3D printer israel

3D Printing Service Israel | Instant Quotes Online

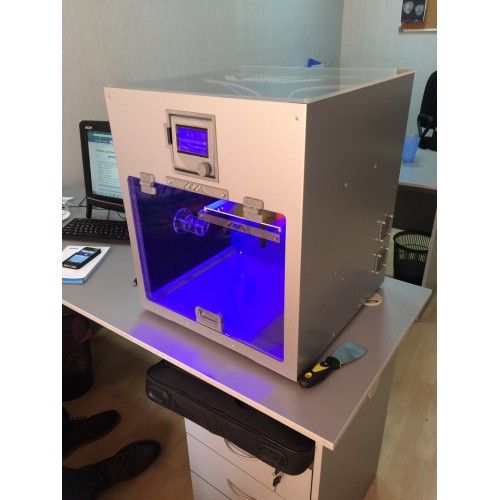

Our 3D printing capabilities

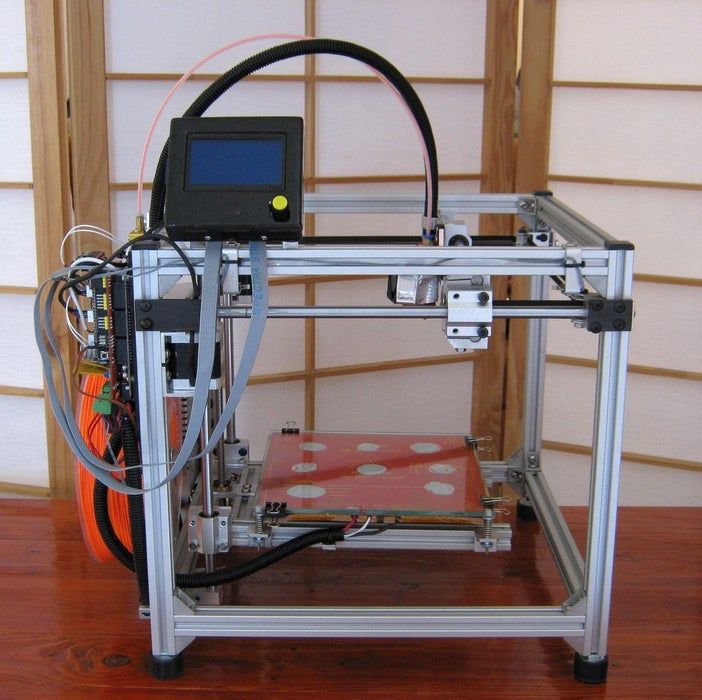

We have over 90 3D printing shops in our network and are well known for manufacturing high-quality parts at competitive prices, from rapid prototyping with Fused Deposition Modeling (FDM) to functional end parts made with Selective Laser Sintering (SLS) or Multi Jet Fusion (MJF).

Gallery of 3D printed parts manufactured by Hubs

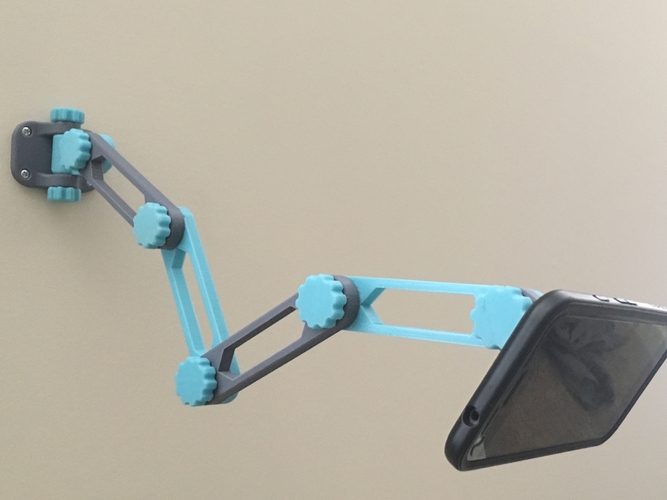

With over 65,000 customers from every industry, including aerospace, defense, robotics, medical, machinery, automotive and electronics, we have extensive experience meeting a diverse range of 3D printing requirements, from prototyping to production: Visual aids, concept models, injection-molding prototypes, form-fit & function prototypes, tooling and casting patterns, jigs, grips and fixtures, and durable end parts.

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

Instant, online 3D printing quotes

-

Upload a CAD to start (STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT, STL, OBJ or X_T)

-

Price updates in real-time as you change materials, lead time, etc.

.

. -

No hidden costs. Our instant quotes are not just indications, but the actual price, and include shipping and customs up front.

Learn about how our quoting algorithm works

Our ordering process

Receive instant quote

Upload your CAD to our online quoting platform

Confirm specs

Configure your part specifications and select a lead time that suits your schedule

Production

We select the best manufacturer for your order, and production begins immediately

Quality control

We take full responsibility for making sure your parts are manufactured according to our standards

Delivery

Our 3D printing service has been rated 4.9/5

Over 239 customers are satisfied with our 3D printing service.

“Great supplier, and the level of service makes me return and seek him out whenever I need something printed.”

“Excellent service, very professional and helpful. Thanks a lot!”

“Super professional. And good-looking too.”

“excellent work. they are very cooperative. i will use their services again.”

“lightning-fast and super friendly. 10/10, will print again.”

“The service was fast and i am completely satisfied”

“Shipped quickly, very cheap, arrived on time.”

“Müşterisine kolaylıklar sağlayan, güvenilir bir hub. Herkese tavsiye ederim.”

“Thank you for fast service & perfect quality!”

“Thank you for a great service! Great communication and fast print! Will order again soon!”

“Thank You! I received my parts in just 2 days with shipping. High printing quality and Grade A service. I highly recommend this hub. ”

“Excellent quality ,communication,speed, packaging, in general everything was great”

“Excellent!Fast service and good quality! ”

“Very quick and good turn around- much appreciated and recommended!”

“Very good quality and friendly communication. Attention to details.

Kudos!”

Attention to details.

Kudos!”

“Fast and nice. Good quality in small parts!”

“Much better than expected, thank you very much ”

“Great professional. Fast service. Excellent job.”

“The print turned out great and the hub was very helpful with everything. Even though this was my first print, they helped me a lot. Excellent Service.”

“Lovely quality, extreme support. Super fast delivery.”

“The serivce was outstanding and I would recommend it!”

“Perfect result. Punctual very good communication”

“Ultra fast and super helpful! Ilias responded to my messages imediately and he printed them right away despite the fact that it was Sunday! What's more, he was very helpful as far as delivery is concerned and he even offered to meet me away form his workshop to hand me the parts himself.”

“Excellent service! High quality and quick delivery.”

“I'm fully satisfied with the results and communication flow.”

Show more reviews

Show less reviews

Teams build better parts

Create your Hubs team and start collaborating

Read more

The Hubs Standard - consistent quality, every time

Hubs takes the stress out of manufacturing by guaranteeing the quality and consistency of every part. Each order is dimensionally and visually inspected to make sure it meets the Hubs Standard.

Each order is dimensionally and visually inspected to make sure it meets the Hubs Standard.

3D printing materials

We can generate instant 3D printing quotes for 25+ plastics. For metal 3D-printed parts, you can request a quote from our parent company, Protolabs.

Available materials

SLS

PA 12 Glass filled PA 12

Desktop FDM

Prototyping PETG Prototyping ASA Prototyping TPU Prototyping ABS Prototyping PLA

Desktop SLA

Formlabs Standard Resin Formlabs Clear Resin Formlabs Tough Resin 2000 Formlabs Rigid Resin 4000 Formlabs Grey Pro Resin Formlabs Flexible Resin 80A Formlabs High Temp Resin Formlabs Durable Resin

MJF

HP PA 12 Glass filled HP PA 12

Industrial FDM

Markforged Onyx ABSplus Stratasys ULTEM 9085 Stratasys Stratasys ASA ABS M30 Stratasys ULTEM 1010 Stratasys

Industrial SLA

Accura 25 (PP-like) Accura ClearVue Accura Xtreme White 200 (ABS-like)

3D printing locations near Israel

Tel Aviv Ródos Irákleio

Chaniá Alexandroúpoli Athens

Piraeus Chalkída Xánthi

Kalamáta

The 3D Printing Handbook

No one understands 3D printing like us - our founders literally wrote the book. Click here to download the sample chapters.

Click here to download the sample chapters.

Buy the book from Amazon

FAQ's

How much does your 3D printing service cost?

The cost of your 3D printed parts depends on factors such as part volume, part complexity, choice of material, which 3D printing technology is used, and if any post processing is required. For more details on these cost factors, see our article on the cost of 3d printing. To check the cost of your 3D printed part, simply upload a CAD (.STL) file and select your material and 3D printing technology to receive a quote within seconds.

How do you guarantee the quality of my prints?

Your parts are made by experienced 3D printing shops within our network. All facilities are regularly audited to ensure they consistently meet the Hubs quality standard. We include a standardized inspection report with every order and offer a First Article Inspection service on orders of 100+ units.

We have partners in our network with the following certifications, available on request: ISO9001, ISO13485 and AS9100.

Follow this link to read more about our quality assurance measures.

How do I select the right 3D printing process for my prints?

You can select the right 3D printing process by examining which materials suit your need and what your use case is.

By material: if you already know which material you would like to use, selecting a 3D printing process is relatively easy, as many materials are technology specific.

By use case: once you know whether you need a functional or visual part, choosing a process is easy.

For more help, read our guide to selecting the right 3D printing process. Find out more about Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF) and Stereolithography (SLA).

How can I reduce the cost of my 3D prints?

In order to reduce the cost of your 3D prints you need to understand the impact certain factors have on cost. The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

Once these have been decided, an easy way to further cut costs is to reduce the amount of material used. This can be done by decreasing the size of your model, hollowing it out, and eliminating the need for support structures.

To learn more, read our full guide on how to reduce the cost of 3D printing.

Where can I learn more about 3D printing?

Our knowledge base is full of in-depth design guidelines, explanations on process and surface finishes, and information on how to create and use CAD files. Our 3D printing content has been written by an expert team of engineers and technicians over the years.

See our complete engineering guide to 3D printing for a full breakdown of the different 3D printing technologies and materials. If you want even more 3D printing, then check out our acclaimed 3D printing handbook here.

We have an extensive range of online resources developed to help engineers improve their capabilities.

Introductory guides

Design guides

Material guides

Applications

CAD & file preparation

Post processing & finishing

Our other manufacturing capabilities

CNC machining

CNC machining

Milling (3-, 4- & full 5-axis), turning and post-processing

-

50+ metals and plastics & 10 surface finishes

-

Tolerances down to ±.0008” (0.020 mm)

-

Lead times from 5 business days

See our CNC machining services

Put your 3D printed parts into production today

Get an instant 3D printing quote

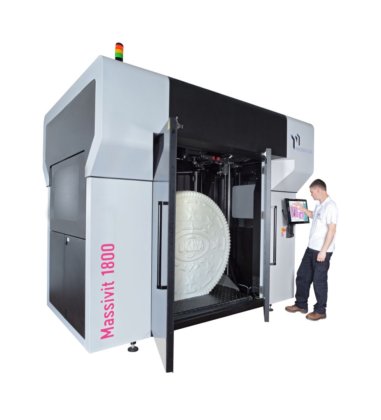

Israeli startup grows 3D printing to larger-than-life size - Sponsored Content

Storing and transporting hazardous liquids is a dangerous business. The secure, 13-foot-high storage tanks currently produced by CGK Group, based in Bruges, Belgium, are all hand-made – an expensive and labor-intensive process.

The secure, 13-foot-high storage tanks currently produced by CGK Group, based in Bruges, Belgium, are all hand-made – an expensive and labor-intensive process.

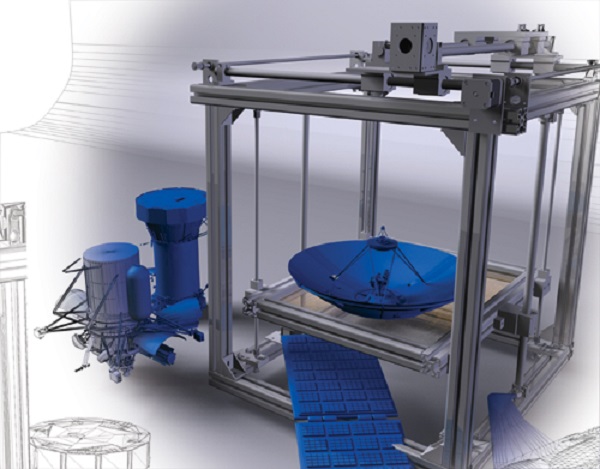

Now, using the world’s largest robotic 3D printing platform created by Largix, an Israeli startup, CGK expects to slash the cost of creating the tanks.

“This will be a gamechanger for us,” says Geert Denutte, the founder of CGK. “Nobody else is doing such technology. We estimate it will save us up to 50 percent in costs.”

In addition, because the technology is automated, it can work “25 hours a day,” says Denutte, dramatically cutting the time required to make the tanks.

Until now, 3D printers have been unable to produce large industrial products at industrial speeds and costs. Largix’s Cold 3D Printing technology will use smart sensors with real-time data and machine learning to produce large objects with the required bonding and welding strengths. It is the first system that makes 3D printing possible for real industrial production, using polypropylene and polyethylene – common thermoplastic polymers that nobody else is capable of printing.

CGK executives were so impressed by the Largix technology that they decided to become investors in the company back in 2019. Now they are expecting delivery of a 3D printing machine that “will change completely” the company’s production of room-sized storage tanks from common plastics, says CGK’s CEO Tijl Charle.

“Largix is the only company that can print in these materials because of their technology,” says Charle. “Nowadays, we produce our made-to-measure vessels out of semi-finished products. This needs a lot of manual labor next to a significant amount of scrap material. The platform will reduce our dependency on labor, increase our productivity and, next to the substantial labor-cost savings, the Largix Robotic Production Platform brings new opportunities in terms of shapes and new materials. ”

”

“3D printing technologies are mainly capable of making models and prototypes from polymers,” says Ronen Orr, co-founder of the company with Amir Sheelo. “Both of us have more than 20 years’ background in traditional industries, making traditional products. We decided to develop a 3D printing technology that would be able to industrially produce real products reinventing traditional, labor-intensive, design and production of custom-made products made of polymers and composite materials, across diversified industries.”

Largix decided first to address the industrial tanks market, seeing significant demand from the food, chemicals and cosmetics industries for large polymeric-based tanks. The company estimates the technology will help manufacturers cut production costs in half and eventually improve overall productivity by 15 times. It will also enable Largix to introduce industrial tanks with features and characteristics that cannot be met today.

“Our next addressable market will be even larger – building and infrastructure construction,” Orr says. “Most custom-made construction is today done manually. We are already engaging with industry leaders to design solutions, based on our proprietary technology, that will deliver major innovation to the construction industry”.

“Most custom-made construction is today done manually. We are already engaging with industry leaders to design solutions, based on our proprietary technology, that will deliver major innovation to the construction industry”.

Largix’s platform is the only one currently available that can deliver the scale, cost and materials needed to address industrial production needs, Orr says. The company plans to launch its product this year and expects to see rapid growth.

In October, the company will be presenting at the K Fair in Germany, the largest European trade fair for plastics and rubber.

Largix is now funding on the OurCrowd investment platform. For more information, click HERE.

Vegan steak 3D printer invented in Israel

Favorites

-

Sports: Kazakhstani weightlifter won the gold of the Asian Championship

-

Sport: Almaty will host the junior stage of the KM in fencing for the first time

-

Sports: 5555 km in 55 days: Kazakhstani cycling marathon reaches the finish line

-

Culture: Kazakh film screening was a success in Busan

-

Sport: 16-year-old Kazakhstani became the champion of Asia

-

Society: 36 cases of COVID-19 registered in Kazakhstan in a day

87

In Israel, they came up with a 3D printer for vegan steaks. And in the States, 199 people voluntarily signed up for cryogenic freezing. About these and other news in the field of modern technologies, in the material of the Khabar 24 correspondent.

This is an Angus 3D printer. It was developed by an Israeli company. Innovative technology produces vegan steaks. They are already served in 1,000 restaurants in Israel, the UK, the Netherlands and Germany. A kilogram of unique meat can be bought for $40. To create a separate piece, the company's employees use layer-by-layer building. Then the plant base is saturated with fats, moisture, smell and taste are added. So the final product is as close as possible to real meat. In total, the company has eight 3D printers. Two are in Israel. Six - in the Netherlands, where the plant will be fully operational in December.

Two are in Israel. Six - in the Netherlands, where the plant will be fully operational in December.

Yaron Eshel, manager of the 3D printer manufacturer:

- This is a touch interface. With it, you can select a steak from the library. Also, the options for roasting, the amount of fat and the category of marbling are loaded into the system. Cooking time takes 15-20 minutes. The steak is built up layer by layer. Thanks to this, we can control the structure of the fibers in order to then fill with fat and moisture. This allows you to get as close as possible to the biological meat that we are used to eating.

CRYO FREEZING

And there is a so-called cryonics center in Arizona. It's hard to believe, but the bodies of 199 people who once voluntarily agreed to cryopreservation are frozen here. Their goal is to revive when the field of medicine takes a step forward. Many of the people are terminally ill with cancer and other ailments. The bodies are stored inside tanks filled with liquid nitrogen. Meanwhile, scientists are skeptical about the activities of the cryonics center and the so-called cryofreezing.

The bodies are stored inside tanks filled with liquid nitrogen. Meanwhile, scientists are skeptical about the activities of the cryonics center and the so-called cryofreezing.

Arthur L. Kaplan NYU professor:

- The people who sort of specialize in studying the distant future are the people who are interested in your money. I don't see people lining up to really study brain structure, physiology, or psychotherapy.

A NEW GENERATION OF EXOSKELETONS

A new generation of exoskeletons has been introduced at Stanford University. It is a device that assists people with mobility problems in walking. The so-called "robotic boot" is equipped with a special engine. It works the calf muscles and gives extra push with every step. According to the creators, their offspring differs from previous exoskeletons in lower energy consumption. They also claim that the invention helps to walk 9% faster and spend 17% less energy than conventional shoes. Technological progress does not stand still, and the discoveries of the last few days are proof of this.

Technological progress does not stand still, and the discoveries of the last few days are proof of this.

Authors: Akerke Baktybaykyzy, Sandugash Baiguanysh

#Israel #freeze #USA #Khabar 24 #technology

Articles by tag

© 2022, Khabar 24 TV channel. All rights reserved.

Hip arthroplasty using a 3D printer for the first time in Israel

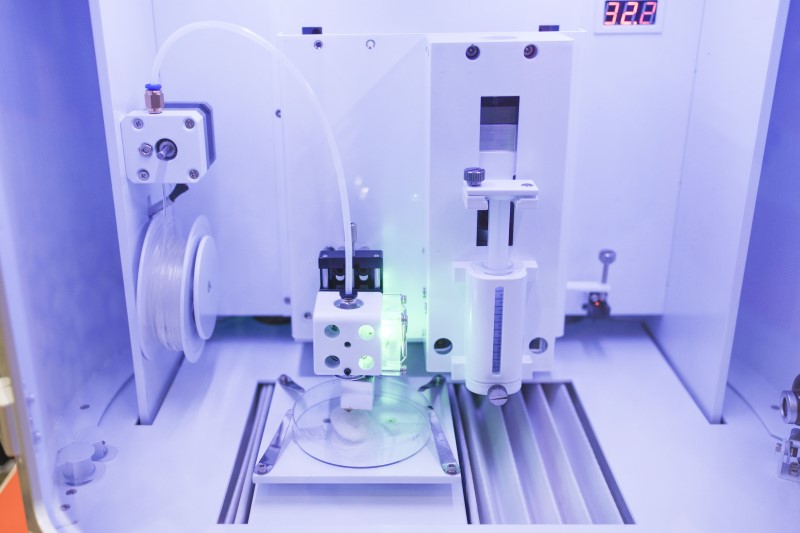

In recent years, a real revolution has taken place in the field of joint replacement in the world. Increasingly, scientists are talking about the possibilities of 3D technologies, which make it possible to design an accurate three-dimensional model of a human organ in accordance with its anatomy in a computer and print it from biological material. For the first time in Israel, the Soroka hospital performed a knee replacement operation using a modeled and printed joint.

Author Elena Levina

When traditional treatments - physiotherapy, drug therapy - do not help, when joint pain turns into a constant, ongoing nightmare - perhaps the next step should be surgery to replace the affected joint. In recent years, a real revolution has taken place in the field of joint replacement in the world.

In recent years, a real revolution has taken place in the field of joint replacement in the world.

Medical revolution - 3D technology

Increasingly, scientists are talking about the possibilities of 3D technologies, which make it possible to design an accurate three-dimensional model of a human organ in accordance with its anatomy in a computer and print it from biological material. For the first time in Israel, the Soroka hospital performed a knee replacement surgery using simulation.

When a joint replacement is required

If joint pains are repeated, and you know that the reason for this is not physical exertion on the limbs, then most likely we are talking about one or another type of arthritis - inflammation. Most often, diseased joints are in the lower extremities, in the knees, and the hip bones. Sometimes the only solution is surgical replacement of damaged joints.

The average age of patients suffering from recurrent joint pain, except for injuries or accidents, is approximately 60 years and older. Due to natural wear and tear and degenerative processes in the body that occur with age. Joint replacements may also be needed for younger people who have suffered fractures and injuries from sports or accidents where surgery is the only option.

Due to natural wear and tear and degenerative processes in the body that occur with age. Joint replacements may also be needed for younger people who have suffered fractures and injuries from sports or accidents where surgery is the only option.

Joint replacement surgery with 3D printers already in Israel!

Ami Asis, a resident of the south of the country, was the first patient in Israel and one of the few in the world whose damaged joint was replaced with a new one created using a 3D printer. Ami, who for many years suffered from pain in the hip joint and lameness, had long dreamed of replacing the damaged joint, but he knew that such operations are very difficult, require high qualification and experience from the doctor, complications are possible due to inaccurate selection of the implant . Dr. Vadim Benkovich, head of the Department of Joint Replacement at the Soroka Hospital in Beersheba, suggested that he implant a 3D-printed implant. After some hesitation, Ami agreed to the procedure. The operation was performed at Soroka hospital in Beer Sheva and took about 30 minutes.

After some hesitation, Ami agreed to the procedure. The operation was performed at Soroka hospital in Beer Sheva and took about 30 minutes.

One-on-one model

Creating a prosthesis in accordance with the individual measurements of the patient, which would exactly repeat the anatomy of his joint, is the basis of a new method of creating an implant using 3D printers. Before the operation, the patient undergoes visual scanning procedures: MRI and CT, but not for a diagnostic examination, for which these procedures are intended, but to recreate an accurate three-dimensional model of the joint. This creates a one-on-one model of the problematic organ to be replaced. This exact copy allows doctors to plan all actions to the smallest detail, to select the adapted equipment suitable for each specific case. Orthopedics in Israel is advancing by leaps and bounds - the doctors of the country have tried various methods of surgery and materials from which implants were created. But the patient's recovery process was always very slow and painful.

But the patient's recovery process was always very slow and painful.

Benefits of using a 3D printer in orthopedics

The advantage of creating a joint model using a 3D printer is that it allows for a very high level of accuracy and reduces work time. This is important, first of all, because we are talking about the most precise "jewelry" operations, which are carried out in a short time and at a very high professional level. Speaking about the advantages of the method of joint replacement using "opened" organs, it is worth noting that, compared with previous methods, there are no traditional consequences of surgical intervention: tissue is less damaged, less blood loss, the patient recovers faster after surgery. In the case of Ami, we are talking about a fairly short time: only a month has passed since the surgery, he can already drive a car, move around, almost without limping, he has stopped taking analgesics for the last week.

Today, Israeli orthopedists are dreaming of the next stage - to perform the most complex operations on the spine, requiring, for example, the replacement of vertebrae, using 3D organ printing technologies.