3D printer london shop

New 3D Printing shop lands in the heart of London | by Jen Botezat | The Nozzle

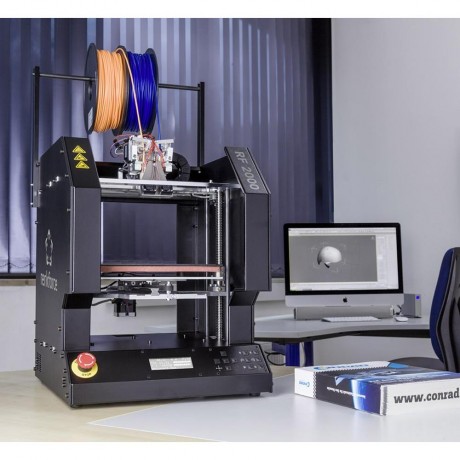

3D printing moves ever closer to the public this week as leading 3D printer distributor iMakr opens its new shop in the heart of London’s busiest shopping destination Oxford Circus.

New iMakr store in London’s busy Oxford CircusAt the grand opening, we discovered the latest 3D printing and scanning machines and spoke to the team’s experts. Let’s go on a journey through the store, spread across two levels, and see what it has to offer eager visitors.

I have to admit, we were most excited to get a complimentary miniature of ourselves! And this was made possible with a full-body “Mini-You” scanning rig at iMakr, which looks like a rather large egg.

The Mini-You scanner/spaceship lands at iMakrThe “scanner” snaps consecutive photos with at least 10 high-resolution cameras while you spin around — absolutely still! — on a turntable, like a giant cake-topper.

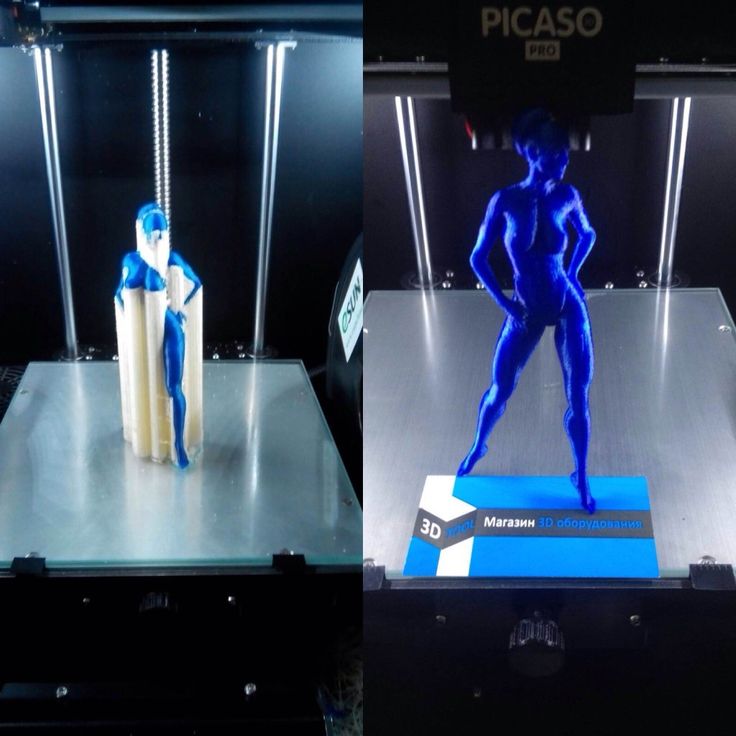

Just getting myself 3D printedThe software then patches together all the photos, taken from all angles, and reconstructs your body in the digital world as a portable file. We ended up with a digital bust of ourselves that we can later 3D print in full-colour SLS (not cheap!).

SLA 3D printing uses curable resins as the base material and satisfies those crafters who require minute details printed to perfection (that’s right, even jewellers).

Although the most high-end machines have traditionally been reserved for industry players, iMakr now offers consumers the EnvisionTEC Ultra 3SP, an SLA machine that prints with amazing quality.

E-glass — perhaps the most impressive 3D materialJust take a look at the crystal-clear droplet, 3D-printed with EnvisionTEC’s E-Glass material. We were stunned by its see-through clarity, used for simulating clear plastics and glass. It has the strength and stability to be used for both prototypes and end-use products.

The first metal 3D printer offered by iMakr was no less impressive. The ORLAS Creator prints high-detailed parts in stainless steel, tool steel, cobalt, chrome, aluminium, nickel based alloys, titanium, and precious metals. Beware, it will take up at least two cubic meters of space despite a build surface of 100 mm x 110 mm.

Beware, it will take up at least two cubic meters of space despite a build surface of 100 mm x 110 mm.

Having this giant at iMakr goes a long way in showing that metal 3D printing is more accessible to consumers than ever before.

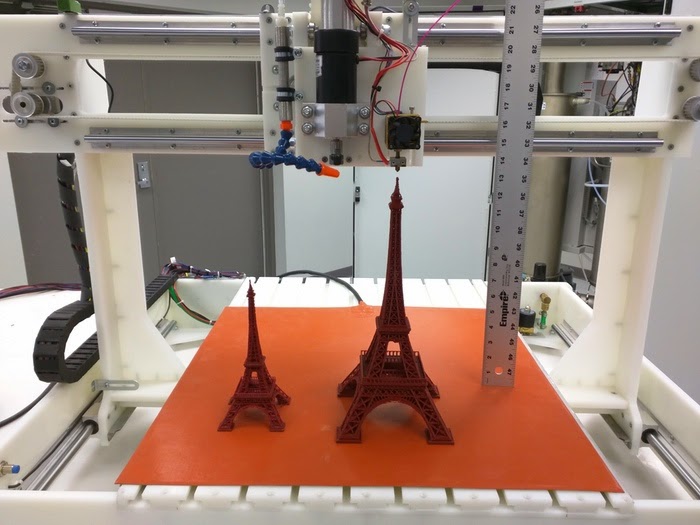

We were pleasantly surprised to see a desktop SLS machine. The strikingly red Sinterit Lisa does a fantastic job 3D printing in powder, as you can see in the image below, the two parts printed in one go. Although the maximum volume is 110 x 150 x 130 mm, the machine achieves an incredible level of detail.

The Sinterit Lisa outdid itself with this surprise egg 3D-printed in one piecePEEK (Polyether Ether Ketone) material is well-known in engineering thanks to its excellent mechanical and chemical resistance properties, even at high temperatures and pressures. Now, iMakr offers two machines that can 3D print with PEEK filament: Intamsys Funmat HT and Apium P155.

PEEK-printing workhorsesAlthough PEEK filament is ideal for specialized science and medical applications, it does come with a hefty price tag of around £600 per kilo, so it’s best reserved for groundbreaking 3D prints worthy of it.

You wouldn’t expect a weathered marble statue on the shop floor of a 3D-printing shop, but this masterpiece was in fact printed with standard PLA.

That’s standard PLA for youBut how? Apparently, the art is in the finish. It took multiple layers of filler, primer, and painting, and a week of effort to achieve this effect, explains iMakr finishing artist Allie. With a degree in fine art, Allie now works exclusively on finishing 3D prints to the desired visual effect.

iMakr stocks some really high-spec scanners, and we have a go at scanning a disturbing head. The handheld scanner flashes a bright light as we move it around the head, and it recreates the digital image in real time through the software.

Scanning this cutieBuying your own scanner is a large investment and only useful if you are planning to scan loads of objects, explains iMakr Research Director Guillaume. “It’s more cost-effective to use the scanning service we provide if you only have a few objects to scan,” he said.

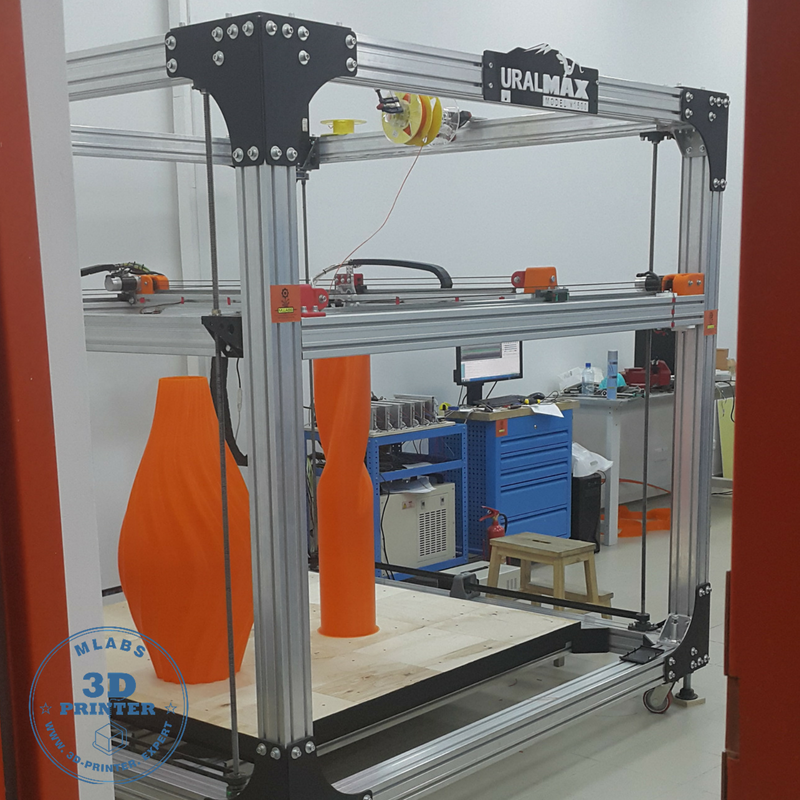

Looking around the store, we immediately notice the lit up gummy bear. He is as tall as the fireplace, and he looks plump and colourful. How was he made?

Can I take him with me?!A huge Delta printer is responsible. It’s so huge in fact, that there’s no use feeding it regular filament. The spools are too small! Instead, it gulps up plastic pellets which melt at the nozzle and ooze out in thick layers. Adding dye to the pellets at random intervals gave the teddy its striated colour. Sit on the chairs at iMakr, and you’ll notice that they are made similarly, on the Delta.

It’s big enoughWe meet iMakr Head Designer James who tells us about his process for working with customers to create custom models.

Grr!“Sometimes customers know exactly what they want, and I will design the model according to those specifications,” James said. “But often, the customers only have a sketch or an idea in their head, so I help interpret their concept and come up with their unique design. ”

”

James shows us the organic shapes he makes, such as his bracelet, using Zbrush for the sculpting element. The jewellery pieces on the table in front of us are really impressive, and James explains how SLA prints can be used as a mold and the final piece cast in silver, as in the case of the ring.

Silver-cast ring from a resin mold printed via SLAWe were so immersed in the tech and our chats that we didn’t notice the time. Apparently, a good three hours had passed, and we were nearing the end-of-night toast.

iMakr Founder Sylvain Preumont and CEO Eric Savant spoke about the history and importance of iMakr. The company has been in the industry for 5 years, and iMakr are now the world’s largest independent 3D printing store.

Their first store opened on Clerkenwell Road in London in 2013, with a second one opening in Manhattan the next year.

The company is moving from Clerkenwell to Oxford Circus, which they expect will be more convenient for tourists and shoppers, and also close to many design studios.

Preumont unveiled plans to open another store in Paris and support a franchise model, that will allow further iMakr stores to pop up around the world.

You can find the new iMakr shop here: 17 Wells Street, W1T 3PF

3D Printing Service London | Instant Quotes Online

Our 3D printing capabilities

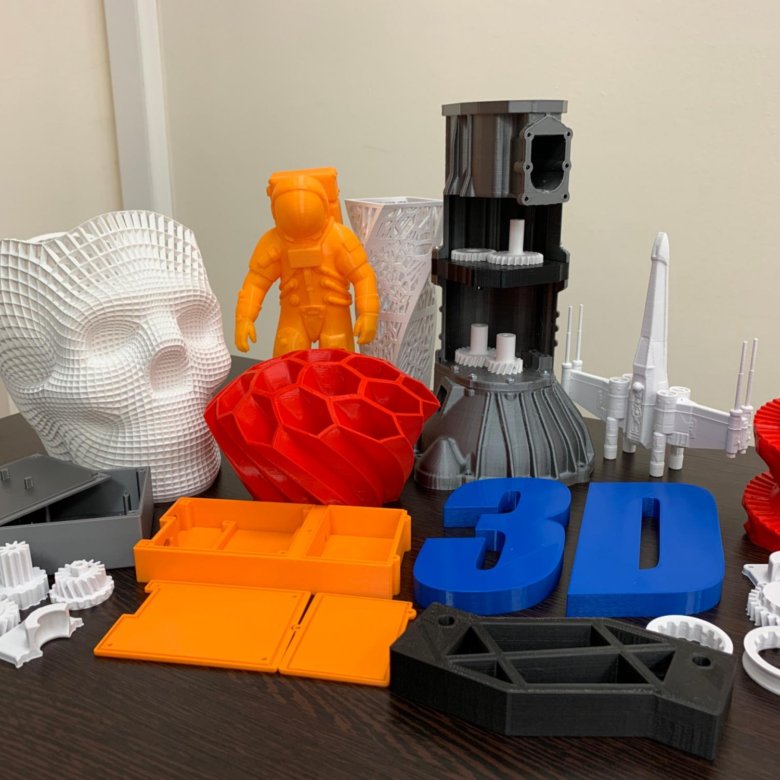

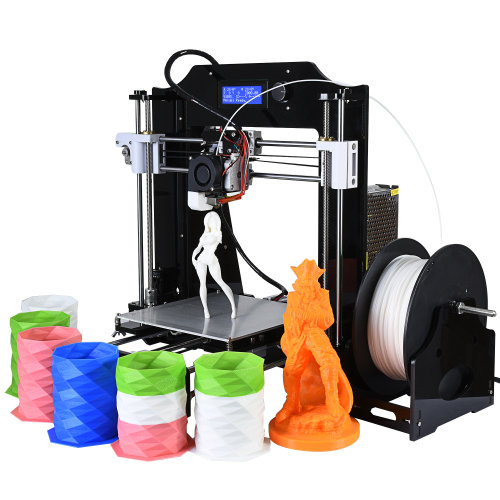

We have over 90 3D printing shops in our network and are well known for manufacturing high-quality parts at competitive prices, from rapid prototyping with Fused Deposition Modeling (FDM) to functional end parts made with Selective Laser Sintering (SLS) or Multi Jet Fusion (MJF).

Gallery of 3D printed parts manufactured by Hubs

With over 65,000 customers from every industry, including aerospace, defense, robotics, medical, machinery, automotive and electronics, we have extensive experience meeting a diverse range of 3D printing requirements, from prototyping to production: Visual aids, concept models, injection-molding prototypes, form-fit & function prototypes, tooling and casting patterns, jigs, grips and fixtures, and durable end parts.

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

Instant, online 3D printing quotes

-

Upload a CAD to start (STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT, STL, OBJ or X_T)

-

Price updates in real-time as you change materials, lead time, etc..

-

No hidden costs. Our instant quotes are not just indications, but the actual price, and include shipping and customs up front.

Learn about how our quoting algorithm works

Our ordering process

Receive instant quote

Upload your CAD to our online quoting platform

Confirm specs

Configure your part specifications and select a lead time that suits your schedule

Production

We select the best manufacturer for your order, and production begins immediately

Quality control

We take full responsibility for making sure your parts are manufactured according to our standards

Delivery

Our 3D printing service has been rated 4.

9/5

9/5 Over 312 customers are satisfied with our 3D printing service.

“Was spot on, can't fault any of it. Even done 2 days early.”

“Picked my parts up in person and I am VERY pleased with everything about them, great print quality and friendly staff to deal with. I will not hesitate to place further orders with this company.”

“My third order, always on time, always what I expect. ”

“Accurate and quick prints with great customer service”

“Looks fantastic. Knowing that this service is available has opened up all kinds of doors.”

“Great service, quality better than i was expecting.”

“Good service, spotted errors with the files I uploaded and fed back very quickly allowing me to correct them before print. Would use again”

“Small order but fast and easy. Will be using again.”

Will be using again.”

“The prints are in excellent quality and the completion time is faster than expected!”

“Excellent experience. First class service. I'm very pleased. Thank you”

“Great! very happy. Friendly and fast service with good communication :)”

“Super fast turnaround for a repeat order!”

“Excellent all round, will definitely use again.”

“Both the print and the customer service was exceptional, needed a part printed quickly for a project and it was ready to pick up the next day - incredible.”

“Received extremely fragile product very well-packed. Delivery was quick and smooth. ”

“quick turnaround, very helpful and communicative. would use again.”

“Helpful - some issues in print due to design but offered prompt and helpful feedback and support”

“Thanks very much - item is exactly what i wanted.”

“Amazing company and will definitely be back.”

“Best print quality I've ever seen on 3dhubs!”

“They suggested that I should go with different material for finished product, and their suggesting was well worth it and I am really happy for it. They responded fast and with pleasure answer my questions. Shipping was fast and reliable. I definitely recommend their service! Blaz”

They responded fast and with pleasure answer my questions. Shipping was fast and reliable. I definitely recommend their service! Blaz”

“Excellent quality and amazing service. Thank you very much”

“The printing quality is good as usual. Thanks for helping me all the time.”

“No problems with the parts supplied: all fitted together perfectly.”

“They were very helpful when I needed to amend my order. The changes were made without any fuss.”

Show more reviews

Show less reviews

Teams build better parts

Create your Hubs team and start collaborating

Read more

The Hubs Standard - consistent quality, every time

Hubs takes the stress out of manufacturing by guaranteeing the quality and consistency of every part. Each order is dimensionally and visually inspected to make sure it meets the Hubs Standard.

3D printing materials

We can generate instant 3D printing quotes for 25+ plastics. For metal 3D-printed parts, you can request a quote from our parent company, Protolabs.

Available materials

SLS

PA 12 Glass filled PA 12

Desktop FDM

Prototyping PETG Prototyping ASA Prototyping TPU Prototyping ABS Prototyping PLA

Desktop SLA

Formlabs Standard Resin Formlabs Clear Resin Formlabs Tough Resin 2000 Formlabs Rigid Resin 4000 Formlabs Grey Pro Resin Formlabs Flexible Resin 80A Formlabs High Temp Resin Formlabs Durable Resin

MJF

HP PA 12 Glass filled HP PA 12

Industrial FDM

Markforged Onyx ABSplus Stratasys ULTEM 9085 Stratasys Stratasys ASA ABS M30 Stratasys ULTEM 1010 Stratasys

Industrial SLA

Accura 25 (PP-like) Accura ClearVue Accura Xtreme White 200 (ABS-like)

3D printing locations near London

Cambridge Cambridge, Canada Luton

London Watford Croydon

Peterborough Milton Keynes Aylesbury

Southend

The 3D Printing Handbook

No one understands 3D printing like us - our founders literally wrote the book. Click here to download the sample chapters.

Click here to download the sample chapters.

Buy the book from Amazon

FAQ's

How much does your 3D printing service cost?

The cost of your 3D printed parts depends on factors such as part volume, part complexity, choice of material, which 3D printing technology is used, and if any post processing is required. For more details on these cost factors, see our article on the cost of 3d printing. To check the cost of your 3D printed part, simply upload a CAD (.STL) file and select your material and 3D printing technology to receive a quote within seconds.

How do you guarantee the quality of my prints?

Your parts are made by experienced 3D printing shops within our network. All facilities are regularly audited to ensure they consistently meet the Hubs quality standard. We include a standardized inspection report with every order and offer a First Article Inspection service on orders of 100+ units.

We have partners in our network with the following certifications, available on request: ISO9001, ISO13485 and AS9100.

Follow this link to read more about our quality assurance measures.

How do I select the right 3D printing process for my prints?

You can select the right 3D printing process by examining which materials suit your need and what your use case is.

By material: if you already know which material you would like to use, selecting a 3D printing process is relatively easy, as many materials are technology specific.

By use case: once you know whether you need a functional or visual part, choosing a process is easy.

For more help, read our guide to selecting the right 3D printing process. Find out more about Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF) and Stereolithography (SLA).

How can I reduce the cost of my 3D prints?

In order to reduce the cost of your 3D prints you need to understand the impact certain factors have on cost. The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

Once these have been decided, an easy way to further cut costs is to reduce the amount of material used. This can be done by decreasing the size of your model, hollowing it out, and eliminating the need for support structures.

To learn more, read our full guide on how to reduce the cost of 3D printing.

Where can I learn more about 3D printing?

Our knowledge base is full of in-depth design guidelines, explanations on process and surface finishes, and information on how to create and use CAD files. Our 3D printing content has been written by an expert team of engineers and technicians over the years.

See our complete engineering guide to 3D printing for a full breakdown of the different 3D printing technologies and materials. If you want even more 3D printing, then check out our acclaimed 3D printing handbook here.

We have an extensive range of online resources developed to help engineers improve their capabilities.

Introductory guides

Design guides

Material guides

Applications

CAD & file preparation

Post processing & finishing

Our other manufacturing capabilities

CNC machining

CNC machining

Milling (3-, 4- & full 5-axis), turning and post-processing

-

50+ metals and plastics & 10 surface finishes

-

Tolerances down to ±.0008” (0.020 mm)

-

Lead times from 5 business days

See our CNC machining services

Put your 3D printed parts into production today

Get an instant 3D printing quote

3DPrintshow exhibition in London / Habr

In my first publication on Habré, I decided to tell in detail about what is happening in the world of 3D printing business. And the best reason for that is the 3DPrintshow in London this weekend, in fact the biggest event in our industry focused on the consumer side of the 3D printing business.

And the best reason for that is the 3DPrintshow in London this weekend, in fact the biggest event in our industry focused on the consumer side of the 3D printing business.

Let me introduce myself: my name is Konstantin, I am the co-founder and CEO of 3DPrintus. My interest in the exhibition is due to the fact that in the Russian market we are developing B2B and B2C directions for the provision of industrial 3D printing services, as well as a product marketplace and a community of designers.

Likbez

To begin with, when developing business in Russia, you always have to look to Europe and the USA, because our partners there are a few steps ahead of us and our task now is to accelerate the development of 3D printing in Russia and the CIS. Therefore, the efforts of each new company in our market is a big plus for the industry as a whole.

So, the most important thing you should know about the development of 3D printing in the world:

1.

The technology has been around for over 30 years. The hysteria in the media about the “third industrial revolution” and the thesis that “now it will be possible to print iPhones and TVs at home” are somewhat premature, to say the least.

2. Market

It is necessary to separate the market and business for the production of 3D printers from the market for the provision of 3D printing services. The volumes of the markets are completely different, as are the companies on them.

3. Technology

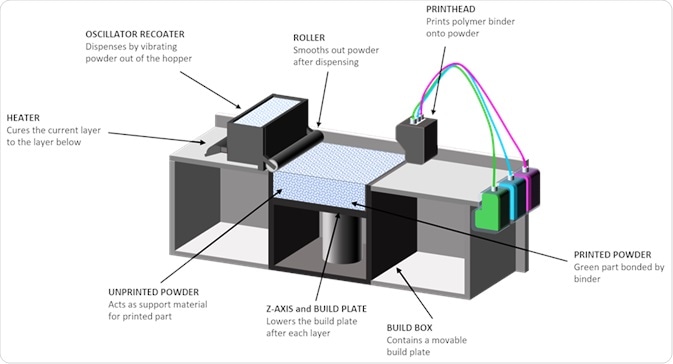

It is important to consider separately the market and technologies of "home" 3D printing and industrial. Industrial appeared much earlier and includes such technologies as SLA, SLS, MJM, PolyJet, 3DP, SLM, FDM. The main technology for home 3D printing is FDM. Also, printers based on SLA and SLS technologies entered the market of “home” devices, which gives a certain qualitative leap forward.

4. Restrictions

Initially and until now, 3D printing is about the production of a limited number of products, goods, prototypes, etc. Technology certainly will not make the cost of producing a unit of a product cheaper than in mass production. But technology makes it very cheap to start production of any product, when you either a) make the first prototypes, b) test the demand in the market.

5. Application

- Prototyping

- Small batch production

- Prototyping

- Architectural prototyping

- Jewelery

- Medical implants and prostheses

- Robotics

- Hardware startups

- Individual decor, accessories, jewelry, art, fashion

- DIY

6. Stage of development

If we objectively look at the current stage of development of the market and technologies, then I will draw the following conclusion:

At the moment, 3D printing is used as an effective means of prototyping and small-scale production. Also, technology is increasingly being used to solve business problems from various fields. The enterprise market welcomes technology and uses it in its work.

Also, technology is increasingly being used to solve business problems from various fields. The enterprise market welcomes technology and uses it in its work.

Undoubtedly, technologies are beginning to influence medicine in the most positive way, they are used in surgical operations.

And finally, technology is reaching our homes and hands: designers around the world are using 3D printing technologies to make various final products, from plastics and metals. And in this area, in the near future, the business of such items made of steel and precious metals will most actively develop, since they are the most understandable for consumers.

However, this market will take more than one year to become massively demanded by consumers around the world.

The result for today is:

80% of applications are prototypes, small series, prototypes, medical prostheses and implants, architectural models and jewelry, 20% are consumer goods.

Exhibition

Let's go back to the exhibition. The 3DPrintshow event itself is not taking place for the first time. Last year, in the same London, where the development of 3D printing is progressing by leaps and bounds, I was also at the show, the report can be read here.

3DPrintshow goes on for three days, each of which has its own theme. This year the themes of the days were as follows:

- Business Day

- Design Day

- Public Day

The days differ in the composition of the lectures, which take place on 4 stages in parallel, all days. All lectures are led by designers, business owners, 3D printing evangelists, community managers and other interesting people. Each lecture lasts about half an hour + half an hour for questions from the audience. In 3 days there is every chance to get a good injection of useful information and insights.

The exposition itself this year consisted of the most interesting and promising companies in Europe and the USA and was conditionally divided into two parts - printer manufacturers and services/startups providing services. Very convenient to navigate inside.

Very convenient to navigate inside.

Also this year there was a private balcony, which housed art objects and clothes created by designers using all available 3D printing technologies. In fact, it is a reflection of the level of technology development. Yes, it should be noted that almost each of them has a very high cost.

Full -color printing from a gypsopolymer

3

Strong and flexible plastic (polyamide) with painting

detailed plastic (photopolymer)

9022 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 Detailed translucent plastic (photopolymer)

PLA

PLA

Strong and flexible plastic (polyamide)

detailed plastic (photopolymer) with painting

PLA-plate

PLA-plate 9000 what is called on the sidelines and in close communication with participants and business owners. This is the only way to get truly objective information about the market situation and prospects, to exchange experiences and opinions.

This is the only way to get truly objective information about the market situation and prospects, to exchange experiences and opinions.

A pleasant bonus for me was that I already knew most of these people through joint projects or at past exhibitions in London and New York, so it was not difficult to get the most interesting information. I will share only the most interesting facts and forecasts.

Presumably, the most interesting event on the market was to be the launch of a new platform from the well-known and "favorite" company Autodesk.

For most non-professional users, the company has had good online 3D modeling products for several years now, such as 123Design, 123Catch, 123Sculpt, Tinkercad, etc.

However, the company decided to go further and launch its own open source platform and printer - Spark, which will have to open up a whole new market for apps, applications and addons for all enthusiasts and third-party developers.

The company announced this wonderful event a few months ago, but unfortunately, at the exhibition and during the lecture, they gave a minimum of information about the new project. They promised that in a couple of months this big event would still happen and the community of users of Autodesk systems would be able to start using its new brainchild.

They promised that in a couple of months this big event would still happen and the community of users of Autodesk systems would be able to start using its new brainchild.

Continuing the topic of software development in the field of 3D printing, I would like to note a wonderful company, our partner, Uformia and their product Uformit.

Colleagues, having gone through many years of development in the field of modeling and mathematical calculations, have created a product based on the principles of parametric design that allows you to set customization parameters for any three-dimensional objects created by designers. Their development is the Symvol plugin for Rhino.

At the same time, for end users and buyers, everything looks like an uncomplicated interface for ordering a personalized pendant, ring, mask and more from precious metals and high-quality plastics.

I would like to draw your attention to the fact that Uformit is doing an excellent job in the medical field. With the help of their software and 3D scanning, a medical corset was created, fitted and personalized for a specific patient.

With the help of their software and 3D scanning, a medical corset was created, fitted and personalized for a specific patient.

I can't ignore the actively developing project Formlabs - a manufacturer of professional "home" printers based on SLA technology.

An excellent and affordable printer for designers who need the fastest yet accurate tool to test their ideas in practice.

The British company Digital Forming has focused its efforts on the development of an online system for designers, which makes it possible to make any model customizable. All the same basics, parametric design.

The next entrant is 3DPrintUK, a design and manufacturing company with the only SLS technology available to them.

I must say that the guys make very high-quality projects in terms of industrial design!

In addition to the external beauty of this solution, you can also notice an interesting engineering solution - a lightweight design. This is the design of the future!

This is the design of the future!

Consumer market

Now let's move on to the story of the companies closest to me in the field of business - 3Dhubs, Shapeways, Sculpteo and i.Materialise. It is they who, in many ways, are the driving force behind the development of the consumer sphere of 3D printing in the world!

Developing our company in Russia, we communicate a lot with Western colleagues and exchange information about prospects and new opportunities.

The motto of the guys from 3Dhubs is local 3d printing. To date, they have created, perhaps, the widest and most accessible network of 3D printer owners in almost every city in the world. Through their website, anyone with a 3D model can have it printed directly from the owner of the printer, who may be in the house next door. And get it from him.

Very convenient and most importantly not expensive. 3Dhubs only charge 20% per transaction between the customer and the owner of the printer.

By the way, I must say that 95% of network printers are home, hence the significant limitation on the quality and quantity of manufactured products.

In addition, just a week ago, the company received a new round of investments in the amount of $4.5 million to develop and expand the network. Serious funds and great prospects that investors see!

The Belgian company Materialise has long been known on the market. For most of its history, the company has been selling industrial printers and providing printing services to the aviation, automotive, military and medical industries.

However, an equally important direction for the company is the development of the i.Materialise project - a 3D printing service and a goods marketplace. The company allows designers to create their own stores and publish products for sale in them.

I note that i.materialise closely monitors the quality of published products and tries to weed out what, in their opinion, it will not be possible to sell. Although this is not officially regulated, but by the number of goods and communication with designers, such a conclusion can be drawn.

Although this is not officially regulated, but by the number of goods and communication with designers, such a conclusion can be drawn.

For the company, the main market and income is 3D printing services for large business customers and the sale of printers.

The French startup Sculpteo is positioning itself as a cloud-based 3D printing system. And not easy. The company has developed a very powerful tool for working with 3D models online.

In fact, professional designers and engineers can easily prepare any 3D model right in their personal account on the website, without using desktop software: making the model hollow inside, checking the thickness of all walls, placing their entire order in the printer chamber and running it in work.

The team spent 4 years to reach the current level of their IT product. Now they are launching a second production near Paris, where about 15 industrial printers will be located.

Investors are looking very promisingly at the development trend of digital cloud production, providing access to the capacities of industrial 3D printers (read mini-factory) and investing in creating the infrastructure of the future.

And, finally, the favorites of the American (and not only) press - Shapeways startup.

Shapeways is first and foremost the largest marketplace for products created by an army of designers (about 30,000) of the community.

The main positioning of the company is to create a community and marketplace for entrepreneurial designers, with their own design stores and products. Mix of Etsy and Amazon. The company has been around for 7 years and has raised about $40+ million in investments. Two offices and production facilities in NY and the Netherlands.

More recently, the press was blown up by the information that Shapeways, together with the well-known toy manufacturer Hasbro, launched a project where every designer can create their own version of characters from the Ponyes series, publish it as part of a competition. Later, the company chose the winners, whose works went to mass production. And all the rest are available for order on the Shapeways website.

Thus, Hasbro was one of the first companies to open (with certain restrictions, of course) the ability to reproduce characters without violating intellectual property. The project was very successful and now, Shapeways is launching a number of characters on similar topics.

This is a very important wake up call for the entire industry. The same revolution was made by Apple with the iTunes store.

Totals

Summing up the results of the exhibition, I would like to send a message to all those who are currently looking for a new sphere of application of their knowledge and skills: whether it be entrepreneurial or professional.

3D printing and the eco-system that is now being created around it is a huge yet unfilled niche for hundreds and thousands of projects. It will take more than one year until the technology is popularized among end customers, but for business it is already a reality and today.

The intersection of additive manufacturing and internet services creates what I think is an incredible mix that I call Digital Manufacturing . And this trend will continue to gain momentum in the coming years.

And this trend will continue to gain momentum in the coming years.

Bonus:

For all those who want to take an express tour of the entire exhibition - first-person video.

3D printer models

Looking for 3D printer models? The Internet is filled with sites that offer them for free. We have collected the TOP 10 catalogs that you can use to search and download free models in STL format. We hope you can find what you are looking for.

- Yeggi

- Yobi 3D

- STLfinder

→ myminifactory.com

My Mini Factory is a 3D model depository operated by iMakr, an online store that sells 3D printers and accessories. It also has one of the biggest 3D printer shops in Central London. The site contains 3D models designed by professionals, and all models stored on it are checked for quality. You can also make a request for the desired model, which their designers will create and put in the public domain. Billing itself as a 3D printing social network, MyMiniFactory is a thriving community of makers who love to showcase their creations. Users vote for the best models, which allows popular creations to rise to the top of the list and gain popularity. The site presents models that are stored on its social network, as well as outside it, for example, on the Thingiverse and YouMagine sites.

Billing itself as a 3D printing social network, MyMiniFactory is a thriving community of makers who love to showcase their creations. Users vote for the best models, which allows popular creations to rise to the top of the list and gain popularity. The site presents models that are stored on its social network, as well as outside it, for example, on the Thingiverse and YouMagine sites.

→ thingiverse.com

The most popular and famous site among 3D printer users, Thingiverse is owned by MakerBot Industries, the creator of the popular Replicator 3D printer series. The site allows users to store and share 3D model files that are used with 3D printers. It's a very popular site and has a large community of people hosting various categories of files on it. So if you're looking for "cool" printable stuff, Thingiverse is worth a visit. It is a portal designed to provide its users with ways to share their designs and to help print 3D creations. The site has a system that tries to find out what you like. The more you interact with the site, downloading and evaluating various developments, the better its recommendations will be.

The more you interact with the site, downloading and evaluating various developments, the better its recommendations will be.

→ 3dshook.com

Another online community for 3D printing enthusiasts showcasing interesting 3D printer accessories, electronics and most importantly 3D models. The site contains many very interesting models of cars and buildings, as well as various add-ons and spare parts for your 3D printer. A huge catalog of paid and free models for a 3D printer. There are original unique products. Convenient search, navigation, rubricator. 3DShook has over 40 categories and adds over 100 new models to its collection every month. On 3DShook you can always find something for your home, animals, kids or something special for yourself.

→ youmagine.com

YouMagine catalog for Cube series consumer 3D printers manufactured by 3D Systems. The site mainly offers various ways to buy 3D printer supplies and files, but it also has a number of cool free items available, mostly in the Kids section. Some of these elements can be customized by children using an online application. The company offers 3D modeling and publishing tools on its website for both hobbyists and professionals. The site offers a content warehouse where the community hosts and shares models. Registration is required to download files.

Some of these elements can be customized by children using an online application. The company offers 3D modeling and publishing tools on its website for both hobbyists and professionals. The site offers a content warehouse where the community hosts and shares models. Registration is required to download files.

→ 123dapp.com

Autodesk 123D is a suite of computer-aided design (CAD) and 3D modeling tools aimed specifically at hobbyists. Along with the toolkit, Autodesk also has a website where users can record their designs and share them with other users. Many of these models can be downloaded and printed using Autodesk as a utility to interface with the MakerBot 3D printer. The goal of the Autodesk website is to "help engineers build products faster." The site offers tools to help them collaborate on their files. For the casual 3D printing enthusiast, the best part of the site is the large library of free files created by a community of over a million engineers. Registration on the site is required, but the number of files that are then available is worth it.

Registration on the site is required, but the number of files that are then available is worth it.

→ cgtrader.com

Being primarily a place to buy and sell a variety of 3D models (not necessarily just those designed for 3D printers), CGTrader does offer a selection of free models that can be used on 3D printers. The site has a system that tries to find out what you like. The more you interact with the site, downloading and evaluating various developments, the body will have better recommendations.

→ cults3d.com

A French community and marketplace where developers can share or sell their creations. The site has a collection of high quality models that you can download. Users can follow the work of the designers they like and get instant updates when a new creation is posted on the site. The site's name, Cults, is a backwards spelling of St. Luc, the patron saint of artists. The site also supports English. This is a relatively new community, so the number of its users is not very large yet.

→ instructables.com

The Instructables website is a community where users can share their DIY projects. This also includes products obtained using 3D printers. The site also provides explanations and instructions describing how to build 3D elements, and some designers take the time to answer questions from site members. Instructables allows users to store and organize their 3D printing projects. This is done to help them work together in the future. You can think of this site as a GitHub 3D printing site where users can share their files, discuss projects, and participate in them. The site also offers the ability to make a request, so if you can't find what you're looking for, you can ask the site's community about it.

→ pinshape.com

Pinshape, a marketplace for 3D models, is similar in style (layout, appearance, and ability to capture likes) to the well-known site Pinterest. You can buy models from designers, or download them for printing yourself if they are offered for free. Pinshape allows users to host and share 3D model files on it. Basically, this site acts as an online store where you can buy 3D printed parts, or order your own 3D model to be printed. But if you look closely enough, you can find people who sell their products and also offer the files you need so you can print them yourself.

Pinshape allows users to host and share 3D model files on it. Basically, this site acts as an online store where you can buy 3D printed parts, or order your own 3D model to be printed. But if you look closely enough, you can find people who sell their products and also offer the files you need so you can print them yourself.

→ 3dfilemarket.com

A new and growing repository of 3D File Market models. All models are tested for suitability for 3D printing. You can download as many models as you like without registration, although you must provide your email address to access the 3D model files. This is a very simple site aimed at being a repository of model files for 3D printers, and nothing more. The basic design of the site allows users to put files on it for public access, and download files that they would like to use. The site contains many small, simple 3D models ready to be printed, as well as a good selection of everyday items and even spare parts for 3D printers.

Search engines for 3D models in various formats, including STL for a 3D printer. Use queries in English, these search services collect information about models from all over the Internet.

→ yeggi.com

Yeggi is a search engine that will browse major 3D printing sites to find files compatible with 3D printers. You can also browse some popular searches to get an idea of what the community is currently interested in.

→ yobi3d.com

When in doubt, use yobi3D to search for files that match the desired 3D printer. This tool is useful if you want to search for one thing across all sites at once. A very convenient format filter, fast search, high-quality previews and stl models prepared for 3D printing for printing.

→ stlfinder.com

This is another STLfinder that surfs the web looking for 3D printing. To select files compatible with 3D printers, he goes through many 3D modeling sites.