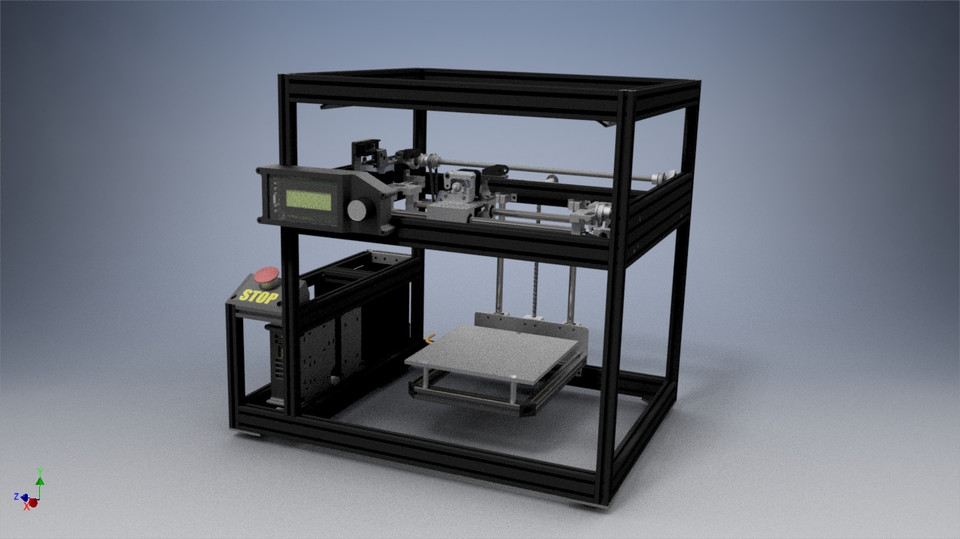

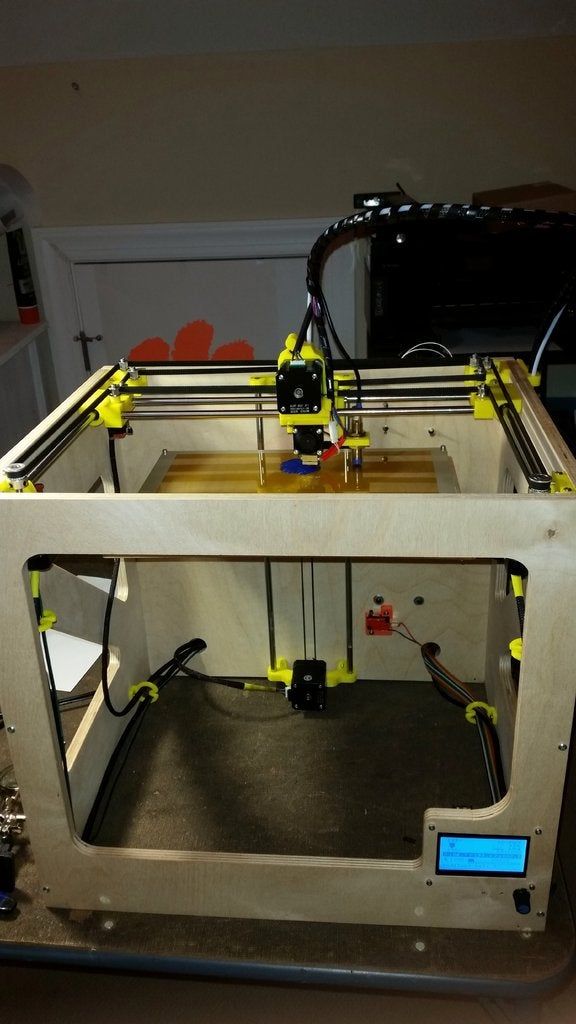

Ipro 3d printer

sPro 230 3D Printer | 3D Systems

Large Capacity Production of Thermoplastic Parts

Building large parts up 750 mm in one piece increases part strength, as attachment points can present a weakness in a part. Building the part in one piece also frees additional resources that would be occupied with the assembly of the different segments. The sPro™ 230 is also ideal for volume production of 3D printed small to medium sized parts.

3D Systems sPro 230 Prints in a Range of Production-Grade Duraform Nylon Materials

About this printer

-

Applications

-

Benefits

-

Tech Specs

Applications

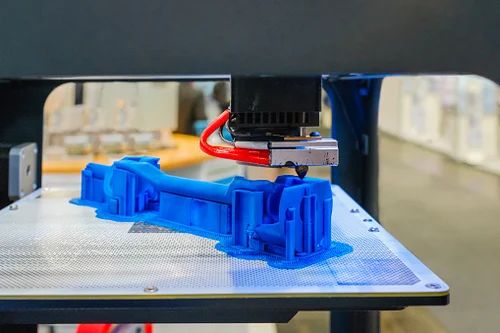

- Impact-resistant, durable parts

- Engine housings and other protective covers

- Large parts produced in one single piece

- Knobs, handles, and other dashboard/interior parts

- Jigs and fixtures

- Reduced weight production parts

- Machinery components

- Lightweight ductwork

- Small to medium run manufacturing

- Healthcare devices and tools manufacturing

Benefits

- Manufacture strong end-use parts and functional prototypes faster

- Produce large whole nylon parts

- Easily print any design without using supports or post processing

- Integrated printer and material solution with expert application support

- Lower cost of ownership with high throughput and capacity

- Superior living hinges, snap fit and other mechanical joints

Tech Specs

- Selective Laser Sintering (SLS) technology

- Max build envelope capacity (W x D x H): 22 x 22 x 30 in (550 x 550 x 750 mm)

- Broad range of DuraForm production-grade nylon 11, nylon 12 and reinforced materials

- High throughput, high-capacity printer

- Automated 3D part nesting

- 3D Sprint® additive manufacturing software supports as a virtual environment

- Open material architecture – flexible print parameters

-

3D printing with plastics offers many choices for engineering grade materials, elastomers and composites.

Do you need flexibility? Strength? Bio-compatibility? More?

-

3D print with plastics to build almost anything - used for prototyping, manufacturing, anatomical models and more. Select a plastic material and 3D technology to deliver the characteristics you need.

Interested in purchasing this printer?

You must have JavaScript enabled to use this form.

First Name

Last Name

Business Email

Company

Country -- Select Country --AfghanistanAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntarcticaAntigua & BarbudaArgentinaArmeniaArubaAscension IslandAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBosnia & HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBritish Virgin IslandsBruneiBulgariaBurkina FasoBurundiCambodiaCameroonCanadaCanary IslandsCape VerdeCaribbean NetherlandsCayman IslandsCentral African RepublicCeuta & MelillaChadChileChinaChristmas IslandClipperton IslandCocos (Keeling) IslandsColombiaComorosCongo - BrazzavilleCongo - KinshasaCook IslandsCosta RicaCroatiaCuraçaoCyprusCzechiaCôte d’IvoireDenmarkDiego GarciaDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEswatiniEthiopiaFalkland IslandsFaroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHeard & McDonald IslandsHondurasHong Kong SAR ChinaHungaryIcelandIndiaIndonesiaIraqIrelandIsle of ManIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKosovoKuwaitKyrgyzstanLaosLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacao SAR ChinaMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesiaMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmar (Burma)NamibiaNauruNepalNetherlandsNetherlands AntillesNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorthern Mariana IslandsNorth MacedoniaNorwayOmanOutlying OceaniaPakistanPalauPalestinian TerritoriesPanamaPapua New GuineaParaguayPeruPhilippinesPitcairn IslandsPolandPortugalPuerto RicoQatarRomaniaRussiaRwandaRéunionSamoaSan MarinoSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSint MaartenSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia & South Sandwich IslandsSouth KoreaSouth SudanSpainSri LankaRepublic of Sudan (North Sudan)St. BarthélemySt. HelenaSt. Kitts & NevisSt. LuciaSt. MartinSt. Pierre & MiquelonSt. Vincent & GrenadinesSurinameSvalbard & Jan MayenSwedenSwitzerlandSão Tomé & PríncipeTaiwanTajikistanTanzaniaThailandTimor-LesteTogoTokelauTongaTrinidad & TobagoTristan da CunhaTunisiaTurkeyTurkmenistanTurks & Caicos IslandsTuvaluU.S. Outlying IslandsU.S. Virgin IslandsUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVatican CityVenezuelaVietnamWallis & FutunaWestern SaharaYemenZambiaZimbabweÅland Islands

BarthélemySt. HelenaSt. Kitts & NevisSt. LuciaSt. MartinSt. Pierre & MiquelonSt. Vincent & GrenadinesSurinameSvalbard & Jan MayenSwedenSwitzerlandSão Tomé & PríncipeTaiwanTajikistanTanzaniaThailandTimor-LesteTogoTokelauTongaTrinidad & TobagoTristan da CunhaTunisiaTurkeyTurkmenistanTurks & Caicos IslandsTuvaluU.S. Outlying IslandsU.S. Virgin IslandsUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVatican CityVenezuelaVietnamWallis & FutunaWestern SaharaYemenZambiaZimbabweÅland Islands

State -- Select State --Buenos AiresCatamarcaChacoChubutCiudad Autónoma de Buenos AiresCórdobaCorrientesEntre RíosFormosaJujuyLa PampaLa RiojaMendozaMisionesNeuquénRío NegroSaltaSan JuanSan LuisSanta CruzSanta FeSantiago del EsteroTierra del FuegoTucumánAustralian Capital TerritoryNew South WalesNorthern TerritoryQueenslandSouth AustraliaTasmaniaVictoriaWestern AustraliaBurgenlandKärntenNiederösterreichOberösterreichSalzburgSteiermarkTirolVorarlbergWienAcreAlagoasAmapáAmazonasBahiaCearáDistrito FederalEspírito SantoGoiásMaranhãoMato GrossoMato Grosso do SulMinas GeraisParáParaíbaParanáPernambucoPiauíRio de JaneiroRio Grande do NorteRio Grande do SulRondôniaRoraimaSanta CatarinaSão PauloSergipeTocantinsAlbertaBritish ColumbiaManitobaNew BrunswickNewfoundland and LabradorNorthwest TerritoriesNova ScotiaNunavutOntarioPrince Edward IslandQuebecSaskatchewanYukon TerritoriesAisén del General Carlos Ibañez del CampoAntofagastaAraucaníaArica y ParinacotaAtacamaBío-BíoCoquimboLibertador General Bernardo O'HigginsLos LagosLos RíosMagallanesMauleRegión Metropolitana de SantiagoTarapacáValparaísoAnhuiBeijingChinese TaipeiChongqingFujianGansuGuangdongGuangxiGuizhouHainanHebeiHeilongjiangHenanHong KongHubeiHunanJiangsuJiangxiJilinLiaoningMacaoNei MongolNingxiaQinghaiShaanxiShandongShanghaiShanxiSichuanTianjinXinjiangXizangYunnanZhejiangÎle-de-FranceOccitanieAuvergne-Rhône-AlpesBourgogne-Franche-ComtéBretagneCentre-Val de LoireCorseGrand EstHauts-de-FranceJuraNormandieNouvelle-AquitainePays de la LoireProvence-Alpes-Côte d'AzurBaden-WürttembergBayernBerlinBrandenburgBremenHamburgHessenMecklenburg-VorpommernNiedersachsenNordrhein-WestfalenRheinland-PfalzSaarlandSachsenSachsen-AnhaltSchleswig-HolsteinThüringenAndaman and Nicobar IslandsAndhra PradeshArunachal PradeshAssamBiharChandigarhChhattisgarhDadra and Nagar HaveliDaman and DiuDelhiGoaGujaratHaryanaHimachal PradeshJammu and KashmirJharkhandKarnatakaKeralaLakshadweepMadhya PradeshMaharashtraManipurMeghalayaMizoramNagalandOdishaPuducherryPunjabRajasthanSikkimTamil NaduTripuraUttar PradeshUttarakhandWest BengalCarlowCavanClareCorkDonegalDublinGalwayKerryKildareKilkennyLaoisLeitrimLimerickLongfordLouthMayoMeathMonaghanOffalyRoscommonSligoTipperaryWaterfordWestmeathWexfordWicklowAgrigentoAlessandriaAnconaAostaArezzoAscoli PicenoAstiAvellinoBariBarletta-Andria-TraniBellunoBeneventoBergamoBiellaBolognaBolzanoBresciaBrindisiCagliariCaltanissettaCampobassoCarbonia-IglesiasCasertaCataniaCatanzaroChietiComoCosenzaCremonaCrotoneCuneoEnnaFermoFerraraFirenzeFoggiaForlì-CesenaFrosinoneGenovaGoriziaGrossetoImperiaIserniaLa SpeziaL'AquilaLatinaLecceLeccoLivornoLodiLuccaMacerataMantovaMassa - CarraraMateraMedio CampidanoMessinaMilanoModenaMonza e BrianzaNapoliNovaraNuoroOgliastraOlbia-TempioOristanoPadovaPalermoParmaPaviaPerugiaPesaro e UrbinoPescaraPiacenzaPisaPistoiaPordenonePotenzaPratoRagusaRavennaReggio CalabriaReggio EmiliaRietiRiminiRomaRovigoSalernoSassariSavonaSienaSondrioSiracusaTarantoTeramoTerniTrapaniTrentoTrevisoTriesteTorinoUdineVareseVeneziaVerbano-Cusio-OssolaVercelliVeronaVibo ValentiaVicenzaViterboAichiAkitaAomoriChibaEhimeFukuiFukuokaFukushimaGifuGunmaHiroshimaHokkaidoHyogoIbarakiIshikawaIwateKagawaKagoshimaKanagawaKochiKumamotoKyotoMieMiyagiMiyazakiNaganoNagasakiNaraNiigataOitaOkayamaOkinawaOsakaSagaSaitamaShigaShimaneShizuokaTochigiTokushimaTokyoTottoriToyamaWakayamaYamagataYamaguchiYamanashiBusanDaeguDaejeonGangwonGwangjuGyeonggiIncheonJejuNorth ChungcheongNorth GyeongsangNorth JeollaSeoulSouth ChungcheongSouth GyeongsangSouth JeollaUlsanJohorKedahKelantanMelakaNegeri SembilanPahangPerakPerlisPulau PinangSabahSarawakSelangorTerengganuWilayah Persekutuan Kuala LumpurWilayah Persekutuan LabuanWilayah Persekutuan PutrajayaAguascalientesBaja CaliforniaBaja California SurCampecheChiapasChihuahuaCoahuilaColimaDurangoFederal DistrictGuanajuatoGuerreroHidalgoJaliscoMexico StateMichoacánMorelosNayaritNuevo LeónOaxacaPueblaQuerétaroQuintana RooSan Luis PotosíSinaloaSonoraTabascoTamaulipasTlaxcalaVeracruzYucatánZacatecasŚląskieŁódzkieŚwiętokrzyskieDolnośląskieKujawsko-pomorskieLubelskieLubuskieMałopolskieMazowieckieOpolskiePodkarpackiePodlaskiePomorskieWarmińsko-mazurskieWielkopolskieZachodniopomorskieAdygeya, RespublikaAltay, RespublikaAltayskiy krayAmurskaya oblast'Arkhangel'skaya oblast'Astrakhanskaya oblast'Bashkortostan, RespublikaBelgorodskaya oblast'Bryanskaya oblast'Buryatiya, RespublikaChechenskaya RespublikaChelyabinskaya oblast'Chukotskiy avtonomnyy okrugChuvashskaya RespublikaDagestan, RespublikaIngushetiya, RespublikaIrkutskaya oblast'Ivanovskaya oblast'Kabardino-Balkarskaya RespublikaKaliningradskaya oblast'Kalmykiya, RespublikaKaluzhskaya oblast'Kamchatskiy krayKarachayevo-Cherkesskaya RespublikaKareliya, RespublikaKemerovskaya oblast'Khabarovskiy krayKhakasiya, RespublikaKhanty-Mansiyskiy avtonomnyy okrug-YugraKirovskaya oblast'Komi, RespublikaKostromskaya oblast'Krasnodarskiy krayKrasnoyarskiy krayKurganskaya oblast'Kurskaya oblast'Leningradskaya oblast'Lipetskaya oblast'Magadanskaya oblast'Mariy El, RespublikaMordoviya, RespublikaMoskovskaya oblast'MoskvaMurmanskaya oblast'Nenetskiy avtonomnyy okrugNizhegorodskaya oblast'Novgorodskaya oblast'Novosibirskaya oblast'Omskaya oblast'Orenburgskaya oblast'Orlovskaya oblast'Penzenskaya oblast'Permskiy krayPrimorskiy krayPskovskaya oblast'Rostovskaya oblast'Ryazanskaya oblast'Sakha, RespublikaSakhalinskaya oblast'Samarskaya oblast'Sankt-PeterburgSaratovskaya oblast'Severnaya Osetiya-Alaniya, RespublikaSmolenskaya oblast'Stavropol'skiy kraySverdlovskaya oblast'Tambovskaya oblast'Tatarstan, RespublikaTomskaya oblast'Tul'skaya oblast'Tverskaya oblast'Tyumenskaya oblast'Tyva, RespublikaUdmurtskaya RespublikaUl'yanovskaya oblast'Vladimirskaya oblast'Volgogradskaya oblast'Vologodskaya oblast'Voronezhskaya oblast'Yamalo-Nenetskiy avtonomnyy okrugYaroslavskaya oblast'Yevreyskaya avtonomnaya oblast'Zabaykal'skiy krayCentral SingaporeNorth EastNorth WestSouth EastSouth WestA CoruñaÁlava / ArabaAlbaceteAlicante / AlacantAlmeríaAsturiasÁvilaBadajozBalearsBarcelonaBurgosCáceresCádizCantabriaCastellón / CastellóCiudad RealCórdobaCuencaGironaGranadaGuadalajaraGuipúzcoa / GipuzkoaHuelvaHuescaJaénLa RiojaLas PalmasLeónLleidaLugoMadridMálagaMurciaNavarra / NafarroaOurensePalenciaPontevedraSalamancaSanta Cruz de TenerifeSegoviaSevillaSoriaTarragonaTeruelToledoValencia / ValènciaValladolidVizcaya / BizkaiaZamoraZaragozaAargauAppenzell AusserrhodenAppenzell InnerrhodenBasel-LandschaftBasel-StadtBernFribourgGenèveGlarusGraubündenJuraLuzernNeuchâtelNidwaldenObwaldenSankt GallenSchaffhausenSchwyzSolothurnThurgauTicinoUriValaisVaudZugZürichChanghua CountyChiayi CityChiayi CountyHsinchu CityHsinchu CountyHualien CountyKaohsiung CityKaohsiung CountyKeelung CityMiaoli CountyNantou CountyPenghu CountyPingtung CountyTaichung CityTaichung CountyTainan CityTainan CountyTaipei CityTaipei CountyTaitung CountyTaoyuan CountyYilan CountyYunlin CountyŞırnakŞanlıurfaİstanbulİzmirAğrıAd?yamanAdanaAfyonkarahisarAksarayAmasyaAnkaraAntalyaArdahanArtvinAydınBalıkesirBartınBatmanBayburtBilecikBingölBitlisBoluBurdurBursaÇanakkaleÇankırıÇorumDenizliDiyarbakırDüzceEdirneElazığErzincanErzurumEskişehirGaziantepGiresunGümüşhaneHakkâriHatayIğdırIspartaKırşehirKırıkkaleKırklareliKahramanmaraşKarabükKaramanKarsKastamonuKayseriKilisKocaeliKonyaKütahyaMalatyaManisaMardinMersinMuşMuğlaNevşehirNiğdeOrduOsmaniyeRizeSakaryaSamsunSiirtSinopSivasTekirdağTokatTrabzonTunceliUşakVanYalovaYozgatZonguldakCrimeaCherkasyChernihivChernivtsiDnipropetrovskDonetskIvano-FrankivskKharkivKhersonKhmelnytskyiKirovohradKyivLuhanskLvivMykolaivOdesaPoltavaRivneSumyTernopilVinnytsiaVolynZakarpattiaZaporzhzhiaZhytomyrAberdeen CityAberdeenshireAngusAntrimArgyll and ButeArmaghAvonBanffshireBedfordshireBerkshireBlaenau GwentBordersBridgendBristolBuckinghamshireCaerphillyCambridgeshireCardiffCarmarthenshireCeredigionChannel IslandsCheshireClackmannanshireClevelandConwyCornwallCumbriaDenbighshireDerbyshireDevonDorsetDownDumfries and GallowayDurhamEast AyrshireEast DunbartonshireEast LothianEast RenfrewshireEast Riding of YorkshireEast SussexEdinburghEssexFalkirkFermanaghFifeFlintshireGlasgowGloucestershireGreater ManchesterGwyneddHampshireHerefordshireHertfordshireHighlandHumbersideInverclydeIsle of AngleseyIsle of ManIsle of WightIsles of ScillyKentLancashireLeicestershireLincolnshireLondonLondonderryMerseysideMerthyr TydfilMiddlesexMidlothianMonmouthshireMorayNeath Port TalbotNewportNorfolkNorth AyrshireNorth East LincolnshireNorth LanarkshireNorth YorkshireNorthamptonshireNorthumberlandNottinghamshireOrkneyOuter HebridesOxfordshirePembrokeshirePerthshire and KinrossPowysRenfrewshireRhondda, Cynon, TaffRoxburghshireRutlandShetlandShropshireSomersetSouth AyrshireSouth LanarkshireSouth YorkshireStaffordshireStirlingSuffolkSurreySwanseaTorfaenTyne and WearTyroneVale of GlamorganWarwickshireWest DunbartonshireWest LothianWest MidlandsWest SussexWest YorkshireWiltshireWorcestershireWrexhamAlabamaAlaskaAmerican SamoaArizonaArkansasCaliforniaColoradoConnecticutDelawareDistrict of ColumbiaFederated MicronesiaFloridaGeorgiaGuamHawaiiIdahoIllinoisIndianaIowaKansasKentuckyLouisianaMaineMarshall IslandsMarylandMassachusettsMichiganMinnesotaMississippiMissouriMontanaNebraskaNevadaNew HampshireNew JerseyNew MexicoNew YorkNorth CarolinaNorth DakotaNorthern Mariana IslandsOhioOklahomaOregonPalauPennsylvaniaPuerto RicoRhode IslandSouth CarolinaSouth DakotaTennesseeTexasUnited States Minor Outlying IslandsUS Virgin IslandsUtahVermontVirginiaWashingtonWest VirginiaWisconsinWyoming

Industry - None -Academic & ResearchAerospace & DefenseDentalHealthcareManufacturing & PrototypingTransportation & Motorsports

Sub-Industry - Select -Medical Device ManufacturersMedical Contract ManufacturersHospital or Medical ClinicMedical SchoolsOther HealthcareDental ClinicsDental Equipment ManufacturersDental LabsDental SchoolsOther DentalMilitary AviationCommercial AviationDefenseSpace & UAVOther Aerospace & DefenseAutomotiveTruck, Bus & RailMotorsportsAftermarket & ServiceRecreation & MarineOther Transportation3D Printing Service BureausFoundriesElectronics & ConnectorsSemiconductorTurbomachineryJewelryConsumer & Durable GoodsOther Manufacturing

Address

Postal Code

Job Level -- Select Job Level --C-LevelPresident or VPDirectorManagerProfessional StaffConsultant or ContractorIntern or StudentHobbyist

Job Function -- Select Job Function --Engineering - SoftwareEngineering - HardwareManufacturingFinanceITLegalMarketingPurchasingSalesService Technician - HardwareService Technician - SoftwareOther

Level of Interest -- Select Your Level of Interest --Beginning ResearchEvaluating Solutions and CompetitorsInterested in Buying in 1-3 MonthsInterested in Buying in 3-6 MonthsInterested in Buying in 6-12 MonthsI would like to speak with a Solutions SpecialistI have a Support Issue or Question

Area of Interest - Select -Printers• Professional Printer (ColorJet, MultiJet)• Production Printer (SLA, SLS, Metal/DMP)• Figure 4• Titan Additive• OtherSoftwareHaptics• HapticsHealthcare• Virtual Surgical Planning• Anatomical Modeling• Kumovis Additive

3D Printer - Select -MJP• ProJet 2500• ProJet 2500 Plus• ProJet 2500W• ProJet 2500 IC• ProJet 3600• ProJet 5600CJP• ProJet 260 Plus• Projet 360• ProJet 460 Plus• ProJet 660Pro• ProJet 860ProDMP• DMP Flex 100• ProX 200• DMP Flex 200• DMP Flex 350• DMP Factory 350• DMP Factory 500• ProX 100• ProX 300SLS• SLS 6100• SLS 380• sPro 140• sPro 230SLA• SLA 750• ProJet 6000• ProJet 7000• ProX 800• ProX 950Figure 4• Figure 4 Standalone• Figure 4 Modular• Figure 4 Production• Figure 4 JewelryNextDent• NextDent 5100Kumovis• Kumovis R1Atlas• Atlas H• Atlas HSMaterialsBioprinter

Software product - Select -3D Connect Manage3D Connect Service3D Modeling Services3D Sprint3D Sprint Pro for SLA3DXpertGeomagic Control XGeomagic Design XGeomagic for SOLIDWORKSGeomagic FreeformGeomagic SculptGeomagic TouchGeomagic Touch XGeomagic WrapOpenHapticsPhantom Premium

Area of Interest - Select -Medical Device Design and ManufacturingMedical SimulatorsAnatomical ModelsD2P SoftwareDental Manufacturing and Design Services

I consent to receive 3D Systems CommunicationsWould you like to receive special offers, product updates, and event news from 3D Systems? By clicking "Yes", you agree to receive follow-up communications from 3D Systems or our partners. You can also choose to opt out of communications at any time. Please click here to view our Privacy Policy or click here to manage your Preferences.

You can also choose to opt out of communications at any time. Please click here to view our Privacy Policy or click here to manage your Preferences.

Area of Interest - None -Appearance ModelsCast UrethaneCJPCNCCNC MetalCNC PlasticDie CastingDigitalization/ScanningDMPEngineering ProjectsFDMInjection MoldingInjection ToolingInvestment CastingInvestment Casting PatternJigs and FixturesMetal CastingMJPMJP-ElastomersQuick Cast PatternsRIMSheet MetalSLASLSToolingVacuum castingVacuum forming

Custom Area of Interest

PPP

PST

Software

Healthcare

ODM

Area of interest Required

This site is protected by reCAPTCHA. The Google Privacy Policy and Terms of Service apply.

You Might Also Be Interested In

sPro 140

High repeatability and throughput of sls production parts

ProX SLS 6100

Production-grade nylon 3D printer delivering best-in-class part quality, fast build times and automated production tools

2020 Industrial Polymer 3D Printer Buying Guide - 3DPrint.

com

comIndustrial 3D printers are those used by companies on the factory floor, generally for manufacturing end products. In a lot of cases, they can also be used for making items such as jigs and fixtures or tooling for manufacturing. In many instances, this ancillary use is more widespread than the dedicated manufacture of millions of products. Millions of dental crowns, dental intermediates, hearing aids, and jewelry casts are being made with 3D printing, but apart from these cases, high volume manufacturing is still quite rare in 3D printing.

It is important to note that there is no such thing as “the best” 3D printer. Depending on your workflow, the amount of space you have, throughput, the materials you use and even the shape of the objects you print, one or another machine could be better. Depending on the size, detail, strength, and wall thickness of a part, many variables could make one system the obvious choice.

To give you one example: in choosing whether to use two vat photopolymerization technologies, stereolithography (SLA) or digital light processing (DLP), and then which machine in each of these categories to use, companies were often lead more by their previous experiences in manufacturing more than the technologies or machines themselves. Firms that were used to large machines with a light on top, in my experience, tended to go for the large iPro SLA systems from 3D Systems. Meanwhile, other firms that were used to desk-side manufacturing were more attracted to Envisiontec DLP.

Firms that were used to large machines with a light on top, in my experience, tended to go for the large iPro SLA systems from 3D Systems. Meanwhile, other firms that were used to desk-side manufacturing were more attracted to Envisiontec DLP.

We could have evaluated these technologies until the cows come home, but we must not forget that a specific organization will be implementing 3D printing within the confines of a particular application and specific process. These factors will drive choice and adoption more so than a spec table or beauty parade.

With this in mind, this guide is simply here to help direct your exploration in researching and acquiring an industrial 3D printing system. We know you’re not going to impulse-buy a $750,000 3D printer based on a blog post, nor should you. But, we’ve interviewed resellers and users of all kinds to establish some of the most interesting systems for you to consider. We know that a top ten list would lead to more clicks, but this approach should be more useful to you.

A lifting tool made by Wartsila printed on an X7 in Carbon Fiber.

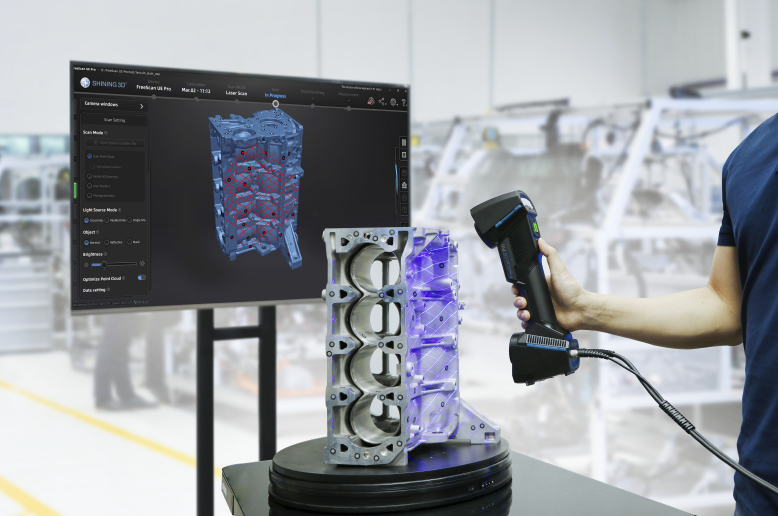

The Markforged X7 is the most heavily outfitted of the firm’s continuous filament fabrication machines, capable of feeding continuous carbon or glass fiber material alongside chopped carbon-filled nylon to create reinforced fused filament fabrication (FFF)-style parts. Geometric freedom may be limited when compared to other systems, but part strength is high due to continuous or chopped fiber strands being printed along with your part. A nifty feature of the X7 is a built-in 3D scanner which makes a contour map that optimizes nozzle adjustments during the printing process. Markforged’s Eiger software still outperforms the rest of the industry and it is key to making it easy to print and manage X7s in shared spaces, labs, and production areas. The X7 costs around $69,000.

Stratasys J750 Digital Anatomy Printer, J700, J720, J850 and J55Models for animation studio Laika printed on the J750.

The J750 from Stratasys is a PolyJet system that jets and cures a photopolymer. It can print color and gradient materials. Parts off of this machine are amazing and can be soft or hard, which can be used, for example, to replicate and simulate tissue and cartilage. Stratasys has released this system with industry and application-specific external research and materials that have been developed just for printing polymer anatomical models.

The company also offers J700 and J720 printers specific to the dental industry. The J850 is a more general system set up for design labs and shared services offering 3D printing for corporate customers. The J55 is meant to be an “entry-level” machine for a mere $100,000. The PolyJet family has a very high cost per part and the materials make manufacturing with them cost-prohibitive. But, if you want colorful, great-finish prototypes in-house, this family of printers will be an excellent choice. These things are perfect for digital anatomy in hospitals, the design centers of major automotive brands, large consumer electronics or fast moving consumer goods companies.

One thing 3NTR machines are uniquely capable of doing is printing flexible and rigid FDM materials in one part. Here is a TPU and ASA component for Denso.

3ntr’s FFF systems are strong and tough, made for production from the ground up. With liquid-cooled printheads, 3ntr machines will see engineers will fall in love with their insides. We’ve heard great things from people using these things in series production as well. Print quality is not amazing, but reliability and repeatability are very high. These machines are born to live out a life on the concrete factory floors, built by a family firm, a brassiere manufacturer, in Oleggio near Milan.

Systems for High-Temperature MaterialsIntamsys Funmat Pro 610 HTThe Intamsys Funmat Pro 610 HT is a capable, high-temperature machine that is especially good with PEI. Intamsys has offered affordable high-temperature systems since inception. Not perfect, they nevertheless represent great value. Intamsys systems have become much easier to use over the past several years. Systems used to be a little rough around the edges. Now better user interfaces, controls, and designs mean that the newest systems not only look slicker but are easier to use as well.

Not perfect, they nevertheless represent great value. Intamsys systems have become much easier to use over the past several years. Systems used to be a little rough around the edges. Now better user interfaces, controls, and designs mean that the newest systems not only look slicker but are easier to use as well.

Roboze’s Argo has a nozzle that can reach 450°C and a chamber temperature that can reach 180°C. The 500 X 500 X 500 mm build volume is accommodating; the vacuum bed works well and there is a preheating chamber for materials. With two independent geared extruders, these beltless 3D printers are much better than Roboze’s earlier offering. The Argo 500 also has a smaller sister the Argo 350. Roboze is also doing a lot of work on materials. While the printers are open, the company has done considerable optimization for its own ULTEM AM9085F, Carbon Polyamide, Carbon PEEK and PEEK offering.

3DGence Industry F420A PEEK part with support, printed on a 3DGence F420.

3DGence has developed a remarkably replete offering and its printers are appreciated by users. Well-engineered and built, they are fast and reliable. The printer has four bays for heating materials and different optimal nozzles for different materials. 3DGence has also worked on software, coming out with a competent slicing package, which is local, and a cloud-based model and print management solution.

The company has also optimized its materials. Compared to other firms, 3DGence has done a lot of work on support material and the optimization of typically-finicky supports. The company offers a HIPS for ABS, ESM 10 which is a water-soluble support for PEEK that I still can’t really get my head around, and a water-soluble BVOH (butene-diol vinyl alcohol, try it!) for PLA. The company also sells a dryer and a support removal system, rounding out a very complete offering.

Minifactory UltraThe Minifactory machines I’ve evaluated always do well. The small Finnish company builds them to high quality and high specifications. Now, the firm has added the Aarni Process Monitoring System to its offering, which allows you to display and collate data for monitoring, optimization, and quality control. Aarni can be used to certify parts and work with traceability systems. This really shows that the firm is conducting the smart engineering needed to offer high-end manufacturers a solution that they can use for critical parts.

The small Finnish company builds them to high quality and high specifications. Now, the firm has added the Aarni Process Monitoring System to its offering, which allows you to display and collate data for monitoring, optimization, and quality control. Aarni can be used to certify parts and work with traceability systems. This really shows that the firm is conducting the smart engineering needed to offer high-end manufacturers a solution that they can use for critical parts.

The AON3D M2 is a dual head high-temperature machine with low heat bleed in the chamber. It has dual independently moving tool heads and liquid cooling. The hot end runs at 470°C, while the heated bed reaches 200°C and the build chamber reaches 135°C. The build volume is 454 x 454 x 640 mm. Montreal-based AON doesn’t have a software offering (it uses Simplify3D) or focus as much on the ecosystem approach, as some of its competitors do.

Large-Scale Manufacturing of Fine and Highly Detailed ItemsEnvisionTEC Perfactory P4Ke-shell material hearing aid shells on a Perfactory print platform.

The EnvisionTEC Perfactory is the granddad of industrial production systems. First on the market in 2002, this line of systems has made tens of millions of intermediates for jewelry and hearing aids. The current version is the P4K, which uses a DLP 4M projector and comes with new optimized materials for hearing aids, transparent parts and more durable parts. These things are simply un-killable and keep on working for years.

3D Systems Figure 4The Figure 4 is a highly automated system with integrated post-processing. Not widely used at the moment, but early signs are very encouraging, especially for small parts at very high volume. Available with dental or jewelry-specific modules and in a Production or Modular variant.

Large-Scale Manufacturing of Tough End-Use PartsEOS Integra P400Rendering of Integra P 400 [Image: EOS]

The Formiga P110 Velocis is probably still my favorite printer because I love the versatility that several of these systems can give you in terms of modular production and because they’ll print just about most things that you throw at them. EOS also has highly automated behemoth,s such as the P500. But, the very different US made Integra p400 was built to be versatile, adaptable, and be integrated into production lines.

EOS also has highly automated behemoth,s such as the P500. But, the very different US made Integra p400 was built to be versatile, adaptable, and be integrated into production lines.

The Stratasys F900 should also be considered when looking at high-temperature machines. This is an extremely good system for FDM industrial parts, offering high reliability, repeatability and detail. Stratasys now has made moves to widen its materials offering through partnerships with Solvay and others, which should do much to address its limited materials when compared to the open printers on the market. It now has PEKK, ULTEMs, PPSF, Nylon, etc. for a total of 16 materials. At the same time, however, because it is so well-dialed into Stratasys’ own material offering, this is a great machine that works like a charm.

HP 5200The HP 5200 now has polypropylene which will be a fantastic material for a lot of new applications. PA 11 and TPUs also make more possible. HP really is expanding its offering and materials at a considerable pace. Especially for large volume manufacturing, the company now offers a lot of value and is considerably more affordable at a cost per part.

PA 11 and TPUs also make more possible. HP really is expanding its offering and materials at a considerable pace. Especially for large volume manufacturing, the company now offers a lot of value and is considerably more affordable at a cost per part.

You can find our 2019 Industrial 3D Printer Buying Guide here.

Subscribe to Our Email Newsletter

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 2020 • 2020 predictions • 3d printers • 3d printing guide • AM • Buyer Guides • Fortus • guide • integra p400 • j55 • J750 • J850 • list • m900 • polymer 3D printing • roboze • roboze argo

Please enable JavaScript to view the comments powered by Disqus.

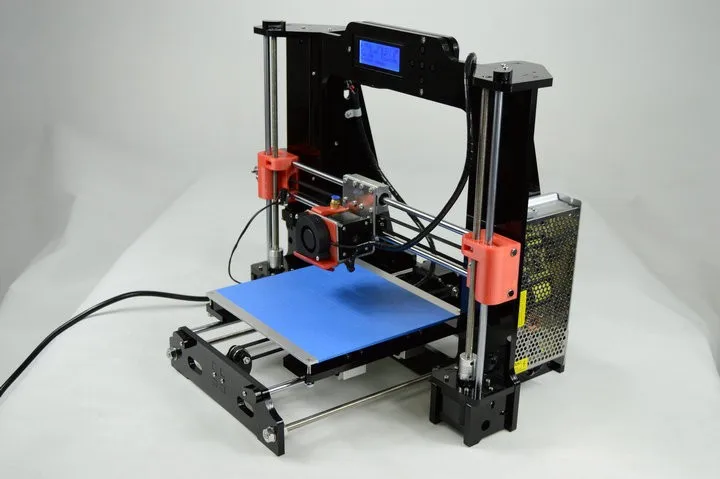

High Temperature 3D Printing to the Masses / Sudo Null IT News

There is an impressive variety of thermoplastics that can be printed on consumer grade desktop 3D printers. But, despite this, most often users turn to polylactide (PLA) threads. This is not only the cheapest of materials, but also the easiest to work with. Its extrusion can already be carried out at a temperature of 180 °C, and good results can be obtained even without preheating the table. The disadvantage of PLA-printed objects is that they are relatively brittle and do not tolerate high temperatures well. For prototyping or printing low-stress components, PLA is great. However, many users quickly go beyond its capabilities.

But, despite this, most often users turn to polylactide (PLA) threads. This is not only the cheapest of materials, but also the easiest to work with. Its extrusion can already be carried out at a temperature of 180 °C, and good results can be obtained even without preheating the table. The disadvantage of PLA-printed objects is that they are relatively brittle and do not tolerate high temperatures well. For prototyping or printing low-stress components, PLA is great. However, many users quickly go beyond its capabilities.

Polyethylene terephthalate (PETG) is usually the next step. It is not much harder to work with compared to PLA, while it is more reliable and can withstand higher temperatures. In general, it is better suited for creating mechanically loaded parts. But if you need to make even stronger and more heat resistant parts, you can switch to acrylonitrile butadiene styrene (ABS), polycarbonate (PC) or nylon. And this is where the problems begin. These materials are extruded at temperatures over 250°C and closed chambers are recommended for best results. These printers are at the top of the budget range that hobbyists are willing to work with.

These printers are at the top of the budget range that hobbyists are willing to work with.

Industrial 3D printers like this one, the Apium P220, start at around $30,000. (PAEK, PEEK, PEKK). Components made from these plastics are suitable for aerospace applications as they can replace metal while remaining much lighter.

Such plastics need to be extruded at temperatures of around 400°C, and a sealed chamber is required for operation, the temperature in which constantly exceeds 100°C. The cheapest printers of this kind cost tens of thousands of dollars, and some models even cost six figures.

Naturally, not so long ago, the same could be said about all 3D printers. Once used only by well-equipped research labs, these machines now sit on the workbenches of hackers and hobbyists the world over. It is difficult to predict whether the same price-cutting race will start for high-temperature 3D printers, but the first steps to democratize the technology have already been made.

Engineering difficulties

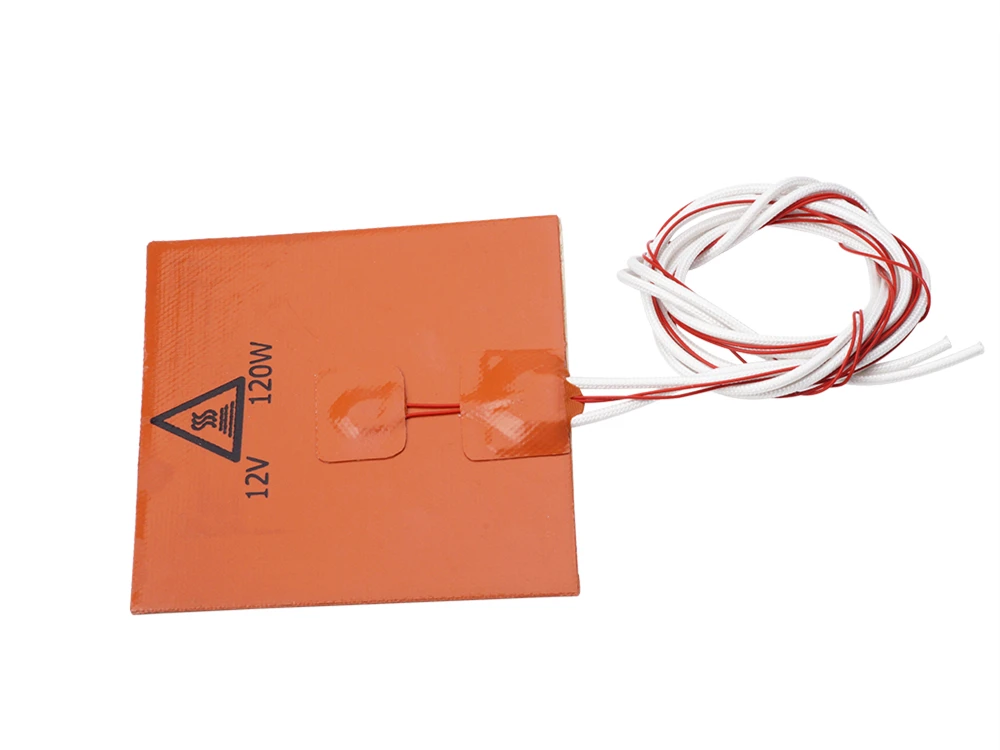

Simply put, a machine that supports these so-called. "engineering plastics", you need to be a hybrid of a 3D printer and a stove. This, of course, is the main problem. The printer itself - of the type and quality we are accustomed to seeing on our desks - will not survive in such conditions. In order for a consumer printer to produce PEI and PEEK plastic parts, it needs to be seriously redesigned. This is exactly what NASA did with the LulzBot TAZ 4 in 2016.

LulzBot TAZ 4 redesigned to support high temperature printing

The first step was to design an insulated housing to fit the TAZ 4 and install a set of 35W infrared lamps for heating. Under such conditions, the printer's electronics would naturally overheat - so it had to be taken outside.

Stepper motors would also overheat. But instead of taking them out, the team at the Langley Research Center decided to build cooling shrouds on each of the motors through which the compressed air must circulate.

Like many desktop 3D printers, the TAZ 4 uses several printed components. Since they are ABS, they would quickly break down in a chamber designed to support PEEK. They were printed from PC, but even this material was not resistant enough for permanent use. In classic RepRap tradition, the team printed the last, third set of components on their most modified printer, in PEI plastic, commercially named Ultem.

Surprisingly, the team had no trouble changing the printer's nozzle to one that could extrude plastic at 400°C. The popular E3D-v6 extruder costs less than $100 and has been shown to be able to maintain this temperature. True, the team had to replace the thermistor with a better one, as well as edit the Marlin firmware so that it allowed it to reach high temperatures. For conventional printers, too high a temperature should cause an emergency shutdown.

Printing results from Ultem 1010 plastic on a redesigned LulzBot TAZ 4.

In the end, the NASA report indicated that the redesign of the LulzBot TAZ 4 was a complete success. They noted that an attempt to print PEI with infrared lamps turned off ended in failure - delamination and distortion of the model, which was to be expected. They did not specify the cost of the conversion, but given that at that time the TAZ 4 cost $2200, the entire project could cost 10 times cheaper than similar commercial proposals.

They noted that an attempt to print PEI with infrared lamps turned off ended in failure - delamination and distortion of the model, which was to be expected. They did not specify the cost of the conversion, but given that at that time the TAZ 4 cost $2200, the entire project could cost 10 times cheaper than similar commercial proposals.

Starting from zero

A NASA experiment has shown that an existing desktop 3D printer can be converted to print with high-temperature engineering plastics, and quite inexpensively. But hardly anyone believes that this approach is the ideal solution. There are too many repetitive operations involved here, and NASA engineers had to abandon some of the decisions made by the LulzBot developers. Still, the experiment provided a valuable baseline for other projects built from scratch.

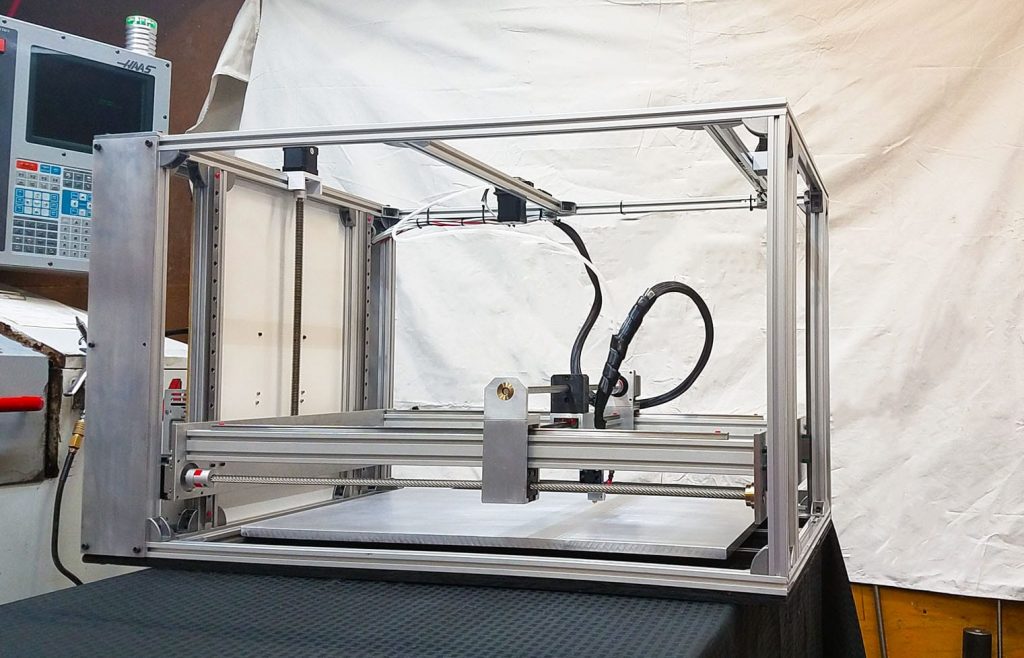

In September 2020, a team from Michigan Technological University demonstrated the Cerberus, an open-source, high-temperature 3D printer capable of creating items from PEI and PEKK, that costs as little as $1,000 to build. Without trying to adapt existing designs, the team started development from scratch, aiming for high temperature printing. All electronics are housed separately from the sealed chamber, which uses a kilowatt heating element to quickly raise the temperature in the chamber to operating temperature.

Without trying to adapt existing designs, the team started development from scratch, aiming for high temperature printing. All electronics are housed separately from the sealed chamber, which uses a kilowatt heating element to quickly raise the temperature in the chamber to operating temperature.

All stepper motors are also outside the chamber. Because of this, the kinematics become more complex than in desktop 3D printers, but Cerberus no longer requires a special motor cooling system.

Building a Cerberus is quite affordable for the aspiring hobbyist. It has a simplified circuit, ready-made control electronics based on the Arduino Mega 2560 and RAMPS 1.4, and the same E3D-v6 extruder as the TAZ 4. In addition, the team posted clear and detailed instructions for assembling the printer - this is not in the NASA report. meet.

Expanding possibilities

Whether it's NASA's redesign of the TAZ 4, or the new Cerberus-type circuits, it's clear that the technical capabilities of PEI and PEEK printing in the home workshop are already available for those who really need them. So far, it's not as easy as buying a $200 3D printer on Amazon, but if there is demand, cheaper machines based on the same principles will appear on the market. The situation is not much different from the current wave of affordable laser cutters hitting the markets in the past few years.

So far, it's not as easy as buying a $200 3D printer on Amazon, but if there is demand, cheaper machines based on the same principles will appear on the market. The situation is not much different from the current wave of affordable laser cutters hitting the markets in the past few years.

Fans all over the world print PPE

Is there a demand for such machines? A year ago, the answer might have been different from today. But in the fight against the coronavirus pandemic, there is a new demand for the rapid production of personal protective equipment (PPE) that no one could have foreseen.

print PPE that can be sterilized at high temperatures. The team believes that masks printed from PEKK can be reused rather than thrown away.

Components that can be printed and re-sterilized will obviously have other potential medical applications. A portable, low-cost machine capable of producing such components has the potential to save lives in places on the planet where supplies and equipment cannot be quickly accessed.

Critics of 3D printing have often said that the main disadvantage of these machines is that the reliability of the items they make rarely allows them to be used for anything other than rough prototyping. But when a $1,000 printer starts making aerospace-grade components, we seem to be moving toward a manufacturing revolution at an unprecedented pace.

Encyclopedia of 3D printing

Welcome to the help section of our portal!

As you can see, the world of 3D printing deserves the title of "mysterious". The rapid development of technology gives rise to a lot of all kinds of terms, concepts and designs, whose essence is far from obvious to a simple layman. The main task of our site is to acquaint you with the latest news from the world of 3D printing, tell you about technological innovations and help you with the purchase of the necessary equipment.

The task is complicated by the fact that currently in Russia there is no official standard for terms related to 3D printing. As a result, many of them are differing translations of the originals, somewhat confusing to the reader. In addition, 3D printer manufacturers themselves often try to monopolize parts of the market by making fairly minor changes to existing technologies in order to obtain a patent, and supplying “new” products with new names, thereby only exacerbating the confusion.

As a result, many of them are differing translations of the originals, somewhat confusing to the reader. In addition, 3D printer manufacturers themselves often try to monopolize parts of the market by making fairly minor changes to existing technologies in order to obtain a patent, and supplying “new” products with new names, thereby only exacerbating the confusion.

But don't despair. In this section, we will try to explain all the nuances of the world of 3D printing: the technologies used, how they work, terminology options, and so on. Keep in mind that the world of 3D printing does not stand still, and therefore we will constantly update and supplement our help section with new information.

Reference sections:

- 1 3D printing

- 2 3D printing technologies

- 3 Consumables for 3D printers

- 4 3D equipment

- 5 slisers

- 6 Articles about 3D printing

- 7 Our reviews about 3D printers and about 3D printing

- 8 Technician

- Literature

- 10 Work with the 3DTODAY portal.

Reference

Reference

3D printing

- What is a 3D printer.

- All about 3D printing. additive manufacturing. Basic concepts.

- 3D printing for dummies or "what is a 3D printer?"

- How to build a 3D printer with your own hands"

- 3D Printer & 3D Printing FAQ

3D Printing Technologies

- Mask Stereolithography (SGC)

- Multi-Jet Simulation (MJM) Technology

- Color Inkjet (CJP)

- Digital LED Projection (DLP)

- 3D Inkjet Printing (3DP)

- Selective Laser Sintering (SLS)

- Selective laser melting (SLM)

- Stereolithography (SLA)

- Selective heat sintering (SHS)

- Lamination Object Manufacturing (LOM)

- Electron beam melting (EBM)

- Direct Metal Laser Sintering (DMLS)

- Electron Beam Fusion Manufacturing (EBFȝ)

- Fused Deposition Modeling (FDM)

- Selective Deposition Lamination (SDL) Technology

3D Printer Consumables

- FDM/FFF Consumables

- 3D printing consumables table.

Melting points and extrusion rates

Melting points and extrusion rates - Photopolymer consumables

- PLA for 3D printing

- ABS plastic for 3D printing

- Printable PVA plastic

- PET plastic for printing

- 3D Printable Nylon

- Laywoo-D3 for 3D printing

- NinjaFlex for 3D printing

- Laybrick for 3D printing

- Stratasys Photopolymer Resins

- 3D Ink Photopolymer Resins

- Asiga Photopolymer Resins

- Photopolymer Resins Digital Wax Systems

- RapidShape 9 Photopolymer Resins0097

- MadeSolid Photopolymer Resins

- 3D Systems Photopolymer Resins

- Fun To Do Photopolymer Resins

- Polystyrene for 3D printing

- 3D printed polycarbonate

- Portable bar extruders.

Filament manufacturing. How to make your own 3D printing consumables

Filament manufacturing. How to make your own 3D printing consumables

3D equipment

- 3D pen

- 3D printer FDM

- Catalog of DIY and OpenSource 3D printers

- Photopolymer 3D printer

- Metal 3D printing

Slicers

- All versions of CURA - download

3D printing articles

- How to avoid deformation of models when 3D printing

- How to choose high quality filament

- Processing of 3D printed models

- How to clear a clogged extruder nozzle

- Product Rescue with Repetier-Host when 3D printing is stopped

- The 3 Commandments of Making 3D Printed Items Cheaper

- Photoshop CS6 modeling and 3D printing tutorial

Our reviews about 3D printers and 3D printing

- We bought a 3D printer and decided to make some money.

What's next?

What's next? - Cheap 3D printers for every taste

- Household 3D printers for your home

- Jewelry 3D printers or what to give your beloved man

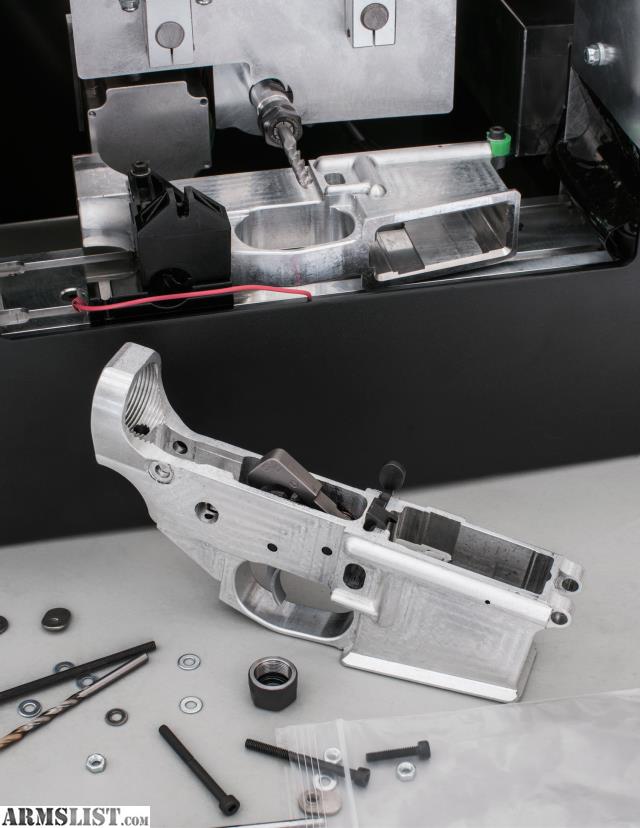

- Metal 3D printing on a home 3D printer. Technology Today and Immediate Prospects

- 3D printer and metal - the present and future of metal 3D printing

- ChefJet Confectionery 3D Printers – The End of the Sugar Cube Era

- MBot Home 3D Printer Review

- 3D printing with chocolate or how to organize your sweet business

- 3D printers for jewelers - unrivaled print quality

Technical service

- Set up the Marlin firmware and upload it to the 3D printer

- We print with ABS plastic without cracks and heat chambers

Literature

- Book: 3D printing - short and clear

Working with the 3Dtoday portal.