Matterhackers pulse 3d printer

Pulse 3D Printer | MatterHackers

- Home

- Store

- Etsy Shop & Small Business Solutions

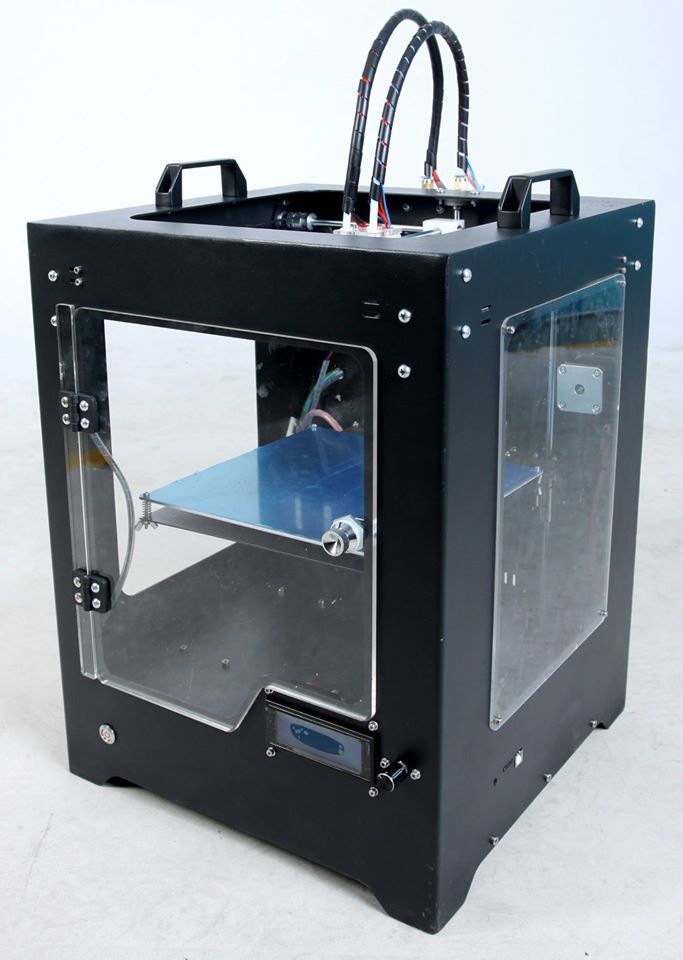

Introducing the Pulse 3D printer—an amazingly high-quality machine, that will meet your 3D printing needs to succeed. Pulse is assembled, tested, and guaranteed by the pros at MatterHackers in Orange County, California.

Remove from wishlist Add to wishlist loading...

Product No. loading...

Notify me when this item becomes available Success You will be notified when ... becomes available.Pulse 3D Printer

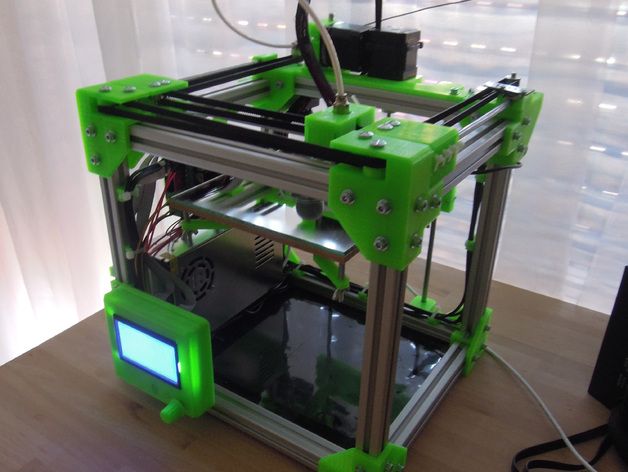

The FDM WorkHorse for Hobbyists and ProfessionalsPulse is an FDM desktop 3D printer designed to be a reliable workhorse, right out of the box, for any application ranging from passionate hobbyists to industry professionals.

Key Features of Pulse 3D Printer:

- Hassle-free FDM printing

- Easy setup for quick startup

- Arrives fully calibrated with industry-leading components

- Interchangeable tool head system for easy and flexible hotend customization

- Free 1 Year Warranty with Lifetime Customer Support

- Pre-Assembled in Orange County, California, USA

Pulse stock features like automatic bed leveling, interchangeable snap-in hotend tool heads, and a magnetic base allow for an optimal 3D printing setup and workflow right from the getgo.

- Convenient 3D Printing From the Start

- Success is seamless

- No Upgrades Required

Tested and Pre-Assembled Calibrated Components

Through careful construction and rigorous testing, our Pulse Pros ensure your Pulse checks all the boxes that make it the quality 3D printer you can rely on for personal and professional projects.

- Fully assembled by trained technicians

- Thoroughly tested by the professionals

- Guaranteed quality printing upon receiving

Less Configuring, More Printing

Your Pulse arrives with fully pre-configured software and settings specific to your upgrades so you can focus on printing with your workhorse machine and less fiddling with getting it to function.

- Ready out of the box

- Comes stock with components that are upgrades on other machines

- Enjoy the perks of the upgrades without the hassle of assembly

What Our Customers Say About Pulse

━━━━━A unit well built and of high quality... ★★★★★-Richard H. Ford | Medical Institute of Northeast Georgia

We were surprised at what we found when we received our first printer. A unit well built and of high quality. .. It worked like a charm right out of the box... No tweaking like other units, just plug it in and run the initial setup as instructed and off you go.

.. It worked like a charm right out of the box... No tweaking like other units, just plug it in and run the initial setup as instructed and off you go.

What Upgrades are Available for the Pulse?

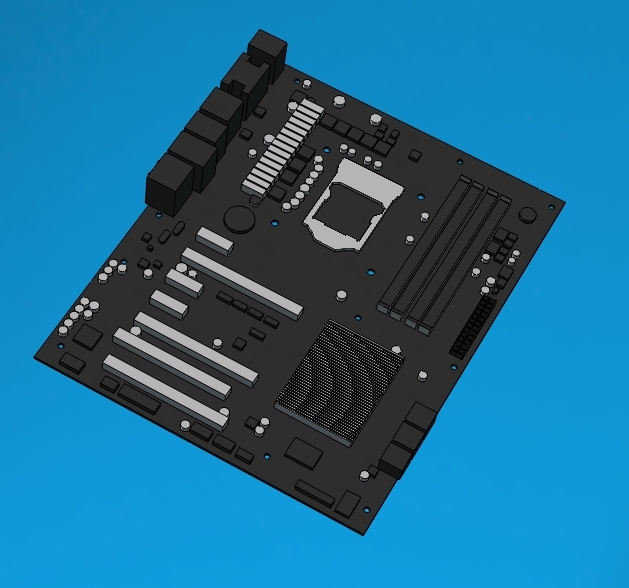

32-Bit CPU +$199

Print faster, cleaner, and more accurately. Assembled with stepper drivers for a silent printing experience. This higher-bit CPU allows the printer to utilize maximum printing capabilities without negatively affecting print quality results. This upgrade REPLACES the 8-bit Einsy RAMBo Board that comes stock with base model.

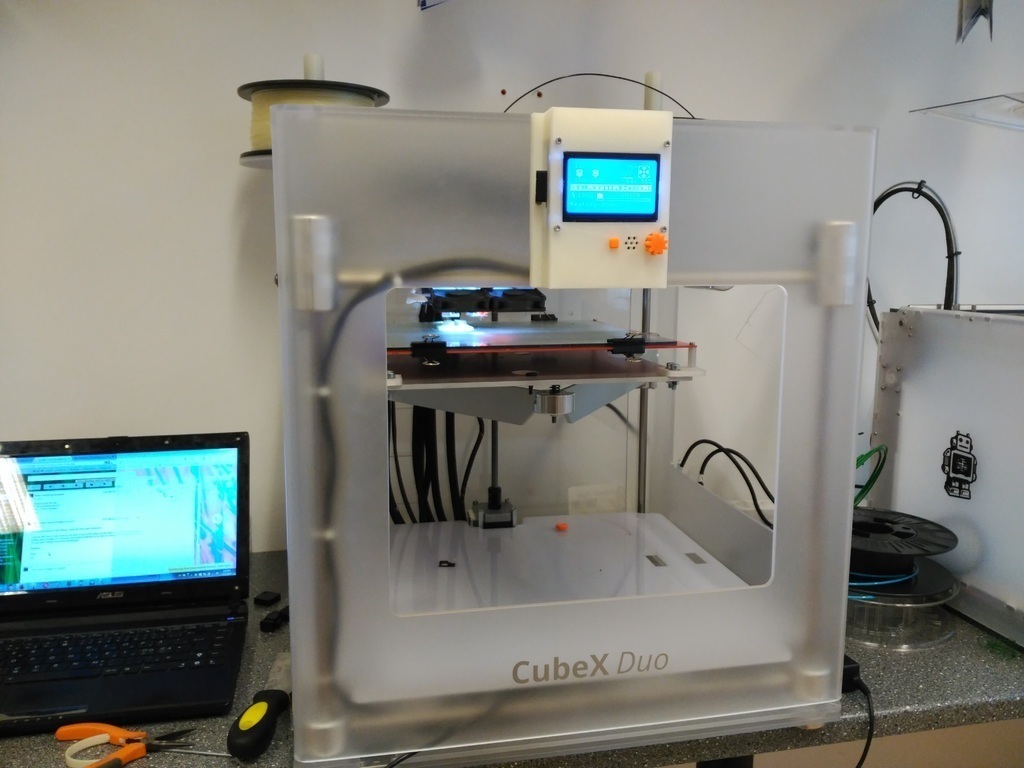

Deluxe Hi-Res LCD Screen +$95

Allows for printing tetherless via standard SD card, manually adjusting nozzle and heated bed capabilities, and customizing the backlight color of the LCD screen across the RGB spectrum. This REPLACES the Standard LCD that comes stock with the base model.

What Add-Ons are Available for the Pulse?

Launchpad Remote Training +$99. 99

99

Access 1 hour of remote training with an Application Engineer to set up for printing success quickly and with confidence.

PrintDry PRO Filament Drying System +$189

Required for long-term success with hygroscopic filaments like Nylon, NylonX, and even PETG and TPU. Temperature is adjustable between 35°C - 70°C and there are small openings on the sides of the chamber for printing while drying. This container has automatic humidity control and can hold two standard spools and more with additional upgrades.

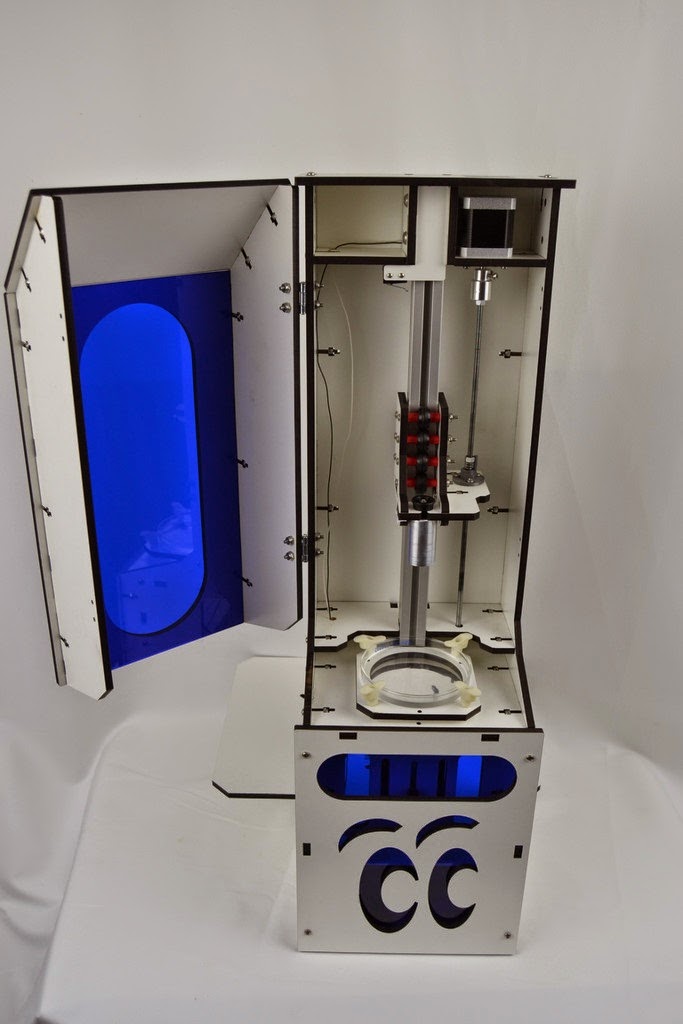

Pulse Enclosure Kit - Black +$279

Helps regulate printer's ambient temperature and reduces warping that may occur during printing. This enclosure kit is also available in white (colors do not affect quality or performance).

LayerLock Powder Coated PEI Build Plate +$35

For optimal, strong bed adhesion with standard filaments such as PLA, ABS, PETG, and flexibles (TPU and TPE). Both sides are powder coated with PEI for longer-lasting durability.

LayerLock Garolite Extra Spring Steel Plate +$49

An extra LayerLock Garolite Build Surface installed on a LayerLock spring steel build plate. Succeed with Nylons as well as standard materials like PLA, PETG, and flexibles.

BuildTak Extra Spring Steel Plate +$35

An extra BuildTak Build Surface installed on a LayerLock spring steel build plate. Succeed with standard materials like PLA, ABS, and PETG as well as flexibles.

Pulse 3D Printer Maintenance Kit +$110

Maintenance is a must for any machine. This kit contains all the essential components and tools for standard, minimal maintenance on your Pulse.

MatterHackers 3D Printing Tool Kit Premium +$96

This kit contains all of the essential tools a maker needs for successful 3D printing, as well as additional items that further streamline your FDM experience for faster and better workflow.

Pules 3D Printer Features:

Auto-Mesh Bed Leveling

Pulse uses a genuine BLTouch probe to automatically level the bed before printing for a nice even bottom layer.

Standard LCD Screen

Standard resolution screen that allows for printing tetherless via standard SD card and manually adjusting nozzle and heated bed capabilities. Note that you will need a standard SD card that has 2-16GB capacity and must be formatted as FAT32.

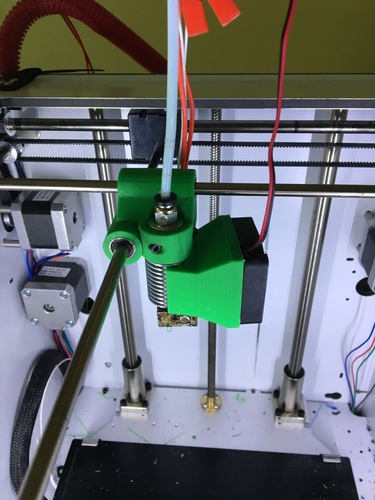

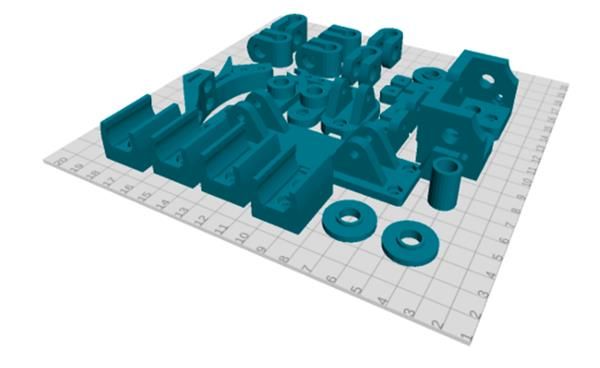

SNAP Quick-Change Tool Head System

Replace or switch between different hotend-nozzle configurations, without any tools, in a snap. Upgrading and repairing the hot extrusion just got a lot easier.

E3D V6 Hotend 1.75mm (Bowden)

The robust and reliable hotend by E3D. Capable of temperatures up to 290°C and compatible with any material that extruders below 300°C.

Hardened Steel Nozzle 0.4mm x 1.75mm

The reliable entry nozzle for printing abrasive, as well as non-abrasive, filaments.

Bondtech BMG Extruder

A reliable extruder that all but eliminates slipping, deformation, and under-extrusion. Produced by industry leaders over at Bondtech.

Capricorn - Premium Bowden Tubing

Premium quality Bowden tubing that follows stricter diameter tolerances and is formulated with additional additives that increase lubricity in order to eliminate jams, clogs, and gaps in printing.

LayerLock Garolite Bed Surface

Garolite is the go-to bed surface to succeed with Nylon, NylonX, and other nylon-based materials that is also capable of printing standard filaments like PLA.

LayerLock MagBase on Heated Bed

This magnetic base allows for build surfaces on steel plates to be detachable making print removal and build surface interchangeability a whole lot easier and convenient. The max temperature of the heated bed is 120°C.

24V Power Supply and Spool Holder

This 24V power supply easily processes any complex tasks so no missteps occur during a print job. Additionally, the spool holder intentionally extends from the power supply so there's a seamless path of filament to the extruder for reliable results.

MatterControl 3D Printer Software Including Power Recovery

This free, open-source, all-in-one software package lets you design, slice, organize, and manage your 3D prints. It contains printer settings ideal for the Pulse XE 3D printer and has helpful features such a power recovery, reloading filament mid-print, real-time modification of Z-offset, and more.

What's in the box?

- Pulse 3D Printer

- 1 x MatterHackers PRO Series Filament

- Power Supply Cord

- Spool Holder Rod

- USB Cable

- Art Knife

- 3 pc Hex Wrench Set

- Getting Started Flyer

Technical Specifications

| Printer Technology | Fused Deposition Modeling |

| Filament Diameter | Ø 1.75 mm |

| Print Area Volume (X x Y x Z) | 250 x 220 x 210 mm (10" x 9" x 8.27") |

| Machine Volume (X x Y x Z) [excl. spool] | 533 x 590.55 x 483 mm (21 x 23.25 x 19 in) *This is the minimum clearance required for the printer to function without issue. |

| CPU | 8-bit |

| Firmware | Marlin |

| Connectivity | USB Serial and standard SD Card |

| Resolution | 20 microns (.02mm) |

| Layer Height | 30 microns to 350 microns (0. 03mm - 0.35mm) 03mm - 0.35mm) |

| Sensor Type | None |

| Nozzle Size | 0.4mm 1.2mm [separate purchase] Supports various nozzle diameters |

| Nozzle Type | E3D Hardened Steel ChampionX DiamondBack [separate purchase] Slice Engineering Vanadium [separate purchase] Supports various nozzle types |

| HotEnd | E3D V6 Slice Engineering Mosquito [separate purchase] Slice Engineering Mosquito Magnum [separate purchase] |

| Max HotEnd Temp | 290°C ±5°C |

| Max Heated Bed Temp | 115°C ±5°C |

| Extruder Type | Bowden |

| Extruder | Bondtech BMG |

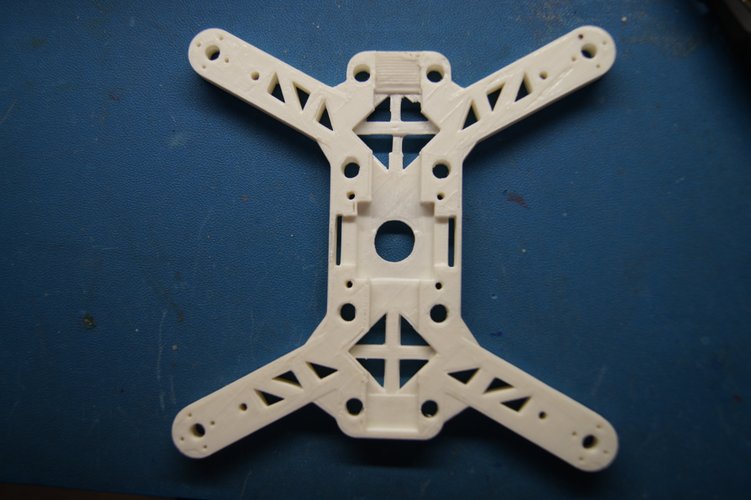

| Supported Materials | PLA, ABS, TPU, TPE, Flex, Ryno, PET, PETT, PETG, CPE, PVA/BVOH, HIPS, nGen, Polyamide / Nylon, PC (Polycarbonate), Polypropylene, Metal, Carbon-filled, Woodfill, Metalfill, and more |

| Print Surface | Removable LayerLock Garolite build plate on a heated bed LayerLock Powder-coated PEI Plate (add-on) LayerLock Polypropylene Build Plate (add-on) LayerLock Glass Build Plate (add-on) LayerLock BuildTak Build Plate (add-on) |

| Speed | Travel speed of up to 250 mm/s and a print speed as high as 60 mm/s |

| Power Recovery | Yes - MatterControl will recover a printer power loss |

| Bed Calibration | Automatic Print Leveling - 25 point BLTouch sensor |

| Remote Control | Yes (limited) - via MatterControl Sync |

| Operating System Compatibility | Windows, Mac OS, Linux |

| Open Standards | Pulse uses open standard technology, which means compatibility with open source tools and no artificial restrictions around the materials you can use. |

| Returns/Warranty | 1-Year Standard Warranty, Lifetime Customer Support |

This item cannot be shipped to a PO Box or APO/FPO/DPO address. This item takes longer to ship due to its size and/or weight.

Pulse 3D Printer | MatterHackers

MatterControl 3D Printing Software DownloadRecent Articles

How To: 3D Print Nylon on Garolite Print Beds

by Alec Richter

If you’ve ever printed with a high temperature material, you’ve probably found that there’s some difficulty in getting your parts to stick to the bed.

How to Succeed with NylonX

by Taylor Landry

NylonX has quickly become one of our favorite filaments for strong, durable, and ready-to-use parts. Here's an in-depth look at Nylon X, and some printing tips to get the most out of this great new material.

How To Succeed When 3D Printing With PLA Filament

by MatterHackers

Discover the best practices for 3D printing with PLA filament - from finding the right temperature, to which surfaces to 3D print on, this step-by-step guide will help you succeed with 3D printing PLA.

How to Succeed when 3D Printing with PETG Filament

by MatterHackers

This in-depth guide provides everything you need to succeed when printing with PETG filament. Embrace the fantastic properties of durable and easy to print, PETG filament!

How To Succeed When Printing With Flexible Filament

by Alec Richter

Let’s take a look at what makes flexible filaments easier to print and how you can add flexible filament to your 3D printing material toolbox.

How To Succeed When Printing With ABS

by MatterHackers

ABS filament is a versatile material that's a great option for when you need your 3D-printed parts to be strong and heat-resistant. Learn how to print this material like a Pro in this in-depth guide.

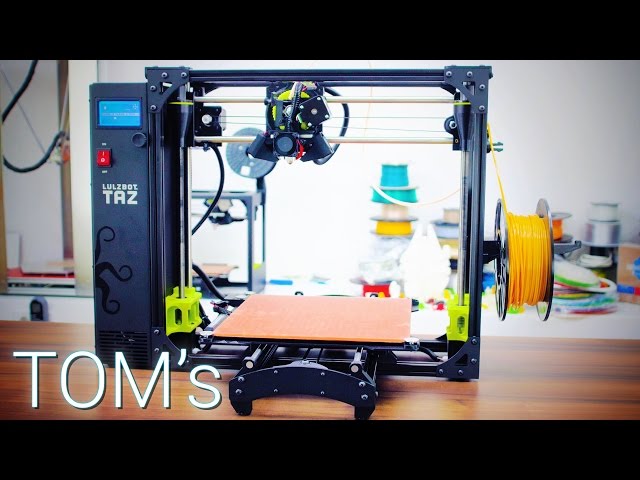

The Pulse 3D printer is a high-quality, fully-customizable 3D printer based on the open-source, Prusa i3, designed to meet the needs of any maker. For professional use, inside the classroom, or even on your workbench at home, you can personalize your Pulse with a variety of upgrades to make your 3D printing experience unique. Your Pulse is hand-built by MatterHackers’ Pros using precision machined components, then thoroughly tested to guarantee successful 3D printing. Your Pulse arrives fully pre-configured with software and settings specific to your selected upgrades, streamlining the experience so you can start creating faster and more efficiently.

Your Pulse is hand-built by MatterHackers’ Pros using precision machined components, then thoroughly tested to guarantee successful 3D printing. Your Pulse arrives fully pre-configured with software and settings specific to your selected upgrades, streamlining the experience so you can start creating faster and more efficiently.

Pulse Getting Started

Getting Started With the Pulse 3D Printer

From unboxing to your first print, we will guide you through the process of unboxing and assembling your brand-new Pulse 3D printer!

Setting Up Your Pulse for Success - Hardware

Unboxing, setting up, and connecting your Pulse to MatterControl is easy thanks to this guide.

Software Setup for Pulse - MatterControl

Once you connect your Pulse to MatterControl, you unlock the full potential of your 3D printer. Take a look at how easy it is to set things up and get started.

Starting Your First 3D Print on Your Pulse

While starting prints is easy, doing it correctly takes just a little instruction. Read on to see the couple steps you need to do before you start making.

Read on to see the couple steps you need to do before you start making.

How to Succeed With PLA Using Your Pulse

PLA is the most common 3D printing filament because of how easy it is to print and the variety of colors. See just what it takes to print your models with ease.

How to Succeed With RYNO Using Your Pulse

3D Printing RYNO on your Pulse is incredibly easy thanks to this handy guide. Read along to see just what it takes to print using the same material your Pulse is made from.

Maintenance

Maintenance for your Pulse 3D Printer

Take a look at what you might need to replace, modify, or change out after you've put your Pulse 3D printer through its paces.

Retraction: Just say "No" to oozing

By understanding a little more about the 3D printing process, and how settings in MatterControl affect extrusion, we can help you reduce and even eliminate oozing and stringing from your 3D prints. This should be a part of the regular maintenance and calibration program for your 3d printer.

This should be a part of the regular maintenance and calibration program for your 3d printer.

How To Calibrate Your 3D Printer's Extruder

This quick and informative guide will help you calibrate your extruder perfectly, resulting in accurate, quality prints.

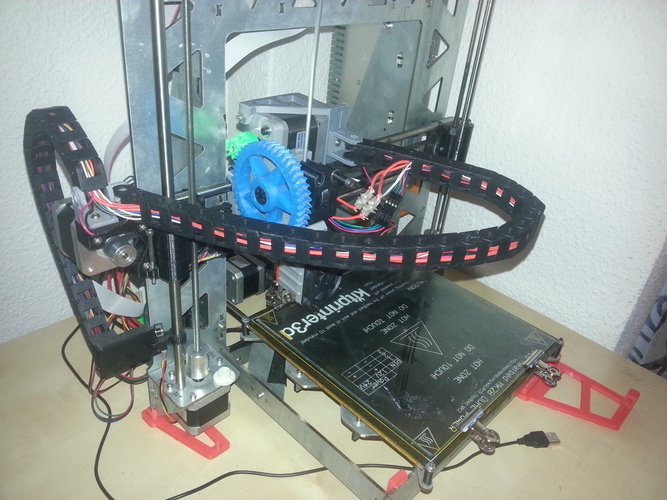

Anatomy of a 3D Printer

Get an understanding of how 3D printing works, from the inside and out. This guide will walk you through each of the critical components of a 3D Printer, answering the question: "How does a 3D printer work?"

Pulse XE

Pulse XE Setup

Unboxing, setting up, and connecting your Pulse XE to MatterControl is easy thanks to this guide.

How to Succeed With NylonX Using Your Pulse XE

The PulseXE is specially designed to print NylonX parts out of the box. Take a look and see what preparations you need to make to get started.

How To: 3D Print Nylon on Garolite Print Beds

If you’ve ever printed with a high temperature material, you’ve probably found that there’s some difficulty in getting your parts to stick to the bed.

Tech Breakdown: Pulse 3D Printer

The Pros at MatterHackers take an in-depth look at the functions and features on the fully customizable Pulse 3D Printer & the NylonX-ready Pulse XE 3D Printer.

How to Succeed with NylonX

NylonX has quickly become one of our favorite filaments for strong, durable, and ready-to-use parts. Here's an in-depth look at Nylon X, and some printing tips to get the most out of this great new material.

Pulse Dual Extrusion

Improved Multi Extruder Alignment Through Visual Coherence

Successful multi material 3D printing starts with nozzle calibration. Improve dual extruder alignment using MatterHackers' unique calibration method.

Setting Up Your Pulse Dual Extrusion for Success

Unboxing, setting up, and connecting your Pulse Dual Extrusion 3D Printer to MatterControl has never been easier with this guide.

Understanding Nozzle Calibration with Pulse Dual Extrusion

Understand how nozzle calibration works in MatterControl to unlock the full potential of your Pulse Dual Extrusion 3D printer.

3D Printers and Scanners - Glossary of Terms and Definitions

Laminated Object Printing (LOM) – Laminated Object Manufacturing is a rapid prototyping technology developed by Cubic Technologies (formerly Helisys). It consists in layer-by-layer gluing of sheet material (paper with an adhesive coating, plastic, foil) with the formation of the contour of each layer using laser cutting. Cubic Technologies has already discontinued its plastic-handling machine, but Mcor recently offered a similar machine that works with colored paper.

PC-ABS (PC-ABS) - Polycarbonate Acrylonitrile Butadiene Styrene - a thermoplastic that has the best characteristics of the two FDM thermoplastics: the strength and heat resistance of PC and the flexibility of ABS.

Laser Engineered Net Shape Melting (LENS) – Laser Engineered Net Shape is an additive manufacturing method in which a product is created layer by layer by continuously feeding metal powder or metal wire fused into a laser beam. The laser creates a melting pool on the print platform, into which the printer nozzle ejects the powder material. In the melting bath, the material solidifies, forming a layer.

The laser creates a melting pool on the print platform, into which the printer nozzle ejects the powder material. In the melting bath, the material solidifies, forming a layer.

Plastic Inkjet (PJP) - 3D printing technology that uses heat and pressure to extrude a continuous bead of material. Thermoplastics are the only material used in PJP 3D printing.

Assembly surface is the surface on which the printed object is created. Often different types of build surfaces are placed on or attached to the printer bed to improve adhesion.

Support (support structure) is a low density material used in 3D printing to support any raised or undercut sections present in the model. The low density of the material makes it easy to remove it from the finished model after processing.

Backing is a layer or layers of extruded thermoplastic used to stabilize the printed object. The backing helps the object adhere to the print platform.

Polyamide is a tough and flexible thermoplastic that can withstand small impacts and resist some bending pressure. The surface has a sandy, grainy appearance and a slightly porous texture.

Polylactic acid (PLA) It is the most popular FDM 3D printing material available.

Polypropylene (PP, polypropylene) is a semi-crystalline material belonging to the family of polyolefins, also known as polyalkenes. Widely used in plastic injection molding industry. Flexible and durable material for FDM printing with excellent physical and mechanical properties. Physiologically inert, which may come into contact with food.

High impact polystyrene (HIPS) is an engineering thermoplastic with good dimensional stability, good impact resistance, excellent machinability and good aesthetic qualities. It combines the hardness of polystyrene with the elasticity of rubber to produce an impact-resistant thermoplastic that is tough and strong without being brittle. In 3D printing, HIPS is an excellent soluble support material. HIPS dissolves in limonene, a readily available solvent derived from the peel of lemons.

In 3D printing, HIPS is an excellent soluble support material. HIPS dissolves in limonene, a readily available solvent derived from the peel of lemons.

Powder Fusion SAF - Selective Absorbction Fusion is the 3D printing technology behind Stratasys' new H Series manufacturing platform. SAF is one category of powder coated 3D printing processes that uses an infrared absorbing liquid to melt polymer powder. This fluid is precisely placed layer by layer to create the shape of the part. When the infrared sensitive liquid is exposed to the printer's fusing lamps, it heats up to a higher temperature than the surrounding material, which "selectively" fuses the powdered particles together but leaves the adjacent material unmelted.

Direct Metal Laser Sintering (DMLS) –Direct Metal Laser Sintering is a metal additive manufacturing technology that uses a fiber optic laser as the energy source. Focusing on a three-dimensional model in STL format, it sinters the powder material at the right points, forming an integral structure. Developed by the German company EOS. A similar technology proposed by Concept Laser is called LaserCUSING.

Developed by the German company EOS. A similar technology proposed by Concept Laser is called LaserCUSING.

PET/PETG Polyethylene terephthalate glycol is a thermoplastic with excellent wear resistance, low friction, high flexural modulus and excellent dimensional stability. PETG is transparent and has a print temperature of around 220C-235C. It is odorless when printed and produces an end result with a marvelous finish. In addition, PETG is an excellent material for printing because it shrinks very little when cooled, so objects printed with PETG do not deform at all.

FAQ - Frequently Asked Questions

What is 3D printing?

3D printing is the process of creating three-dimensional solid objects from a digital file.

The creation of a 3D printed object is achieved through additive processes. In an additive process, an object is created by stacking successive layers of material until the object is created. Each of these layers can be thought of as a thinly sliced cross section of the object.

Each of these layers can be thought of as a thinly sliced cross section of the object.

3D printing is the opposite of subtractive manufacturing where a piece of metal or plastic is cut/hollowed out, for example with a milling machine.

3D printing allows you to create complex shapes using less material than traditional production methods.

How does a 3D printer work?

3D printers are part of the additive manufacturing family and use methods similar to traditional inkjet printers, albeit in 3D.

Creating a 3D object from scratch requires a combination of advanced software, powder materials and precision tools.

Are additive manufacturing and 3D printing the same thing?

While the terms "Additive Manufacturing" and "3D Printing" are often used interchangeably, this is not entirely correct. 3D printing is an important step in the additive manufacturing process, but AM (Additive Manufacturing) covers many more steps, from the initial design of a digital part to polishing and other post-processing steps. In other words, additive manufacturing includes not only 3D printing, but all the processes required to produce objects.

In other words, additive manufacturing includes not only 3D printing, but all the processes required to produce objects.

Is additive manufacturing sustainable?

Because 3D printers add material rather than removing it, there is virtually no waste in the process. Often, any excess material can be reused to make the next part. 3D printers can use recycled plastic as a material to create new products that offer an attractive recycling solution. Additive manufacturing is a particularly attractive method when using expensive materials such as titanium or some industrial polymers because fewer raw materials are needed to create a product.

3D printing – what is the business benefit?

- Economical and unique products

In traditional manufacturing, it is often cheaper to create hundreds of identical products than it is to create one unique product. But not in the case of additive manufacturing, where each product or part can be unique. At the same time, products can be of complex configuration, which is often impossible or difficult in traditional production.

At the same time, products can be of complex configuration, which is often impossible or difficult in traditional production.

- Availability

Professional 3D printers start at $10,000 and are highly automated, making in-house production possible for a vast number of businesses that once relied on outsourcing.

- Fast, cost-effective spare parts and end-of-production replacement

Many old machines and equipment, from classic cars to unique machine tools, end up in landfills because critical parts are either no longer available or too expensive to manufacture. Additive manufacturing eliminates this problem by being able to quickly print any part of any shape.

- In-house manufacturing eliminates supplier dependency

In traditional manufacturing, a business may have only a few suppliers of parts and products. Which, in essence, limits opportunities, forcing you to submit to price pressures and supply disruptions caused by everything from geopolitics to pandemics. Own production eliminates dependence on external suppliers and production that causes environmental pollution.

Own production eliminates dependence on external suppliers and production that causes environmental pollution.

- Reducing inventory

The ability to 3D print parts quickly and as needed eliminates the need to stock dozens or hundreds of parts and products that may never be sold. A business is often forced to rely on a minimum order level dictated by a supplier, even when a minimum quantity is required.

For more information about the benefits of additive technologies in general and 3D printing in particular, you can check with our specialists - leave a request or call +7 (495) 956-7770

Additive manufacturing technologies - what are they?

Although additive manufacturing produces physical products, it is largely digital. Every additively manufactured product starts life as a 3D digital model, and virtually all of them are created with CAD (computer-aided design) software.

CAD has been around for over 50 years and is used in a wide range of industries from consumer goods to architecture. When creating 3D models for additive manufacturing, designers often apply design principles for additive manufacturing (DfAM). DfAM is a design philosophy that emphasizes product development with 3D printing in mind from the very first stage of an idea.

When creating 3D models for additive manufacturing, designers often apply design principles for additive manufacturing (DfAM). DfAM is a design philosophy that emphasizes product development with 3D printing in mind from the very first stage of an idea.

3D modellers use DfAM principles to create product models in CAD software. They must consider the material properties and 3D printing technology that will be used for the part (e.g. material shrinkage), and apply techniques such as topology optimization, support planning, and lattice structures to optimize parts for additive manufacturing.

Other software - among others:

- 3D scanning applications

- Print Preparation Software

- Simulation Software

- 3D Printer Operating Systems

Numerical software makes AM seem like a complex process, but most 3D printers are easy to operate on their own and developers 3D printing software companies are actively competing to make their products as automated and easy to use as possible. Therefore, 3D printing is now subject to almost everyone.

Therefore, 3D printing is now subject to almost everyone.

What is the cost of additive manufacturing/3D printing?

It is not possible to give an average price for additive manufacturing/3D printing because printer and material costs vary widely by technology. So, for example, the prices for powder for 3D printing with metal and plastic for FDM printing are different. The same goes for the 3D printers themselves. Plus, your total budget for equipping a business or enterprise depends on the potential volume of production per unit of time, your capabilities and needs, and payback expectations. And many more.

You can check all the details by phone +7 (495) 956-7770, by mail or from the feedback forms on the website.

What is 3D scanning?

3D laser scanning is a non-contact, non-destructive technology that digitally captures the shape of physical objects using a laser beam line. 3D laser scanners create "point clouds" of data from the surface of an object.

3D laser scanners create "point clouds" of data from the surface of an object.

In other words, 3D laser scanning is a way to convey the exact size and shape of a physical object into the computer world as a digital 3D representation.

3D laser scanners measure fine details and capture arbitrary shapes to quickly create high-precision point clouds.

3D laser scanning is ideal for measuring and inspecting contoured surfaces and complex geometries that require huge amounts of data to accurately describe and where this cannot be done with conventional measurement methods or a touch probe.

What 3D scanning technologies are available?

The different types of 3D scanning methods and the principles on which they are based are as follows:

– Laser triangulation 3D scanning technology.

– 3D Scanning Structured Light Technology.

- Photogrammetry.

– 3D contact scanning technology.

– 3D laser pulsed scanning technology.

How do 3D laser scanners work?

3D laser scanners use a process called trigonometric triangulation to accurately capture a million-dot 3D shape. Laser scanners work by projecting a laser line or lines onto an object and then capturing its reflection using one or more sensors.

The sensors are located at a known distance from the laser source. Accurate spot measurements can then be made by calculating the angle of reflection of the laser beam. Laser scanners are very popular and come in a variety of designs.

These include portable handheld devices, manipulators, CMMs, long range and single point rangefinder trackers.

How do 3D structured light scanners work?

Structured Light 3D Scanner is a type of 3D scanner that uses the following components to capture 3D scans:

- Hardware: The capture unit is the physical part of the scanner, consisting of

projection light (white light, blue LED) and usually 1 or 2

cameras.

- Software: 3D scanning software that runs the scanner.

The software acts as a control center that performs the entire operation, from capturing the 3D data of the physical object to cleaning the output, the 3D model. The model contains valuable information such as measurements, surface characteristics, and information about the geometry of the physical object.

They are useful for applications such as reverse engineering, product verification, CG for creating CGI in games and movies, or 3D rendering for viewing.

To start the scanning process, the capture unit projects a series of reference patterns onto the surface of the part. A light source projects a series of patterns onto an object, usually in the form of several parallel beams. Patterns are distorted when projected onto the surface of an object. The scanner captures these images using cameras. The cameras feed the images back to the 3D scanning software.

It uses these images and software algorithms, using a triangulation method, to calculate object depth and surface information. The end result of a 3D scanner is a 3D digital representation on a computer in the form of a 3D scan.

The end result of a 3D scanner is a 3D digital representation on a computer in the form of a 3D scan.

How do medium and long range 3D scanners work?

Long range D-scanners come in two basic formats: pulse and phase. Both are well suited for large objects such as buildings, structures, aircraft and military vehicles.

Phase shift 3D scanners are also well suited for scanning vehicles, large pumps and industrial equipment.

These scanners capture millions of points by rotating 360 degrees while rotating a mirror that redirects the laser outward onto the object or areas for 3D scanning.

- 3D Laser Pulse Scanners

Laser Pulse Scanners, also known as TOF scanners, are based on a very simple concept: the speed of light is known very precisely.

Thus, if the time it takes for the laser to reach the object and reflect from the sensor is known, the distance from the sensor to the object is also known.

These systems use picosecond-accurate circuitry to measure the time it takes millions of laser pulses to return to the sensor and calculate the distance.

By rotating the laser and sensor (usually through a mirror), the scanner can scan 360 degrees around itself.

– Phase Shift 3D Laser Scanners

Phase shift laser systems are another type of TOF 3D scanning technology and they work conceptually similar to pulsed systems.

In addition to pulsing the laser, these systems also modulate the power of the laser beam, and the scanner compares the phase of the laser sent and returned to the sensor.

Phase shift measurement is generally more accurate and quieter, but not as flexible for long distance scanning as pulsed 3D scanners.

3D laser pulse scanners can scan objects up to 1000m away, while phase shift scanners are better suited for scanning objects up to 300m or less.

How does photogrammetry work?

This technology is quite simple. It involves stitching photographs of an object taken from different angles. Photos are taken with a camera or even a smartphone with certain camera settings, and the stitching of these photos is done by special software.

It involves stitching photographs of an object taken from different angles. Photos are taken with a camera or even a smartphone with certain camera settings, and the stitching of these photos is done by special software.

The software identifies the pixels corresponding to the same physical point and combines the images accordingly.

Parameters such as lens focal length and lens distortion must be entered by the user into the software to create an accurate model.

The big advantage of using photogrammetry is the level of accuracy and speed of obtaining data about the object. The disadvantage of this method is the time it takes to process the image data through the software and the sensitivity of the final result to photo resolution. A high resolution and DPI camera is required to get a good end result.

How do contact 3D scanners work?

This 3D scanning technology involves a 3D data collection contact form.