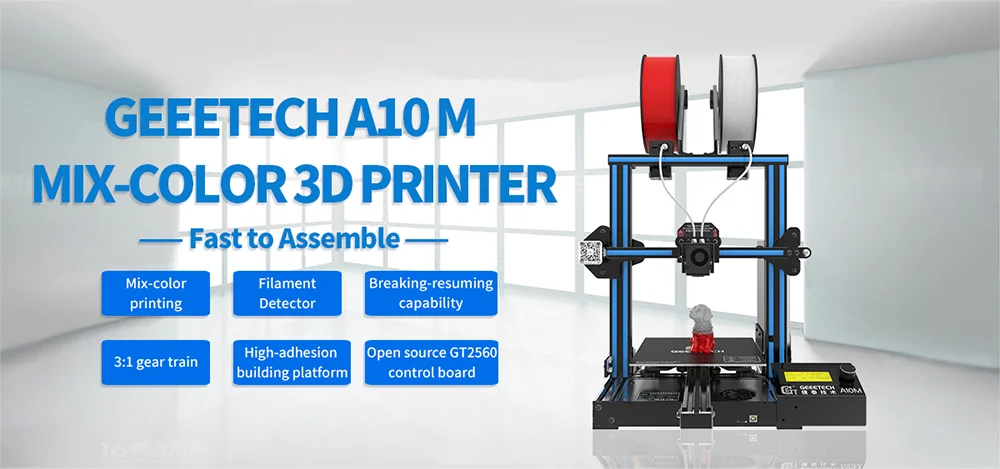

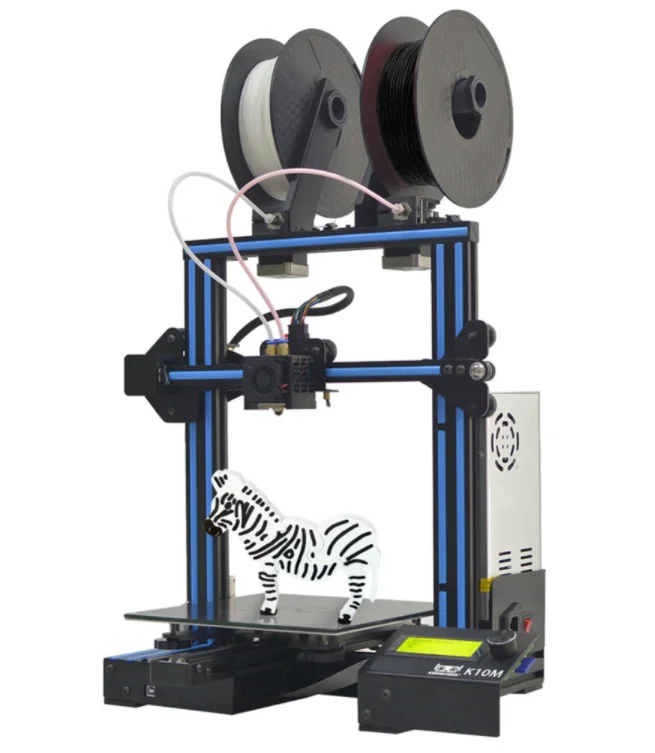

Geeetech a10m mix color 3d printer

A Low-Cost, High Effort Color Mixing 3D Printer

Read More Reviews

Read More Reviews

Read More Reviews

Read More Reviews

Read More Reviews

Read More Reviews

Read More Reviews

Read More Reviews

Read More Reviews

Read More Reviews

See on amazon

A printer which on paper gives a lot for a low price, but it is not that simple in practice. You'll spend more time fiddling with settings than using the Geeetech A10M. There's potential here, but finding it takes some patience. Use coupon code MAKEUSE10 for a discount!

Specifications

- Brand: Geeetech

- Build Volume: 8.66 x 8.66 x 10.2 inches (220 x 220 x 260mm)

- Printing Accuracy: Up to 0.1mm

- Connectivity: SD card, USB, optional Wi-Fi upgrade

- Heated Build Plate: Yes

- Feed Type: Bowden Tube

- Dimensions: 7.

4 x 9.25 x 18.31 inches (18.80 x 23.50 x 46.50 cm)

- Weight: 16.7 lbs (7.6 kg)

- Dual-Color Printing: As standard, color mixing

Pros

- Color Mixing is impressive when it works

- Easy to find replacement parts

- Very cheap for a dual-extrusion printer

- Completely moddable and easy to upgrade

Cons

- Incredibly hard to get good prints

- Flawed design on the filament spool holders

Buy This Product

Shop at amazon

The Geeetech A10M is a low budget dual-extrusion color mixing 3d printer costing just $239. While the initial setup and general use are easy, getting decent 3d prints from it is difficult to master.

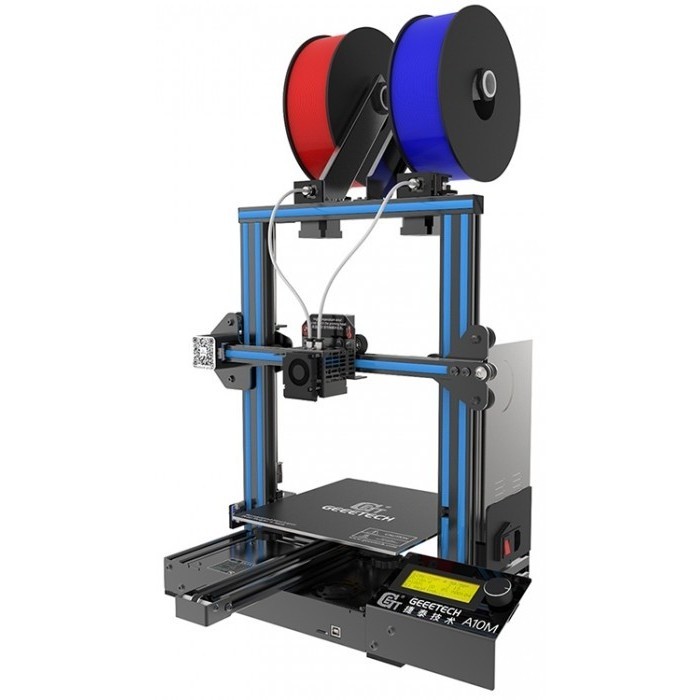

Two Extruders, One Nozzle

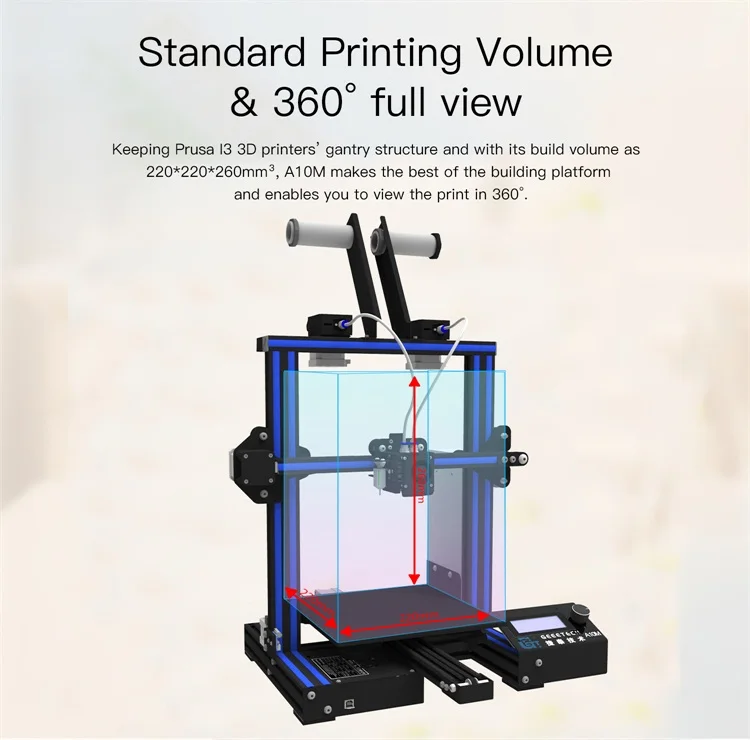

At first glance, the Geeetech A10M has a very familiar design. It shares the same frame and stepper motor configuration as many other 3D printers at this price range. The build volume is 8.66 x 8.66 x 10.2 inches and it has a heated bed featuring a composite sticky-backed build plate cover.

It shares the same frame and stepper motor configuration as many other 3D printers at this price range. The build volume is 8.66 x 8.66 x 10.2 inches and it has a heated bed featuring a composite sticky-backed build plate cover.

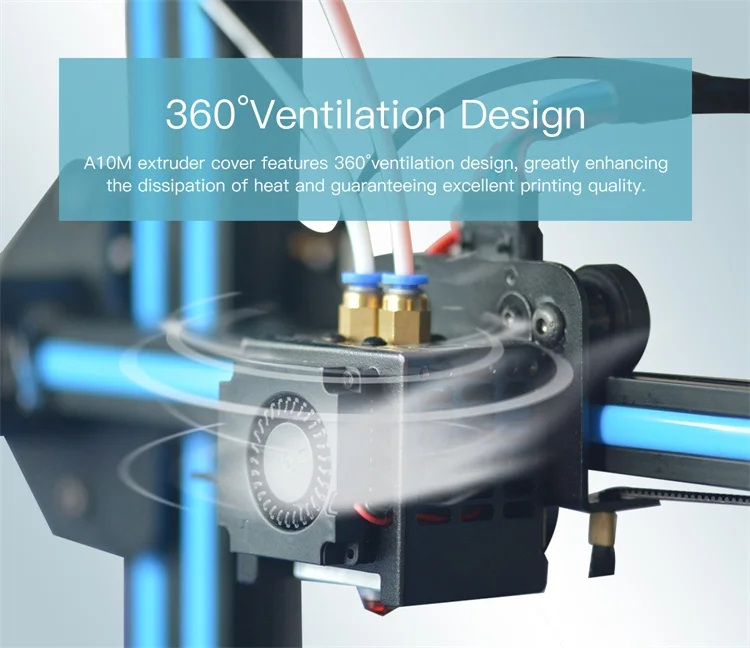

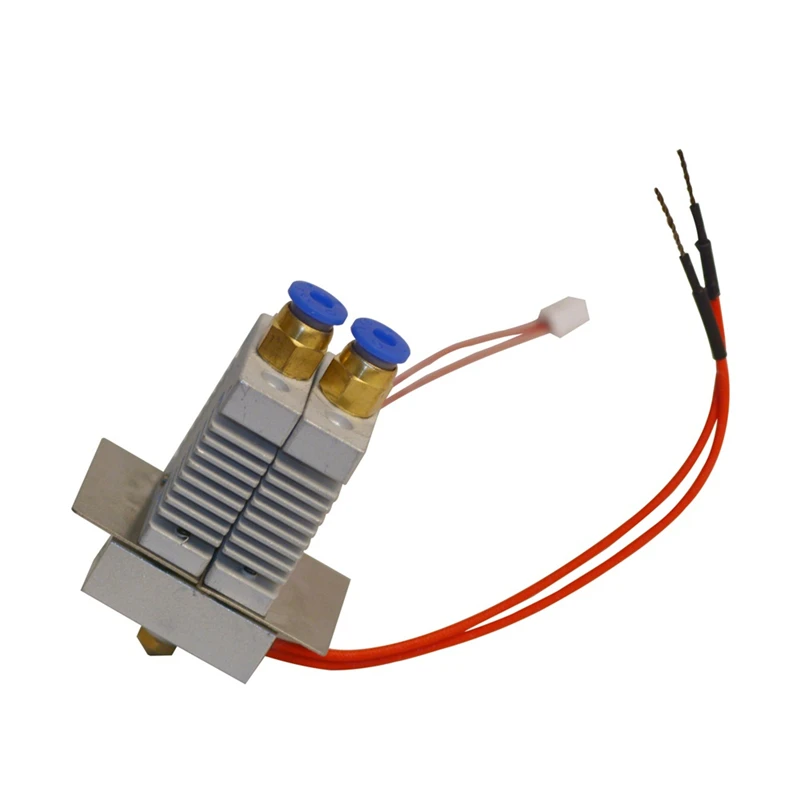

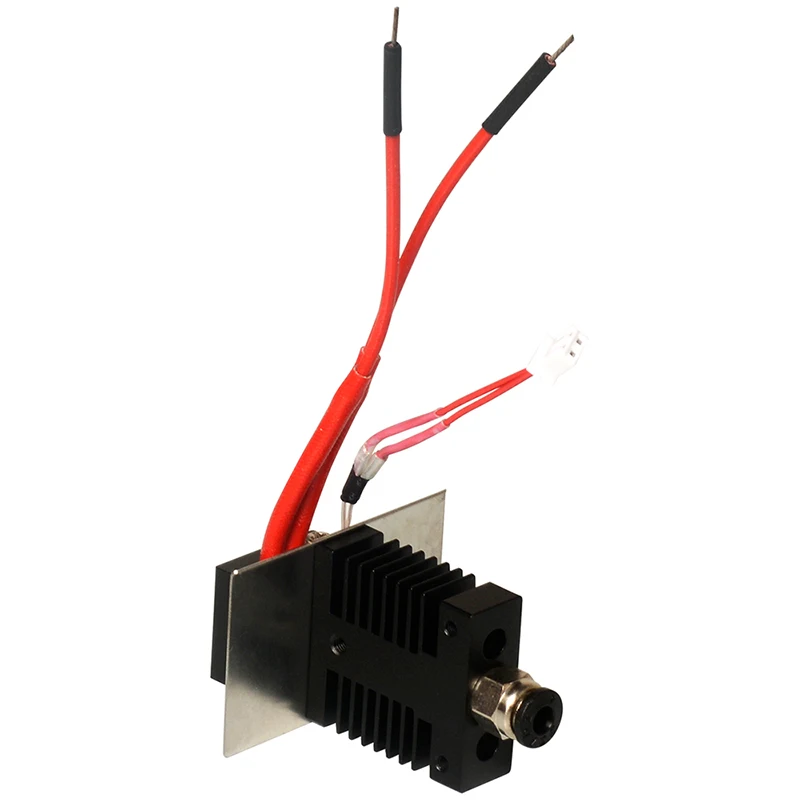

Where things differ is the dual extruders mounted to the top of the frame, feeding into a single color-mixing chamber via two Bowden tubes. The filament is then printed via a single 0.4mm diameter brass nozzle, allowing for two-color printing along with mixed colors and gradients.

It also features a 360-degree fan ventilation system at the hot end, which does a decent job of regulating temperature, but makes quite a lot of noise when in operation. A nice touch is the filament run-out sensors, which send stop signals to the printer when no more filament is available.

It has a simple LCD 2004 display, which is one color and has a backlight, controlled via a rotary encoder. It also features a hard reset tactile button for when things inevitably go wrong.

The A10M takes both regular SD cards and microSD cards and can be connected to a computer directly via a USB cable. There is an optional Wi-Fi module and 3D leveling sensor for the printer, but they weren't supplied for this review.

- Build volume: 8.66 x 8.66 x 10.2 inches (220 x 220 x 260mm)

- Printing accuracy: 0.1mm

- Frame: Aluminum

- Nozzle diameter: 0.4mm

- Max. print temperature: 250C

- Connectivity: SD Card, USB

- File format: G-code, STL

- XY-axis positioning accuracy: 0.011mm

- Z-axis positioning accuracy: 0.0025mm

- Voltage: 110-240V

- Power: 360W

- Weight: 7.6kg

- Dimensions: 7.4 x 9.25 x 18.31 inches (18.80 x 23.50 x 46.50 cm)

Fully Assembled, Apart From the Bits That Aren't

Many 3d printers come assembled but in two parts, and setting them up is as simple as attaching the z-axis gantry to the base. The A10M is slightly more involved, as you need to attach both extruders to the frame, along with the LCD screen.

Putting it together is a mostly simple process, and the full-color guide with photographs gives step by step instructions. Attaching the Z-axis limit switch took some doing, however, as it's tucked down near the bottom of the frame, but those with nimble fingers might not have an issue.

The power supply for the A10M isn't in the base. It comes as a separate unit that attaches to the Z-axis frame. Geeetech provides all the tools required for assembly, along with various spare parts, screws, cleaning tools, and a metal scraper for freeing prints from the build plate.

Preparing to Print

Before printing, the quick-start guide advises leveling the build plate. Like many printers, the A10M comes with a tool for making sure your nozzle is at the correct height - a piece of card.

There is a menu option for leveling the bed, which moves the nozzle to each corner before prompting to move to the next when ready. Leveling is done by hand, using four plastic hand screws under the bed. It's an easy process, and once done, I didn't find the bed slipped at all during the rest of the review.

It's an easy process, and once done, I didn't find the bed slipped at all during the rest of the review.

The extruders have spring-loaded plastic catches allowing you to push filament down into the Bowden tubes. From there, you can set the printer to pre-heat for PLA or ABS use via the menu and extrude some filament from each extruder to check there are no blockages.

A Test Print in Two Senses

You get enough filament in the package to print a test file provided by Geeetech, which is a gradient colored dog. Printing was seemingly all going to plan, but there was a power cut halfway through. This turned out to be a fortuitous way to test the automatic continue function of the Marlin 1.1.8 firmware the A10M uses, which is designed for this eventuality.

Things didn't go to plan. There was an ominous line around the dog's neck at the end of printing, and attempting to get it off the build plate did not end well.

I'm not sure what went wrong here, but given the unusual circumstances, I moved on to other prints without thinking too much of it. Unfortunately, that's when things got quite difficult.

Unfortunately, that's when things got quite difficult.

A Forest of Failed Prints

From here, I had issues with almost every print I did. Most 3D printers need some adjustments to get things right, but after multiple attempts, tweaking setting after setting, things didn't improve all that much.

Some of my prints had evidence of significant layer shifting, despite there seeming to be nothing that would cause it.

Other prints had problems with retraction, leaving a stringy mess behind and prints with a mottled surface. Unusually, changing settings that would typically result in this getting better did not seem to do all that much. This, like all FDM printers, is never going to get prints quite as detailed as resin printers like the Nova3d Bene4 Mono we recently reviewed, but it should be capable of printing with an accuracy of up 0.1mm layer height.

Color mixing was hit and miss, with gradients generally coming out well, but block colors sometimes appearing blended and sometimes just not working at all. I could go on, but the simplest way to express how hard this printer can be to use is this: Out of perhaps 20 prints, I'd consider 3 to be fully successful.

I could go on, but the simplest way to express how hard this printer can be to use is this: Out of perhaps 20 prints, I'd consider 3 to be fully successful.

In truth, hitting the sweet spot can be tough with all 3D printers, so this is the stuff that might improve over time, but there are some design flaws that can be game-breaking.

A Large Oversight

The filament run-out sensors are a great idea in principle. When your filament runs out the printer stops. They are attached right behind each extruder so that filament can run through them off the spool before being extruded to the hot end.

The problem is that regular-sized spools hang down into the runout sensors and even get caught on the plastic spring switch for loading filament into the extruder. Because of this, I never could test the runout sensors. During one print, the plastic switch even caught on to the spool, ruining it.

You could always point out that this printer might not have been designed for these types of spools, but I was using Geeetech's own branded PLA on spools I consider to be regularly sized for 3D printing.

While many of the other issues of this printer can be put down to requiring patience and specialist knowledge to master, this seems like a large oversight in design.

On the plus side, Geeetech's customer service is excellent, and it provides support via their Facebook group, forum, and email. Its official YouTube channel also has a number of videos showing how to clean, configure, and maintain the printer, including one I followed to combat layer shifting in the Y-axis.

Due to this printer's budget nature and the potential color-mixing can bring, there is also a committed community using the A10M, and a Facebook group for Geeetech Printer Owners.

If you own this printer and are having a hard time, there is a lot of help out there to work out what is wrong, which is something many beginners will appreciate.

The Software Side

Geeetech recommends using Repetier-Host for slicing models before printing, which is easy to use and similar to most other programs for producing Gcode. There are also profiles for the A10M for Cura, Simplify3d, and Slic3r, among others.

There are also profiles for the A10M for Cura, Simplify3d, and Slic3r, among others.

Repetier-Host uses the CuraEngine slicer and produces Gcode for printing via USB, SD card, or Wi-Fi if you've got the module. They also provide software called Color Mixer for importing Gcode to add gradients, color steps, or mix filament colors.

It's easy to use, and a simple way to visualize how colors will turn out before printing.

A Printer for Tinkerers

Despite all the issues, I don't think the Geeetech A10M is a bad printer. It's just one aimed at people who are willing to put the time in to learn it's quirks. The design is completely modular, and you can swap out hardware and software at will. The mainboard even has a bootloader and is compatible with the Arduino IDE.

One thing is certain: The A10M is not for beginners or those looking for a stress-free 3D printer that's functional out of the box. If you like tinkering for hours on end and prefer fixing broken toys to buying new ones, it might just be for you.

Who knows, at the end of the tunnel, there might just be a perfect dual-color 3D print.

Buy Geeetech A10M Mix Color 3D Printer Kit

Updated Version with new control mother board, LCD and frame.New!

Geeetech A10M 3D printer, adopting open source GT2560 control board, delivers mix-color objects and greatly enriches your 3D printing life. Keeping the good performance of its predecessor A10, it aims to provide users with quality printout and satisfactory printing experience.

Keeping Prusa I3 3D printers’ gantry structure and with its build volume as 220*220*260mm³, A10M makes the best of the building platform and gives you a full view of the printing details. Its well-designed extruder greatly reduces the risk of clogging or leaking. The Bowden design of the extruder makes the printing head move lightly and stably, greatly enhancing the printing efficiency. The V-shaped wheels and rails on each axis, made from wear-resistant aluminum profile, could, in a large measure, reduce the printing noise and offer you a quiet 3D printing environment.

Main Features:

1.Prints in Mixed color combo.

2. Classic blue and black color combo imparts a touch of solemnity and simplicity.

3. Large build volune as 220*220*260mm³, A10M makes the best of the building platform and gives you a full view of the printing details.

4. Featuring printing accuracy of 0.1 mm, A10M delivers exquisite mixed color prints with delicate texture, sleek contour and stable structure.

4. The V-shaped wheels and rails on each axis, made from wear-resistant aluminum profile, could, in a large measure, reduce the printing noise.

5. A10M comes with OPEN SOURCE GT2560 control board, providing limitless space for you to modify the firmware and tinker with your printer.

**Free and faster shipping (incl. of taxes) applies if the order ships from the local warehouses (US/EU/UK/AU/etc). Estimated shipping time may vary and you may have to pay import taxes/additional shipping costs if the order ships from the seller's original manufacturing facilities, usually China, Taiwan, Hong Kong, etc. We ship compatible plugs based on your location. Please refer to our FAQ for more details. If you have any presale questions, please contact us.

We ship compatible plugs based on your location. Please refer to our FAQ for more details. If you have any presale questions, please contact us.

| Product Condition | |

| Item Condition | New |

| Manufacturer Warranty | 1 year |

| Printing Specifications | |

| X Y Axis Position Accuracy | 0.011mm |

| Z Axis Position Accuracy | 0.0025mm |

| Print size ( X Y Z ) | 220*220*260mm |

| Print Speed | 180 mm/sec |

| Layer Resolution | 50 microns |

| Print Precision (Layer Thickness) | 0.05-0.4mm |

| Filament Diameter | 1.75 mm |

| Nozzle Diameter | 0.4 mm |

| Filament Compatibility | ABS / PLA /flexible PLA/wood-polymer/PVA/HIPS/PETG, etc. |

| Print in multi color | Yes Mix Color. |

| Mechanical Specifications | |

| Chassis | Aluminum profile |

| No.of Extruders | One |

| Print Plate (Build Platform) | Heatbed |

| Software Specifications | |

| 3D Printing Software | EasyPrint 3D, Repetier-Host, Simplify 3D, Cura, Slic3r, etc. |

| Supported File Formats | STL, Gcode |

| Operating System | Windows/Mac/Linux |

| Temperature Specifications | |

| Extruder Temperature | 250 Deg C |

| Heating Bed Temperature | 100 Deg C |

| Electrical Specifications | |

| Power Requirements | Power supply: Input: 115V/230V Output: DC 24V, 360W |

| Connectivity (Interface) | USB, Online, SD Card , Wifi (Optional) |

| Electronics Specifications | |

| Display | LCD 2004 |

| Shipping specifications | |

| Machine weight | 7. 6kg 6kg |

| Shipping box weight | 9.45 kg |

| Shipping box dimensions | 500*470*310 mm |

| Shipping Location | China, EU, USA and AU. |

| Lead Time (Processing/Handling Time) | 5 Business Days. |

Best Dual Extruder 3D Printers & 2022 Updates

Dual extruder 3D printers take the mono-color slumber away. 3D printing using multiple colors, multiple materials to reinforce specific areas, or using dissolvable filaments such as PVA or HIPS to achieve a smooth finish.

We've been lucky enough to try a few dual extruder 3D printers firsthand and have come up with our recommendations for the best dual extruder printers available in 2022. We also explain the differences between different types of dual extruders (IDEX, mixed color 3D printing, dual extruder upgrade) and whether you should upgrade your printer.

Contents

- What are the advantages of a dual extruder 3D printer?

- What is the best dual extruder 3D printer?

- Budget Dual Extruder 3D Printers (under $1,000)

- 1.

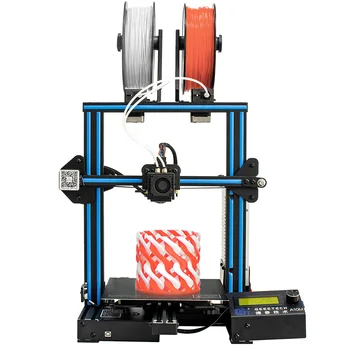

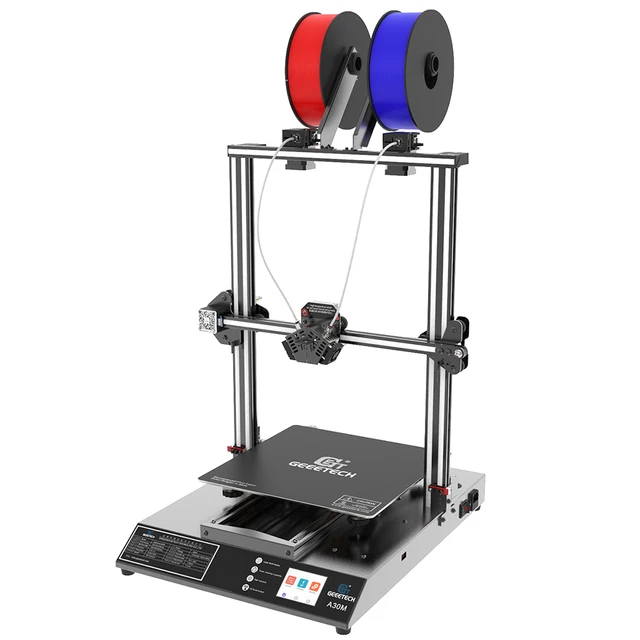

Geeetech A20M / A10M - Best Budget Dual Extruder 3D Printers

Geeetech A20M / A10M - Best Budget Dual Extruder 3D Printers - 2. BIBO 3D Printer (Touch Laser if purchased with laser engraver) 3. Flashforge Creator Pro 2 - Affordable IDEX

- 3D Printer 4. BCN3D Sigma D25 - IDEX 9 3D Printer0010

- 5. Ultimaker S3 - Highly Accurate Dual Extruder 3D Printer

- 6. Raise3D Pro2 / Pro2 Plus

- 7. Ultimaker S5

- Best Dual Extruder Upgrades

- 8. Mosaic Palette 2S / 2S Pro - Best Upgrades dual extrusion filament splicer

- 9. Prusa Multi Material Upgrade 2S - Prusa Upgrade Kit

- Dual extruder 3D printer FAQ

What are the advantages of dual extruder 3D printer?

The main advantages of a dual extruder 3D printer include:

Better for supports: one extruder prints your material of choice, such as ABS or PLA, while the second extruder prints water-soluble supports, such as PVA filament. These supports dissolve easily in water and produce smoother prints without having to manually remove them.

Multiple Colors: Dual filament 3D printers can print multiple colors of the same filament type such as PLA for stunning multi-color details.

Multiple parts at the same time (IDEX): IDEX 3D printers such as the BCN3D Sigma D25 have two extruders that work completely separately and can print different parts at the same time.

What is the best dual extruder 3D printer?

That's why we've ranked the best dual extruder 3D printers on the market. We rated these printers for value for money, reliability, build volume, ease of use, and various other features.

Budget Dual Extruder 3D Printers (under $1,000)

These amazing 3D printers break the rules of the definition of "dual extruder 3D printing". To be clear, they can be loaded with two separate filaments, such as red and yellow PLA, but they will come out of the same nozzle, mixing the two colors during the printing process. Some call it dual nozzle 3D printing.

Some call it dual nozzle 3D printing.

The results are amazing. Connect red, orange and yellow threads and watch your printed vase look like an exotic cocktail. The printers offer four dual 3D printing modes: single color, dual color, gradient and mixed. This provides a huge selection of print designs for such an inexpensive dual extruder 3D printer.

In terms of specifications, the A20M has a good working volume of 255 x 255 x 255 mm, while the A10M is only slightly smaller. The A20M also boasts improved stability as it is better anchored. Overall, this is an accurate (layer resolution down to 0.1 mm), interesting and inexpensive two-color 3D printer that combines colors and filaments through a single nozzle.

single nozzle geeetech a20m filament mixer.

2. BIBO 3D printer (touch laser if purchased with laser engraver)

- Dual extruder 3D printer cost: $599

- Assembly volume: 214 x 180 x 160

How do we get started with the BIBO eccentric printer? Well, the most important thing is that it also performs another function. It can be used as a laser engraver! The engraver can permanently carve your favorite designs on wood, as well as cut paper or felt materials - and print in 3D!

It can be used as a laser engraver! The engraver can permanently carve your favorite designs on wood, as well as cut paper or felt materials - and print in 3D!

You can purchase BIBO as a 3D printer kit or pre-assembled, with or without a laser engraver. And if he performs another function, this does not mean that he cannot succeed in both. In fact, this is a very efficient multi-extruder 3D printer with a minimum layer height of 0.05 mm and stable printing in a closed working chamber.

This is a great printer, crazy and ambitious. Even the product images on Amazon showcase the machine's character and personality. We love it.

3. Flashforge Creator Pro 2 - affordable 3D printer IDEX

- Creator Pro 2 price: $649

- Assembly volume: 200 x 148 x 150 mm

The popular and beloved Flashforge Creator Pro has started to show its age since it was released in 2016, so Flashforge followed it up with the vastly improved Creator Pro 2. assembly volume on the x-axis. It retained a minimum resolution of 100 microns and a Teflon tube extruder for 3D printing of PLA, ABS and nylon in a closed working chamber.

assembly volume on the x-axis. It retained a minimum resolution of 100 microns and a Teflon tube extruder for 3D printing of PLA, ABS and nylon in a closed working chamber.

However, the main change that makes this printer so profitable is undoubtedly the IDEX upgrade. In the IDEX 3D printer, the nozzles work independently, unlike the dependent, attached nozzles on the original Creator Pro, with different modes such as Mirror Mode for 3D printing multiple identical models at the same time - a big time saver, trust me.

Other quality-of-life improvements include an improved touch screen interface, as well as important nozzle updates that prevent unused nozzles from oozing out and messing up the print bed or even causing errors. You won't find a more affordable IDEX printer.

4. BCN3D Sigma D25 — IDEX 3D printer

- Manufacturer: Spain

- Price: $3,995

- Assembly volume: 210 x 297 x 210 mm

Spanish 3D printer manufacturer BCN3D has made a name for itself with reliable dual extruder 3D printers. All of their printers, including the Sigma and Epsilon series, use BCN3D's IDEX (Independent Dual Extruder System) 3D printing technology, a unique and key advantage.

All of their printers, including the Sigma and Epsilon series, use BCN3D's IDEX (Independent Dual Extruder System) 3D printing technology, a unique and key advantage.

IDEX 3D printing allows each extruder to move completely independently, not limited to working on the same model at the same time as in other 3D printers. Two different parts can be created at the same time, cutting the time required to create several small parts in half. The Sigma D25 also features high quality E3D hot ends for quality printing on a variety of materials, including stiffer filaments, and a filament low sensor informs you when the filament has run out.

For those who need a 3D printer for rapid prototyping, being able to print multiple parts for testing at the same time is a huge advantage. The BCN3D Sigma D25 uses 2.85mm filaments instead of the standard 1.75mm so be aware of this, but is compatible with any 2.85mm filament. You can use a variety of 3D printer nozzle sizes, from 0.3mm to 1. 0mm, and a clear and easy-to-navigate touch screen interface.

0mm, and a clear and easy-to-navigate touch screen interface.

Interestingly, Sigma D25 is also an open source 3D printer: printer firmware, workflow, software and other files are available on BCN3D GitHub. It works seamlessly with the Cura 3D slicer and is easy to set up and use right from the start. Overall this is a great, reliable and efficient dual extruder 3D printer. With a resolution of 50 microns, this is a high quality, high resolution 3D printer for accurate rapid prototyping.

5. Ultimaker S3 - very precise dual extruder 3D printer

- Manufacturing company Holland

- Ultimaker S3 price: $3,850

- Assembly volume: 230 x 190 x 200 mm

Ultimaker is another behemoth of desktop 3D printing, producing award-winning deposition modeling printers. With a dual extruder and incredible precision down to 20 microns, the Ultimaker S3 is a fantastic option for small businesses, manufacturers and prosumers.

For precision multi-material 3D printing, nothing beats the Ultimaker S3. It is widely used to create accurate architectural models as building design prototypes, to create accurate industrial and engineering prototypes, and in many other industries. Upon release, it won dozens of awards and is still one of the best dual extruder 3D printers.

It is widely used to create accurate architectural models as building design prototypes, to create accurate industrial and engineering prototypes, and in many other industries. Upon release, it won dozens of awards and is still one of the best dual extruder 3D printers.

With a print volume of 230 x 190 x 200 mm, the Ultimaker S3 can handle most printing needs. It also has a built-in camera that allows you to monitor the printing process remotely.

Connected via WiFi, Ethernet or USB stick, the Ultimaker S3 is designed to be easy to use. While the Ultimaker 3 doesn't come cheap at $3,850, it's accurate, fast, reliable, and easy to use. This makes it overall one of the best dual extruder 3D printers on the market today.

6. Raise3D Pro2 / Pro2 Plus

- Price: $3,999

- Assembly volume: 305 x 305 x 300 mm

Also featured in our overall ranking of the best 3D printers, the Raise3D Pro2 series impresses with its reliability, size and range of printable materials. In addition to standard PLA, ABS, and PETG printing, the Pro2 and Pro2 Plus 3D print with nylon, polycarbonate, carbon fiber, ASA, and metal-filled filaments on either of the two extruders.

In addition to standard PLA, ABS, and PETG printing, the Pro2 and Pro2 Plus 3D print with nylon, polycarbonate, carbon fiber, ASA, and metal-filled filaments on either of the two extruders.

Its big brother, the Raise3D Pro2 Plus, costs $5,999

The Raise3D Pro2 also boasts a fantastic build volume of 305 x 305 x 300mm, enough for everyday and industrial printing. The printer is also very accurate, with a minimum layer height of 0.01mm, and is equipped with a 7-inch touch screen for easy printer control. The Raise3D Pro2 costs just under $4,000 and overall is a fantastic dual-extruder printer for the price.

7. Ultimaker S5

- Price: $5,995 - Available at Dynamism Store

- Assembly volume: 330 x 240 x 300 mm

Ultimaker is highly regarded, and for good reason - the company can't go wrong. After the Ultimaker 3, the Ultimaker S5 is an updated, improved and slightly more expensive dual extruder 3D printer that will compete with the Makerbot Method.

A 330 x 250 x 300mm large-format 3D printer built for more scalable production, the Ultimaker S5 already has satisfied customers at Volkswagen, Decathlon and many more. It features a very advanced print leveling system, an improved touch screen, and can be connected to a phone via the Ultimaker app, which notifies you when a print is complete. The Ultimaker S5 is undoubtedly a great dual extruder 3D printer.

Best Dual Extruder Upgrades

8. Mosaic Palette 2S / 2S Pro - Best Upgrades for Dual Extrusion Filament Splicer

- Palette 2S Price: $599

- Palette 2S Pro Price: $799

If you want to print multiple colors without a dual extruder, consider Palette as well. Instead of 3D printing with two multi-colored filaments from separate extruders, the Palette 2S and 2S Pro fuse up to four multi-colored filaments - or different materials - together during printing to create multi-color or multi-material parts.

They work by running your model through specially designed software - CANVAS for Palette - to assign different colors to different areas of your model before printing. When a particular area needs to be printed, the Palette software splices the colored filaments to print that particular area in the material or color you choose.

When a particular area needs to be printed, the Palette software splices the colored filaments to print that particular area in the material or color you choose.

This makes Palette ideal for creating architectural models for construction projects, colorful desktop models of your favorite designs or D&D models, and multicolor prototyping businesses. The standard Palette 2S model includes all of these features, while the Palette 2S Pro can also splice up to 20% faster and comes with an extended 2-year warranty and replacement parts.

Palette is compatible with hundreds of 3D printers, including almost all of the most popular options. For more information, you can check your printer's compatibility here, and as for choosing between the Palette 2S and 2S Pro: The 2S Pro cuts filament 20% faster and comes with a longer warranty - so if that's important to you, spend the extra money on 2S Pro.

9. Prusa Multi Material Upgrade 2S - Prusa Upgrade Kit

- Price: $299

While you can upgrade the palette for most 3D printers, Prusa printer owners can purchase a similar Multi Material Upgrade kit that allows you to print up to 5 different materials at the same time. Prusa printers are some of the best 3D printers under $1,000 and this upgrade turns your Prusa into a multi-color or multi-material 3D printer.

Prusa printers are some of the best 3D printers under $1,000 and this upgrade turns your Prusa into a multi-color or multi-material 3D printer.

MMU2S is an improvement over the previous version of the Multi Material Upgrade Kit 2.0, key changes include a material feed sensor, buffer and a much improved overall calibration process.

The Filament Sensor goes further, checking not only for the presence of filament, but also to see if it has reached the Bondtech gears for printing. This provides much more reliable extrusion and makes filament calibration and loading easier.

The filament buffer also saves you the hassle because each of your filaments (especially if you're using all 5!) won't get tangled or tangled. Organizing and separating each filament also saves space on your desk or 3D printer table.

Q&A for Dual Extruder 3D Printers

What is a dual extruder 3D printer?

Dual extruder 3D printers have two print heads or nozzles instead of one print head like standard FDM 3D printers. Dual printing frees you from the limitations of using only one type of 3D printer filament and allows you to create multicolored parts with ease.

Dual printing frees you from the limitations of using only one type of 3D printer filament and allows you to create multicolored parts with ease.

Dual head 3D printing improves printing with soluble supports such as HIPS and PVA and also allows multi-color parts to be printed.

Most budget dual extruder 3D printers are dual nozzle printers, meaning they have two nozzles but extrude from a single head, but we also include more advanced printers. These advanced options include IDEX 3D printers with two printheads that move completely independently for efficient and versatile printing.

What are the main types of dual extruder 3D printers?

The main types are:

1. Dependent Dual Extruder 3D Printers - Most inexpensive multi-extruder 3D printers are dependent, that is, two nozzles that extrude separate filaments are attached to one print head. They follow the same path, filling areas (such as a support or main part) in turn.

2. Dual Extruder Independent 3D Printers (IDEX 3D Printers) - IDEX extruders use two printheads independently of each other, doubling productivity when printing multiple parts at the same time.

3. Dual Extruder Printer Upgrades - These upgrade kits, such as the Palette 2S series and Prusa Multi Material Upgrade 2.0, transform a single extruder 3D printer into a printer that can print up to 5 colors at once using splicing systems and specialized software and plans for filling 3D models.

4. Mixed color 3D printers are some of the cheapest dual extruder 3D printers, and maybe not even dual extruders. They use one printhead and one nozzle, but two filaments to mix the colors while melting. You can print models in half color, or mix colors like red and blue to create a purple tint.

Can the 3D printer be upgraded with a dual extruder?

Yes, you can. Dual extruder upgrades such as Palette 2S (compatible with most popular 3D printers) and Prusa Multi Material Upgrade 2.0 (for Prusa 3D printers) will turn your standard FDM printer into a multi-color 3D printer.

However, manually modifying a 3D printer and adding a second extruder is more difficult. There are guides for turning your 3D printer into a dual extruder 3D printer like the Ender 3, but for the less tech-savvy, we recommend avoiding this.

There are guides for turning your 3D printer into a dual extruder 3D printer like the Ender 3, but for the less tech-savvy, we recommend avoiding this.

Should I buy a 3D printer with two extruders?

If you want to print multi-color prints at home for fun or create better quality smooth surface prototypes using dissolvable supports, a dual extruder 3D printer is worth getting.

However, if you don't need multimaterial or multicolor prints, or want to print high resolution character models that are better suited to resin 3D printing, for example, then it might not be worth it.

Source Table 3D printer GeeTech A20M “Make yourself” for training, wireless 3D printer with different colors on m.alibaba.com

Information

Request

Start Chat

Trading Warranty

Integrated order protection service on Alibaba.com

Product quality

Timely delivery

Learn more about shipping and other trade services.

Product characteristics

Models: 1, Strength (W): 1

800-001-0561

Individual orders

Emblem to order

50 pcs. (MOQ)

Independent packaging

50 pcs. MOQ)

Graphic customization

50pcs(MOQ)

| Port: | shenzhen 298 | multi -color |

| Production capabilities: | 10000 per month | |

| After -sales maintenance: | Fine support abroad, free maintenance and repair, video maintenance | 2 hotbed:100℃ |

| Certification: | CE FCC, CE, CE FCC PSE |

Processing time

10 days

1+ pcs.

Subject to agreement

100+ pcs.

Shenzhen Getech Technology Co., Ltd.

CNManufacturer, Trading Company

≤3hResponse time

US$ 60,000+63 Sales

100.