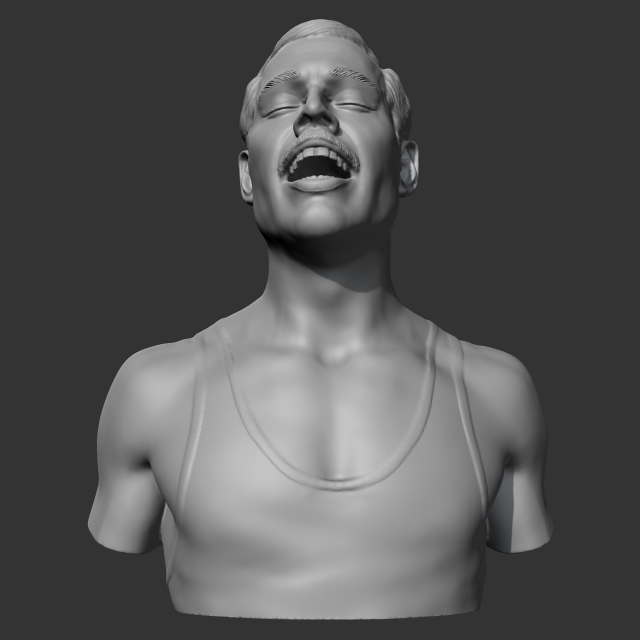

Meme man 3d print

▷ meme man 3d models 【 STLFinder 】

Meme Man - STONKS

pinshape

"How to get the Rich.exe selling one tridimensional Boi" The pleased thrills will pervade your void and you will be able to produce a meme man using this enslaved code. Feel moisted by this digital boy and let your plastic spaghetter do the...

Stonks with Meme Man head

prusaprinters

In honor of the “stonks" meme, here is a simple model that has Meme Man's head on a rising arrow coming out of the word stonks. Attribution for Meme Man head model:Author: ETGgamesLicense: CC AttributionTitle: Meme Man / Mr. ...SuccLink:...

Meme Man

thingiverse

Do with this what you will

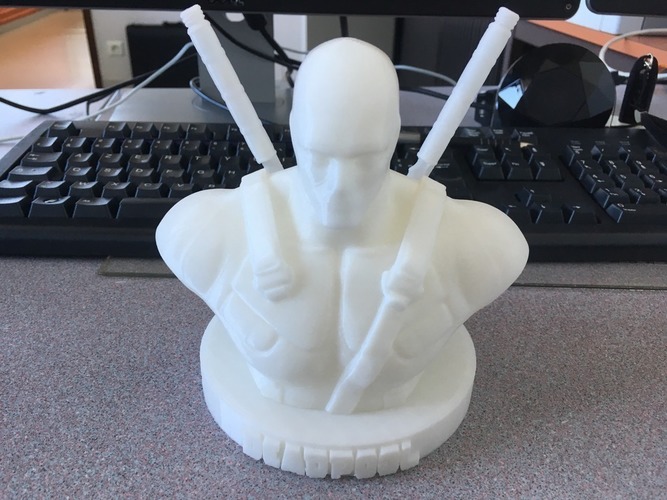

Mr. Succ (Meme Man)

thingiverse

DISCLAIMER: Designed by TANMATE (https://sketchfab.com/cuppaj0e) I converted TANMATE's Mr. ...Succ model into a STL-file using Blender. Source: https://sketchfab.com/3d-models/meme-manmr-succspecial-meme-fresh-head-3d1f49bc7e6e446fb0d97e98cd40e749

Stonks - Meme Man - Meme Trophy

cults3d

The best award for a great idea An intentional misspelling of "stocks" originated with an internet meme. It was originally a way of talking about amateur or bad financial decisions. ... Like all memes, it gets twisted around and re-purposed a lot, but...

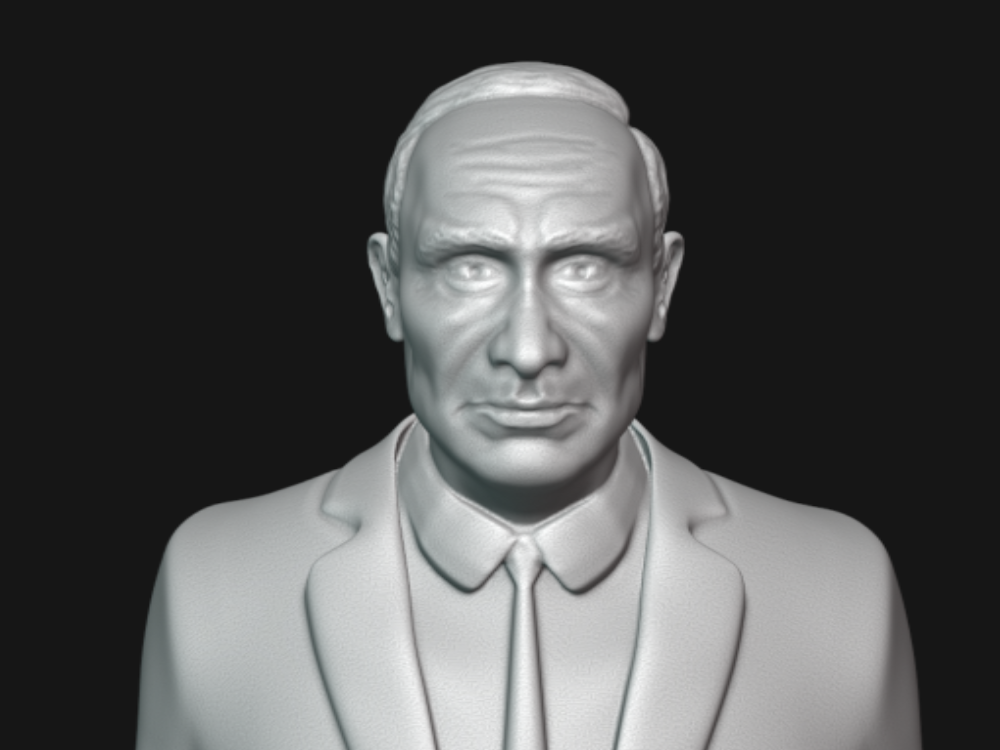

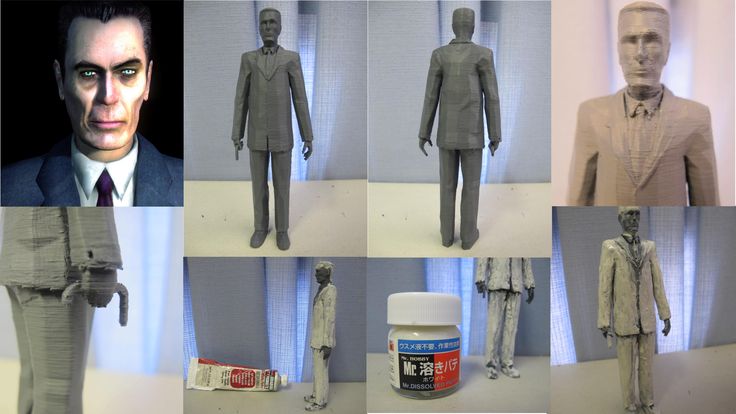

Meme Man / Mr. Succ

Succ

sketchfab

I shed light upon this cold world. ...You are welcome.

Meme Man Ornament Lithopane

thingiverse

Customized version of https://www.thingiverse.com/thing:189268 Created with Customizer! ...https://www.thingiverse.com/apps/customizer/run?thing_id=189268

Meme Man Mr. Succ

thingiverse

The existing ones do not have eyeballs, so they are not Stonks. And so I made one modified from TANMATE's model at Sketchfab.

I rebuilt the eyeballs and made it a solid wall and hollow, so it is good to print. I also put a 15mm hole at the bottom...

I also put a 15mm hole at the bottom...

Deep Fried Meme Man

thingiverse

A nice SPICY print which will leave you impressed with the outcome. When printing this i made sure i used supports and a brim to ensure the print sticks to the bed. This has been printed by myself and has turned out good - in the process of painting...

REBERT THE AUTISTIC MEME MAN

sketchfab

No description provided.

Stonks AKA "Meme Man" Mask

thingiverse

Had a request to make a Halloween costume for a friend. Used the "Enslaved Plastic" model as a base, then used Meshmixer to hollow+thicken and repair any mesh-errors.

Tried printing at 249mm high. First print was at ~45 deg. angle and fell over...

Used the "Enslaved Plastic" model as a base, then used Meshmixer to hollow+thicken and repair any mesh-errors.

Tried printing at 249mm high. First print was at ~45 deg. angle and fell over...

Meme Man/Mr. Succ/Special Meme Fresh Head

sketchfab

T͇͍̺h̬̪e̮̬̻͉̲ ̭͚s͏̯͙͈͔̦͉e͎̬̘̙͈a͕̭̬͎r͚̙̻̪̯͘c҉̗͍̫̱̩̣̠h͝ ͇̩̠̲i̙̖͍͈͈͎͢s̘̰ ̗̗̬̻ͅf̶̙͕̙̱̼̝in̥̠̮͖̮̤à̫̜͉ͅl̲̗̟͎̦̘͖͟ḷ̘͖̣͚̬y͇̩̼̭̩͓ ̫̰̣͇̪͙̤o͙̜̬̣v͝e̦̯͔̯̝̤̫r Plz credit me if you’re using it

Pokemon Diglett HDTPM IS MAMADÍSIMO, He-man Muscled Meme He-man

cults3d

It is an action figure with a beautiful stone necklace and equipped with a stone sword, a chain with a stone and tanned skin. Once a pokemon researcher decided to find out the obvious ... If Diglett is hidden underground and only shows his head,...

Once a pokemon researcher decided to find out the obvious ... If Diglett is hidden underground and only shows his head,...

Pac-Man MEME Keychain

pinshape

Pac-Man MEME Keychain model for 3D PRINT Format tipe: .STL I wish you like it! ... Printing parameters: INFILL 8% NOZZLE: 0.6mm LAYER: 0.32 BED TEMP: 60º FAN SPEED: 100% SPEED: 60mm/s

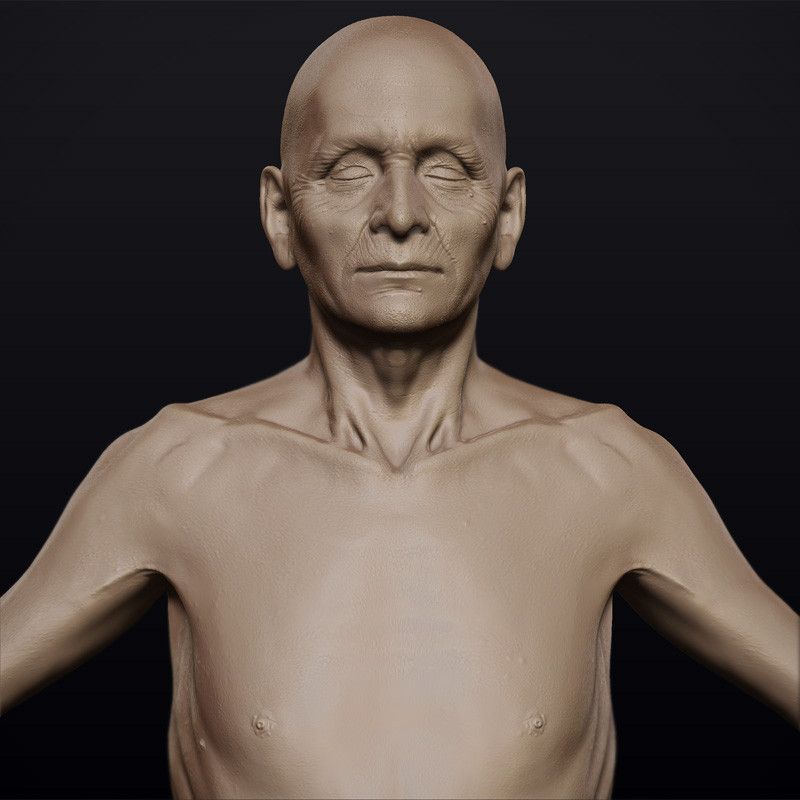

Whatsapp Black Man Meme

pinshape

Model realized in 3ds max and meshmixer. ...Bring life to one of the most viral and irreverent whatsapp meme.

The Black Man Meme

pinshape

This is one of the most disturbing meme I ever seen so far. ..it was only a matter of time to get te .stl file! ... You can print him easily with fdm machines (default size is 10 cm) and comes with joints and keys for better printability.

..it was only a matter of time to get te .stl file! ... You can print him easily with fdm machines (default size is 10 cm) and comes with joints and keys for better printability.

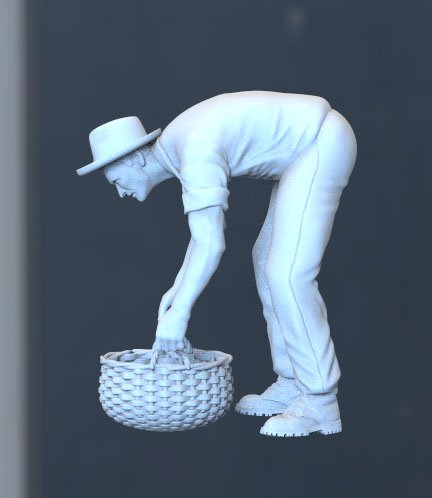

Man demanding STL meme

thingiverse

I saw a meme where a man demands an STL so I made an STL of it

Whatsapp Black Man Meme 3D print model

cgtrader

The most disturbing meme of whatsapp can be on your desk now! Hope you like it!! ...

Meme One Punch Man meets Thors Hammer Toilet Prank 3D model

cgtrader

Meme One Punch Man meets Thor's Hammer A mashup of One Punch Man with Thor's wicked Toilet Prank. Suddenly realise these 2 models can weave a funny and wonderful diorama story scene, enjoy! ...

Suddenly realise these 2 models can weave a funny and wonderful diorama story scene, enjoy! ...

Mail man kick - Post office meme Low-poly 3D model

cgtrader

This is a simple scene that I did to create a meme of the official Argentine post office and the mood it generates in people's minds. Inside you will find a simple mannequin in kick pose and a bunch of cloned boxes. The only one box flying has speed...

Hey Man You See That Guy Over There MEME

thingiverse

Made to hit HOT on 9gag ;)

https://9gag.com/gag/av7py9X

Printed with low quality because I wanted to do it guick, so it doesn't look so good. Settings whatever you want.

Here it was:

Low quality ABS 0,29 layer hight on Zortrax M200.

... Time...

Settings whatever you want.

Here it was:

Low quality ABS 0,29 layer hight on Zortrax M200.

... Time...

Pikachu meme

thingiverse

meme

Meme Coasters

myminifactory

Meme Coasters

Cartman meme

sketchfab

Meh memechallenge #meme #southpark

meme coasters

thingiverse

meme drink coaster

Meme

sketchfab

No description provided.

meme

sketchfab

Scanned using 3D Systems #SenseForRealSense Software

meme

sketchfab

No description provided.

meme

thingiverse

Customized version of http://www.thingiverse.com/thing:305087 Created with Customizer! ...http://www.thingiverse.com/apps/customizer/run?thing_id=305087 Instructions Using the following options:...

Meme

sketchfab

No description provided.

STL file Stonks - Meme Man

Football Helmet Pencil Holder

€1

Italian hand Meme - Italy most famous hand Gesture

€2

Garpez Aldo Giovanni e Giacomo, Tre Uomini e una Gamba

€5

Ron's Gone Wrong - Ron Robot - Happy Face

€2

Macintosh Shell/Case

€3

Ron's Gone Wrong - Ron Robot - Cute Face

€2

Italian Hand Award - Italy Hand Prize

€2

Ron's Gone Wrong - Ron Robot - Smile Face

€2

Best 3D printer files of the Gadget category

Print-in-Place Wood Transport Module

€3. 36

36

Arduino Arcade Bartop

Free

Led Lighting Square

€3

Mate 20 Pro stand for Renault and Dasia cars

Free

Holiday Ball (Holiday-Themed Cosplay Pokeball & Ornament)

€1.92

Print-in-Place Box Truck Module

Free

Universal Phone GoPro Mount

Free

XBOX One stick extender for drone simulators

Free

Best sellers of the category Gadget

JEEP WRANGLER PEN HOLDER - 3-IN-1

€1.85

G26 frame DD26 - Super enforced

€7

Air motor, printed fully assembled, ready to use

€3. 17

17

G17- DD17 Rails Frame

€7.50

ENGINE CYLINDER BLOCK - WALL KEY HANGER

€1.85

F18 SUPER HORNET - 50 MM EDF JET [RC PLANE]

€12.01

DJI Avata Bumper

€3.50

App for Cookie Cutters

€3.49

BARABA repeating crossbow pistol with aluminum profile core

€8

App to create dual text illusion

€3.49

App to create switchable business cards

€3.49

ELEPHANT PIGGY BANK - NO PAINTING REQUIRED

€3

wall key holder (dragon ball)

€1.25

Ender 3 S1 Original Fan Upgrade (Alternative)

€1. -50% €0.63 25

25

DJI AVATA GoPro Mount

€2.50

Alligator 2 foldable rear lever

€2

Would you like to support Cults?

You like Cults and you want to help us continue the adventure independently? Please note that we are a small team of 3 people, therefore it is very simple to support us to maintain the activity and create future developments. Here are 4 solutions accessible to all:

ADVERTISING: Disable your AdBlock banner blocker and click on our banner ads.

AFFILIATION: Make your purchases online by clicking on our affiliate links here Amazon.

DONATE: If you want, you can make a donation via PayPal.

WORD OF MOUTH: Invite your friends to come, discover the platform and the magnificent 3D files shared by the community!

Elena Face Meme STL File for 3D Keychain Printing・Template for Download and 3D Printing・Cults

Adventure Time Mint Butler

1.74 €

Free Christmas pine

Free

gingerbread man, cookie, christmas, christmas

Free

Best 3D Printer Files in the Gadget Category

MECHANICAL CHRISTMAS GIFT BOX

€3.15 -fifty% 1.57 €

Cheshire cat

2.50 €

Micro Geocache during

Free

Shoulder Arm

Free

Corner drive

2. 16 €

16 €

Raspberry Pi 2 large GPIO opening with cover

Free

iPhone swivel base

1 €

Deactivated

Bestsellers in the Gadget category

Owl - wall key holder

1.84 €

Alligator 2 foldable rear lever

2 €

Keyfob application

3.49 €

Survival pistol with arrows

6.39 €

Air motor, printed, fully assembled, ready to use

3.17 €

Karambit keychain spinner tiktok keyrambit NO BEARING

€1. -ten% 1.54 €  71

71

Ender 3 S1 Original fan upgrade (alternative)

€1.25 -fifty% 0.63 €

Application for cutting cookies

3.49 €

wall key holder (dragon ball)

1.25 €

F18 SUPER HORNET - 50 MM EDF JET [RC AIRCRAFT]

12.01 €

Mount for GoPro DJI AVATA

2,50 €

G17- DD17 Frame with rails

7.50 €

Kinetic floating Christmas tree

1.89 €

ELEPHANT PINK - NO PAINTING

3 €

WALL KEY HOLDER - EYE (FULL COLLECTION)

1. 88 €

88 €

ENGINE BLOCK - WALL KEY HANGER

1,85 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so support us in maintaining the activities of and creating future developments is very simple. Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

Construction 3D printing is waiting for a breakthrough / Sudo Null IT News

3D printing technology originated in the 80s of the 20th century, but construction 3D printing appeared much later. The first construction projects using this technology appeared only in 2014. We are talking, first of all, about the so-called small architectural forms (benches, flower beds, fences). They never even dreamed about building houses. But already in 2015, the Russian startup Apis Cor made a splash - it printed a whole house in the Moscow region. Since then, news about new 3D printed houses has periodically appeared. However, despite the fact that the technology proved to be very promising in terms of the speed of construction of housing and the reduction in the cost of construction, no mass implementation followed.

The first construction projects using this technology appeared only in 2014. We are talking, first of all, about the so-called small architectural forms (benches, flower beds, fences). They never even dreamed about building houses. But already in 2015, the Russian startup Apis Cor made a splash - it printed a whole house in the Moscow region. Since then, news about new 3D printed houses has periodically appeared. However, despite the fact that the technology proved to be very promising in terms of the speed of construction of housing and the reduction in the cost of construction, no mass implementation followed.

Construction is the world's number one market. And, if many technological innovations are being introduced in the field of high-rise construction, then little has changed in the field of low-rise construction over the past decades. The last 30 years have seen the availability of the Internet, mobile phones, mobile internet, robotics taken to a new level, etc., but when you get to a house construction site, you are unlikely to find many technological innovations. Automation is practically non-existent, and manual labor prevails. 2020 was a test of strength for the whole world, and also led to the highest level of inflation, which, first of all, hit the construction market, there was a dramatic change in prices for metals, cement, wood and much more.

Automation is practically non-existent, and manual labor prevails. 2020 was a test of strength for the whole world, and also led to the highest level of inflation, which, first of all, hit the construction market, there was a dramatic change in prices for metals, cement, wood and much more.

This Internet meme shows what happened to the cost of building materials in just a year. And the process is still going on. At the same time, there is a serious rise in the cost of labor, and there is an acute shortage of it. All this leads to a sharp rise in the cost of building houses. No matter how strange it may sound, statistics show that the growth of automation does not occur when everything is fine, but precisely in crisis situations, during increased competition, reduced demand and the need to urgently look for new technologies to increase production efficiency. So it happened this time, and after some vegetation, 3D construction printing received a new impetus for development.

Preparing to write an article, I turned to the founder of Arkon - Boris Kozlov y. Arkon was established in 2020 and is engaged in the production of construction 3D printers, both a workshop type for creating prefabs (prefabricated houses) and a portal one capable of printing a two-story house. I asked Boris the key, in my opinion, question:

Arkon was established in 2020 and is engaged in the production of construction 3D printers, both a workshop type for creating prefabs (prefabricated houses) and a portal one capable of printing a two-story house. I asked Boris the key, in my opinion, question:

- Construction 3D printing appeared in 2014, but no mass introduction of this technology followed in 7-8 years. Why do you think this happened, and why is there a surge of new projects right now?

- It seems to me that the reason is the snowball effect. The technology had to mature, grow from a hypothesis to a pilot implementation, and finally to commercialization and scaling (what is happening now). In addition, it should be borne in mind that construction is one of the most conservative industries, where, unlike even aviation and the automotive industry, there is still an extremely low introduction of digital solutions and automation in the field of the production process itself - the construction itself.

The issue of regulation and certification also plays an important role - this process is long and creates an additional lag.

In 2014 - 2016 the first samples of building 3D printers and prototypes of printed buildings appeared. The concepts of various form factors of construction 3D printers and types of printing materials were tested.

2017-2018 in the world, the first notable investments were made in a number of construction 3D printing start-ups. Further, by 2020, these investments "rolled" in the form of reaching a certain level of technology maturity - the first commercial products (3D printers and houses) appeared.

Finally, in 2020-2022 it became clear that the hypotheses of the effectiveness of construction 3D printing were justified (cheaper, faster, more environmentally friendly), and large investments began in the industry. A striking example is the investment of GE (the French division of General Electric) in the Danish COBOD or the achievement of a capitalization of $ 2 billion by the American company ICON.

In 2022-2023 over 1,000 buildings will be printed worldwide already, scaling from single buildings/pilot projects to entire villages and major infrastructure/reinforced concrete implementations. In addition, in a number of countries, by now, a regulatory framework has been created or is being actively created for the introduction of additive technologies in the construction industry.

Thus, I believe that the specified time period is a fairly natural cycle of technology development, which is likely to experience exponential growth in the next decade.

According to ResearchAndMarket report, the global construction 3D printing market is valued at USD 354.3 million in 2022 and is projected to reach USD 11068.1 million by 2027, an increase of 99.04%.

Various market processes affect the prices and behavior of participants in the global 3D construction printing market. They create price signals that are the result of changes in the demand and supply curves for a product or service. They can be associated with both macroeconomic and microeconomic factors. Even human emotions can also drive decisions, influence the market, and create price signals.

They can be associated with both macroeconomic and microeconomic factors. Even human emotions can also drive decisions, influence the market, and create price signals.

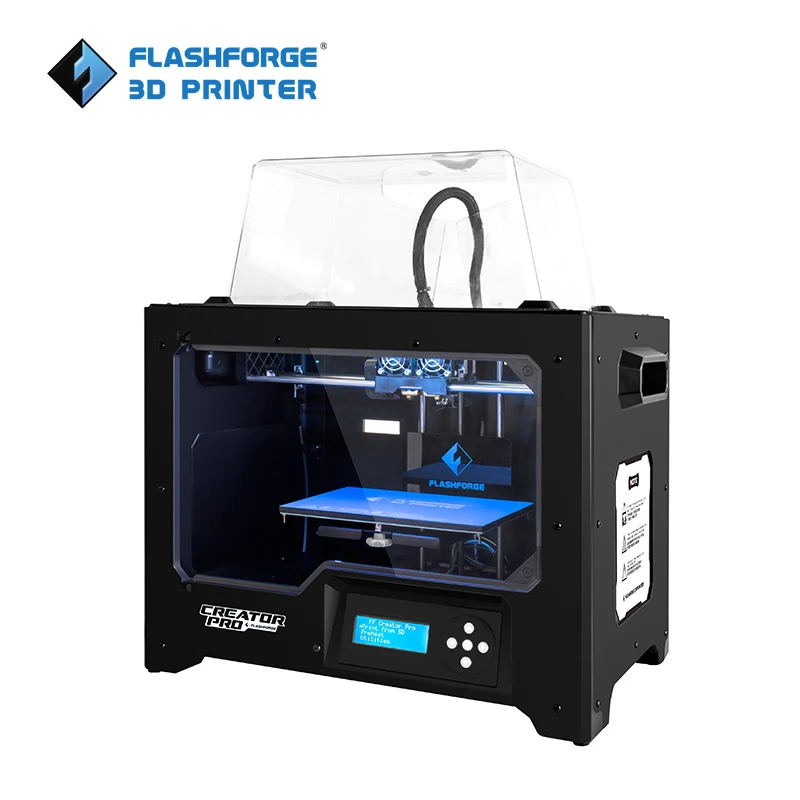

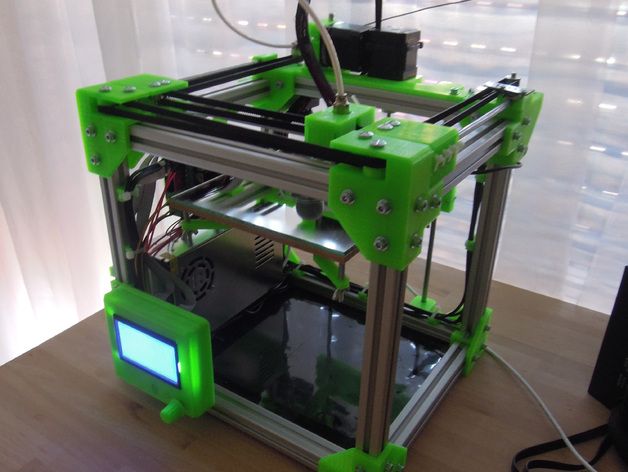

Now let's take a quick look at what is the construction 3D printer. Without delving too deeply into the technology, we can say that construction 3D printers are very similar to classic FDM/FFF printers that print with plastic, but instead of plastic, the material here is a cement mixture, which is fed directly into the nozzle and forms an object by layer-by-layer overlay. Printers are also portal, on the basis of a flying boom, with a robotic arm.

Shown on the left is a boom-based construction printer. The figure on the right is a gantry construction 3D printer

In the figure above, a construction 3D printer in the form of a robot arm mounted on a mobile platform.

Everything changed completely when, in the summer of 2021, the American company ICON, which was trying to introduce 3D printing into the construction of various auxiliary facilities, signed a contract with one of the largest American developers, Lennar, to build a village of 100 houses in Texas and immediately became a unicorn , having received 200 million dollars of investments from several investment funds.

At the same time, the Danish company COBOD, created by the world's largest construction formwork company PERRI, began selling its gantry 3D construction printers, as well as participating in construction projects around the world. In the photo below, a modern two-story house built in Germany and a school building in Malawi, built in record time with a minimal budget.

There is little that unites developed, developing and poor countries, everywhere their problems and tasks, but The lack of affordable housing is a global agenda . If in poor countries there is an acute problem with the increase in the number of homeless people due to a lack of housing, as such, then in developing countries it is necessary to dramatically accelerate the number of new housing being built to meet the needs of a growing population. In developed countries, the problem is primarily in the cost of housing, which has risen in price to such an extent that it has become practically inaccessible to young people. And with the simultaneous increase in life expectancy in these countries, this problem is only getting worse.

And with the simultaneous increase in life expectancy in these countries, this problem is only getting worse.

At the same time, the trend for “green agenda ”, CO2 emission reduction, building with more environmentally friendly materials, etc. is developing. But, unfortunately, so far the construction industry is the absolute leader in CO2 emissions, as well as in the amount of garbage that each construction site leaves behind. This is not to say that construction 3D printing solves all these problems, but at least it is moving in the right direction. Let's look at this with a few illustrative examples.

3D printed walls. Today, when we talk about 3D printing houses, we are talking about printing walls. Everything else (foundation, windows, doors, ceilings and roof) is done in the traditional way. 3D printed walls are built as fixed formwork, which significantly saves the amount of cement used, which in turn reduces construction costs and reduces the environmental impact of cement production. In addition, with this method of construction, no additional waste is produced, the strength of the structure does not suffer. It can be reinforced, as shown in the photo on the left, and engineering communications can be immediately laid, as shown in the photo on the right, which also affects the final speed of the construction of the object. At the same time, the total weight of the structure is reduced, the remaining cavities can be filled with lightweight foam concrete, insulation, straw or any other available material. Such a lightweight design can use a lighter foundation. The construction method itself is more economical in terms of material, and therefore environmentally friendly.

In addition, with this method of construction, no additional waste is produced, the strength of the structure does not suffer. It can be reinforced, as shown in the photo on the left, and engineering communications can be immediately laid, as shown in the photo on the right, which also affects the final speed of the construction of the object. At the same time, the total weight of the structure is reduced, the remaining cavities can be filled with lightweight foam concrete, insulation, straw or any other available material. Such a lightweight design can use a lighter foundation. The construction method itself is more economical in terms of material, and therefore environmentally friendly.

Eco-concrete with the addition of polymers is being actively developed, the production of which reduces CO2 emissions from 30% to 100%. The Apis Cor company mentioned at the beginning of the article, which built a house in the suburbs in 2015, is now based in hot Florida, plans to start using this material in its projects.

Another startup from Russia, Mighty Buildings, headquartered in California, initially relied on a polymer with the addition of mineral chips. And while the company doesn't build entire houses, only wall panels, it has won numerous design awards, as well as a $400 million valuation in several investment rounds.

As a result, with a rough calculation, we can say that the total savings on the construction of walls can reach 30%, and the total cost of the house can be reduced by 10%. This is true for houses designed for conventional construction. And if you initially design with 3D printing, you can improve this ratio by optimizing the laying of communications, the ability to immediately print interior walls, bookmark niches for bathrooms, fireplaces, built-in wardrobes and kitchens, as was done in the house built by COBOD in Germany.

"There are spots on the sun." Despite all the advantages of construction 3D printing, has several significant disadvantages of . The main one is layering, which cannot be avoided at the current level of technology development.

The main one is layering, which cannot be avoided at the current level of technology development.

The photo above shows the layering of the 3D printed walls.

This task can be worked in several directions:

-

Ribbed walls can be plastered, painted and played with as a design element. That's how ICON does it in the US, for example their latest project House Zero is done that way and has won a number of design awards.

-

Use special "shutters" on the print head that allow smooth layers, as COBOD and other manufacturers do. The photo below shows that this does not ensure the complete absence of layering.

-

Fully sand the surface to get the usual smooth wall for plastering, painting, wallpapering or other finishing. It is possible, but it will require huge labor costs, which can reduce the overall efficiency of using 3D printing.

Pictured above is a 3D printed wall sanded smooth.

The second problem is the required temperature. Ideally, printing should take place at temperatures between +5C° and +30C°. Humidity is also important. Using additives, you can push these boundaries, but not indefinitely. At strong sub-zero temperatures, printing will be possible in the field only if the construction site is covered with a dome and the required temperature is reached inside with the help of heat guns. In conditions of intense heat, it is preferable to print at night. Another solution could be to print the wall panels in the shop and assemble them on site. Of course, each of these decisions will have a negative impact on the economic efficiency of the project.

Building 3D printing can be useful not only for the construction of houses . With its help, you can solve many other problems, and there its disadvantages will not matter. For example, the American concern GE uses COBOD printers to build towers for wind turbines in the shop. Ribbed surface and temperature restrictions in this case do not play any role.