Ascent 3d printing

B9 Core 5 Ascent Series

We are currently fulfilling orders on time. The vast majority of our components come from inside the US, and we don’t currently anticipate any supply chain disruption due to COVID-19. However, the situation around the world is changing rapidly and we are monitoring regularly. We will post any known disruptions on our website as we become aware of them.

Please verify the shipping address for your order if you are working remotely or at a different location. If your business is unable to receive a package at their normal business address, FexEx offers a Hold at Location option for over 14,000 locations including FedEx Office and Walgreens locations. Please contact [email protected] if you have questions about your order or need to use the Hold at location option.

| Image | Product Qty/Name | Price |

|

Ascent Series 3D Printers

B9 Core 5 Ascent 550 - 405 - 12. |

$23,955.00 $23,955.00 $25,955.00 $23,955.00 $25,955.00 |

- Description

- Reviews

B9 Core 5 Ascent Series

- For sale only in the USA

The B9 Core 5 Series Ascent is a customizable platform designed to meet your unique business needs. Choose between an 8- or 12.5-inch z-height and a 385nm or 405nm light engine.

Choose between an 8- or 12.5-inch z-height and a 385nm or 405nm light engine.

Key Features

Bring your designs to life over lunch, not overnight. The B9 Core Series offers unmatched resolution, surface finish, and speed so you can spend more time on what matters - growing your business.

What's Included in the box:

Each B9 Core 5 Ascent will receive everything you need to start printing right away.

- 1 kg of Resin (customer's choice)

- Resin Vat

- B9Creations Finishing Kit

- Remote Factory Startup

- 1 year warranty

Technical Data

Machine

Core 5 Ascent 550 – 405 12.5 Inch Z-height

Core 5 Ascent XL – 405 8 Inch Z-height

Core 5 Ascent XL – 385 8 Inch Z-height

Core 5 Ascent XL – 405 12.5 Inch Z-height

Core 5 Ascent XL – 385 12.

5 Inch Z-height

Build Envelope

96 x 54 x 320 mm

124.8 x 70.2 x 205 mm

124.8 x 70.2 x 205 mm

124.8 x 70.2 x 320 mm

124.8 x 70.2 x 320 mm

Light Source

Industrial HD UV LED Light Engine - 405 nm

Industrial HD UV LED Light Engine - 385 nm

Industrial HD UV LED Light Engine - 385 nm

Industrial HD UV LED Light Engine - 405 nm

Industrial HD UV LED Light Engine - 405 nm

Software

B9Create 1.0

FAST™ Technology Powered by B9Create

FAST™ Technology Powered by B9Create

FAST™ Technology Powered by B9Create

FAST™ Technology Powered by B9Create

Effective Resolution (X,Y)

50μm

<25μm

<25μm

<25μm

<25μm

Min/Max Build Speed*

15-85+ mm/hr

Z Resolution

10μm*

Material System

B9Creations Resins & 3rd Party Materials

Connectivity

Wi-Fi, Ethernet & USB drive

Printer Dimensions

267 x 420 x 800mm (10.

5 x 16.5 x 31.5")

Printer Weight

35kg (78lbs)

Power

12VDC 7A

Warranty

1-Year

Full Speed Ahead

- The Fastest DLP 3D printer on the market

- Reduce post-processing time with FAST Technology and our B9Clean XL and B9 Model Cure XL

Top Choice for Value

- Lowest cost per unit of throughput

- Return on investment in 12-18 months

- Financing available

Curious to learn more about high-speed 3D printing but unsure of the quality? Feel the resolution of B9Creations with a sample shipped directly to you. Request a sample.

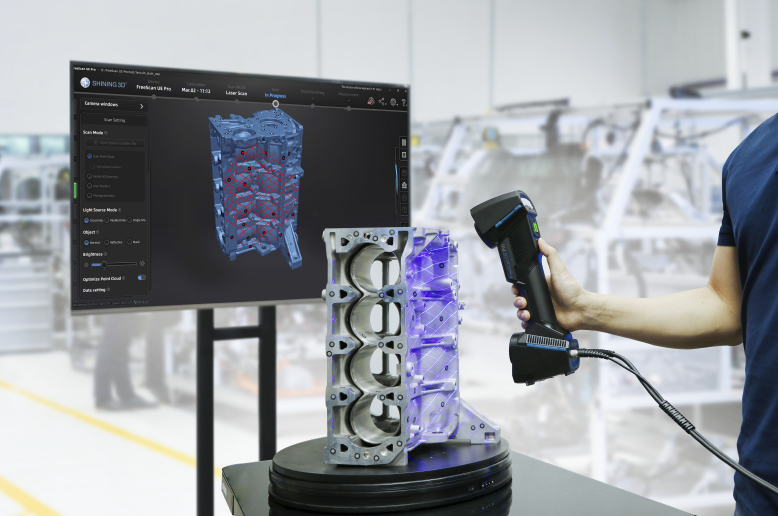

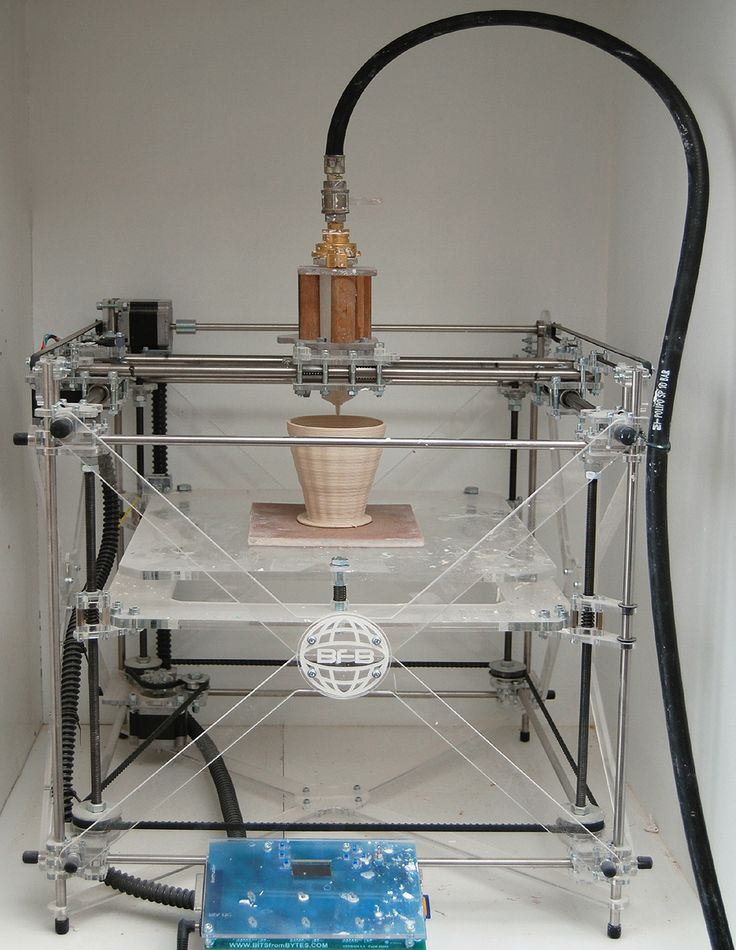

Prototyping and Tooling Using Large-Scale Composite 3D Printing Event Details

Photo Credit: Ascent Aerospace

VIEW NOW

August 16, 2022 |

Learn the ins and outs of large format additive manufacturing (LFAM) currently in use for tooling and prototyping for industrial manufacturing markets.

Presented By

Visit the Ascent Aerospace Showroom

Learn the ins and outs of large format additive manufacturing (LFAM) currently in use for tooling and prototyping for industrial manufacturing markets. With increased market adoption, improved print quality and more material availability, LFAM has made tooling and prototype articles a viable option for 3D printing and opens the door for aerospace, marine, transportation and energy applications at a large scale. Tooling fabricated on the LSAM can also be combined with traditional manufacturing techniques, such as composite layup and metal fabrication, to develop tool strings for a wider application space.

Participants of this webinar will learn about several case studies detailing specific printed projects and the benefits and tradeoffs to traditional builds. The presentation will include an overview of project definition and the required approach to accommodate rapid, large-scale additive manufacturing. The case studies will identify both successes within the project space as well as lessons learned from challenging opportunities.

The case studies will identify both successes within the project space as well as lessons learned from challenging opportunities.

Presenter 1:

Sean Henson

Global Product Manager, Composites and Additive Manufacturing

Sean Henson is the global product manager for Composites and Additive Manufacturing at Ascent Aerospace. He has led the market introduction of Ascent’s HyVarC hybrid layup mold tooling solution as well as the development of additive manufacturing capabilities within Ascent. Sean has a Bachelor of Science in engineering in materials science, a Bachelor of Arts in economics from the University of Pennsylvania (2012), a Master of Science in aerospace, aeronautical and astronautical engineering and an MBA from the Massachusetts Institute of Technology’s Leaders for Global Operations program (2017).

All content on this page is provided by the presenting company.

Valorant's Pal Rising Free 3D File・Template to Download and 3D Print・Cults

Halloween Coffin Plant Container

Free

Geometric wall art 4 pcs for bigger print, deer

Free

New roller blind ring

Free

Best 3D printer files in Game category

Deck box

0,93 €

TO TO RO Roly-Poly Toy

Free

Magic ball - Magic ball

Free

EPIC 6 stage coilgun

Free

Little adventures - MTV-7

4 €

RAF WW II Spitfire

Free

Hive Game Directions (English) QR Code Gift Tag

1. 98 €

98 €

Fire Truck / Camion de Pompier

1 €

Bestsellers in the Game category

Octopus 2.0

3.96 €

Good flexi dragon

1.77 €

GIANT CROCODILE HINGED

4.54 €

RC 1/10 Dodge Challenger

7,50 €

Flying unicorn

1.05 €

Space Dwarf All - terrain vehicle

€15.88

Vodfolk Explorer

9.93 €

Chopper motorcycle print-in-place

1 €

Dancing Skeleton

3. 47 €

47 €

Heavily armored warriors Catafrac - set of limbs

1,85 €

Cute hedgehog Flexy

1.05 €

Articulated dragon

3.96 €

Savages Fotianna

9.93 €

CRAMER Truggy RC 4x4 Full 3D Printed

7,50 €

Snake and rattlesnake

3.96 €

Heavy Imperial Fire Support Weapon [Preliminary Support]

5 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so supporting us in maintaining activities and creating future developments is very easy. Here are 4 solutions available to everyone:

Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE YOUR FRIENDS: * Invite your friends, discover the platform and the great 3D files shared by the community!

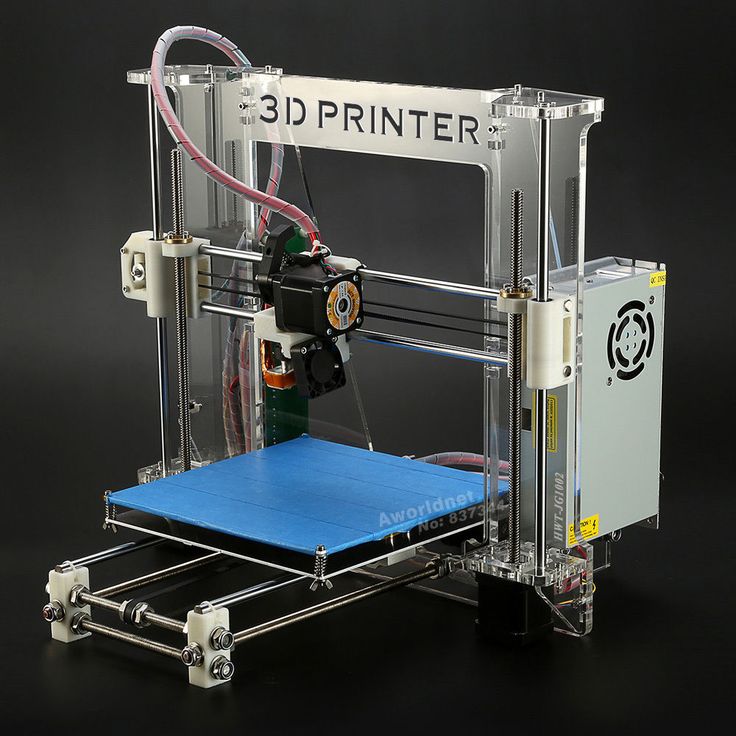

3D printing: 3 facts everyone should know?

01/19/2016

Be careful when simplifying things, because you can miss the point. For example, Motley Fool 's blog tells three things that anyone who wants to invest in a 3D printing company needs to know.

Motley Fool provides financial services and solutions through the various products they want you to purchase. Here, the principle of "quality at the buyer's risk" probably applies.

's recent blog "3D Printing in 2016: 3 Facts Everyone Should Know" was supposed to be an analysis of the current state of the 3D printing industry, answering the question: "What can investors expect from such an investment?" Some of the statements there are absolutely wrong.

For example, they claim that HP's Multi Jet Fusion technology and Carbon3D's Clip technology will be faster than older designs. This statement is basically true. However, the idea that older technologies will reduce the quality of these companies' products is a mistake. Old designs will be considered worse just because of the lower speed?

According to this logic - why do we need engines of different power for different purposes, if we can simply take the most powerful one?

Are these analysts claiming that speed is the key when evaluating the seven major 3D printing technologies? Can they list these technologies at all? And which of them is better to use in this or that case?

If you need to create something very quickly, CNC and injection molding are the best technologies. You just need to make sure that the model meets its requirements. However, if the requirements for your model are much higher and beyond the above technologies, 3D printing/additive manufacturing will help you.

You just need to make sure that the model meets its requirements. However, if the requirements for your model are much higher and beyond the above technologies, 3D printing/additive manufacturing will help you.

To say that production speed is the only important parameter of any 3D printer is ignorance, and this only indicates ignorance of the topic. Speed is not the only factor that engineers evaluate when choosing a technology for a project. Motley Fool's comments only speak to how little the financial company knows about engineering.

The main question these financial analysts are running around and around is: "Why don't engineers use 3D printing/additive manufacturing more, because these technologies are faster?" There is only one answer: education. Just as these analysts first need to learn more about the technology, so engineers try to increase their understanding of the subject first.

For 30 years, older technologies have served faithfully, but five years ago, someone saw the opportunity to use them to create products faster, at the speed of CNC technology.