3D house printing companies

The Manufacturers of 3D Printed Houses

Published on October 20, 2022 by Jamie D.

3D printing in construction has come more into focus than ever before. According to a report from Exactitude Consulting, the market is expected to grow from $503M in 2020 to about $6.5B in 2029. And as readers may know, there are numerous projects already out there, including homes which are being lived in. As such, we decided to shine a spotlight on the many manufacturers of construction 3D printers who are driving this booming sector. Currently, there are a number of different types of construction 3D printers, from polar machines to gantry-mounted printers to mobile robots. Today, they are capable of extruding concrete that enable the construction of various structures of varying degrees of complexity, from houses to bridges and offices. In the following alphabetical listing, we take a look at the main manufacturers of 3D printed houses on the market!

Apis Cor

Apis Cor is an American company from Melbourne that developed a 3D printer capable of building a house in just 24 hours, in extreme weather. As for current technology, Apis Cor has a printer nicknamed ‘Frank’. This is an easy to handle mobile printer capable of creating buildings up to 3 floors. He does not require any additional assembly; he arrives at the site ready to work. ‘Frank’ has a younger ‘brother’ printer named Gary: he is in charge of ensuring a high quality of 3D printing material. But they also have a ‘sister’, ‘Mary’, who is in charge of 3D printing material supply. ‘Mary’ doesn’t need bags of material, getting dirty mixing by hand, rain or snow, ‘Mary’ is always ready to work – just add water, connect her to ‘Frank’ and ‘Gary’ for teamwork and build!

‘Frank’ the printer. (Photo credit: Apis Cor).

BatiPrint

BatiPrint is a project that came from a team of researchers from the University of Nantes, where the startup is still based. One of the most important manufacturers of 3D printed houses, it aims to accelerate 4.0 construction by building and renovating using robotics and additive manufacturing. For its solutions, it partnered with LS2N, a laboratory specialised in the development of robotics, to create a 4-meter-long robot that deposits 3 layers of materials in succession: two layers of expanding foam and one third of concrete. This industrial robot is polyarticulated and mobile, allowing it to operate directly on site. It is capable of building 7-meter walls. Additionally, the company turns to recycled or biosourced materials to help increase sustainability in construction. For their projects, we can point notably to the creation of the first social housing in Nantes.

For its solutions, it partnered with LS2N, a laboratory specialised in the development of robotics, to create a 4-meter-long robot that deposits 3 layers of materials in succession: two layers of expanding foam and one third of concrete. This industrial robot is polyarticulated and mobile, allowing it to operate directly on site. It is capable of building 7-meter walls. Additionally, the company turns to recycled or biosourced materials to help increase sustainability in construction. For their projects, we can point notably to the creation of the first social housing in Nantes.

Photo credit: BatiPrint

Black Buffalo 3DBlack Buffalo 3D is a US based manufacturer of 3D printers for construction. They use durable, hard-wearing cement-based ink with which they claim to make constructions stronger than a block wall. Their motivation is to solve the growing housing crisis and reduce the carbon footprint of construction, using technology that can print constructions up to 4 stories high in a matter of weeks and create cost savings of around 50%. Their NeXON™ gantry printer and range of raw materials promise to revolutionize construction for the benefit of the consumer.

Their NeXON™ gantry printer and range of raw materials promise to revolutionize construction for the benefit of the consumer.

Photo credit: Black Buffalo 3D

COBOD

The Danish-based manufacturer of 3D printed houses, COBOD began its activities in 2017 with the construction of the first 3D printed building in Copenhagen. They are now present on every populated continent. The company’s first 3D printer was called BOD (Building On Demand) and with it they started working all over Europe, which allowed them to learn and optimize their machine. In this way they later developed the second generation of the 3D printer, the BOD2. They have recently released the COBOD configurator which offers a digital version of the BOD2 printer, with adjustable printheads and size. There is even a simulation of their buildings under construction. Recent projects from the company include the first 3D printed office extension in Austria and the construction of the first two-story home in the US.

Photo credit: COBOD

Constructions 3D

Constructions 3D is a French project by the company Machines-3D in collaboration with the Belgian architect Gaël Collaro, the leaders in 3D printing with mortar. The purpose of this project is to build customizable houses from recyclable materials directly in the locality where you want to create the construction, so they have developed their own 3D printers of houses. They currently have 3 printers. The Maxiprinter is the turnkey solution: a concrete printer which solves several problems faced by the construction industry. The transport of the container, as well as the robustness of the machine derived from its hydraulic system. They also have the Miniprinter Pro with a printing volume of 1.2 x 1.2 x 1.2 m which has an automated pumping system with 3 available pump options. And finally the Miniprinter Edu: designed to respond to the need of education and research sectors looking to develop the construction skills of their students and teams in relation to 3D digital tools. The video shows one of their projects in Bruay-sur-Escaut, at the Citadelle des Savoir-Faire.

The video shows one of their projects in Bruay-sur-Escaut, at the Citadelle des Savoir-Faire.

Contour Crafting

To build the average home in the U.S., it takes between six and nine months. Now imagine what it would be like if a personalized house could be built in just one day. Contour Crafting has addressed this issue. Thanks to advanced robotics, they able to build custom homes in just a few hours. Whether for low-income people or to rebuild after disasters – and for just one-fifth of the traditional cost of building a house! As for the material used for the 3D printer by Contour Crafting, this uses a fast-setting, concrete-like material.

Cybe Construction

CyBe Construction is a Dutch company that had previously launched 2 3D concrete printers, Cybe RC 3Dp and Cybe R 3Dp. It has now launched a third Cybe G, a 3D printer of a four column, three beam configuration capable of printing anywhere within the set 3D zone. This printer is perfect for construction companies interested in building affordable housing. The gantry prints with a print head and nozzle controlled by ABB. But not only that, they have also developed a patented material, based on a concrete mix. Both machines with 6 axes could print at a speed of 200 mm/second, enabling concrete structures to be manufactured quickly. Cybe’s technology is considered to be one of the most innovative and reliable ways to build a concrete unit.

It has now launched a third Cybe G, a 3D printer of a four column, three beam configuration capable of printing anywhere within the set 3D zone. This printer is perfect for construction companies interested in building affordable housing. The gantry prints with a print head and nozzle controlled by ABB. But not only that, they have also developed a patented material, based on a concrete mix. Both machines with 6 axes could print at a speed of 200 mm/second, enabling concrete structures to be manufactured quickly. Cybe’s technology is considered to be one of the most innovative and reliable ways to build a concrete unit.

Left, Cybe G; right, Cybe 3C. (Photo credits: Cybe Construction)

ICON

ICON was formed in 2015. The Austin, Texas-based company is one of the largest construction providers using 3D printing, robotic solutions and software. Their numerous projects have included working together with homebuilder Lennar to build a community of 100 3D printed homes, and a collaboration with NASA to simulate conditions on Mars. Most recently, they have renewed a partnership with the US military, this time for a major project to build military barracks. This diversified portfolio shows why ICON dominates the US market with their building solutions, as well as playing a key role in other countries.

Most recently, they have renewed a partnership with the US military, this time for a major project to build military barracks. This diversified portfolio shows why ICON dominates the US market with their building solutions, as well as playing a key role in other countries.

Photo credit: ICON

Mighty Buildings

The next on our list of manufacturers of 3D printed houses is Oakland, California-based Mighty Buildings. This company is transforming the industry using robotics and materials innovation. They pay attention to two issues that are very present today: housing availability and the climate crisis. 80% of the production of their operations are automated, 60% of the materials are recycled and there is 99% less expense per house built with 3D printing. For the last 5 years they have been working towards achieving zero waste in the production process, designing system kits and a concrete formula that would reduce time, costs and emissions. Some of the projects already completed are in California a three bedroom, two and a half bath house, community pool, garage. Or another project in the Caribbean with four bedrooms, four and a half bathrooms. Dream homes that can be built thanks to 4.0 technology.

Or another project in the Caribbean with four bedrooms, four and a half bathrooms. Dream homes that can be built thanks to 4.0 technology.

Photo credit: Mighty Buildings

MudBots

American company MudBots is known for their ability to build homes from small 15′ x 15′ models to large 100′ x 100′ models using 3D printers. For the first time, MudBots introduced its line of 3D printers at the World of Concrete 2019 in Las Vegas, and since then, it has carried out all the projects in the field of house construction through 3D concrete printing around the world. This series includes Model E15-15h20, Model E25-25h20, Model E35-35h20, Model E50-50h20, Model E75-75h20 and Model E100-50h20 printers, each of which has different features and different construction times.

SQ4D

The American company SQ4D specializes in the design and construction of installations created using 3D printing. Their ARCS line of construction 3D printers consists of a robot arm located in a gantry that surrounds the printing area, creating the structure by means of a concrete extrusion process. Notably, they state that they hope to offer the world a more safe, affordable and sustainable successor to traditional building methods. And it has certainly been successful up to now. In fact, in February 2021, SQ4D were the first to put a 3D printed house on the market. This happened in Long Island, NY.

Their ARCS line of construction 3D printers consists of a robot arm located in a gantry that surrounds the printing area, creating the structure by means of a concrete extrusion process. Notably, they state that they hope to offer the world a more safe, affordable and sustainable successor to traditional building methods. And it has certainly been successful up to now. In fact, in February 2021, SQ4D were the first to put a 3D printed house on the market. This happened in Long Island, NY.

Caption: SQ4D were the first manufacturers to put a 3D printed home on the market. (photo credit: SQ4D).

WASP

Since 2012, the Italian company WASP (World’s Advanced Saving Project) has been one of the key manufacturers of 3D printed houses. They work based on the principles of the circular economy and sustainability. In 2021, they entered the market using their own multi-printer Crane WASP, producing houses in a very short time using 3D printers. Their 3D printer Crane WASP is the first modular as well as multi-stage 3D printer ever to appear on the market. It can be built in any shape in just a few days and has a printing area of 50 square meters per printer unit. This made it possible, for example, to carry out the TECLA project together with Mario Cucinella Architects, which represents a global habitat for sustainable living.

It can be built in any shape in just a few days and has a printing area of 50 square meters per printer unit. This made it possible, for example, to carry out the TECLA project together with Mario Cucinella Architects, which represents a global habitat for sustainable living.

XtreeE

XTreeE is a French manufacturer of 3D printed houses, created in 2015, which creates complex concrete structures. It works with ABB branded robots and develops its own software in-house. In addition, it seeks to create more mobile machines to overcome certain manufacturing constraints. The startup explains that its machine is based on a technology close to that of molten material deposition. One of its most well-known projects is the delivery in Reims of the five first fully-certified 3D printed houses in France. Thanks to XtreeE’s 3D printing technologies, it was possible to design hollow walls to be able to integrate pipes and insulating material.

Thanks to XtreeE’s 3D printing technologies, it was possible to design hollow walls to be able to integrate pipes and insulating material.

Photo credit: XTreeE

What do you think of these 3D printed house manufacturers? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!

ICON – 3D Technology

Reservations Begin 2023

Located alongside the scenic San Gabriel River in the hills of Georgetown, TX, the Wolf Ranch community of 3D-printed homes by ICON in collaboration with Lennar is minutes from everything. This modern community blends the Texas Hill Country with access to the entire Austin metro area.

Sign Up + Be The First To Know

Explore the Genesis Collection at Wolf Ranch

01 02 03 04 05 06 07 08Built by ICON and Lennar, one of the nation’s leading homebuilders, and codesigned by BIG-Bjarke Ingels Group, the innovative community of one hundred 3D-printed homes features eight floorplans, 24 elevations and will be powered by the sun with rooftop solar panels.

See The Homes

100 Homes

08 Models

24 Elevations

How We Build

The Future of Homebuilding

ICON’s 3D-printed, high-performance homes feature elevated architectural and energy-efficient designs that highlight the benefits of resiliency and sustainability with the digital possibilities of additive construction. Delivered at speed and at scale using a fleet of ICON’s Vulcan robotic construction systems, software and advanced materials, each home’s full wall system including interior and exterior walls are produced with less waste and with more design freedom.

Learn More

ICON’s 3D-printed, high-performance homes feature elevated architectural and energy-efficient designs that highlight the benefits of resiliency and sustainability with the digital possibilities of additive construction. Delivered at speed and at scale using a fleet of ICON’s Vulcan robotic construction systems, software and advanced materials, each home’s full wall system including interior and exterior walls are produced with less waste and with more design freedom.

Delivered at speed and at scale using a fleet of ICON’s Vulcan robotic construction systems, software and advanced materials, each home’s full wall system including interior and exterior walls are produced with less waste and with more design freedom.

Learn More

Robotic Construction

We Make the Machines, Materials, and Software

That Build Our HomesConstruction-scale 3D printing not only delivers higher-quality homes faster and more affordably, but fleets of printers can change the way that entire communities are built for the better.

Learn More

3D concrete printing, building 3D printing, house printing

3D printing

- Construction 3D printing

- house printing

- 3D printing with transparent concrete

- Creation of MAF from concrete

Contact a consultant

3D printing of houses - modern solutions in construction

Our 3D4Art project team believes that modern building objects should not only be comfortable and warm, but also unique, bright and original. We invite you to dream about housing with unusual design solutions, with a complex composition, which will allow you not only to enjoy comfort, but also just to admire. Thanks to the development of additive technologies in construction, unique creative projects are becoming a reality, outperforming dull, angular boxes created in traditional ways in terms of cost and implementation time.

We invite you to dream about housing with unusual design solutions, with a complex composition, which will allow you not only to enjoy comfort, but also just to admire. Thanks to the development of additive technologies in construction, unique creative projects are becoming a reality, outperforming dull, angular boxes created in traditional ways in terms of cost and implementation time.

Construction 3D printing

Construction of private houses

Small architectural forms

Sale of 3D printers

CONSULTING IN CONSTRUCTION 3D PRINTING WITH CONCRETE

Our team has gone through the development and testing of additive technologies in construction from printing simple products to complex and large-scale compositions. And we are ready to provide professional support to companies aimed at developing this new and promising market.

Our specialists will develop the best solutions for your needs!

- +7 919 017 7436

Ask a Question

Learn more

3d printing - freedom of creativity

Our team invites you to become part of the historical period when unique creative projects become a reality, outperforming dull, angular boxes created in traditional ways in terms of cost and implementation time.

MORE ABOUT US

3D Concrete Finished Products Catalog

Our team invites you to become a part of the historical period when unique creative projects become a reality, outperforming dull, angular boxes created in traditional ways in terms of cost and implementation time.

CATALOG OF 3D CONCRETE PRODUCTS

UNIQUE CONCRETE SURFACE

Unique concrete surface technology . Only we in Russia and a few in Europe are able to create such concrete surfaces.

You can see the samples for yourself. Our experts will coordinate the time for a meeting with a consultant and help with the choice.

- +7 919 017 7436

Ask a Question

View all surfaces

Interesting news about us

ALL ARTICLES AND NEWS

FEEDBACK ABOUT OUR WORK

Alexander Maslov General Director of GC "AMT-SPETSAVIA"

Roman Pavlenko, 3d4art company in December 20, completed an order to print a complex house. Form with large overhangs, never before has anything like this been printed by anyone in the world of . The quality is excellent. For the customer, each block, and there are one and a half hundred of them, was coated with concrete varnish and packed to avoid chipping. None of the blocks were damaged in transit. Amazing geometric accuracy . We - equipment manufacturers are delighted with the work of Roman and his team. Thank you, you are not ashamed to send customers with orders for any printing.

Form with large overhangs, never before has anything like this been printed by anyone in the world of . The quality is excellent. For the customer, each block, and there are one and a half hundred of them, was coated with concrete varnish and packed to avoid chipping. None of the blocks were damaged in transit. Amazing geometric accuracy . We - equipment manufacturers are delighted with the work of Roman and his team. Thank you, you are not ashamed to send customers with orders for any printing.

Alexander Maslov General Director of AMT-SPETSAVIA

Artyom Dakhin Head of the company "3D Concrete", Irkutsk

Having become the owner of a construction printer, the question arose about the composition of the mixture for printing. Having tried a bunch of options with different components, in different ratios, having spent a lot of effort, time and money, I never got a satisfying result. Having plunged into the search, on the Internet I came across the site 3d4art. ru, where there was a service for remote maintenance and control of the technological process. As a result, in two months, under strict guidance, I got an amazing team, which is a pleasure to work with! At the same time, the composition is quite cheap from the selected available components. I RECOMMEND!

ru, where there was a service for remote maintenance and control of the technological process. As a result, in two months, under strict guidance, I got an amazing team, which is a pleasure to work with! At the same time, the composition is quite cheap from the selected available components. I RECOMMEND!

Contact us

Ask a Question

- [email protected]

- +7 919 017 7436

- Kolchugino, Vladimir region, st. Sovetskaya, d.62

- Moscow, Nauchny proezd, 17.

- Working hours: from 8:00 am to 21:00 seven days a week

Construction 3D printing is waiting for a breakthrough The first construction projects using this technology appeared only in 2014. We are talking, first of all, about the so-called small architectural forms (benches, flower beds, fences). They never even dreamed about building houses. But already in 2015, the Russian startup Apis Cor made a splash - it printed a whole house in the Moscow region.

Since then, news about new 3D printed houses has periodically appeared. However, despite the fact that the technology proved to be very promising in terms of the speed of construction of housing and the reduction in the cost of construction, no mass implementation followed.

Since then, news about new 3D printed houses has periodically appeared. However, despite the fact that the technology proved to be very promising in terms of the speed of construction of housing and the reduction in the cost of construction, no mass implementation followed. Construction is the world's number one market. And, if many technological innovations are being introduced in the field of high-rise construction, then little has changed in the field of low-rise construction over the past decades. The last 30 years have seen the availability of the Internet, mobile phones, mobile internet, robotics taken to a new level, etc., but when you get to a house construction site, you are unlikely to find many technological innovations. Automation is practically non-existent, and manual labor prevails. 2020 was a test of strength for the whole world, and also led to the highest level of inflation, which, first of all, hit the construction market, there was a dramatic change in prices for metals, cement, wood and much more.

This Internet meme shows what happened to the cost of building materials in just a year. And the process is still going on. At the same time, there is a serious rise in the cost of labor, and there is an acute shortage of it. All this leads to a sharp rise in the cost of building houses. No matter how strange it may sound, statistics show that the growth of automation does not occur when everything is fine, but precisely in crisis situations, during increased competition, reduced demand and the need to urgently look for new technologies to increase production efficiency. So it happened this time, and after some stagnation, construction 3D printing received a new impetus for development.

Preparing to write an article, I turned to the founder of Arkon - Boris Kozlov y. Arkon was established in 2020 and is engaged in the production of construction 3D printers, both a workshop type for creating prefabs (prefabricated houses) and a portal one capable of printing a two-story house. I asked Boris the key, in my opinion, question:

I asked Boris the key, in my opinion, question:

- Construction 3D printing appeared in 2014, but no mass introduction of this technology followed in 7-8 years. Why do you think this happened, and why is there a surge of new projects right now?

- It seems to me that the reason is the snowball effect. The technology had to mature, grow from a hypothesis to a pilot implementation, and finally to commercialization and scaling (what is happening now). In addition, it should be borne in mind that construction is one of the most conservative industries, where, unlike even aviation and the automotive industry, there is still an extremely low introduction of digital solutions and automation in the field of the production process itself - the construction itself. The issue of regulation and certification also plays an important role - this process is long and creates an additional lag.

In 2014-2016 the first samples of building 3D printers and prototypes of printed buildings appeared.

The concepts of various form factors of construction 3D printers and types of printing materials were tested.

In 2017-2018 in the world, the first notable investments were made in a number of construction 3D printing start-ups. Further, by 2020, these investments "rolled" in the form of reaching a certain level of technology maturity - the first commercial products (3D printers and houses) appeared.

Finally, in 2020-2022 it became clear that the hypotheses of the effectiveness of construction 3D printing were justified (cheaper, faster, more environmentally friendly), and large investments began in the industry. A striking example is the investment of GE (the French division of General Electric) in the Danish COBOD or the achievement of a capitalization of $ 2 billion by the American company ICON.

In 2022-2023 over 1,000 buildings will be printed worldwide already, scaling from single buildings/pilot projects to entire villages and major infrastructure/reinforced concrete implementations.

In addition, in a number of countries, by now, a regulatory framework has been created or is being actively created for the introduction of additive technologies in the construction industry.

Thus, I believe that the specified time period is a fairly natural cycle of technology development, which is likely to experience exponential growth in the next decade.

According to ResearchAndMarket report, the global construction 3D printing market is valued at $354.3M in 2022 and is projected to reach $11068.1M by 2027, growing by 99.04%.

Various market processes affect the prices and behavior of participants in the global 3D construction printing market. They create price signals that are the result of changes in the demand and supply curves for a product or service. They can be associated with both macroeconomic and microeconomic factors. Even human emotions can also drive decisions, influence the market, and create price signals.

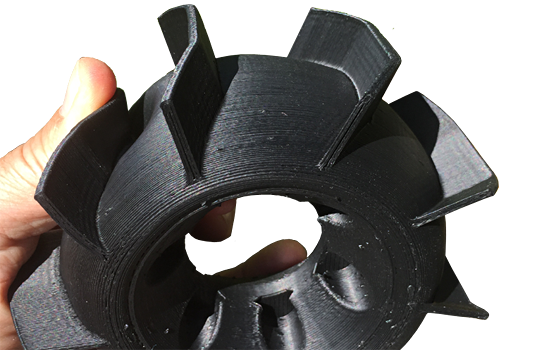

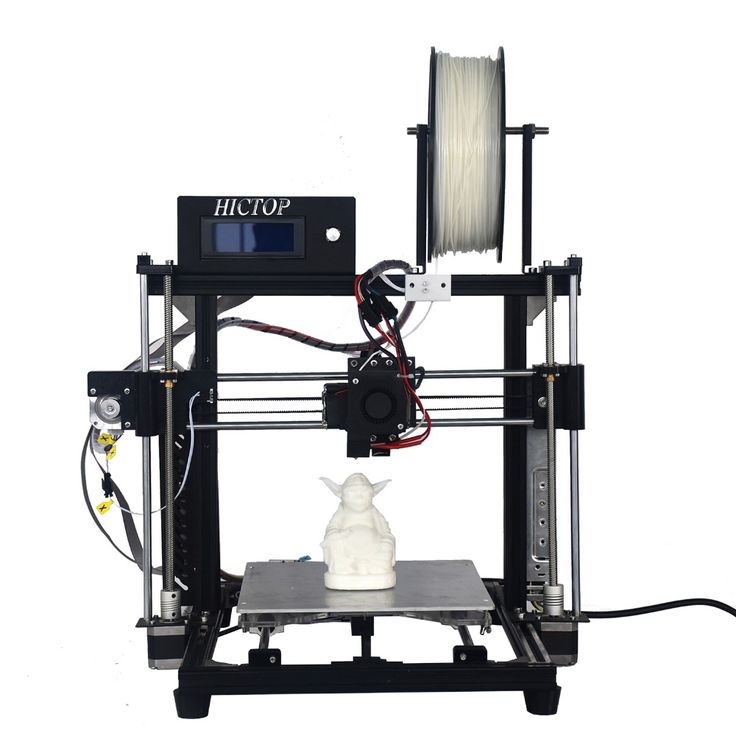

Now let's take a quick look at what the construction 3D printer is. Without delving too deeply into the technology, we can say that construction 3D printers are very similar to classic FDM/FFF printers that print with plastic, but instead of plastic, the material here is a cement mixture, which is fed directly into the nozzle and forms an object by layer-by-layer overlay. Printers are also portal, on the basis of a flying boom, with a robotic arm.

Without delving too deeply into the technology, we can say that construction 3D printers are very similar to classic FDM/FFF printers that print with plastic, but instead of plastic, the material here is a cement mixture, which is fed directly into the nozzle and forms an object by layer-by-layer overlay. Printers are also portal, on the basis of a flying boom, with a robotic arm.

Pictured left is a construction printer based on a boom. The figure on the right is a gantry construction 3D printer

In the figure above, a construction 3D printer in the form of a robotic arm mounted on a mobile platform.

Everything changed completely when, in the summer of 2021, the American company ICON, which was trying to introduce 3D printing into the construction of various auxiliary facilities, signed a contract with one of the largest American developers, Lennar, to build a village with 100 houses in Texas and immediately became a unicorn , having received 200 million dollars of investments from several investment funds.

At the same time, the Danish company COBOD, created by the world's largest construction formwork company PERRI, began selling its gantry 3D construction printers and participating in construction projects around the world. In the photo below, a modern two-story house built in Germany and a school building in Malawi, built in record time with a minimal budget.

There is little that unites developed, developing and poor countries, everywhere their problems and tasks, but The lack of affordable housing is a global agenda . If in poor countries there is an acute problem with the increase in the number of homeless people due to a lack of housing, as such, then in developing countries it is necessary to dramatically accelerate the number of new housing being built to meet the needs of a growing population. In developed countries, the problem is primarily in the cost of housing, which has risen in price to such an extent that it has become practically inaccessible to young people. And with the simultaneous increase in life expectancy in these countries, this problem is only getting worse.

And with the simultaneous increase in life expectancy in these countries, this problem is only getting worse.

At the same time, the trend towards “green agenda ”, CO2 emission reduction, building with more environmentally friendly materials, etc. is developing. But, unfortunately, so far the construction industry is the absolute leader in CO2 emissions, as well as in the amount of garbage that each construction site leaves behind. This is not to say that construction 3D printing solves all these problems, but at least it is moving in the right direction. Let's look at this with a few illustrative examples.

3D printed walls. Today, when we talk about 3D printing houses, we are talking about printing walls. Everything else (foundation, windows, doors, ceilings and roof) is done in the traditional way. 3D printed walls are built as fixed formwork, which significantly saves the amount of cement used, which in turn reduces construction costs and reduces the environmental impact of cement production. In addition, with this method of construction, no additional waste is produced, the strength of the structure does not suffer. It can be reinforced, as shown in the photo on the left, and engineering communications can be immediately laid, as shown in the photo on the right, which also affects the final speed of the construction of the object. At the same time, the total weight of the structure is reduced, the remaining cavities can be filled with lightweight foam concrete, insulation, straw or any other available material. Such a lightweight design can use a lighter foundation. The construction method itself is more economical in terms of material, and therefore environmentally friendly.

In addition, with this method of construction, no additional waste is produced, the strength of the structure does not suffer. It can be reinforced, as shown in the photo on the left, and engineering communications can be immediately laid, as shown in the photo on the right, which also affects the final speed of the construction of the object. At the same time, the total weight of the structure is reduced, the remaining cavities can be filled with lightweight foam concrete, insulation, straw or any other available material. Such a lightweight design can use a lighter foundation. The construction method itself is more economical in terms of material, and therefore environmentally friendly.

Eco-concrete with the addition of polymers is being actively developed, the production of which reduces CO2 emissions from 30% to 100%. The Apis Cor company mentioned at the beginning of the article, which built a house in the suburbs in 2015, is now based in hot Florida, plans to start using this material in its projects.

Another startup from Russia, Mighty Buildings, headquartered in California, initially relied on a polymer with the addition of mineral chips. And while the company doesn't build entire homes, it only makes wall panels, it has won numerous design awards, as well as a $400 million valuation in several investment rounds.

As a result, with a rough calculation, we can say that the total savings on the construction of walls can reach 30%, and the total cost of the house can be reduced by 10%. This is true for houses designed for conventional construction. And if you initially design with 3D printing, you can improve this ratio by optimizing the laying of communications, the ability to immediately print interior walls, bookmark niches for bathrooms, fireplaces, built-in wardrobes and kitchens, as was done in the house built by COBOD in Germany.

"There are spots on the sun." Despite all the advantages of construction 3D printing, has several significant disadvantages of . The main one is layering, which cannot be avoided at the current level of technology development.

The main one is layering, which cannot be avoided at the current level of technology development.

The photo above shows the layering of the 3D printed walls.

This task can be worked in several directions:

-

Ribbed walls can be plastered, painted and played up as a design element. That's how ICON does it in the US, for example their latest project House Zero is done that way and has won a number of design awards.

-

Use special "shutters" on the print head that allow smooth layers, as COBOD and other manufacturers do. The photo below shows that this does not ensure the complete absence of layering.

-

Fully sand the surface to get the usual smooth wall for plastering, painting, wallpapering or other finishing. It is possible, but it will require huge labor costs, which can reduce the overall efficiency of using 3D printing.

Pictured above is a 3D printed wall sanded smooth.

The second problem is the required temperature. Ideally, printing should take place at temperatures between +5C° and +30C°. Humidity is also important. Using additives, you can push these boundaries, but not indefinitely. At strong sub-zero temperatures, printing will be possible in the field only if the construction site is covered with a dome and the required temperature is reached inside with the help of heat guns. In conditions of intense heat, it is preferable to print at night. Another solution could be to print the wall panels in the shop and assemble them on site. Of course, each of these decisions will have a negative impact on the economic efficiency of the project.

Building 3D printing can be useful not only for the construction of houses . With its help, you can solve many other problems, and there its disadvantages will not matter. For example, the American concern GE uses COBOD printers to build towers for wind turbines in the shop. Ribbed surface and temperature restrictions in this case do not play any role.