3D printer jewelry price

5 Best 3D Printers For Jewelry 2022 (All Price Ranges!)

3D printing jewelry rarely means 3D printing actual wearable pieces made from filament or resin, but instead using a jewelry 3D printer to create high-resolution wax models of the eventual gold or platinum design, used to create a mold that is burned out and cast via investment casting or lost wax casting.

- We also have an article ranking some of the most beautiful 3D printed jewelry.

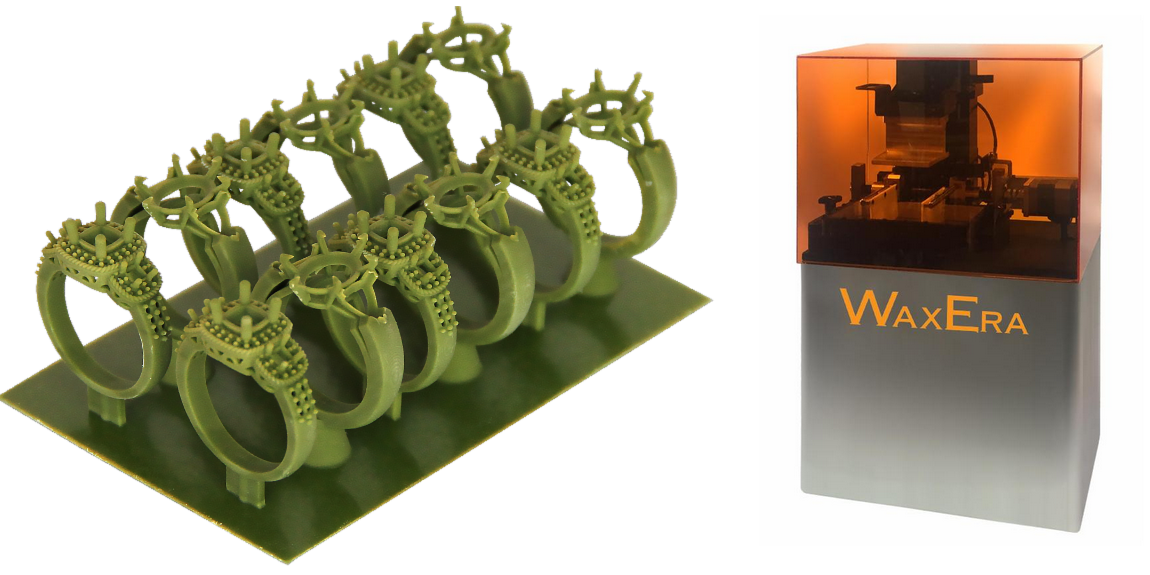

In fact, much jewelry is now created this way. There are entire factories of resin 3D printers set up to create castable wax resin models to be molded and then melted to create high-end jewelry.

However, owning your own jewelry 3D printer gives you more control over your production, and saves you money compared with paying someone to print your own molds. Castable resin molds can be produced for rings and other jewelry pieces for just the cost of the resin used, perhaps a dollar or two, whereas you could end up paying $25+ for someone to print it for you.

To insert the table into a page, post, or text widget, copy the Shortcode and paste it into the editor.

| Name | Build volume (mm) | Price | Where to buy |

|---|---|---|---|

| Elegoo Mars 2 Pro | 129 x 80 x 160 | $250 | Elegoo here |

| Peopoly Phenom | 276 x 155 x 400 | $1,999 | Matterhackers here |

| Formlabs Form 3 | 145 x 145 x 185 | $3,499 | Dynamism Store here |

| Solidscape S325 | 6″ x 6″ x 4″ | Quote | Get a Quote here |

| EnvisionTEC D4K Jewelry | 148 x 83 x 110 | Quote | Get a Quote here |

- CAD File: Either design your own jewelry piece on CAD software, pay someone to design your desired piece, or pay for an existing jewelry STL file online and download it.

- Slice & Prepare: If not already an STL or other compatible file, export it as one.

Then import it into your 3D slicer and slice it for printing.

Then import it into your 3D slicer and slice it for printing. - Print the model: Use a castable wax resin designed for jewelry model 3D printing.

- Molding: Pour your molding material over your wax jewelry model, and leave it to harden.

- Melt the wax: Heat your new mold so that the original wax model melts and evaporates, leaving a hollow empty space inside with the exact dimensions of your planned jewelry piece.

- Casting: Pour melted liquid metal e.g. gold, silver or platinum into the mold to cast it.

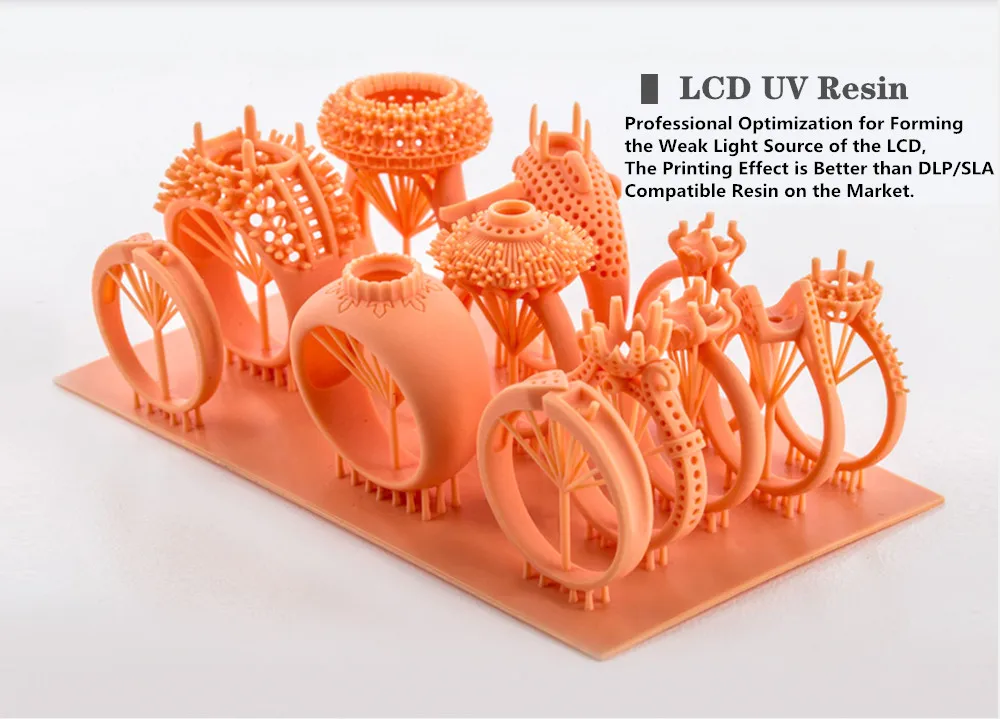

Resin 3D printers are considered the best 3D printers for jewelry. They are used with specialized castable wax resins, which rather than going from solid to liquid when heated, transition directly into a gas from their solid state.

Though prevalent, FDM 3D printers are very rarely used as 3D printers for jewelry. They are not capable of the same resolutions, crisp surface finishes or accuracies required for intricate and delicate jewelry pieces. Jewelry 3D prints need to be incredibly highly detailed and accurate — an inaccurate mold will create inaccurate and unimpressive jewelry.

Jewelry 3D prints need to be incredibly highly detailed and accurate — an inaccurate mold will create inaccurate and unimpressive jewelry.

Additionally, the better the jewelry 3D printer quality, the less finishing the resulting jewelry piece will need to perfect it.

What do jewelry 3D printers make?Usually they 3D print wax jewelry molds, for example of ring designs before any stones are set, or individual chain links.

However, they can also be used to create like-for-like “fitting pieces” for testing the fit of an as-yet unmade ring for a client’s finger. Though making the final ring would be expensive and take time, an exact replica can be made on a jewelry 3D printer in just minutes to test the sizing.

This saves the trouble of creating a piece just to find it doesn’t fit properly. Whereas for jewelry molds specialized castable resins are required, for these fitting pieces standard resins can be used.

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

Learn more

The best 3D printers for jewelry

1 — Elegoo Mars 2 Pro

- Jewelry 3D printer price: $250 — Available at Elegoo store here / Available on Amazon here

- Build volume: 129 x 80 x 160 mm

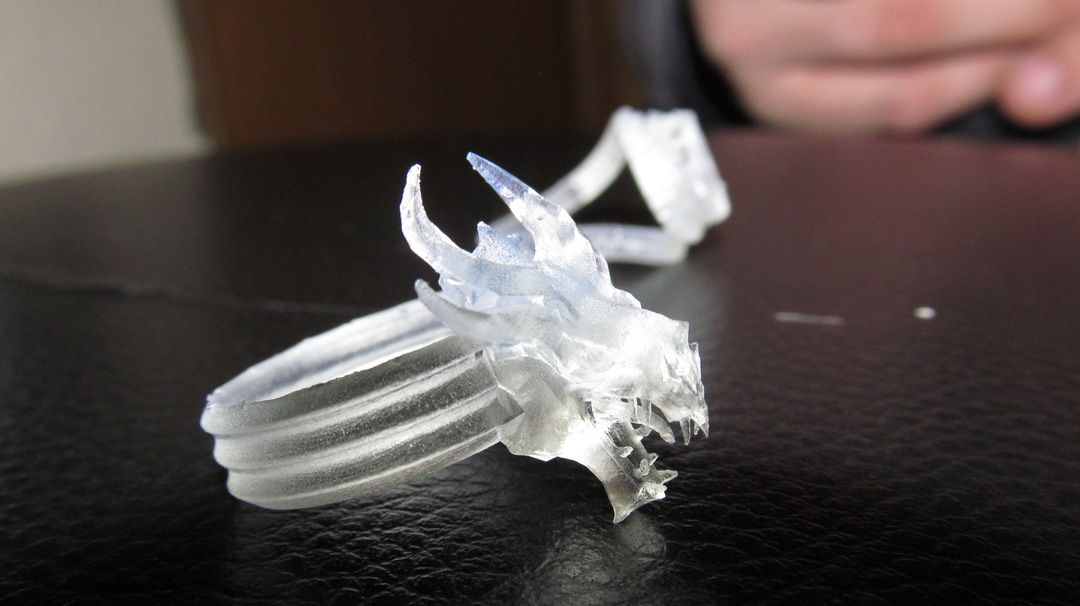

Featuring a 6-inch monochrome LCD screen offering HD 2K resolution, the Elegoo Mars 2 Pro offers precise jewelry printing for the price. Rather than DLP or SLA, the Mars 2 Pro uses LCD printing to cure entire resin layers at once, quickening print speeds and able to print at 30-50mm/h.This is the detail we achieved when using the Elegoo Mars 2 pro – enough for fine jewelry pieces.

Other 3D printers for jewelry on this list offer better quality, but for the price the Mars 2 Pro is a great option. It is sturdily built with its CNC-machined aluminum structure for better stability, and the mono LCD is upgraded for improved lifespan to save you money over the long term. It’s one of the best 3D printers for jewelry under $500.

The Elegoo Mars has Z-axis resolutions of up to 0. 00125mm, XY-resolutions of 0.05mm, and weighs 6.2kg. It also supports 12 different languages, so if you’re not a native English speaker you can choose your own language.

00125mm, XY-resolutions of 0.05mm, and weighs 6.2kg. It also supports 12 different languages, so if you’re not a native English speaker you can choose your own language.

The video below even shows, from start to finish, how accurately you can make wax models for gold jewelry using a standard Elegoo Mars. Even this standard version produces good quality wax models, and the Elegoo Mars 2 Pro comes with several upgrades on the original.

Printing on our Elegoo Mars 2 Pro – read our full review here.2 — Peopoly Phenom

- Jewelry 3D printer price: $1,999 — Available on Matterhackers here

- Build volume: 276 x 155 x 400 mm

The Peopoly Phenom offers truly enormous printing volumes, almost unheard of for a jewelry 3D printer. For jewelers looking to produce many rings or other pieces simultaneously, this larger volume provides space for dozens of wax jewelry models. If you’re in demand for jewelry and want to make as many as possible then this larger build volume is crucial.

With its 4K high resolution projection quality using MSLA technologies, the Phenom produces crisp, accurate and consistent jewelry molds. MSLA takes elements from both LED and LCD technologies, the result being fast, accurate and repeatable jewelry 3D printing.

- The even larger version, the Peopoly Phenom L, is available here.

- For faster print speeds, the premium Peopoly Noir is available here.

The Phenom uses Chitubox resin 3D slicer, useful if you’ve previously used it previously on another printer. Overall, it’s one of the best 3D printers for jewelry, and a great choice for people looking to make large numbers of castable wax jewelry models.

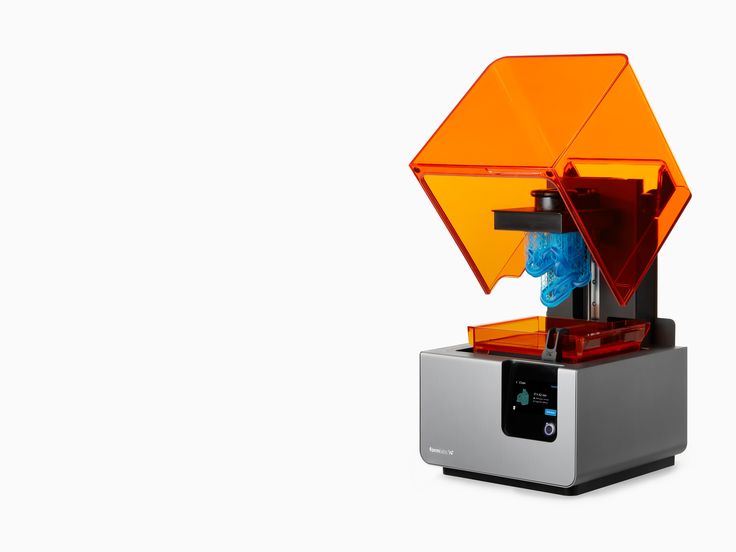

3 — Formlabs Form 3

- 3D for jewelry price: $3,499 — Available on Dynamism here

- Build volume: 145 x 145 x 185 mm

Seen as the gold-standard in professional resin printing, the Form 3 is capable of fantastic precision, with its new custom Light Processing Unit (LPU) using lenses and mirrors to accurately print jewelry models.

For the price, the Form 3 offers 25-micron resolutions and very consistent and repeatable printing. For those looking for a 3D printer for jewelry able to produce the same design flawlessly again and again, or for producing custom intricate designs, the Form 3 can handle both without issue.

Formlabs make their own castable wax resins designed for jewelry with “crisp settings, sharp prongs and smooth shanks.” Within the Formlabs workflow therefore is a complete jewelry production process for wax models, though the Form 3 also excels as a dental 3D printer and in other industries, too.The Form 4, and several jewelry wax models it 3D printed.

4 — Solidscape S325

- Price: Requires a quote

- Build volume: 6” x 6” x 4”

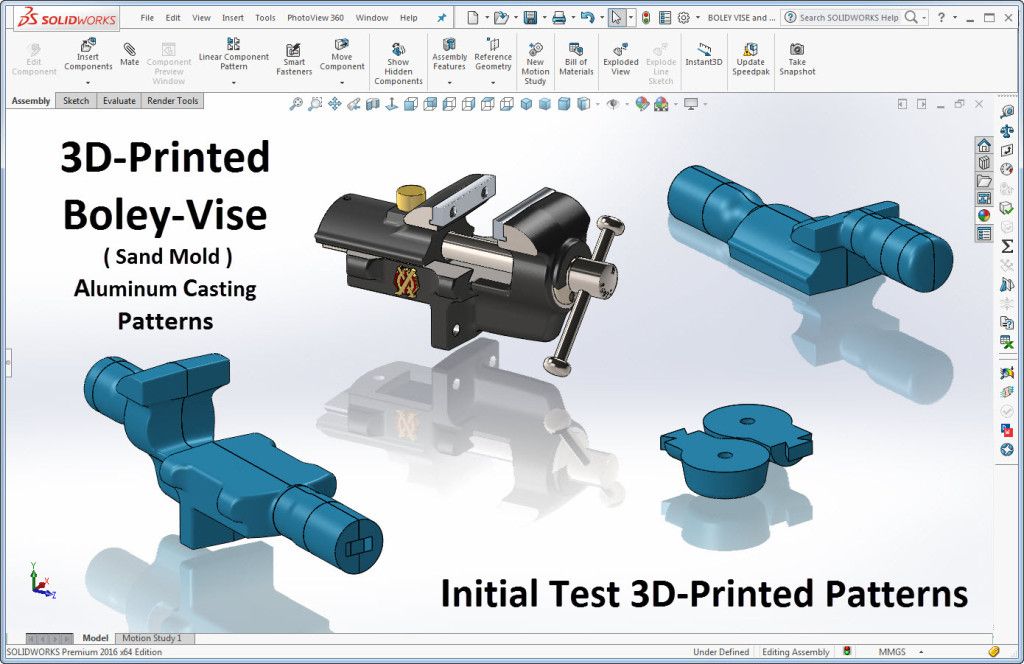

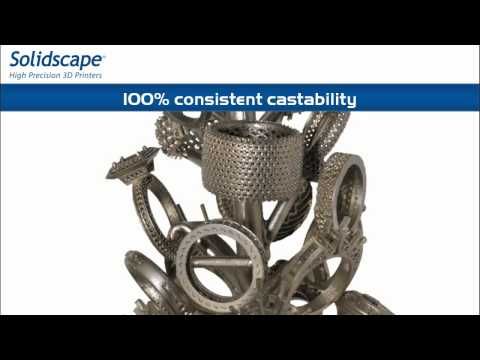

Soliscape make specially designed jewelry 3D printers, so any Solidscape printer you buy is optimized for jewelry printing. Whereas other printers like the Form 3 are designed to excel in a number of industries, the Solidscape S325 is designed with jewelry wholly in mind.

The S325 is the cheapest of Solidscape’s jewelry 3D printer range. It offers great accuracy, material jetting wax models for the precise and effective investment casting of precious metals. Solidscape stress that all their models are castable in gold and platinum, and do not expand or shrink during the investment casting process.

The S325 is capable of 0.001-inch layer thicknesses, with accuracies of 0.005 inches. Overall, as a specialized 3D printer for jewelry, Solidscape have a rich history in jewelry 3D printing and can be trusted to deliver high-quality and precise ring wax models, time and time again.

Get a quote*

*One of our trusted partners will be in touch following a quote request.Compressed by jpeg-recompress

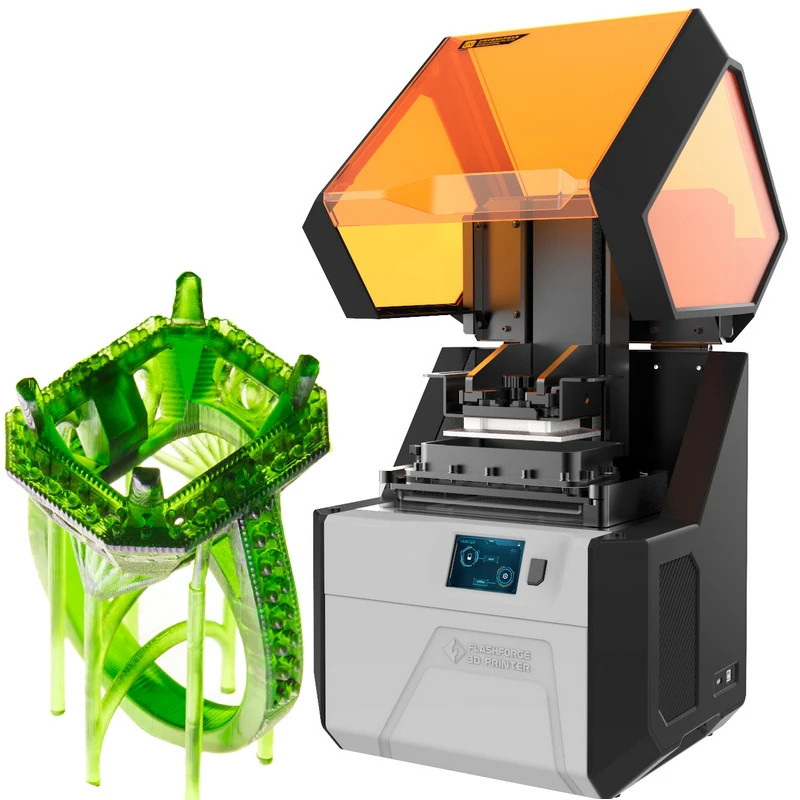

5 — EnvisionTEC D4K Pro Jewelry 3D printer

- Jewelry 3D printer price: Requires a quote

- Build volume: 148 x 83 x 110 mm

Described by EnvisionTEC are the highest resolution professional-grade desktop 3D printer, as well as claiming to have the fastest speed, the D4K is well suited to jewelry 3D printing. Speed and accuracy are key to jewelry production, with the printer’s 4K UV DLP projector able to create crisp wax models at speed to be cast into stunning jewelry pieces.

Speed and accuracy are key to jewelry production, with the printer’s 4K UV DLP projector able to create crisp wax models at speed to be cast into stunning jewelry pieces.

EnvisionTEC are the originators of DLP 3D printing, having pioneered the process more than a decade ago. Now, their advanced D4K Pro can produce accuracies of up to 25 microns in the XY resolution, and 1 micron on the Z axis.

The jewelry 3D printer works well with EnvisionTEC’s WIC100 Series wax material, used to then burn out and investment cast precious jewelry. Though it’s an industrial 3D printer costing over $10,000, larger jewelers will find the D4K one of the best 3D jewelry mold printers.

Get a quote*

*One of our trusted partners will be in touch following a quote request.

Advantages of owning a jewelry 3D printer

- Saves money long term: rather than paying a 3D printing service $20+ to print your mold for you, you can print your own wax jewelry molds for just a dollar each.

- Control your own jewelry production: with the ability to print jewelry in-house, you control your own workflow and apart from resin shortages, cannot be slowed down by supplier failures. Your order will always be top priority.

- Fast: going from CAD model to a piece ready to be investment cast is quick, especially when you can print and cast everything in one place.

- Very accurate: precise, smooth and intricate jewelry is not an issue for jewelry 3D printers, some able to print with below 10-micron accuracy to capture your ring’s most delicate and beautiful features.

- Repeatable and scalable: 3D printers for jewelry can create potentially dozens of identical or customized ring molds at once, perfect for scalable jewelry production.

7 Best 3D Printers For Jewelry Making & Casting (2022 Update)

- Last Updated: December 20, 2022

- Pat Nathaniel

Whether you’re starting a new hobby or a new business, 3D printing jewelry is an exciting project to take on.

A few clicks and some resin, and you magically get a completely customized piece of fine jewelry – it’s like alchemy is finally real!

At this point you want to make your dream a reality. We’re going to take a dive into the different printers you have as options, and then we’ll get into some things you need to know about jewelry making so you’re well-equipped to print your first piece.

Elegoo Saturn 2 8K

Build volume: 219 x 123 x 250 mm

Get Discount Now

Check Latest Price

Phrozen Sonic Mini 8K

Build volume: 165 x 72 x 180 mm

Get Discount Now

Check Latest Price

Peopoly Moai

Build volume: 130 x 130 x 180 mm

Check Latest Price

Table of Contents

- Top 3D Printers For Jewelry At A Glance

- 1. Phrozen Sonic Mini 8K (Best Choice)

- 2. Formlabs Form 3+ (Best Print Quality)

- 3.

Phrozen Sonic Mini 4K (Best Budget)

Phrozen Sonic Mini 4K (Best Budget) - 4. Elegoo Saturn 2 8K (Best Value)

- 5. Peopoly Moai (Premium Choice)

- 6. Creality Ender 3 Pro (Best FDM)

- 7. Solidscape S325 (Best Professional Choice)

- How Does 3D Printing Jewelry Work?

- Process of 3D Printing Jewelry

- Available 3D Printing Processes

- Should I Use FDM or SLA for Jewelry?

- FDM

- SLA

- Why 3D Print Jewelry?

- Conclusion

Top 3D Printers For Jewelry At A Glance

We’ve researched over 20 different 3D printers for jewelry making for our own business and below are our top 7.

- Phrozen Sonic Mini 8K (Best Choice)

- Formlabs Form 3+ (Best Print Quality)

- Phrozen Sonic Mini 4K (Best Budget)

- Elegoo Saturn 2 8K (Best Value)

- Peopoly Moai (Premium Choice)

- Creality Ender 3 Pro (Best FDM)

- Solidscape S325 (Best Professional Choice)

1.

Phrozen Sonic Mini 8K (Best Choice)

Phrozen Sonic Mini 8K (Best Choice) 3D Printer Type: LCD | Materials: 405 nm Resin | Build Volume: 165 x 72 x 180 mm

Easily the best 3D printer out there for making jewelry at a consumer level is the Phrozen Sonic Mini 8K. Phrozen shows up on this list a few times, and the only reason I can give for this is that their team is insanely good at making high-detail 3D printers.

The Phrozen Sonic Mini 8K is built around its crown jewel: an 8K monochrome LCD screen. This part makes the machine capable of printing models with 8K pixel resolution, which means prints can have a ton of detail If this doesn’t spark your interest, then I don’t know what will; just look at the prints made by this machine:

Source: Youtube Adam Savage’s TestedOn top of the high LCD resolution of the Phrozen Sonic Mini 8K, the printer also brings a terrific X/Y printing resolution of just 22 µm, or 0.022 mm. This is about as precise as you can get today, and, for reference, the Phrozen Sonic Mini 4K has a precision of only 35 µm (not as good).

Sadly, the price you pay for this incredible print quality comes in the form of print space. Moreover, as indicated by the “Mini” in the name, the Phrozen Sonic Mini 8K has a relatively small build space of only 165 x 72 x 180 mm. While this limits you to printing only small models, it shouldn’t be a problem for making jewelry.

So, if you want an overall beast of a resin 3D printer that can make jewelry pieces more detailed than your wildest dreams, I strongly recommend the Phrozen Sonic Mini 8K.

- 8K printing resolution

- Amazing X/Y printing precision

- Sturdy frame

- Touchscreen user interface

- Requires 8K resin for maximum print quality

- Somewhat small print space

Get Discount (Official Store)

Check Latest Price

2.

Formlabs Form 3+ (Best Print Quality)

Formlabs Form 3+ (Best Print Quality) 3D Printer Type: LFS | Materials: Resins | Build Volume: 145 x 145 x 170 mm

When it comes to print quality with SLA 3D printers, it’s hard not to think of Formlabs. Formlabs practically invented consumer-level resin 3D printing, and the Form 3+ is one of their latest innovations, bringing top-notch print quality to the field.

The Form 3+ replaced the Form 2, which used to be on our list until we realized the former is much more precise. Moreover, Form 3+ has an X/Y printing resolution of just 25 µm, almost the same as the Phrozen Sonic Mini 8K. Additionally, the overall quality of prints made on the Form 3+ is immaculate, with high-detail prints coming out like this:

But my favorite part about the Formlabs Form 3+ isn’t even the crazy print quality, but its reliability. Formlabs goes above and beyond to make sure that their machines are the most reliable on the market, and they’ve done a terrific job with Form 3+. Loaded with sensors, the Form 3+ basically never fails, and if it does, it lets you know the exact issue!

Loaded with sensors, the Form 3+ basically never fails, and if it does, it lets you know the exact issue!

Additionally, using the Form 3+ is a delight due to the full-color touchscreen display onboard the printer that runs a well-designed and easy-to-use interface. It’s also important to note the print size on Form 3+: a solid 145 x 145 x 185 mm. Not the biggest around, but certainly large enough to handle any and all jewelry prints.

Unfortunately, Formlabs Form 3+ has some issues when it comes to compatibility. For one, Formlabs makes it difficult to modify or upgrade the machine outside of their ecosystem. And through RFID chips in the resin tanks, they prevent you from using 3rd-party resins.

- Insanely high print quality

- Great printing precision

- Sturdy frame

- Easy-to-use touchscreen interface

- Can’t use 3rd-party resins

- Doesn’t allow for upgrades or modifications

Check Latest Price

3.

Phrozen Sonic Mini 4K (Best Budget)

Phrozen Sonic Mini 4K (Best Budget) 3D Printer Type: LFS | Materials: 405 nm UV Resin | Build Volume: 134 x 75 x 130 mm

If you want exceptional print quality without breaking the bank then the new and improved Phrozen Sonic Mini 4K is for you.

Compared to other affordable resin 3D printers like the Anycubic Photon S and Elegoo Mars 2 Pro, we found the printing quality superior in the former. The XY layer resolution of the Mini 4K is 35 microns vs the 50 microns of those two printers.

As you know, in the world of television and mobile phones, 4K screens produce high-quality images. Similarly, thanks to the 4K LCD screen with the Mini 4K, you’ll get a better print resolution.

In all fairness, the differences between prints from the three printers weren’t pronounced. But in detail-packed jewelry, you’ll notice the power of the 4K LCD.

Source: Youtube Uncle JessyThe Sonic Mini 4K also prints faster – one layer in 2 seconds fast (although the newer models of the Photon and Mars are keeping up).

If you want a beginner-friendly resin 3D printer for jewelry, then the Mini 4K is for you. It’s that easy to use. Just plug in, level, and start printing. The default settings in Chitubox work without any adjustments although you’ll have to tweak it for certain designs.

In terms of printer noise, the Sonic Mini 4K is a bit noisier than the original Sonic Mini. The noise mainly comes from Mini’s Z-axis stepper motor during the changing of layers.

All in all, for 3D printing jewelry and miniatures you can’t go wrong with the Sonic Mini 4K. It excels where print details are a must.

- Exceptional print quality for super fine details

- Easy to level the bed

- Built tough

- Touch screen is very responsive

- Beginner-friendly

- Possible flex in the build plate arm for large print areas

- Screen can get easily damaged

Get Discount (Official Store)

Check Latest Price

4.

Elegoo Saturn 2 8K (Best Value)

Elegoo Saturn 2 8K (Best Value) 3D Printer Type: MSLA | Materials: 405 nm UV Resin | Build Volume: 219 x 123 x 250 mm

Another 8K printer on this list is the Elegoo Saturn 2 8K, which, in my opinion, is the best bang for your buck when it comes to printing high-detail jewelry.

The Saturn 2 is made by Elegoo, one of the most popular manufacturers of budget-friendly resin 3D printers. And the Saturn 2 definitely is budget-friendly, offering 8K printing capabilities for less than $600!

As an 8K 3D printer, the Elegoo Saturn 2 uses an 8K pixel resolution LCD screen that allows for very high-detail prints. And parts are very precise because the Elegoo Saturn 2 has an X/Y resolution of 28.5 microns. This isn’t as good as the Formlabs Form 3+ or Phrozen Sonic Mini 8K, but it’s still very precise and a great deal considering the price of the Saturn 2.

With the Saturn 2, you can make some super detailed 8k-resolution prints, like the one seen below:

Plus, the Saturn 2 gives you a decent amount of print space, totaling 219 x 123 250 mm. This is more than enough for typical jewelry prints and will allow you to print multiple rings or necklace pendants at once, no problem!

This is more than enough for typical jewelry prints and will allow you to print multiple rings or necklace pendants at once, no problem!

Another thing I love about the Elegoo Saturn 2 is the print speed: up to 70 mm/hour. This is very fast and means you can pump out more jewelry projects compared to other printers, which typically have a max speed of 40-60 mm/hour.

So, if you want to print large without sacrificing print quality or detail, the Elegoo Saturn 2 8K is the perfect option. And it won’t break the bank!

- Great bang for your buck

- 8K printing resolution

- Terrific printing precision

- Fast print speed

- Large build space

- More prone to issues with the VAT

- Not as precise as other 8K printers

Get Discount (Official Store)

Check Latest Price

5.

Peopoly Moai (Premium Choice)

Peopoly Moai (Premium Choice) 3D Printer Type: SLA | Materials: Any Resin Designed for SLA Printers | Build Volume: 130 x 130 x 180 mm

The logical next printer to look at on this list is the Peopoly Moai. Everything you love about SLA 3D printers at a more reasonable price.

This checks the same boxes as Form 2; it’s super accurate, quiet to operate, easy to use, and you can easily print using a resin bath. The difference is that this machine is a lot less expensive, and the resin is also less expensive. The other thing that’s great about the Moai is it allows 3rd party resin!

Source: Youtube Teaching TechThis machine isn’t as polished or sophisticated as the Formlabs’ 3D printer, but it is no stick in the mud, either. It will deliver great accuracy and precision for a fair price. Peopoly’s Moai resin 3D printer is an excellent choice for beginners who have the cash. It’s also the perfect choice for people who like to experiment and tinker.

It’s also the perfect choice for people who like to experiment and tinker.

Since it’s open-source and allows 3rd party resins, you have a lot of room to test the boundaries of this printer.

We recommend the Moai as the best jewelry 3D printer for beginners and it’s equally friendly to limit-testers and experimenters.

- Compatible with 3rd party resins

- Robust assembly

- Great supporting documents

- Good value

- Beginner-friendly

- Assembly required

- Prints are sometimes messy

Check Latest Price

6.

Creality Ender 3 Pro (Best FDM)

Creality Ender 3 Pro (Best FDM) 3D Printer Type: FDM | Materials: PLA, ABS, TPU & PETG | Build Volume: 220 x 220 x 250 mm

For a couple of hundred bucks, you can start learning how to make custom jewelry. The Creality Ender 3 Pro is not the most polished or glamorous printer, but it’s a workhorse.

A lot of people consider it the best FDM 3D printer for jewelry in its price category, myself included. What you get are reasonably accurate and quality prints (for a non-resin 3D printer). You can start learning the process and experimenting without breaking the bank.

The 3D printer is also really sturdy and durable.

If you’re not comfortable investing thousands into a 3D printer, the Creality Ender 3 Pro gives you the option to start small and see how passionate you are about the space.

Unlike the rest of the 3D printers in this list, since this is an FDM 3D printer you’re not pigeonholed to just using resins. Sure, it’s not the best 3D printing tech for making jewelry, but it can do a ton of other stuff. You can enjoy the full range of freedom that comes with having an FDM printer.

Sure, it’s not the best 3D printing tech for making jewelry, but it can do a ton of other stuff. You can enjoy the full range of freedom that comes with having an FDM printer.

That said, FDM 3D printers print quality is noticeably less smooth and accurate than their resin 3D printer counterparts.

Admittedly, sometimes I break things just so I can 3D print replacements – and that’s something you can’t do with an SLA 3D printer.

- Very budget-friendly

- Robust machine

- Decent accuracy

- High-quality print potential

- Some reliability issues

- Assembly required

- Print bed is sometimes warped

Get Discount (Official Store)

Check Latest Price

7.

Solidscape S325 (Best Professional Choice)

Solidscape S325 (Best Professional Choice) 3D Printer Type: Material Jetting | Materials: Midas Castable Material & Melt Dissolvable Support | Build Volume: 152 × 152 × 101 mm

Our last option for you is the Solidscape S325. This printer is a bit more professional than the other options on this list. As such, it costs a good bit more, but it also offers a lot more print quality, reliability, and other benefits!

The S325 is a professional 3D printer that’s meant specifically for making jewelry molds. In fact, the S325 doesn’t actually use traditional SLA printing technology; instead, it uses material jetting, a different type of 3D printing.

With material jetting, the Solidscape S325 can print in wax materials, which traditional SLA 3D printers don’t work with. Being able to print wax is super useful for jewelry 3D printing because it makes the mold-making process a breeze.

And, despite the different technology, the Solidscape S325 still yields a ton of detail in 3D-printed jewelry pieces.

What I personally find most fascinating about this printer is its support abilities. Moreover, the Solidscape S325 prints support, generated by its proprietary 3D slicer software, using a material that dissolves post-printing. As such, you can print very intricate models, with overhangs, without worrying about supports hurting the visual quality of the model.

So, if you want to get into 3D printing jewelry professionally or make a business out of it, then you’ll need a printer like the Solidscape S325 to ensure high-quality prints in materials specifically meant for jewelry.

- Can print in wax and other special materials

- Dissolvable support capabilities

- Very reliable

- High print quality

- Proprietary 3D slicer software

- Tons of customer support

- Very expensive

- Requries consultation with a sales representative

Check Latest Price

How Does 3D Printing Jewelry Work?

Just to clear things up, you’re not going to be printing custom gold jewelry right from the nozzle of your 3D printer. Instead, you’re going to be printing a high-detail mold that you can use to make your custom jewelry. Or, if you’re fine with a plastic piece, you’ll be printing high-detail resin jewelry.

Instead, you’re going to be printing a high-detail mold that you can use to make your custom jewelry. Or, if you’re fine with a plastic piece, you’ll be printing high-detail resin jewelry.

If you’ve made jewelry the traditional way before, you know the low-tech method of making these molds. You start by hand-crafting or CNC machining a version of the ring or jewelry piece, and then you create a mold around the part. After that, you solidify the mold and pour in your molten silver or gold to make the final ring!

3D printing a ring or other jewelry piece relies on the same processes, but it utilizes the technology of the 21st century. Moreover, instead of milling or hand-carving, you’re using a 3D printer to make a more detailed and precise jewelry piece, so you can make a more detailed mold.

Basically, any 3D printer, including hobbyist options like the Ender 3, can work for making jewelry molds. However, for a more detailed mold and, thus, a more intricate final jewelry piece, you’ll want to use a higher-end resin 3D printer.

Process of 3D Printing Jewelry

In case you don’t know the process for 3D printing jewelry, let’s take a quick look at it.

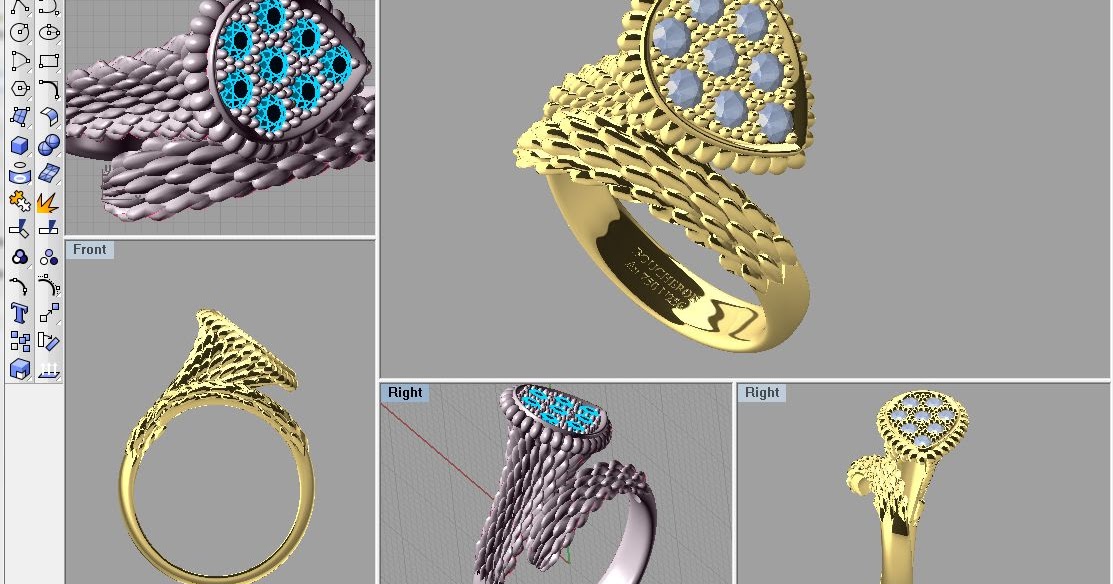

First, you have to find a design for a jewelry piece or make a 3D model yourself. The latter method is better if you want a custom jewelry item and you can design your model in a CAD software, like Onshape or Blender.

Once you’ve got your ring 3D model, you’ll need to 3D print the part. No, we’re not making it out of gold, so you’ll need to print it in a plastic filament, resin, or special wax. Try to use a material that’s meant for high-detail printing, like Phrozen Aqua Grey 8K resin.

After you have the 3D printed version of your jewelry price, you’ll need to get it ready for casting in a more durable material like gold or silver. You can make a mold of your 3D printed model using wax!

Finally, pour your molten precious metal into that mold. After some time, the magic is done! You have a shiny ring!

But that whole process is really the easy part. The more challenging part is figuring out what 3D printer is right for you. Like a “choose your own adventure” book, you have some options to start you down your path.

The more challenging part is figuring out what 3D printer is right for you. Like a “choose your own adventure” book, you have some options to start you down your path.

Available 3D Printing Processes

When it comes to 3D printing a jewelry piece, there are a few different types of 3D printers you can use.

Most consumer-grade 3D printers are Fused Deposition Modeling (FDM) machines. FDM 3D printers use a heating element known as the hot end to melt stringed plastic material and lay it out, layer-by-layer, into your 3D model.

However, the more popular type of 3D printer for making jewelry is Stereolithography, or SLA for short. Instead of a heating element and stringed plastic, SLA 3D printers use a special laser with liquid resin. The liquid plastic resin is poured into a tub called the VAT, and the laser is placed beneath a screen, which solidifies the resin, layer by layer, to form your desired 3D model.

SLA is a more favorable tech for jewelry because of its high-detail printing abilities, but FDM is the more universal printing technology.

Should I Use FDM or SLA for Jewelry?

Okay, now that the nerdy science talk is over, let’s take a look at the two main methods of 3D printing used to make jewelry. Below, I’ve discussed how both FDM and SLA 3D printers work as well as each of their benefits.

FDM

The big benefit of using an FDM printer for making jewelry is that the cost is really low. The upfront cost of the printer is lower, and the operating cost is much lower. Of course, there’s a downside to this.

The quality you get with an FDM printer isn’t close to the quality you get with an SLA printer – it’s a lot worse. Moreover, you can’t capture as much detail or small features in prints on an FDM 3D printer as you can with an SLA machine.

As such, if your jewelry doesn’t require a lot of fine detail or you want to save money, then an FDM printer will be perfect for you. Additionally, an FDM printer is the better option if you plan on printing a ton of non-jewelry projects because FDM parts are stronger than those made on an SLA printer.

SLA

On the other hand, SLA 3D printers are typically more expensive than FDM printers. While the cost of an SLA printer has dropped dramatically over the past few years, you also need other hardware, like a washing station and a UV curing light, to use an SLA machine. And these costs should be considered when looking at the price of an SLA machine.

But the extra money for an SLA 3D printer is definitely worth it if you’re looking to print high-detail models. For example, if you wanted to 3D print a jewelry piece that had a very intricate design, an SLA 3D printer would be best.

It’s actually insane how much detail SLA 3D printers yield in models. Most SLA 3D printers today use a 4K pixel resolution LCD screen, but some printers, like the Phrozen Sonic Mini 8K, can print with 8K pixel resolution quality!

Sadly, there are some other problems with SLA 3D printers. For example, the resin is toxic and smells bad, making the printing process more dangerous. And, after a print is finished, you have to wash the part and cure it with a UV light.

But if you want to print high-detail models and are okay with spending a lil’ extra, then an SLA 3D printer is definitely for you!

Why 3D Print Jewelry?

Source: Youtube Slava TVSo we highlighted how to 3D print jewelry, and what goes into it. But are you totally convinced that you should even try it? Why 3D print jewelry?

Why 3D print anything? The answer is exactly the same.

You have complete freedom over the design. You can make highly customized pieces and serve a niche market. If you can operate 3D CAD, you can completely design your own pieces to print.

Pieces can be made that seem to defy physics. You can 3D print such intricate pieces with odd geometries. This is great for modern pieces of jewelry.

For some pieces, there is no alternative. Traditional methods cannot scratch the surface of what you can make with a 3D printer. Some of your physics-defying pieces simply cannot be made on a CNC mill, so there’s no other option.

Prototyping is so much faster. I’m from a manufacturing background so trust me when I say that nothing compares to the lifecycle speed of a project when you’re using a 3D printer.

The time between the initial concept, designing, and getting your first working prototype could be 8 hours with a 3D printer. Traditional manufacturing methods might take a week for the same amount of progress.

The cost is so low. Crazy low. You don’t need a staff of trained machinists, design engineers, and project managers. You are the entire team. You don’t need a $250,000 CNC milling machine; a printer that costs a couple of hundred dollars will suffice. You don’t need a $100 piece of raw material to prototype with, $5 is plenty. Finally, you don’t need to pay someone hourly to make it, you hit “go” and leave the room.

So why 3D print jewelry? It’s faster, cheaper, more customizable, and you can make any shape you want.

Conclusion

I hope you get as excited as I do when I hear about all the different ways to 3D print jewelry and start growing your business or just making fun pieces as gifts to family and friends.

The process isn’t so hard to learn when you get your hands on a printer.

Whether you go with an FDM printer, an SLA printer, a budget option, or a professional high-quality printer, you’re going to love the new world you unlock with your 3D printer.

As for what printer to use, if you want to make high-detail jewelry pieces, I strongly suggest the Phrozen Sonic Mini 8K or Formlabs Form 3+. Both printers offer exceptional print quality, but the Sonic Mini 8K is probably better for those who don’t need as much print space.

And, if you’re on a budget, but still want to print high-detail models, then the Elegoo Saturn 2 8K should be your speed. It’s very budget-friendly, and has an 8K LCD screen for yielding high-quality prints.

On the FDM side, you have the Creality Ender 3 Pro which is perhaps the best option in this space. It’s budget-friendly and, as it’s an FDM 3D printer, the Ender 3 Pro is also a great machine for non-jewelry prints, so there’s a lot of opportunity for you!

Finally, if you’re ready to invest in your business and grow it, consider the top-of-the-line Solidscape S325 printer.

Enjoy your time with your new 3D printer! There’s a lot of learning and growing to be had!

Pat Nathaniel

Pat is the editor-in-chief at Printing Atoms. He has a BS in Mechanical Engineering from the University of Florida and wants to spread the word on 3D printing. When he's not writing, he likes to tinker with his Ender 3 Pro, test filament brands, and scuba dive.

3D printed jewelry

3D printing of jewelry for professionals

Jewelry is an ancient craft, however, professionals are increasingly turning to modern 3D printing technology.

The best application of 3D printing in the jewelry industry is prototyping and mold making.

Prototyping . 3D printing will save you time and money when making your jewelry. During the development phase, you may want to create an economical plastic copy first. With its help, clarify all the nuances, and then proceed to create your masterpiece. nine0005

nine0005

Creation of casting templates. A very efficient method of jewelry production is based on mold making. The template of the jewelry is 3D printed from a special resin that ensures clean burnout without residual ash. Based on the template, a mold is made into which molten metal (gold, platinum, silver, etc.) is subsequently poured.

The main technology for 3D printing of jewelry is DLP. It satisfies two main requirements: a high level of detail and the production of products with a very smooth surface. nine0005

Order 3D printing of jewelry

Jewelry 3D Printing for Hobbyists

There are a huge amount of 3D printed jewelry models on the Internet. There are also a huge number of web applications that allow you to create an online ring, bracelet, necklace or hairpin of your own design.

Despite the fact that desktop 3D printers print with plastic, the exclusivity of your jewelry is sure to attract attention. nine0005

Order printing jewelry on a 3D printer

Benefits of 3D printing for the jewelry industry

Cost effective. Prototyping a jewel using 3D printing is much cheaper than traditional or CNC manufacturing.

Prototyping a jewel using 3D printing is much cheaper than traditional or CNC manufacturing.

Fast. The use of 3D printing significantly reduces product development and production time.

No restrictions on 3D design. nine0012 3D printing allows complex shapes and complex designs to be created that would be impossible to achieve with traditional prototyping/manufacturing technologies. This aspect is very important in a creative field such as jewelry.

Reviews of our customers

Reviews of our customers

I ordered 3D printing at 100 and 200 microns + modeling, everything was done within a day + sending. I am very satisfied with the quality, not a single flaw, I will use again! nine0005

Maxim

Dnepropetrovsk

Professional and very high quality service. Orders are responded to quickly and completed in a timely manner.

Petr

Odessa

An idea came up with an unusual project. In our city they could not help. I turned to 3d for u and did not regret it. We developed a layout, agreed and printed the first sample. Now we order in bulk. The timing and price are amazing.

In our city they could not help. I turned to 3d for u and did not regret it. We developed a layout, agreed and printed the first sample. Now we order in bulk. The timing and price are amazing.

Oleg

Nikolaev

Guys, thank you very much! nine0075 Developed my own project. All that was - a handwritten image on a notebook sheet. Both the layout and the project itself are excellent.

Victoria

Odessa

I started working with the company when I didn't have my own printer. I took orders, they printed them and gave them to me. After I bought a printer, but I still apply for modeling.

Alexey

Odessa

I ordered 3D printing for 100 and 200 microns + modeling, everything was done within a day + sending. I am very satisfied with the quality, not a single flaw, I will use again! nine0005

Maxim

Dnepropetrovsk

Professional and very high quality service. Orders are responded to quickly and completed in a timely manner.

Petr

Odessa

An idea came up with an unusual project. In our city they could not help. I turned to 3d for u and did not regret it. We developed a layout, agreed and printed the first sample. Now we order in bulk. The timing and price are amazing.

Oleg

Nikolaev

Guys, thank you very much! nine0075 Developed my own project. All that was - a handwritten image on a notebook sheet. Both the layout and the project itself are excellent.

Victoria

Odessa

I started working with the company when I didn't have my own printer. I took orders, they printed them and gave them to me. After I bought a printer, but I still apply for modeling.

Alexey

Odessa

Our clients have already applied 3D printing in the following industries:

3D PROTOTYPE PRINTING

3D Printing Makets

3D Seal of spare parts

3D Printing Souvenirs

Jewelry 3D printing

3D Printing.

LITOPHANIA

LITOPHANIA

3D PRINT FAN ART

3D PRINT ROBOTICS

Jewelry printing using SLA technology. Jewelry 3D printing

Articles

Jewelry manufacturing using stereolithography allows you to quickly and inexpensively create jewelry with a unique design. nine0005

The use of SLA technology in jewelry

In jewelry, there are two options for using 3D printing:

- Production of products that are immediately ready to wear: that is, a product is printed on the printer, which is then slightly modified, painted - and the jewelry is ready.

- 3D printing blanks for the subsequent casting of jewelry parts from real precious metals: 3D modeling technologies and SLA printers are used to create three-dimensional blanks of future jewelry, which are characterized by the highest accuracy, with the ability to detail the smallest elements. nine0166

Photopolymers in dentistry

In this case, the common expression "jewelry precision" should be taken literally. Due to this property, the production of products using SLA technology is in demand not only in jewelry, but also in dentistry for creating surgical templates.

Due to this property, the production of products using SLA technology is in demand not only in jewelry, but also in dentistry for creating surgical templates.

With all the advantages of making jewelry using SLA printing technology, there is a minus - the high cost of consumables: photopolymer resin, which looks like epoxy. nine0005

A resin blank is used to create a precious detail in the following way: a 3D model is covered with plaster, which, when solidified, repeats all the outlines of the future jewelry. The mold cast in plaster is filled with precious metal - and the exclusive jewel is ready. Due to the peculiarities of production, the finished jewelry practically does not need to be finalized, which greatly saves time and reduces the cost of the jewelry piece.

Benefits of 3D printing for dentists and jewelers

- High accuracy: the production of jewelry models using SLA technology almost completely eliminates the influence of the human factor and errors, the entire process of creating a product is automated as much as possible.

The absence of the need for serious refinement can also be attributed to the same point - that is, the detail is obtained as the designer or customer saw it, without “surprises” that looked good in the sketch, but were not provided for in the actual operation of the jewelry.

The absence of the need for serious refinement can also be attributed to the same point - that is, the detail is obtained as the designer or customer saw it, without “surprises” that looked good in the sketch, but were not provided for in the actual operation of the jewelry. - Editability: Before a piece of jewelry is printed on a 3D printer (regardless of technology), a virtual 3D model is created for subsequent printing in a special program. This virtual 3D model can be corrected at any time and the layout with the changes made can be printed - it is much cheaper and faster than “experimenting” with precious metals in the process of creating a precious item. nine0166

- Availability: the production of jewelry using SLA technology is developing very quickly, and, given the high demand, in the near future they will only become cheaper until they become available to absolutely everyone. Even now, the cost of 3D printing services is relatively low, especially considering the exclusivity of the result.

Learn more