Best glue for pla 3d prints

How to glue PLA? 5 ways to do it

In this article I’ll share my secrets and tricks to glue PLA. When I came up with the idea of writing this post I didn’t even know that there were so many ways to do it, but remembering different ideas, experiments and videos, I’ve managed to bring together 5 different ways to do it.

Are you curious to know what these 5 techniques are? Read on. 👇👇👇

📖 What do you want to read?

How to glue PLA with adhesive

The easiest way to glue PLA for most cases is to use an adhesive, so the question is, what kind of glue can I use? We have used several types of glue and we can recommend the ones that have worked for us: cyanoacrylate and special adhesives for plastics.

Cyanoacrylate glue is usually the best choice for bonding PLA parts. Any brand will do. I prefer it on small tubes so it won’t spoil if I don’t use it in a while.What adhesives to use for PLA?

- Cyanoacrylate.

Cyanoacrylate is the technical name of the adhesives we know as Super Glue, Loctite, extra-strong glue or instant glue. It is a glue that works for everything, including PLA; it allows to bond it in an easy and fast way with an adhesive that almost all of us have for our home or workshop.

- Plastic adhesives. Many brands of adhesives sell specific adhesives for plastics, because generally these are a little difficult to glue. I have personally tried UHU for hard plastics, but there is nothing to envy about bonding it with a more typical cyanoacrylate glue.

Glue PLA with epoxy

If you decide to glue the PLA pieces with epoxy you will have 3 extra advantages:

- You’ll get a stronger bond than with conventional adhesives and glues.

- You can fill small gaps if the two bonding surfaces are not flat enough or cracks remain.

- You can also use epoxy to improve the surface finishing with the epoxy smoothing technique (apply an external layer to the part to remove 3D printing layer marks).

But you will have to endure the main disadvantage, which is that preparing, manipulating and applying epoxy is much more complicated and has to be done in a space that you don’t mind dirtying and well ventilated so as not to breathe the gases it gives off.

A lot of epoxy resins are sold to smooth 3D printing parts and any of them will help you to glue your pieces: you will kill two birds with one stone. The most famous product I have tried is SmoothOn’s XTC-30 resin. For both gluing and smoothing, you will be able to use any epoxy resin with the proper consistency (which allows you to apply it with a brush to work the piece for 10-15 minutes).

This is the XTC-30 epoxy, which is used for both gluing and smoothing PLA parts. As you can see, the packaging is terrible, but the product works wellUsing a hot glue gun

The hot-melt glue gun is an essential part of any workshop. It is suitable for making quick joints, covering gaps, gluing cardboard, insulating electronic components… You won’t get the prettiest bonds, but for prototypes and areas that are not seen, it’s the fastest choice.

PLA can be glued with hot-melt adhesive; the only thing we have to take into account is that from 60-70 ºC the plastic begins to soften, so we have to be careful not to melt the areas of the pieces that we are going to bond.

This is the hot-melt gun that I have, a Parkside gas model. You can use a gas or electric pistol, the only difference is that it warms up a little earlier and can be carried around the workshop without worrying about the cable.Glue PLA con acetone

Glueing PLA using acetone is an experimental technique that I discovered in the following video of Thomas Sanladerer, one of the most famous 3D printing youtubers.

As you’re going to see, the initial intention of the video was to smooth the PLA pieces with acetone, but the result is not very satisfactory. However, the surfaces of the pieces soften enough to allow them to stick to each other. You can use acetone to join large flat surfaces of ABS.

The Dremel’s technique for PLA welding

This technique doesn’t require glue or any other material: it consists of friction welding the PLA using a Dremel or any other rotary tool. A piece of filament is inserted into the Dremel’s mandrel and rotated in contact with the part so that the filament, melted by friction, fills the gaps and bonds the PLA parts.

I’ve been able to personally try this way of gluing PLA but it doesn’t quite convince me: it’s a bit messy to do (you have to stop and change the filament every time you spend it), I didn’t get a good bond or a good finish.

Perhaps for projects where you have to fill some cracks, it may be worth it, but I do not find sense to weld the pieces in this way instead of using any of the other methods.

Did you like the article?

You can’t say I haven’t given you options, you already have 5 different ways to glue your PLA parts!

If you’ve come this far, you’ve been interested in what I’ve told you. You can help me by leaving your opinion in the comments. I reply to everyone!

Read you later.

Best Glue for PLA - Your Complete Guide to PLA Adhesives

This post may contain affiliate links. We may earn a small commission from purchases made through them, at no additional cost to you. You help to support resin-expert.com

Plastics. They are a hot topic in today’s world. Love them or hate them, they are part of our everyday life. Not only are they functional in our day-to-day lives, but they are useful in our creative endeavors, like 3D printing. To make the most use of this, you will need the best glue for PLA. Follow our guide below on PLA adhesives and joining 3D printed parts below.

Follow our guide below on PLA adhesives and joining 3D printed parts below.

Table of Contents

- 1 The Importance of Plastics

- 2 What is PLA?

- 3 Types of Glue

- 3.1 Superglues (Cyanoacrylate)

- 3.2 Epoxy Resin

- 3.3 3D Printing Pen

- 3.4 Other Glue Types

- 4 Things to Consider When Buying PLA Glue

- 4.1 Flexibility of the Glue

- 4.2 How to Prepare Your PLA Surface

- 4.3 Drying Time

- 4.4 Effects of the Gluing Process

- 4.5 Appearance

- 5 Frequently Asked Questions

- 5.1 What Glue Can Be Used for 3D Printed Plastic?

- 5.2 Will Hot Glue Work to Glue PLA Together?

- 5.3 How Can PLA Plastic Be Glued Together?

- 5.4 Can I Use Gorilla Glue on PLA?

- 5.5 Can PLA be Melted by Acetone?

The Importance of Plastics

Materials that can be used for 3D printing include plastics, metal (such as stainless steel, titanium, aluminium and even gold), resins, powders, graphite and graphine, and paper. We are assuming you are interested in working with plastic in particular.

We are assuming you are interested in working with plastic in particular.

Did you know that there are currently more than 9 billion tons of plastic in the world? Of these 9 billion tons, there are more than six different types of plastic, that are classified according to type. Plastics take years to break down. Some can even take thousands of years.

Although the sheer scale of plastic production, combined with their exceptionally low rate of decomposition, has caused a big problem in terms of pollution, they remain one of the most convenient, not to mention some of the cheapest materials available. Some of the characteristics that make plastic a favorable material to use, include the following:

- They are lightweight

- They are durable in severe weather conditions

- They are insoluble in water

- Some plastics can be very strong

- Plastics can be made in any color, and can be made transparent

- They do not conduct heat or electricity

What is PLA?

As you can see, plastic in all of its shapes and forms has a lot going for it, if you are looking for a durable material that has a wide variety of uses and that can be produced relatively cheaply. And, while most plastics take longer than our lifetimes to decompose, causing worlds of problems for the environment, the problem of pollution is solved by plastics like Polylactic Acid (PLA) plastics.

And, while most plastics take longer than our lifetimes to decompose, causing worlds of problems for the environment, the problem of pollution is solved by plastics like Polylactic Acid (PLA) plastics.

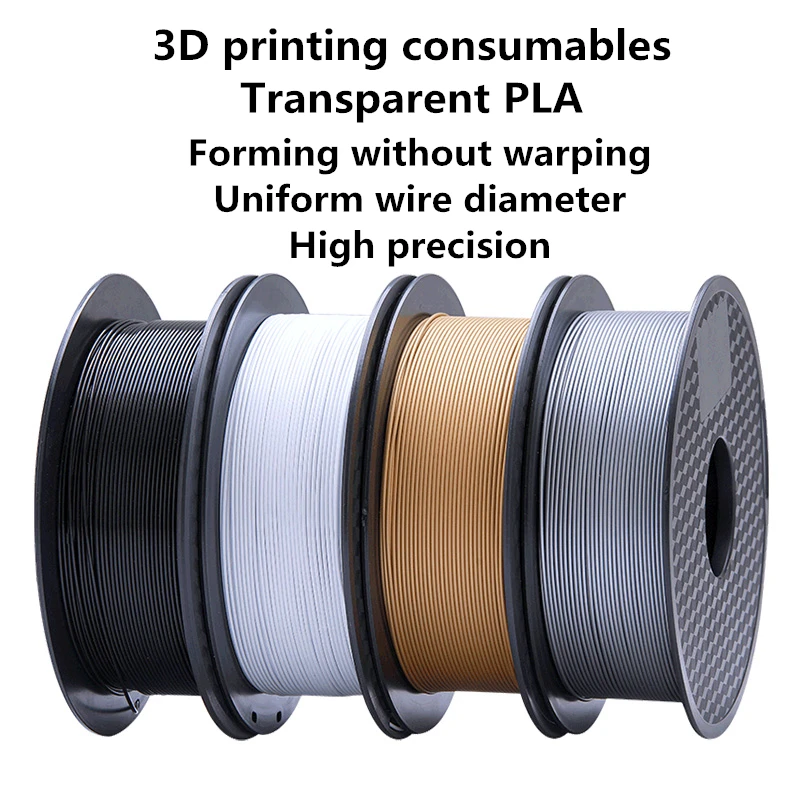

PLA is a renewable, biodegradable form of plastic. In contrast to other plastics that are made from non-renewable resources like petroleum, PLA is a type of plastic that is biodegradable because it is made from organic material like corn starch and sugarcane. While petroleum-based plastics can take hundreds or thousands of years to break down, PLA plastic takes a mere six months to two years to break down. It is also relatively cheap to produce.

There are many different kinds of PLA plastic, but the common factor among all of them is that they are made from organic material. Its properties are similar to those of polystyrene (PS), polyethylene (PE) and Polypropylene (PP). PLA is regarded as “thermoplastic”, which refers to the way in which it responds to heat.

You will notice PLA being used in various contexts of everyday life. Some bottles are made out of PLA plastics. For example, food containers and certain items used in the medical field (such as plates and screws that need to be discarded after use).

Some bottles are made out of PLA plastics. For example, food containers and certain items used in the medical field (such as plates and screws that need to be discarded after use).

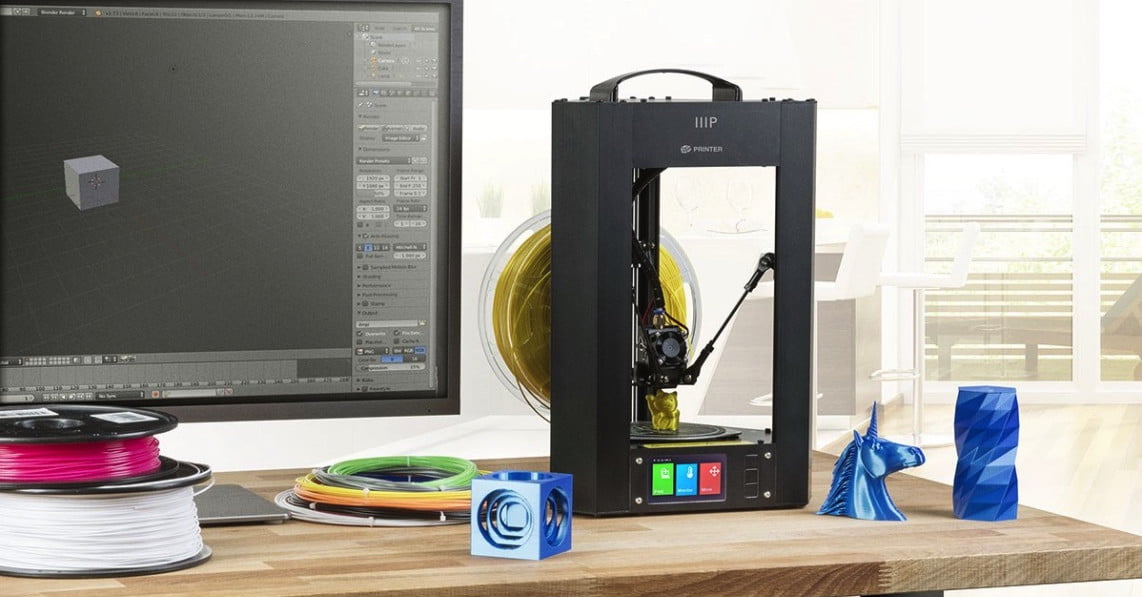

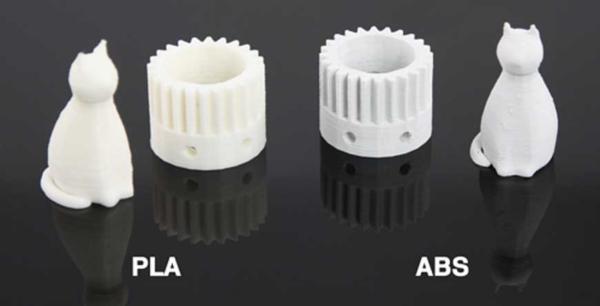

It is also a favorite among 3D printing enthusiasts. There are at least four different types of plastic that can be used for 3D printing, each with its own set of advantages and disadvantages. The two most commonly used types of plastic that are used in 3D printing are ABS and PLA plastic. They are both thermoplastics, which means that they heat up and change form when heated, and solidify again when cooled down, without losing their structural integrity.

Today, there are many manufacturers of PLA, such as WeForYou, Evoknik, NaturaWorks and Corbion. Although many people enjoy using ABS plastic for 3D printing, PLA has a number of superior qualities that make it the most commonly used plastic in 3D printing.

To name one of the features that make PLA a superior choice, PLA requires a lower temperature than ABS for printing. Another advantage PLA has over ABS plastic is that it is able to print corners that are sharper. As a filament for 3D printing, many colors are available in PLA plastic. It is usually available as a thin film or plastic pellets rather than sheet stock or rod.

Another advantage PLA has over ABS plastic is that it is able to print corners that are sharper. As a filament for 3D printing, many colors are available in PLA plastic. It is usually available as a thin film or plastic pellets rather than sheet stock or rod.

PLA requires a lower temperature than ABS for printing. The melting point of PLA is 180 degrees Celsius, while ABS plastic melts between 200 and 260 degrees. The benefit of the lower melting point is that you do not need a heated printing bed or a closed chamber. Another advantage PLA has over ABS plastic is that it is able to print corners that are sharper. It is also easy to work with. After printing, it doesn’t require much work: at most, light sanding and rub with acetone to create smooth surfaces.

The downside to using PLA is that there is a danger that the print head will become clogged with PLA, as it has a higher viscosity than ABS. ABS is also more flexible and resistant than PLA. Despite these drawbacks, PLA remains the most popular option for gluing PLA plastic pieces together.

Types of Glue

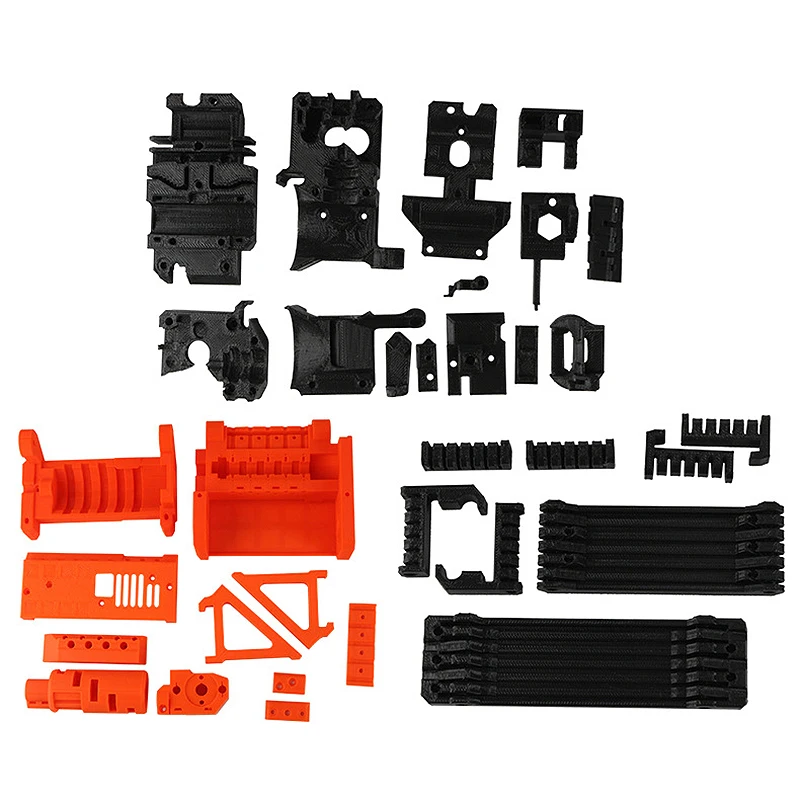

Gluing pieces of PLA together is an art in itself. This process is underrated among those who are new to the process of 3D printing. Contrary to popular belief, joining 3D printed parts is at least as important as the printing process itself, especially if you are printing something that is larger than your printing bed.

There are various ways of gluing pieces of PLA together, such as by using superglue, epoxy, hot glue guns, 3D pens and acetone. Each of these different bonding agents have a different method of use, and has its own set of pros and cons. In this article, we will hone in on three and include a description of what we think is the best product that is currently on the market for each respective glue. But first, here is a guide to help you to know what to take into account when you choose the type of glue that will best suit your 3D printing needs.

Superglues (Cyanoacrylate)

This is a household glue that is commonly used for an exceptionally wide variety of applications. It is hands-down one of the most popular in the world of 3D printing. Why? It’s fast-drying, cheap, easy to use and doesn’t leave much of a seam.

It is hands-down one of the most popular in the world of 3D printing. Why? It’s fast-drying, cheap, easy to use and doesn’t leave much of a seam.

The convenience and affordability come at a price, though. Being quick-drying, there is always a risk that you don’t line up your parts together or, even worse, spill a drop of glue on your project to remain there for the rest of time. Superglue sometimes requires sanding of the surfaces, which helps joining 3D printed parts. Once bonded, superglue does not offer much in terms of flexibility, and is one of the more rigid glues that you might buy. Another problem with superglue is that although the bond is very strong, it can be super brittle as the layer of glue keeping your PLA pieces together is thin. Not the best choice if you are wanting your join to be more flexible.

How to Glue PLA using Superglue

The quick-action nature of superglue requires that you have all your proverbial ducks in a row before unleashing the sticky stuff on your precious 3D printing project. Because super glue has a very powerful bond, you should take some precautions before you get started. The best bet if you want to avoid a world of pain after you are done gluing, in our opinion, is to wear gloves, and use a newspaper or plastic sheeting to protect your furniture. It goes without saying that you should ensure that you store you glue out of reach of children.

Because super glue has a very powerful bond, you should take some precautions before you get started. The best bet if you want to avoid a world of pain after you are done gluing, in our opinion, is to wear gloves, and use a newspaper or plastic sheeting to protect your furniture. It goes without saying that you should ensure that you store you glue out of reach of children.

Now that you have taken the necessary precautions, the next thing you need to do is prepare your PLA properly. Use fine sandpaper to ensure the surfaces you want to stick together are flat and even. Alcohol can be used to make sure there is no dirt or dust attached to either of the surfaces. Surfaces need to be completely dry before you use the glue.

When gluing PLA, bear in mind that superglue dries fast, really fast. This means that you should have your surfaces properly aligned before you stick them together. Hold the two surfaces together for about 60 seconds once the glue has been applied, then leave to cure for an extra few minutes.

Super Glue Recommendation: GORILLA Super Glue Gel

This is one of our favourite superglues, as it can be used on a variety of surfaces and is especially effective with gluing PLA plastics together for 3D printing. As the best glue for PLA, this product is a super-fast-acting bonding agent that has a thicker consistency than normal superglue. And, it’s gel-like consistency makes it possible for use on vertical surfaces without running the risk of dripping.

This product dries within 10 to 45 seconds, making it far more convenient to use than other glues as clamps are not required. This product is versatile in the sense that it is effective when applied to various surfaces like plastic, wood, metal, leather, ceramics and paper so you can use it for more than just your 3D printing needs. The glue comes in bottles of 0.71 fluid ounces.

GORILLA Super Glue Gel

- No-run control gel formula that is great for use on vertical surfaces

- Versatile glue with an anti-clog cap to prevent it from drying out

- Specially formulated for increased impact resistance and strength

View on Amazon

PROS

- Strong bond that can tolerate high impact

- Quick-drying

- Works very well for 3D printing with PLA plastics

- Thicker gel, so less messy than thinner superglues

- Dries clear, no colouring

- Thin seam

CONS

- Doesn’t work with all substances

- Toxic formula with strong odors

- Can be difficult to dispense

Epoxy Resin

The next best PLA adhesive is epoxy resin. It is an extremely versatile bonding agent that is used in a variety of contexts (3D printing being one of them). We recommend this as the next best thing after super glue because, like superglue, the bond that epoxy creates is exceptionally strong. If your surfaces are not flush (i.e. the surfaces are not completely flat, resulting in small gaps), these gaps can be filled by the epoxy.

It is an extremely versatile bonding agent that is used in a variety of contexts (3D printing being one of them). We recommend this as the next best thing after super glue because, like superglue, the bond that epoxy creates is exceptionally strong. If your surfaces are not flush (i.e. the surfaces are not completely flat, resulting in small gaps), these gaps can be filled by the epoxy.

That is, in addition, to be an effective glue, it is also a space-filler. What’s more, epoxy can be applied to your finished product to improve the overall quality of the surfaces and can be painted over. It’s not the best option if you are wanting flexibility, but it is not as rigid as superglue.

How to Glue PLA Using Epoxy Resin

Using epoxy is a little more labor-intensive than its “super-gluey” counterpart, but the result is worth the extra effort. It is usually packaged in two separate containers: one that contains the resin, and the other contains the hardener. You will have to mix these together, depending on the ratio that is described in the instructions that accompany the product (ratios for different brands may be different). Precise instructions will be available on the packaging of the epoxy resin that you decide to buy.

Precise instructions will be available on the packaging of the epoxy resin that you decide to buy.

The drying time for epoxy resin can be anything from a few minutes to a couple of hours. Some brands are sold that dry in only 5 minutes. Once it is mixed though, you may need to work quickly. Using brands that cure at a slower rate gives you the advantage of having more time to get the alignment of your surfaces right.

Note that some brands develop high temperatures when mixed together, which may have an effect on your 3D printer glue and the PLA you are using Heat can, however, be managed by using a product that has a slower curing process.

Epoxy Recommendation: SMOOTH-ON XTC-3D: High Performance 3D Print Coating

This product comes highly recommended, not only by us, but by the hundreds of customers who regularly use it. We like it for a number of reasons, not least because of the fact that it functions not only as a glue, but as a smooth coating for any plastic surfaces.

SMOOTH-ON XTC-3D High Performance 3D Print Coating

- An epoxy coating for 3D printed objects

- Compatible with SLA and SLS prints

- Works with a wide range of rigid media for a smooth effect

View on Amazon

PROS

- Smooths surfaces

- Fills in gaps

- High gloss finish

- Doesn’t melt PLA plastic

- Provides protective coating

CONS

- Rigid bind

- Thick seal

- Not suitable for gluing small parts together, or if your project has fine details

- You have to work quickly, otherwise it heats up too much

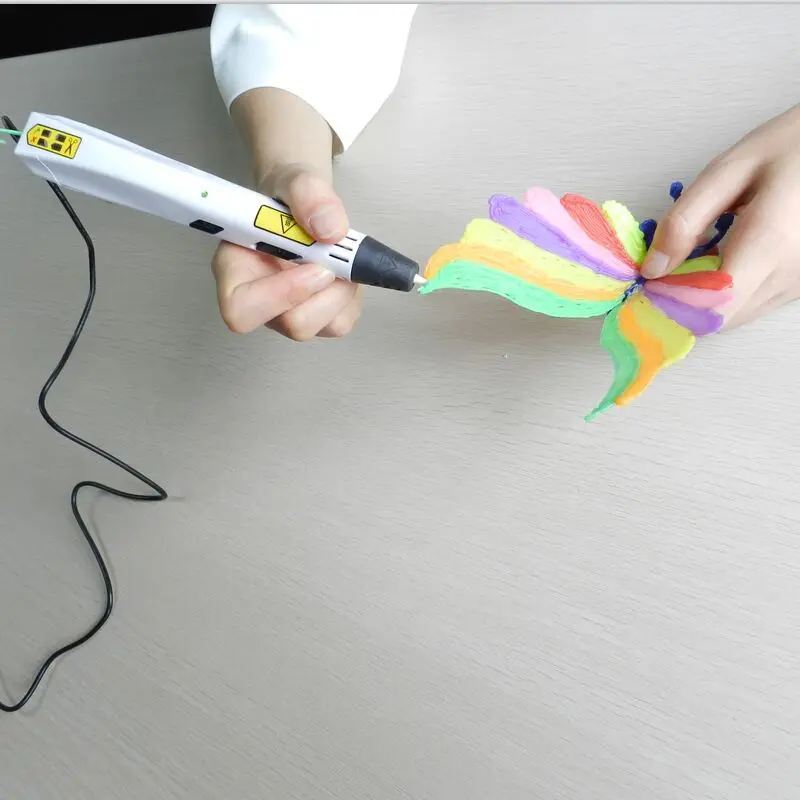

3D Printing Pen

A lot can be said for the use of 3D printing pens as glue. These tools are basically used as a hot glue gun, but with PLA instead of glue. The beauty of 3D printing pens is that they can be used for more intricate work, or as a filler (if there are gaps in your surfaces). 3D printing pens act like a welding tool, either by melting your two surfaces together or by filling the gaps between your two surfaces.

The beauty of 3D printing pens is that they can be used for more intricate work, or as a filler (if there are gaps in your surfaces). 3D printing pens act like a welding tool, either by melting your two surfaces together or by filling the gaps between your two surfaces.

Another factor working in these versatile tools’ favor is that they can be used in a number of different craft projects, not just for gluing plastic together. Some people like to use them to make 3D patterns on a variety of surfaces, for example. One of the main reasons why we suggest these pens as one of the top three ways of gluing your PLA together is because they are very easy to use!

Printing Pen Recommendation: SCRIB3dP1 3D Printer Pen

Behold, the SCRIB3dP1 Printer Pen, which is our pen of choice for a many good reasons. This pen is versatile, easy to use, accurate, and effective. Oh, its also plenty of fun to work with!

SCRIB3D Advanced 3D Printing Pen With Display

- Advanced 3D printing pen with variable speed control

- Includes a large LCD screen for heat control

- Includes three colors of PLA plastic

View on Amazon

PROS

- Versatile (can be used for other arts and crafts)

- Includes three different PLA colors

- User-friendly

- Has a range of temperatures, which it makes it suitable for different materials

- Anti-clogging features

- Auto-sleep function (safety precaution)

CONS

- May need to be reheated

- Operates slowly

As you can see, these are minor drawbacks when compared to the advantages that 3D printer pens have to offer. Depending on the quality of the pen that you buy, and how well you look after your pen, they can last for many years. You will, of course, have to continue to keep buying the PLA to refill the pen as you use it.

Depending on the quality of the pen that you buy, and how well you look after your pen, they can last for many years. You will, of course, have to continue to keep buying the PLA to refill the pen as you use it.

To get an idea of precisely how user-friendly these pens are when compared to other more complicated methods of gluing your plastic together, take a look at these simple instructions on how to use the SCRIB3dP1 pen:

- Insert the cable into the back end of the pen

- Choose the color filament you want to use

- Turn the pen on

- Leave the pen to warm up for 2-3 minutes (you will see a red light when it is warming up)

- Press the “forward” button twice in quick succession to start

- Feed the PLA filament into the back of the pen

- When the filament reaches the front of the pen, click the “forward” button. This will stop the pen from running if you prefer not to have a continuous flow of plastic

- Apply the PLA plastic as desired

- When you are finished, press and hold the “reverse” button to in order to retract your filament

Other Glue Types

So far, we have described what we think are the top three options for your PLA gluing needs. However, when it comes to stick small parts of plastic together, there are many more options than the ones we have described above. Read on for some more ideas for the best glue for PLA.

However, when it comes to stick small parts of plastic together, there are many more options than the ones we have described above. Read on for some more ideas for the best glue for PLA.

Hot Glue Gun

A glue gun is a user-friendly way of binding a variety of mediums. It is a great investment, as it can be used time and time again, for anything from wood to plastic. When choosing your hot glue gun for 3D printing, you can choose between a mini glue-gun (recommended for beginners) and a full-sized glue gun for more hardcore projects.

On any glue gun instruction manual (as is the case with any glue, for that matter), you will find a few words of caution. For name one, you should not use this equipment in humid environments. Secondly, once you have used a glue stick, you should not remove it (instead, add another glue stick behind it to push the old one forward). You should also not disassemble your glue gun in any circumstances. If you are opting for a glue gun to glue your 3D parts together, you should also note that so long as your glue gun is getting power, you should be running it continuously.

The glue that would be used here comes in sticks that fit into the glue gun, which can be transparent or opaque. Word of warning if you are wanting a more quick-drying, rigid bond for your PLA bits and pieces: this glue can be quite flexible, and can take a long time to dry. This is one of the best glue for PLA options thanks to its easy use and versatility.

Acetone

Another good PLA adhesive is Acetone. Acetone, aka paint thinner, is organic in nature and is used as a solvent in general use, and when used to stick pieces of PLA plastic together. Although not exactly a glue as it works by dissolving the plastics allowing them to merge, the strength of the bond that is provided with this product, as well as the fact that the seal is basically invisible if used properly, makes it worth mentioning as an experimental alternative to the glues that have already been mentioned.

Despite these significant advantages, there are elements that are cause for concern, if you do not take the necessary precautions when using acetone. It should only be used in ventilated areas, failing to heed this advice could result in dizziness. It is also highly flammable, so should not be used in near heat or open flames. There is also the danger of using too much acetone and burning through your filament.

It should only be used in ventilated areas, failing to heed this advice could result in dizziness. It is also highly flammable, so should not be used in near heat or open flames. There is also the danger of using too much acetone and burning through your filament.

To use acetone as a 3D printer glue, apply a thin coat on both surfaces, using a brush or cloth. The way this works is the layer of acetone dilutes the plastics, allowing them to mix with one another in such a way that a new plastic is formed as the bonding agent, rather than glue. Drying time depends on the amount of acetone you have used, as well as the size of the parts you are sticking together. But it can take anything from a few minutes to a few hours to dry, possibly with the help of clamps.

As you have seen, each agent described in this article has its own set of considerable advantages and disadvantages when used for gluing PLA. Taking the time to find out about their respective pros and cons can make a difference not only in terms of whether your gluing is successful or not, but it can also have a significant effect on what your final product looks like.

| Name of Product | Drying Time | Flexibility | Strength of Bond | Seam Visibility |

| Superglue | Less than 1 minute | Rigid | Very strong | Very thin |

| Epoxy | A few minutes to a couple of hours | Semi-flexible | Very strong | Thick, but can be used as a filler so seam is not noticeable |

| Acetone | A few minutes to a few hours | Rigid | Very strong | Invisible |

| Hot Glue Gun | 10 to 20 minutes | Flexible | Strong | Thick seam |

| 3D Printing Pen | A few seconds | Rigid | Strong | Thick, but can be used as a filler so seam is not notiecable |

Things to Consider When Buying PLA Glue

There are a number of things you should consider before you choose what glue to use, because not all glues are created equal. Take some time to think about the following factors before you buy your glue.

Take some time to think about the following factors before you buy your glue.

Flexibility of the Glue

Different types of glue offer different degrees of flexibility. Some (like superglue) are more rigid, while others allow some leeway for manoeuvring of the different parts of your 3D object. Consider the purpose and desired appearance of your final product when you think about flexibility.

How to Prepare Your PLA Surface

Something you should also take into account before you buy your glue, is whether or not you need to sand your surfaces before gluing them together. For some glues, having a bit of friction helps with adhesion, but this does not apply to all glue types. This is important to know when choosing the best glue for PLA.

Drying Time

Glues have varying setting times. Some require hours or days, in which case you will probably need clamps. If your 3D object cannot be clamped, or if you don’t have clamps, you will need a glue with a shorter drying time. A fast-drying product is generally the best glue for PLA.

Some require hours or days, in which case you will probably need clamps. If your 3D object cannot be clamped, or if you don’t have clamps, you will need a glue with a shorter drying time. A fast-drying product is generally the best glue for PLA.

Effects of the Gluing Process

Some glues become hot when they are curing. PLA plastics are sensitive to heat, and might start to change form, soften or melt at certain temperatures that are generated during the curing process. Glues can also react to different substances resulting in marks that form on your project, or vene result in burning through the plastic itself.

Appearance

Some glues leave a visible seem, others leave marks, and others require a few millimetres of glue in order to work effectively. This is an important factor when you are planning which glue you are going to use, as it could affect your design in ways that are not visually appealing and that may affect the overall look. The best glue for PLA is clear and seamless.

Frequently Asked Questions

What Glue Can Be Used for 3D Printed Plastic?

Lots of different types of glues can be used for gluing 3D printed plastic together. Superglue is probably the best option for gluing PLA plastic pieces together (which is the most commonly used plastic for 3D printing) because it is a cheap, quick-drying, and strong adhesive. It can be brittle though, so is not very durable.

Will Hot Glue Work to Glue PLA Together?

Yes, you can use hot glue on PLA plastic. Bear in mind, however, that the glue needs to reach a certain temperature in order to melt, and it is possible that your PLA will become deformed during the gluing process. Hot glue tends to be quite flexible and can take a while to dry, depending on the brand you use.

How Can PLA Plastic Be Glued Together?

There is a variety of glues that will work; which one you choose will depend on your needs and preferences. Your options include hot glue, superglue, 3D printing pens, acetone, and plumber’s cement. Each type of glue has different application processes, drying times, and other qualities that could affect the appearance of your 3D design and your experience working with the glue and plastic.

Each type of glue has different application processes, drying times, and other qualities that could affect the appearance of your 3D design and your experience working with the glue and plastic.

Can I Use Gorilla Glue on PLA?

Yes, Gorilla Glue works as an effective glue for PLA plastics used as a filament for 3D printing. Many people prefer the Gorilla super glue because its thicker consistency makes it less likely to drip and is generally easier to work with.

Can PLA be Melted by Acetone?

Pure PLA cannot be melted by acetone, but acetone does work as a solvent for PLA that is used for 3D printing. This is because other chemicals are added to the plastics that are used for printing, and these are what are affected by the acetone.

There you have it – an essential introduction into the world of 3D printing and how to glue PLA plastic together in the most efficient, user-friendly and durable ways.

Whether you are trying PLA plastic for 3D printing for the first time, or are an old hand, we hope the information is of value to you as you learn and grow in your creative journey!

(There is a solution) What adhesives for PLA?

PLA is good, and bonding has been a topic on some of our most favorite maker channels. For example, Stefan from the CNC kitchen (this video) and Joel 3DPrinting Nerd (this video). Here is some information from them along with my own experience. By the way, most of these adhesives are not exactly specific to PLA and work for many other materials as well. However, be careful with PLA containing infilt, as this can seriously change its properties.

Step 0: Safety first!

Some of these methods work with chemicals that can irritate the skin (resin, cyanoacrylate), have irritating fumes (acetone), or are flammable (acetone). Others (cyanoacrylate) are not heat resistant and break down into their components when exposed to heat.

Use proper protection when handling adhesive! If necessary, use eye and respiratory protection, as well as gloves. Read the manual for the products you work with!

Preparation

For most adhesives, it is desirable to prepare the surface: sand it to increase surface area, remove grease from fingerprints, etc. Follow instructions!

Adhesives

- Cyanoacrylate - yes, one-size-fits-all is also the solution for PLA: Superglue. However, be careful what type you get! Some are clearly better than others, and the use of an accelerator can change the properties of the adhesive.

- Together with talcum powder, CA glue can easily fill gaps.

- CA is not heat stable and decomposes into quite toxic smoke if heated too much! This can be handy for breaking metal-CA-metal bonds when machining small parts, but keep this in mind if you want to use inserts or plastic soles in the same areas! Do not contact CA in these cases.

- Epoxy is a favorite for very hard bonding, a few drops can stick a car to the roof.

.. and it gets warm when cured. If you use a slow curing resin, you can safely use it to bond PLA without deforming the part.

.. and it gets warm when cured. If you use a slow curing resin, you can safely use it to bond PLA without deforming the part. - Uncured resins and their hardeners are highly irritating to the skin.

- Urethane - 2 Component urethanes offer strong yet flexible bonds and work great according to Joel. Their curing process is also exothermic, so be careful not to "weld" your piece.

- 2-Phase Putty - A similar vein includes 2-Phase Putties, such as Green Matter or Miliputt, which harden after mixing. Their heat dissipation is not too great, and they make it easy to fill gaps. My favorite things, although not expensive model putty, but things from home depot: things like Pattex Repair sorry no english website for this or UHU Repair All Powerkitt cures in an hour, amazingly cheap and smooth finish.

- Acetone - We all know that you can smooth and bond ABS with acetone or acetone-ABS slurry. Tom (Thomas Sanladerer) did some experiments with him.

He found that it worked for at least for some types of PLA like this: put some acetone on the stain and press the second piece (which was also prepared this way) against it and they might melt together after a while.

He found that it worked for at least for some types of PLA like this: put some acetone on the stain and press the second piece (which was also prepared this way) against it and they might melt together after a while. - The effectiveness of this depends on which PLA you received.

- Acetone is highly flammable.

- There is a type of adhesive commonly called "Kraftkleber" or "Alleskleber" in Germany, such as UHU Hart or Pattex Kraftkleber German . While they often stick to PLA, I personally don't like their adhesive power and often find them rather messy to work with.

- Wood Glue - Yes, Wood Glue. PVA wood glue, as well as its water-insoluble cousin ("Express"), has proven to me to be a pretty good surface finish for smoothing out printed lines, as well as a good solution for attaching paper and wood to prints. This is less of a solution for plastic-to-plastic ties, but works fine.

Adhesive? Why glue?!

"Solder"

What better way to join parts than welding or soldering?! Often, none. My personal favorite is PLA glue is PLA itself, using it as PLA solder. This method also works for most other types of filaments, but is not recommended for ABS and other plastics that emit fumes without the use of respiratory protection!

My personal favorite is PLA glue is PLA itself, using it as PLA solder. This method also works for most other types of filaments, but is not recommended for ABS and other plastics that emit fumes without the use of respiratory protection!

- Take the pieces and make sure there is a cavity on both sides that can be filled.

- Take a soldering iron and set it to about 200°C.

- Take the length of the PLA filament.

- Melt the thread with a soldering iron and use it as solder when joining the two parts. Make sure at least some filament gets into the cavities and gets stuck there - it can help to stick the soldering iron into the goop there to get it to fuse with the filler/walls and press the hot pieces of PLA goop together against the iron before pulling it out by pressing pieces together.

- As the PLA cools and solidifies, the joint usually becomes more rigid than the actual layer boundaries.

Pen

Instead of using a soldering iron, you can also use the 3D printing pen , which eats filament, not PCL or some kind of gel! , but personally I don't like them.

Inserts!

On the other hand, a soldering iron is also a very good solution for making inserts in PLA - heat up a metal insert (like a nut) and press it against a smaller hole and it will mold the plastic around itself into a perfect fit without glue.

Friction Welding

An alternative to using direct heat from a soldering iron is Friction Welding . To do this, take a rotating power tool and some filament. Insert the thread into the tool, tighten and cut so that about an inch comes out of the claw. Turn it on at medium speed, around 800 to 1200 rpm. Now, as soon as you press the tip of the spinning thread against another PLA, it heats up and melts, creating a weld. Joel has a good explanation.

Best adhesive found

jrBush

Loading

24.04.2019

3105

Personal diaries

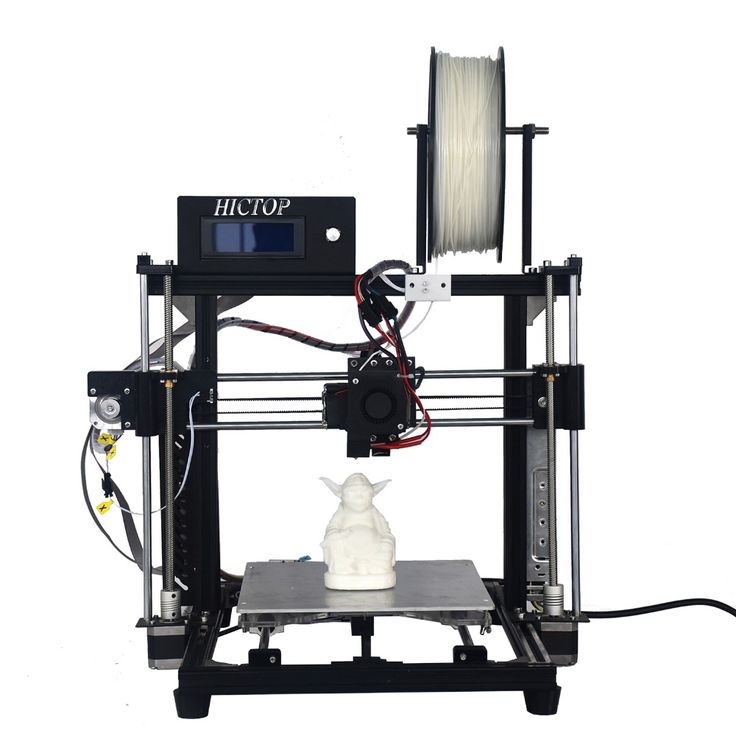

WANHAO DUPLICATOR I3 MINI

Hello everyone, the time has come for me to share my experience in the field of 3D printing, I don’t know how experienced I am, but at the moment I printed 2kg. Filament.

Filament.

So we're talking about table glue.

I will say that from the moment I was given the printer and until this post I had no problems with adhesion, but after the tube of pencil that came with the printer ran out and I went to the store for the first glue I came across, I had to go online and find out what many users of 3D printers experience problems with sticking to the table, or rather the lack of it, so I’ll say that really not all glue sticks are suitable for this,

For myself, I think the ideal glue is “Erich Krause” to spread thicker and there are no problems, by the way, it is not necessary to clean the glue with alcohol or window cleaner after each print, you can safely apply a layer on top of the old glue.

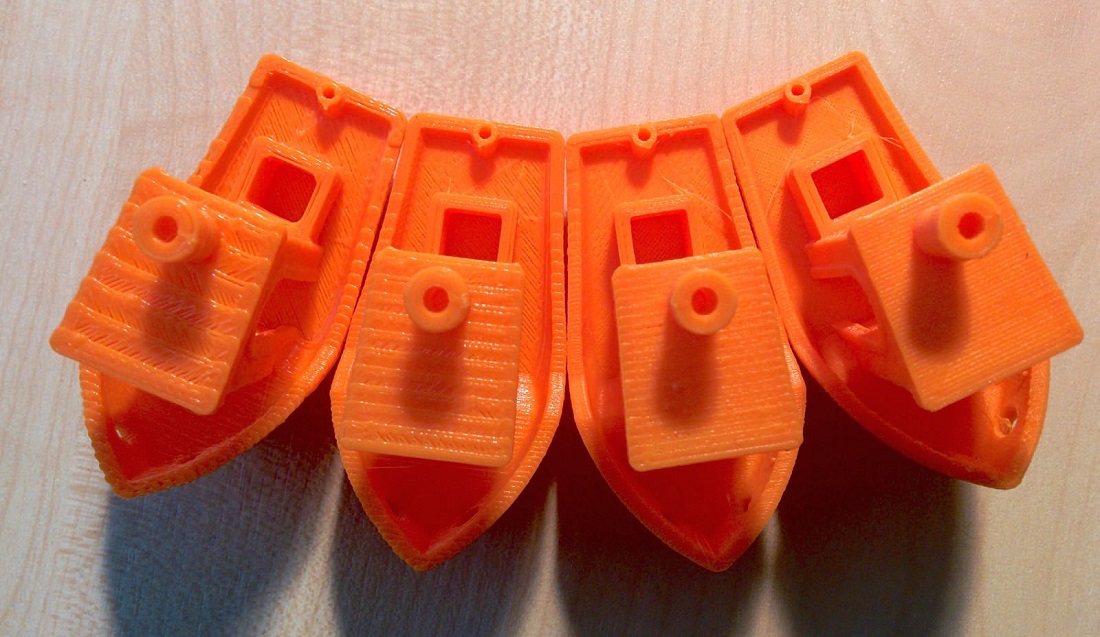

So there is one glue that made me write this post, and not because it was difficult for me to extract the part, but because I could not do it, see for yourself:

0002 Don't want

1

Article comments

Even more interesting articles

nik_vr

Loading

11/05/2022

1904

four

Subscribe to the author

Subscribe

Don't want to

I've been planning to print something from TPU for a long time, but I never got around to it.