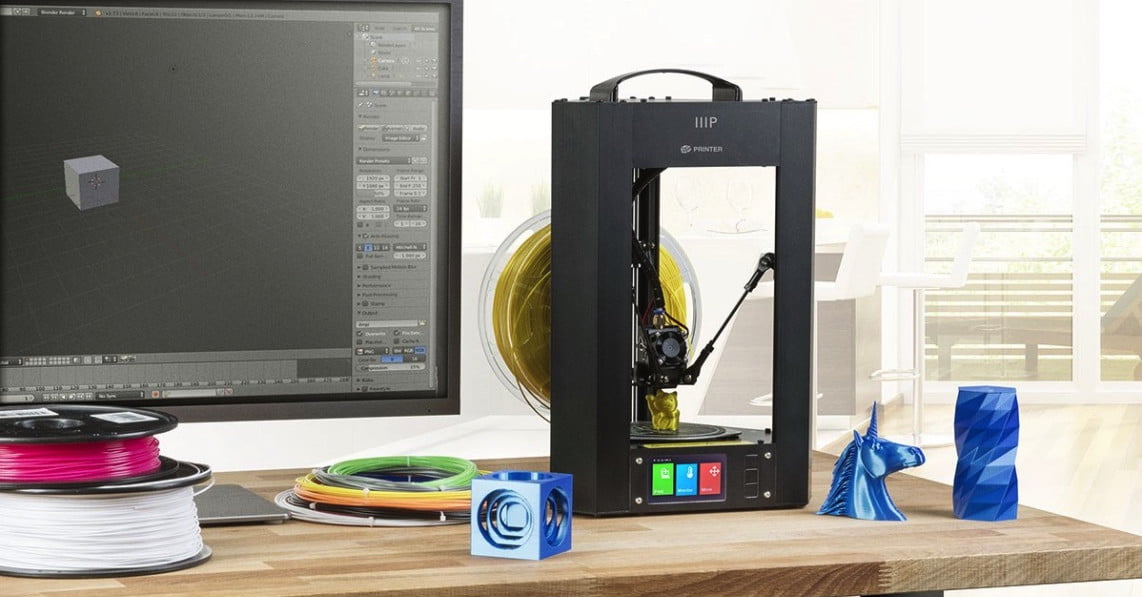

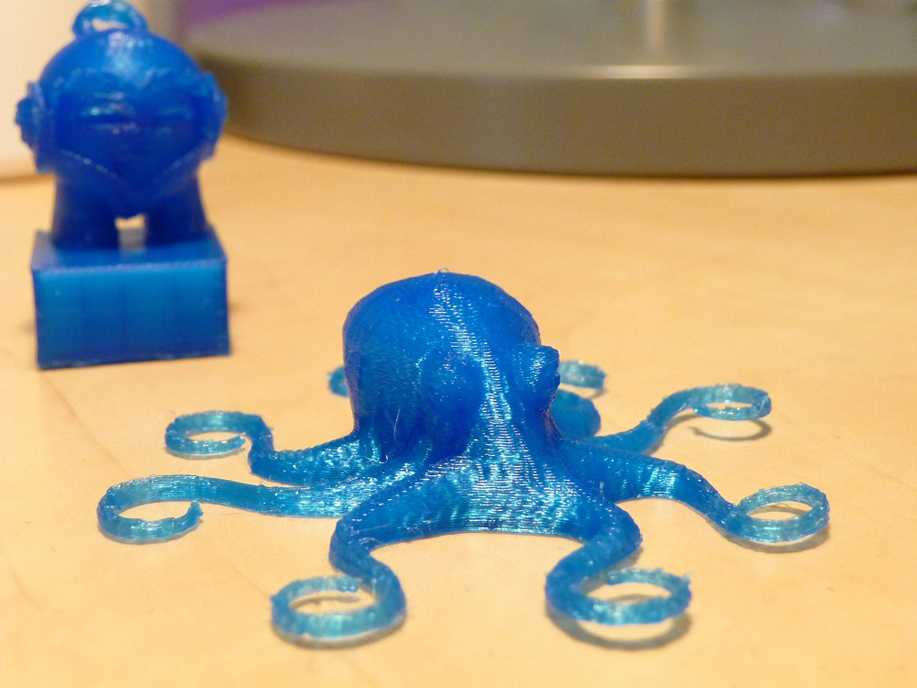

3D printing, or additive manufacturing, is increasing in popularity. This technology is becoming less expensive and more accessible to both businesses and consumers. It is currently used in a wide variety of settings, such as labs, factories, hospitals, schools, libraries, and homes. Despite its popularity, 3D printing is still a relatively new technology and there are many gaps in the information available about health and safety risks. The National Institute for Occupational Safety and Health (NIOSH) is studying the potential hazards of 3D printing and ways to reduce health and safety risks for workers.

What is 3D printing?

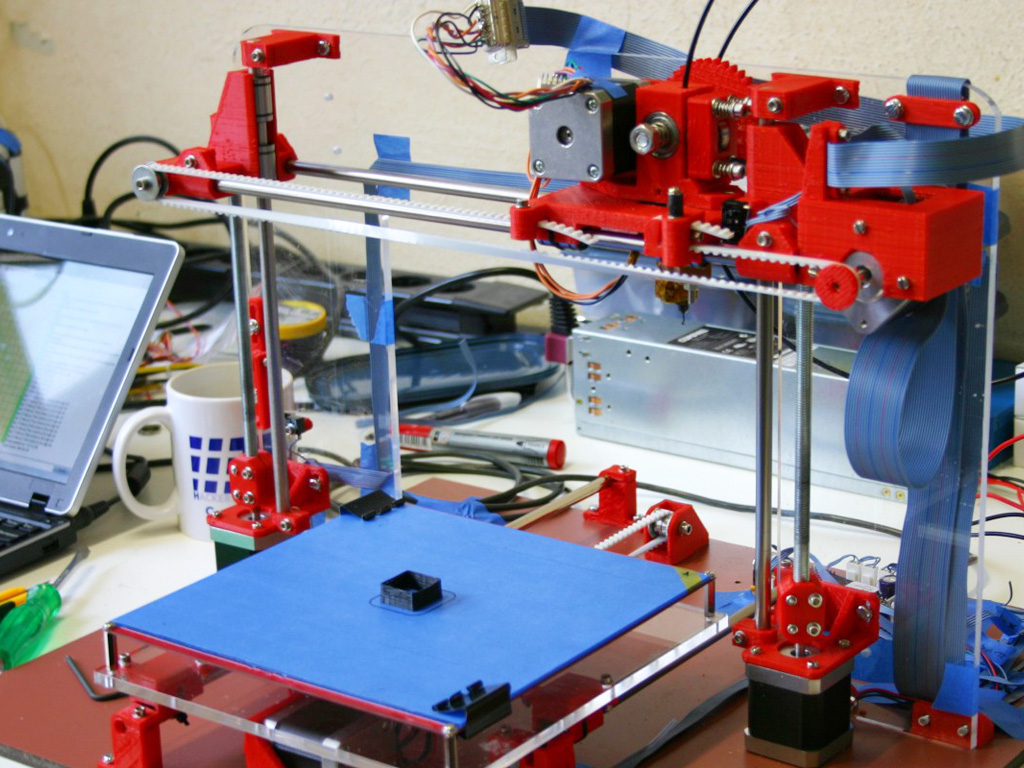

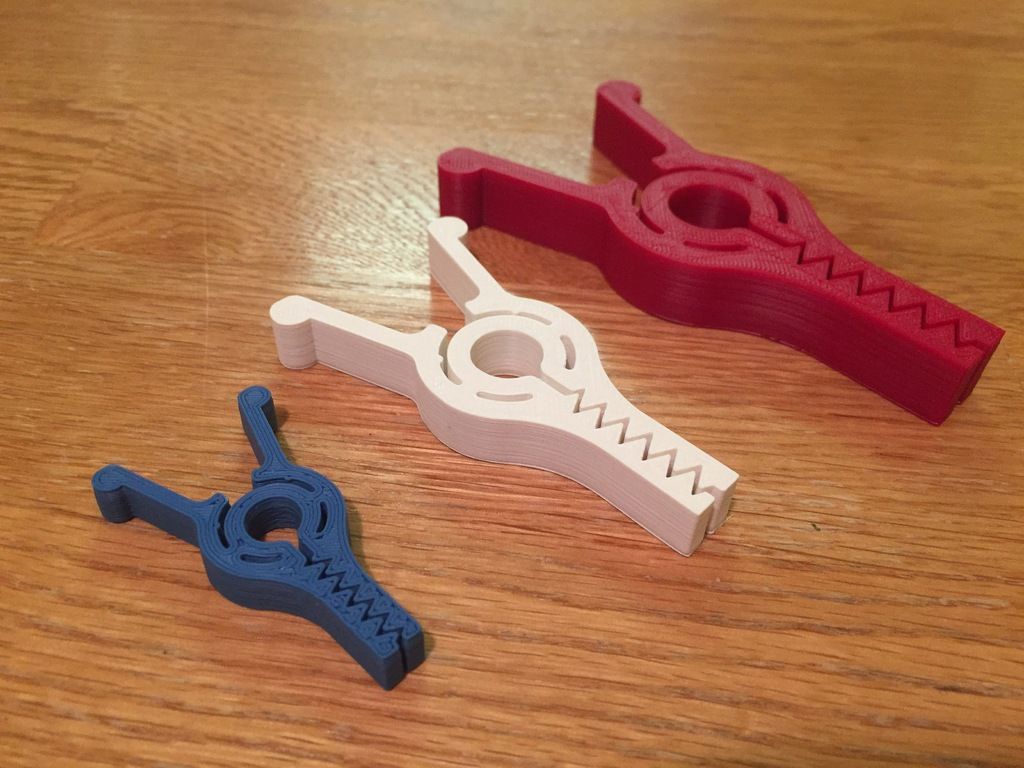

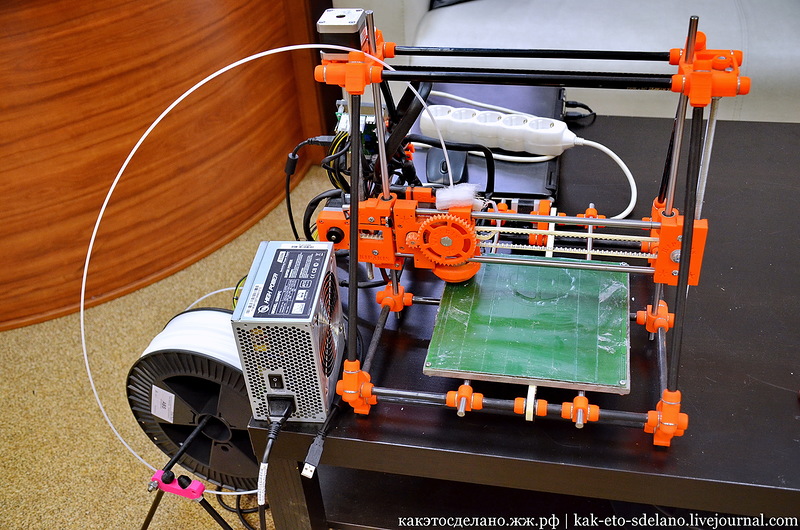

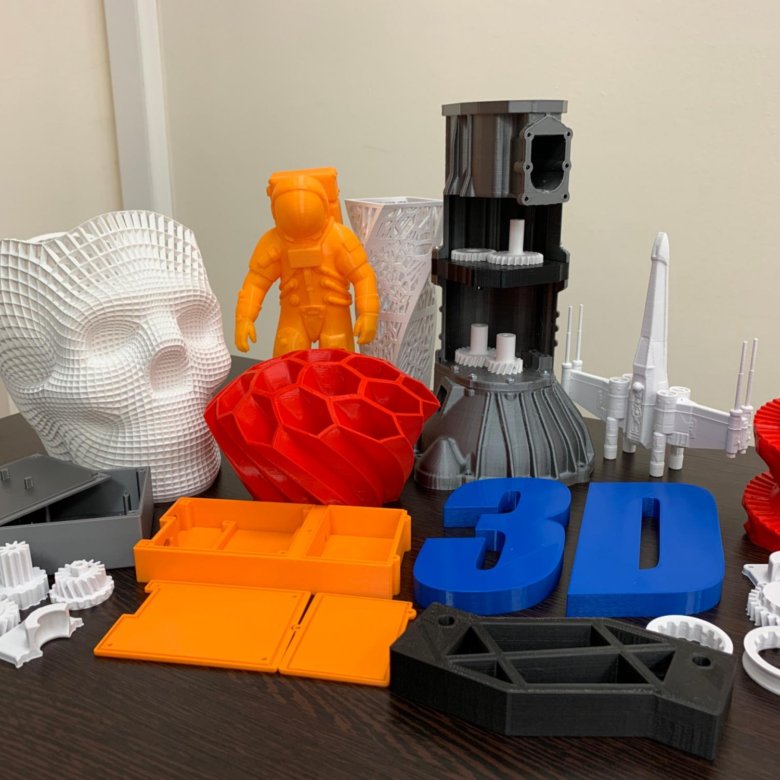

3D printers create three-dimensional (or 3D) objects via computers. A computer file “tells” the 3D printer what object to create and how. 3D printers essentially stack layers of a material to get the desired product. Different types of 3D printers do this in different ways. For example, some use high temperatures, some use ultraviolet light, and others use lasers. 3D printers also use different print materials, such as plastics, rubbers, and metals.

Industries traditionally used 3D printing for prototyping. However, it is now also used for production. Industries using 3D printing include the automotive, aerospace, electronics, medical, and many others.

Potential Hazards of 3D Printing

3D printing hazards vary depending on the type of printer and materials used. For example, print materials that are powders are more likely to be inhaled or cause skin problems than others. 3D printers that use lasers have different hazards than printers that use high temperatures to melt materials. Some common hazards include:

- Breathing in harmful materials: 3D printing can release particulates and other harmful chemicals into the air.

- Skin contact with harmful materials: Users can get hazardous materials, such as metal powders, solvents and other chemicals, on their skin.

- Static, fire and explosion: Some materials used can be flammable or combustible.

High temperatures from some printers can cause burns.

High temperatures from some printers can cause burns.

Ways to Protect Workers from 3D Printing Hazards

NIOSH has studied multiple ways to reduce exposure to 3D printing hazards. Some options include

- Limiting equipment access to trained or authorized personnel

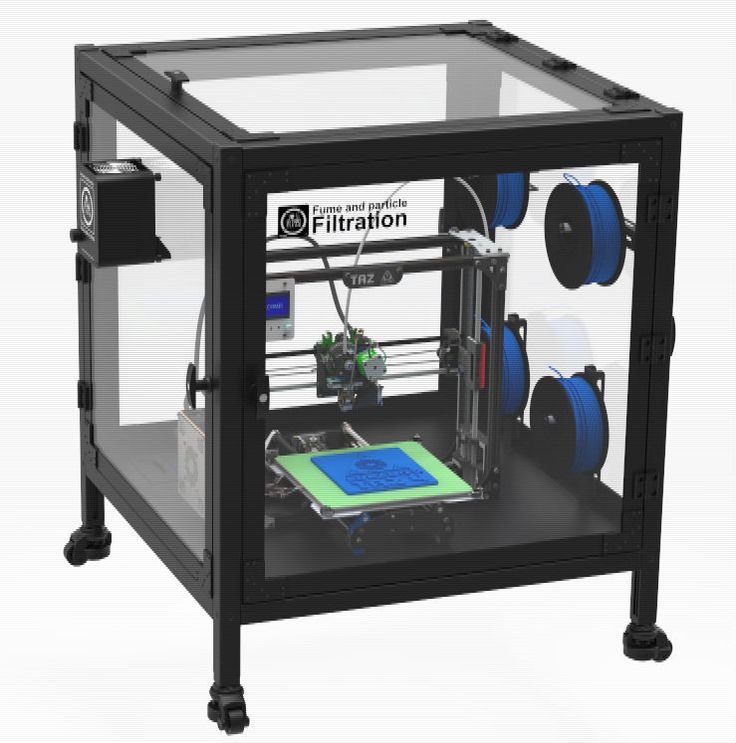

- Using enclosures for 3D printers and ventilation to capture chemical emissions

- Using materials with lower emissions

- Reducing time spent near the printer while it is running

- Training workers on potential hazards and how to protect themselves

- Wearing appropriate personal protective equipment, such as safety glasses, gloves, or lab coats

The ways to reduce exposure depend on the type of printer and materials used. NIOSH has created two posters to help workers explore ways to reduce potential 3D printing hazards. One poster focuses on 3D printing with metal powders and the other focuses on filaments:

- 3D Printing with Metal Powders: Health and Safety Questions to Ask

- 3D Printing with Filaments: Health and Safety Questions to Ask

Help NIOSH Learn More about 3D Printing

Do you use 3D printing in your workplace? You can help NIOSH continue assessing 3D printing hazards and controls. Companies can contact the Nanotechnology and Advanced Materials Field Studies Team to assess possible work-related health hazards with 3D printing in their workplace.

Companies can contact the Nanotechnology and Advanced Materials Field Studies Team to assess possible work-related health hazards with 3D printing in their workplace.

More Information

- Additive Manufacturing

- NIOSH Science Blog: Characterizing 3D Printing Emissions and Controls in an Office Environment

- 3D Printing with Metal Powders: Health and Safety Questions to Ask

- 3D Printing with Filaments: Health and Safety Questions to Ask

7 3D Printer Safety Rules You Should Be Following Now – 3D Printerly

3D printers are a complex piece of machinery that comes with safety rules every user should follow. I’ve put together a list of these rules so follow these rules and be confident about your safety through your 3D printing journey.

Safety is your responsibility, so read these carefully before your start 3D printing. This is mainly focused around FDM printers, which differ from liquid resin-based printers.

1. Watch Out For Burn Risks

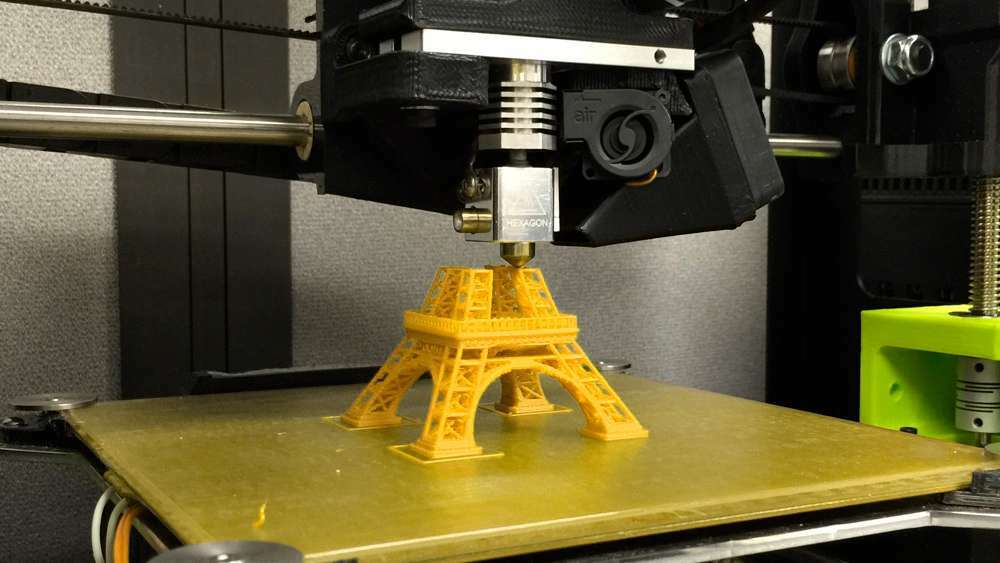

Watch Out For Burn RisksAs many people know, 3D printers work with very high temperatures, from the print surface, to the hot end.

Filaments that are used with printers are melted to get hardened filament into a property which can be put down layer by layer.

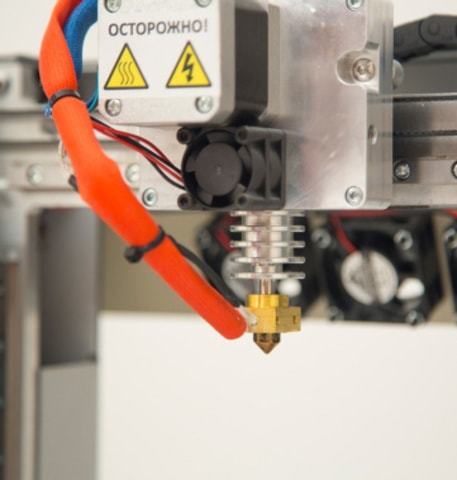

The hot end is what heats the filaments up and these temperatures can run anywhere from 190 to 300 C+, depending on what material you are printing with.

Any type of contact with temperatures this high will burn you and it won’t be a pleasant experience!

Many 3D printer users have let their guard down and got burnt while reaching into a machine, doing maintenance on their printer, or even changing filaments. This is easily avoidable if you keep this safety rule in mind.

Several FDM printers have what’s called a heated bed which assists the first layer of a print with extra adhesion. These also get up to high temperatures can can exceed 100C+. As fun as printing is, you do have to keep in mind, safety is very important.

As fun as printing is, you do have to keep in mind, safety is very important.

The risk of burn doesn’t only affect you, it can happen to a family member, a friend, your pets, and especially kids! Kids you have to watch out for especially because we all know how when you tell them not to touch something, the opposite tends to be the result.

How to minimise burn risks- Put your 3D printer in an area which isn’t easily accessible

- Wear gloves when handling your 3D printer.

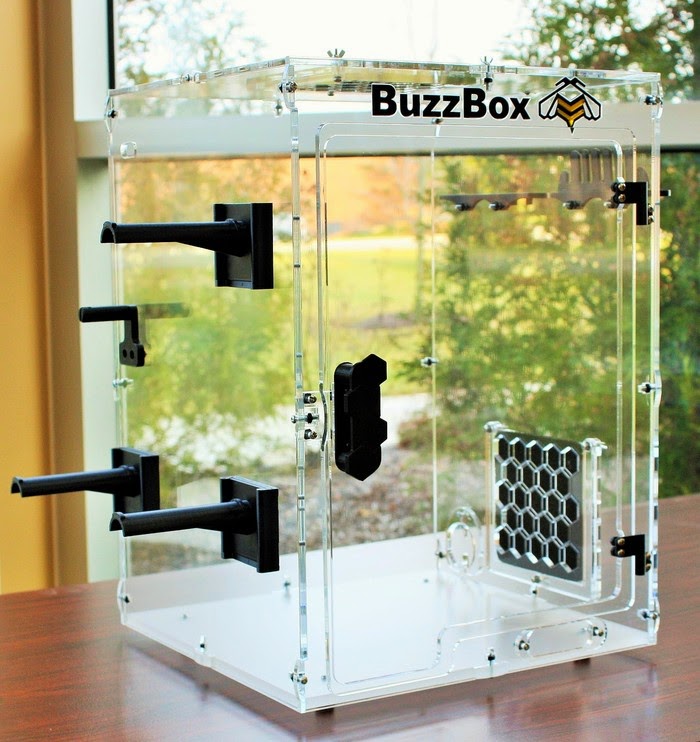

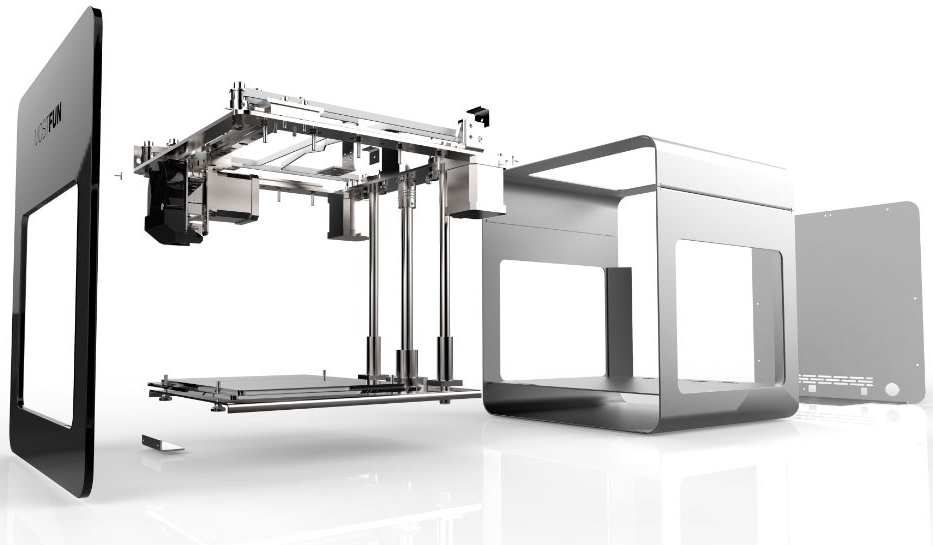

- Protect yourself with a enclosure or barrier of sorts – many printers come with an enclosure, if not, it’s possible to make a DIY enclosure.

- Keep a mental note in your head that your 3D printer gets very hot.

Josef Prusa made this awesome video on how to build a simple and cheap 3D printer enclosure.

2.

Don’t Fall For Pinch Points Injuries

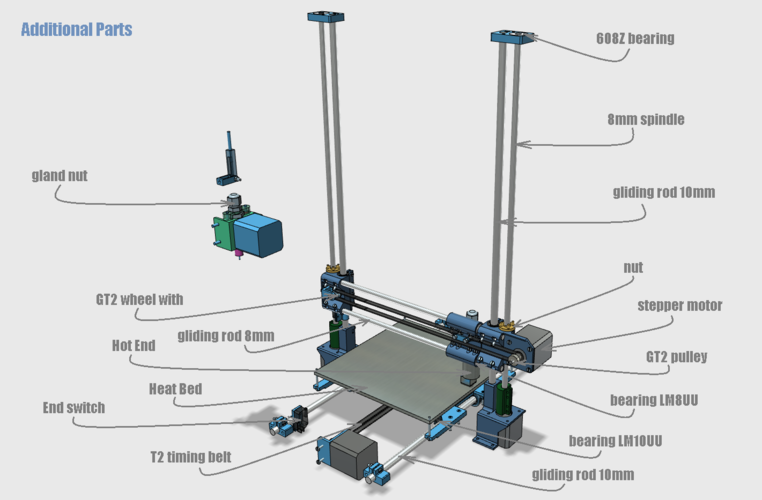

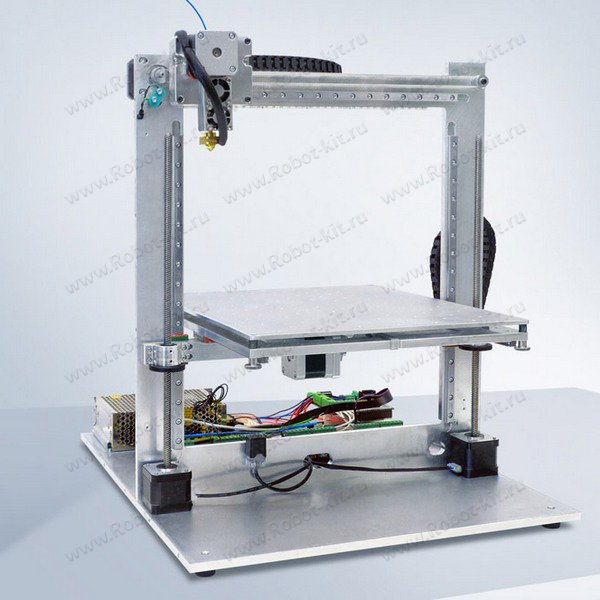

Don’t Fall For Pinch Points Injuries3D printers have a lot of mechanical movement from the X, Y and Z axis. All this movement gives rise to the risk of you getting pinched from your 3D printer.

3D printers mindlessly follow codes given from software on exactly where to move and how fast to move. Most 3D printers use something called Open Loop Systems to create movement directions.

Most of the time, these movements are pretty precise but one of the main flaws here is that there is no feedback system to tell the printer whether it moved to the correct location or whether it got obstructed in the process.

There are closed loop systems which are able to detect collisions and react in a proper fashion, but they are pretty uncommon with hobby 3D printers.

This presents a danger to a 3D printer user because these movements can easily pinch your fingers if they get in the way.

Some printers are more powerful than others and are differently designed in terms of the axis which assist movements, so it’s important to keep safety a top priority.

A printer on a higher power printing mode will present more risk than usual.

There are 3D printers out there that have a collision detection mode which will work to prevent this issue happening, but most printers out there do not.

These risks are more of an issue with industrial sized 3D printers, but even with consumer grade 3D printers it still presents safety issues which need to be addressed.

How to minimise print point injuries- Wear some good quality gloves for protection

- Again, protect yourself with an enclosure

- Only reach for your printer when you are certain it’s off

- Protective equipment like gloves can be used for safe measures

These Cut Resistant Gloves from Amazon do the job. Features: lightweight, durable, flexible, strong grip, comfortable. Many of the safety rules can be easily fixed with a pair of good quality gloves so I recommend you get a pair for yourself.

3. Be Extra Careful With Scraper Blades

A safety rule that several 3D printer users can attest to involves using those sharp, dangerous scraper blades which are used to remove 3D prints after they are finished.

So many people in 3D printing communities online have admitted to being the victim of scraper blade injuries after using too much force and not enough restraint.

This can so easily be avoided with the safety rule of being very careful when using a scaper blade.

Many 3D printers that people have do require a certain set of tools which have sharp edges, which can end with you getting cuts and scrapes.

Scraper blades will also be filled with contaminants from previous use, so a cut could end with a very unwanted infection.

This isn’t one to take lightly because it really can result in a trip to the hospital, and potentially permanent nerve damage! Please stay safe and don’t get complacent with your 3D printer.

How to minimise scraper blade injuries

- Always scrape away from your body and fingers.

- Both hands behind the blade

- Wear good quality gloves when removing your 3D prints

- Use a good quality print surface so prints aren’t stuck down so hard

A premium, extremely useful tool to avoid injuries from blades is the BuildTak Spatula also from Amazon.

It has a durable handle with an ergonomic rubber grip, a rigid stainless steel blade, and a thin front edge which easily gets underneath finished prints. Although pricey, it is a tool that will last you years and make life a lot easier for you in your 3D printing journey.

The spatula will save your prints getting damaged from removal, as well as keeping your print surface nick-free!

A high quality print surface that has high praises is the BuildTak Surface (3 Pieces) from Amazon.

Many users have boasted of much higher quality prints and using their first sheet for several months without needing to replace it.

When you have the confidence of knowing your build surface is fit for purpose, you feel comfortable printing more complex items and printing for much longer knowing your prints aren’t likely to fail.

With a combination of the build surface and the BuildTak spatula you can easily prevent spatula cuts and scrapes, which have already gotten many users out there. It’s good to invest into your future now and reap the benefits of increased safety and less frustrations removing your 3D prints.

4. Avoid Electric Shocks From Your PrinterThis is one that not many people are aware of, but it’s definitely one safety concern that you should know about.

Sometimes voltage can spill out from your 3D printer to the point where you can feel it throughout the entire frame. It’s important to know what the possible causes of this are, because it can be dangerous for your safety and others.

Possible reasons why you might get a mains voltage electric shock from your 3D printer are:

- Faulty ground connections – the filtering capacitors in the power supply fail and can’t dump the voltage to the ground.

- A mains wire becomes lose and makes contact with the frame of your 3D printer.

There is usually a lot of conductive metal in a 3D printer so voltage can flow through your 3D printer if you are not careful with safety.

Many 3D printer users have discussed the potential for electric shocks because they do have the potential to be a problem, especially with 3D printer kits.

This issue does affect different brands of 3D printers so you want to be able to make sure your printer is safe with the right precautions.

Some 3D printer manufacturers have begun using mains voltage bed heaters to lower heating times. It’s great for the heating times, but now you have increased your risk by having mains potential wires around and wires tend to fatigue over time.

This could leave you open to mains voltages which can be very dangerous.

Make sure you keep your DIY capabilities in mind when assembling a 3D printer kit or performing repairs. If you have doubts about what you are doing, make sure you get the advice of a trained expert.

The 3D printer itself may not be the issue, it could be to do with grounding your electrical outlets. A ground wire is the third hole in an outlet and is an important safety feature. It prevents your electrical systems getting a surge of excess electricity.

How to minimise the risk of an electric shock- Sometimes it’s possible to ‘ground’ your 3D printer

- Make sure you have mains power with earth

- Rewiring a 2 pin plug to a 3 pin plug has helped many people stop electric shocks

- Keep humidity between 20%-30% to lower static

- Get a 3D printer with an enclosed power supply (similar to a laptop’s power supply) attached to your normal DC outlets.

When your electrical system is in good standing, you minimise the risk of electric shocks occurring so it’s a good thing to check for if you don’t know already. The Mains Power Tester from Amazon gives you the ability to check if your sockets are wired correctly, as well as testing for polarity and earth.

5. Avoid Risk of Fire By Taking PrecautionsThis won’t affect most 3D printers out there, but there have definitely been cases of 3D printers catching on fire.

The potential of a fire breaking out from your 3D printer is low, but one instance of it happening can spell very dire consequences for you.

You have many components on a 3D printer which run at very high temperatures, for hours on end so if you don’t have safeguards in place it a risk that can happen.

Many 3D printers on the market today do actually have many protections against these issues, such as auto-shut down when certain faults occur.

One of these protections is called the thermal runaway which is a safety feature designed to prevent your printers catching fire.

When there is a disconnect between your printers temperature reading and heater, your heater can reach dangerously high temperatures, potentially becoming a fire hazard.

The thermal runaway prevents this by keeping track of hot end temperatures and shutting down the printer when the temperature falls by more than 15C for more than 45 seconds.

Most electronics you have actually have this same safety feature, such as laptops because in the past, their CPUs were known to cause fires.

The following are a few posts on Reddit about this happening:

My fully upgraded anet a8 caught fire yesterday

House caught on fire thanks to cheap printer from China

Fortunately, most stories that involve fires are from cheap, Chinese knock off printers so get a good quality printer and the chances of this happening are extremely low.

3D printer manufacturers are well aware of this issue and have put safety at the forefront of their products, so these stories are very rare nowadays.

How to minimise fire risks- Make sure your 3D printer has thermal runaway protection enabled

- Fireproof the area around your 3D printer – away from flammable material such as curtains, put on metal surface

- Try to avoid self-assembled 3D printer kits, if you don’t have the experience

- Use a smoke detector

- Have fire safety equipment around your 3D printer

Below is a video to test if you have your Thermal Runaway Protection enabled on your 3D printer.

Products to help with this safety ruleEvery 3D printer user should have a smoke alarm somewhere near their printer. Even though the risk is low, with safety in mind, you want to make sure you are ready if something does happen. This highly rated smoke alarm from Amazon is a great choice for you. It comes with batteries, has a 7 year working life, with a low battery reminder and a standard test button.

Even though the risk is low, with safety in mind, you want to make sure you are ready if something does happen. This highly rated smoke alarm from Amazon is a great choice for you. It comes with batteries, has a 7 year working life, with a low battery reminder and a standard test button.

If an electrical fire occurs, you don’t want to use water to put it out as water and electric is a dangerous combination. Instead, you want to use a small Powder Fire Extinguisher. It has a standard pressure gauge and an easy to use mount.

I hope you never have to use it, but I hope you are prepared to if you do.

This could be the difference between adequately putting out a fire or waiting for the fire service to save what’s left of your home!

The last piece of the fire safety items I recommend is a Fire Blanket. It’s made for easy removal in the event of an emergency, certified and has a 5 year warranty.

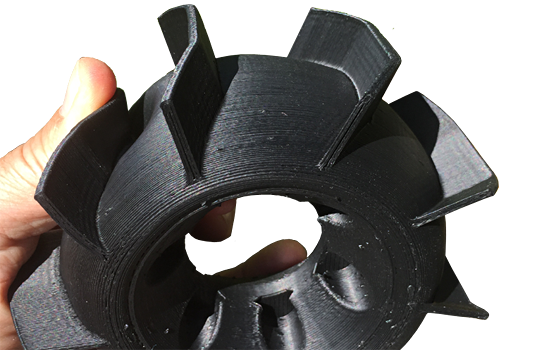

6. Removing Support Structures From Finished Prints

This is especially a problem with PLA and has caused many injuries in the 3D printing community. When you print objects that require a support, removing them can cause issues.

When you print objects that require a support, removing them can cause issues.

The support material tends to be sharp and can cut your hands very easily. It’s also very painful when you have shards of material go under your fingernails so keep safety in mind when doing this!

People have reported getting permanent scars from removing support material. It’s a real issue that is easily preventable if you remember this safety rule.

How to minimise injuries from removing support structures- Find software which minimise the use of supports

- Work slowly when removing support structures

- Use gloves when removing support material

- Wear a long-sleeved top for extra cut protection

- Use a machine which dissolves support material (like PVA) – requires printer with two extruders

Again, get yourself some Cut Resistant Gloves to protect your hands. These gloves are worth a lot less than the potential injuries you can get!

These gloves are worth a lot less than the potential injuries you can get!

Many people use a needle nose plier, which is more so used to support that can be broken away rather than cut.

A pair of Draper Redline Long-Nose Pliers (Amazon) will be your best friend for removing the extra filament on your prints. These are made of carbon steel which has been hardened and tempered and will make increase safety when used properly.

If you need to cut support with more precise control a better option would be a flash cutter, as it is a good combination of precision and strength.

These Precision Wire Cutters by Boenfu will get you the results you need. They are specially designed to tackle hard to reach areas and are made of forged steel for great durability.

7. Be Aware of Dangerous Fumes From Materials

The data on dangerous fumes from melted filament hasn’t brought us definitive conclusions on how it affects our health, but it’s better to be safe than sorry.

Many people have reported serious health effects of exposure to fumes from a 3D printer, as well as the effects on the lungs of people with respiratory issues.

This can get worse depending on what materials you are dealing with.

PLA is known to be one of the safest filaments on the market so if it’s not possible for you to print in a ventilated area I’d recommend PLA the most.

PETG is also a relatively safe material to print with.

ABS is a material which is well-known to give off toxic, carcinogenic fumes so you want to keep safe from these substances.

According to a 2016 study, ABS and Nylon emit high levels of styrene which has been known to cause fatigue, headaches and drowsiness.

Previous research has shown that 3D printers can emit large volumes of ultrafine particles and harmful volatile organic compounds.

When dealing with certain materials, you should definitely have caution and know the respiratory risks if you don’t minimise them.

According to Sentry Air Systems, activated carbon is rated excellent at removing the contaminants specifically from ABS (styrene) which is one of the highest polluting materials in 3D printing. If it works excellent with ABS, we know it does a pretty good job overall.

How to minimise the risk of dangerous fumes- 3D print in a well-ventilated area, ideally near a vent or window

- Have some type of air filtration system such as a HEPA filter or activated carbon filter

- Use less hazard-fume producing material such as PLA

- Use a 3D printer with an enclosure

One of the most popular portable air purifiers out there is the LEVOIT from Amazon. It has true HEPA and active carbon filtering properties.

The cool thing about this air purifier is it’s ability to filter 99.97% of pollutants and particles as small as 0.3 microns, which HEPA filters cannot do alone. It’s easy to use and is perfect for protecting you against dangerous fumes. Running it for 24 hours a day for a year can cost as little as $6.

It’s easy to use and is perfect for protecting you against dangerous fumes. Running it for 24 hours a day for a year can cost as little as $6.

Safe printing!

Potential dangers of a 3D printer. Part 1

In early February, a great tragedy occurred in the United States - a young family and pets died in their house under unclear circumstances. And the first suspect was a 3D printer. Allegedly, carbon monoxide released during 3D printing could cause poisoning for people and their pets. While the police cannot reliably establish the source of the gas leak and the causes of the tragedy, however, we decided to remind once again what potential dangers lie in wait for the owners of home printing devices and how to protect yourself and your loved ones from their impact.

1. Getting burned

It must be remembered that the principle of operation of the FDM printer is based on the melting of a plastic filament. Thus, the heating elements of the device present a great danger when touched. As a rule, the temperature of the extruder of a working device can vary from 170 to 300ºС. The specific figure depends on the type of material and appearance of the product you choose.

As a rule, the temperature of the extruder of a working device can vary from 170 to 300ºС. The specific figure depends on the type of material and appearance of the product you choose.

The melting temperature of the filament used in printers is sufficient to cause burns. For ABS plastic, it is about 210-270ºС, for PLA - 180-190ºС. This is enough to get painful damage in contact with both the material itself and the heating elements of the printer: the table and the extruder nozzle.

For PLA printing, this risk is lower because a heating bed is not needed, but if you are working with ABS, be extremely careful not to touch the hot elements. The risk of injury is directly proportional to the area of the heating surfaces. Remember that the temperature should be checked only by the readings of the sensors that are displayed in the printing program or on the display of the device, and not by hand or improvised means.

In situations where direct contact with hot surfaces is required, such as when cleaning the nozzle, special tools and personal protective equipment must be used, and extreme care and discretion must be exercised.

Also, keep children and pets away from the printer and never leave them alone with the printer. It is always easier to prevent danger than to deal with its consequences.

2. Electrical injury

Like any mains powered device, a 3D printer can cause electrical injury to a person. Naturally, with proper operation of the device this will not happen. Even in the event of a ground fault, the voltage in the exposed parts of the 3D printer will usually not exceed 12-24 V, which is considered safe and will only cause a slight shock.

However, when disassembling the case of the device for repair, replacement of a part, or cleaning of plastic, the possibility of receiving a 220 V electric shock increases many times over.

It must be remembered that any electrical appliance must be disconnected from the mains before servicing. Some printers have an external rather than an internal transformer, but this should not be a reason to forget about safety and leave the plug in the outlet.

Also not to mention the risks of short circuits. The probability of such an event in a 3D printer, as in any other household appliance, is small. But if you are assembling a set according to the drawings, be careful when connecting the wires. In the best case, the printer simply will not turn on or the fuse will burn out, but in the worst case, everything can end in an electrical injury or fire.

Evgenia Kurochkina, Development Director at ZENIT 3D, comments:

“There is no more danger from using a 3D printer than from any other electrical device used in everyday life or in professional activities. But, nevertheless, they are presented on the market as 3D printers with a high degree of security and, let's say, ordinary ones. What you should pay attention to when choosing a 3D printer using FDM technology and when working with it.

Such devices, as a rule, have two heating elements: an extruder and a heated platform or simply a table. The temperature of these nodes can reach up to 310ºС (extruder) and 110ºС at the table. To avoid burns during printing, the printer must always be with closed walls (so that a child or a pet does not accidentally climb in). The presence of a display and light indication will help to understand, even if the printer is already idle, what is the temperature of its heating elements at the moment.

The temperature of these nodes can reach up to 310ºС (extruder) and 110ºС at the table. To avoid burns during printing, the printer must always be with closed walls (so that a child or a pet does not accidentally climb in). The presence of a display and light indication will help to understand, even if the printer is already idle, what is the temperature of its heating elements at the moment.

Many manufacturers save money at the expense of safety. One of the options for such savings is to "power" the heating table directly from 220 V. In our opinion, this is wrong and unsafe. For example, when working with a 3D printer, many people use a spatula to remove a part, it is quite sharp, and any inaccurate action with a spatula when the table is on can lead to a short circuit and a 220 V current shock. Realizing this, we went the other way, and instead of 220 All ZENIT 3D printers supply only 24V to the table.

The extruder is the hottest part and must be handled with the utmost care. To remove the remaining plastic from the extruder, it is imperative to use a special tool.

To remove the remaining plastic from the extruder, it is imperative to use a special tool.

As for the electrical part, there is also something to look for when choosing a 3D printer. All wires and connections must be insulated, and best of all, hidden in the printer case. Any open connections, contacts, wires, boards in the event of an accidental short circuit can at least damage the equipment, at worst - harm health

Our company, developing 3D printers, considers the safety of its devices to be one of the important tasks. In particular, when developing the new ZENIT 3D model, which will be launched on the market in 2017, we paid a lot of attention to the safety aspect.”

3. Fire hazard

While we're on the subject of fires, let's talk about fire hazards not related to electricity. In point 1, we already wrote about high temperatures of heating surfaces in the context of burns, but an open printer case can also ignite materials lying around the printer. Paper and flammable liquids that have a low flash point should be kept away from a working printer, especially if it is an open type.

Paper and flammable liquids that have a low flash point should be kept away from a working printer, especially if it is an open type.

Another problem could be overheating of the extruder. For example, the ignition temperature of PLA plastic is about 388ºC. Purely theoretically, it may happen that a broken printer temperature sensor will cause spontaneous combustion of the material. If your printer also has a plywood or plastic case, this automatically turns it into fuel for the resulting fire.

Therefore, it is recommended that you install a fire alarm in areas where you print and keep a fire extinguisher handy at all times. Also, you can not leave a working device alone for a long time. It is clear that it is impossible to constantly monitor the printing for several hours, but it is better to monitor the operation of the printer from time to time.

A compromise would be to purchase a compact camera installed in the print room and broadcast to a smartphone or tablet.

4. Moving parts

3D printers have a lot of moving parts. These are motors, pulleys, threaded rods, carriage and fans. All this can easily grab you by the protruding part of the body and cause a lot of trouble. Avoid contact with moving parts of the printer while it is in operation! Do not reach in or attempt to correct a sliding object or push the carriage by hand.

If your 3D printer is an open type, wear tight-fitting clothing and keep an eye on your hair to minimize the risk of cloth and hair getting caught in moving parts. It is also worth worrying about the placement of the spool with consumables in advance, so that in the future the thread does not catch on foreign objects and knock the printer to the floor.

If the device does grab your clothing or hair, turn off the printer immediately and manually move the carriage until the pinched part of your body is completely free.

Irina Solomnikova, Commercial Director of IMPRINTA comments:

“If we talk about the possibility of carbon monoxide poisoning, then yes, such tragedies as in the USA are possible and, unfortunately, common. If we consider the 3D printer as the cause of the tragedy, then the repetition of such a case is unlikely. However, the source of carbon monoxide in this tragedy has not been established. As many people know, there can be many reasons for the occurrence of carbon monoxide. This includes the operation of a car, a fire, the operation of gas water heaters and stoves, improper operation of stoves, damage to a gas pipeline, etc.

If we consider the 3D printer as the cause of the tragedy, then the repetition of such a case is unlikely. However, the source of carbon monoxide in this tragedy has not been established. As many people know, there can be many reasons for the occurrence of carbon monoxide. This includes the operation of a car, a fire, the operation of gas water heaters and stoves, improper operation of stoves, damage to a gas pipeline, etc.

But it is definitely worth remembering that when using a 3D printer, you should follow safety precautions and use it for its intended purpose. Misuse of any appliance, such as a game console, microwave oven, telephone, iron, etc., can lead to unpleasant consequences.

The rules for using the 3D printer are very simple:

- The 3D printer must be installed in a ventilated area.

- The 3D printer must be placed on a level, stable surface.

- Before connecting to the network, it is worth checking the reliability of the power supply.

- Some parts of the printer get very hot. Do not touch them while the printer is in operation to avoid burns.

- The printer has moving parts. During the operation of the 3D printer, it is necessary to avoid getting foreign objects into the moving mechanisms of the printer, this can lead to injury and damage to the equipment.

- Do not place anything on the 3D printer.

- Be aware that some media may be toxic. When choosing a material, you must carefully read the description, temperature conditions and use only trusted manufacturers of printing materials.

- Do not leave small children unsupervised while the printer is in operation.

- Don't leave your printer running when you leave home.

If you follow these simple rules, as well as following the instructions, the use of a 3D printer will be safe both in the office and at home.

In conclusion, we add that a 3D printer, like any device, can harm a person. But let this not be a reason to abandon its use, but a reason to think about safety precautions. In particular, pay attention to your workplace, study the instruction manual and follow basic safety precautions. Then, instead of problems, a 3D printer will bring only the joy of creativity and positive emotions.

In particular, pay attention to your workplace, study the instruction manual and follow basic safety precautions. Then, instead of problems, a 3D printer will bring only the joy of creativity and positive emotions.

In the next part of the article, we will talk about the potential dangers of 3D printing consumables.

If you know or have encountered any other risks that come from 3D printers, write about it in the comments.

Tags: Irina Solomnikova, Evgenia Kurochkina, ZENIT 3D, IMPRINTA, 3D printer, 3D printing

How safe are resins for 3D printing?

Filament Deposition Modeling (FDM) material extrusion is the most popular polymer 3D printing method, but resins are becoming more and more important to consumers. Resin technologies such as stereolithography (SLA) were previously only used in dental laboratories, engineering departments and manufacturing plants due to the high cost of the equipment. Now that machines have become more affordable, more and more ordinary users are using SLA technology, which calls into question their safety.

Unlike FDM devices, resin printers use photosensitive liquids to print, curing materials with ultraviolet light. Liquid polymers pose a greater potential health risk than raw materials in fiber form. The toxicity of the resource may put off some users, but printing with resin can be safe if the right algorithm is followed.

What are the Potential Risks of Resins

The word "toxicity" is troubling, but according to the definitions developed by occupational health and safety professionals, any substance that, under certain conditions, can cause health problems or disease, is "toxic". According to this formulation, many substances around us are potentially dangerous, including perfumes and mattress filling. But are there any particular risks when using liquid resins for 3D printing?

The main concern with photopolymer resins is that they can cause skin irritation on contact. In some cases, contact of the substance with unprotected skin results in burns and blisters, which may require medical attention. If the materials come into contact with the eyes, they will cause irreparable damage.

If the materials come into contact with the eyes, they will cause irreparable damage.

Many resins are sensitizers, which means that prolonged exposure sometimes causes a mild allergic reaction. The chemicals that make up most resins are irritants that provoke the appearance of dermatitis - inflammation of the skin due to rejection of foreign elements. The skin quickly absorbs such chemicals, so prolonged contact with the composition or exposure to a large dose can lead to more serious consequences.

Another problem with resin 3D printing is air pollution. The material releases fumes, potentially reducing indoor air quality (IQA). Poor IQA scores can lead to headaches, fatigue, or more serious reactions such as breathing problems. These effects are due to volatile organic compounds (VOCs) and other small particles that cause an inflammatory response in the airways, leading to swelling or tenderness.

Long-term effects from working with liquid polymer are rare but significant:

• If the vapors are inhaled for a long time, chronic diseases of the respiratory system may appear.

• Some of the VOCs emitted by resins are suspected to be carcinogens, so they are likely to cause cancer after prolonged exposure.

• Constant physical contact can lead to severe allergies.

Standards and manufacturer's instructions

On the other hand, most resins on the market do not pose a significant hazard. Companies that produce such materials must comply with government standards and additional recommendations ISO 9001. Regulations ensure that chemicals produced by businesses are minimally harmful. However, some hazardous elements, such as asphalt fumes and synthetic mineral fibers used in fiberglass, are still widely used and over half a million workers are exposed to them.

Manufacturers usually provide Material Safety Data Sheets (MSDS) that list any potential health concerns. For example, corneal burns from overexposure to the eyes, or nausea and vomiting if swallowed. All these documents are provided in order to provide users with maximum safety when using consumables.

Some compounds may be more dangerous than others for certain people. If a person does not know if they are allergic to any materials, they should act as if they are and handle the product with care.

Safety Steps

Several government agencies have conducted research into the safety of epoxy 3D printing. They all showed that long-term emissions from printing are mostly negligible, although risks exist if proper precautions are not taken. Since studies have found traces of hazardous substances when working with resin formulations, safety regulations must be observed.

3D printing resins are not as scary as they seem, but they still need to be handled with care. First of all, direct contact of the mass liquid with any part of the body must be avoided. Safety goggles and nitrile or latex gloves should always be worn to prevent toxins from getting into the eyes or onto the skin.

Also make sure that the workplace is well ventilated. Ventilation is critical for any 3D printer, but especially for resin printing equipment.