Kodak 3d photo printer

Review: The Kodak Portrait 3D printer - a reliable dual extrusion machine

3D Printing Industry reviews the Kodak Portrait 3D printer.

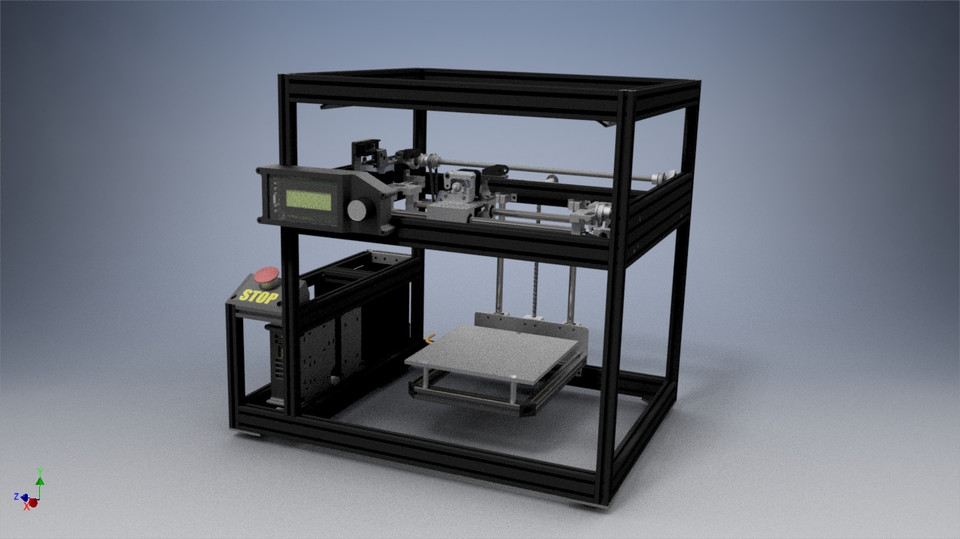

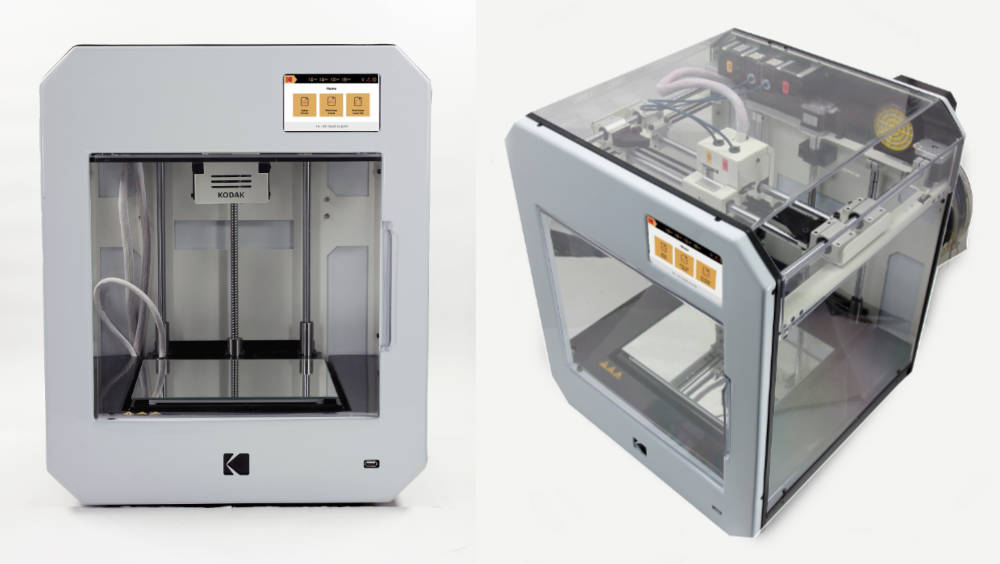

Designed by Smart International and licensed with the Kodak brand, the Portrait 3D printer is a desktop sized professional-grade dual extrusion FFF system. The printer is priced at $3,499 and aimed at engineering and design professionals with a set of precise motors and specialist features such as a filament runout sensor and an in-built camera for remote viewing. The printer is expected to be popular with educational institutions.

The Portrait has a typical build volume of 215 x 210 x 235mm when operating in single extruder mode and 170 x 210 x 235mm when in dual extruder mode. The Portrait’s printhead houses two easily replaceable nozzles, an all-metal nozzle and a PTFE nozzle. With a maximum temperature of 295°C, the all-metal nozzle is capable of extruding tougher engineering thermoplastics such as ABS or PETG. An enclosed build area aids with temperature control.

The Kodak Portrait accepts filaments of diameter 1.75mm and extrudes through 0.4mm nozzles. Layer heights can be varied from 20 – 250 microns and most digital and mechanical functions are controlled through the 5” full color touchscreen on the front of the printer. Connectivity options include Wi-Fi, LAN and a USB port. The Portrait is supported by the Kodak 3D slicer.

Kodak Portrait 3D printer. Photo via Kodak.Setup and first impressions of the Kodak Portrait

Upon unboxing the Kodak Portrait, the user is greeted with a toolkit and an assortment of accessories. The toolkit contains maintenance items such as an unclogging needle, a calibration card, and lubrication for the threaded rods. The accessory pack includes two spools of PLA filament, filament cases to prevent moisture absorption, and spool holders to mount on the rear of the printer.

While most of the essential components of the Portrait come fully assembled, several items in the accessory pack will need to be secured to the printer with screws and a Phillips screwdriver before use. The instructions for this step are illustrated in the quick start guide found in the box. The setup process takes about ten minutes.

The instructions for this step are illustrated in the quick start guide found in the box. The setup process takes about ten minutes.

It is clear from handling the Portrait just how robust the body is. A full steel chassis, bounded by plexiglass panels on three sides, makes for reduced shaking while giving users full visual access to the build area. The glass print bed, capable of maintaining 105°C, is attached to the body via four magnets. Consequently, it can be removed very easily for cleaning or replacement. The print head is free to move in the XY plane while the bed elevates to cater to Z axis changes. The Portrait also features a HEPA filter with activated carbon which filters the fan extracted air to reduce fumes and odors. This makes it suitable for long-term indoor use such as in classrooms.

Bed calibration is automatic and as simple as finding the function in the printer’s easy to navigate menus. A deeper dive into the settings will give the user the option to choose from a multitude of languages. Intuitive temperature profiles for the various compatible materials and helpful animations make loading and unloading filaments very simple. However, if the printer is backed up against a wall, the spool feeders on the back plate can be difficult to reach due to the relatively large frame of the Portrait.

Intuitive temperature profiles for the various compatible materials and helpful animations make loading and unloading filaments very simple. However, if the printer is backed up against a wall, the spool feeders on the back plate can be difficult to reach due to the relatively large frame of the Portrait.

The Kodak 3D slicer and Cloud

The Kodak slicer is a repackaging of the well established Cura slicer, with a Kodak themed color scheme. The UI is as intuitive as ever; once the user selects a 3D STL file, it appears in the virtual workspace in the center of the UI. One of four customization modes can then be selected: basic, advanced, expert or custom. The model can be translated, rotated and rescaled as desired, with additional settings for layer height, travel speed, temperature, supports, cooling and, of course, dual extrusion. Once the file is ready to be sliced, the gcode is automatically saved onto whatever USB is plugged into the computer and the estimated print time is displayed in the bottom right corner.

In dual extrusion mode, models to be printed by extruder one are displayed in yellow while those printed by extruder two are displayed in green. Switching between the two extruders is as simple as clicking on the desired extruder at the top. The same orientation settings apply in dual extrusion mode.

Kodak slicer in dual extrusion mode. Image by 3D Printing Industry.The Kodak slicer overall works very well. If a model is unprintable due to size or orientation, the slicer is quick to tell you so. The only real limitation of the slicer is the lack of an automatic preview stage during the slicing process. Without a preview, it is almost impossible to gauge where the supports will be printed and how much material will be used. To view where the supports will be printed, the user must select layer view in the views dropdown. Most slicers incorporate an automatic preview stage at some point in the file preparation process before slicing.

The slicer is not the only file preparation option provided by Kodak. One of the more exciting services that accompany the Portrait is the web browser-based Kodak Cloud. Users can utilize the cloud service for file orientation, slicing, initiating prints and managing the general workflow across several Portrait systems. The history of a Portrait’s prints is accessible in the cloud, alongside useful information such as hours printed, amount of material used and number of failed prints.

One of the more exciting services that accompany the Portrait is the web browser-based Kodak Cloud. Users can utilize the cloud service for file orientation, slicing, initiating prints and managing the general workflow across several Portrait systems. The history of a Portrait’s prints is accessible in the cloud, alongside useful information such as hours printed, amount of material used and number of failed prints.

The easy to use service allows users to import 3D files locally or through Dropbox or Google. The imported files can then be translated, rotated and rescaled just like the offline slicer. Once the layout is finalized, the sliced gcode is saved to the projects section. Assuming Wi-Fi or LAN connectivity has been set up on the Portrait, the print can then be initiated, paused or canceled remotely. A minor but frustrating flaw of the cloud service is the lack of a flatten by face feature in the file preparation stage. This often makes it difficult to find the optimal placement of a model as it needs to be done manually.

Benchmarking the Kodak Portrait

As with all our printers at 3D Printing Industry, we put the Kodak Portrait through its paces with a plethora of benchmarking tests to see if the system really does live up to its claims. The first print carried out on the Portrait was a standard benchy in PLA+. The benchy model is a jack-of-all-trades benchmarking test due to its abundance of overhangs, circular trajectories, bridges and holes.

Set of benchy models 3D printed on the Kodak Portrait. Photo by 3D Printing Industry.The Kodak Portrait initially had some difficulties with over extrusion and droopiness but a swift tinkering of some of the parameters yielded an outstanding print. Temperatures and print speeds were lowered while fan speeds were increased. Using the optimized settings, the benchy was printed with smooth curvature and no stringing.

Next up was the repeatability test, which tests a printer’s ability to recreate shapes precisely and consistently. The test comprised three different parts which were all printed five times. As the intended dimensions of the models are known, the discrepancy between the original and real dimensions along with the deviation between them can be calculated.

The test comprised three different parts which were all printed five times. As the intended dimensions of the models are known, the discrepancy between the original and real dimensions along with the deviation between them can be calculated.

The printed squares saw excellent results. A maximum standard deviation of 0.04 coupled with exterior dimensions almost identical to the intended dimensions resulted in the five squares being almost indistinguishable. The interior diameter was less precise and displayed a greater deviation, however. The hexagons and tubes saw similar results. Incredibly low standard deviations of 0.05 and 0.06 respectively, along with extremely precise exterior dimensions, resulted in the parts being very repeatable. Again, the interior crevices and diameters saw a slight drop in precision. From this test, we can see what gives the Portrait its professional-grade status. Overall, the heights and external shells of all three models fabricated precisely with little deviation between them. However, the discrepancies between the smaller interior dimensions lead us to believe the Portrait struggles with micro-movements in the XY plane.

However, the discrepancies between the smaller interior dimensions lead us to believe the Portrait struggles with micro-movements in the XY plane.

We then tested the machine’s ability to print tall, thin structures with the 235mm tall tower test. FFF systems tend to have some trouble with taller models due to the vibrations and consequent shaking caused by the stepper motors. This shaking often results in obvious layer lines towards the top of the printed part.

The tower test (right). Photo by 3D Printing Industry.The Portrait, in this instance, held its own admirably. The tower was straight all the way up, fabricated without knocking over, and had minimal layer line visibility. This can be attributed to the machine’s sturdy, steel 24.4kg frame dampening the vibrations caused by XYZ translation.

Difficult-to-print materials

Professional systems should be able to print professional materials, so we investigated the Portrait’s ability to handle some notoriously troublesome filaments. First up was a pair of PETG containers printed at 240°C.

First up was a pair of PETG containers printed at 240°C.

The Portrait handled PETG very well. There were no major issues with the models; some stringing formed on the corners and layer lines were visible upon closer inspection but the surface finish was great with the Kodak filament.

A turbine was then printed in white nylon 6 at 240°C. The general consensus is that nylon filament is not a very cooperative material. It does have extensive industrial applications however, due to its light weight and high tensile strength.

Nylon turbine test. Photo by 3D Printing Industry.The turbine print materialized very well – it could even be used as a functional part. Apart from the slight under extrusion at the base of the part, the turbine had no other issues and printed true to scale. All the blades were printed without supports so this test also demonstrated the overhang abilities of the Kodak Portrait.

Dual extrusion tests

One of key features of the Portrait is its dual nozzle assembly. We put this to test with a vase printed in PLA and ABS. The PLA was extruded at 200°C while the ABS was extruded at 230°C.

We put this to test with a vase printed in PLA and ABS. The PLA was extruded at 200°C while the ABS was extruded at 230°C.

The print quality of the vase was excellent. The Portrait truly delivers on its dual extrusion promises as the interface between the two materials was clear as day while maintaining strength. The machine’s potent dual extrusion capabilities can be extremely valuable to professional designers.

The final print was the ‘ball in a cage’ model printed in PLA and PVA. This fun contraption relies on PVA’s unique water solubility property to properly operate. Once the PVA supports dissolve away, all that’s left is the PLA ball in the PLA cage.

Dual extrusion ‘ball in a cage’ test. Photo by 3D Printing Industry.This dual extrusion print added to the list of the Portrait’s successes. Once the PVA was removed, the ball was free to move around in the cage. The fine grid structure on the face of the cage is also a great demonstration of the printer’s use of soluble PVA supports to fabricate fine geometries.

The verdict

After all the trials and tribulations, the Kodak Portrait has earned its professional-grade price tag. With premium features like the filament runout sensor and the in-built camera for remote monitoring and timelapses, the Portrait makes a fine addition to any workbench. Some minor alterations to the default PLA temperature profile along with the ability to change the print parameters once the build has already started would make the machine a first choice for anyone looking to produce high quality functional prints. The cloud service works well, the dual extrusion works even better, and the Kodak Portrait does exactly what it’s supposed to.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Kodak Portrait 3D printer. Photo via Kodak.

KODAK Portrait 3D Printer is now available in North America…

Kodak and Smart International, the authorized global brand licensee of 3D printing, are pleased to announce North American and European availability of the KODAK Portrait 3D Printer. In conjunction with this announcement, The KODAK Portrait 3D Printer will be on display at the Formnext industry tradeshow in Frankfurt, Germany, November 13th – November 15th.

Positioned for the 3D desktop professional market, the KODAK Portrait Printer consistently delivers accurate results and remains user-friendly. The KODAK 3D Printer will approach this growing arena of imaging with distinctive features such as the dual extrusion system and a fully enclosed all-steel structure, allowing high-temperature builds, and is complemented with enabling software and a wide range of high-quality materials.

The dual extrusion system features automatic nozzle lifting and swappable PTFE and all-metal hotends for optimal material compatibility. Featuring an intuitive touchscreen, automatic leveling and calibration, and preset print parameters for every material, the KODAK Portrait 3D Printer is ready to use straight from the box for those already familiar with the technology or newcomers with creative needs.

With free access to the KODAK 3D Cloud, an IT-compliant printer management software created by 3DprinterOS, it is now possible to manage a print farm for any number of machines, in any number of locations, from anywhere in the world. Users can access via Wi-Fi or LAN port and slice online, monitor their prints and receive over-the-air updates.

Using the 3D printer, environments ranging from classroom, laboratory, office or studio, users can print highly-precise creative designs. The KODAK Portrait 3D Printer has a fully-enclosed print chamber with HEPA and activated carbon filter, reducing unwanted odors and keeping fingers away from hot moving parts. The wide range of filaments are not limited to different grades of PLA, but also offer ABS, Flex 98, HIPS, PETG, water soluble PVA and two grades of Nylon. They are specially manufactured and packaged to ensure low moisture and high dimensional accuracy, and come in a wide color palette, including, of course, Kodak’s Trade Dress Yellow.

The wide range of filaments are not limited to different grades of PLA, but also offer ABS, Flex 98, HIPS, PETG, water soluble PVA and two grades of Nylon. They are specially manufactured and packaged to ensure low moisture and high dimensional accuracy, and come in a wide color palette, including, of course, Kodak’s Trade Dress Yellow.

The KODAK Portrait 3D Printer will be shown at Formnext in Booth J71 in Hall 3.1, where there will also be a press conference in Room Fragment on Thursday 15th November at 4:00pm.

“We are looking at the future of 3D printing and manufacturing, and our KODAK Portrait 3D Printer has been designed to be best-in-class, with capabilities that have the potential to disrupt the traditional manufacturing systems, leading to cost-effective solutions which can reduce environmental impact, with printers speaking to each other across the globe. We are very happy to have collaborated with Kodak and look forward to many future endeavors.’’ said Roberto Gawianski, CEO, Smart International.

“We are delighted to launch the new 3D printer with Smart International and build upon our excitement about this growth industry and the impact that it can have on professional 3D printing and imaging overall,” said Joel Satin, Director of Brand Licensing and Vice-President, Consumer and Film Division, Kodak.

To learn more about the printer and its capabilities, go to www.kodak.com/go/3dprinting.

And watch the full-length video of the printer in action here: https://youtu.be/9mHo-2Moar0.

About Smart International

Smart International has developed an ecosystem of solutions for professional 3D printing. Years of collaboration with engineers, designers, architects, artists, educators, have set the bar high. Only accurate and reliable technology with materials developed for a wide range of applications will help their creations endure and shine. Visit smart3d.tech for more information and Twitter @Kodak3dprinting, Facebook and Instagram.

About Kodak

Kodak is a technology company focused on imaging. We provide – directly and through partnerships with other innovative companies – hardware, software, consumables and services to customers in graphic arts, commercial print, publishing, packaging, entertainment and commercial films, and consumer products markets. With our world-class R&D capabilities, innovative solutions portfolio and highly trusted brand, Kodak is helping customers around the globe to sustainably grow their own businesses and enjoy their lives. For additional information on Kodak, visit us at kodak.com, follow us on Twitter @Kodak, or like us on Facebook at Kodak.

We provide – directly and through partnerships with other innovative companies – hardware, software, consumables and services to customers in graphic arts, commercial print, publishing, packaging, entertainment and commercial films, and consumer products markets. With our world-class R&D capabilities, innovative solutions portfolio and highly trusted brand, Kodak is helping customers around the globe to sustainably grow their own businesses and enjoy their lives. For additional information on Kodak, visit us at kodak.com, follow us on Twitter @Kodak, or like us on Facebook at Kodak.

KODAK 3D Printer is back on the move with 4 unique features

We haven't heard much from Kodak on their new 3D printer for a while, but now they're back in action.

We first saw their machine earlier this year at CES, where they showed off their portrait 3D printer. At the time, we noted that the machine has a number of exciting features that have been designed to make life much easier for the operator, such as their dual tilt nozzle which helps avoid collisions during 3D printing.

We were told that they were slightly behind on obtaining specific regulatory approvals for the equipment, which are now complete. Now they are fully prepared to sell cars.

But in the meantime they have added even more useful features to the machine, one of which is quite unique.

Successful 3D printing of an object with pathological ABS geometry on a Kodak Portrait 3D printer [Source: Fabbaloo] 1. Fully closed

The device is now completely closed, which means that it can easily capture the dissipated heat from the heated print surface to increase the ambient temperature in the print chamber. This will help a lot in 3D printing some deformable materials like ABS plastic.

2. KODAK 3D Cloud

The machine is now connecting to Kodak. A 3D printing ecosystem that can, for example, queue print jobs, cut them in the cloud, store GCODE files for future reprints, and monitor print operations in real time using the built-in camera in a portrait 3D printer. The cloud service is based on Microsoft Azure and we believe it is actually a variant of 3DPrinterOS.

The cloud service is based on Microsoft Azure and we believe it is actually a variant of 3DPrinterOS.

3. Double hot end

But the last improvement is quite unique: they have equipped E3D-Online's double hot ends differently. One hot end has a PTFE feed tube and the other is all metal.

Why do this?

Flexible nylon 3 6D printed on a Kodak Portrait [Source: Fabbaloo]PTFE nozzle is ideal for softer materials and in particular for flexible filaments like TPU. They must be printed at much slower speeds than conventional rigid filaments, and too much friction will be generated when passing through the all-metal nozzles.

Meanwhile, the second nozzle is all-metal, meaning it can be heated to very high temperatures. PTFE nozzles have a temperature limit because the PTFE material starts to break down at around 260°C - and some nasty chemicals are released in the process. Thus, Kodak has created a second hot end capable of printing high-temperature materials on a 3D printer.

Both of these hot end scenarios are well known. However, the Kodak implemented BOTH on the same machine. . This means that if you want to print a TPU today, for example, you simply print it on nozzle 1. You don't have to take the machine apart to change nozzles, as is done with many other 3D printers. Similarly, the second nozzle is ready to print on high temperature materials at any time without changing equipment.

It is downloaded and sent to the Kodak Portrait 3D printer for flexible or high temperature materials [Source: Fabbaloo]This is a very handy feature for 3D printer operators that we haven't seen before. It's actually quite a simple idea and I'm wondering why it hasn't become more popular.

4. 4 year warranty.

Kodak also explained its warranty program. For $400/year, you get a 4-year hardware warranty. This is arguably one of the longest warranties available in the entire 3D printing world, and it's not all that expensive. The warranty includes an annual "inspection" at their now numerous service partners.

This is arguably one of the longest warranties available in the entire 3D printing world, and it's not all that expensive. The warranty includes an annual "inspection" at their now numerous service partners.

Kodak tells us the machine is now available from "many resellers in the US, Canada and Europe."

This is the strength of a brand like Kodak.

Learn more about 3D printing at Fabbaloo!

This post contains affiliate links that help support SolidSmack with a small commission earned from the sale, at no additional cost to you!

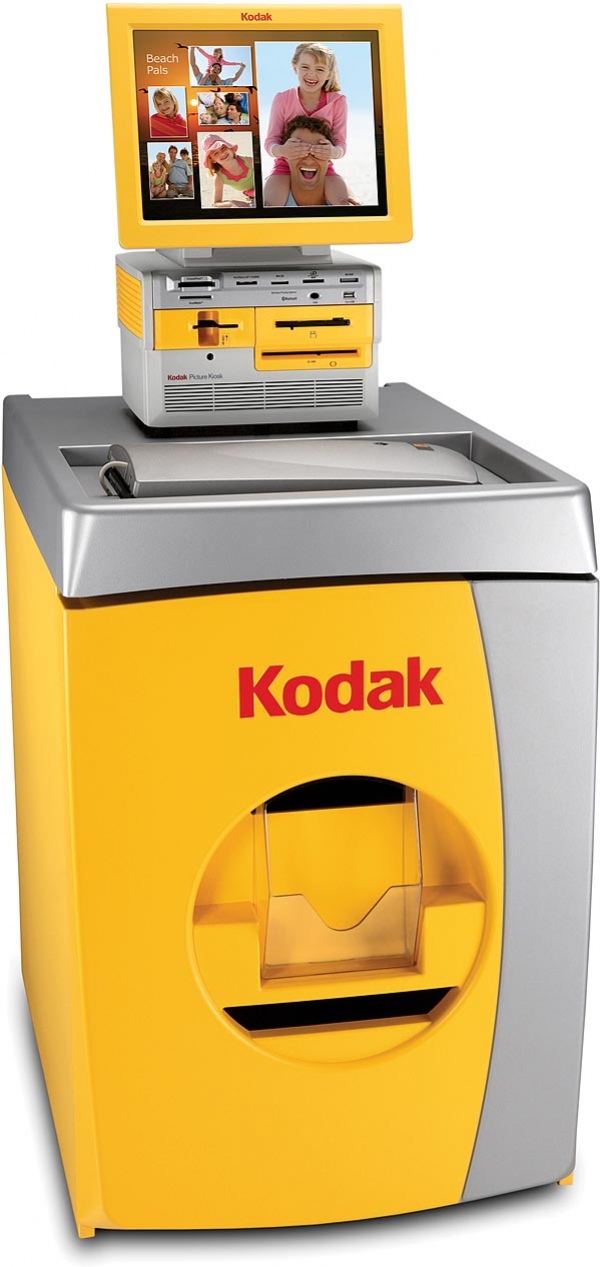

KODAK Instant Mobile Photo Printer 9 User Manual0001

KODAK Instant Mobile Photo Printer User Manual

KODAK STEP INSTANT MOBILE PHOTO PRINTER Quick Start Guide

Contents

Download the KODAK STEP Prints app

Scan the QR code: https://www.kodakphotoplus.com/pages/kodak-step-prints-app

Pairing your iOS™ devices via Bluetooth®

- Press and hold the power button for 4-5 seconds.

- Make sure your mobile device is in Bluetooth® mode.

- Press "KODAK STEP" when it appears.

Precautions

- Do not attempt to disassemble this unit for any reason.

- Never leave the printer or ZINK® paper in a location that can become very hot or exposed to direct sunlight for long periods of time. This may cause your printer to overheat or cause other problems.

- Don't get wet! If you need to clean the printer, use a soft cloth that is slightly soiled. amp Moisten it with water or rubbing alcohol and gently wipe off the dirty spots. Do not under any circumstances submerge it in water.

- Be careful with your printer. Try not to drop and shake hard. There are many very small

parts inside the printer that can break if pushed too hard. - Do not use products such as alcohol, benzine, thinner, or any other organic solvent when cleaning or attempting to

clean this product. - Do not use this device in an environment where it will be exposed to strong dust or humidity/moisture.

- Do not use this printer while bathing or showering.

- Do not place or charge the printer where it could fall into a bathtub or sink.

- Do not place, drop, or immerse the printer in water or any other liquid.

- If the printer somehow falls into the water, even though you have taken all the above precautions, do not0013 water, especially if it is charging. If it is charging, turn it off immediately and then remove it.

- Be careful not to drop objects or spill liquid on the printer.

- This printer will absolutely not work without downloading the Android or iOS app. If you don't have an Android phone or iPhone, unfortunately this printer won't work for you.

Customer Service:

US Support:

[email protected]

844-516-1539

International Support:

[email protected]

844-516-1540

View One-year limited warranty details at: https://www.kodakphotoplus. com/pages /kodak-step-instant-mobile-photo-printer-support

com/pages /kodak-step-instant-mobile-photo-printer-support

kodakphotoplus.com

The Kodak trademark, logo and design are used under license from Eastman Kodak.

ZINK, ZERO INK and the ZINK logo are trademarks of ZINK Holdings, LLC. iPad, iPhone, iPod, and iPod touch are trademarks of Apple Inc., registered in the US and other countries.

"Made for iPod", "Made for iPhone", and "Made for iPad" means that an electronic accessory has been designed to connect specifically to iPod, iPhone, or iPad, respectively, and has been certified by the developer to meet Apple performance specifications. standards. Apple is not responsible for the operation of this device or its compliance with safety and regulatory standards. Please note that the use of this accessory with an iPod, iPhone, or iPad may affect wireless performance.

Bluetooth is a trademark of the Bluetooth SIG, Inc. USA.

Android is a trademark of Google LLC.

Google Play is a trademark of Google LLC.