Things to know before buying a 3d printer

10 Things You Should Know Before Buying 3D Printers

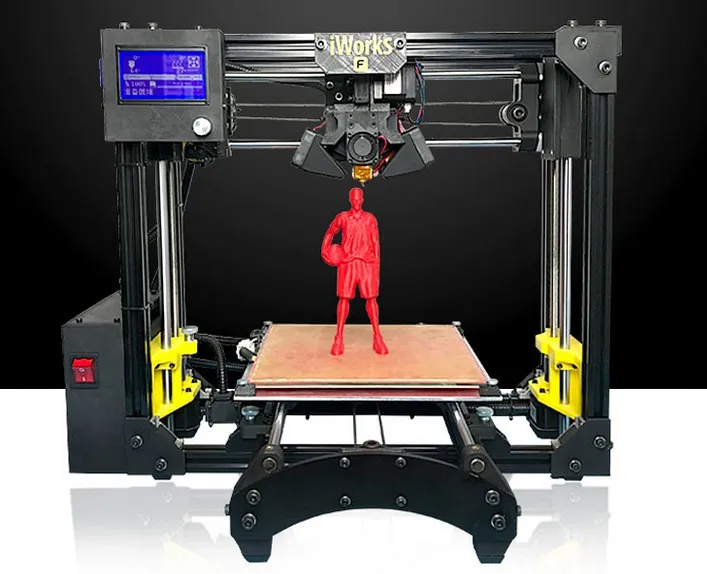

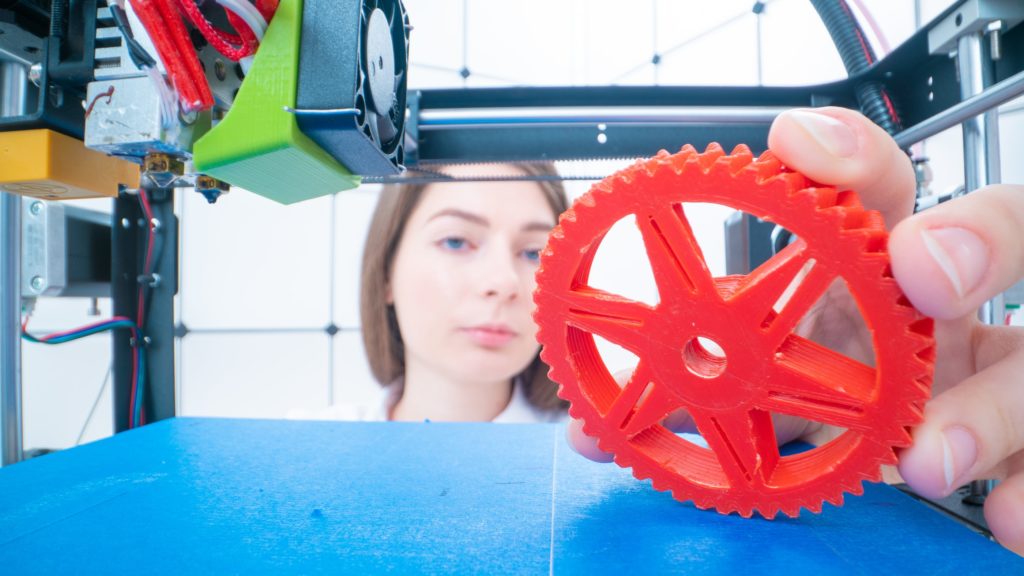

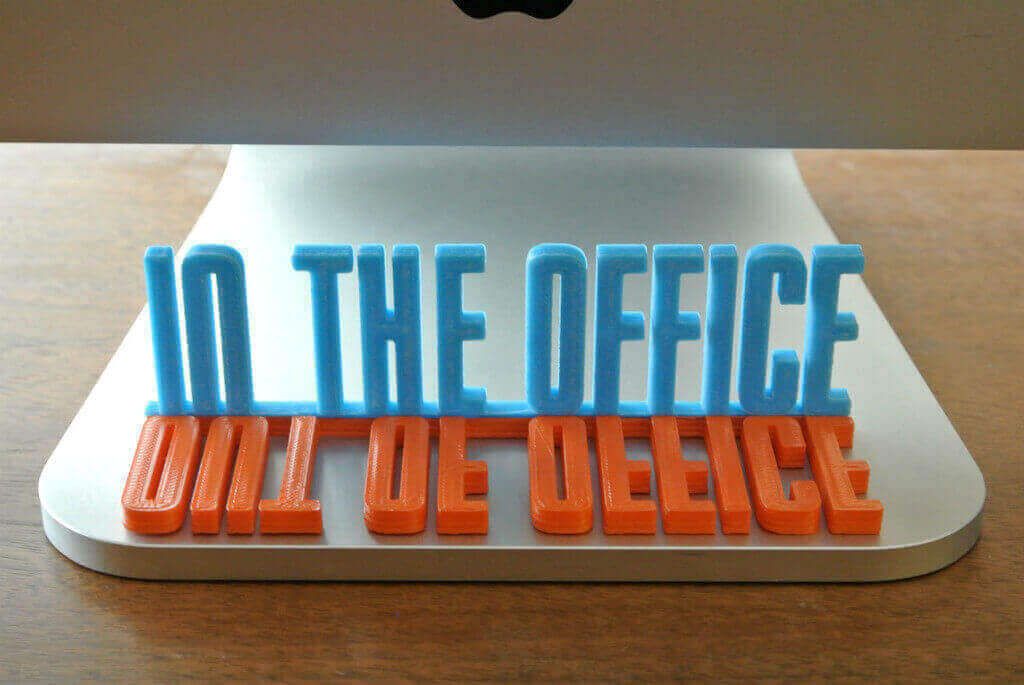

So you have decided to buy yourself a 3D printer after hearing about the amazing things it can build. You want to get started on printing models of your own a custom phone case, cosplay materials, figurines, musical instruments – the possibilities are endless.

Hold your horses, there are a few things you need to know before diving into the world of 3D printing.

There are a lot of 3D printers on the market today that have varying specifications, which in turn cater to different demands.

On top of that, there are technicalities about 3D printing that you really should look into. To help you decide on which printer to make your first, we have complied a list of 10 things you need to know before you buy a 3D printer.

10 Cheap and Affordable 3D Printers to Buy

10 Cheap and Affordable 3D Printers to Buy

There was a time when 3D printers were a novelty - but not anymore. You see hundreds of... Read more

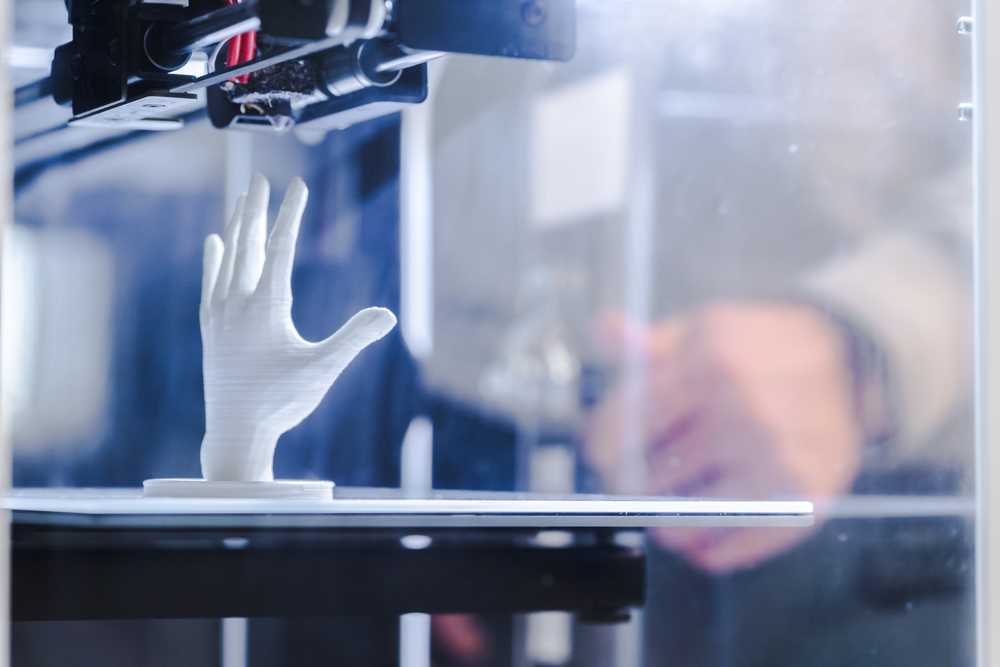

1. Types of 3D printers

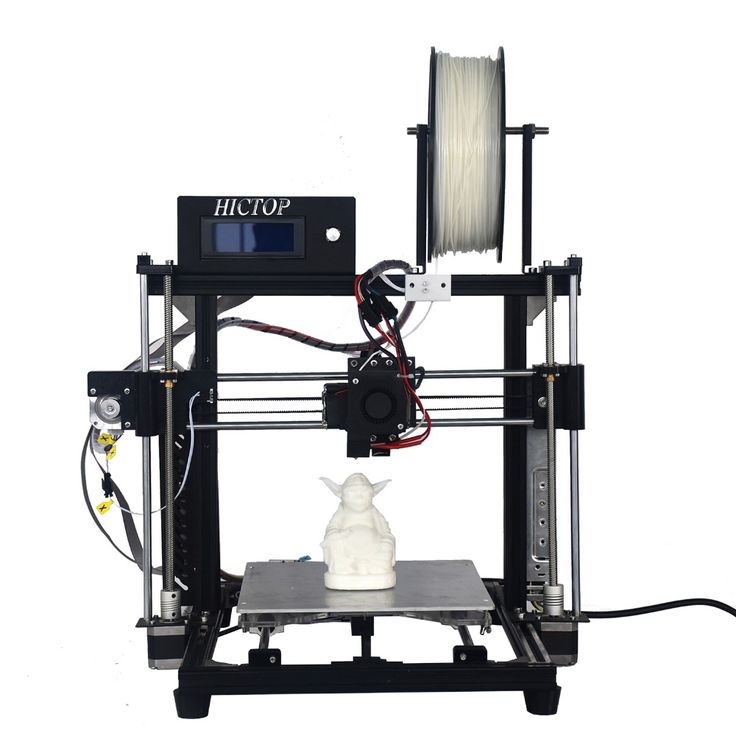

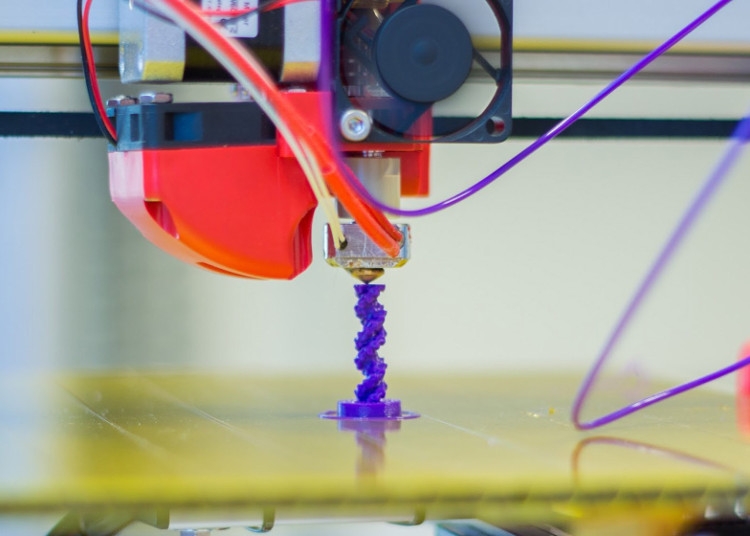

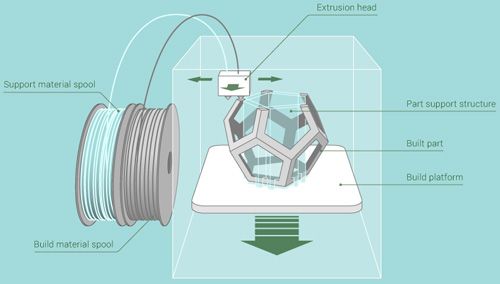

3D printing is a broad term that covers the technologies required for producing physical materials. The one you probably heard of in the media and the most popular among hobbyists is the one that uses Fused Deposition Modeling (FDM).

Fused Deposition Modeling (FDM)

FDM is an additive process, where a model is created by heating and extruding plastic, pieced together layer by layer.

Most of the 3D printers referred in this post works on FDM, as they are more widely available and easy to find.

There are 2 other types of 3D printing available: Stereolithography and Selective Laser Sintering (SLS). They are much more expensive compared to FDM.

Stereolithography

Stereolithography also uses the additive process but instead of extruding plastics, the process utilizes an ultraviolet light beam to harden a model from a pool of photosensitive liquid.

This allows for a higher quality printout.

Selective Laser Sintering (SLS)

SLS is similar to stereolithography, except that the process involves lasers and powders instead of UV light beams and liquid. A laser is used to melt the powder, creating a layer of the printed material.

This allows some models to print metal objects, which is not possible in the other two processes.

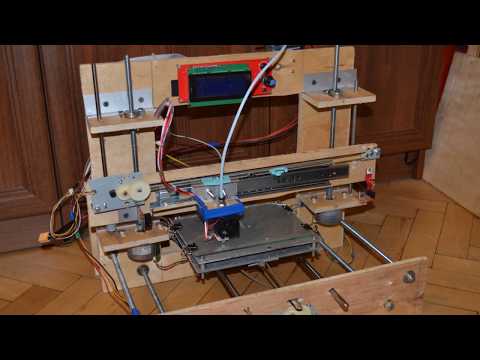

2. Build Your Own Or Buy One

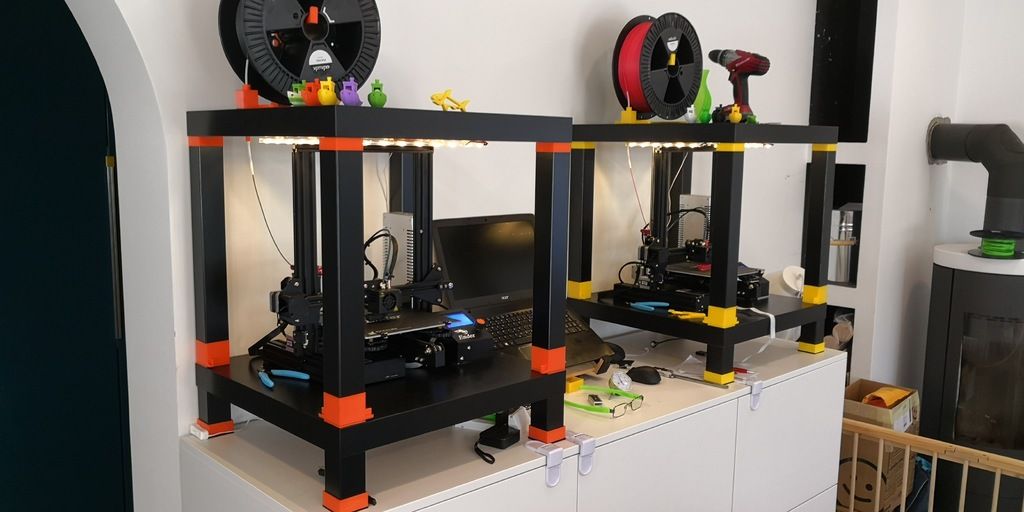

The 3D printing community is one made of creators and makers, so it makes sense that many people would like to try their hand in building a 3D printer on their own.

There are building instructions and 3D printer kits available online if you decide to go with this route.

Building your own printer can be cheaper than buying one but if you don’t have the time, you could always buy a pre-assembled printer.

Your final decision will depend on whether you are interested in tinkering with the technology, or just want to start printing right away.

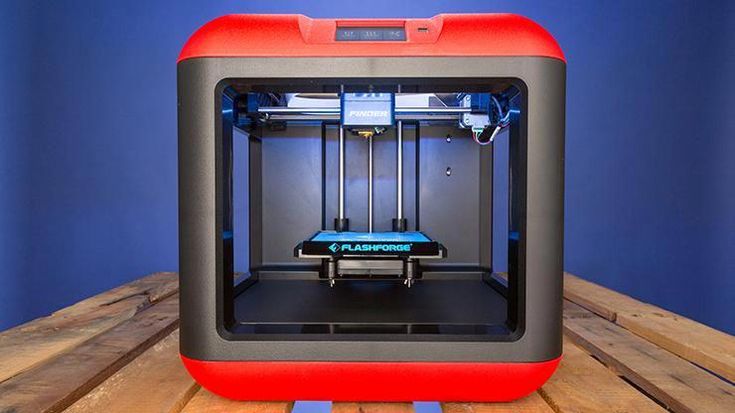

3. Price

One of the main factors that can help turn 3D printers mainstream is their market price. Prices depend mainly on the quality of the output.

In general, the higher-quality ones tend to go above $1000; professional printers can even go above $2000, e.g. the MakerBot series. But if you are just dipping your toes in 3D printing, you can start with simple models that go for as low as $100.

With rising popularity and heavy competition, the prices of printers will only go down while the quality improves. Note that these printers do not come with the materials you require to print your products.

You will need to separately acquire the materials as different products may require different materials.

4. Materials used to print

The two materials required for 3D printing are Poly Lactic Acid (PLA) and Acrylonitrile Butadiene Styrene (ABS). Both are thermoplastics that will become soft and malleable when heated, frozen when cooled.

They are sold as 1kg (2.2lbs) spools of filament, priced in the $30 range.

Let’s take a look at the good and bad of both materials.

Poly Lactic Acid (PLA)

PLA is a type of plastic that is derived from corn starch, excellent for beginners to start dabbling with. Also great for creating small, simple household items. Other characteristics include:

- Biodegradable and environmentally sound

- Cools quickly, which prevents problems with model warping

- Available in both solid and translucent colors, gives printed objects a glossy look

- Disadvantage: Its low melting point may cause models to deform under high heat

- Disadvantage: It is difficult to work with if you require joints and interlocking parts

Acrylonitrile Butadiene Styrene (ABS)

ABS is a petroleum-based plastic that is a popular choice because of its strength and flexibility – think Lego bricks (which can be made using 3D printers, if you didn’t know).

- Its flexibility makes creating interlocking pieces easier to create and work with.

- It also has a higher melting point, so your creations will be less likely to deform under high heat.

- Disadvantage: It takes longer to cool compared to PLA; models are susceptible to warping.

- Disadvantage: It emits fumes during printing (more on this below).

How to Choose

You need to know which material is suitable for your final product. From there you can choose which type of printer you should buy. It is important to know that not all printers can accept both materials – some will work with only either one type.

When it comes to filament size – 1.75mm or 3mm in diameter – it doesn’t factor much into the end quality. More popular printer brands go with 1.75mm so it is recommended that you start with that.

5. Safety

When it comes to 3D printing, there are a few safety issues to take note.

Playing With Heat

The most important thing to remember is that you are working with heated plastics. Extruders, plastics and in some printers, the print bed itself can get very hot and can cause bad burns if you are not careful.

Some printers have no enclosure around the print area; practice extra caution with these printers.

Beware of Fumes

It is important to keep your 3D printer in an well-ventilated room. During the printing process, expect fumes to be emitted, particularly when you use ABS plastics.

These fumes are reported to be rather overwhelming although there is little to no research that states the impact they have on general health.

Still, it is best to take the necessary precautions, particularly if you will be using 3D printers a lot.

Food-Grade Plastic

3D printers can be use to create many types of household items, including kitchenware. Both ABS and PLA are generally food safe but if there are additives added in, those additives may not be.

Another major concern is that products created with FDM-type 3D printers have porous surfaces on which bacteria can collect in.

You can coat the object to make it safer to use but it is best to limit the usage of 3D printed kitchenware.

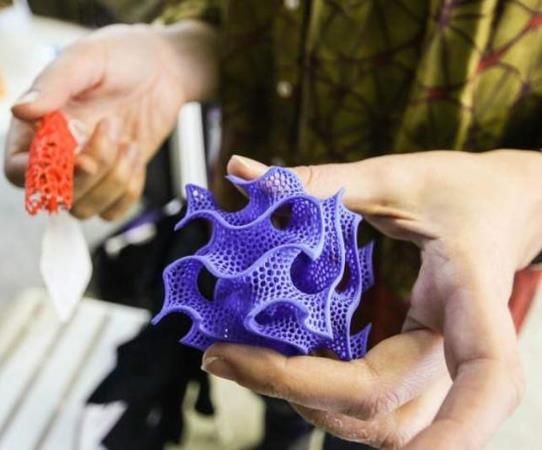

6. Quality

To produce high quality 3D printed products, you need to take note of two things: print resolution and print speed.

Print resolution refers to the level of detail the printer can get, measured in microns – the smaller it is, the higher level of detail in the objects you can create.

Print speed measures how fast the printer can move its extruder – the higher the print speed, the faster it will print.

Note that other features may affect the print speed, such as the acceleration and deceleration of the printer, which helps prevent the printer from shaking.

In the end though, the best way to gauge the quality of a printer is to look at its output. You can look at photos, available online, of the final output of 3D printers before buying.

You can look at photos, available online, of the final output of 3D printers before buying.

7. Obtaining A 3D Model

When it comes to getting a 3D model, there are two routes: you can create it yourself or download a pre-made model blueprint from the Internet.

If you intend to create your own model, there are a variety of software, both free and commercial, that will help you bring your creation into the real world. If you like, you can even learn 3D modeling.

Learning to model in a computer is a difficult task that will take time and effort to truly get used to. Fortunately, for those who are short on time, there are websites that provide 3D models of many different items, made by enthusiasts from all over.

A quick google search can probably yield you the item that you’re looking for.

8. STL Files

The STL file (STereoLithography) is the standard file format that you will use to print your 3D model into a physical object.

The file can be generated using most CAD programs so if you are building your own 3D models, chances are the software you are using can output one.

Basically inside an STL file is the information needed to produce a 3D model. The model itself is broken down to a series of triangles and a list of their XYZ coordinates is used by the printer to create the physical object, layer by layer.

9. Slicing Software

Once you have an STL file of the model you want to print, you will have to put them through a slicing software. What slicing does is that it “tells” your printer how to print your model.

It provides instructions on the number of layers needed, the starting position of the printer and the parts of the model that should be solid or hollow.

There are a number of software to help you with this although some software come with the printer. A good example would be MakerBot’s MakerWare.

10. Community

The great thing about a new tech trend is that there is almost always an online community devoted to it. It is no different with 3D printers.

It is no different with 3D printers.

Check online for a community of people who own a particular brand, to get more insight and answers to questions you may have about the ins and outs of that printer.

If the community is small or worse, nonexistent, the lack of users should raise a red flag about that particular brand.

All you need to make a sound investment is to read up more about that brand and its competitors so you know what you are getting into.

One of the main factors that can help turn 3D printers mainstream is their market price. Prices depend mainly on the quality of the output.

In general, the higher-quality ones tend to go above $1000; professional printers can even go above $2000, e.g. the MakerBot series.

But if you are just dipping your toes in 3D printing, you can start with simple models that go for as low as $100.

With rising popularity and heavy competition, the prices of printers will only go down while the quality improves.

Note that these printers do not come with the materials you require to print your products. You will need to separately acquire the materials as different products may require different materials.

4. Materials used to print

The two materials required for 3D printing are Poly Lactic Acid (PLA) and Acrylonitrile Butadiene Styrene (ABS). Both are thermoplastics that will become soft and malleable when heated, frozen when cooled.

They are sold as 1kg (2.2lbs) spools of filament, priced in the $30 range.

Let’s take a look at the good and bad of both materials.

Poly Lactic Acid (PLA)

PLA is a type of plastic that is derived from corn starch, excellent for beginners to start dabbling with. Also great for creating small, simple household items. Other characteristics include:

- Biodegradable and environmentally sound

- Cools quickly, which prevents problems with model warping

- Available in both solid and translucent colors, gives printed objects a glossy look

- Disadvantage: Its low melting point may cause models to deform under high heat

- Disadvantage: It is difficult to work with if you require joints and interlocking parts

Acrylonitrile Butadiene Styrene (ABS)

ABS is a petroleum-based plastic that is a popular choice because of its strength and flexibility – think Lego bricks (which can be made using 3D printers, if you didn’t know).

- Its flexibility makes creating interlocking pieces easier to create and work with.

- It also has a higher melting point, so your creations will be less likely to deform under high heat.

- Disadvantage: It takes longer to cool compared to PLA; models are susceptible to warping.

- Disadvantage: It emits fumes during printing (more on this below).

How to Choose

You need to know which material is suitable for your final product. From there you can choose which type of printer you should buy.

It is important to know that not all printers can accept both materials – some will work with only either one type.

When it comes to filament size – 1.75mm or 3mm in diameter – it doesn’t factor much into the end quality. More popular printer brands go with 1.75mm so it is recommended that you start with that.

5. Safety

When it comes to 3D printing, there are a few safety issues to take note.

Playing With Heat

The most important thing to remember is that you are working with heated plastics. Extruders, plastics and in some printers, the print bed itself can get very hot and can cause bad burns if you are not careful. Some printers have no enclosure around the print area; practice extra caution with these printers.

Beware Of Fumes

It is important to keep your 3D printer in an well-ventilated room. During the printing process, expect fumes to be emitted, particularly when you use ABS plastics. These fumes are reported to be rather overwhelming although there is little to no research that states the impact they have on general health. Still, it is best to take the necessary precautions, particularly if you will be using 3D printers a lot.

Food-Grade Plastic

3D printers can be use to create many types of household items, including kitchenware. Both ABS and PLA are generally food safe but if there are additives added in, those additives may not be. Another major concern is that products created with FDM-type 3D printers have porous surfaces on which bacteria can collect in. You can coat the object to make it safer to use but it is best to limit the usage of 3D printed kitchenware.

Another major concern is that products created with FDM-type 3D printers have porous surfaces on which bacteria can collect in. You can coat the object to make it safer to use but it is best to limit the usage of 3D printed kitchenware.

6. Quality

To produce high quality 3D printed products, you need to take note of two things: print resolution and print speed.

Print resolution refers to the level of detail the printer can get, measured in microns – the smaller it is, the higher level of detail in the objects you can create. Print speed measures how fast the printer can move its extruder – the higher the print speed, the faster it will print. Note that other features may affect the print speed, such as the acceleration and deceleration of the printer, which helps prevent the printer from shaking.

In the end though, the best way to gauge the quality of a printer is to look at its output. You can look at photos, available online, of the final output of 3D printers before buying.

You can look at photos, available online, of the final output of 3D printers before buying.

7. Obtaining A 3D Model

When it comes to getting a 3D model, there are two routes: you can create it yourself or download a pre-made model blueprint from the Internet. If you intend to create your own model, there are a variety of software, both free and commercial, that will help you bring your creation into the real world. If you like, you can even learn 3D modeling.

Learning to model in a computer is a difficult task that will take time and effort to truly get used to. Fortunately, for those who are short on time, there are websites that provide 3D models of many different items, made by enthusiasts from all over. A quick google search can probably yield you the item that you’re looking for.

8. STL Files

The STL file (STereoLithography) is the standard file format that you will use to print your 3D model into a physical object. The file can be generated using most CAD programs so if you are building your own 3D models, chances are the software you are using can output one.

The file can be generated using most CAD programs so if you are building your own 3D models, chances are the software you are using can output one.

Basically inside an STL file is the information needed to produce a 3D model. The model itself is broken down to a series of triangles and a list of their XYZ coordinates is used by the printer to create the physical object, layer by layer.

9. Slicing Software

Once you have an STL file of the model you want to print, you will have to put them through a slicing software.

What slicing does is that it “tells” your printer how to print your model. It provides instructions on the number of layers needed, the starting position of the printer and the parts of the model that should be solid or hollow.

There are a number of software to help you with this although some software come with the printer. A good example would be MakerBot’s MakerWare.

10. Community

The great thing about a new tech trend is that there is almost always an online community devoted to it. It is no different with 3D printers. Check online for a community of people who own a particular brand, to get more insight and answers to questions you may have about the ins and outs of that printer.

It is no different with 3D printers. Check online for a community of people who own a particular brand, to get more insight and answers to questions you may have about the ins and outs of that printer.

If the community is small or worse, nonexistent, the lack of users should raise a red flag about that particular brand. All you need to make a sound investment is to read up more about that brand and its competitors so you know what you are getting into.

10 Important Things To Know Before Buying A 3D Printer

With the recent invention of a mosquito-repellant 3-D printed ring, the future possibility of 3D printing is reaching new heights. In just over the last two decades, 3D printing as a technology and industry has grown by leaps and bounds. From being a specialty, niche technology, 3D printing can now be seen in even consumers' homes.

Companies have plans to build entire schools and houses using 3D printers. But for those just getting into the field and looking to buy a 3D printer for the first time, there are some basic factors to keep in mind.

Expensive Does Not Mean Better

While sometimes a more expensive printer can equate to better quality, this is not always true. Over the last couple of years, the competition in the 3-D printing industry has skyrocketed, which has also led to cheaper and better products.

RELATED: Best Cheap Printers (Updated 2022)

The price of a 3D printer can depend on a lot of factors, like whether it is an FDM or SLS printer, the features each model provides and the brand associated, etc., but for beginners, even cheaper 3D printers can provide adequate quality and features. Printers such as the Ender 3 can do pretty much everything a beginner would require.

PLA Is The Most Beginner Friendly Material

There are different materials available for 3D printers, and each one of them has different pros and cons. PLA or Poly Lactic Acid materials are the most versatile, cheapest, and safest to use. They are also some of the best materials to use for entry-level 3D printers.

PLA can be used to produce long-lasting objects, and it doesn't release as many harmful fumes during the process. PLA is also cheaper compared to other options, and it is biodegradable, as well. PLA also has a lower melting point which makes it easier for entry-level printers to utilize.

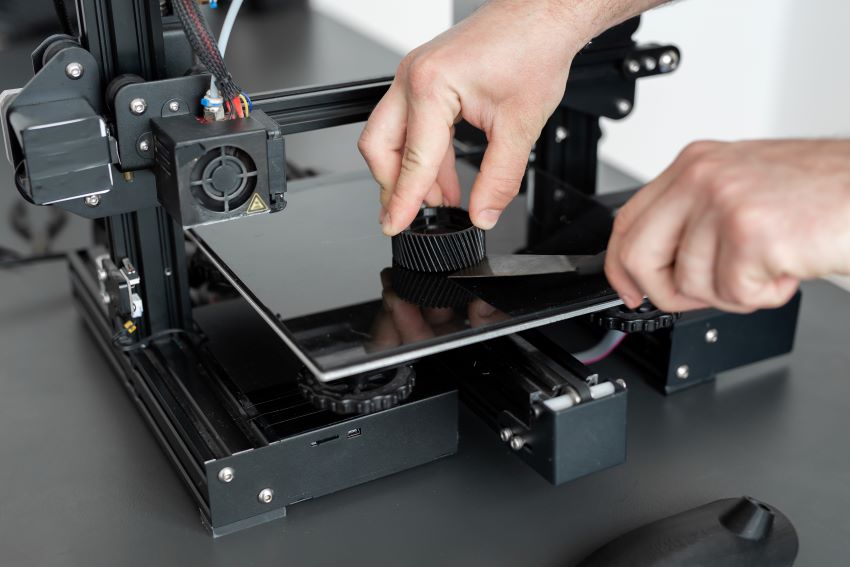

It Is Better To Get An Auto Leveling Printer

If the printing bed of a 3D printer is not level, it can lead to unstable foundations, clogging, or scratch marks on the object. While manual leveling printers have their advantages with certain functions, a beginner will rarely ever use them. Users can also get an auto-leveling attachment with their manual printers.

An auto-leveling printer has sensors attached near the tip of the nozzle, which measures distance and balance and adjusts accordingly to make sure the bed is level before starting the process. There are some great 3D printers for even less than $500.

Make Sure The Filament Is Of Good Quality

The filament determines the quality of the object being printed. Bad-quality filament will lead to a brittle, deformed, or rough final object. Consumers can find a good quality PLA filament for about $30 per kg, and this can last most users for more than a month.

Bad-quality filament will lead to a brittle, deformed, or rough final object. Consumers can find a good quality PLA filament for about $30 per kg, and this can last most users for more than a month.

The price of the filament varies depending on the brand, quality, color, if it is glow-in-the-dark, extra strength, or has a better texture. Keep in mind that cheaper filaments don't always mean bad quality, it is better to always read the reviews. Other materials, like ABS or resin, might cost more.

Understand The Basic Workings Of A 3D Printer

It is very important to understand the basic functioning of a 3D printer, as there can be a need for future upgrades, replacing parts, keeping rods lubricated, and replacing worn-out nozzles.

If a 3D printer is well maintained, cleaned, and updated from time to time, it can last for years while performing efficiently. Usually, 3D printers and their nozzles can last from three to six months with heavy use and up to three years with casual use. Understanding how a 3D printer works is very important when it comes to being comfortable with the machine.

Understanding how a 3D printer works is very important when it comes to being comfortable with the machine.

Pay Attention To Print Bed Quality

The quality of a print bed will play a huge role in the final print quality. A bad print bed can lead to issues such as layer adhesion, not retaining temperature efficiently, prints sticking to the bed, or an uneven printing bed.

Print beds are made of plastic, aluminum, or glass, the latter being one of the most popular, usually because of the ease of removal of the final object. Some of the best and easiest printers to use consider the quality of the printer bed.

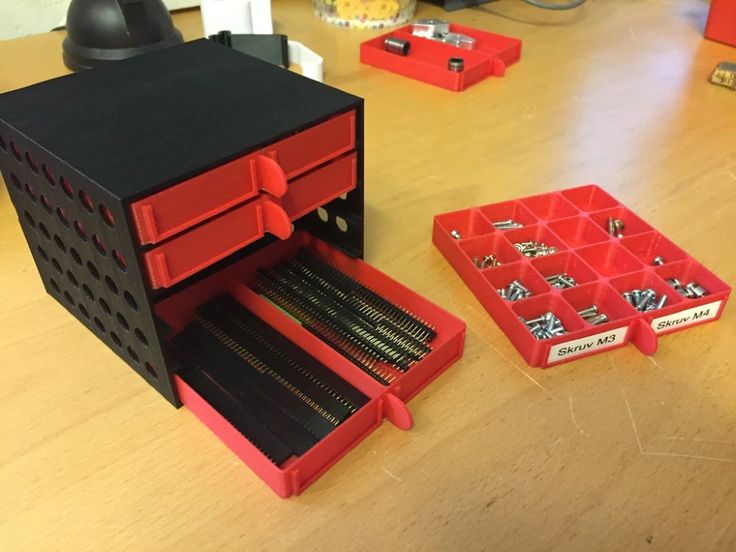

Keep A Set Of Tools At Your Disposal

Getting a 3D printer and some filament is not the end of the printing process, users will also require a set of tools to ease the final printing process. This usually includes a spatula, filament storage container, adhesive substances, and tweezers for cleaning final prints and nozzles.

RELATED: The Best Weapons, Tools, & Gadgets In The Mandalorian

A spatula is handy while removing the final print from the bed and without proper filament storage, the life of the filament can be greatly reduced.

Keep Safety In Mind

Operating a 3D printer can be very fun, but at the same time, it can also be dangerous to your property and your health. Make sure your 3D printer is in a well-ventilated room and that there are no fire hazards close by.

RELATED: The Best All-In-One Printers

Keep the printer out of reach of children and pets, as they can get very hot and also release harmful fumes. Getting an enclosure for the printer is also a great idea to keep it dust free and waterproof.

The Slower, The Better

Getting the perfect 3D print can be a slow process. The overall quality of the final object heavily depends on the speed with which the printer is printing. This is one of the choices that people have to make: to either get a faster print but compromise on the quality or get the highest quality but wait for a long time.

The size of the nozzle will also impact the speed and quality of the prints. For example, if a 0.4mm nozzle takes 11 hours at 150mm/s, a 0. 8mm nozzle can do it under 8 hours at 65mm/s. But at the same time, a bigger nozzle might not give the most detailed final product.

8mm nozzle can do it under 8 hours at 65mm/s. But at the same time, a bigger nozzle might not give the most detailed final product.

Stick With FDM Printers

The two most common types of 3D printers are SLA and FDM. While the former prints an object layer by layer using a liquid resin material and UV light and can also deliver a higher resolution and smoother finish, they can also be very expensive and the filament also costs a lot more.

FDA printers, on the other hand, are much better for beginners. They are cheaper and there is a wide variety of filament to choose from. They are also much easier to maintain. One thing to note is that SLA printers are getting cheaper, so that could be a future option for a beginner hobbyist.

NEXT: The 10 Best Smartphone Printers

What you need to know before buying a

3D printer

What should be considered when buying a 3D printer and how to choose the right 3D printer for your project? Find out in this post. With so many models on the market today, choosing a 3D printer can be more difficult than you might think. In this post, we will look at the key factors to consider when buying a 3D printer.

With so many models on the market today, choosing a 3D printer can be more difficult than you might think. In this post, we will look at the key factors to consider when buying a 3D printer.

FDM / SLS / stereolithography

Most of the printers currently available on the market are FDM printers. FDM stands for fuse displacement modeling and basically means that the object is printed layer by layer.

Two other types of printers are stereolithography and SLS (Selective Laser Sintering). They are significantly more expensive and are mainly used in industrial projects.

Stereolithography provides higher print quality by using a UV light to enhance the mode, while SLS uses lasers and powders to create a layer of printed material.

Most commercial printers are FDM - and if you're looking to buy one for your home, you'll likely be choosing between the wide range of FDM printers available on the market.

Assembled 3D printer or DIY 3D printer?

This is another question to answer when choosing a 3D printer. Since 3D printers are mostly used by manufacturers and in the creative community, it makes sense that the tool itself could be assembled by the hands of those who plan to use it.

Since 3D printers are mostly used by manufacturers and in the creative community, it makes sense that the tool itself could be assembled by the hands of those who plan to use it.

However, making a 3D printer completely from scratch can be quite a challenge. Luckily, for your creative enjoyment, you can find a huge variety of 3D printer DIY kits with clear building instructions. If you prefer to jump right in and skip assembly, use a pre-built 3D printer model that's ready to go right out of the box.

Expensive 3D printer or cheap 3D printer?

As with most purchases, price is a major factor when choosing a 3D printer. In most cases, price is a direct indicator of product quality. However, depending on the type of projects you plan to use the 3D printer for, you may or may not need a machine that is at the top of the line.

These days, you can easily find a pre-assembled 3D printer for $300 or less—one that fits most types of home projects. If you just want to fix small items or have a fun tool to play with, you can even start with a 3D printing pen for under $30. If you've already dipped your fingers into 3D printing and are looking for a more professional 3D printer with a wider print bed and higher temperatures, you can expect to pay around $1,000 for top quality models over $2,000.

If you just want to fix small items or have a fun tool to play with, you can even start with a 3D printing pen for under $30. If you've already dipped your fingers into 3D printing and are looking for a more professional 3D printer with a wider print bed and higher temperatures, you can expect to pay around $1,000 for top quality models over $2,000.

3D Print Quality

Print quality is often measured by two key metrics: end product detail and print speed. The level of detail a printer can achieve is measured in microns—the lower the number, the better the print quality. In terms of speed, the faster the printer's extruder moves, the faster your object will be created.

Another important factor to consider is print volume, the maximum size of an object that can be printed. Some printers come with a relatively small build volume, but one that fits most DIY projects is 280 x 210mm x 180mm (Geeeetech Prusa I3 M201 3D Printer), while others offer a larger build size of 340 x 500mm ( TEVO Little Monster Delta 3D). Printer ).

Printer ).

3D printing filament

Check which materials your printer is compatible with. While most 3D printers work with two main filament types: PLA and ABS, some models support more options that allow you to use wood, metal, and other materials. Learn more about 3D printing filaments in the 3D printer filament guide.

Is your 3D printer safe?

When working with high temperatures, it is always important to ensure that all precautions have been taken and that your work environment and tools are safe.

Some printers have specially made housings around the printable area that can be very hot. Other models do not have this type of protection. If you are not very familiar with the printing process or the tool will be used by children, it is recommended that you choose a printer in which the printing area remains covered.

Training: how to work with a 3D printer?

Before you start 3D printing, you need to spend some time learning about printer settings and the software required to print your object. Lower tier printers may require additional manual calibration, while higher tier models may have some of these features automated. Whichever model you choose, expect to take some time to get used to the printer and understand the ins and outs of the printing process. But once you do, the possibilities are wonderfully endless.

Lower tier printers may require additional manual calibration, while higher tier models may have some of these features automated. Whichever model you choose, expect to take some time to get used to the printer and understand the ins and outs of the printing process. But once you do, the possibilities are wonderfully endless.

8 things you should know before buying your first 3D printer

|

But do not rush to make plans. The market offers a lot of 3D printers. All of them are designed for different purposes and differ in specifications. In addition, there are a few facts that you absolutely need to know before you plunge into the world of 3D printing.

All of them are designed for different purposes and differ in specifications. In addition, there are a few facts that you absolutely need to know before you plunge into the world of 3D printing.

Printer types

3D printing is a rather broad term. It combines many of the technologies needed to produce physical objects. Among amateur printers, FDM devices are the most popular.

FDM is an additive process in which a model is created by melting and extruding plastic in layers.

Two other types of printing are stereolithography and selective laser sintering. Printers based on them are more expensive and are more often used in industrial production than in the home.

Buying ready made or building your own?

The web is full of instructions for selecting components for a 3D printer and building your own from scratch. Building your own device can be cheaper than buying a ready-made one. But this lesson is not for beginners: you will need knowledge of soldering, physics, programming, not to mention the ability to understand the technical characteristics of components. Don't want to spend time learning all the subtleties? Buy a pre-assembled printer that comes as a parts kit.

Don't want to spend time learning all the subtleties? Buy a pre-assembled printer that comes as a parts kit.

The final decision depends on whether you want to go deeper into the technology or just want to start printing right away.

Printing materials

A simple DIY FDM printer that works with PLA and ABS materials. Both are thermoplastics that soften when heated and harden when cooled. They are sold in the form of threads wound on spools weighing 1 kg or more. They are also suitable for working with a 3D pen.

Not all printers support both materials mentioned. There are models that work with only one type of plastic.

Material Features

PLA is a plastic made from corn starch. It is relatively easy to process, suitable for creating household items, and very popular among hobbyists.

Features:

- biodegradable;

- cools down quickly;

- is available in different colors (transparent is also available).

- low melting point (may cause models to deform when heated).

ABS - Petroleum based plastic. It is popular due to its durability, easy processing and painting. Remember Lego bricks? Since 1963 they have been made of ABS. Compared to PLA, this material has a higher melting point, the finished parts are less susceptible to deformation from high temperatures.

Features:

- takes a long time to cool down;

- in the process of cooling the model is subject to deformation;

- plastic emits harmful fumes during printing.

Safety

The main thing to remember when printing is that you are working with high temperatures. The extruder, printing table and the plastic itself can heat up to over 200 degrees. Carelessness during operation will result in severe burns. Be especially careful with printers that do not have a protective case.

The 3D printer must be placed in a well ventilated area. As already mentioned, molten ABS releases harmful substances. There hasn't been enough research done yet to confirm that ABS is bad for health, but it still doesn't hurt to take precautions.

As already mentioned, molten ABS releases harmful substances. There hasn't been enough research done yet to confirm that ABS is bad for health, but it still doesn't hurt to take precautions.

Often, 3D printer buyers hope to use the device to print household items such as dishes, cutlery, etc. ABS and PLA materials are safe on their own, but some of the additives and dyes they contain may not be compatible with food. The product created on the FDM printer has a layered surface on which bacteria are easily collected. It is possible to carry out special processing to smooth the surface, but it is better not to risk it and not print any kitchen or utensils on a 3D printer at all, including pet feeders and aquarium decorations.

Print quality

Print quality depends on two things - resolution and speed.

Resolution is the level of detail. It is expressed in microns. The lower the resolution, the correspondingly higher the level of detail, and the joints between the layers are not so noticeable.

Print speed indicates how fast the extruder is moving. The faster the print speed, the faster the model will be ready, but its surface may be uneven. Violent shaking of the printer during printing may cause the model to come off the platen and move. You can find out the maximum possible print speed without loss of quality by thoroughly testing your printer. Well, or by looking at the reviews on YouTube.

3D models

Printable models can be made by yourself or downloaded from the Internet. For 3D modeling, there are many paid and free programs, complex and accessible for beginners. The file ready for printing is saved in stl format.

Slicer

Before printing, the stl file must be run through the slicer. A slicer is a program for slicing an object. In it, the model is divided into layers, the initial and final position of the extruder is determined, it is indicated which areas of the model should be hollow, and which ones should be filled, and with what density.

During the printing process, you will surely encounter many technical difficulties, such as poor adhesion of the model to the platen, extrusion problems, plastic jams, etc. In a large city, you can find a service for servicing, repairing and setting up printers. But if you live in a small town, you will have to deal with many problems on your own. Don't be afraid - you are not alone. Numerous forums and sites where 3D printing enthusiasts communicate will help you find solutions.

Popular publications

Most popular publications on the topic

-

- Guides / April 17, 2018

-

- Guides / April 23, 2018

-

- Guides / June 19, 2018

-

- Guides / April 24, 2018

-

- Guides / December 24, 2017

New publications

Most recent publications on the site

- Test: only perfectly educated people will score 10/10

- Tests / December 04, 2022

- Hulu Top 100 TV Shows: Part 1

- Movies and series / December 04, 2022

- The best alien invasion games.

Learn more