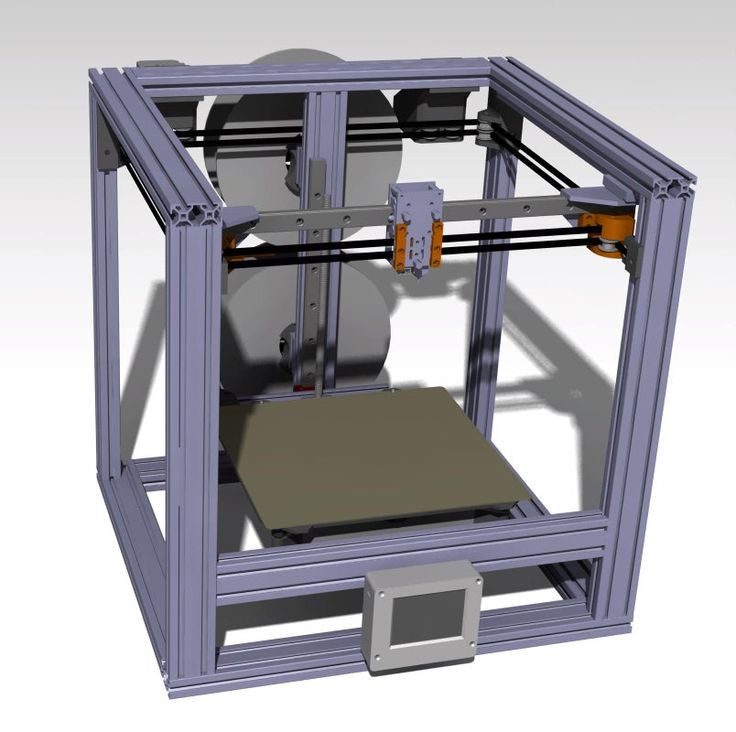

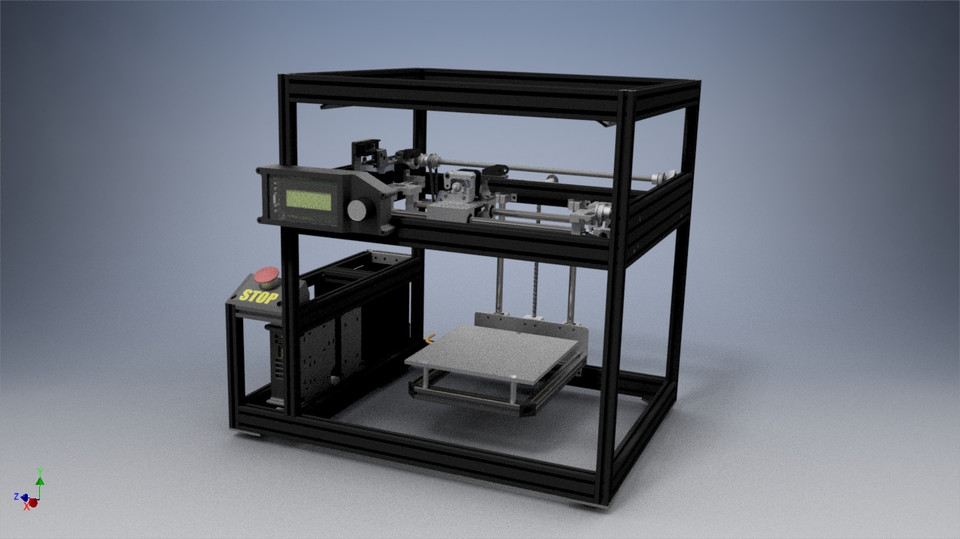

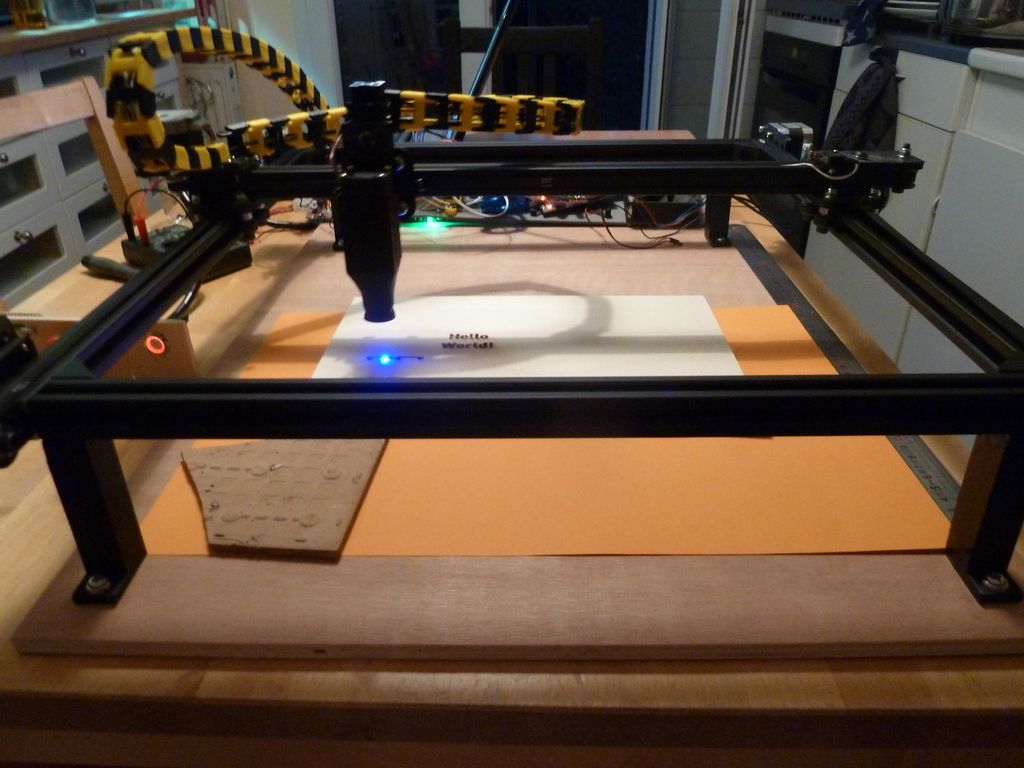

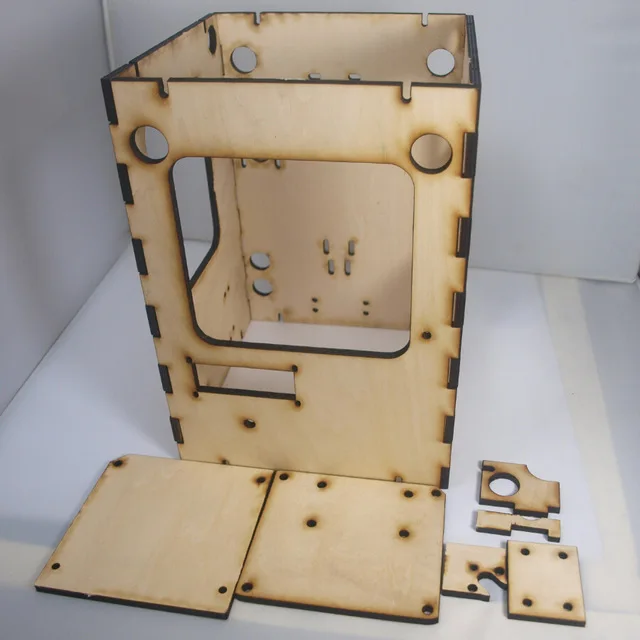

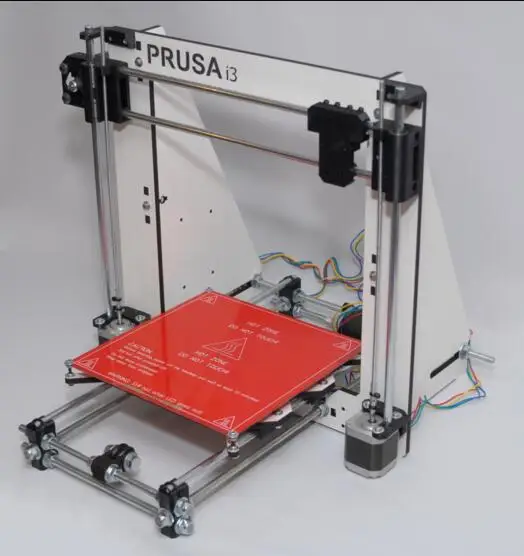

3D printer frame parts

3D Printer Parts: Complete List of 3D Printing Components

ADVERTISEMENT

3D printers are becoming popular with time. Some prefer to buy the fully assembled machines while few like to explore a little more with DIY 3D printers.

While working with DIY machines, the most exciting part is exploring the different 3D printer parts that make it such a powerful technology. Though it is difficult at times to complete the assembly in few hours, the experience does provide a lot of know-how about the 3D printer anatomy.

By learning about the parts, one gets better understanding of the working of 3D printers. Hence, can utilize the knowledge later when actually printing with the machine.

One can even solve minor to major problems such a nozzle jam and many others, when familiar with the inside out of these 3D printers.

In short, if users are looking forward to a strong career in 3D printing, the right way would be start with the different parts that make up for the most revolutionary technology.

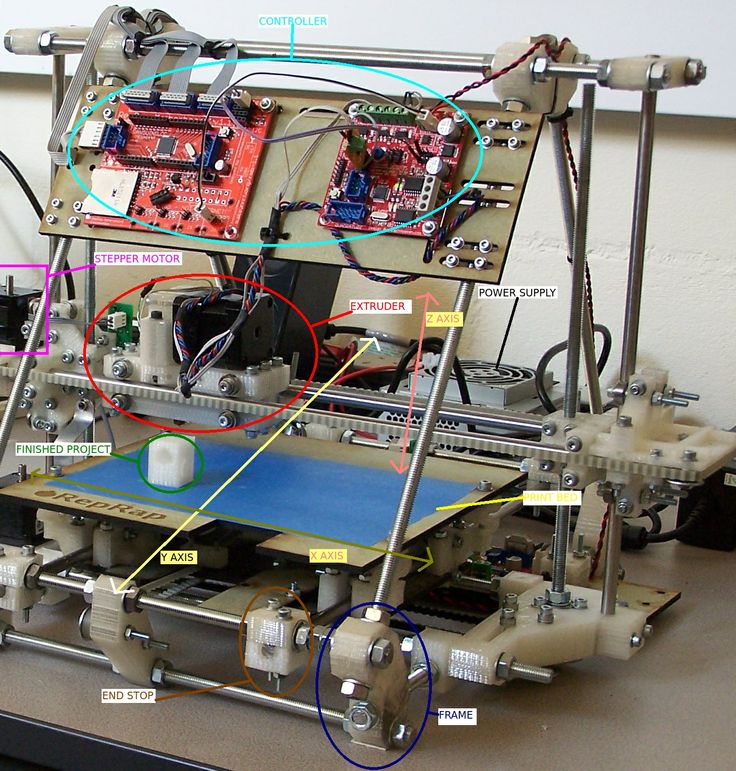

List of Major 3D Printer Parts

3D printers are complex, however, when examined closely, they can be made super easy to understand and work with. The first step must be to check out the 3D printer parts list.

These components of 3D printers help accomplish tasks from printing smaller to larger parts with ease. The list here contains the component of cartesian printers which are recommended for beginners.

ADVERTISEMENT

MotherBoard or Controller Board

The motherboard which is also known as mainboard or control board. As the name suggests, this component is responsible for maintaining the smooth processing of the machine.

Being responsible for all the fundamental operations, motherboard works as the brain of the 3D printers. It directs the motion components as per the instructions sent from a computer and at the same time, interprets signals from the sensors.

It directs the motion components as per the instructions sent from a computer and at the same time, interprets signals from the sensors.

You must have guessed how crucial it is to have a great quality controller board for achieving high performance from a 3D printer. Even if you put every best part in your machine, while ignoring the controller board, your 3D printer would be worthless.

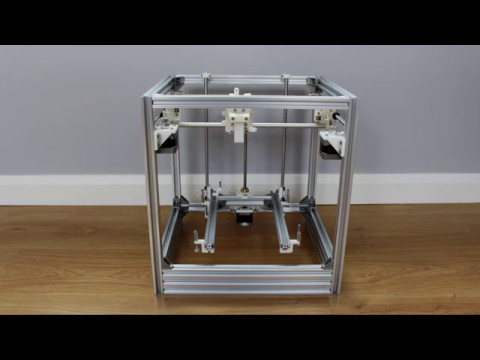

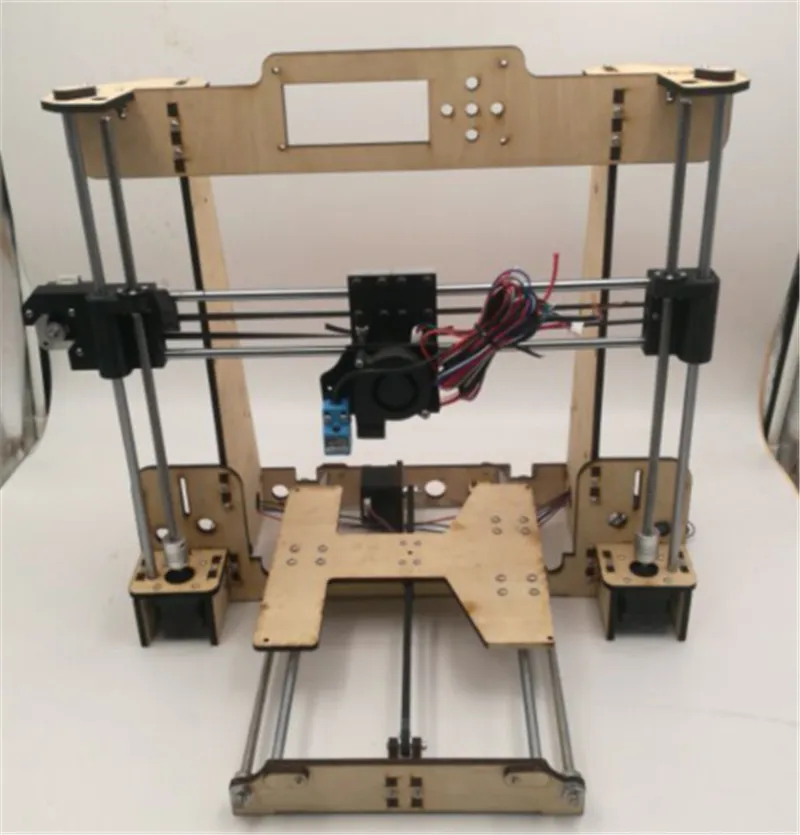

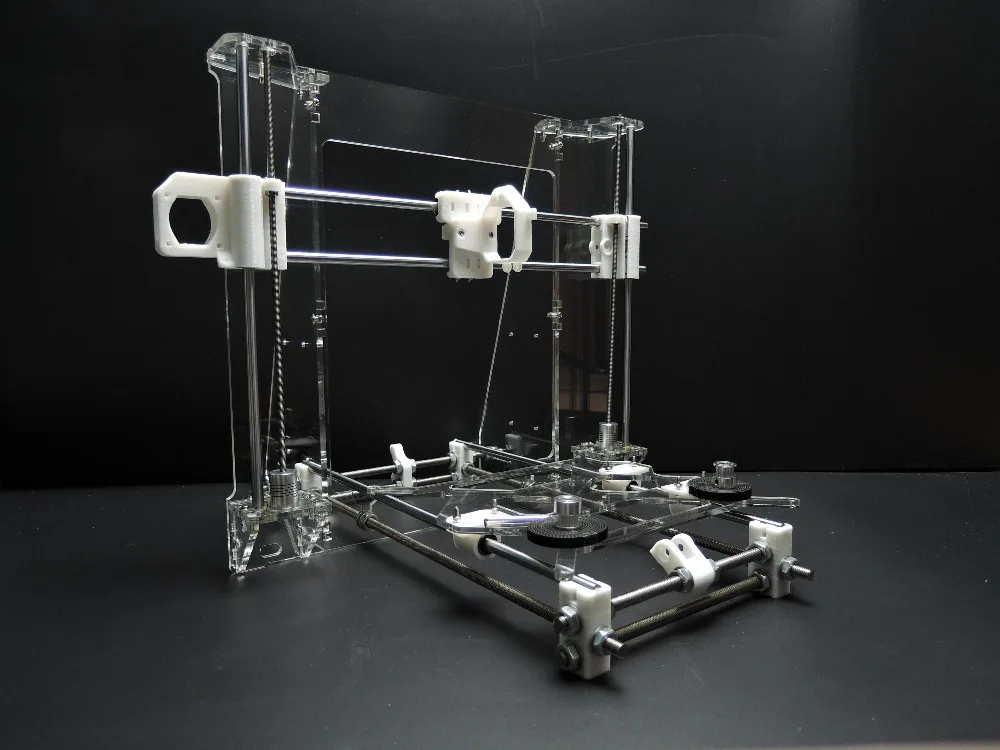

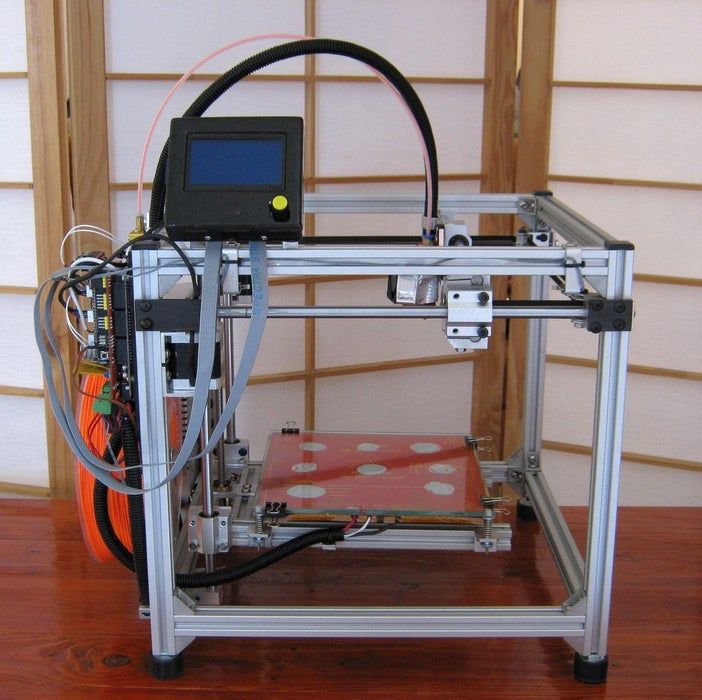

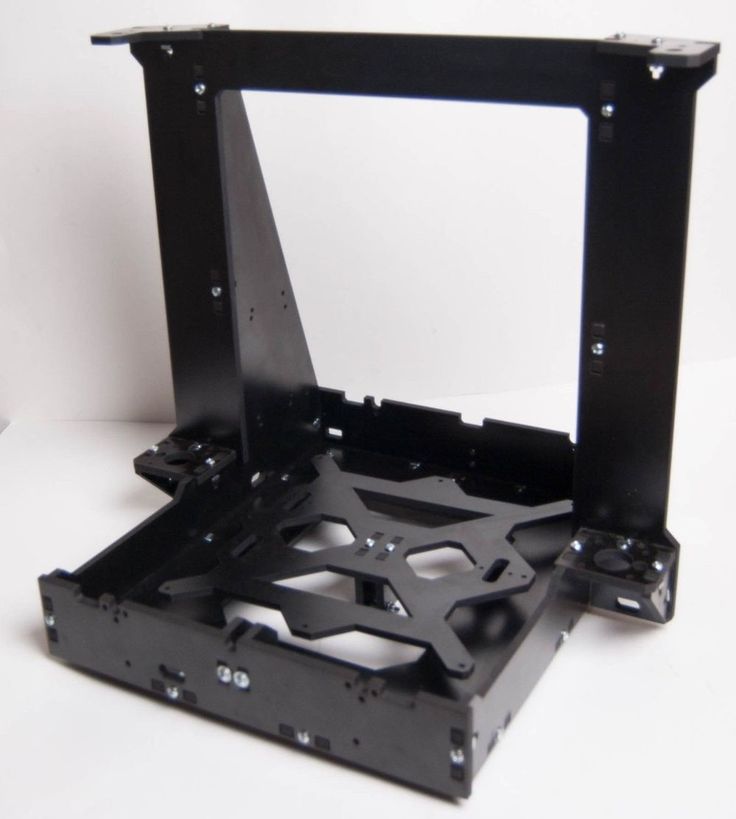

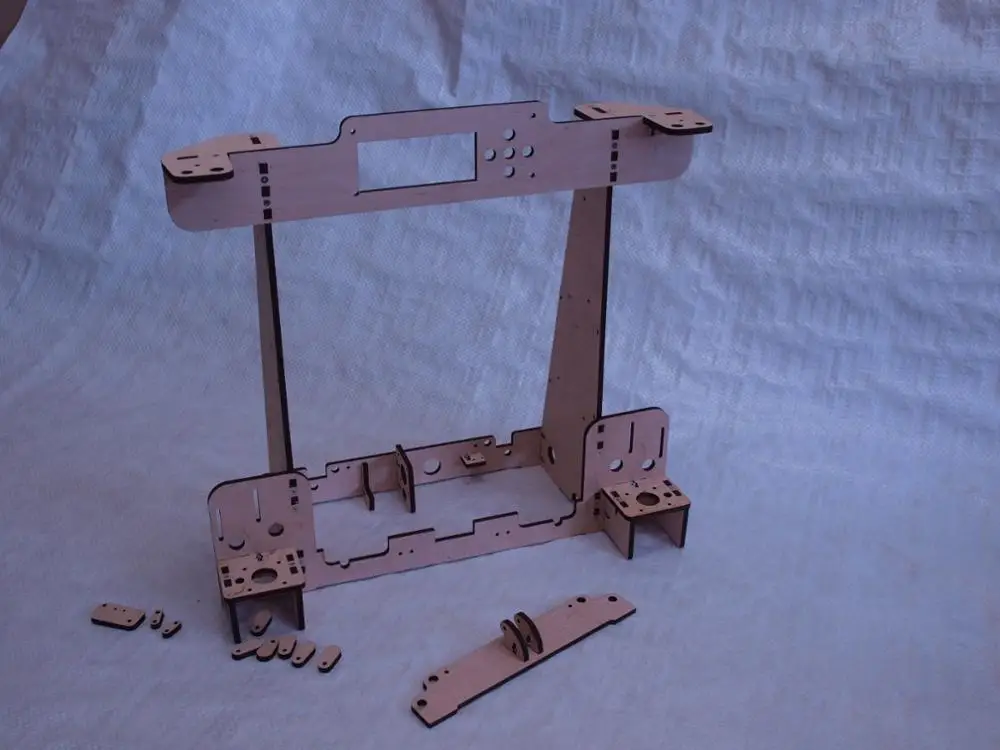

Frame

Frame helps keep all the other components of your 3D printer together at one place. It also maintains the stability of the entire machine. If your frame is robust, you will have a more durable 3D printer.

Companies use different materials and the most common ones are the metal and acrylic. In old days, wood was used for the frame of the consumer 3D printers.

However, to maintain the highest stability, one must choose the metal body. These printers aren’t always expensive as well.

For example, Monoprice offers budget 3D printers under $300 with aluminium frame. Yes, you heard it right. With limited budget, you can still own a metal frame 3D printer.

Yes, you heard it right. With limited budget, you can still own a metal frame 3D printer.

When talking about frames, the open and closed frame designs also make a difference. A closed frame offers better results by maintaining consistent temperature around the print space. There are few printers that also offer semi-enclosed frames.

ADVERTISEMENT

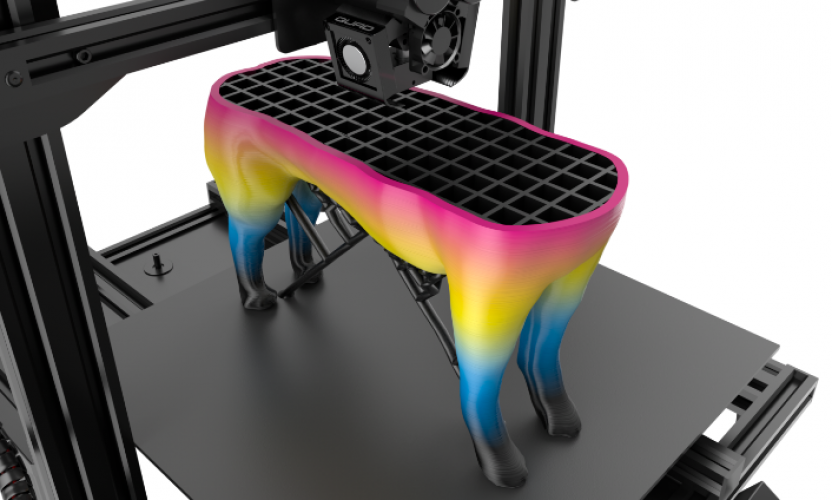

Print Material

Filament is used for the FDM 3D printers. Filaments are available in spools. These are heated to certain temperature and are liquified to be deposited on the print bed.

This happens in layers. The objects created by 3D printers are made of these filaments. There are many types of filaments used for 3D printing. And, each one of them have different properties. They have their own advantages and limitations.

When getting a printer, one must take care of the compatibility with different filaments. Not all printers allow multiple filament compatibility.

Some can process only one kind of filaments, mostly PLA. And, others can work with multiple choices of filaments including PLA, ABS and many others.

And, others can work with multiple choices of filaments including PLA, ABS and many others.

There are other 3D printers that only accept the proprietary filaments. Hence, you must be aware of your 3D printing needs before opting for a 3D Printer and the filaments it supports.

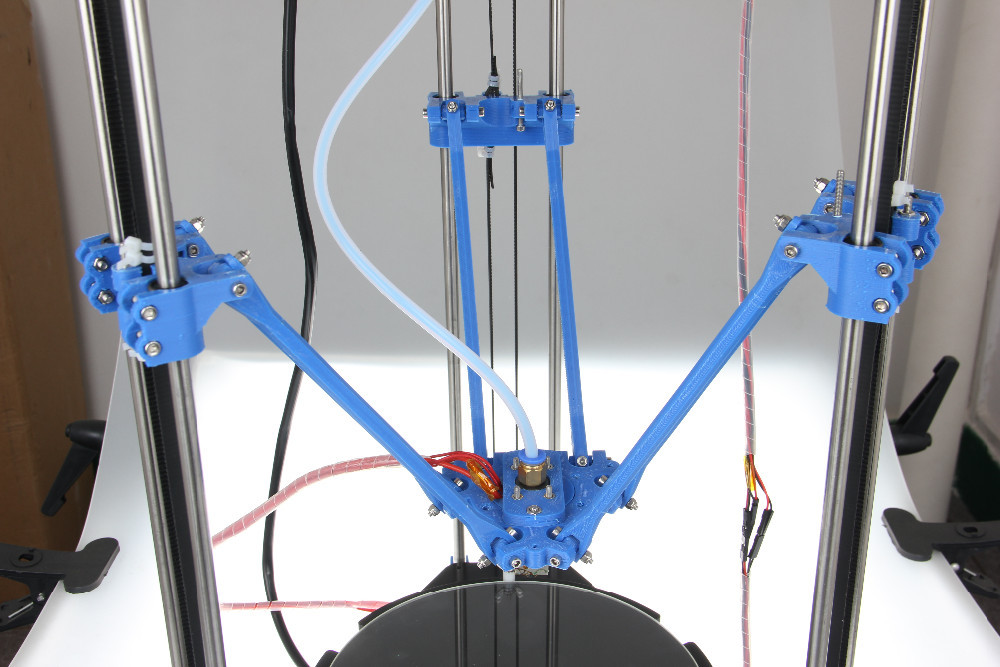

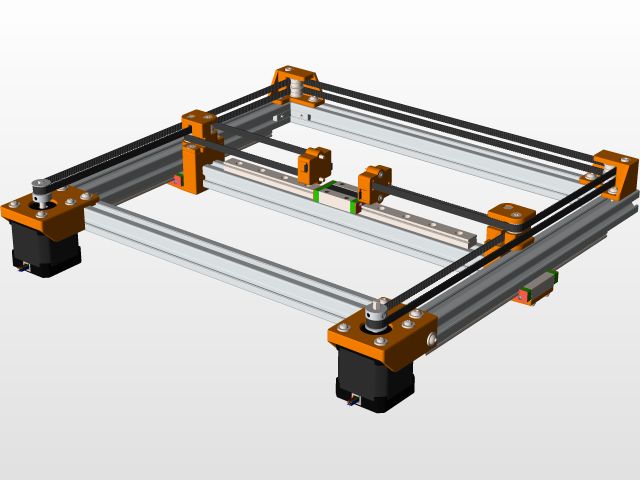

Motion Controllers

You must know that the 3D printers, as the name suggests works along the three axes. Motion controllers receive instructions from the mother board about the movement they must make, while they are the ones who perform the actual movements.

- Belts: The belts connected to motors are responsible for moving X-axis and Y-axis. The movement happens from side to side. This movement does affect the print speed and precision, hence are very crucial for the attaining best results. One must ensure that the belts aren’t loose or the print may ruin. For this, one can use tensioners.

- Stepper Motors: These are responsible for the mechanical movement of the device and are controlled by Stepper driver.

These motors connect with X, Y as well as Z axis. These motors help in driving the print head, print bed, along with the leadscrews. Because the rotations are made in steps, they are called Stepper motors.

These motors connect with X, Y as well as Z axis. These motors help in driving the print head, print bed, along with the leadscrews. Because the rotations are made in steps, they are called Stepper motors. - Threaded rods: Threaded rods are connected to the stepper motors. With the movement of threaded rods, the print head moves in upward and downward directions. In few 3D printers, the print bed movement also relies on threaded rods. So, the Z axis movement is dependent on Threaded rods. Although these could be used for the movement along the X and Y axis, being expensive, majority of the printers use belts. Belts are faster and lighter alongside being cheap.

- End Stops: End stops ensure that the end points are marked along the three axes when the movement of components take place. It identifies the range of movement of each component.

ADVERTISEMENT

PSU

PSU, abbreviated as Power Supply Unit helps in supplying power for a smooth operation of 3D printer. You can find the PSU mounted on the frame. Or, it can also be available separately along with another controller box. However, mounted one provides compact look and occupies less space.

You can find the PSU mounted on the frame. Or, it can also be available separately along with another controller box. However, mounted one provides compact look and occupies less space.

PSU strength would decide what temperature your 3D printer is capable of working with. For advanced materials, one must choose the one with higher temperature range allowance.

Print Bed

Mostly, anyone who has worked with 3D printer would know what a print bed is. This is the component where the models are created.

The filaments are deposited on the print bed, one layer at a time for building the entire object. One of the major 3D printer parts that does decide the quality and surface finish of the printed object.

Different 3D Printers boasts different kinds of print bed. You can find heated as well as non-heated print beds. A non heated print bed may be enough for PLA, however, for advanced filaments, heated beds are recommended. These helps in enhancing adhesion and stability for first layer of the print.

Also, the print beds are designed using different materials. For example, aluminium and glass print beds. Both have its own benefits and limitations. Aluminium print beds heat up faster and glass print beds, being flatter, provides better finish and are easy to maintain as well.

Some 3D printers offer automatic calibration of print beds. However, users need to level the bed manually in some.

ADVERTISEMENT

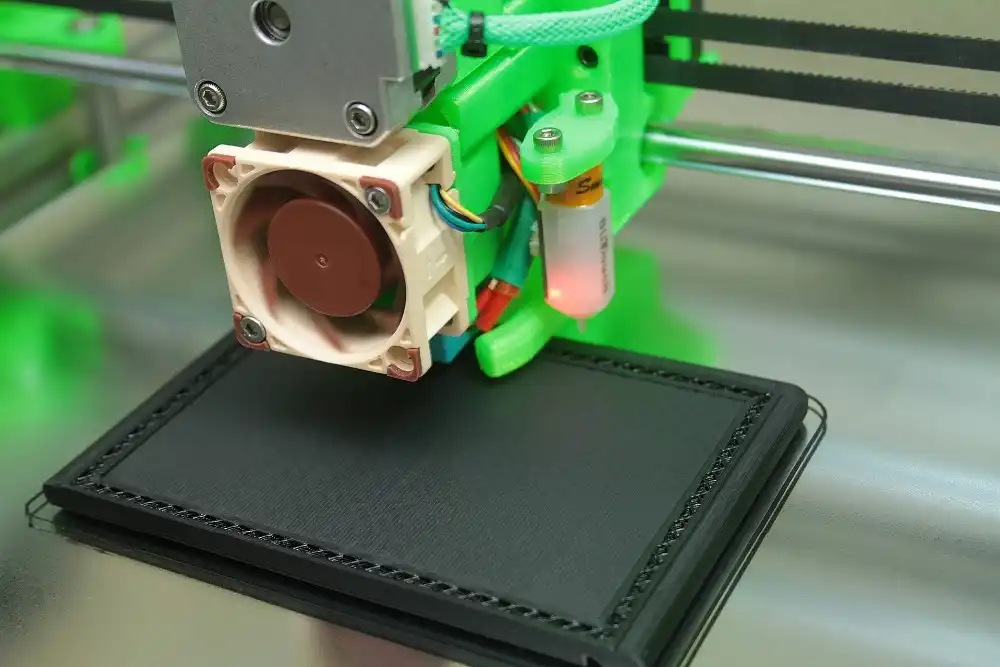

Extruder

The extruder, also known as print head extrudes the filament and deposit it on the print bed. The extruder can be categorized in two sections. One is called the cold end while the other is known as the hot end.

The job of the cold end is to lock the filament while pushing it gradually downwards to the hot end.

The hot end that has a nozzle attached to it at the end, maintains a high temperature greater than the melting point of the filament. The hot end melts the filament which is further deposited on the print bed.

The extruder itself is made of different parts.

- The Filament Drive Gear: Also known as extruder drive gear is responsible for pushing the filament into the hot end.

- The Heat Sink: The heat sink along with the heat Sink Fan ensures that the material is still in solid state until it reaches the nozzle.

- The Heater Cartridge: This is the component that works to heat up the filament.

- The Thermocouple: To maintain the right temperature, the extruder uses a temperature sensor. This is used for the hot end.

- The Cooling Fan: Once the melted filament is deposited, it must be cooled down for setting before the next layer gets deposited. The job of the cooling fan is to ensure the same.

- Nozzle: This forms the tip of the extruder. The filament is melted and it comes out of the nozzle for deposition. There are different sizes of nozzles that the printers use. 0.4 mm is the most common one. By keeping the smaller diameter of nozzle, one can achieve finer details with greater accuracy.

And, larger nozzle helps in printing at a higher speed.

And, larger nozzle helps in printing at a higher speed.

Some 3D printers are equipped with dual extruders as well. With a dual extruder, one can print simultaneously with two different filaments. Dual extruders have two kinds of setup. Either both the nozzles are included in one print head or connected with two different print heads.

ADVERTISEMENT

Feeder System

There are two most common feeder system used in 3D printers: Bowden feeder system and Direct feeder system. In a Bowden setup, there are different locations for cold and hot ends.

While a filament tube is used to direct the filament towards the hot end. This setup can dramatically increase the print speed as the extruder becomes lighter.

When talking about the direct setup, the cold end and the hot end are directly connected. The direct feeder system is most common among the users who work with flexible filaments.

Connectivity

When it comes to connectivity with other device, 3D printers differ a lot. Some provide only the ethernet or USB port for connection. However, many new 3D printers are now available with Wi-Fi setup as well.

The interface can also help connect the mobile phone or laptop through Wi-Fi connection to your 3D printer. The file transfer can also be done using any of the three options.

For a standalone experience, many 3D printers also come with SD card slots. These slots are used for file transfer while the printer works without a need for any other device.

User Interface

These days, most of the 3D printers, even the budget ones, comes with an LCD user interface. With the help of this interface, one can control the printer settings without a need for computer.

Hence, these machines can work as standalone machines. The majority of the 3D printer has a mounted interface. However, you may find some models with separate controller box including the LCD interface.

This interface can help check and set the machine parameters. You can also use this interface to initiate the loading or unloading of filament. Moreover, an auto-leveling system can be initialized with the help of this small screen on the 3D printer.

The Conclusion

The 3D printing technology is growing with leaps and bounds. Doesn’t matter if are from a technical background or a non-technical one. Users can definitely learn to operate 3D printers because of all the help available online.

And, to know a little more than what others know, would certainly put you in a better place. So, why not start with the components of 3D printers?

3D printers are housed with many smaller and larger parts. Every part has their own role to play. Some tackles the movement while some work for accuracy various other important jobs.

These parts work in conjugation to provide a stable and uniform precision. The objects printed with a 3D printer bear varying properties and quality, depending on the difference in these parts and components.

However, all of these components have equal share when it comes to the operation of the 3D printers. Knowing about these 3D printer parts is a great way to start the journey towards 3D printing.

Who knows, you can someday, be able to create your own 3D printer. Possibilities are endless and when basics are strong, one can dream for higher goals.

3D Printer Parts - Best 3D Printer Accessories Online shopping

Surely you have heard a lot about 3D printers and what you can do with them. There are many wonderful machines that can make your creator aspirations come true. But, when buying a 3D printer, which model should you choose? How much should you spend? And what is the best place to buy a 3D printer? Here is a guide to the essential questions when buying a 3D printer.

| Topics in this buyer's guide: |

What is a 3D Printers?

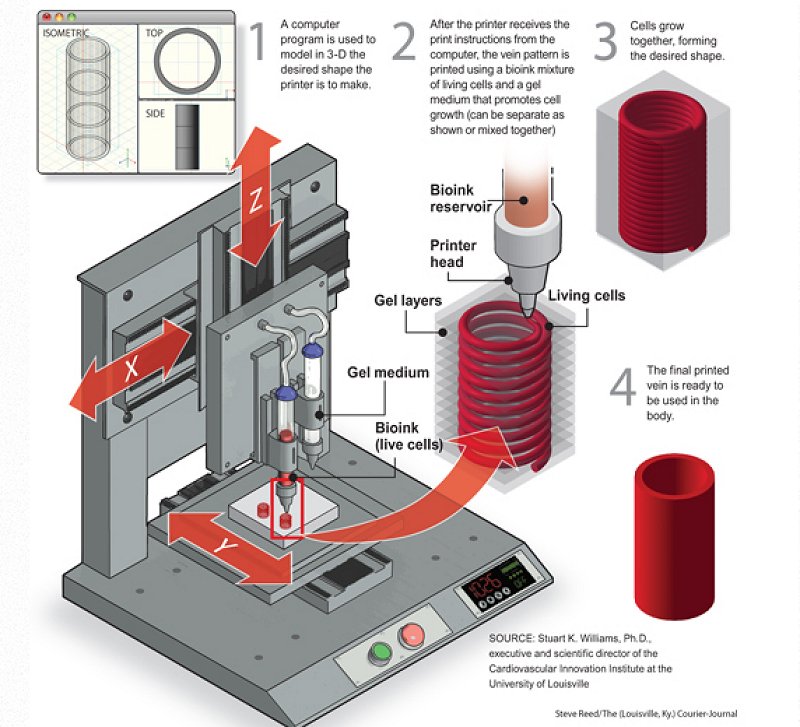

3D printing is a kind of rapid prototyping technology, also known as Additive Manufacturing.

It is a technology based on digital model files, using powder-like metal or plastic and other adhesive materials to construct objects by printing layer by layer. 3D printers can generate parts of any shape directly from computer graphics data without machining or any molds, thus greatly shortening the product development cycle, increasing productivity and reducing production costs.

If you want, you can anything possible through 3D printing.

Education: it can visualize the contents of books, and make the deep knowledge easy to understand through 3D printing models, making it easier for children to learn.

Art: help art lovers develop their imagination, and can help display the highly artistic design and accurate image through 3D printers.

Industry: quickly and accurately convert the design in the computer into a model, manufacture part molds, or print out assembled objects, greatly reducing research and development time.

Architecture: Architectural models were built by hand and took a long time in the past, now with 3D printing technology, you can quickly print the architectural model you want through a 3D printer.

Important Features of 3D Printers

Print Size

According to the maximum range that the X, Y and Z axis can move, determine the size that the machine can print.

Simple Operation

Whether the printer is simple to assemble, the print settings are simple, and the customer can directly operate.

Resumption

After Power-off & Out-of-material Detection Resumption after power-off if there is a sudden power outage, the printer will follow the unfinished printing instructions, no need reprinting, saving time and materials. Out-of-material detection: early warning and replacement of insufficient filaments to improve printing speed.

Leveling Calibration

Manual leveling: adjust the horizontal direction of the hot bed manually. Automatic leveling: the machine automatically adjusts the horizontal direction of the hot bed.

Deposition of molten material vs stereolithography 3D printers

3D printers by deposition of molten material

This type of printers is the one that more quantity and variety of models are currently on the market, and according to its assembly you will find two types, assembled printers, which come to practically to connect and ready, and printers to mount, in the that you are going to have to do the assembly of the printer.

Stereolithographic 3d printers

Stereolithographic printers, are designed for a more professional and advanced user , since the realization of the prints is more complex than with the other type, and it is not advisable to start with this type of 3D printers. Also we leave here the link to the guide of these printers in case you are curious to see them.

Popular vendors and manufacturers of 3D printers

Anet

Anet is a hi-tech enterprise integrating design, research and development, production and sales of 3D printer, 3D printing accessories and 3D printing filaments. The core technology is independently researched and developed by company and has complete independent intellectual property. The product is advanced, widely used, can be applied to new modeling, teaching practice, medical and health, architectural design, handicraft design and personal DIY and other fields, effectively improve product development speed, significantly reduced production costs and labor costs.

Creality

Creality was established in China. As an excellent brand, Creality focuses on Industrial & Scientific, offering the best products. Through diligent development and corporate governance, its products have been sold exceptionally well around the world. We have an endless strive to deliver the best products.

Anycubic

Anycubic was established in China. Anycubic offers the best products as amazing 3D Printer. Anycubic focused on the 3D Printer. Through diligent development and corporate governance, its products have sold exceptionally well around the world.We have an endless strive to deliver the best products.

Alfawise

Alfawise delivers exciting and dynamic home technology. From powerhouse automatic robot cleaners to 3D printers, enjoy affordable technology at every price point. Alfawise combines premium design language, smart design and essential home ideas for less.

5 Things to Consider Before Buying 3D Printers

1. Figure out your purpose of 3D printers

Figure out your purpose of 3D printers

What types of things do you want to print? Just as a hobby? Or do you want to use it in business and sell your model? Or do you want to use it in education? Industrial? These are the questions you need to ask yourself before you start looking for relevant information.

The best 3D printers for schools / education: Anycubic 4Max pro 3D Printer

It is a large 3D printer, good quality, closed and at a really good price. It is a very robust printer. This makes it perfect for working with children around (in fact, it is the one I usually recommend when asked by colleges and institutes for a 3D printer.

It has everything a technology teacher needs: reliability over time, that children cannot reach it, that it is of great volume to print enough things (classes are usually 25 children) and that it has a minimum of quality.

When you are a teacher, you do not have time to be out of school hours calibrating a machine, you need that once assembled you do not need to play practically anything, set it up in class, to print and go.

In addition, from experience I know of some teachers who resorted to other open alternatives, and had to end up isolating the printer in a methacrylate box for fear that children could burn with the hotend or spoil the 3D printer, this is already done in the Anycubic 4 Max Pro.

Finally, the box makes printing materials sensitive to temperature change easier, such as ABS, which makes it perfect for users who want to solve this problem by leaving the printer in cold places.

The best 3D printers for kids: Creality CR-100 3D Printer Upgraded Version

This 3D printer is focused on anyone who wants a 3D printer that looks beautiful in their home and does not want to complicate life at all, or calibrate anything, or design anything, or looking for 3D parts. Perfect for young children who want to get into 3D printing.

You just have to see the technical specifications of Creality CR-100 3D Printer: Intelligent operation, intelligent touch screen design, one-touch wake-up printing. .., all designed for the 3D printer to detect its own problems and fix them and you don't have to touch anything .

.., all designed for the 3D printer to detect its own problems and fix them and you don't have to touch anything .

As you can see, it is a 3D printer focused on children that allows you to touch the right and necessary, prints well and has very cool 3D models in its application for the little ones . That said, a 3D printer, for children and parents who do not want to complicate life

The best 3D printers for home: Alfawise U30 3D Printer

Alfawise U30 is an incredible 3D printer designed for professionals and amateurs alike.

It trains hands-on ability, and only 1 hour is required to finish the assembly. It boasts high cost-performance ratio - any DIY enthusiast will not be unable to resist. U30 has a large build volume - 220 x 220 x 250mm for most challenges. More importantly, printing with Alfawise U30 is hassle-free because the two resume functions prevent any imperfection and failure due to power outage and filament run-out. Control the process and set parameters on the touchscreen. Enjoy easier and more successful home made 3D printing!

Control the process and set parameters on the touchscreen. Enjoy easier and more successful home made 3D printing!

2. Your budget of 3D printers

In most cases, 3D printers are priced based on the performance and quality of the machine itself. Think about what a 3D printer means to you, estimate your price in advance. Then choose the best 3D printer for your price range. Consumables will be your main expense in the future, so a 3D printer that is compatible with multiple consumable types will be the best choice.

- The best 3D printers under $200: Anet A8 Desktop 3D Printer

● 220 x 220 x 240mm printing volume, just right for you

● Piano-black laser-cut acrylic frame for maintain the garage-built feel and the handmade charm

● All metal pulleys for improved functionality and performance

● Quick-release feed gears for faster and fluent filament feeding

● Stainless steel rail rods, gears, bearings and connectors for smooth and precise movement

● Suitable for a wide range of customers, young or old, professional or amateur etc.

● Multiple 3D printing filament supportable, ABS / PLA / wood / PVA / PP / luminescent

- The best 3D printers under $300: Alfawise U30 Pro

● The latest open source Marlin firmware for total control of the 3D printer, makers' freedom

● Plug-and-play TMC2208 stepper motor driver, also for smooth operation and precise printing

● Humanized UI design, the operation is more simple and convenient.

● Super large nut, easier for levelling.

● Filament run-out protection and power outage protection guarantee successful print

● Efficient heating and uniform temperature for excellent adhesion and smooth base of prints

- The best 3D printers under $500: Creality CR - 10 V2 Updated Version

● Two-way sphenoid cooling nozzle, uniform heat dissipation in both directions, with heat dissipation channel, the printing is more accurate

● Compatible with far and near end feeding, guarantee the fast and precise printing

● Full metal extrusion mechanism for stable wear resistance

● Compatible with BL-touch automatic and manual leveling, give you additional option

● TMC2208 ultra-quiet drive, silent printing, user-friendly design

● Power failure detection and filament run-out detection, save your labor and no worry about time

3. Supported filaments of 3D printers

Supported filaments of 3D printers

3D printer filaments are mainly PLA, ABS, PETG, TPU and wood. If you tend to use multiple types of materials in your model, you must first ensure that you find a compatible 3D printer. Only in this way can you complete the printing task.

4. Print speed, accuracy, and layer thickness of 3D printers

The three parameters of speed, accuracy, and layer thickness are related to each other. The finer the accuracy of 3D printing, the smaller the layer thickness, but the slower the printing speed. When the printing speed becomes faster, the thicker the layer is, the rougher the model is. When printing the model, you can balance the parameters according to the model effect.

5. Nozzle diameter of 3D printers

Generally, the nozzle diameters of 3D printers are 0.4mm and 0.8mm. The larger the diameter of the nozzle the thicker the consumables that are printed on a layer, the less the level of printing, the less the number of nozzle movements and the printing time quick. If you want to make the texture of the printed model surface more fine, use a small diameter nozzle.

3 Best LCD 3D Printers in 2020

With the continuous development of the 3D printing industry, 3D printer models are also emerging. Major manufacturers continue to introduce new ones. 3D printing research and development technology is constantly improving, producing a large number of high-performance and high-precision 3D printers. Here we have organized 3 best LCD 3D Printers for you.

| Brand model | NOVA3D LCD 3D Printer | Creality LD-002R LCD 3D Printer | LOTMAXX CH-10 LCD 3D Printer |

| Price | $379.99 | $279.99 | $369.99 |

| Print size | 130 x 70 x 150mm | 119 x 65 x 160mm | 120 x 68 x 155mm |

| Print speed | 30 - 40mm/h | 50 - 70mm/h | 20mm / h |

| Print layer thicknes | 0. | 0.02 - 0.05mm | 0.025 - 0.1 mm |

| Touch screen | 4.3 inch | 3.5 inch | 3.5 inch |

| Print material | Resin | Resin | Resin |

| Why buy this | Support automatic / manual leveling Intelligent cooling and cooling Uniform light source to ensure print quality | 2K solid-state display system with high accuracy Super carbon filtering system to reduce printing odor Uniform light source to ensure print quality | Fast slicing speed, automatic detection Support edge anti-aliasing setting, easy to operate Hollow model can save resin Support hierarchical preview of the model Quiet printing |

Techno Print 3D Company

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

XYZprinting, best known for its daVinci line of desktop 3D printers, is bringing five new devices to the professional and industrial environment. One will use laser sintering technology, the second full color inkjet printing and three DLP machines. First of all, the novelties will be of interest to dentists and jewelers. Read more→

Cleaning the nozzle of a 3D printer is a fairly common process that any user of such a device has to deal with. This is not at all a complicated procedure that anyone can handle. You can complete this task in 15 minutes, using only handy tools and accessories. Read more→

Acetone steam polishing of ABS plastic is a process for smoothing the surface of 3D printed models. The result of this treatment makes your printed products look as if they were made by a professional mold casting method. If you want to understand how this is done correctly, then read this article. Aceto Read more→

If you want to understand how this is done correctly, then read this article. Aceto Read more→

Part 2. KAMAZ 432690 on a 3D printer: assembly, painting and result

3D printing

I continue the story about KamAZ fully printed on a 3D printer in 12th scale. Models of this project you can download on the sites: MyMiniFactory and Cults3D.

In the last article, I talked about the development and printing of this truck, and today I will show the assembly process and the result!

Assembling

As I wrote earlier, I am building this project on a universal chassis, on which the KamAZ Master hood has already been assembled. The frame parts of this chassis are connected with M2 screws and nuts. Frame printed with 60% infill and 4mm wall thickness. The arm and shock brackets are glued to the frame with dichloromethane, so I use a 3m respirator and nitrile gloves when gluing the parts together.

Fig. 1 Frame, axles, gearmotor, transfer case and wheels are fully 3D printed (except for bearings, screws and electronics)

Chassis mounted brushless motor size 3650 (36 mm diameter and 50 mm motor length without shaft), motor control unit, transmitter and LiPo battery 2S (7. 4 Volts). You can mount a brushed motor on this chassis if you like crawling. With it, we get the opportunity to start smoothly and not slip into slippage, as on a brushless motor (which, unlike a collector motor, makes it possible to turn nickels and accelerate faster).

4 Volts). You can mount a brushed motor on this chassis if you like crawling. With it, we get the opportunity to start smoothly and not slip into slippage, as on a brushless motor (which, unlike a collector motor, makes it possible to turn nickels and accelerate faster).

⠀ Fig. 2 Capotite KamAZ and assembled chassis, on which a body and cabin are easily installed using several screws

Painting

painted with Tamiev paints from airbrush without preliminary processing of plastic and cheating. . I ordered the printing of logos in a printing house on a UV plotter with white on a transparent adhesive tape. I developed the logo layout myself, it is freely available at the link. After applying the stickers, I covered the model with semi-matt Tamiya varnish.