3D printing companies nj

New Jersey 3D Printing Services

Fast turnaround and high quality 3D printing in NJ. Get 3D printed parts without the hassle.

No signup required.

What makes PrintAWorld different from the other New Jersey 3D printing companies

Get access to industrial 3D printers

High resolution and large scale 3d printers are expensive. At PrintAWorld, you'll get the benefits of industrial 3d printing without the cost that comes with it.

Get expert help

We’ll help you every step of the way from the design to figuring out the best way to get your project done within budget and time.

Fast turnaround

On a tight a deadline? No problem! With our 3D printing and fabrication capabilities, we can make your trophies faster than traditional trophy makers. We can even make them in 2 days!*

Select projects that we did for our clients in New Jersey

How our 3D printing service in New Jersey works

0

1

.

Send us a few information

The material you need, quantities and a short description of your project. If you're unsure, don't sweat it. We will guide you to the perfect solution!

0

2

.

Upload a 3D File

Send us your.stl or .obj files. Don't have a file ready? We also provide a professional 3D modeling service.

0

3

.

Receive a quote

You'll get an email and a call from us immediately so we can talk about the best and most cost effective way to approach your project. No minimum order quantities!

0

4

.

Pay and print

Once the quote is approved we will start 3D printing your idea.

We'll keep you updated and we'll make sure the result is exactly what you want or even more. No minimum orders.

We'll keep you updated and we'll make sure the result is exactly what you want or even more. No minimum orders.0

5

.

Shipping or pickup

We offer nationwide delivery or you can pick it up from one of our local studios near you.

3D printing materials that we offer

Looking for a material that isn't listed here? Shoot us an email at [email protected]

ABS

ABS plastic is a strong and durable material. They're ideal for prototyping mechanical parts. For prototypes that require high-precision, consider CNC machining ABS or printing in other materials. For production parts, we suggest using injection molding instead.

Nylon PA12

Nylons is a strong and durable material that is also flexible. Ideal for live hinges and functional parts.

Standard Resin

Perfect for complex 3d models that require high details and smooth finishing.

SOMOS Resin

SOMOS resin is the industrial version of standard resin. It's perfect for almost any 3d that require smooth finishing and high details. We recommend this material for any projects such as high-detailed models, architecture, art sculptures and engineering prototypes.

SOMOS Waterclear 10122 Resin

Somos® WaterClear Ultra 10122 is a clear resin that produces colorless, functional and accurate parts that simulate an acrylic appearance. Parts produced from Somos® WaterClear Ultra 10122 exhibit excellent water and temperature resistance.

F.A.Q

How much does 3D printing in New Jersey costs?

The cost of 3D printing depends on the 3D model, the material you choose and type of finishing required. Rushed orders adds additional cost as well.

How long does your 3D printing service take?

Depending on the complexity of the project, our standard turnaround time is 3-5 days. Rushed projects can take as fast as 1 day.

Do you offer delivery?

We can ship anywhere in the U.S. and the world. If you have your own Fedex or delivery account, we can use that.

FDM 3D Printing Service | Tangible Creative

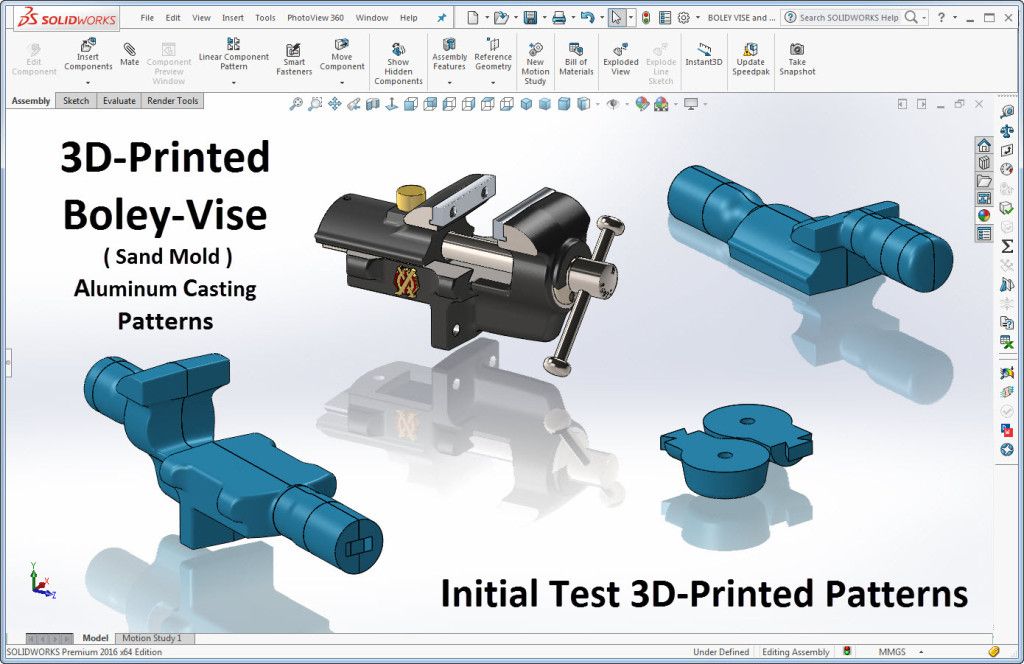

Fused Deposition Modelling (“FDM”) or Fused Filament Fabrication (FFF), the most common 3D printing process, is a material extrusion type additive manufacturing process. S.Scott Crump, the Stratasys founder, first developed and patented the FDM 3D printing process in 1988. And when the patent expired in 2009, it paved the way for commercial FDM printers.

Tangible Creative has over 100 FDM 3D printers in our Newark, New Jersey warehouse. By utilizing our full wall of printers, we can produce thousands of 3D printed parts. Read on to learn more about our FDM 3D printing service.

Fused Deposition Modelling (“FDM”) or Fused Filament Fabrication (FFF), the most common 3D printing process, is a material extrusion type additive manufacturing process. S.Scott Crump, the Stratasys founder, first developed and patented the FDM 3D printing process in 1988. And when the patent expired in 2009, it paved the way for commercial FDM printers.

And when the patent expired in 2009, it paved the way for commercial FDM printers.

Tangible Creative has over 100 FDM 3D printers in our Newark, New Jersey warehouse. By utilizing our full wall of printers, we can produce thousands of 3D printed parts. Read on to learn more about our FDM 3D printing service.

Second, the .STL file is converted into G-code. This process is called slicing and is performed by the slicer software. The G-code is the file format read by the printer that guides the printer where to print. At last, the g-code is provided to the 3D printer, and our FDM 3D printing service is ready to print.

Things to keep in mind:Layer thickness: This dictates the quality and resolution of the part. Each printer has a minimum layer thickness which is the diameter of the nozzle of the FDM printer. The lower the number, the better the details on the part. On the other hand, this will increase the print time. Hence, depending on the part, the layer thickness should be carefully selected.

Our FDM/FFF printers can print with a minimum layer thickness of 0.1mm and a maximum of 0.5mm.

Support structure: Only overhangs of more than 45° angle need support structures. Generally, it should be avoided because it increases the print time and creates material wastage. Hence, to avoid support structures, redesigning the CAD model, or simply changing the orientation of the part could help.

Build Size: The size of the printer limits the size of the part. Hence, before starting the print, the printer size should be considered. The maximum build size we generally offer is 400mm × 400mm × 450mm. Please contact us to discuss options for creating larger prints.

FDM Printing Materials:ABS (Acrylonitrile Butadiene Styrene): ABS is a thermoplastic with high impact strength. It is tough and impact-resistant but also prone to warping. Also, ABS is non-biodegradable. Hence, in most cases, ABS should be avoided.

PLA (Polylactic acid): A biodegradable thermoplastic with high tensile strength. In the FDM printing process, it is the preferred material for everyday printing and prototyping because it is more sustainable. 3D-printed parts made of PLA can be biodegraded within a year, given the right environment.

TPU (Thermoplastic polyurethane): A thermoplastic elastomer with medium tensile strength and high flexibility. We specialize in TPU printing for projects that require elasticity and movement.

PETG (Polyethylene terephthalate glycol): A thermoplastic polyester with high impact strength and ductility.

Specialized materials: Apart from the mentioned materials, our FDM 3D printing service offers specialized materials like polycarbonate (PC), metal-filled filaments, etc.

3D file Census of blue crab and clams

FCSII Finbox Router Jig

9,40 €

Topographic map of New Jersey (NJ)

0. 93 €

93 €

90 Degree Drawer Bracket

2.81 €

Test Tube Drying Rack (API Test Kit)

1.87 €

nine0003 Magnetic travel play set - 6 games in 19.41 €

Ring and hook game - 3D printing

4,70 €

Magnetic chess and checkers

4.70 €

Heart Pendant - Valentine's Day Gift

Free

The best files for 3D printers in the Tools category nine0037

Cage modular DSLR

Free

Hammer pegboard mounts

Free

HINTECH Face Cover - Tutorial Included

Free

Quick change filament dry box up to 6 spools

€15. 90

90

Screw lock carabiner

Free

COOKIE CUTTER MASHA AND THE BEAR

0,93 €

Bestsellers in the Tools category

SUPERBOX

1,50 €

nine0003 Phone holder2.44 €

PET-Machine, make your own plastic bottle filament at home!

15 €

Ender 3 S1 pro fan duct 5015 4020

1,30 €

Tool holder for 3D printer V3.0

1.04 €

ENDER 3 S1/S1 PRO COIL HOLDER AND DEPORTED COIL

€2.13 -twenty% 1. 71 €

71 €

PRECISE DIAL INDICATOR 3D PRINT DIY

1.91 €

Armadillo - flexible wire conduit

1.68 €

Ender 3 S1 BEST cable guide - vertical

2.50 €

INDICATOR FOR BETTER BED LEVELING FOR ENDER 3 V2

2.81 €

Cooling system Minimus Hotend

2.33 €

Display holder FLSUN v400

€9.99 -fifty% 4.99€

Shrek Pooping Toothpaste Topper

2.82 €

Cut-Man - PET bottle cutter with handle!

€3.49

Quick print stackable parts containers / storage boxes

2. 87 €

87 €

Fire hydrant storage container

1.88 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so it is very easy to support us in maintaining activities and creating future developments. Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads. nine0006

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

Qin Dynasty 3D Printing, MakerBot's New Adventures, and More News of the Week! nine0001

News

Subscribe to the author

Subscribe

I do not want

7

MAakerBOT CARKS 3D printers

More than recently, in 2013, the legendary Makerbot company bathed in the rays of Slava and laid down on the livra. With the successful Replicator 2 3D printer on hand and a growing stream of orders, MakerBot opened its own factory in Brooklyn. Then disaster struck: the scandal with the raw fifth generation seriously tarnished the company's reputation, and its founder, Bree Pettis, moved to Stratasys, and then completely left the big stage. MakerBot began reshuffles and mass layoffs. Now the company has broken another bottom, announcing the cessation of production of "replicators" in New York. nine0006

With the successful Replicator 2 3D printer on hand and a growing stream of orders, MakerBot opened its own factory in Brooklyn. Then disaster struck: the scandal with the raw fifth generation seriously tarnished the company's reputation, and its founder, Bree Pettis, moved to Stratasys, and then completely left the big stage. MakerBot began reshuffles and mass layoffs. Now the company has broken another bottom, announcing the cessation of production of "replicators" in New York. nine0006

Like a true manager, MakerBot CEO Jonathan Jaglom keeps a good face on a bad game. The 3D printers will be manufactured by the international company Jabil Circuit, which provides contract manufacturing services for electronics. According to Jaglom, “Working with Jabil will enable us to better position ourselves in a rapidly changing marketplace and reduce production costs in order to become more competitive on the global stage. We expect that a more flexible manufacturing model will allow us to quickly change production volumes based on current demand and without the constant costs of running a factory in New York. ” nine0006

” nine0006

In simple terms, this means that MakerBot is shutting down facilities in an area of 20,000 square meters. meters and transfers production abroad - where exactly, you have to choose Jabil. Most likely to China or Malaysia. For the company's employees, this means another wave of mass layoffs, but apparently, MakerBot has no other choice. Despite the company's claims of commitment to the "Brooklyn culture", localized production can not afford it, and the company somehow needs to be saved. At least, there should be no problems with production in China, because craftsmen from the Celestial Empire have been successfully stamping clones of "replicators" for so long and successfully. nine0006

In the best of imperial tradition

Polymaker has come up with a great showcase for the Polysher, a 3D printed spray smoothing machine. To do this, the developers invited an artist named Tian Tian. The object of the demonstration was a 3D printed vase processed with Polysher and hand painted by the artist in the style of the Qin Dynasty.

School of Design and Digital Arts at Shanghai Aurora College. The artist has a particular fondness for antique vases. The vases of the Qin Dynasty date back to the 13th century, and the delicate decorations were created with careful strokes of a fine brush. The smoothness of the vessels is of great importance, since any irregularities can distort the movement of the brush and ruin the drawing. Of course, in the case of raw 3D printed models, layering leads to just such difficulties, but after smoothing the vase in Polysher, the artist managed to achieve the desired result. nine0006

What's more, Tian Tian liked the idea of creating art with 3D printing: "When I decorate a vase created by another designer, there always comes a point where I can't fully express myself in the drawing." Very Zen, Tian. However, the popularity of Polysher is also ensured in the Russian market. Read more about Polysher here.

With the breeze and without the motorcade

Holland is remarkable not only for its love of bicycles and 3D printing, but also for the fact that all segments of society are exposed to this love. So Economics Minister Henk Kamp could not resist the opportunity to ride a 3D printed bicycle. A two-wheeler called Arc Bicycle was printed by a team of students from the Delft University of Technology with the help of technical experts from MX3D. nine0006

The run-in took place during the Innovation Expo in Amsterdam, where more than 200 innovations were showcased. More than 4,000 entrepreneurs and academics, as well as about 70 ministers from all over the European Union, came to the exhibition. MX3D, a start-up that builds the world's first 3D printed bridge and, at its leisure, helps students make bicycles with its 3D printed welder robot, was also featured.

The bike weighs about the same as a regular steel frame version. “It was important for us to create a functional object that people use on a daily basis. Since we are students in the Netherlands, the idea of a 3D printed bicycle came to our minds. The bike frame serves as a good demonstrator due to multidirectional loads,” explains one of the designers, Stef de Groot. Someone who, but Minister Kamp appreciated the project at its true worth. As for MX3D, their project to 3D print a canal bridge in the center of Amsterdam is due to be completed in 2017. nine0006

REC takes Europe by storm

The Russian company REC has signed an agreement to supply consumables to the German retailer iGo3D. The agreement was reached at the Hannover Messe industrial fair taking place these days.